Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Reduce flushing water consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

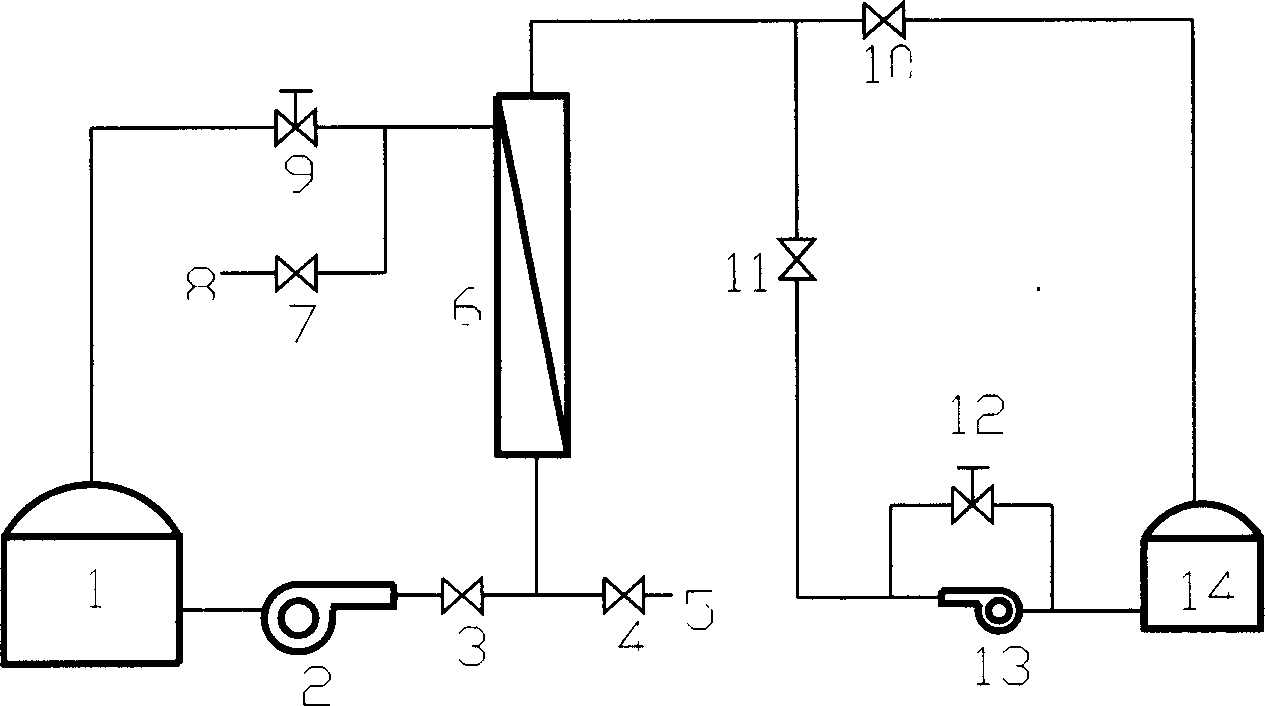

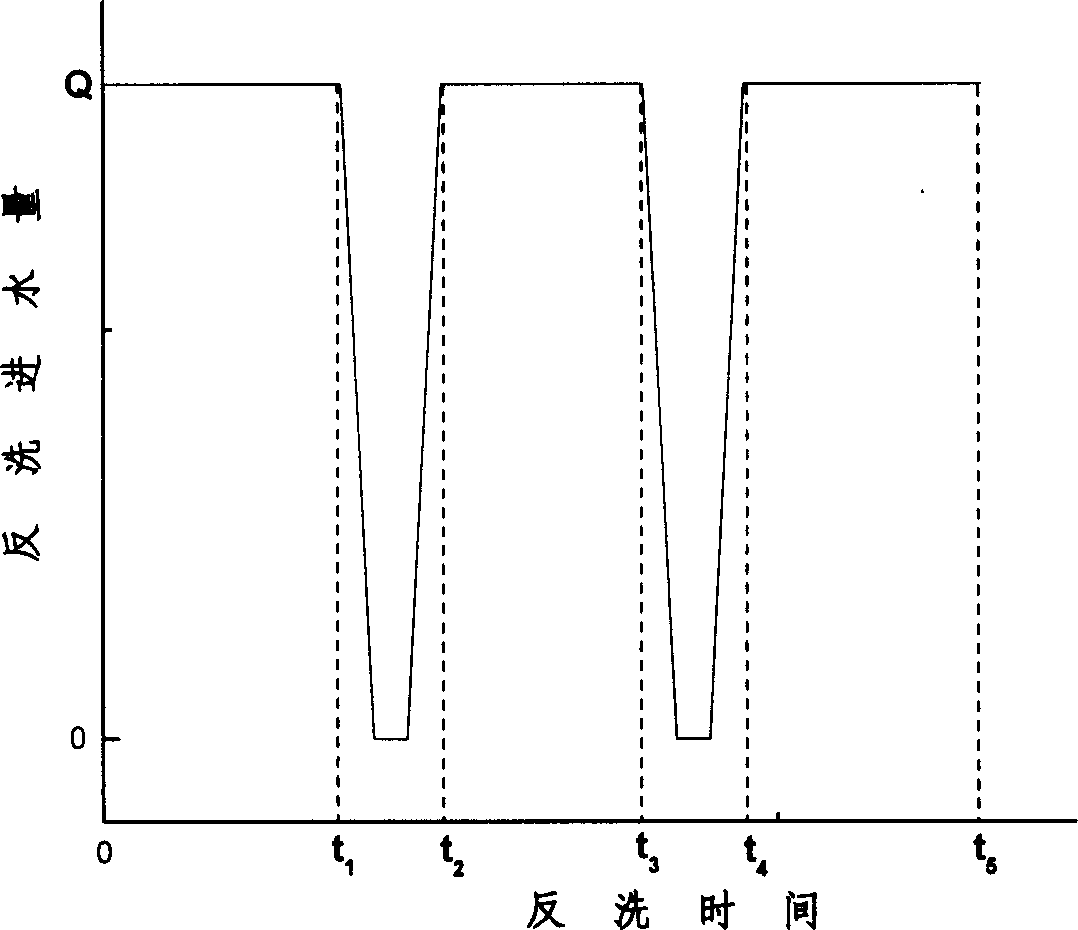

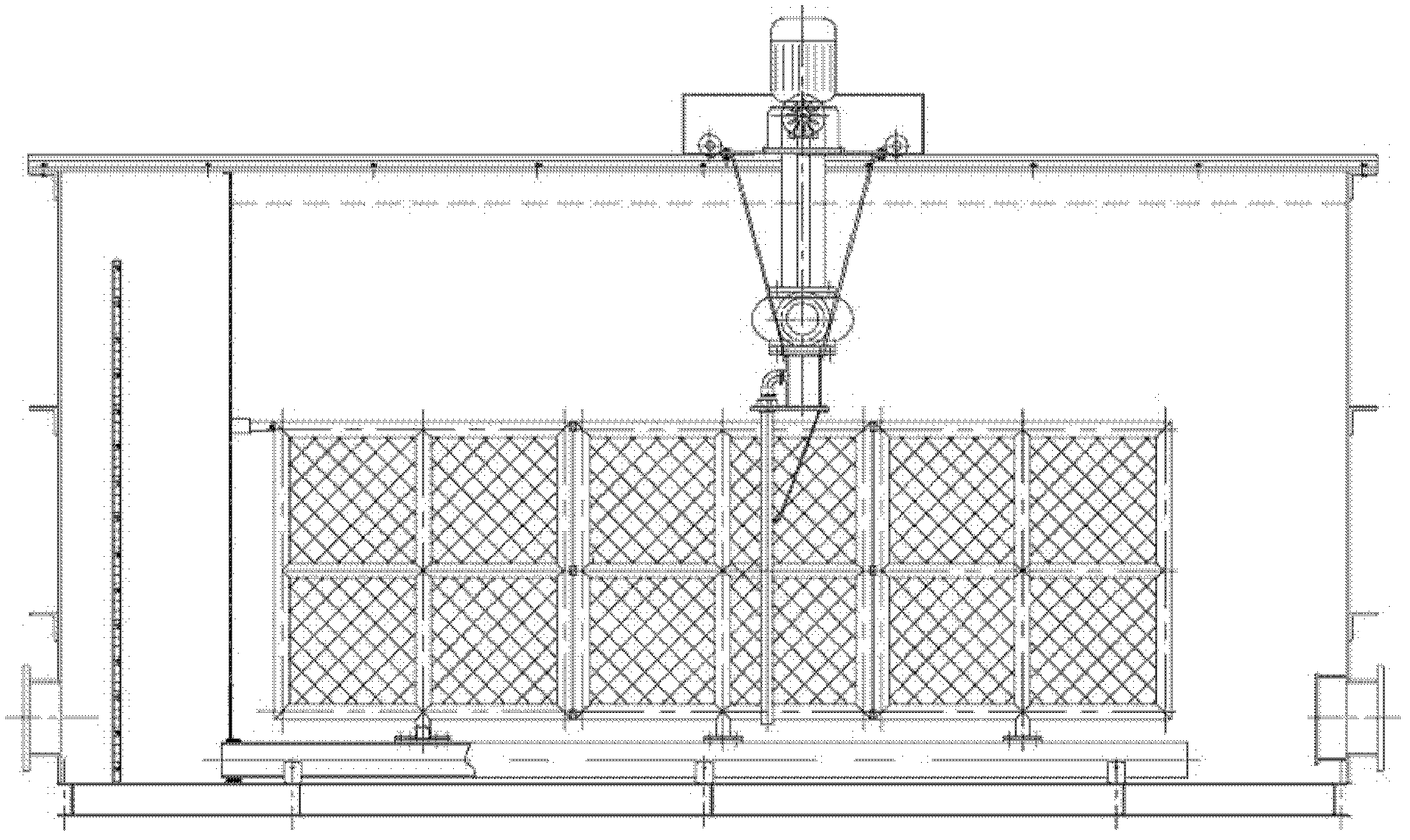

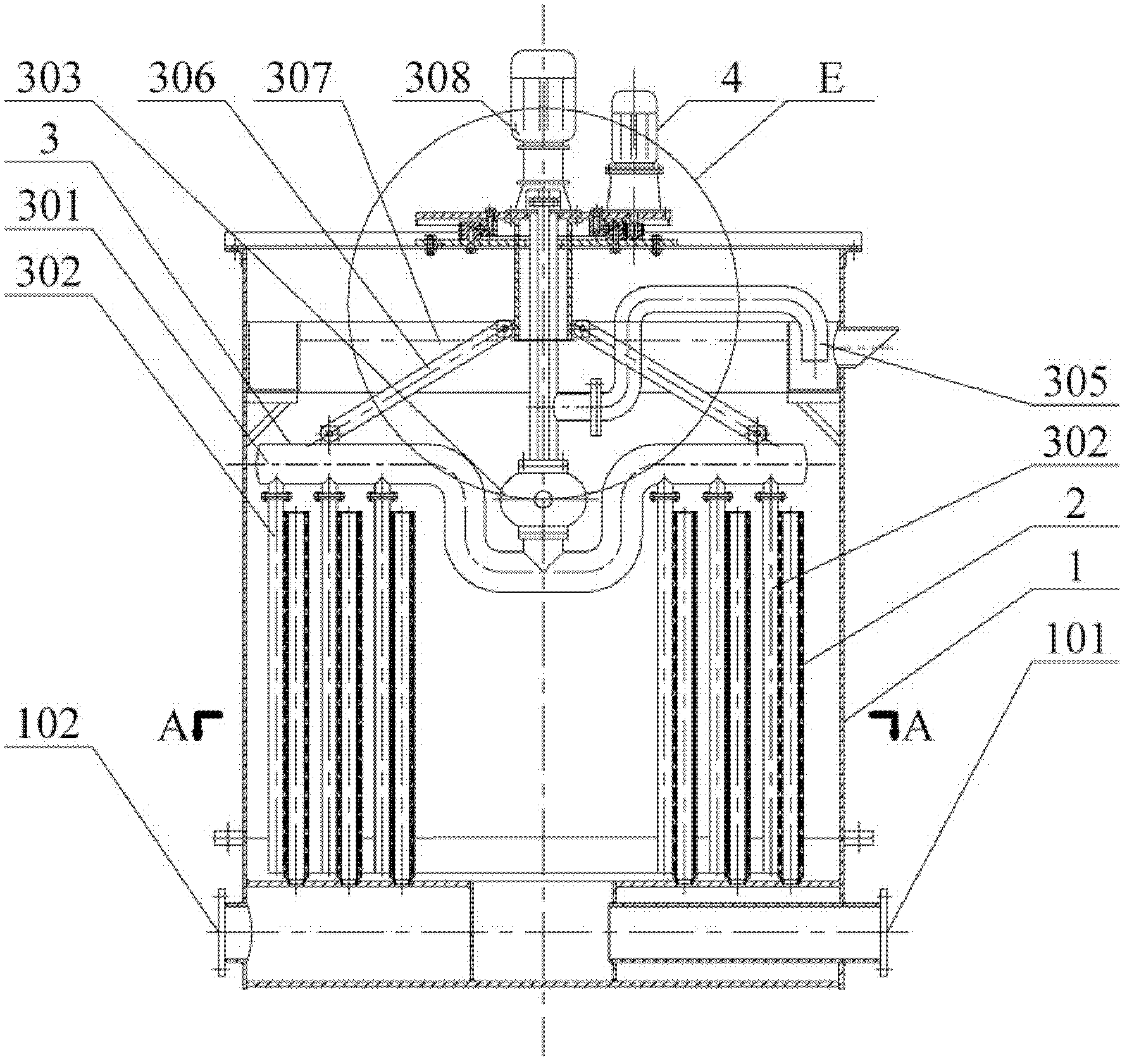

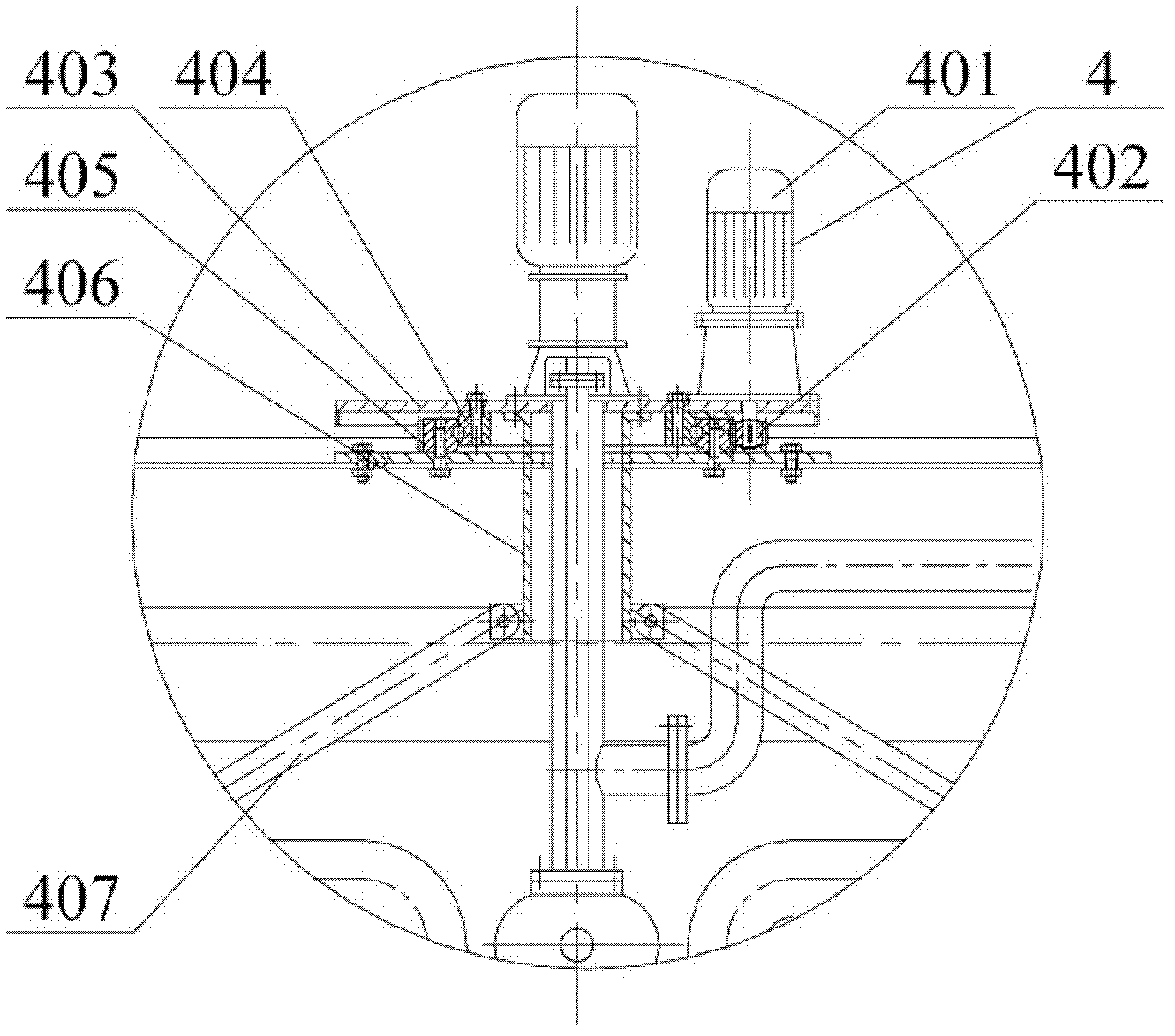

Method for rinsing membrane-filtering unit of hollow fiber

