Coal road stripe region burst-preventing method

A coal roadway and regional technology, which is applied in the field of outburst reduction in a single coal seam coal roadway strip area, can solve the problems of uncontrollable damage range and direction, complicated procedures and processes, and needs to be investigated and perfected, so as to improve the effect of regional outburst prevention , shorten the construction time and increase the air permeability of the coal seam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

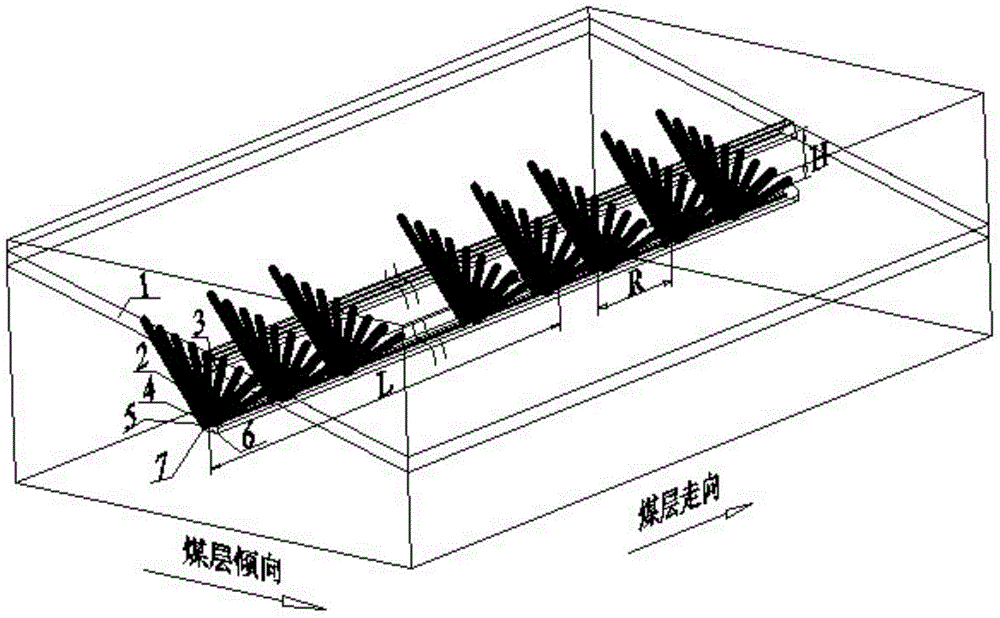

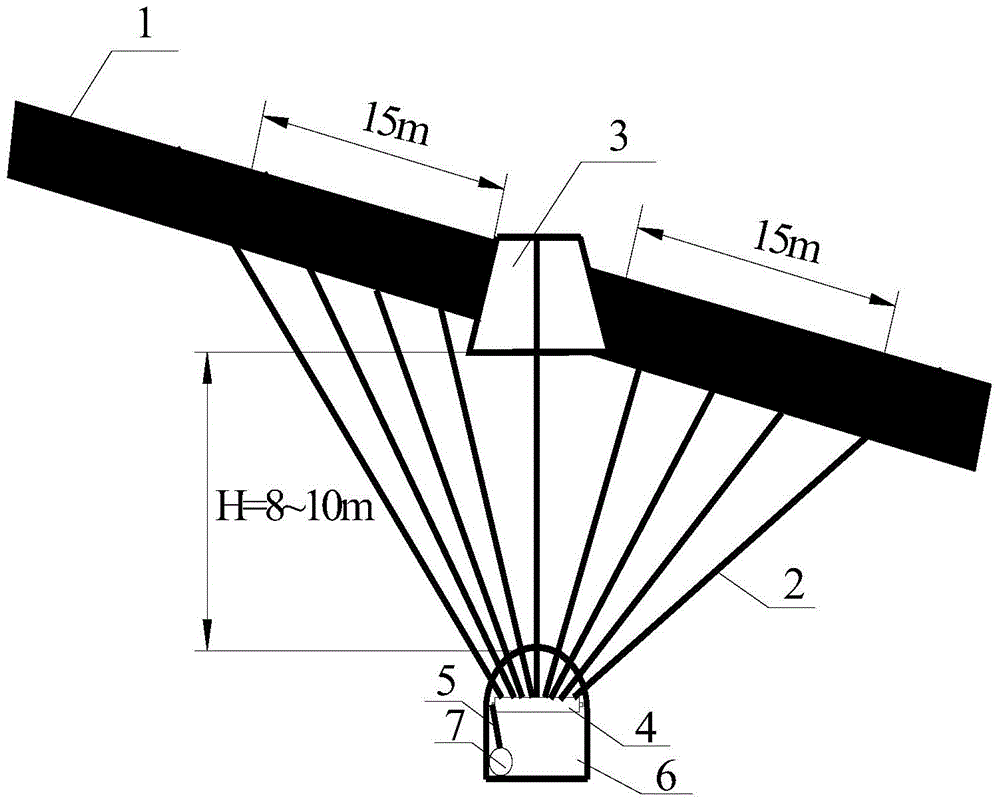

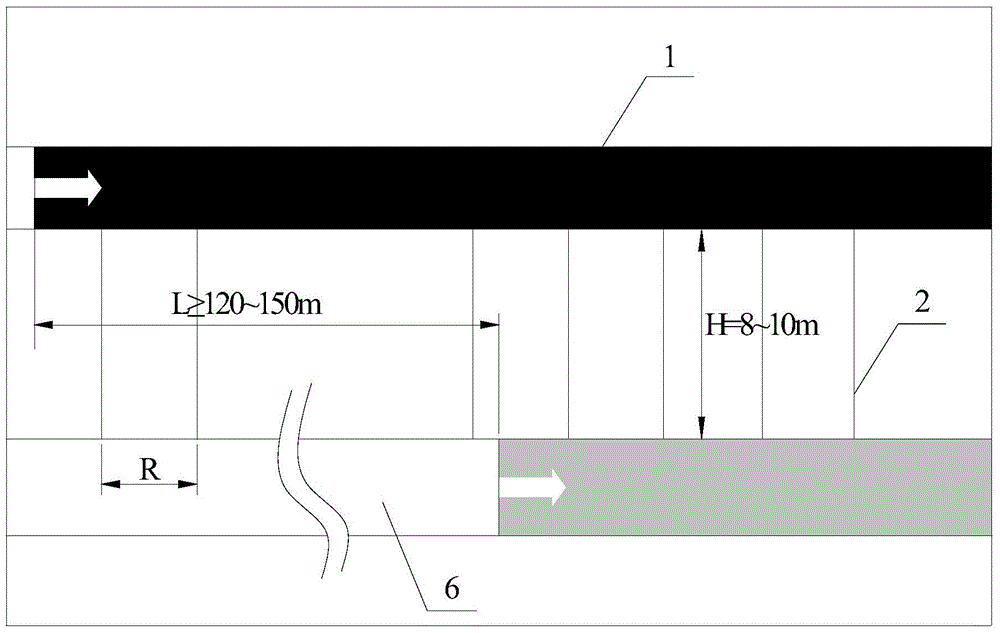

[0034] The floor rock roadway 6 is located directly below the coal seam roadway 3 to be excavated in the inclined coal seam, with an upper distance of 8m from the coal seam; during the excavation process of the floor rock roadway, when faults are encountered, necessary outburst prevention technical measures shall be taken to appropriately increase the upper distance of the floor rock roadway 6 Coal seam 1 to ensure the safety of excavation; floor rock roadway 6 is excavated at least 135m ahead of the coal roadway to ensure sufficient extraction time; floor rock roadway 6 is generally not less than 3 months for gas extraction through layer-crossing drilling; The floor rock roadway 6 pressure relief gas drainage project includes excavation of the floor rock roadway 6, construction drilling, sealing, and installation of the main pipeline. Arranged in a fan shape, the distance between the drill holes in the middle is large, and the distance between the drill holes on both sides is ...

Embodiment 2

