Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

94results about How to "Reduce image defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

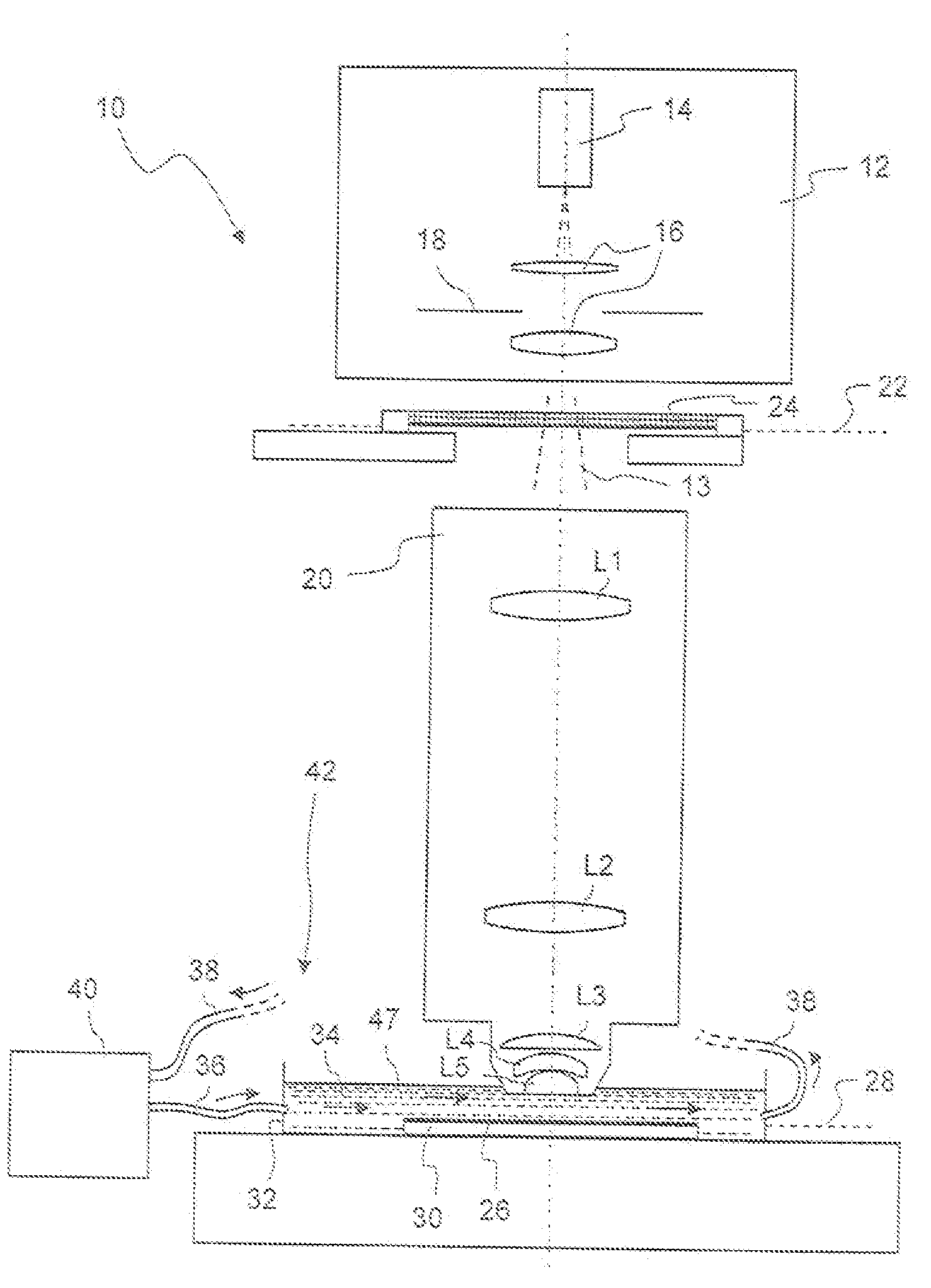

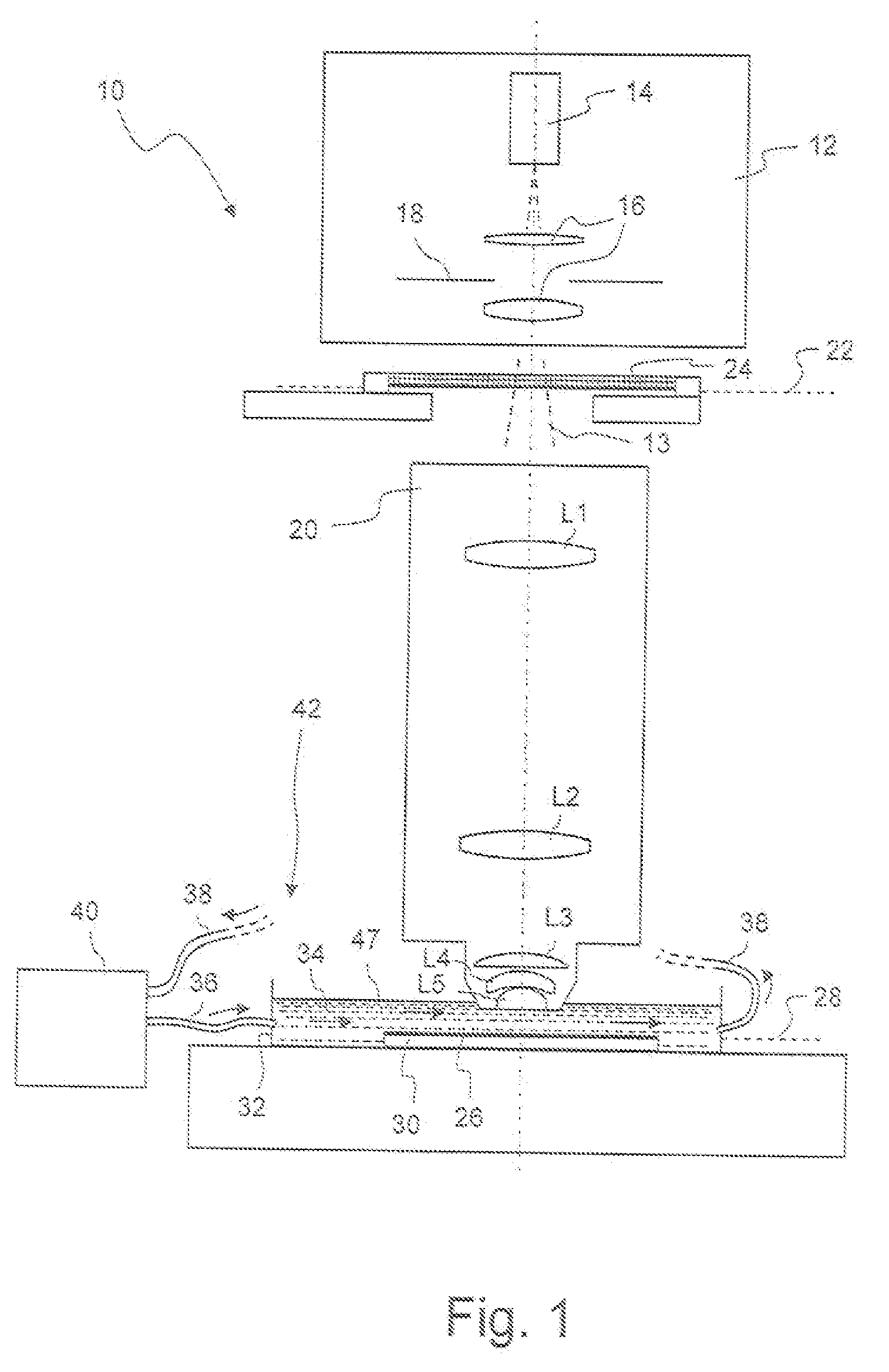

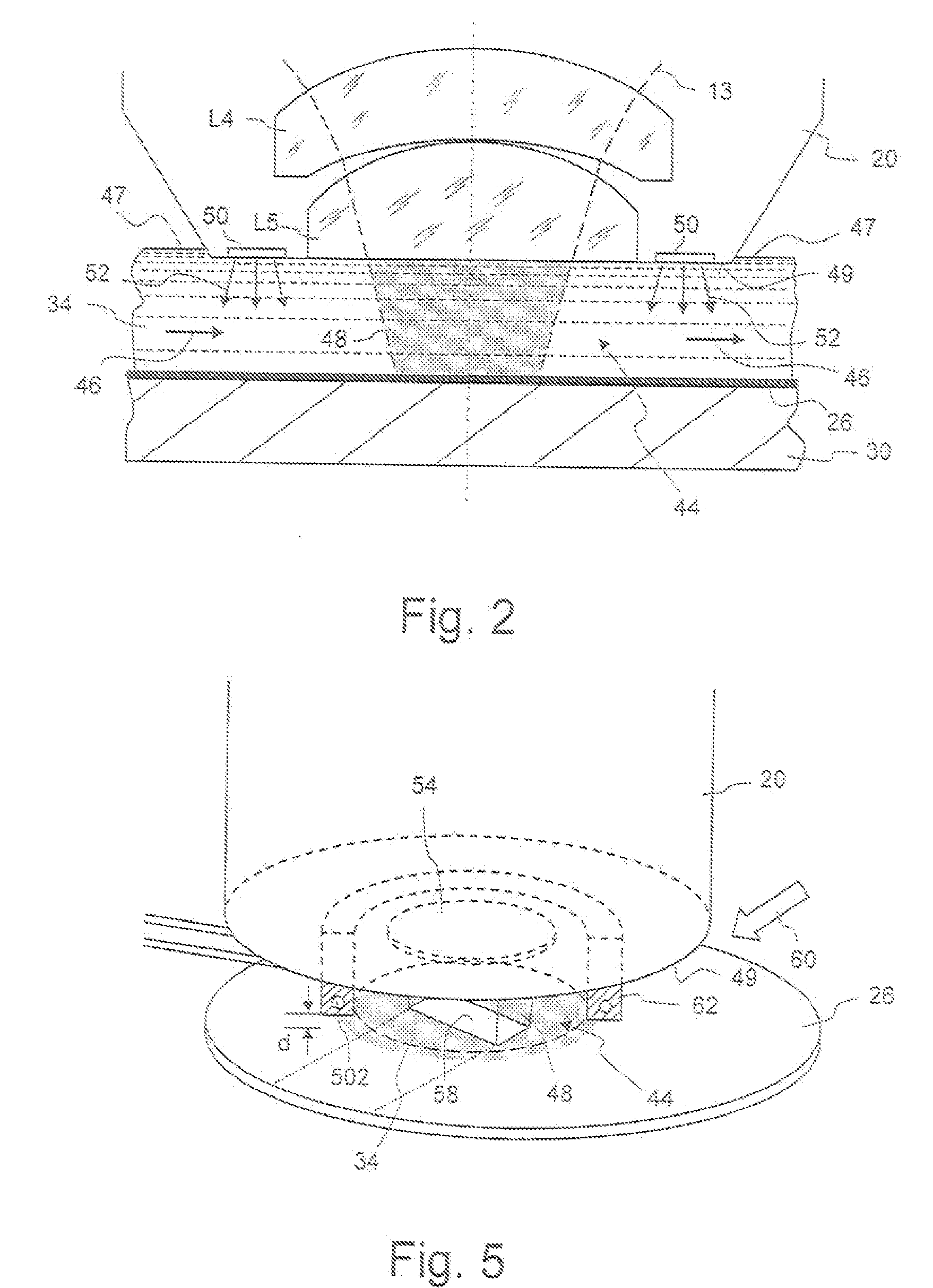

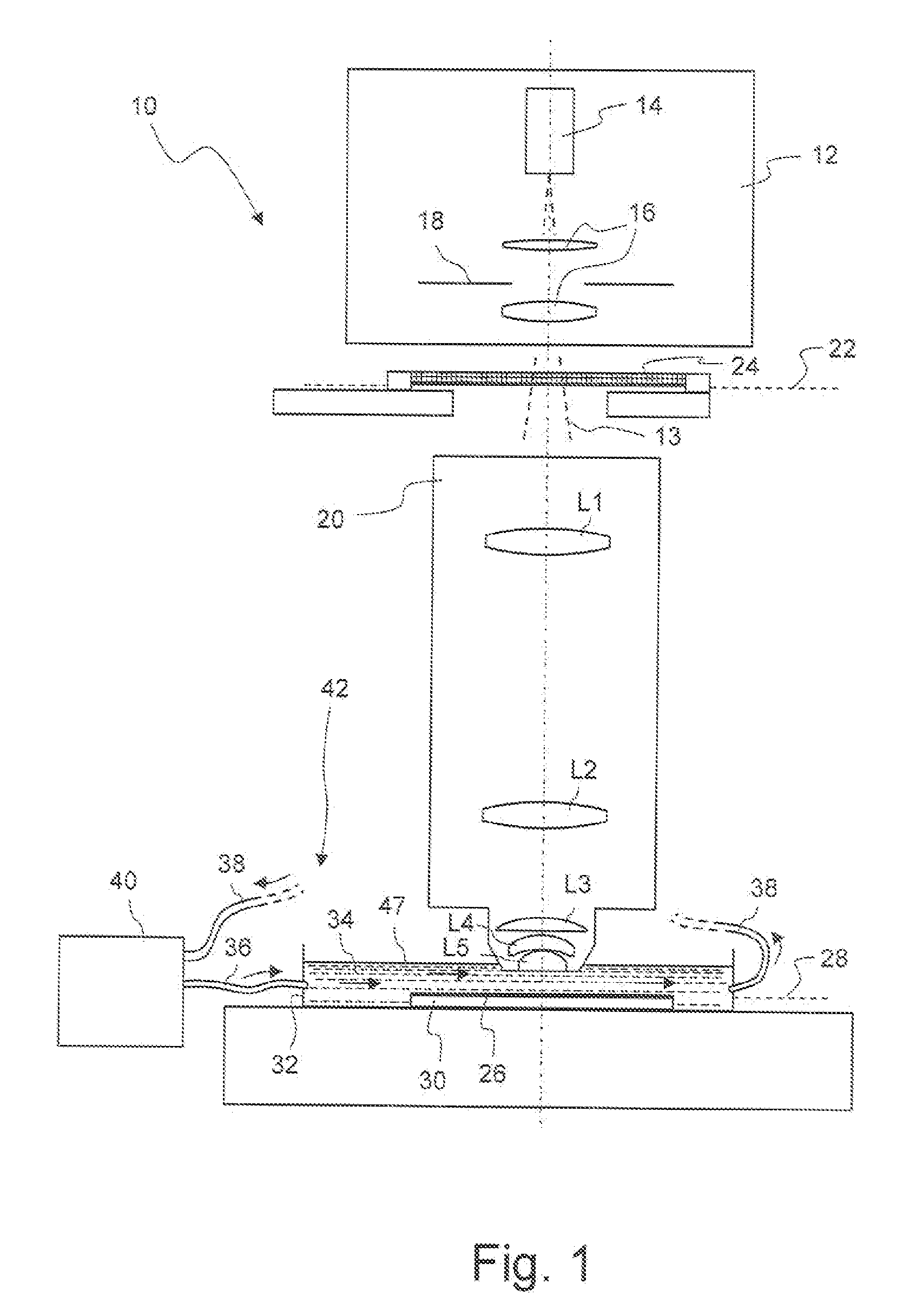

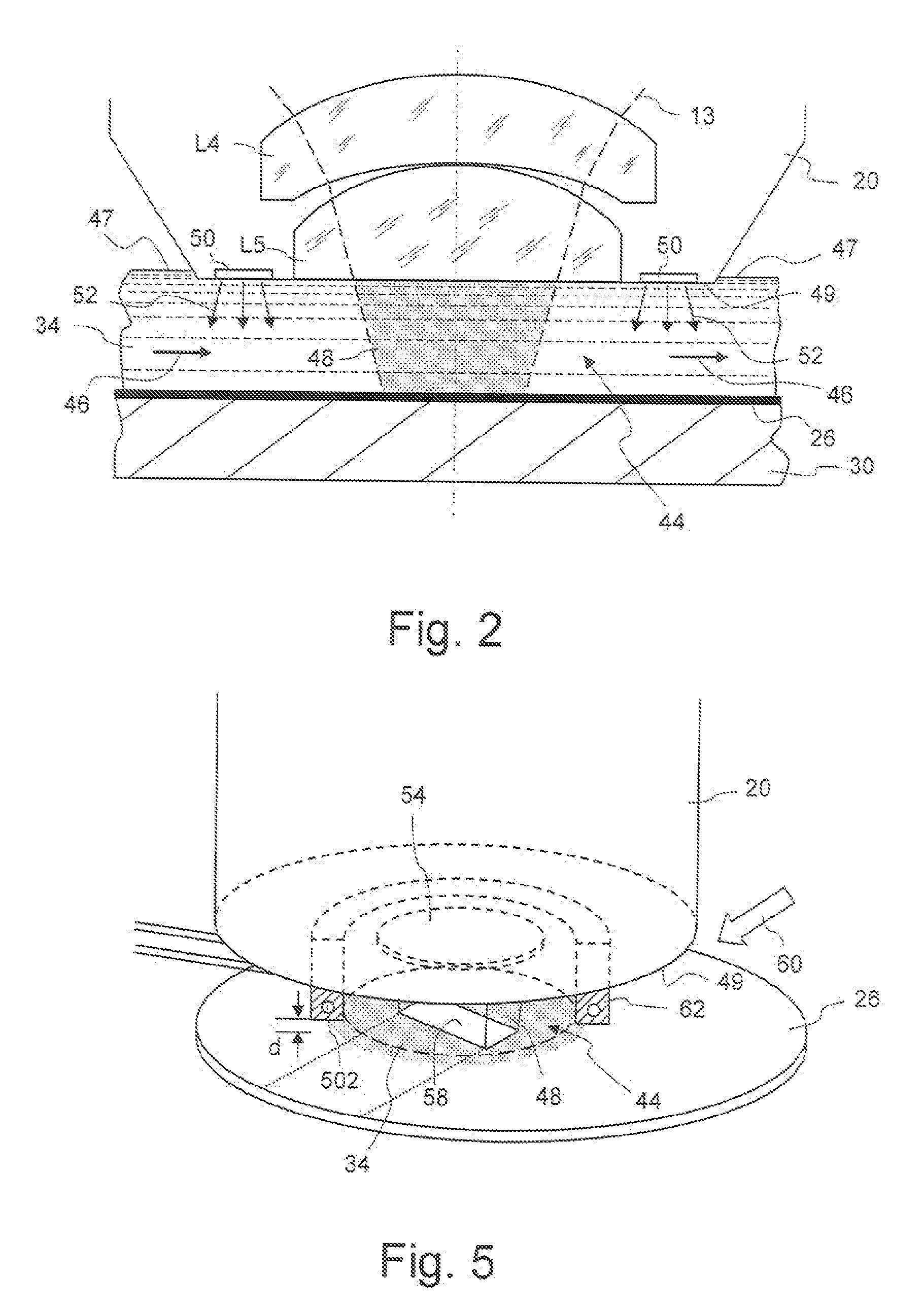

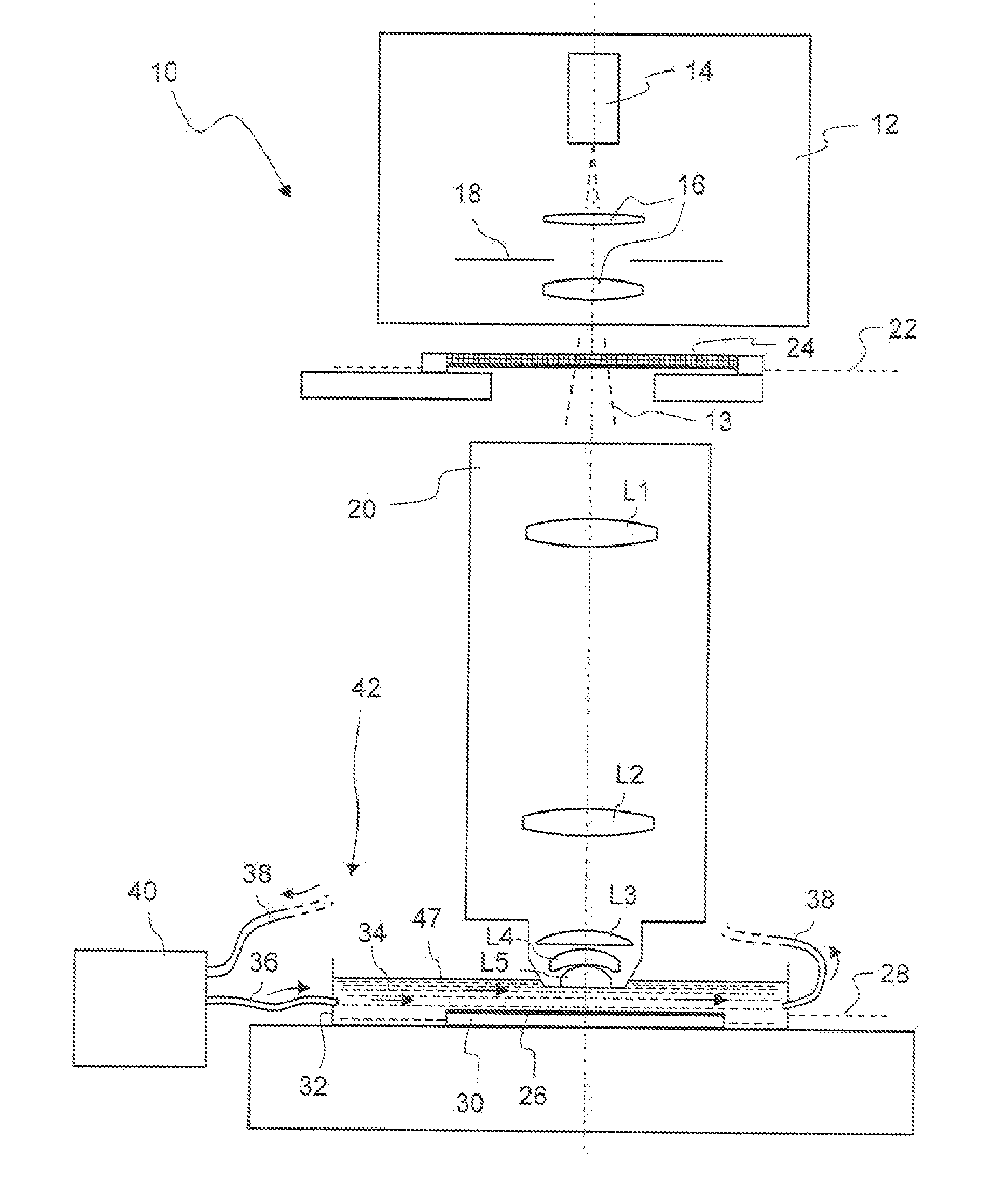

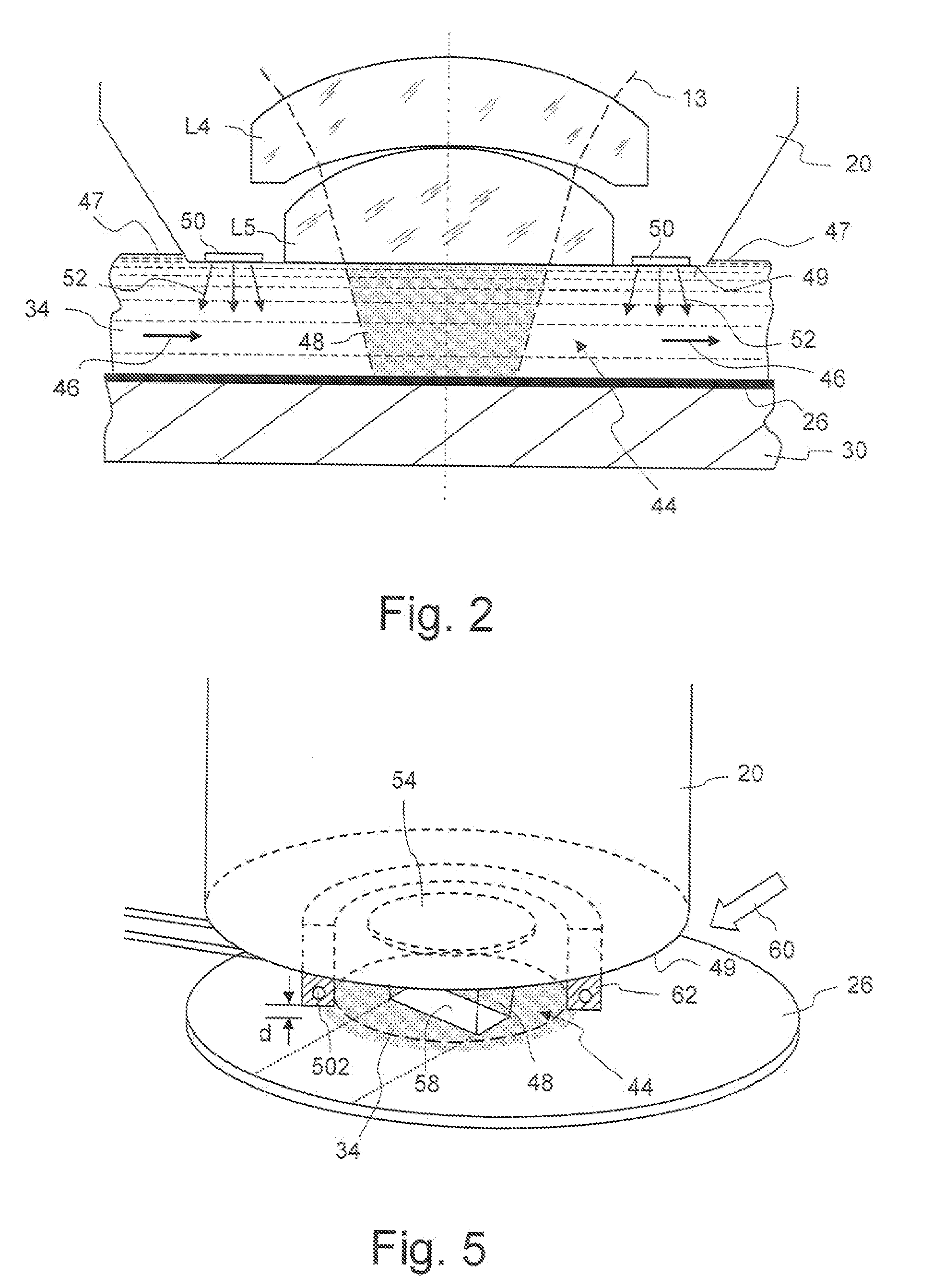

Microlithographic projection exposure apparatus and measuring device for a projection lens

InactiveUS20070070316A1Reduce image defectsSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusRefractive indexProjection lens

A microlithographic projection exposure apparatus includes a projection lens that is configured for immersion operation. For this purpose an immersion liquid is introduced into an immersion space that is located between a last lens of the projection lens on the image side and a photosensitive layer to be exposed. To reduce fluctuations of refractive index resulting from temperature gradients occurring within the immersion liquid, the projection exposure apparatus includes heat transfer elements that heat or cool partial volumes of the immersion liquid so as to achieve an at least substantially homogenous or at least substantially rotationally symmetric temperature distribution within the immersion liquid.

