Poly-generation shaftless coal underground gasification method

An underground gasification, well-less technology, applied in coal gasification, underground mining, earth drilling and mining, etc., can solve problems such as underground environmental pollution, large-area underground fires, gas explosions, etc., to reduce the amount of drilling engineering and improve Utilization rate and the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

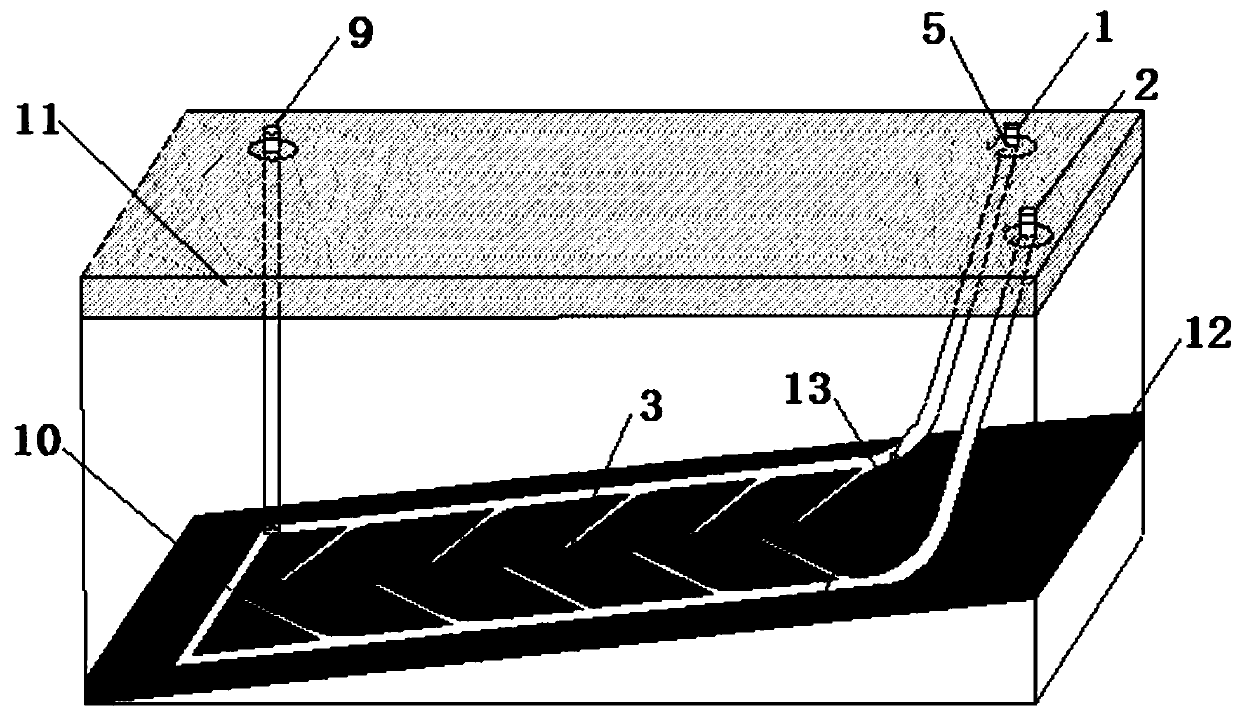

[0021] Below in conjunction with accompanying drawing, the present invention will be further described (hereinafter referred to as figure 1 The left side direction is described as the front).

[0022] like figure 1 As shown, the multi-generation well-less underground coal gasification method specifically includes the following steps:

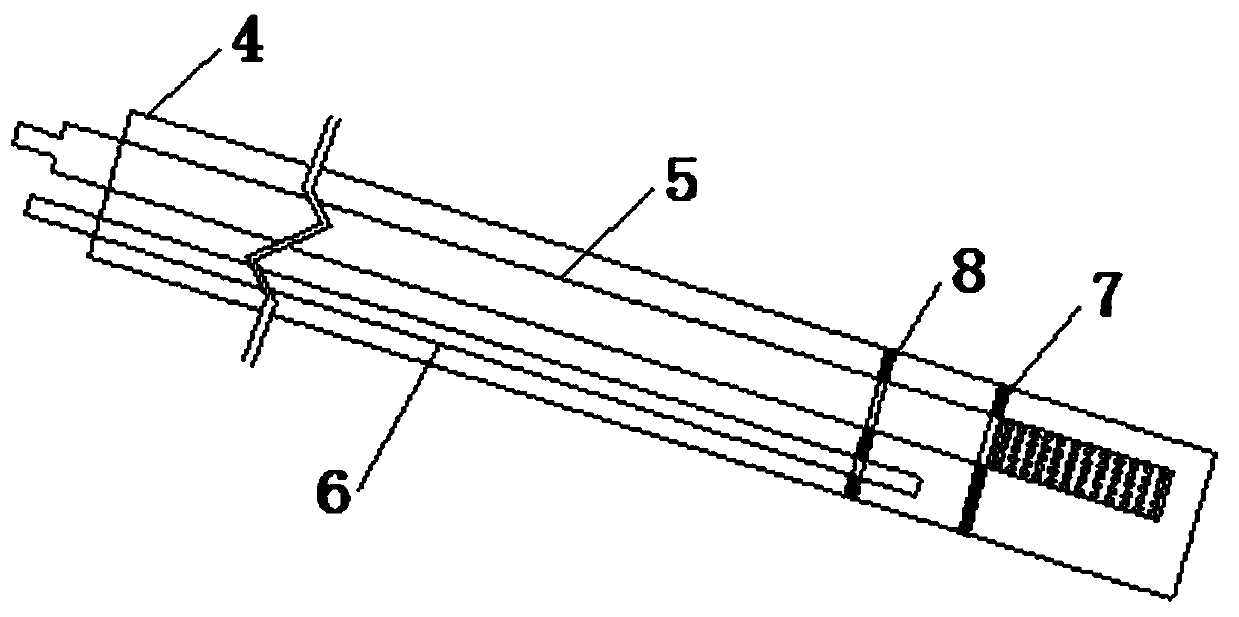

[0023] a) Drilling operation: firstly adopt the directional drilling technology, from the ground 11 to the direction of the coal seam 12 and construct two inclined boreholes from back to front, that is, the included angle between the inclined borehole and the coal seam 12 in front is The obtuse angle setting, such setting can facilitate the subsequent turning and drilling of the coal seam drilling section. After the two inclined drilling holes are drilled to the coal seam 12 respectively, they continue to drill forward along the coal seam 12 for a set distance to form two coal seam drilling sections. Two inclined boreholes and two coal seam bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com