Extraction method combining roof extraction roadway cross-layer drilling presplitting blasting with multi-branch directional holes

A technology of layer-penetrating drilling and pre-splitting blasting, which is applied in mining fluids, mining equipment, earthwork drilling and mining, etc. It can solve the problem of drainage effect, the drainage time can not achieve the ideal effect, low gas permeability and large attenuation coefficient And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

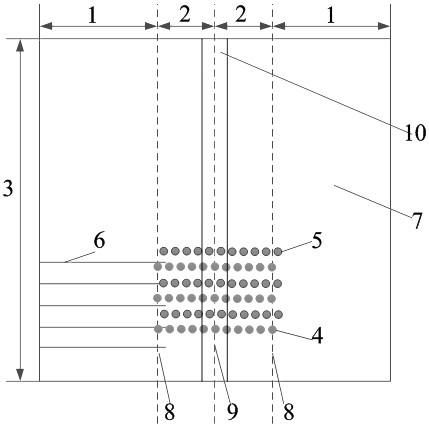

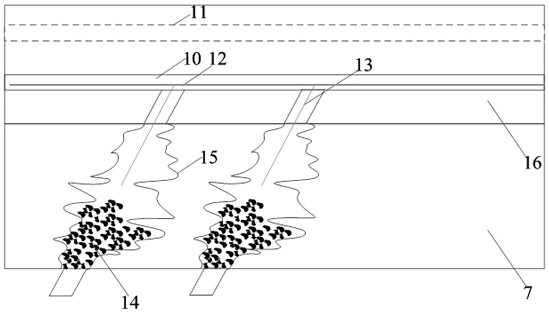

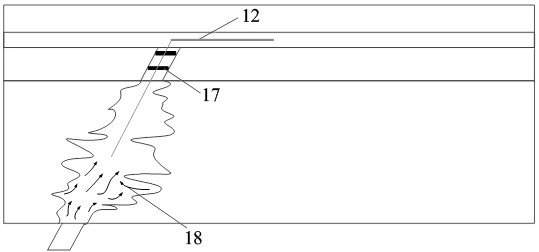

[0023] The present invention will be further described in conjunction with the accompanying drawings.

[0024] As shown in the figure, a roof drainage roadway penetration drilling pre-splitting blasting extraction method includes a rock roadway constructed above the roof of the mining coal seam, a layer-penetrating drill hole in the rock roadway to the lower coal seam, and lowering of the coal mine in the drill hole The permissible explosives use the pre-splitting blasting method to loosen and relieve the pressure of the drilled holes, seal the drilled holes after blasting, and construct directional branch holes in the roadway.

[0025] The rock roadway above the mining coal seam, that is, at the planned working face position, before the coal roadway or other rock roadway is not constructed, in the rock formation above the coal seam between the air inlet roadway and the air return roadway planned and constructed on the working face , digging a rocky roadway.

[0026] The rock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com