Owner:CARL ZEISS SMT GMBH

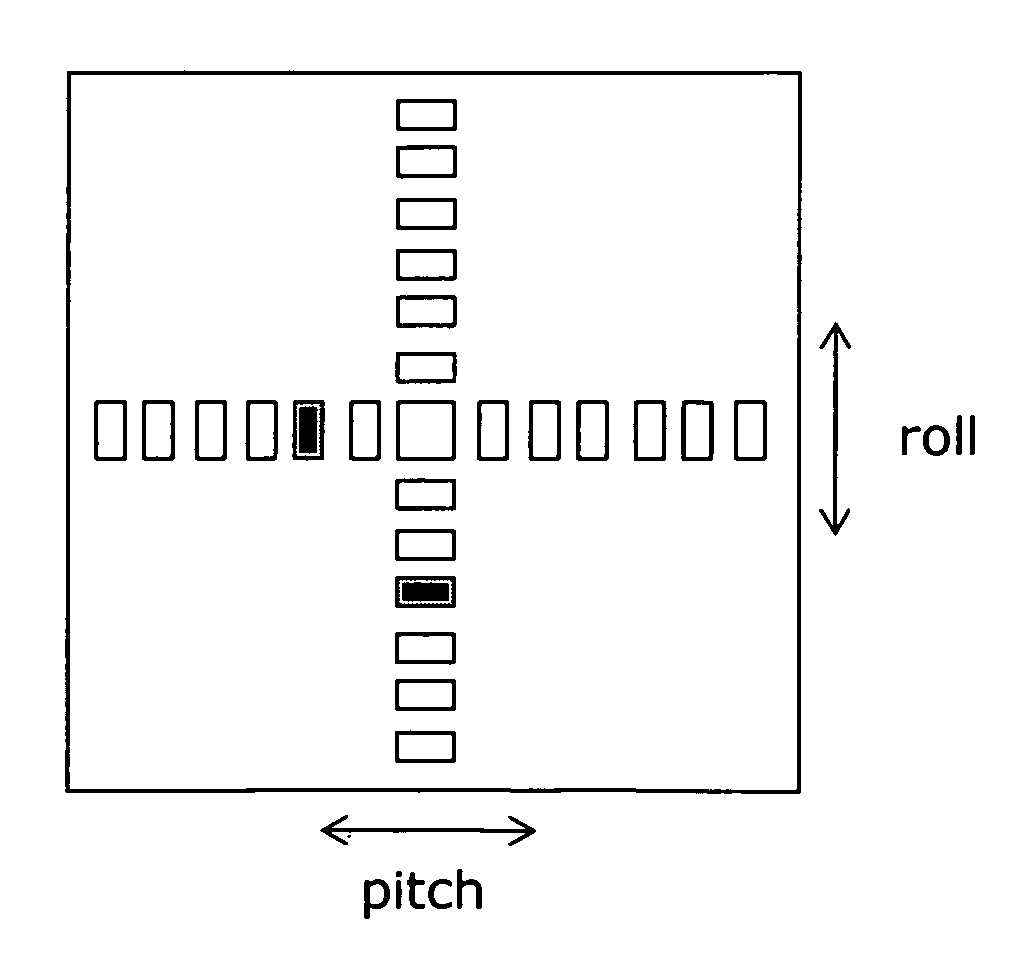

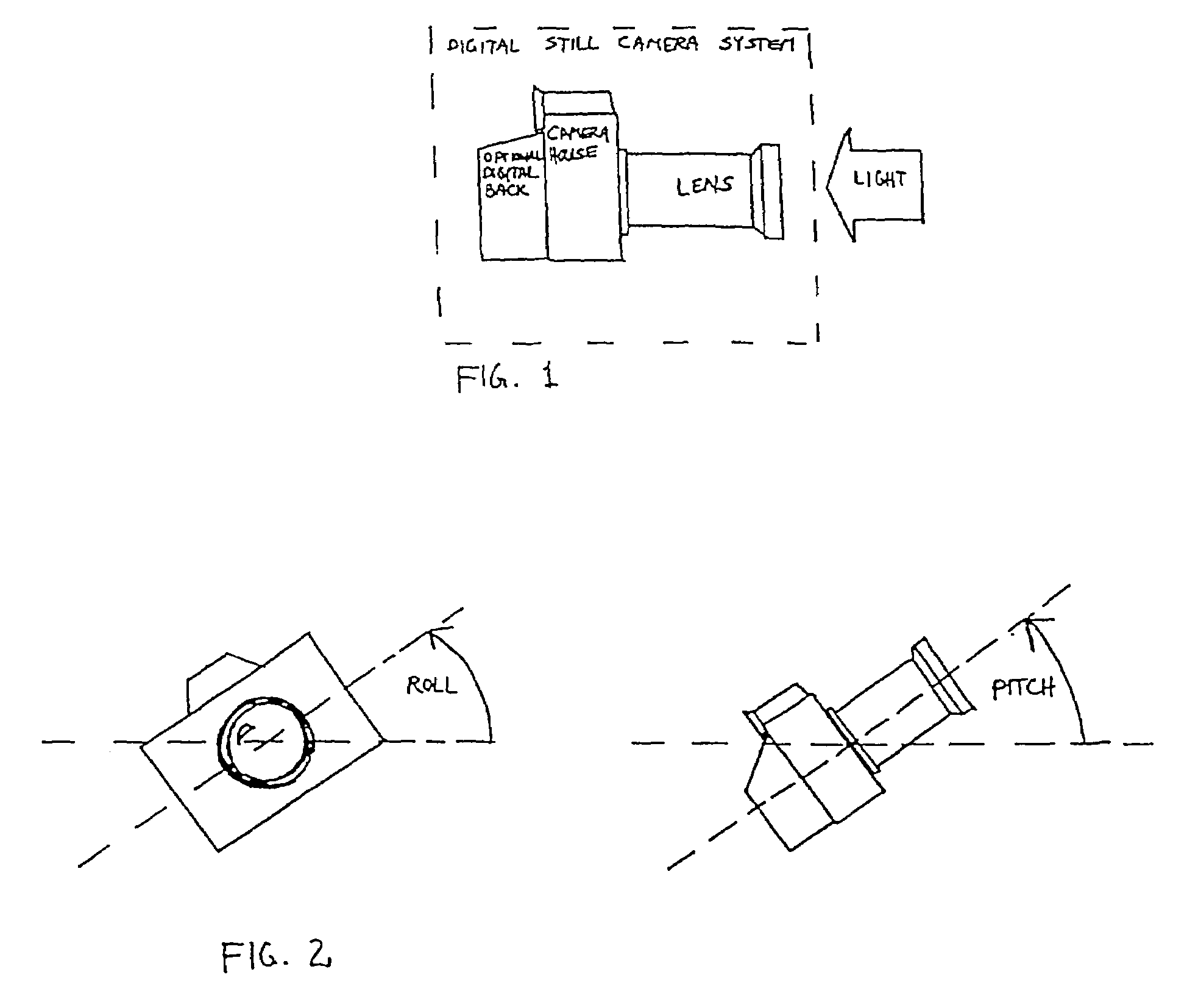

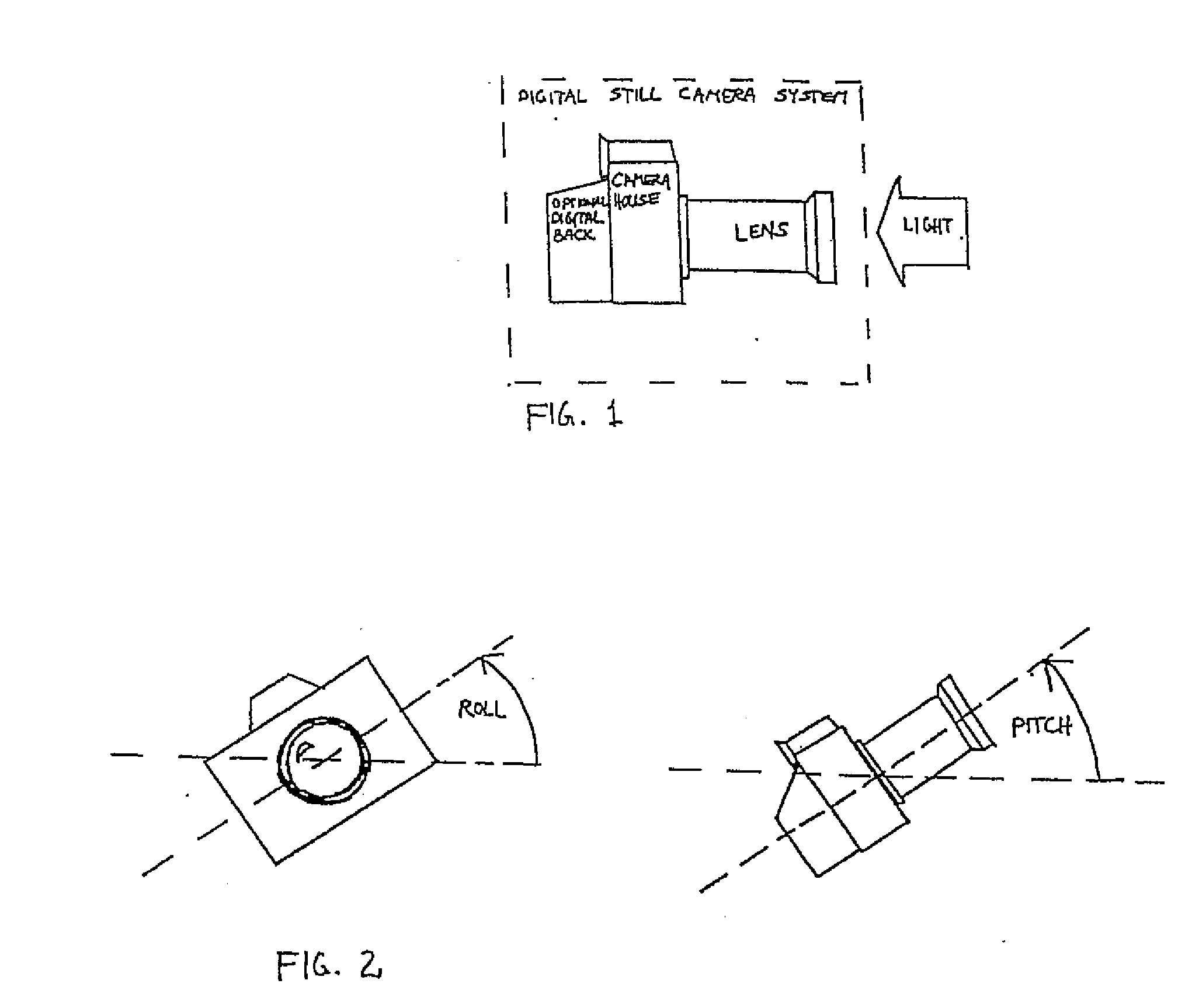

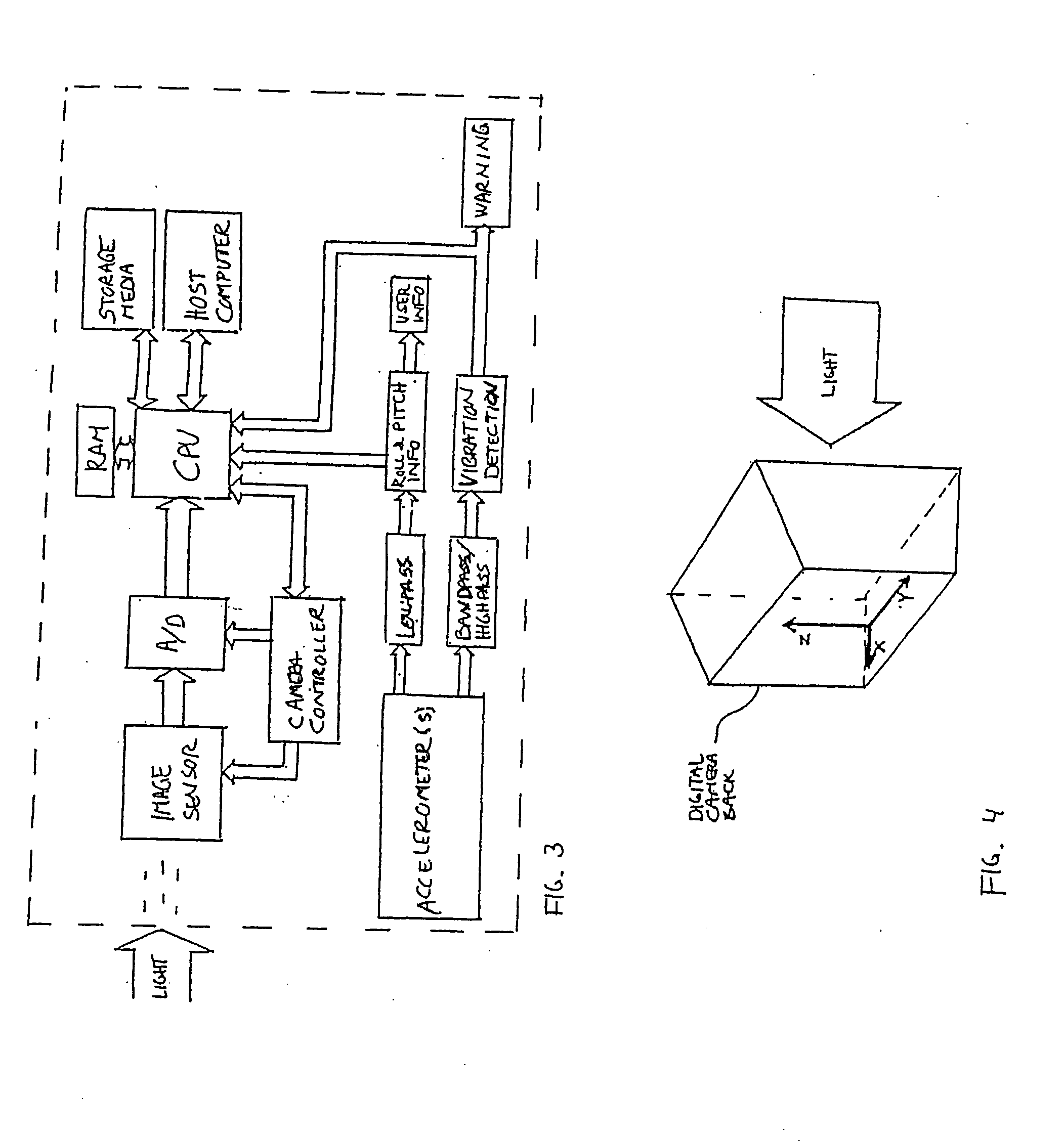

Digital camera with integrated accelerometers

ActiveUS7554578B2Reduce moiré image defectIncrease sharpnessTelevision system detailsTelevision system scanning detailsDigital cameraComputer graphics (images)

A digital camera system has integrated accelerometers for determining static and dynamic accelerations of the digital camera system. Data relating to static and dynamic accelerations are stored with recorded image data for further processing, such as for correcting image data for roll, pitch and vibrations and for displaying recorded images with a predetermined orientation using information about, e.g., roll. Data may also be used on-the-fly for smear suppression caused by vibrations.

Owner:PHASE ONE

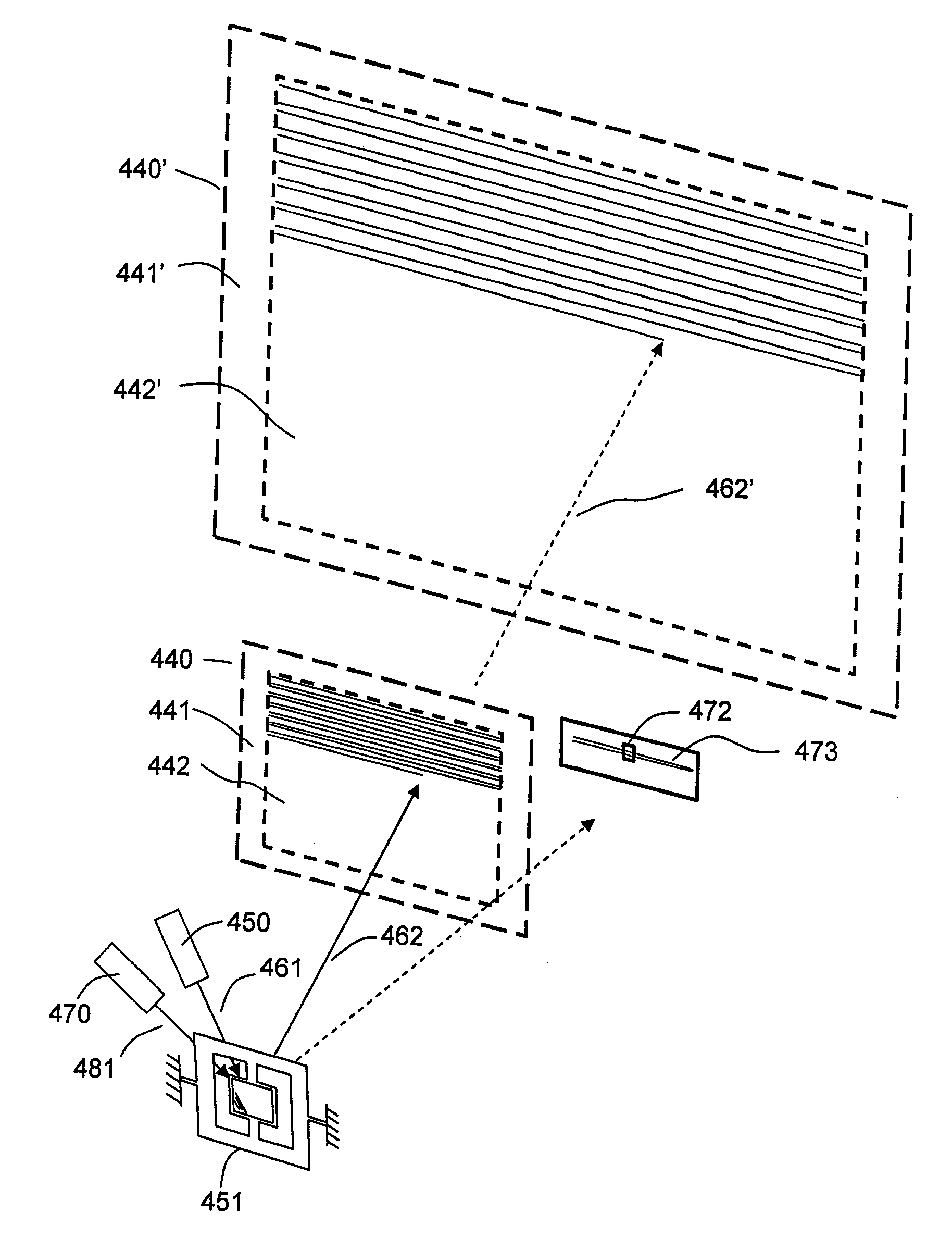

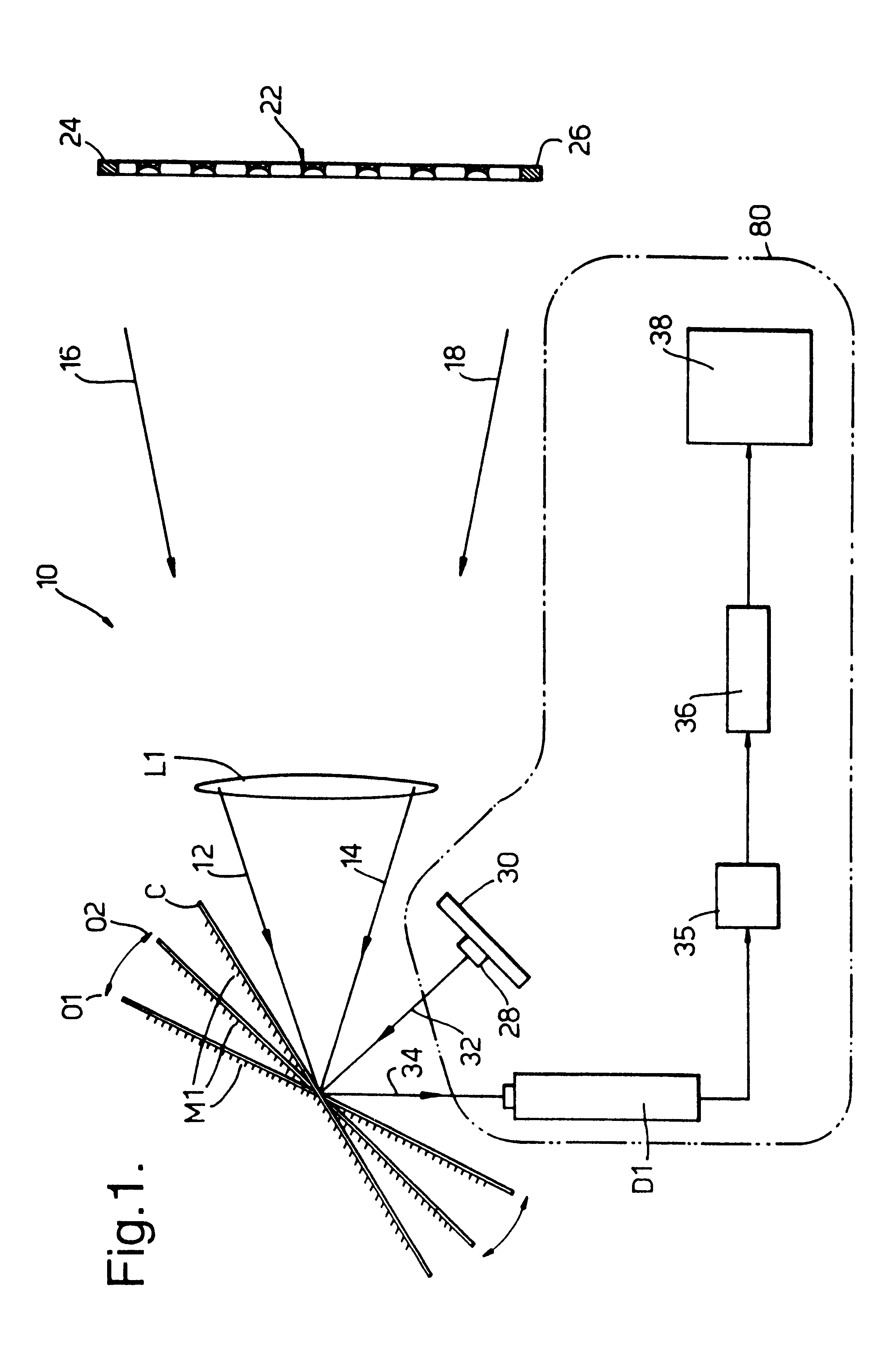

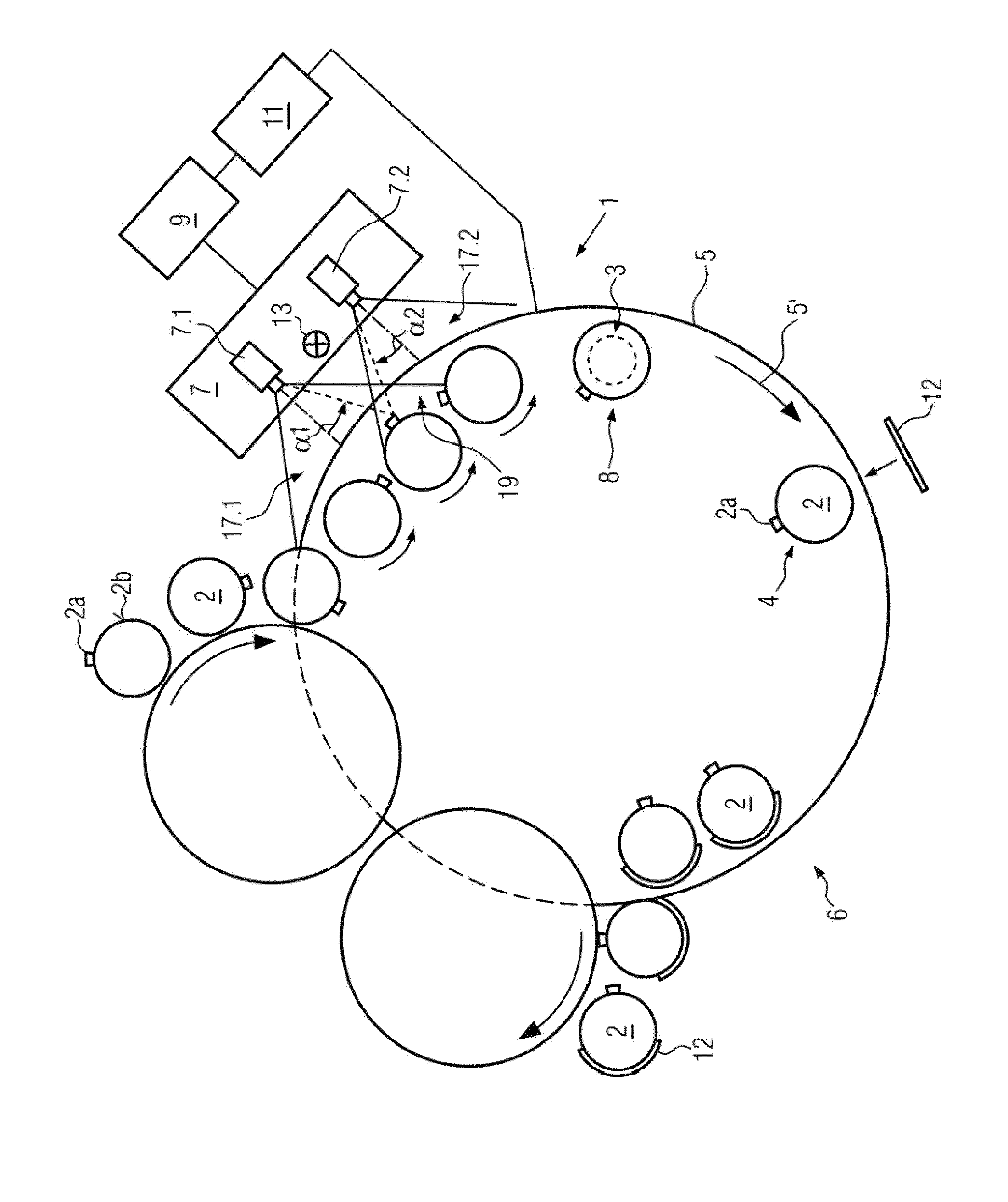

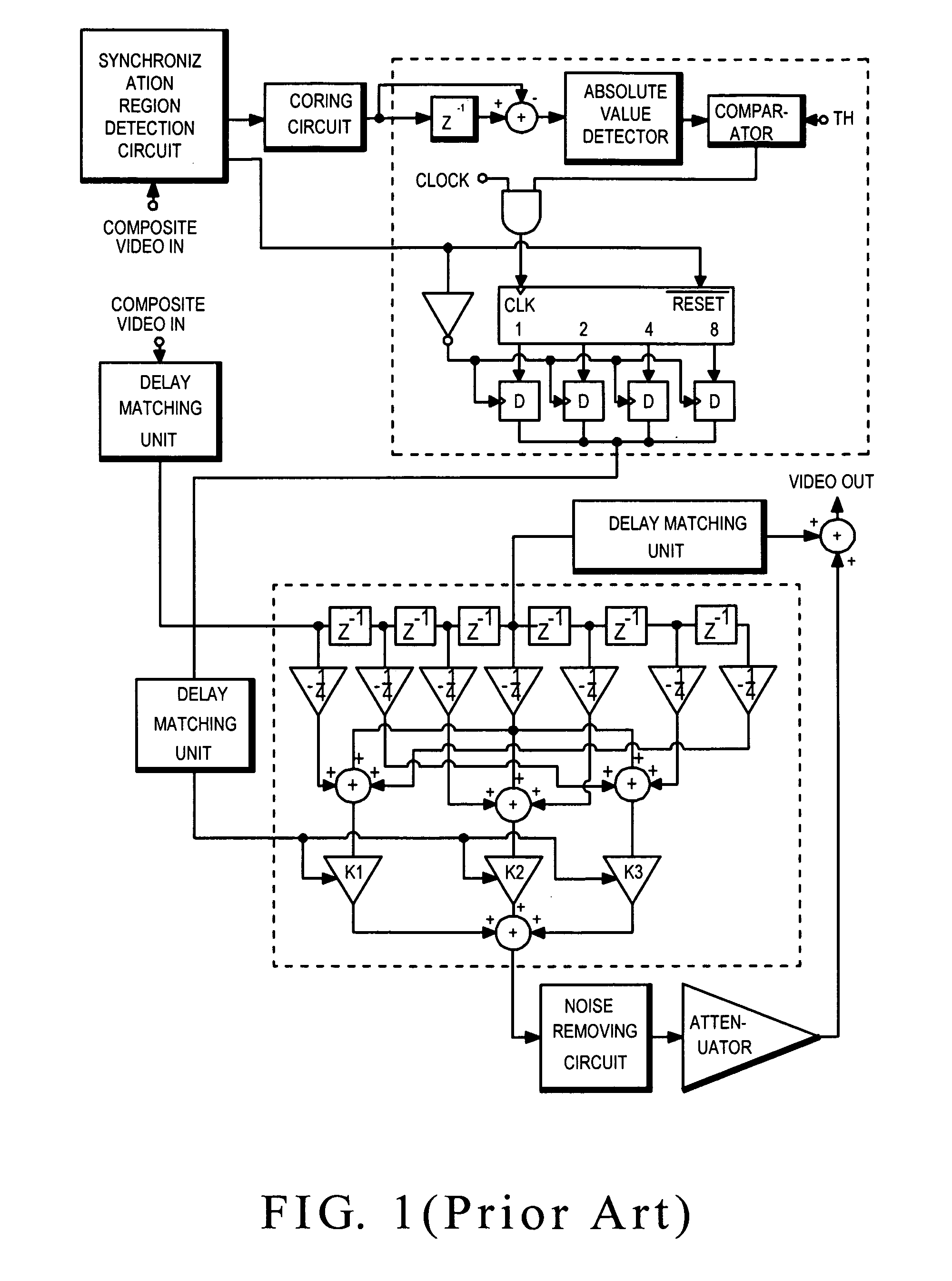

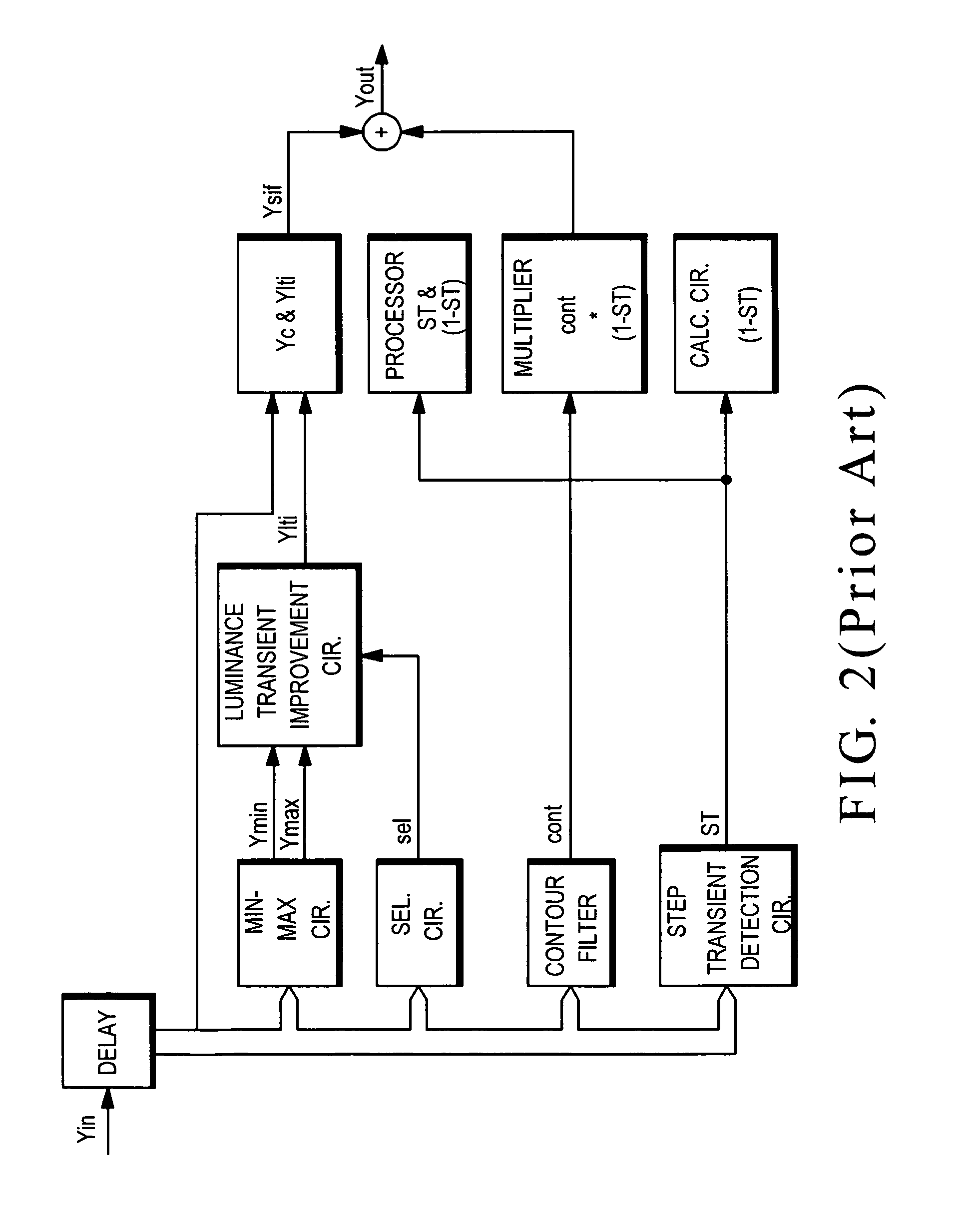

Scanning projection apparatus with phase detection and compensation

ActiveUS20100033691A1Reduce inherent image defectIncrease brightnessTelevision system detailsLaser detailsPhase differenceScan line

