Electrophotographic photosensitive member, manufacturing method of electrophotographic photosensitive member, process cartridge and electrophotographic apparatus, and phthalocyanine crystal and manufacturing method of phthalocyanine crystal

a manufacturing method and photosensitive technology, applied in the field of electrophotographic photosensitive members, can solve the problems of potential variation and difficulty in conversion to a desired crystalline form in some cases, and achieve the effect of reducing image defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1-1

[0076]As described below, hydroxygallium phthalocyanine was produced by the same as in Synthesis Example 1 and Example 1-1 described in Japanese Patent Application Laid-Open No. 2011-94101. Under nitrogen flow atmosphere, 5.46 parts of phthalonitrile and 45 parts of α-chloronaphthalene were fed into a reaction tank, then heated up to a temperature of 30° C., and maintained at the temperature. Subsequently, 3.75 parts of gallium trichloride was fed thereto at the temperature (30° C.). At the feeding time, the mixture liquid had a water content of 150 ppm. The temperature was then increased to 200° C. Under the nitrogen flow atmosphere, a reaction was caused at a temperature of 200° C. for 4.5 hours, which was then cooled to a temperature of 150° C. for filtering a product. The produced residue was dispersed and cleaned with N,N-dimethylformamide at a temperature of 140° C. for 2 hours, and then filtrated. The produced residue was cleaned with methanol and dried to produce 4.65 parts ...

example 1-2

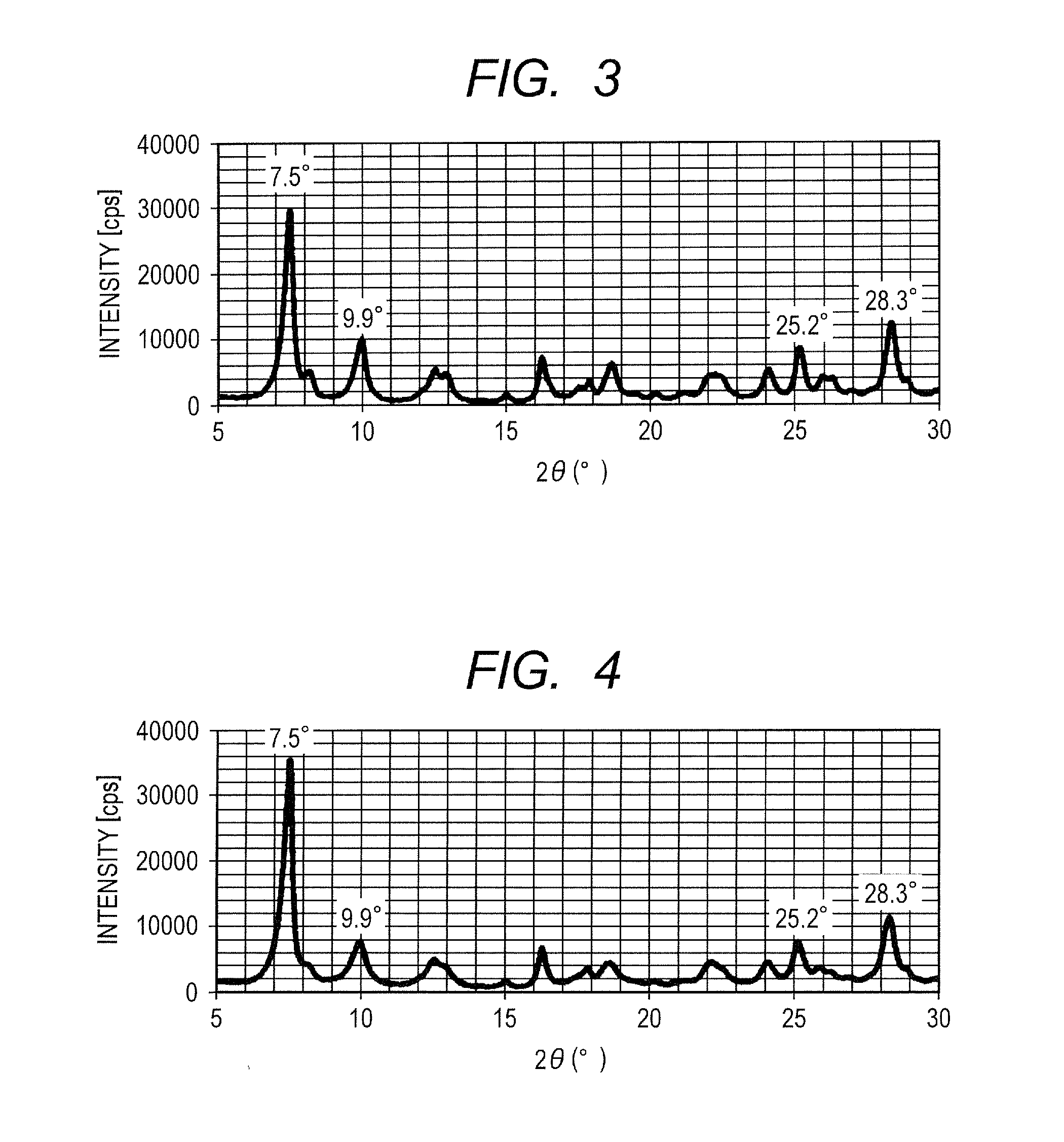

[0079]A hydroxygallium phthalocyanine crystal in an amount of 0.42 parts was obtained by the same treatment as in Example 1-1, except that the milling treatment time was changed from 1000 hours to 2000 hours in Example 1-1. The powder X-ray diffraction pattern of the produced crystal was the same as in Example 1-1. The angle and the intensity of the peak emerging at Bragg angle 2θ of 9.9°±0.2°, the intensity on a side 2.8° wider from the peak angle, and the ratio of the intensity are described in Table 1.

[0080]It was confirmed that 0.80% by mass N,N-dimethylformamide is contained relative to phthalocyanine in the phthalocyanine crystal by the NMR measurement.

example 1-3

[0081]A hydroxygallium phthalocyanine crystal in an amount of 0.44 parts was obtained by the same treatment as in Example 1-1, except that the milling treatment time was changed from 1000 hours to 500 hours in Example 1-1. The powder X-ray diffraction pattern of the produced crystal was the same as in Example 1-1. The angle and the intensity of the peak emerging at Bragg angle 2θ of 9.9°±0.2°, the intensity on a side 2.8° wider from the peak angle, and the ratio of the intensity are described in Table 1.

[0082]It was confirmed that 1.23% by mass N,N-dimethylformamide is contained relative to phthalocyanine in the phthalocyanine crystal by the NMR measurement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bragg angles 2θ | aaaaa | aaaaa |

| Bragg angles 2θ | aaaaa | aaaaa |

| Bragg angles 2θ | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com