[0036] Floor rock roadway 6 is used to be located directly below coal roadway 3 to be excavated in the inclined coal seam, and the upper distance is 10m from the coal seam; bottom rock roadway 6 is excavated at least 150m ahead of the coal roadway to ensure sufficient extraction time; Drainage takes 3.5 months; the boreholes are arranged in a fan shape in the roadway, the distance between the holes in the middle is large, and the distance between the holes on both sides is small; the diameter of the borehole is 90mm, and the hole is opened on the roof of the roadway, and the final hole penetrates into the roof of the coal seam 0.5 m, the sealing length of the drainage drilling above the floor rock roadway to the coal seam, the sealing length of the drainage drilling on both sides is 6m, the negative pressure of the drainage drilling hole is 15kpa, and the gas drainage is carried out through the drainage system after sealing.

Embodiment 3

[0038] A kind of outburst prevention method of a coal roadway strip area of the present invention has been successfully practiced in deep mines such as Shangyi, Jianxin, Pinghu and Qujiang in Fengcheng, Jiangxi Province, when excavating a single seriously outburst and inclined medium-thick coal seam. Mining inclined single severe overhang B 4 Coal seam, mining depth 600~1100m, coal seam dip angle 10~14°, thickness 2.2~3.5m, coal seam hardness coefficient f=0.3~0.8, gas pressure 3.0~9.2MPa, gas content 13.5~25.3m 3 / t. The lithology of the floor is fine sandstone or medium-grained sandstone, and the design section of the rock roadway is 7.84-12.6m 2 , and overlap with the coal roadway to be excavated, and the distance between the roadway top and the coal seam is 8-10m. According to the test and investigation, during the excavation of the rock roadway, the pressure relief gas discharge is at 14.4-196.6m 3 / min; the surrounding rock of the floor rock roadway has partition cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com