A scanning projection apparatus for displaying image comprises a light source for generating a light beam, a beam scanner which deflects the light beam to project a two dimensional image field, a modulation means for modulating the intensity of the light beam, and a sensor to detect the scanned light beam. The light source may consist of a plurality of semiconductor lasers and / or solid state lasers to generate light beams with wavelengths of red, green and blue colors aligned into a single light path. The image field is divided into an active image field for displaying image and a dark field in the perimeter of the image field wherein the light beam is switched off to reduce inherent image defects. The sensor is positioned outside the active image field to detect a scan line once per image frame to eliminate image distortion due to phase difference between the actual and the predicted positions of the scanned beam, and to detect both the horizontal and the vertical scanning operations of the beam scanner for safety precaution.

Owner:AURISE INVESTMENT CO LTD

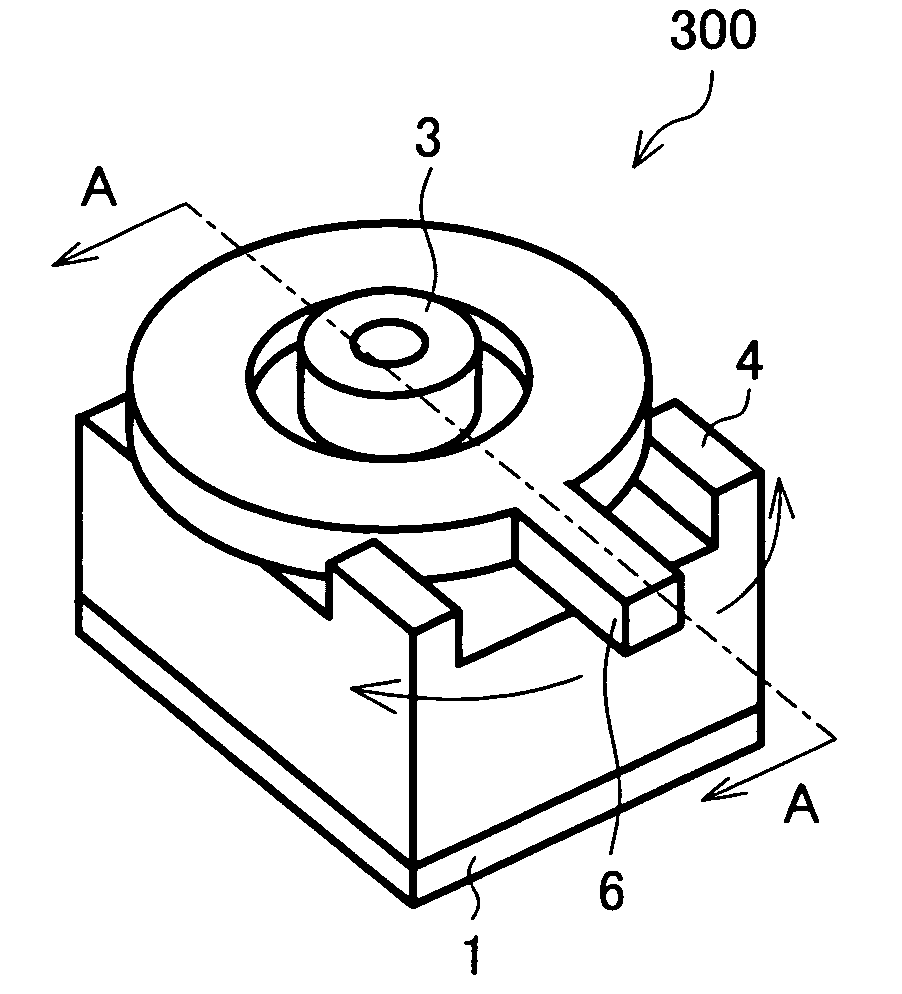

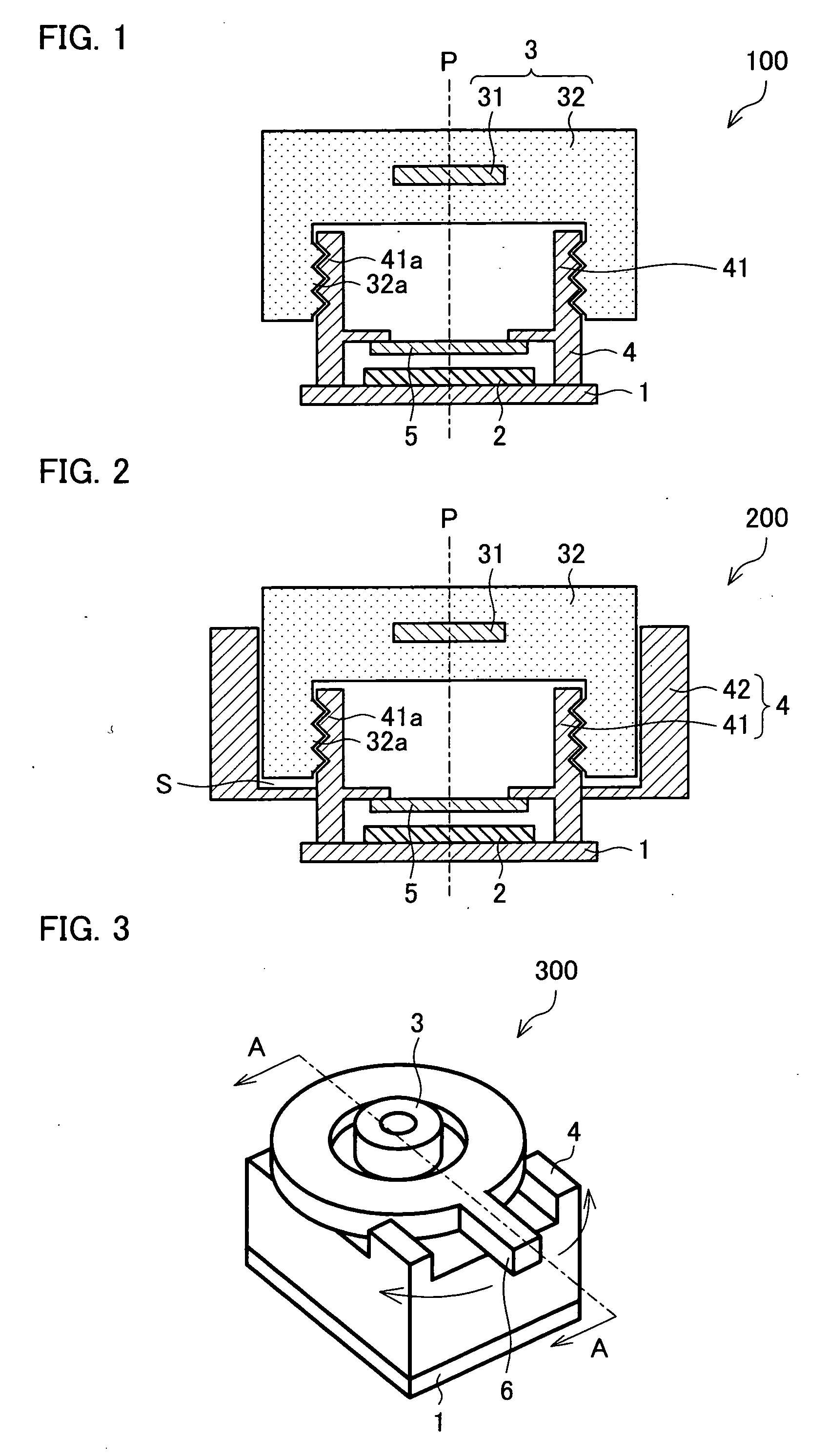

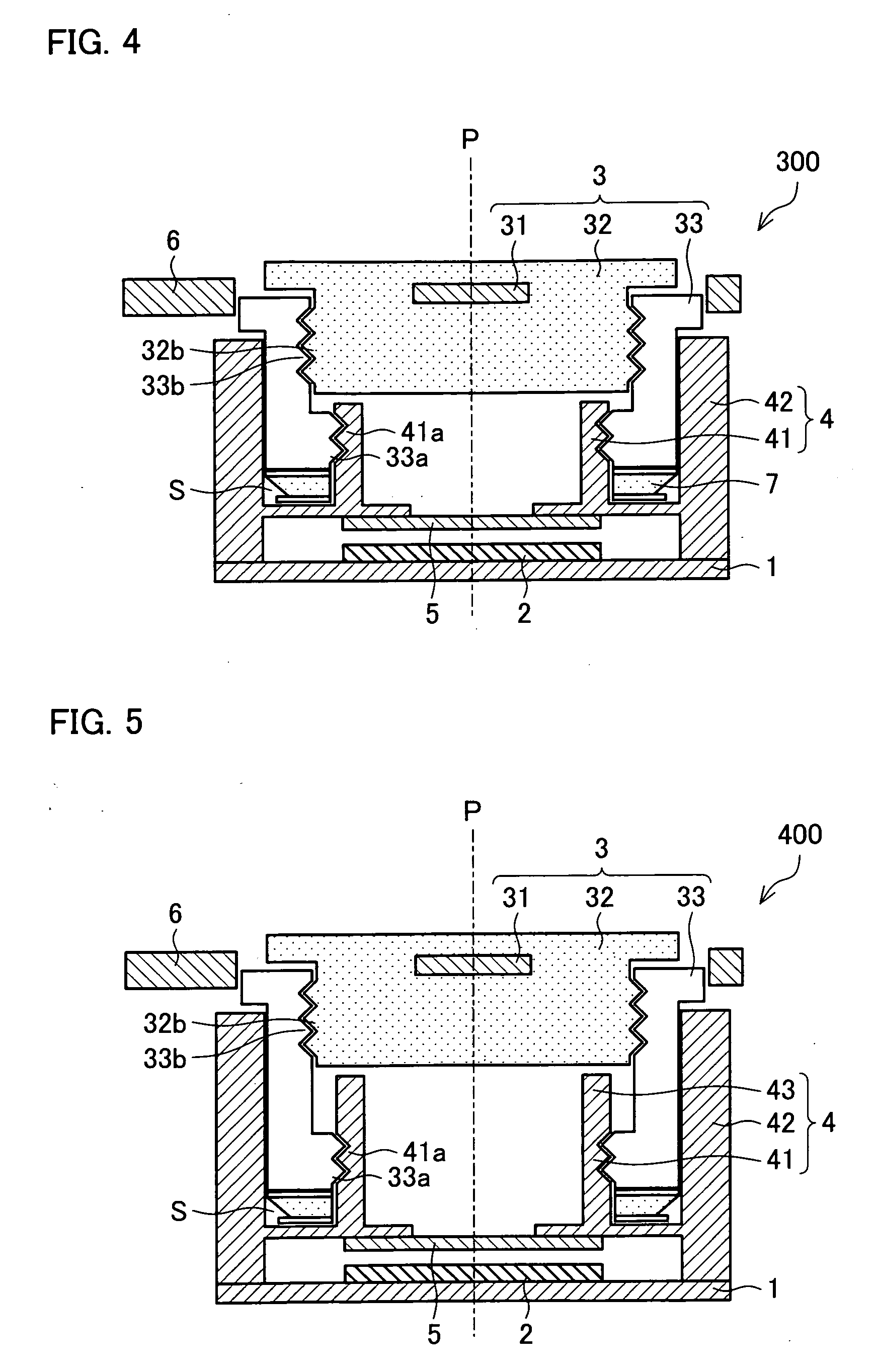

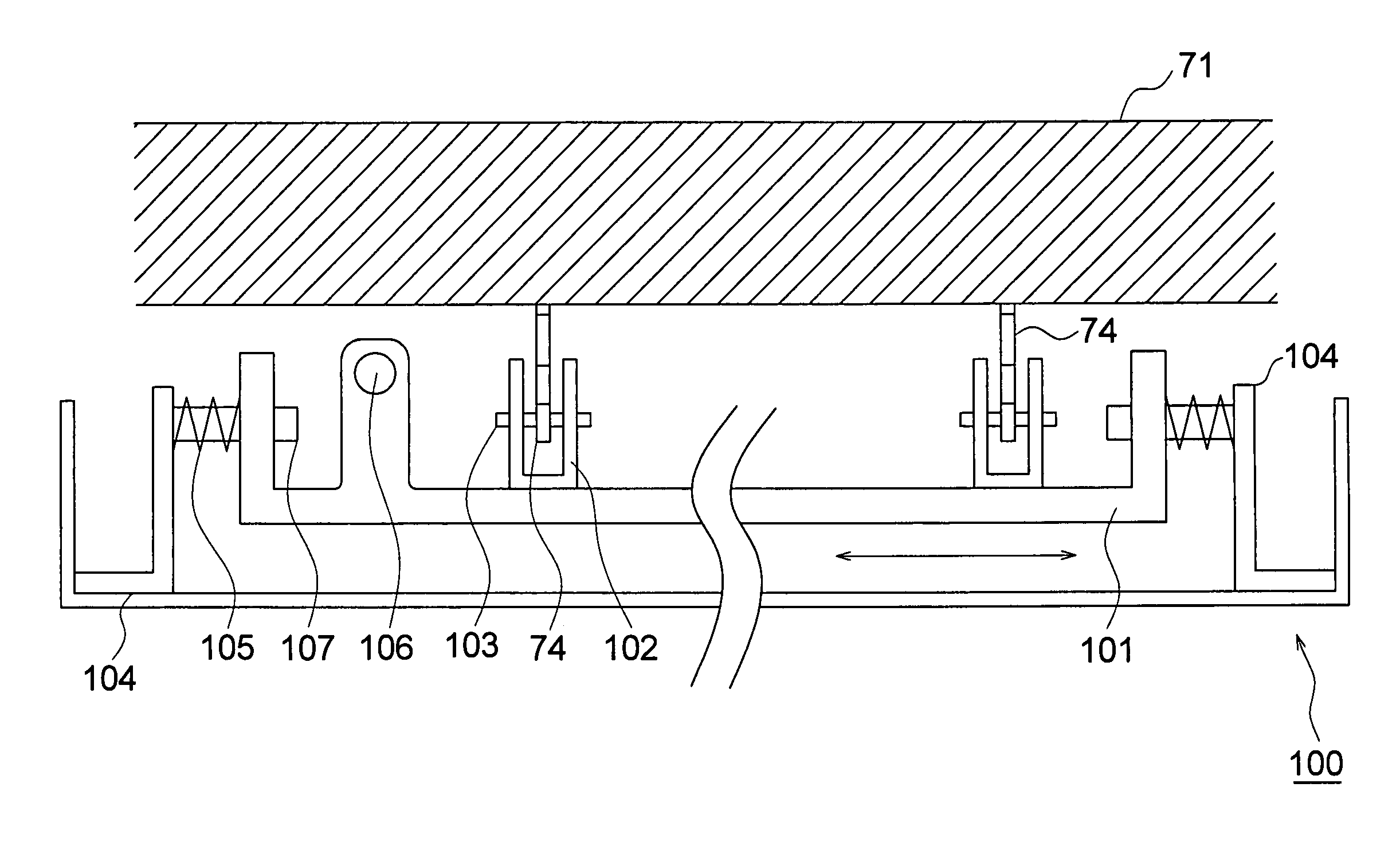

Solid-state image pickup device and electronic apparatus including same

InactiveUS20090219433A1Prevent contaminationReduce image defectTelevision system detailsSolid-state devicesSolid-stateEngineering

A camera module 100 of the present invention is arranged such that a lens barrel 32 is provided with an internal screw thread 32a on its internal side, and that a holding section 41, which is a portion of a lens holder 4, the portion holding a lens unit 3, is provided with an external screw thread 41a on its external side, the external screw thread 41a being engaged with the internal screw thread 32a. As a result, it is possible to provide the camera module 100 capable of preventing contamination by dirt into a light path and thereby reducing imaging defects.

Owner:SHARP KK

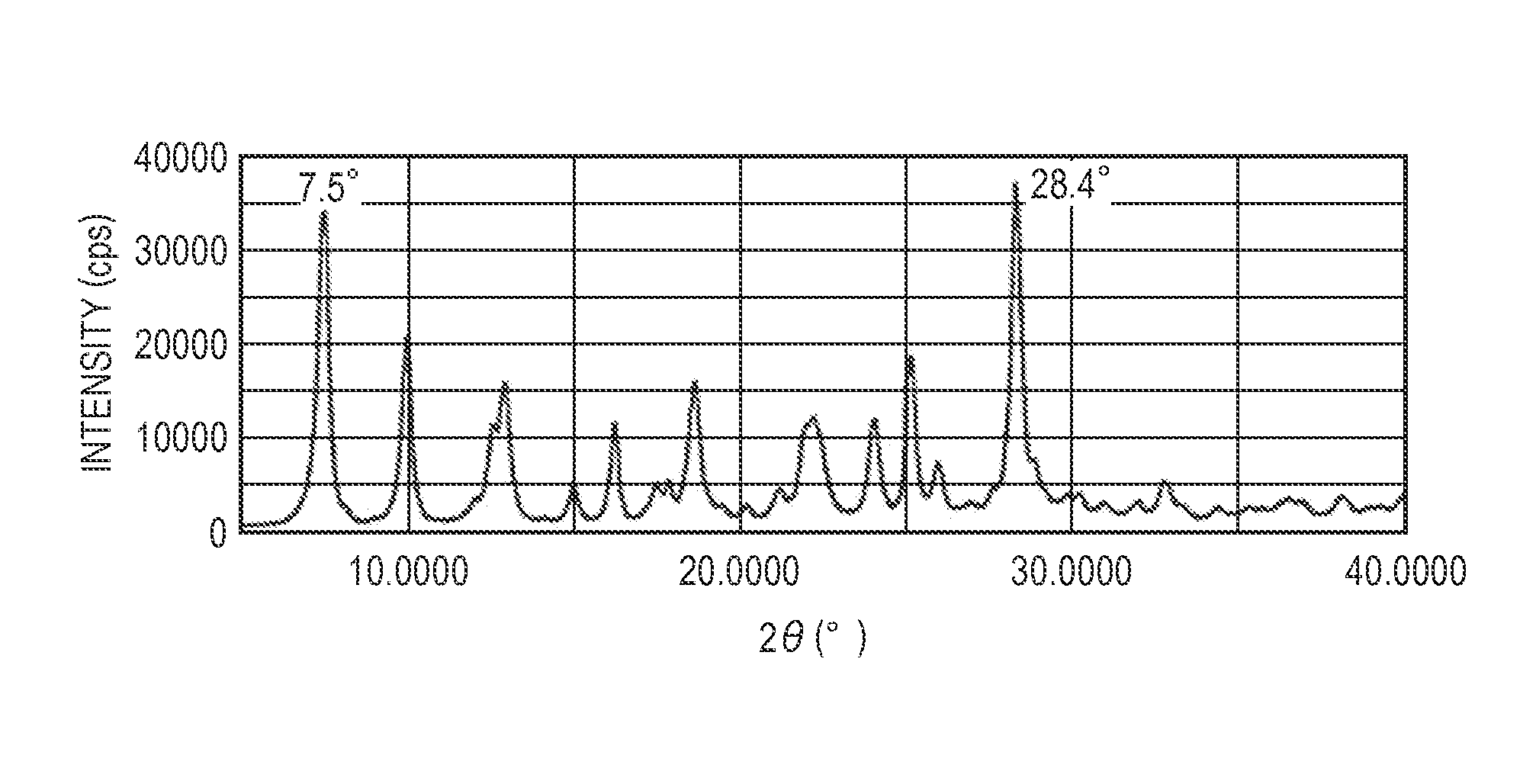

Electrophotographic photosensitive member, manufacturing method of electrophotographic photosensitive member, process cartridge and electrophotographic apparatus, and phthalocyanine crystal and manufacturing method of phthalocyanine crystal

InactiveUS20150346617A1Reduce image defectsMaintain good propertiesPorphines/azaporphinesElectrographic process apparatusPhthalocyanineElectron

The present invention provides: an electrophotographic photosensitive member which reduces image defects due to ghosting not only under a normal temperature and normal humidity environment but also even under a low temperature and low humidity environment; and a novel phthalocyanine crystal. The electrophotographic photosensitive member of the present invention includes a photosensitive layer which comprises a phthalocyanine crystal in which a dimethyl sulfoxide is contained. The content of the dimethyl sulfoxide is 0.1% by mass or more and 1.7% by mass or less based on the phthalocyanine crystal.

Owner:CANON KK

Scanning projection apparatus with phase detection and compensation

ActiveUS7972014B2Reduce image defectsIncrease brightnessTelevision system detailsProjectorsPhase differenceWavelength

A scanning projection apparatus for displaying image comprises a light source for generating a light beam, a beam scanner which deflects the light beam to project a two dimensional image field, a modulation means for modulating the intensity of the light beam, and a sensor to detect the scanned light beam. The light source may consist of a plurality of semiconductor lasers and / or solid state lasers to generate light beams with wavelengths of red, green and blue colors aligned into a single light path. The image field is divided into an active image field for displaying image and a dark field in the perimeter of the image field wherein the light beam is switched off to reduce inherent image defects. The sensor is positioned outside the active image field to detect a scan line once per image frame to eliminate image distortion due to phase difference between the actual and the predicted positions of the scanned beam, and to detect both the horizontal and the vertical scanning operations of the beam scanner for safety precaution.

Owner:AURISE INVESTMENT CO LTD

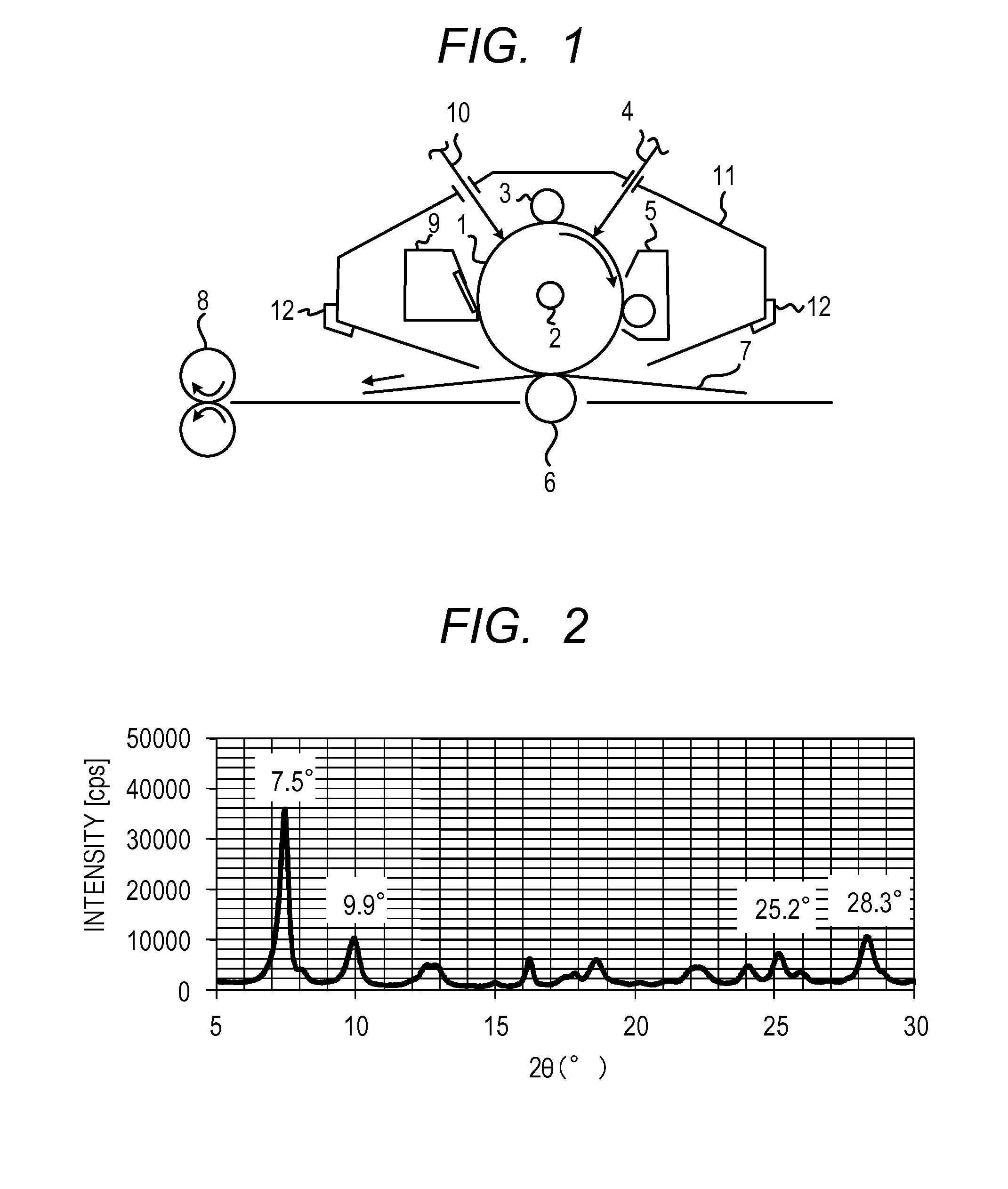

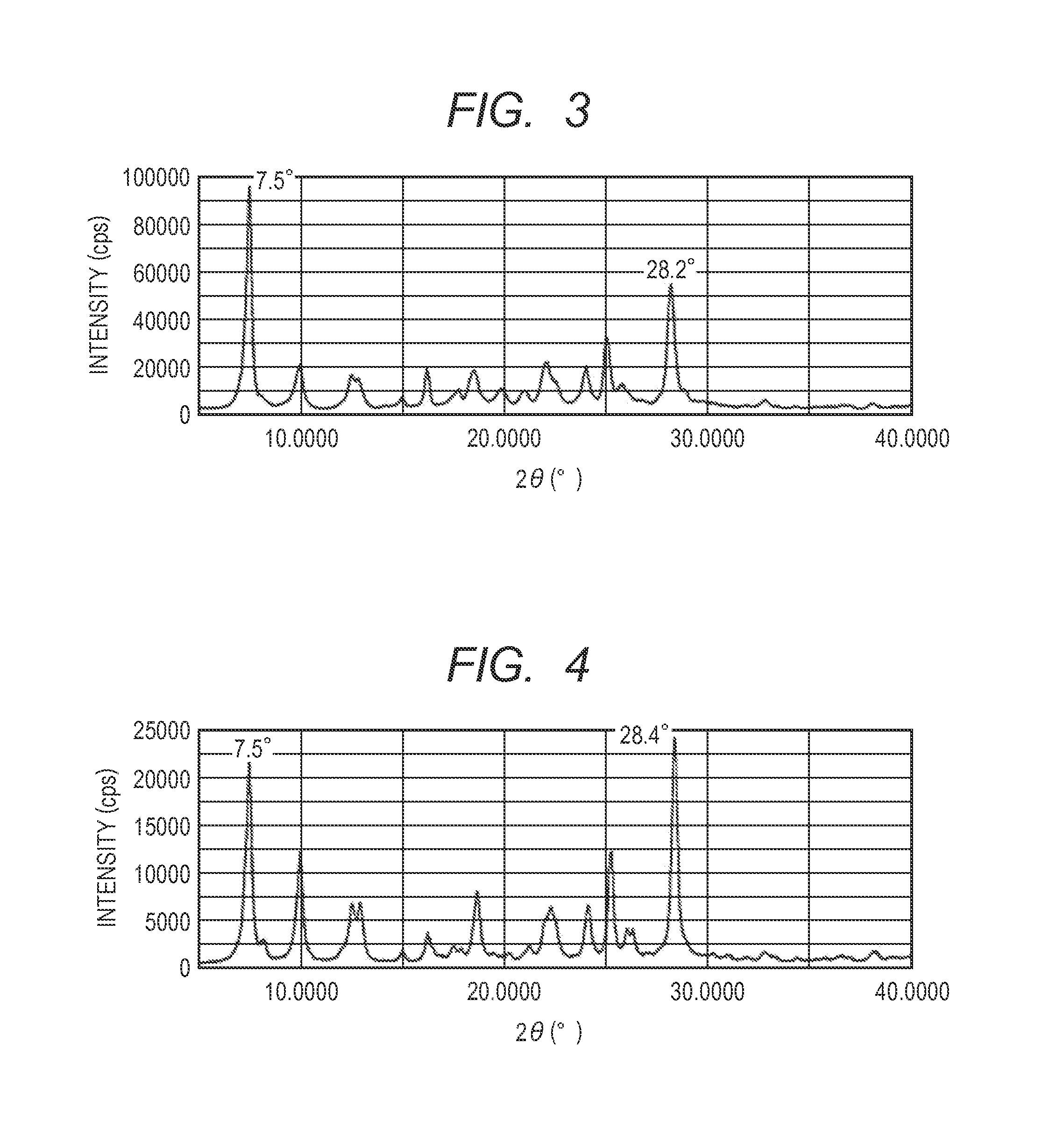

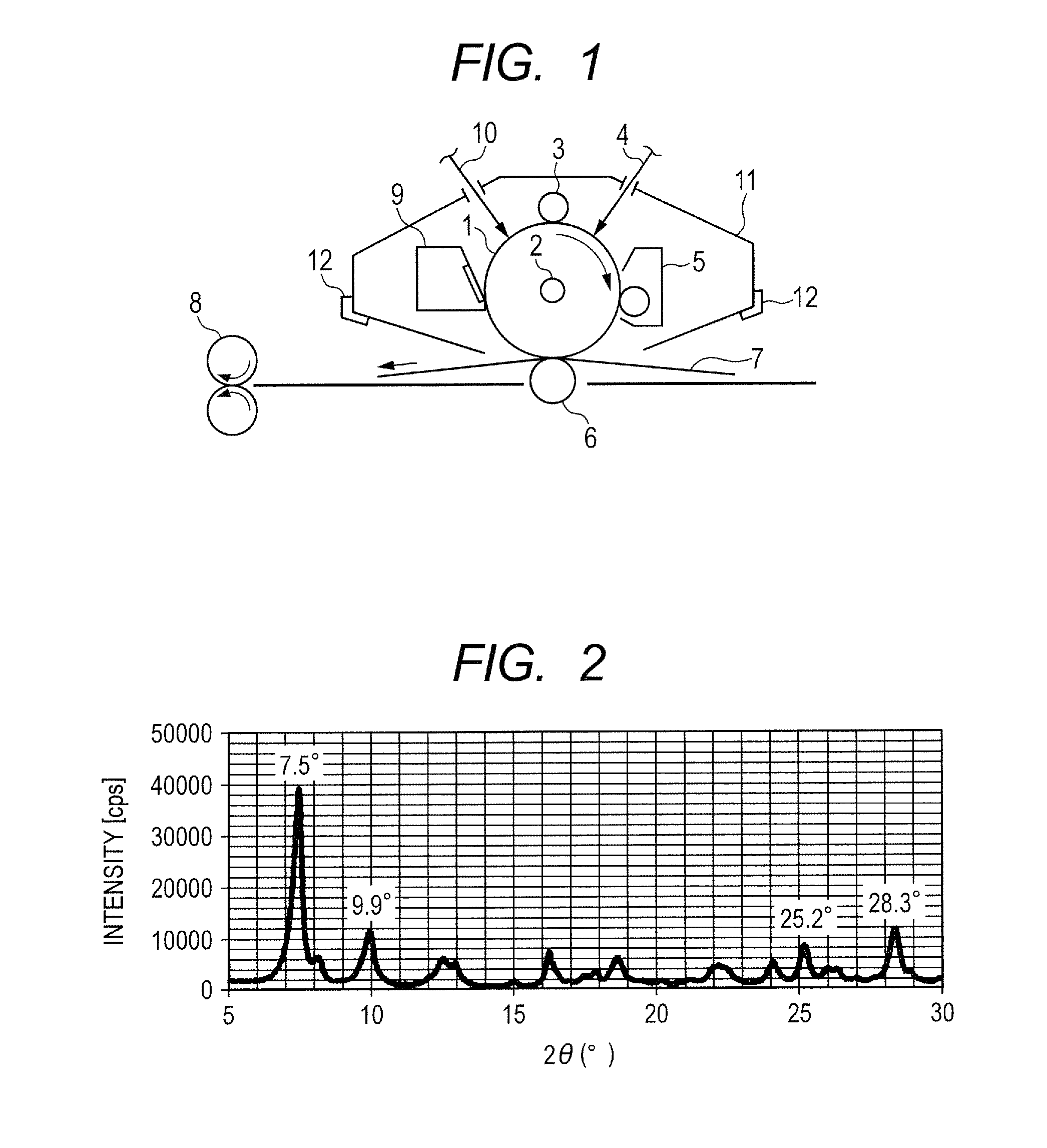

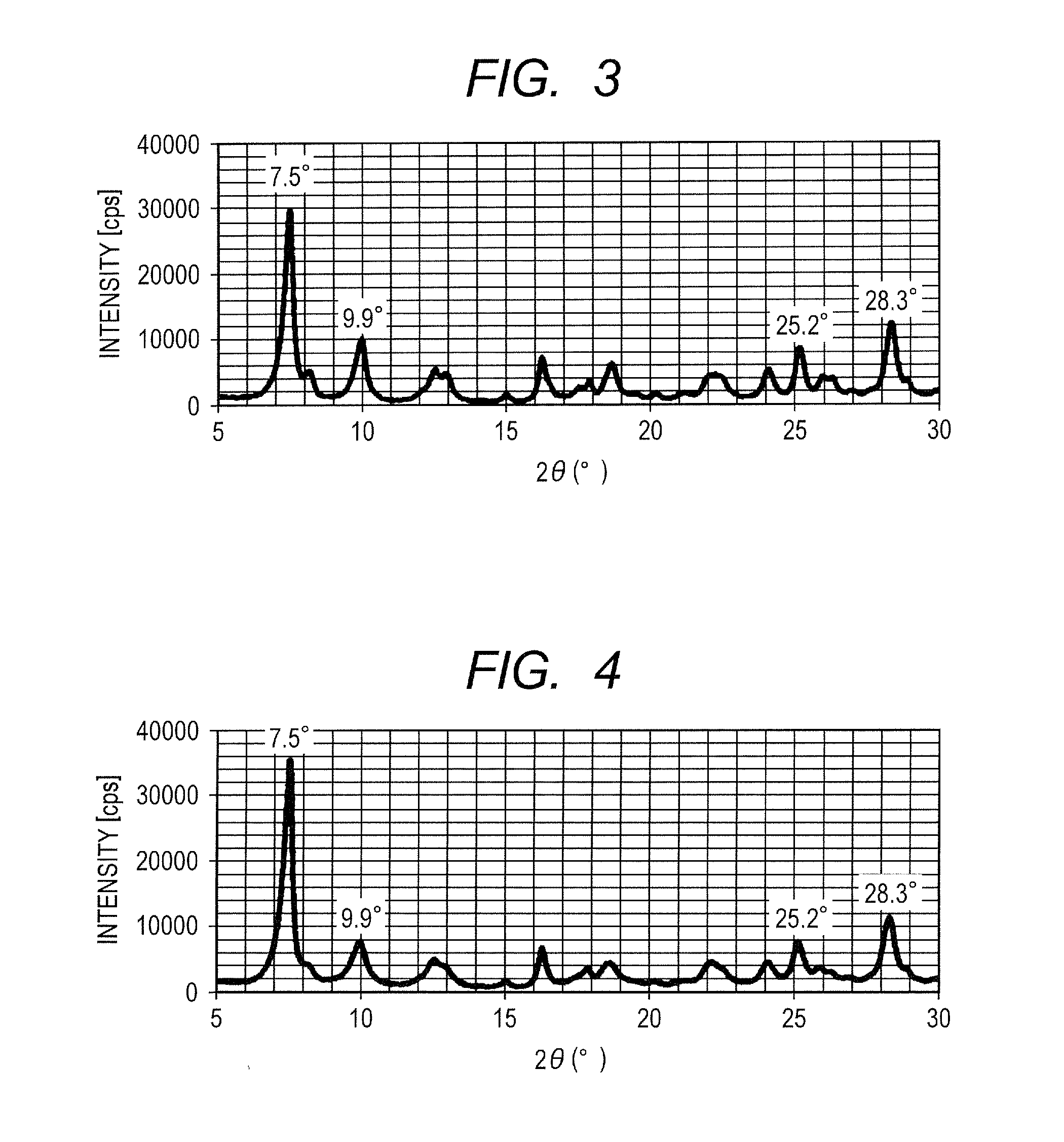

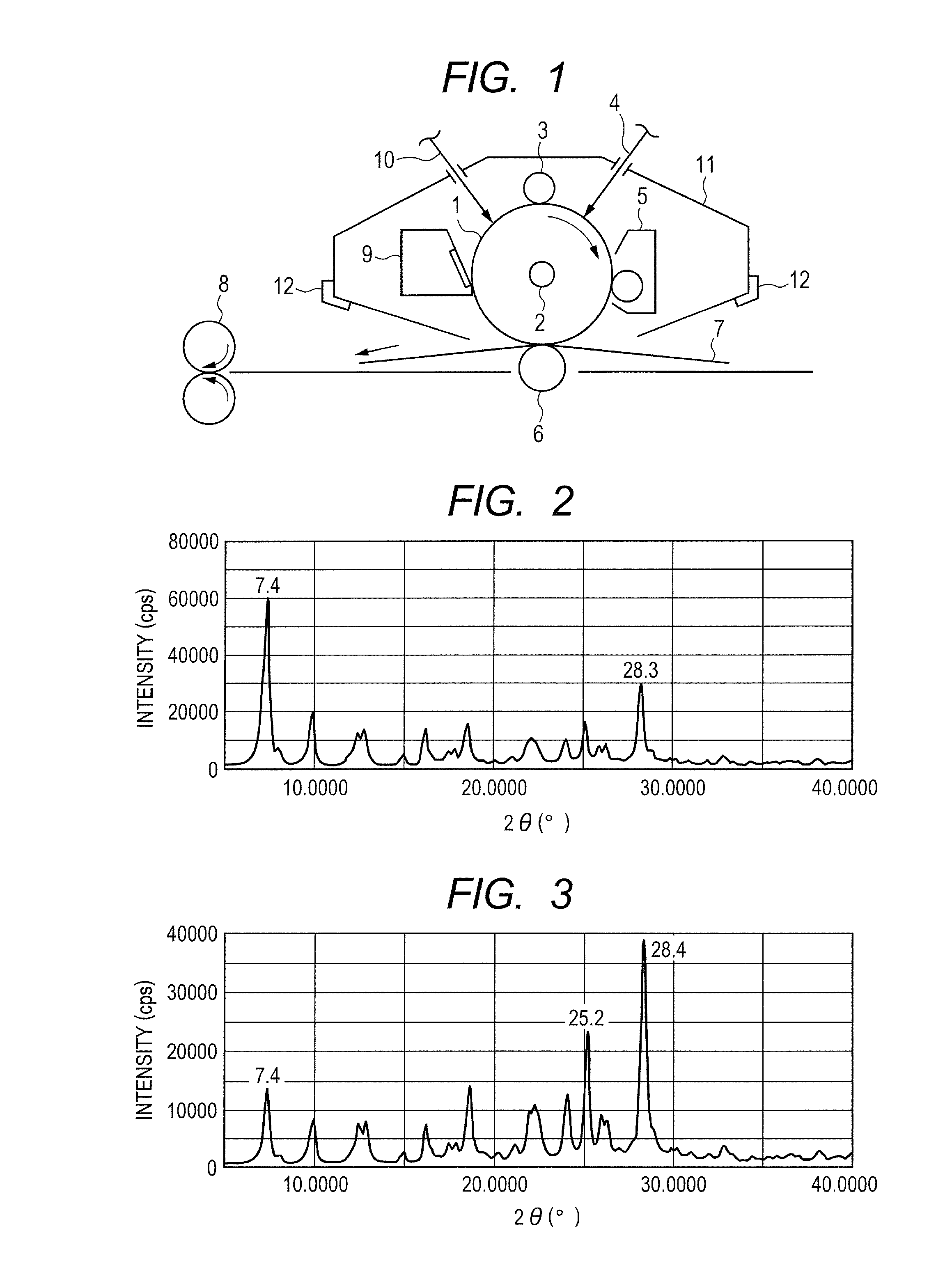

Electrophotographic photosensitive member, manufacturing method of electrophotographic photosensitive member, process cartridge and electrophotographic apparatus, and a solid solution and manufacturing method of a solid solution

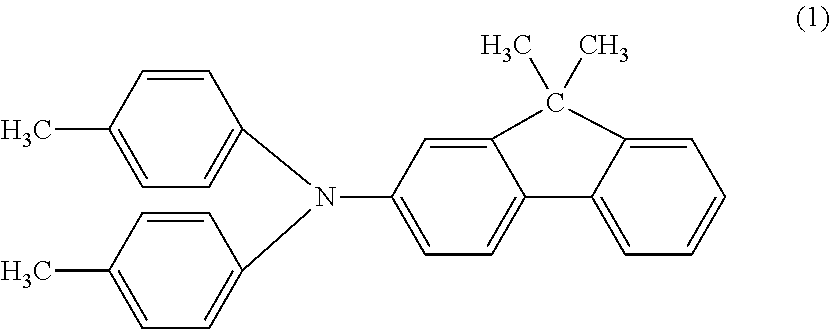

ActiveUS9459545B2Reduce image defectsMaintain good propertiesPorphines/azaporphinesElectrography/magnetographyEngineeringPhthalocyanine

The present invention provides an electrophotographic photosensitive member which can output images with reduced image defects due to ghosting not only under a normal temperature and normal humidity environment but also even under a low temperature and low humidity environment as especially severe conditions, and a manufacturing method thereof; and a process cartridge and an electrophotographic apparatus each having the electrophotographic photosensitive member. Accordingly, the electrophotographic photosensitive member of the present invention having a support and a photosensitive layer on the support includes the photosensitive layer which contains a solid solution of hydroxygallium phthalocyanine and a compound represented by the following Formula (1) or Formula (1)′, the solid solution having peaks at Bragg angles 2θ of 7.4°±0.3° and 28.3°±0.3° in CuKα characteristic X-ray diffraction.

Owner:CANON KK

Electrophotographic photosensitive member, process cartridge, electrophotographic apparatus and phthalocyanine crystal

InactiveUS20160091807A1Reduce image defectsMaintain good propertiesPorphines/azaporphinesElectrographic process apparatusCompound (substance)Phthalocyanine

The present invention provides an electrophotographic photosensitive member comprising a support, and a photosensitive layer formed on the support, wherein the photosensitive layer contains a phthalocyanine crystal in which a 4-piperidone compound represented by the following formula (1) is contained.

Owner:CANON KK

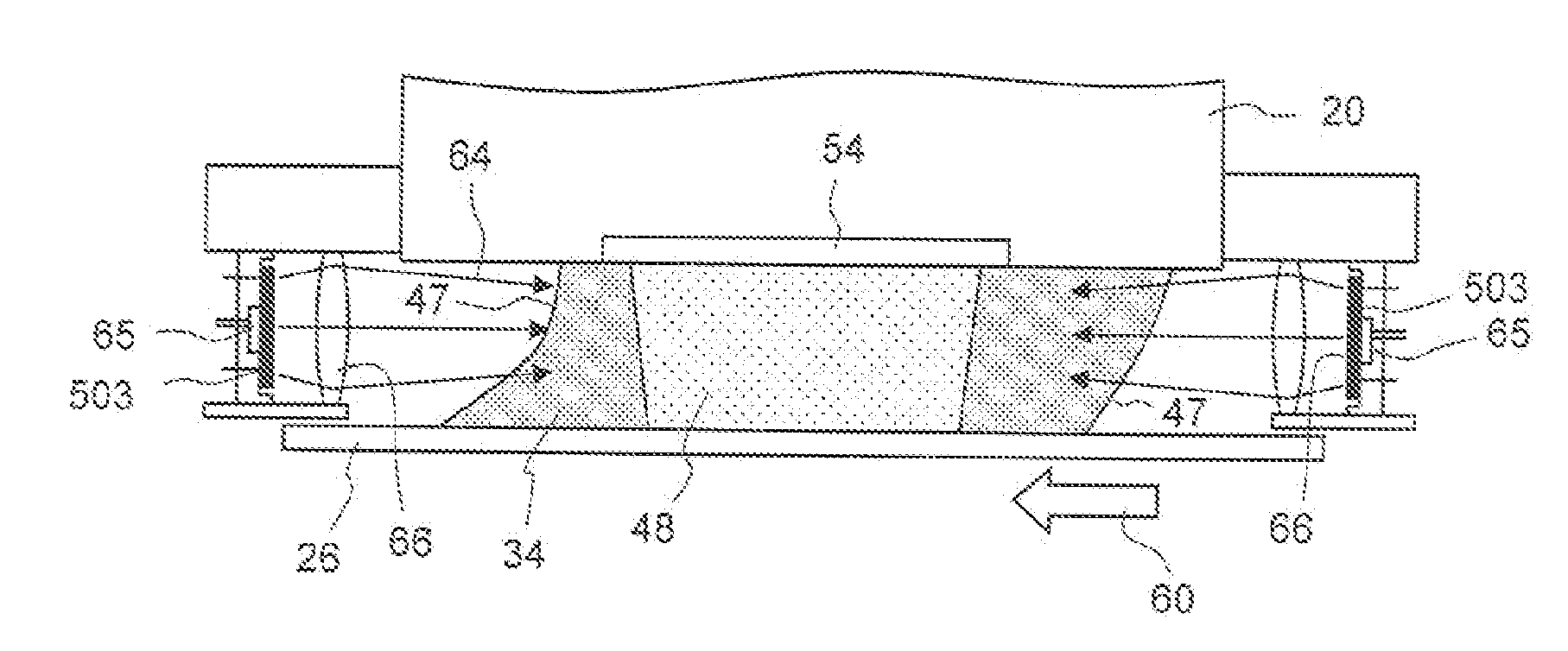

Exposure apparatus and measuring device for a projection lens

InactiveUS20100141912A1Reduce image defectsSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusMeasurement deviceRefractive index

A microlithographic projection exposure apparatus includes a projection lens that is configured for immersion operation. For this purpose an immersion liquid is introduced into an immersion space that is located between a last lens of the projection lens on the image side and a photosensitive layer to be exposed. To reduce fluctuations of refractive index resulting from temperature gradients occurring within the immersion liquid, the projection exposure apparatus includes heat transfer elements that heat or cool partial volumes of the immersion liquid so as to achieve an at least substantially homogenous or at least substantially rotationally symmetric temperature distribution within the immersion liquid.

Owner:CARL ZEISS SMT GMBH

Microlithographic projection exposure apparatus and measuring device for a projection lens

InactiveUS20080309894A1Reduce image defectsSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusRefractive indexProjection lens

A microlithographic projection exposure apparatus includes a projection lens that is configured for immersion operation. For this purpose an immersion liquid is introduced into an immersion space that is located between a last lens of the projection lens on the image side and a photosensitive layer to be exposed. To reduce fluctuations of refractive index resulting from temperature gradients occurring within the immersion liquid, the projection exposure apparatus includes heat transfer elements that heat or cool partial volumes of the immersion liquid so as to achieve an at least substantially homogenous or at least substantially rotationally symmetric temperature distribution within the immersion liquid.

Owner:CARL ZEISS SMT GMBH

Electrophotographic photosensitive member, manufacturing method of electrophotographic photosensitive member, process cartridge and electrophotographic apparatus, and phthalocyanine crystal and manufacturing method of phthalocyanine crystal

InactiveUS20150346616A1Reduce image defectsMaintain good propertiesPolycrystalline material growthFrom normal temperature solutionsN dimethylformamidePhthalocyanine

The present invention provides: an electrophotographic photosensitive member which reduces image defects due to ghosting not only under a normal temperature and normal humidity environment but also even under a low temperature and low humidity environment; and a novel phthalocyanine crystal. The electrophotographic photosensitive member of the present invention comprises a photosensitive layer which comprises a phthalocyanine crystal in which a N,N-dimethylformamide is contained. The content of the N,N-dimethylformamide is 0.1% by mass or more and 1.5% by mass or less based on the phthalocyanine crystal.

Owner:CANON KK

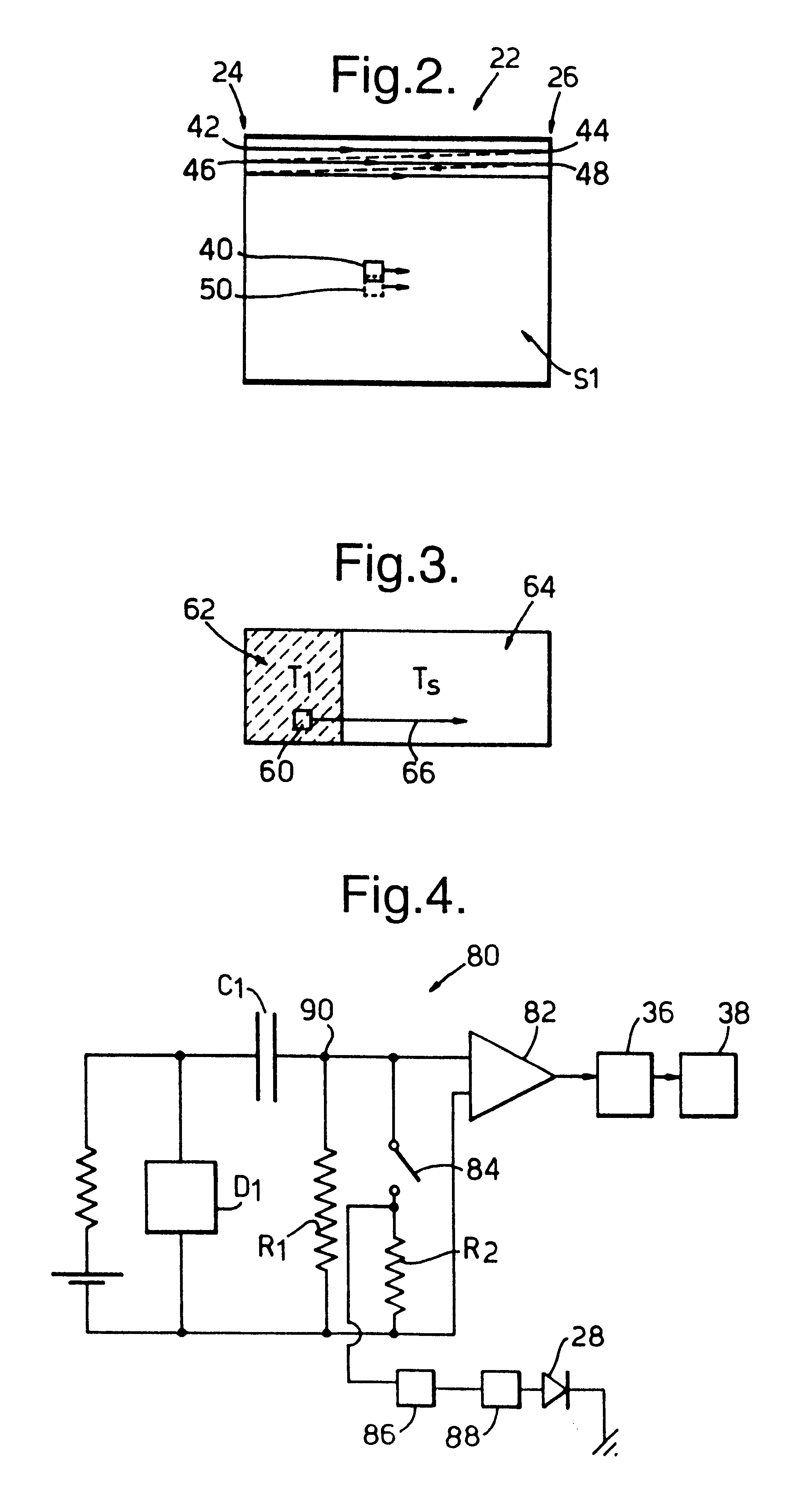

Thermal imaging system

InactiveUS6175113B1Reduce image defectsImage defectTelevision system detailsSolid-state devicesPhysicsBlack-body radiation

A thermal imaging system (10) which is accoupled and by scanning recreates a thermal image by superimposing measured variations in infrared emission from a scene (22) onto a reference level supplied by a light emitting diode (28). The diode (28) is both a positive and negative luminescent emitter. Emitted flux is current controlled to be equivalent to black body radiation at a range of temperatures which may be colder or hotter than ambient. A signal generated with the system (10) switches between scene and diode observation is a measure of the difference between the mean scene temperature and the diode effective temperature. In response to this digital, control means adjust the bias current through the diode (28) in order to reduce the temperature difference. The reference temperature converges towards the mean scene temperature as this process is repeated. Absolute temperature is thus restored and some image defects removed.

Owner:QINETIQ LTD

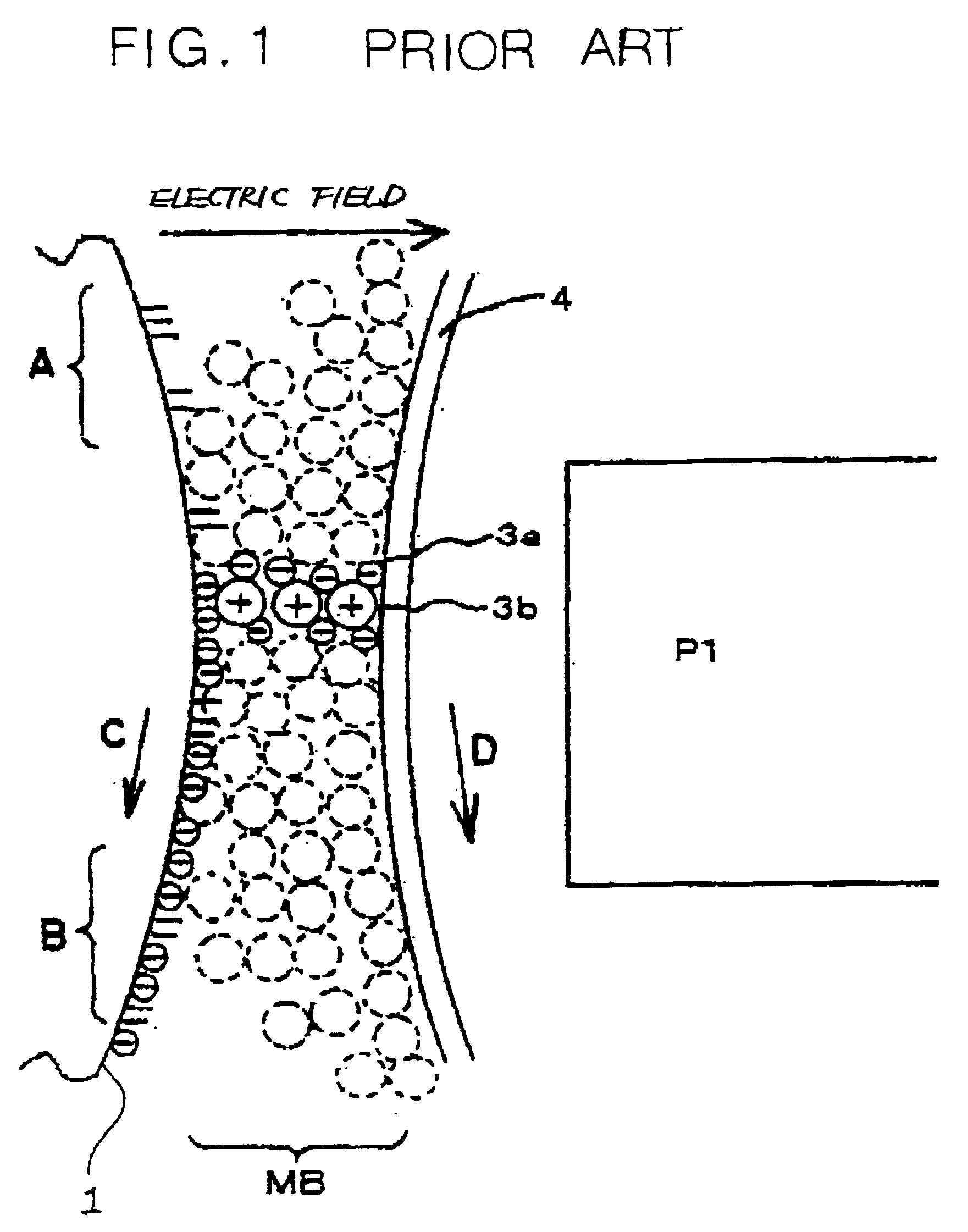

Developing device using a two-ingredient type developer and image forming apparatus including the same

InactiveUS20030108362A1Reducing toner scatteringIncrease line speedElectrographic process apparatusDevelopersAdditive ingredientImage resolution

A developing device of the present invention uses a developer containing magnetic toner grains and includes a main pole for development disposed in a sleeve. Flux density generated by the magnetic pole in a direction normal to the surface of the sleeve outside of the surface has an attenuation ratio of 50% or above. The toner grains have a weight mean grain size of 6.0 mum to 8.0 mum while the toner grains having grain sizes of 5 mum and below occupy 40 number % to 80 number % of the entire developer. The toner grains have magnetization strength of 10 emu / g to 25 emu / g in a magnetic field of 5 kOe or magnetization strength of 7 emu / g to 20 emu / g in a magnetic field of 1 kOe. The toner grains reduce toner scattering and image defects despite that they are magnetic, thereby implementing ultrahigh resolution, image reproducibility.

Owner:RICOH KK

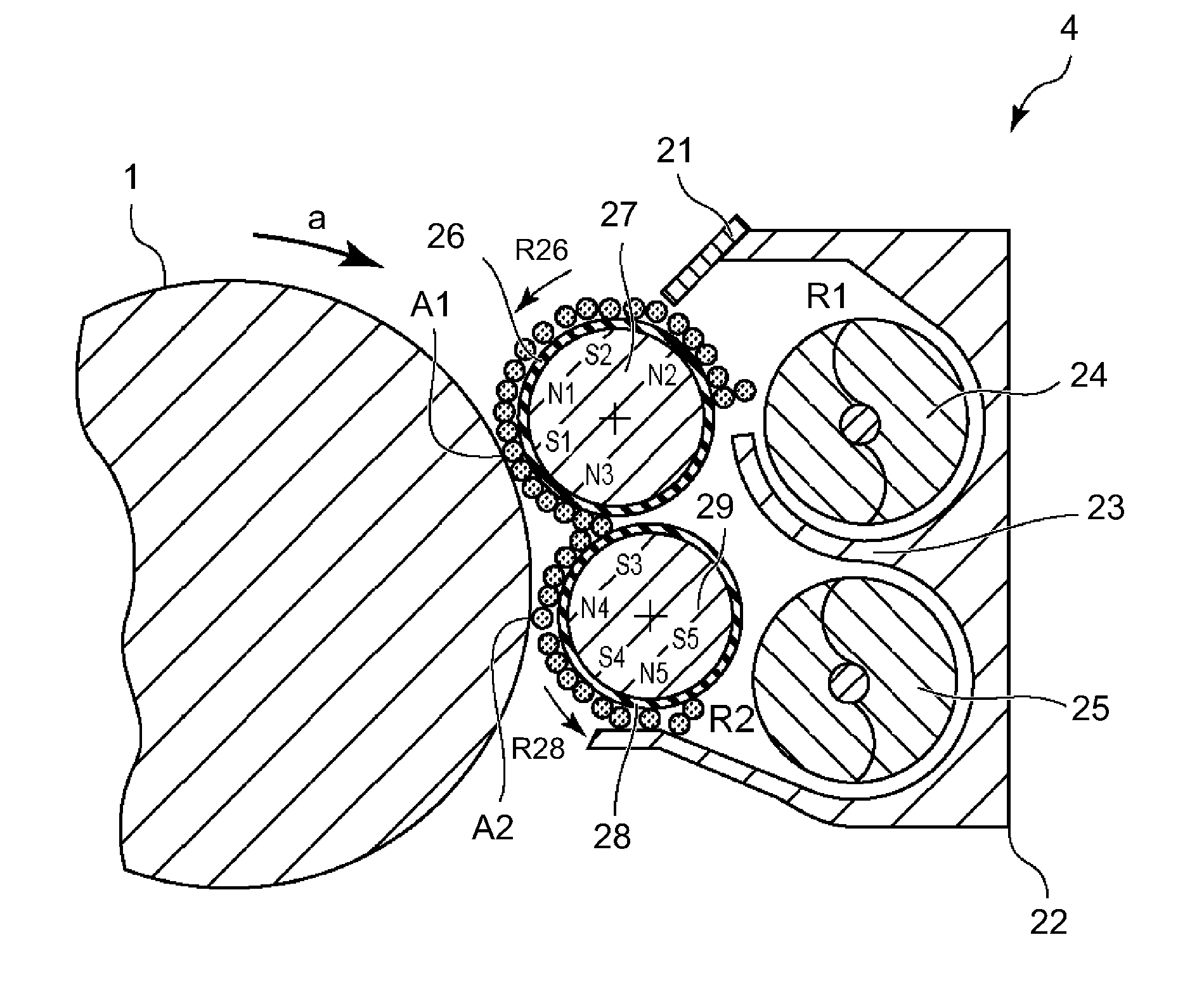

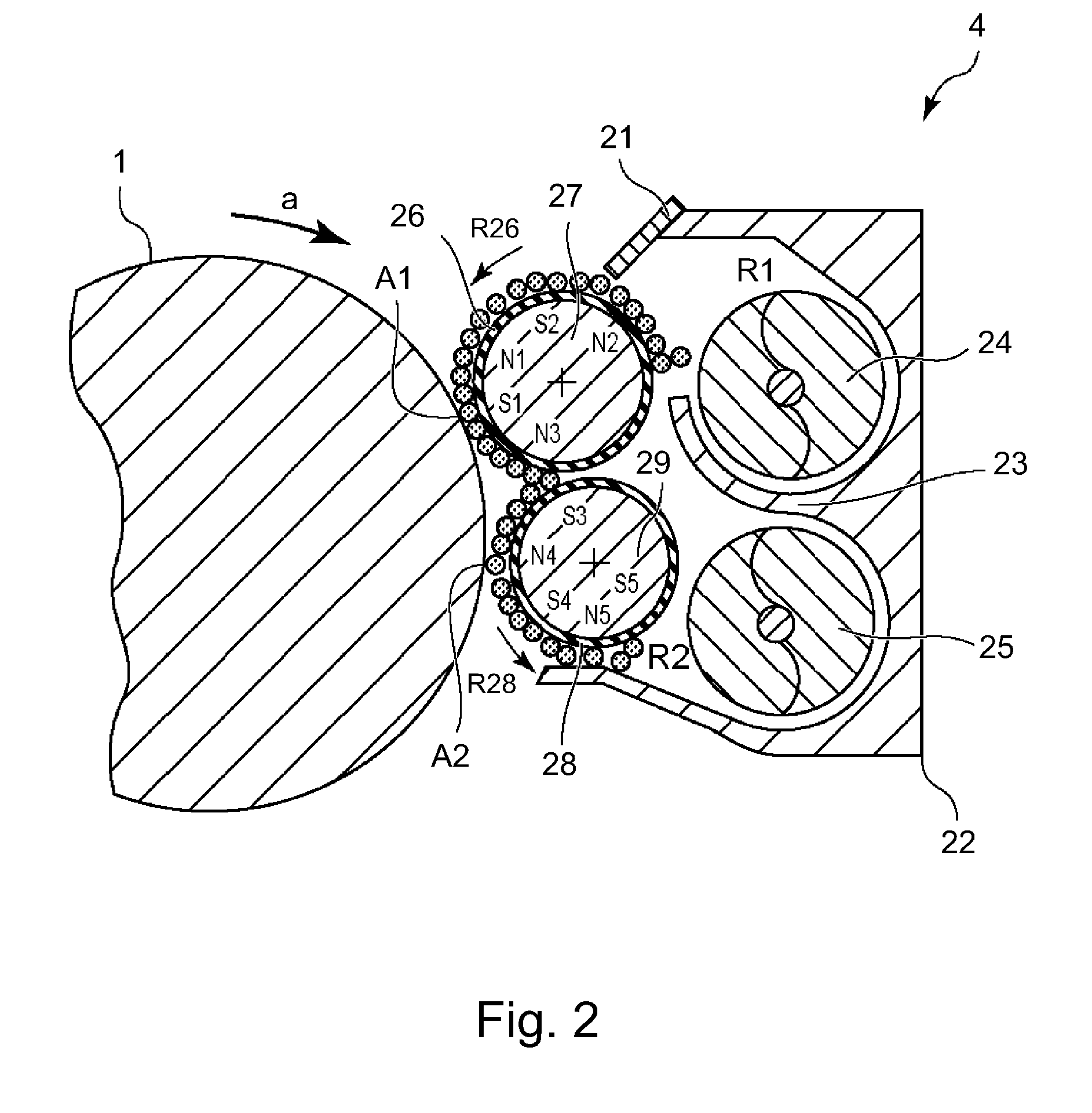

Developing device

A developing device includes first and second developer carrying members for developing an electrostatic latent image formed on an image bearing member. The first developer carrying member has a surface provided with grooves and feeds a developer carried thereon to a first developing region which is an opposing portion where the first developer carrying member opposes the image bearing member. The second developer carrying member carries the developer delivered from the first developer carrying member and feeds the developer to a second developing region which is an opposing portion where the second developer carrying member opposes the image bearing member. The second developer carrying member has a surface provided with grooves different in angle from those of the surface of the first developer carrying member.

Owner:CANON KK

Process for producing electrophotographic photosensitive member, and electrophotographic photosensitive member and electrophotographic apparatus making use of the same

InactiveUS7033717B2Improve image qualityEasy to handleElectrographic process apparatusAbnormal growthsHigh frequency power

An electrophotographic photosensitive member production process is provided having the steps of placing a cylindrical substrate having a conductive surface in a first film-forming chamber, and decomposing a source gas with high-frequency power to deposit on the cylindrical substrate a first layer formed of a non-single-crystal material, taking out of the first film-forming chamber the cylindrical substrate with the first layer deposited thereon, and placing the cylindrical substrate with the first layer deposited thereon in a second film-forming chamber, and decomposing a source gas with a high-frequency power to deposit on the first layer a second layer having an upper-part blocking layer formed of a non-single-crystal material. Even where abnormal growth portions called spherical protuberances are present on the photosensitive member surface, they can be made not to appear on images, and image defects can vastly be remedied.

Owner:CANON KK

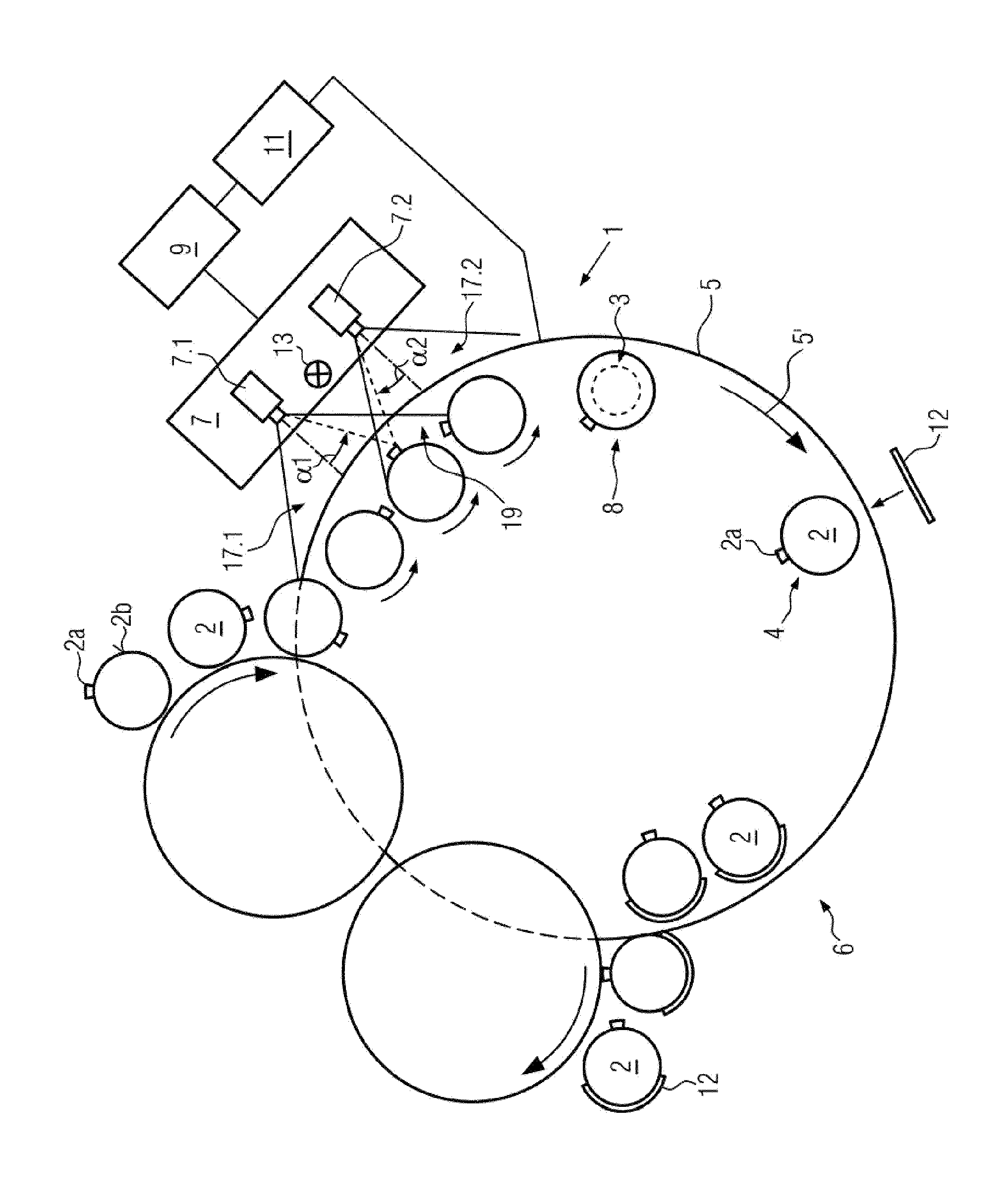

Device and method for aligning containers

ActiveUS20140299445A1Reduce image defectsImprove accuracyMaterial analysis by optical meansControl devices for conveyorsEngineeringMechanical engineering

Owner:KRONES AG

Electrophotographic photosensitive member, process cartridge and electrophotographic apparatus

ActiveUS20140170540A1Reduce image defectsElectrographic process apparatusCorona dischargePhthalocyaninePolymer chemistry

The photosensitive layer of an electrophotographic photosensitive member contains (a) a gallium phthalocyanine crystal, (b) a specific amine compound and (c) a specific polyvinylacetal resin.

Owner:CANON KK

Digital camera with integrated accelerometers

InactiveUS20090251565A1Solve the large power consumptionApplicable for applicationTelevision system detailsColor television detailsAccelerometerComputer graphics (images)

A digital camera system has integrated accelerometers for determining static and dynamic accelerations of the digital cameral system. Data relating to static and dynamic accelerations are stored with recorded image data for further processing, such as for correcting image data for roll, pitch and vibrations and for displaying recorded images with a predetermined orientation using information about, e.g., roll. Data may also be used on-the-fly for smear suppression caused by vibrations.

Owner:PHASE ONE

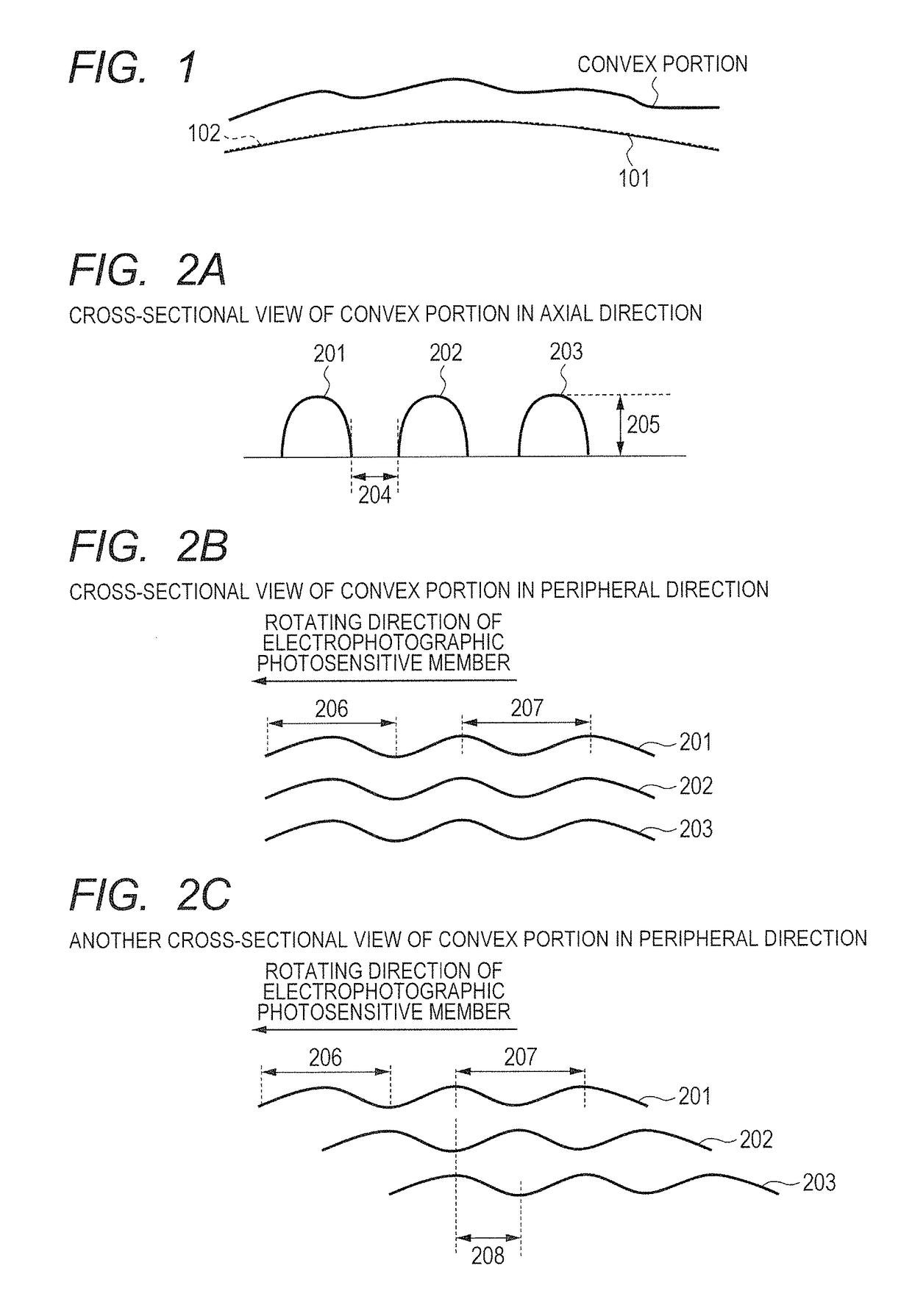

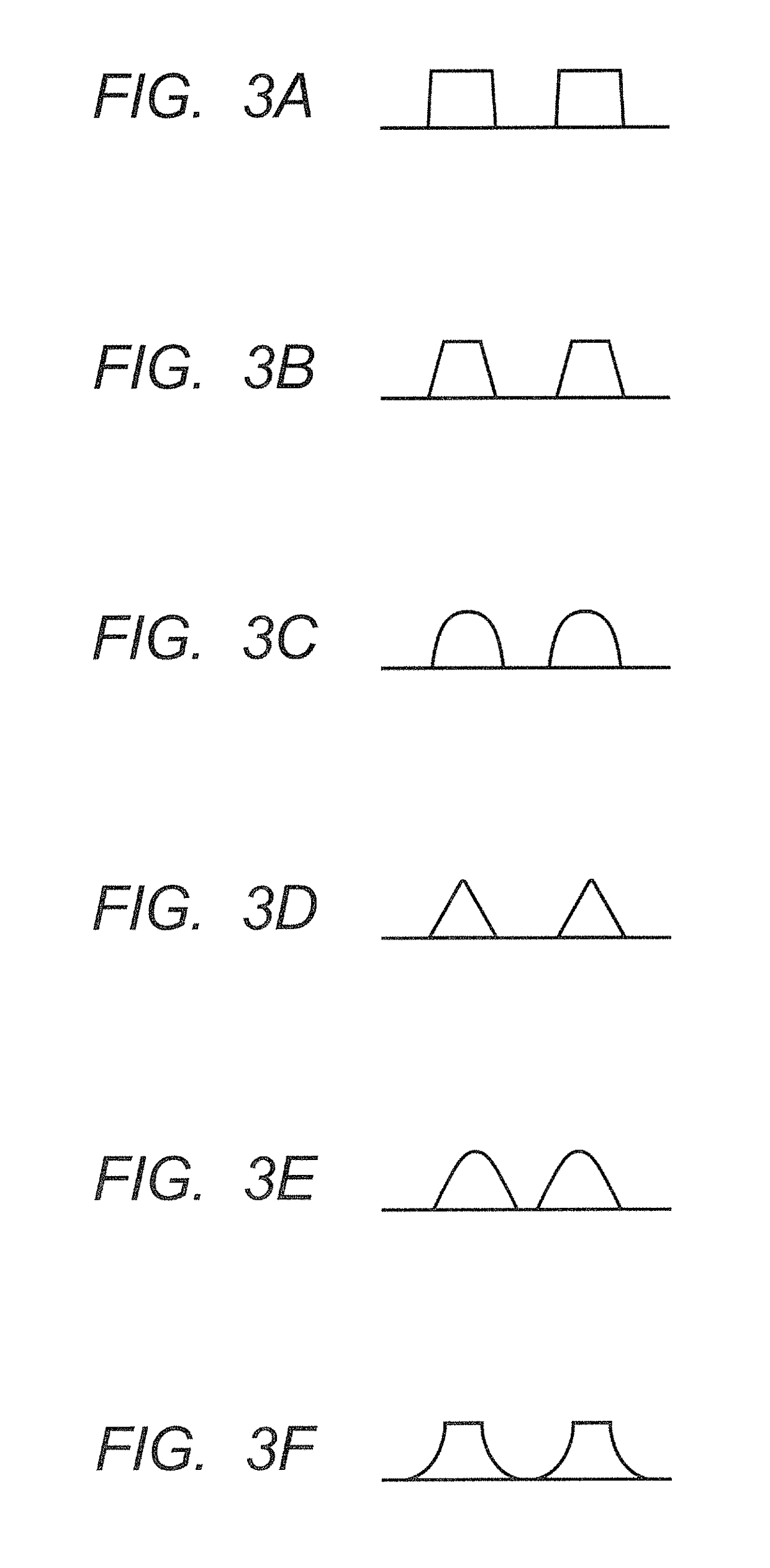

Electrophotographic photosensitive member, process cartridge and electrophotographic apparatus

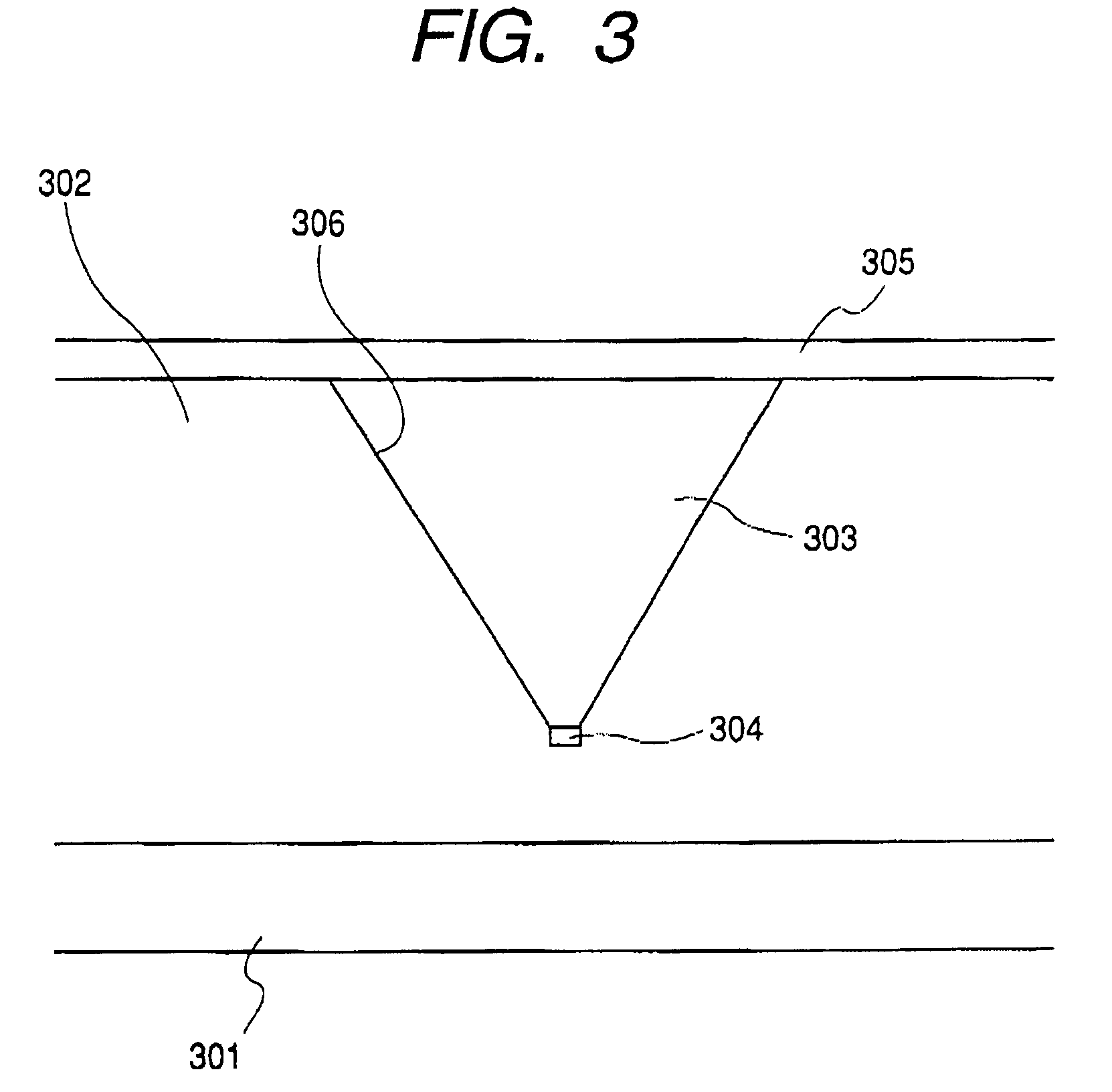

ActiveUS9817324B2Reduce image defectsElectrographic process apparatusEngineeringElectrical and Electronics engineering

An electrophotographic photosensitive member, a process cartridge and an electrophotographic apparatus wherein a streak-like image defect otherwise occurring in output in a low printing mode performed under a H / H environment can be reduced are provided. A surface of the photosensitive member has a convex and concave portions continuously in a peripheral direction of the photosensitive member, and alternately in an axial direction of the photosensitive member, a width w of the concave portion is 30 to 100 μm, a depth d of the concave portion is 1 to 5 μm, the convex portion has a rising slope and a descending slope in the peripheral direction of the photosensitive member, and a distance from a starting point of the rising slope to an end point of the descending slope and a distance from a starting point of the descending slope to an end point of the rising slope are 300 μm or less.

Owner:CANON KK

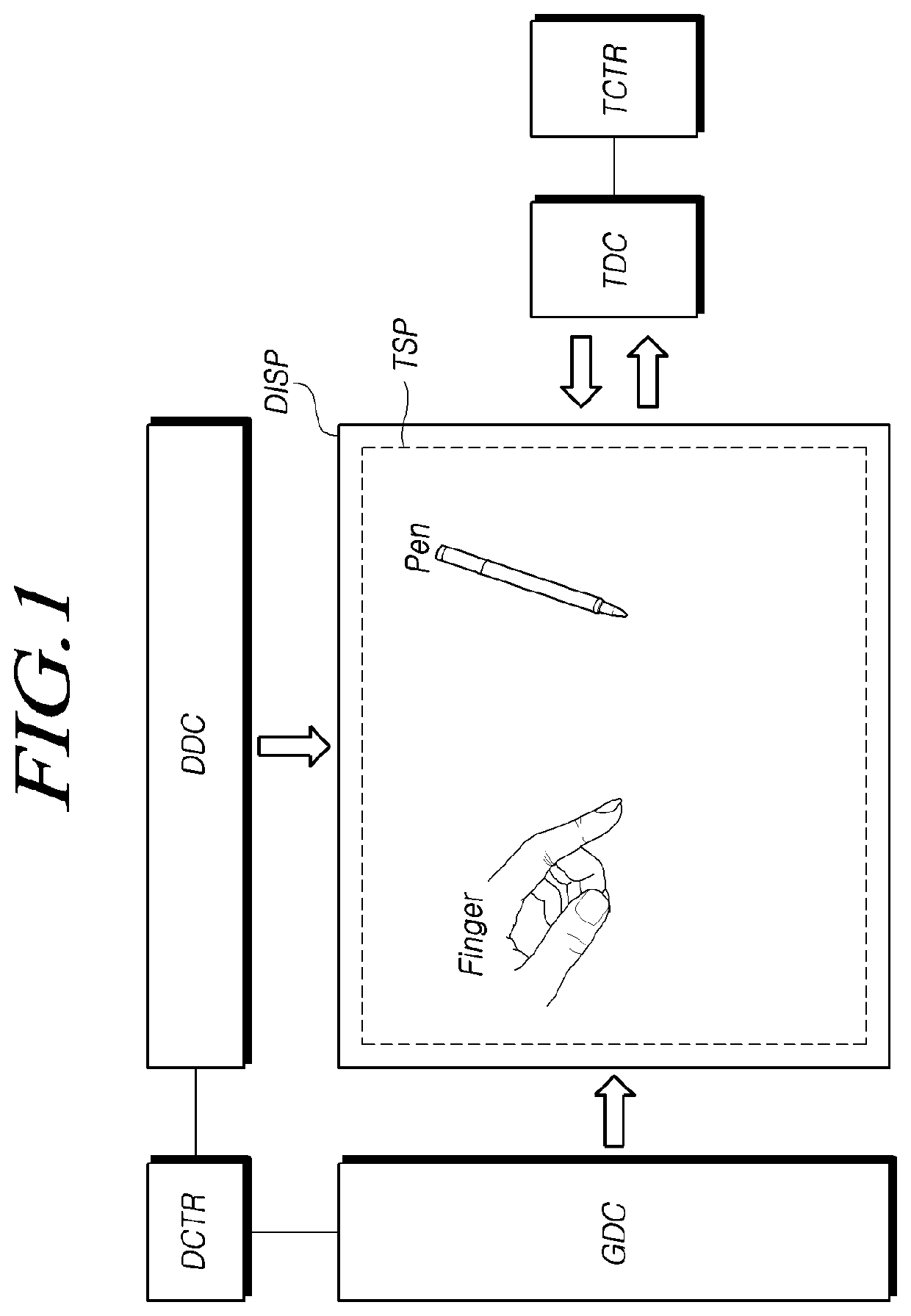

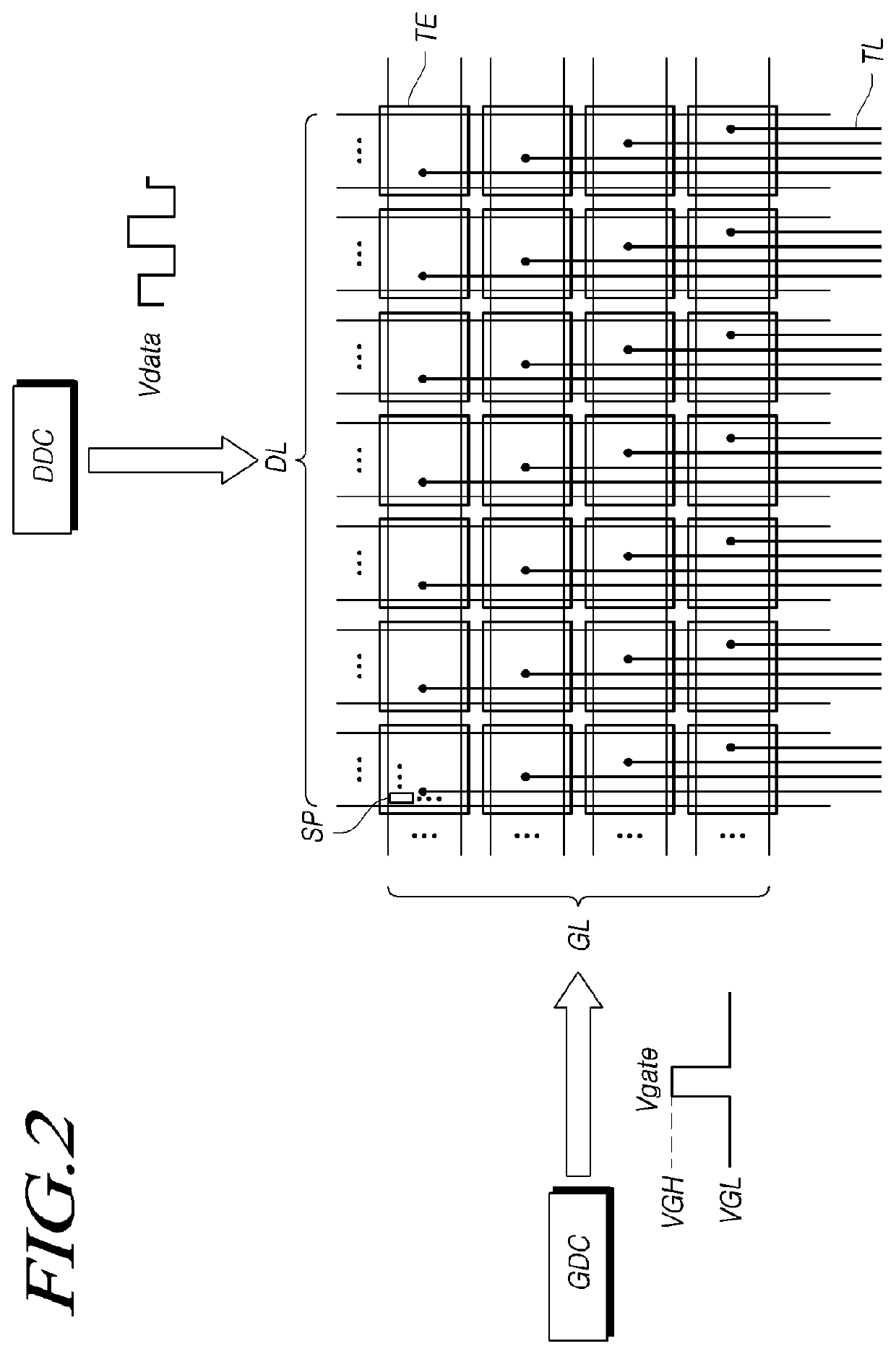

Touch display device, driving circuit, and driving method

ActiveUS11003278B2Display stableStable executionStatic indicating devicesInput/output processes for data processingDisplay deviceHemt circuits

A touch display device, a driving circuit, and a driving method are provided. An image defect which occurs when display driving and touch driving are simultaneously executed can be reduced by performing control such that a voltage level of a touch electrode driving signal (TDS) varies in a section other than a high-level period (Pon) of an ON-clock signal (ON_CLK) and / or a high-level period (Poff) of an OFF-clock signal (OFF_CLK).

Owner:LG DISPLAY CO LTD

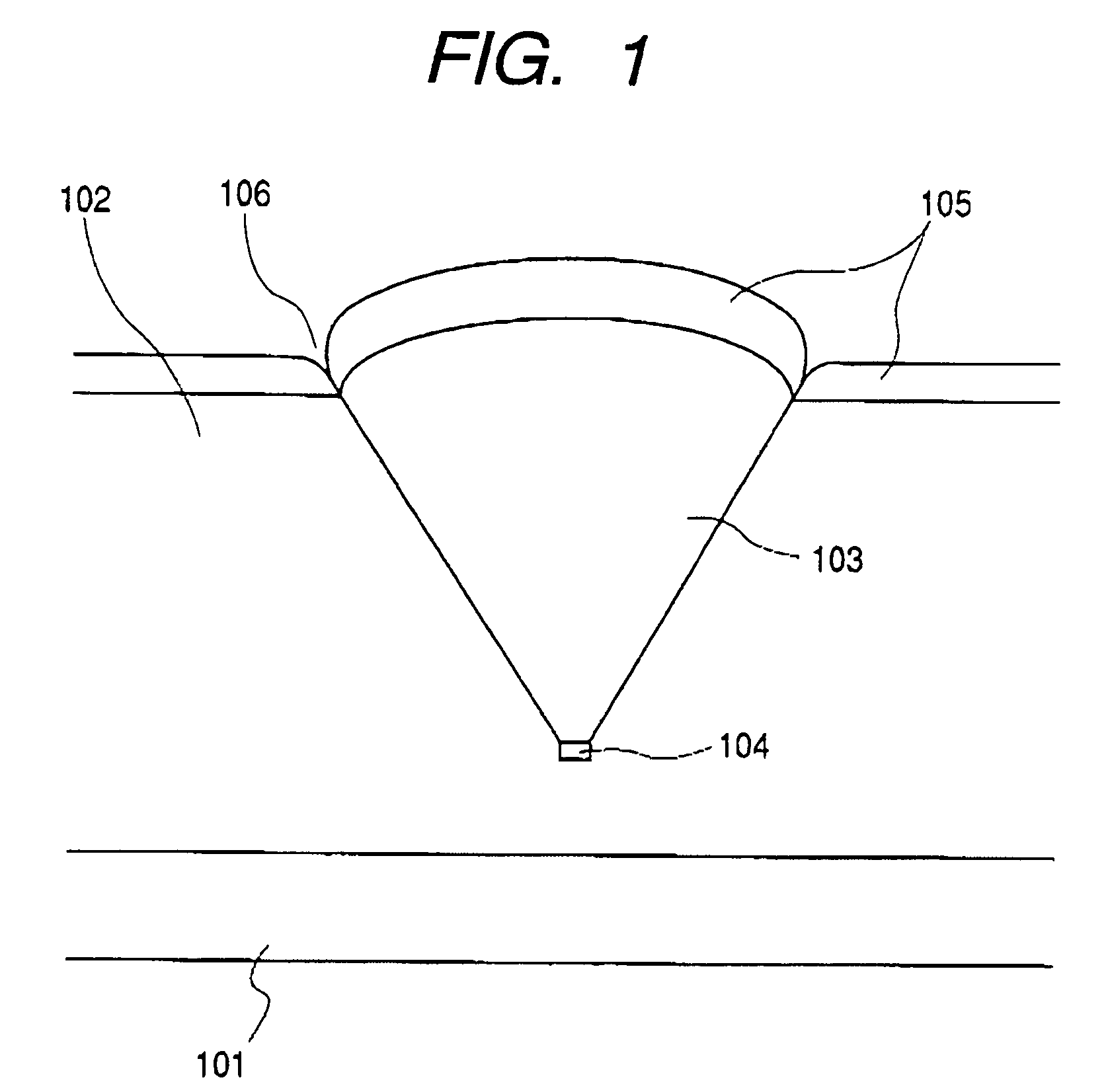

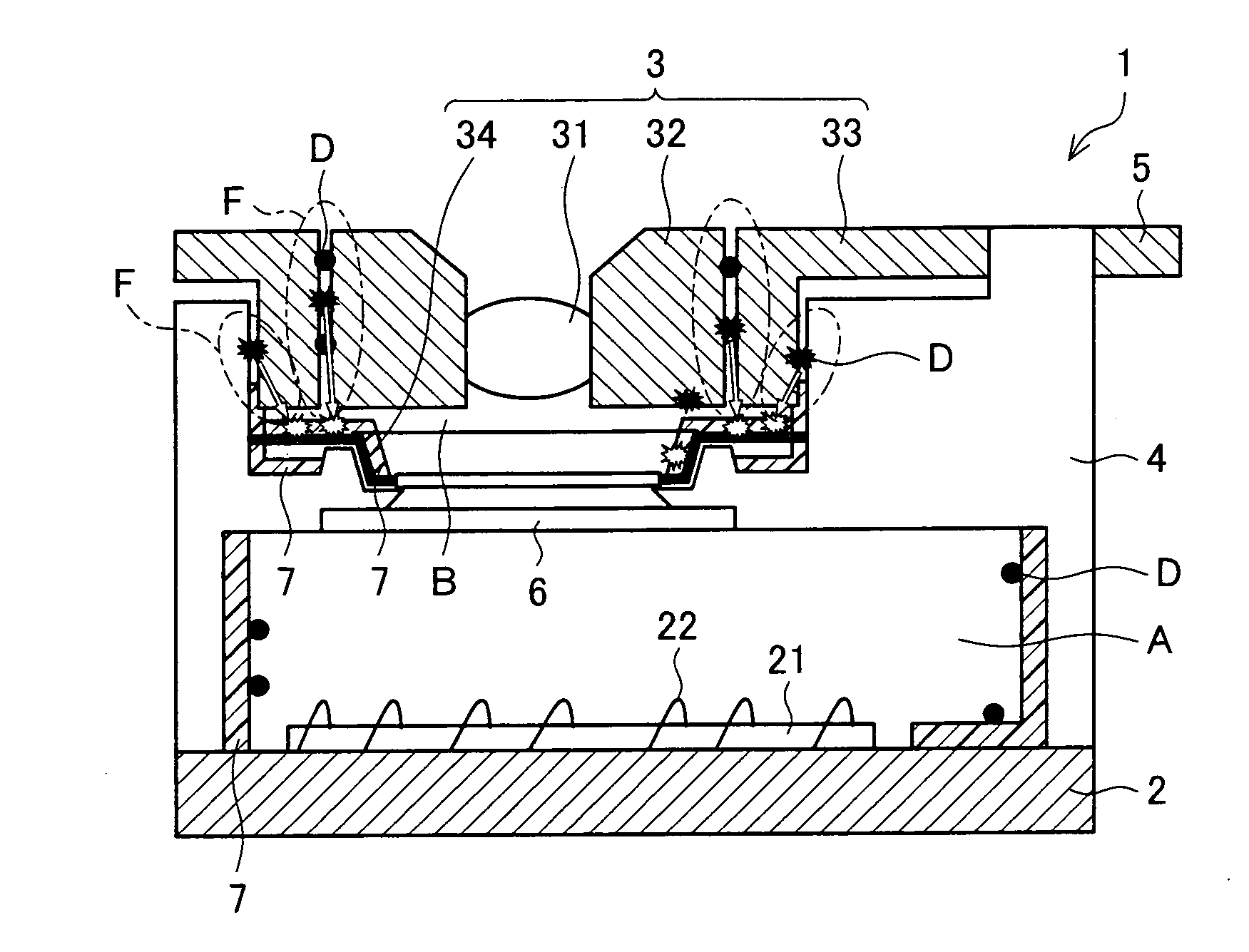

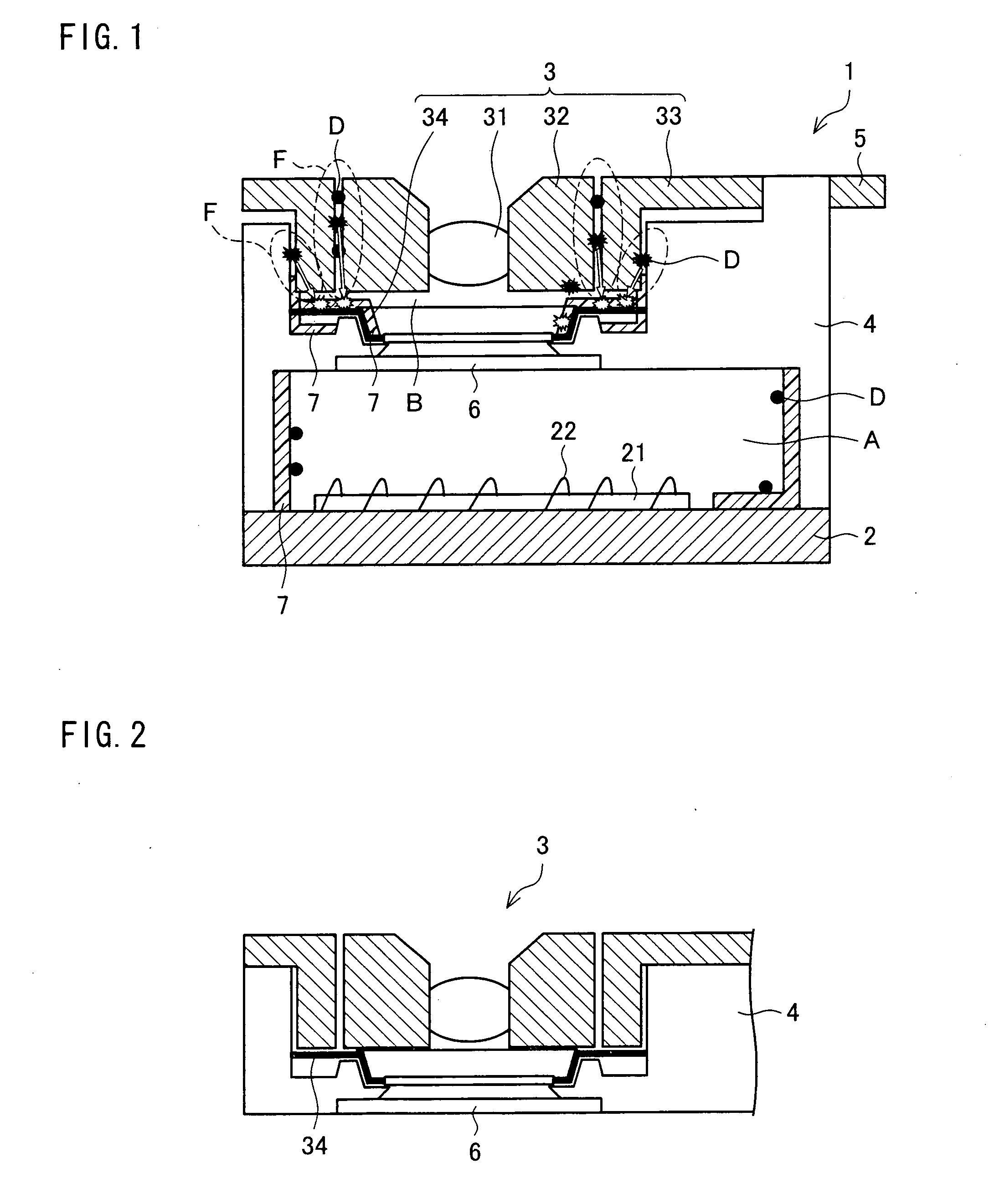

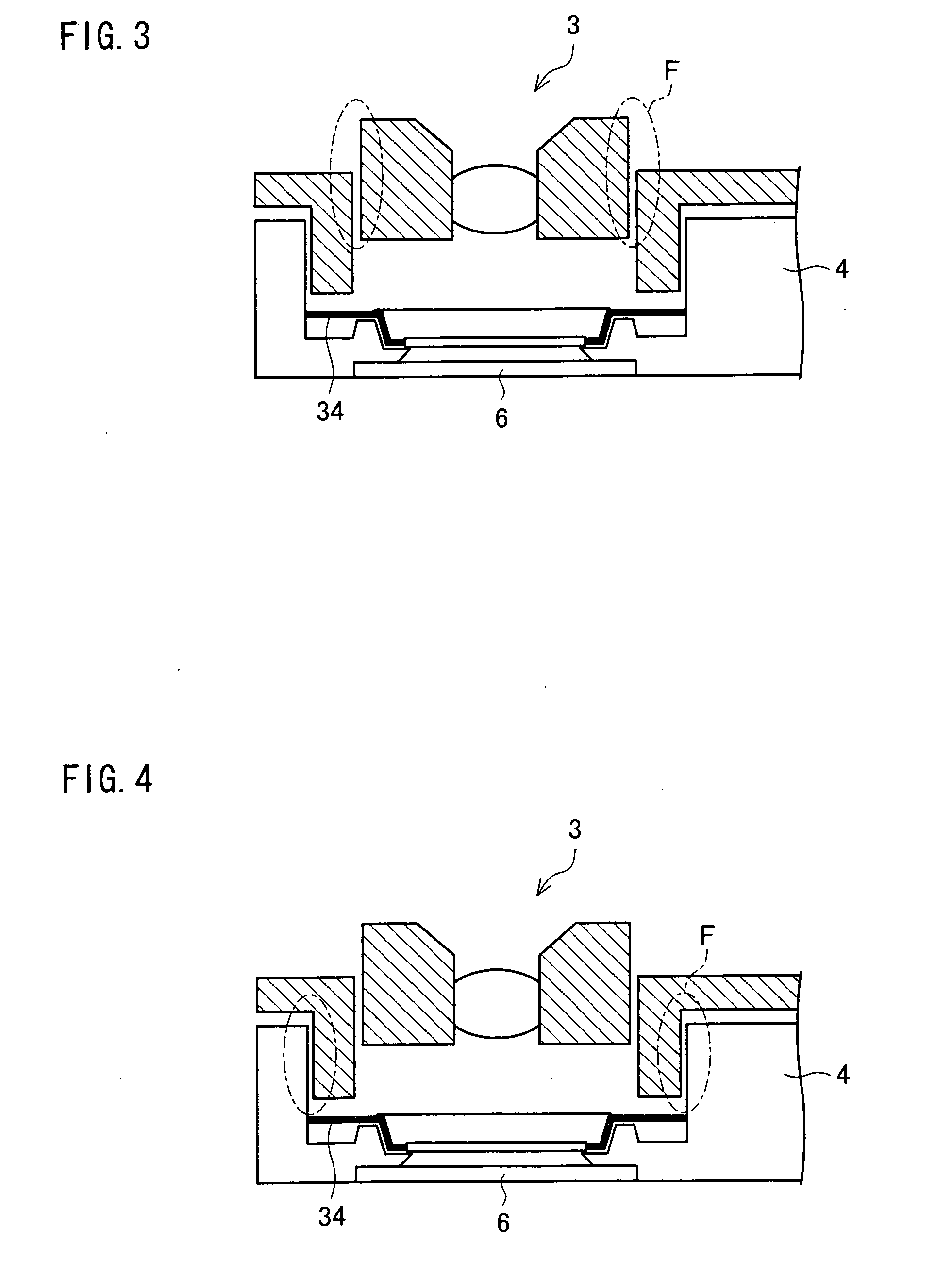

Solid-state image sensing device, method and apparatus for manufacturing same, and electronic device

ActiveUS20100019134A1Improve productivityReduce image defectsTelevision system detailsBeam/ray focussing/reflecting arrangementsOptical pathSolid-state

A camera module (1) is an assembly of a lens holder (4) and a wiring board (2). The lens holder (4) holds an optical structure (3) which forms an image of a subject. The wiring board (2) has formed thereon a solid-state image sensing element (21) which converts the image of the subject formed by the optical structure (3) to electrical signals. Grease (7) is applied to the camera module (1) in such a manner that the grease is not present in an optical path in the optical structure (3). The grease (7) catches the dust (D) produced during manufacture and while in use, thereby prevented the dust (D) from causing image defects. A solid-state image sensing device is thus provided which is capable of preventing the dust produced during manufacture and while in use from causing image defects.

Owner:SHARP KK

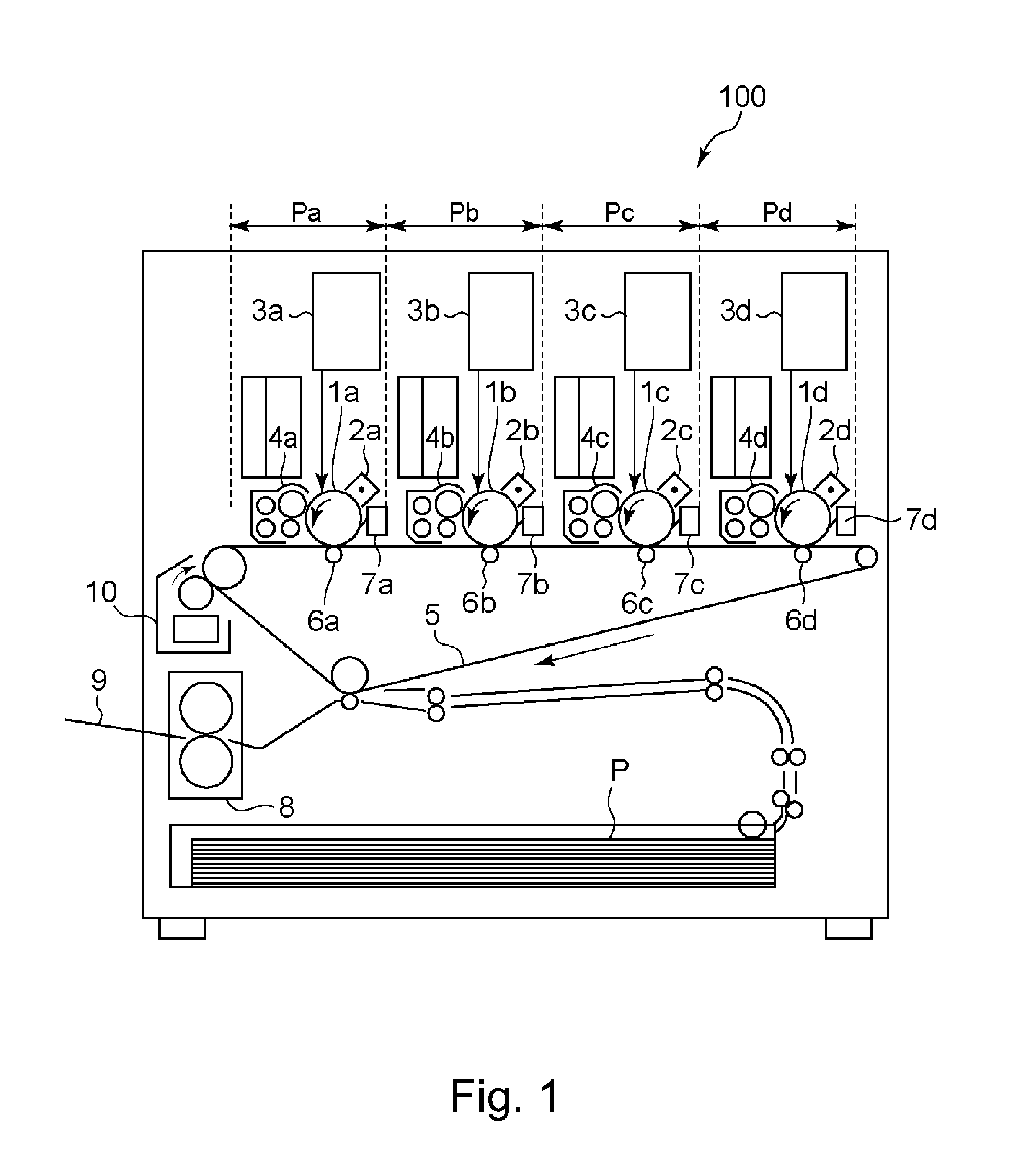

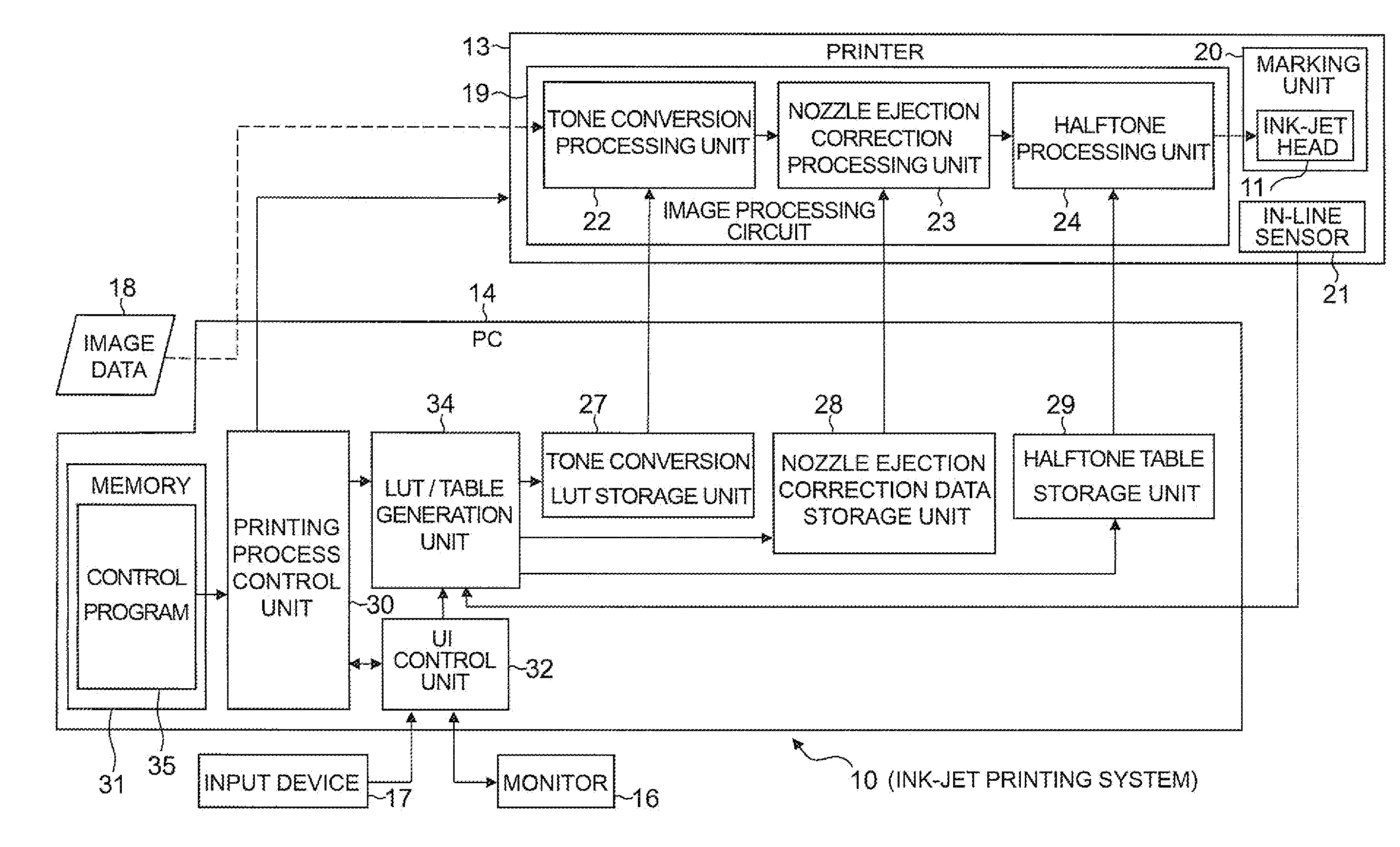

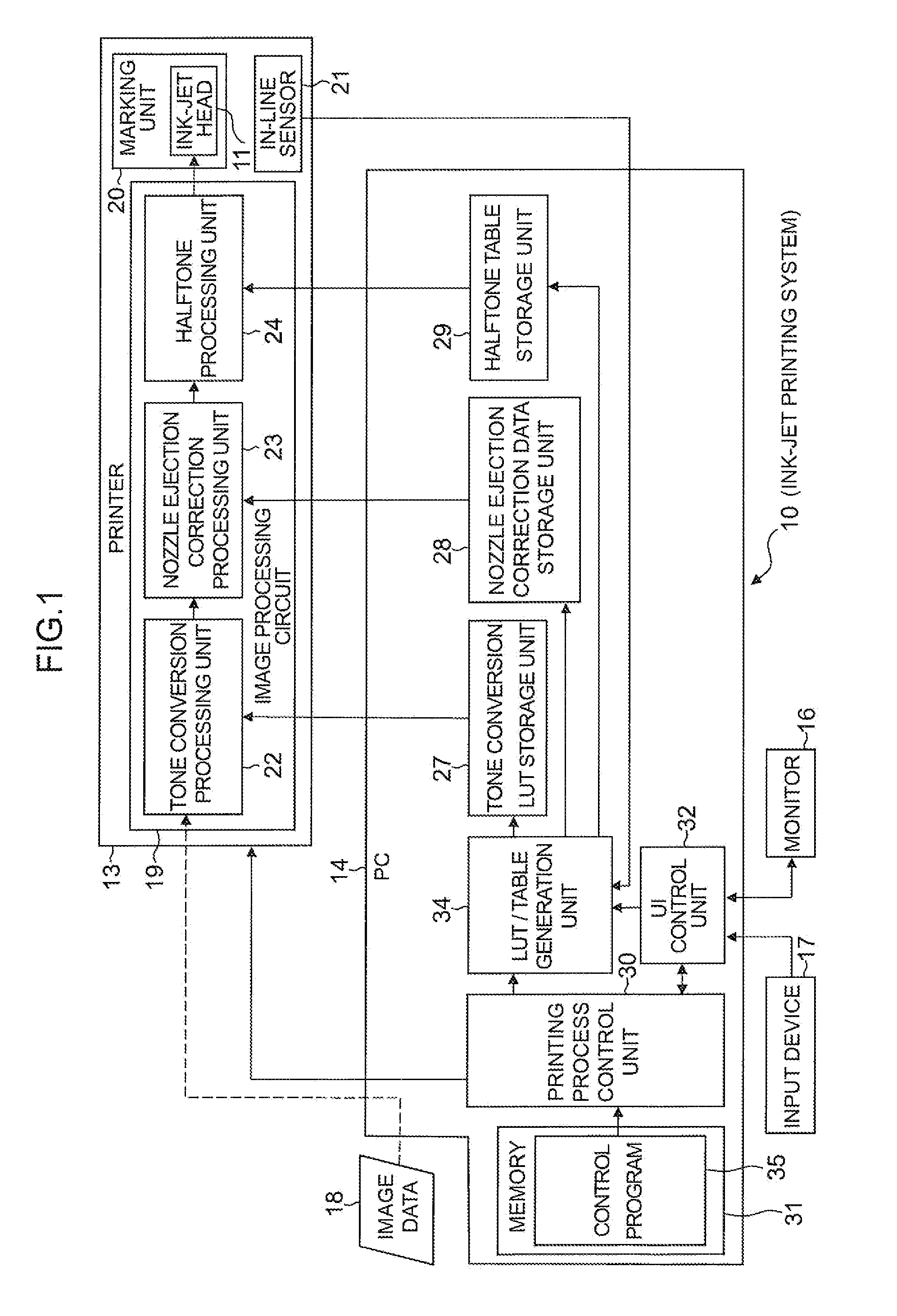

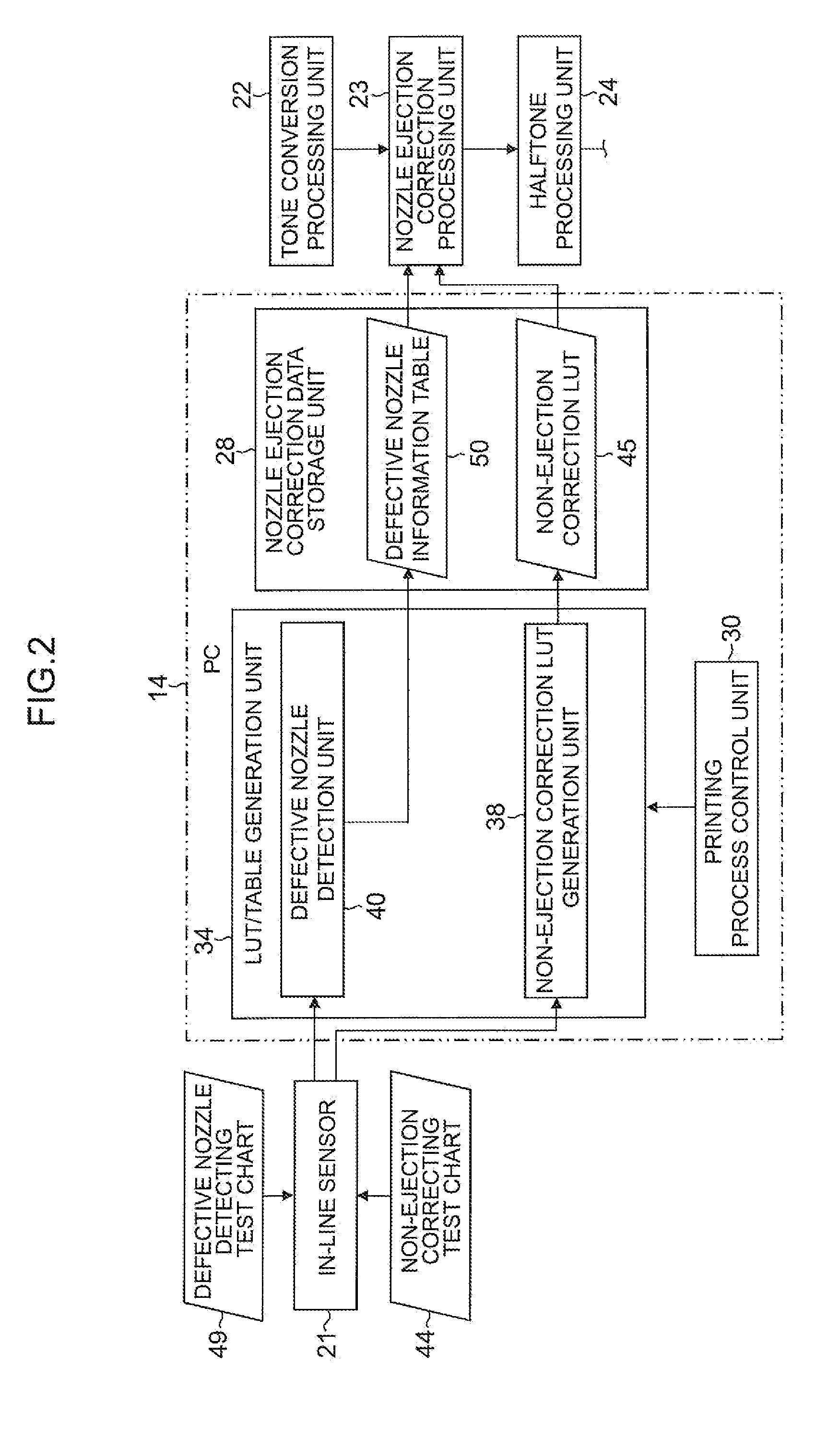

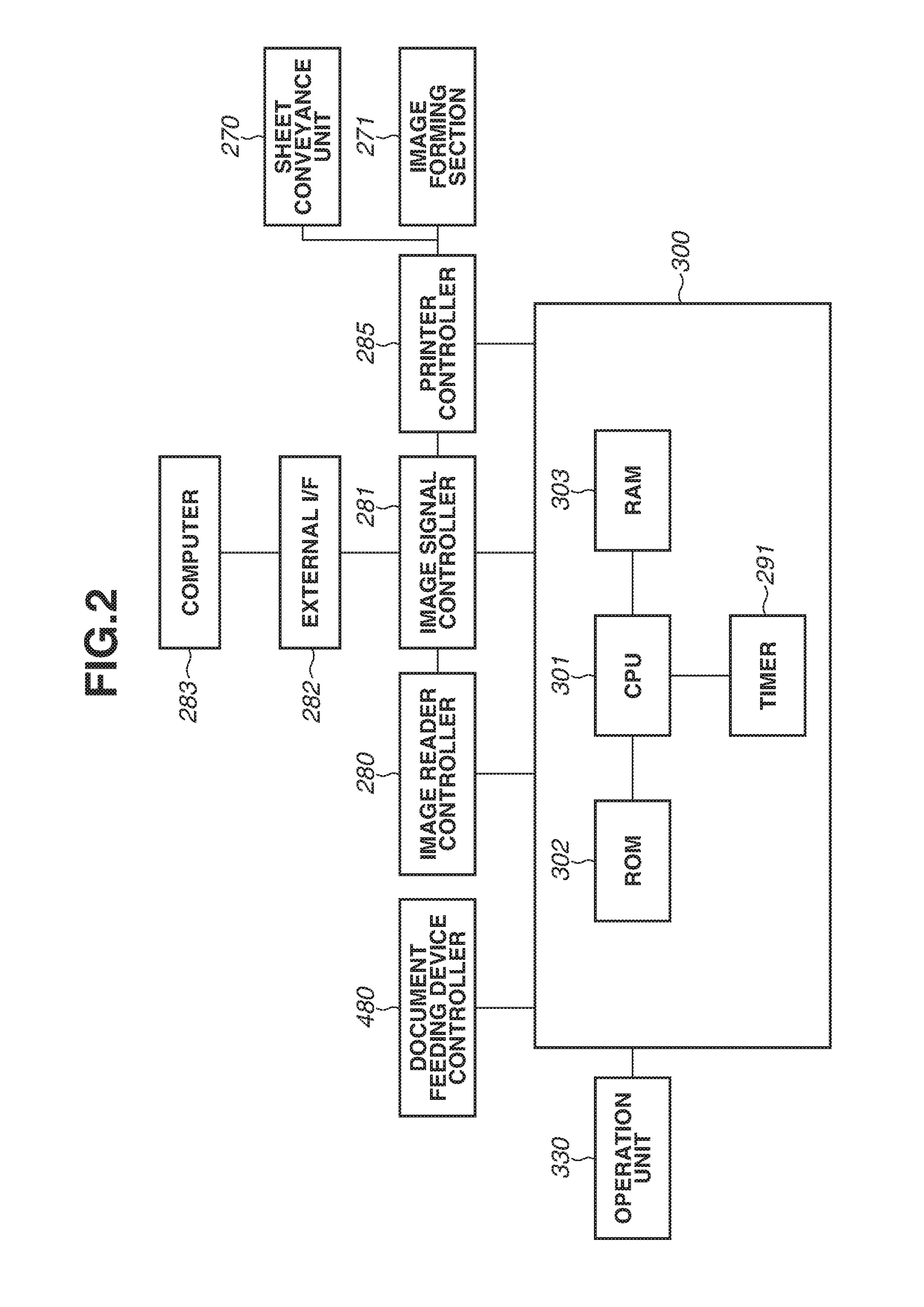

Image recording apparatus, control method thereof, and recording medium

ActiveUS20140300656A1Reduce image defectReduce image defectsOther printing apparatusImage recordingRecording head

A method for controlling an image recording apparatus includes: detecting a defective recording element out of a plurality of recording elements on a recording head for recording an image on a recording medium; performing a correction processing including suspension of an output of the defective recording element and increase of an output of a recording element at least adjacent to the defective recording element according to a detection result; determining whether or not an image defect is caused in the image by the suspension of output of the defective recording element, before performing the correction processing, according to the detection result; selecting a forced recording element that is forced to output ink out of defective recording elements when it is determined that the image defect is caused; and suspending the output of the defective recording element other than the forced recording element when the forced recording element is selected.

Owner:FUJIFILM CORP

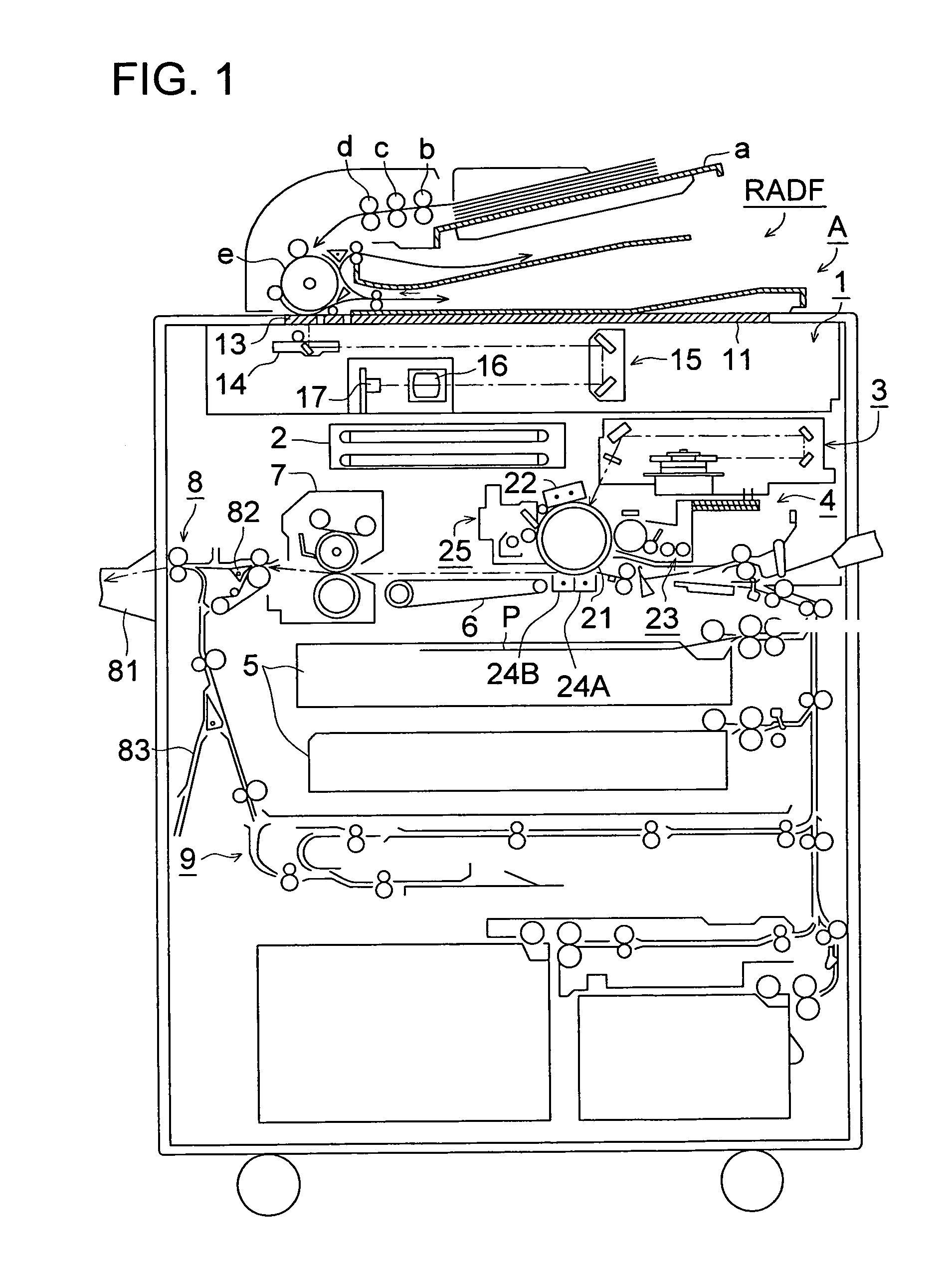

Image forming apparatus

ActiveUS9927753B2Easy to operateReduce image defectsFunction indicatorsElectrographic process apparatusImage formationEngineering

An image forming apparatus includes a feeder including a tray and a pickup member, a size determiner, a sheet type setter, and a controller. The tray stacks a sheet thereon, and the pickup member feeds a contacted sheet. The feeder switches between a first state where the pickup member and the stacked sheet are in contact and a second state where the pickup member and the stacked sheet are separate. The size determiner determines a stacked sheet size. The sheet type setter sets a stacked sheet type. Where the type of the set sheet is a first type, the feeder switches from the second state to the first state when the size of the sheet is determined. Where the type of the set sheet is a second type, the feeder refrains from switching from the second state to the first state even when the size of the sheet is determined.

Owner:CANON KK

Fixing device and image forming apparatus with horizontally moving separating claw

InactiveUS7463858B2Reduce image defectsMaintain separation performanceElectrographic process apparatusEngineeringMechanical engineering

The fixing device and image forming apparatus employ a horizontally moving claw for separating a sheet on which a toner image has been fixed. The claw moves in a horizontally reciprocating manner at a velocity between 0.001 mm / seconds to 0.1 mm / seconds. Moving at that speed, it has been found to reduce scratching of the fixing drum. The device and image forming apparatus also employ a claw having a width between 1.0 mm and 5.0 mm. The claw contacts the drum with a pressure in a range of 3.0×9.8 mN to 7.0×9.8 mN.

Owner:KONICA MINOLTA BUSINESS TECH INC

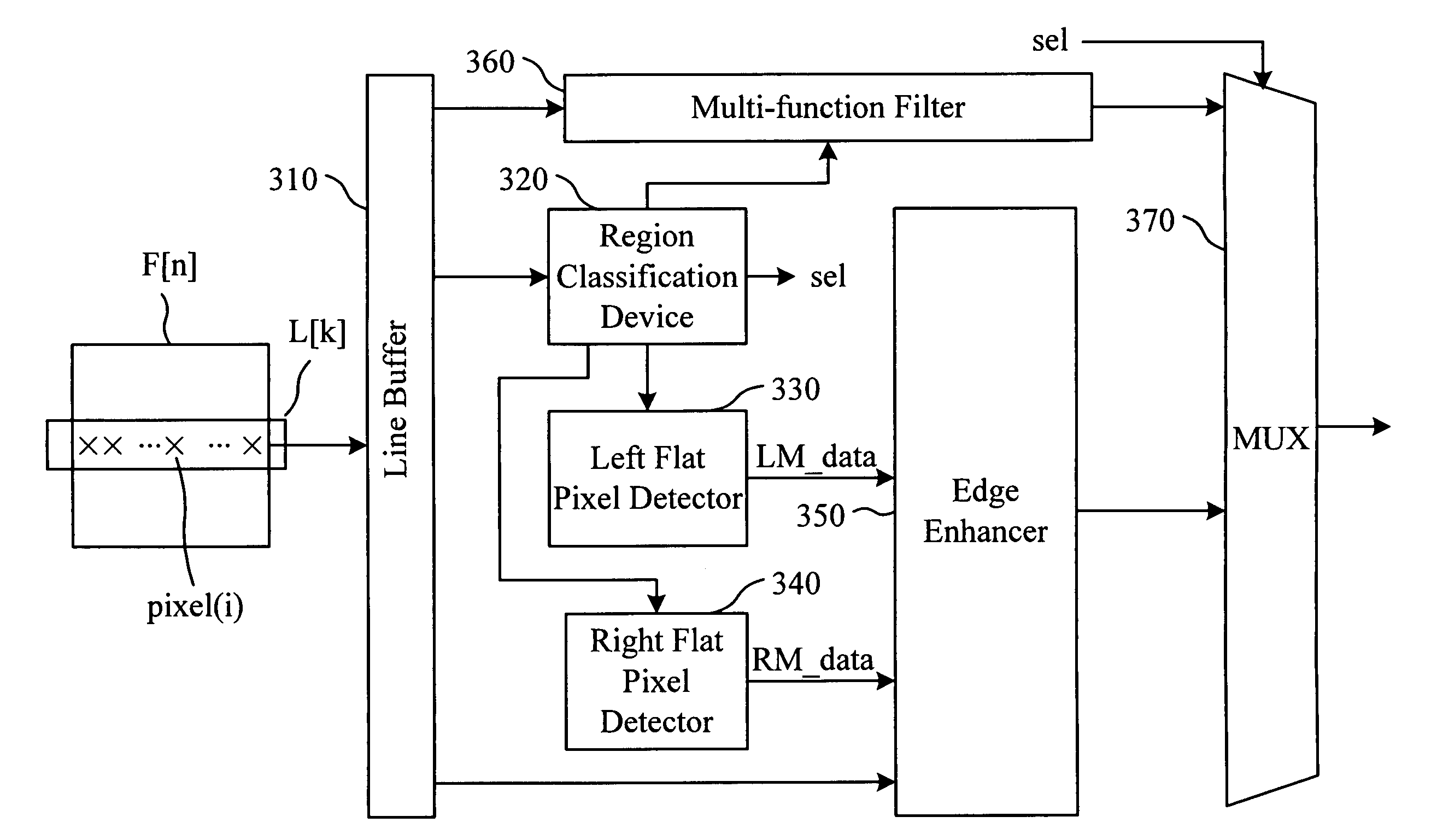

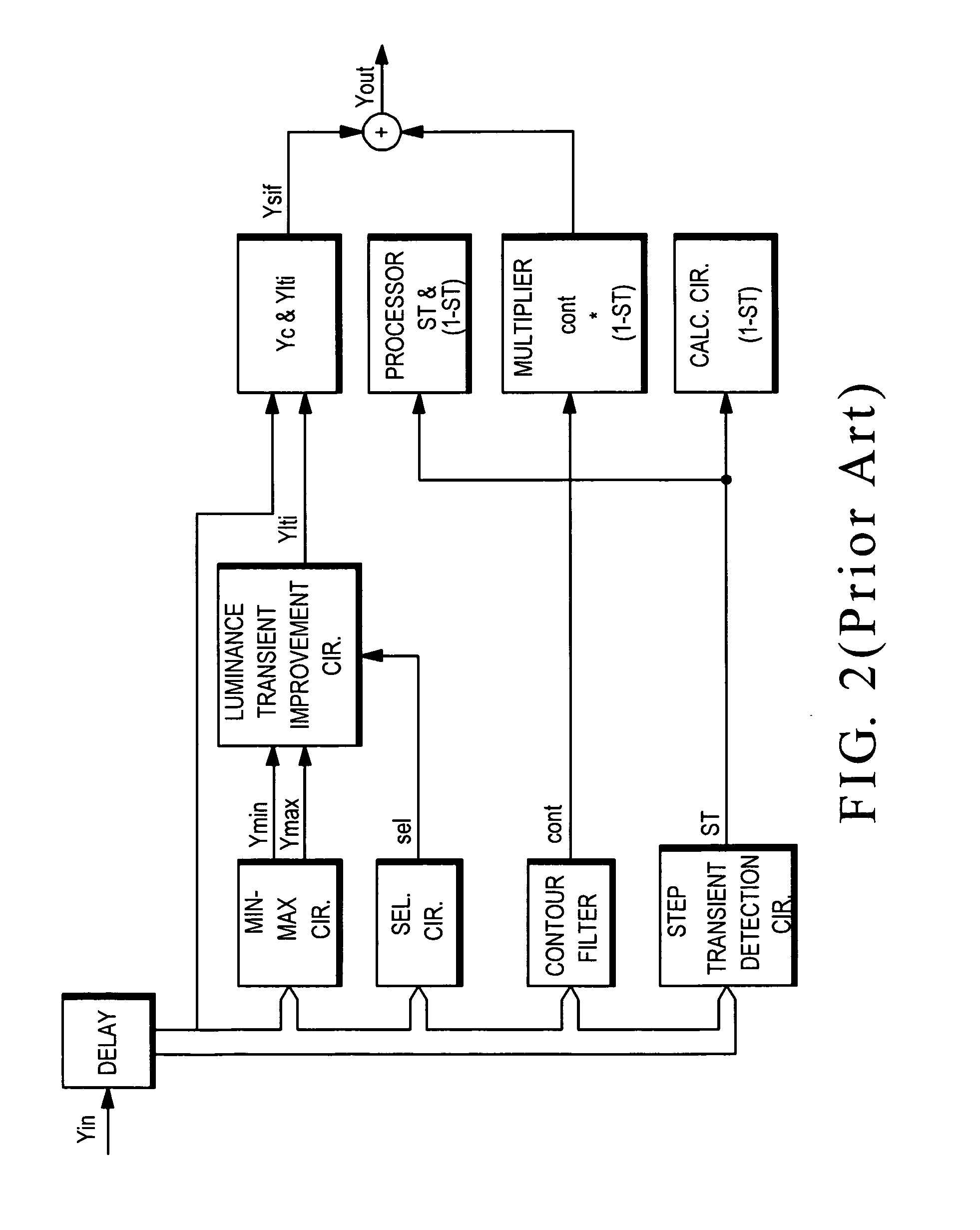

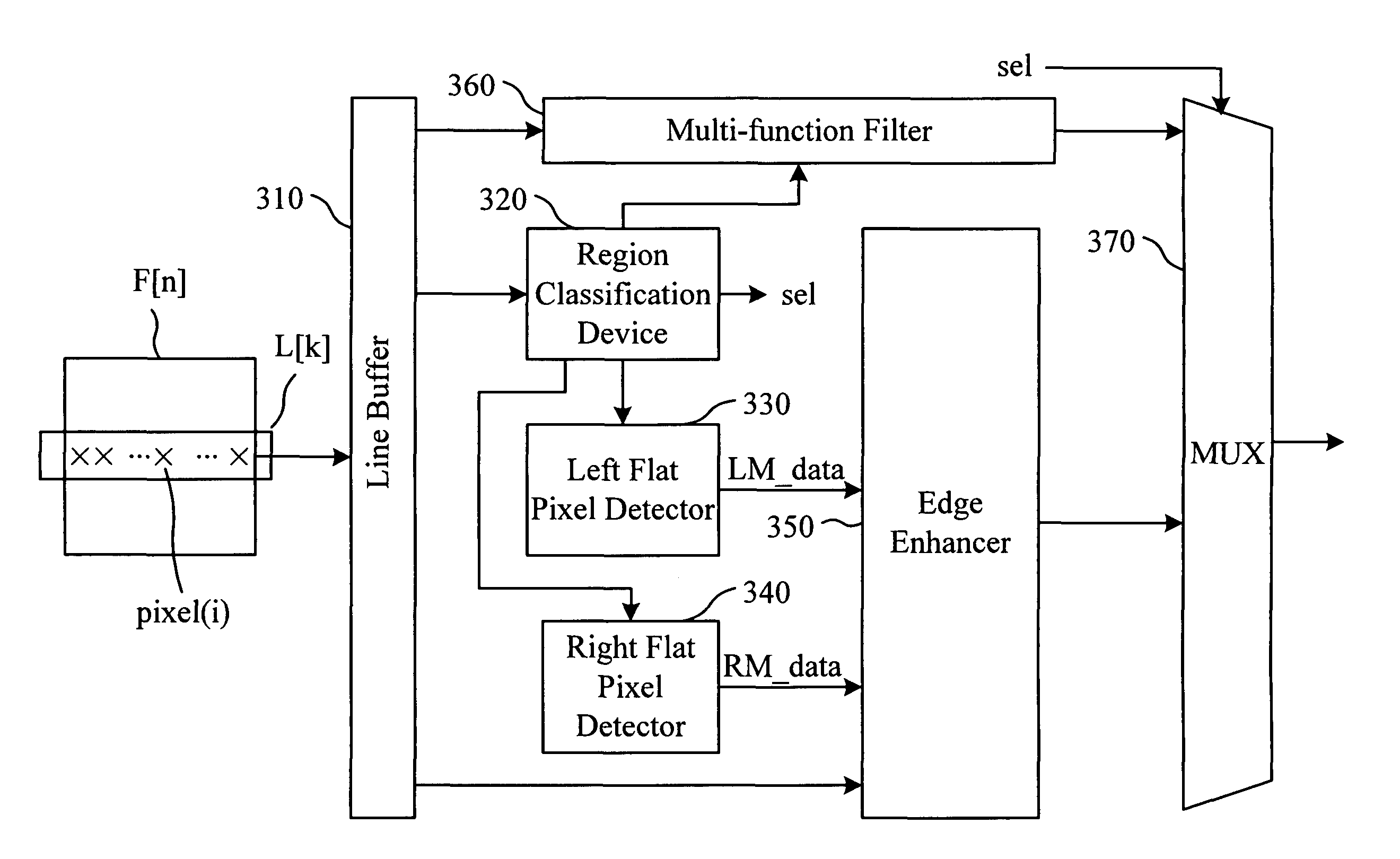

System for applying multi-direction and multi-slope region detection to image edge enhancement

ActiveUS20090180706A1Improve sharpnessReduce image defectsImage enhancementImage analysisRegion detectionEdge enhancement

A system for applying multi-direction and multi-slope region detection to image edge enhancement is provided to perform the image edge enhancement on an image. For pixel (i) indicating i-th pixel of line of the image, a line buffer temporarily stores the pixel (i) and its neighboring pixels. A region classification device classifies the pixel (i) into a region type. A left flat pixel detector depends on the region type to search the neighboring pixels of the pixel (i) for a left flat region pixel. A right flat pixel detector depends on the region type to search the neighboring pixels of the pixel (i) for a right flat region pixel. An edge enhancer performs an edge enhancement operation on the pixel (i) and neighboring pixels when the pixel (i) is an extended region and the left and the right flat region pixels are included in the neighboring pixels.

Owner:XIAMEN XM PLUS TECH CO LTD

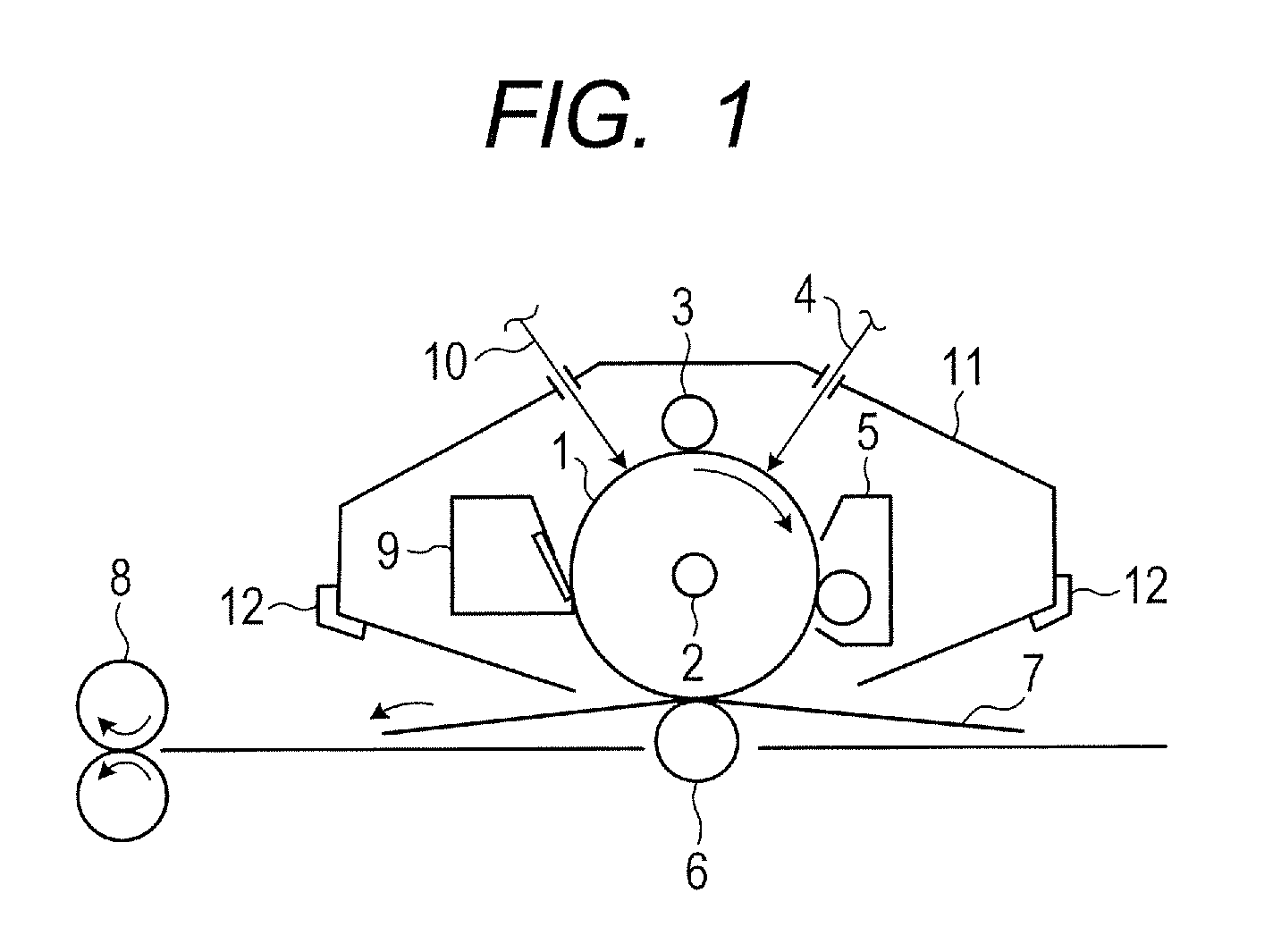

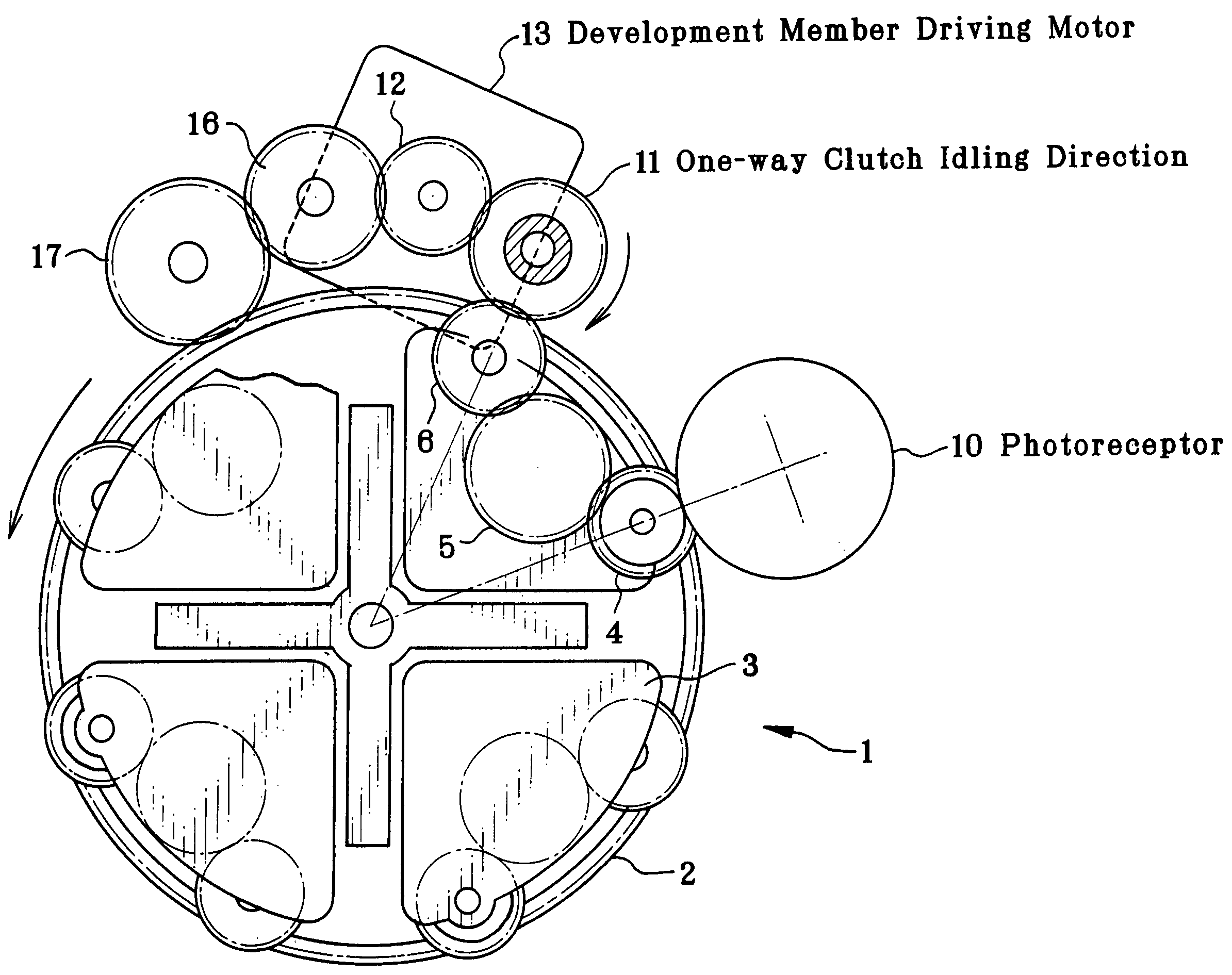

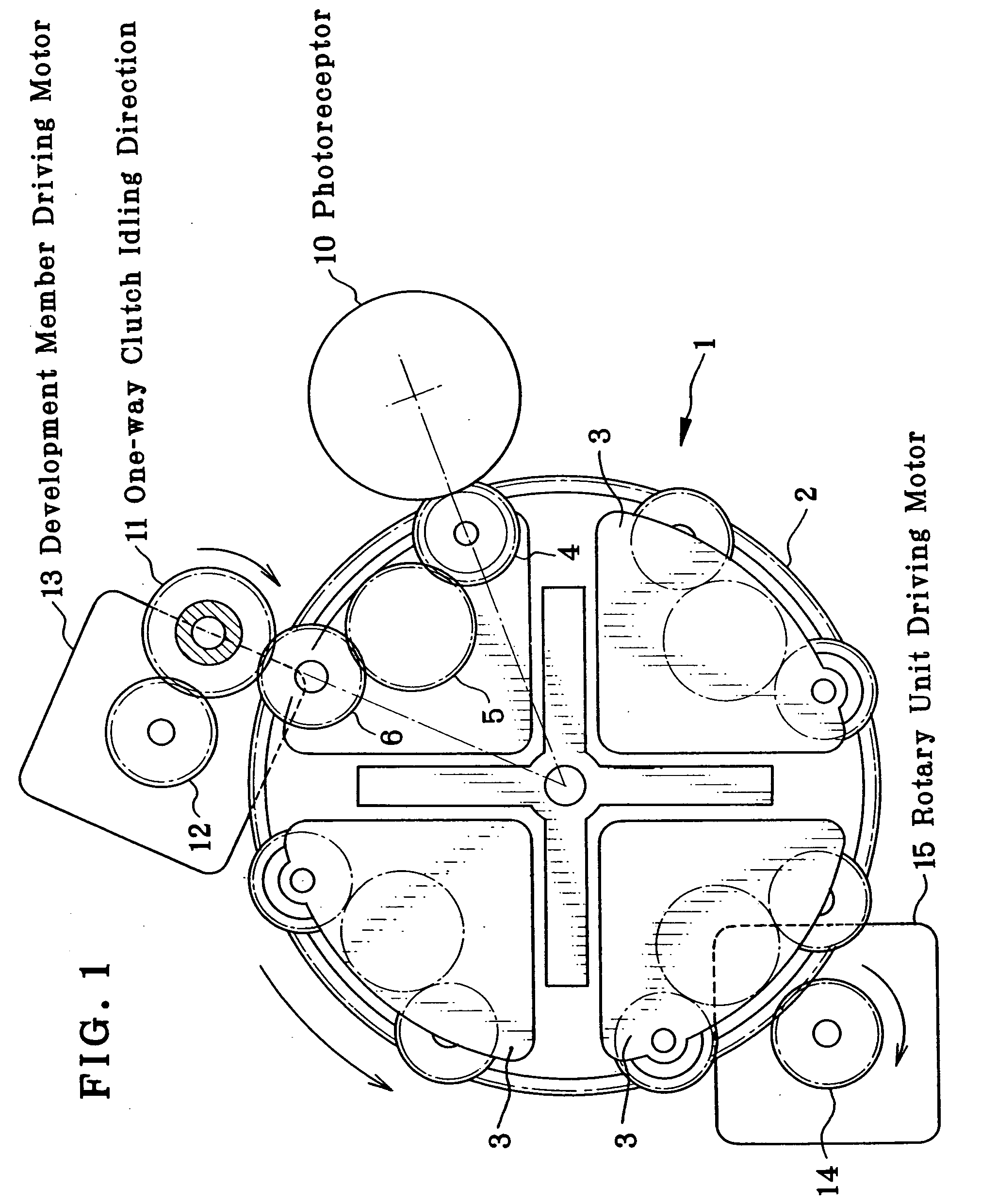

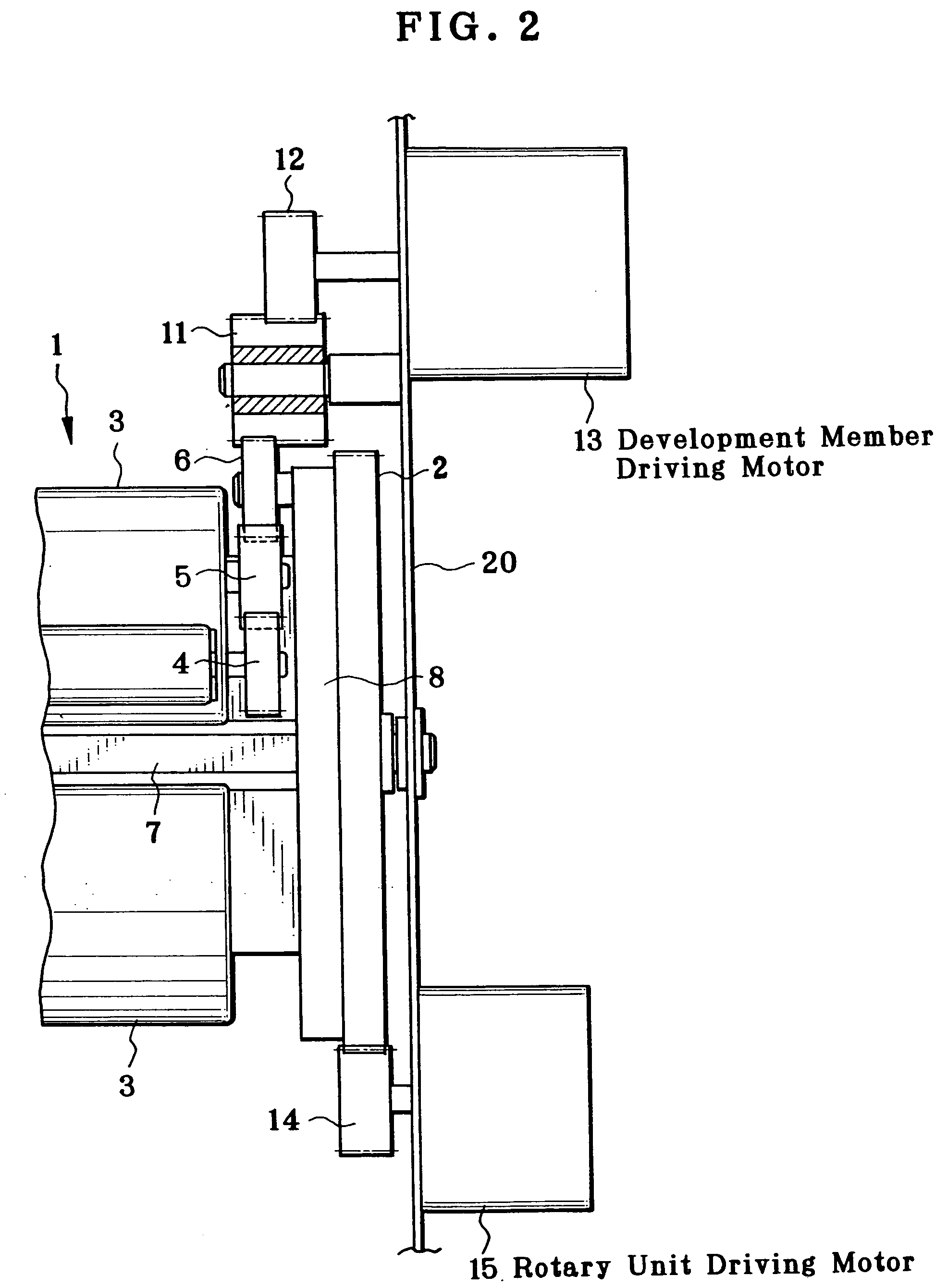

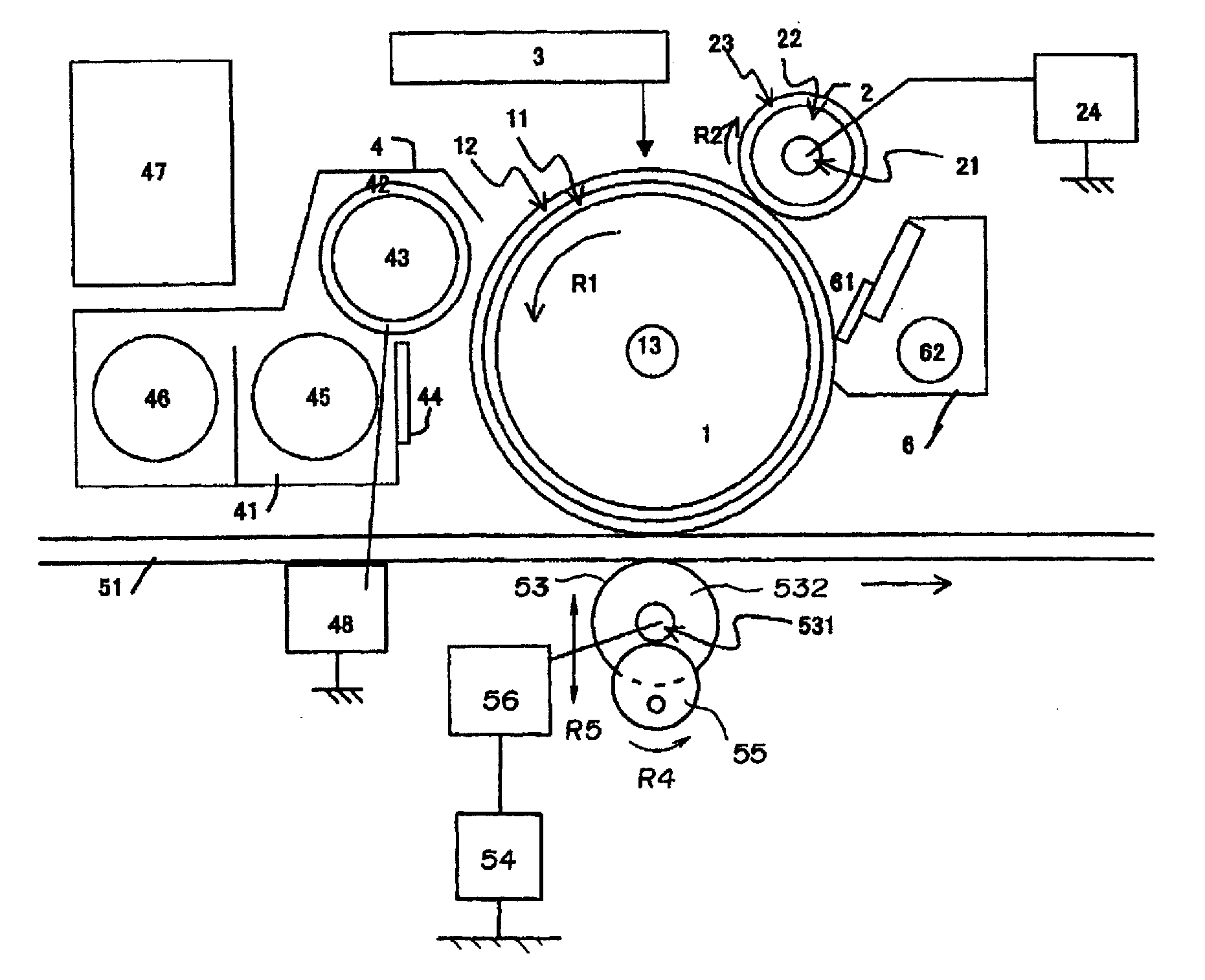

Rotary developing device

InactiveUS20050041996A1Shorten the timeAvoid it happening againElectrographic process apparatusElectromagnetic clutchEngineering

A rotary developing device having a cylindrical rotary developing unit, and a plurality of development members mounted around the periphery of the rotary developing unit. The rotary developing unit is driven to bring one of the development members to the developing position facing a photoreceptor and subsequently the transmission of the driving power to the development member is conducted. In the rotary developing device, the driving direction of the development members at a driving power transmitting section is set to be the same as the driving direction of the rotary developing unit and a simple additional structure employing an electromagnetic clutch or a one-way clutch is applied to the driving power transmitting section, thereby avoiding a collision of tooth tops between gears, damping the impact generated by a collision, and reducing vibration and damage of tooth tops. Therefore, the production of image defects due to registration error are prevented.

Owner:SEIKO EPSON CORP

Image forming apparatus

An image forming apparatus according to an exemplary embodiment of the invention includes a first image forming portion, a second image forming portion, a secondary transfer device, a transfer power supply, a controller.The first and second image forming portions include image bearing members, chargers, development devices, and transfer members.The first charger charges the first image bearing member in the same polarity as a predetermined polarity.The second charger for charging the second image bearing member in a polarity opposite the predetermined polarity.The controller controls the transfer power supply such that the transfer voltage applied to the second transfer member in the second image forming portion is not changed nor turned on and off in a period during which the toner image is transferred to the intermediate transfer member in the first image forming portion.

Owner:CANON KK

System for applying multi-direction and multi-slope region detection to image edge enhancement

ActiveUS8139890B2Improve sharpnessReduce image defectsImage enhancementImage analysisImage edgeSpeech enhancement

A system for applying multi-direction and multi-slope region detection to image edge enhancement is provided to perform the image edge enhancement on an image. For pixel (i) indicating i-th pixel of line of the image, a line buffer temporarily stores the pixel (i) and its neighboring pixels. A region classification device classifies the pixel (i) into a region type. A left flat pixel detector depends on the region type to search the neighboring pixels of the pixel (i) for a left flat region pixel. A right flat pixel detector depends on the region type to search the neighboring pixels of the pixel (i) for a right flat region pixel. An edge enhancer performs an edge enhancement operation on the pixel (i) and neighboring pixels when the pixel (i) is an extended region and the left and the right flat region pixels are included in the neighboring pixels.

Owner:XIAMEN XM PLUS TECH LTD

Device and method for aligning containers

ActiveUS9199757B2Reduce image defectsImprove accuracyOptically investigating flaws/contaminationConveyor partsEngineeringDependability

Owner:KRONES AG

Image forming apparatus with multiple image forming portions and image transfers

InactiveUS7848671B2Reduce image defectsElectrographic process apparatusImage transferImage formation

An image forming apparatus according to an exemplary embodiment of the invention includes a first image forming portion, a second image forming portion, a secondary transfer device, a transfer power supply, a controller.The first and second image forming portions include image bearing members, chargers, development devices, and transfer members.The first charger charges the first image bearing member in the same polarity as a predetermined polarity.The second charger for charging the second image bearing member in a polarity opposite the predetermined polarity.The controller controls the transfer power supply such that the transfer voltage applied to the second transfer member in the second image forming portion is not changed nor turned on and off in a period during which the toner image is transferred to the intermediate transfer member in the first image forming portion.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com