InactiveCN1695776AImprove vibrationEfficient removalSemi-permeable membranesFiberHollow fibre membrane

A method for flushing the hollow fibre membrane filter features that when the flow and quality of the product of membrane module are lowered, a flushing pump is turned on to perform reverse flushing and the reverse flushing channel is then cut off the perform forward flushing. Said reverse fushing and forward flushing are alternatively performed until the flow is restored to normal value.

Owner:TIANJIN UNIV

Paper pulping bleaching and waste water purification integration technology

InactiveCN101597871AShort production processProtect environmentPulp liquor regenerationPulp bleachingEnzymePulp bleaching

A paper pulping bleaching and waste purification integration technology comprises two technology stages of paper pulping bleaching and waste water purification; wherein the paper pulping bleaching technology stage comprises: (1) slicing; (2) solution preparing; (3) initial reaction by adding enzyme and medicament; (4) deep reaction by adding medicament; (5) sieving, sedimentation and grinding; and (6) pulp washing, bleaching and stabilizing to obtain paper pulp finished product; and the waste water purification technology stage comprises: (1) purification, sedimentation and separation; and (2) concentration, drying and sediment recovery. The invention combines chemistry and biology, pulping and bleaching are completed in the same container in an integration way, neither chorine element is required nor black liquor is produced during pulping and bleaching, COD, BOD, SS and chrominance in pulping water are reduced to the utmost extent, waste water of pulping can be reused in pulp washing after purification treatment, and finally zero discharge or standard discharge of the whole waste water of pulping is realized.

Owner:XIAN TONGRUN BIOTECH

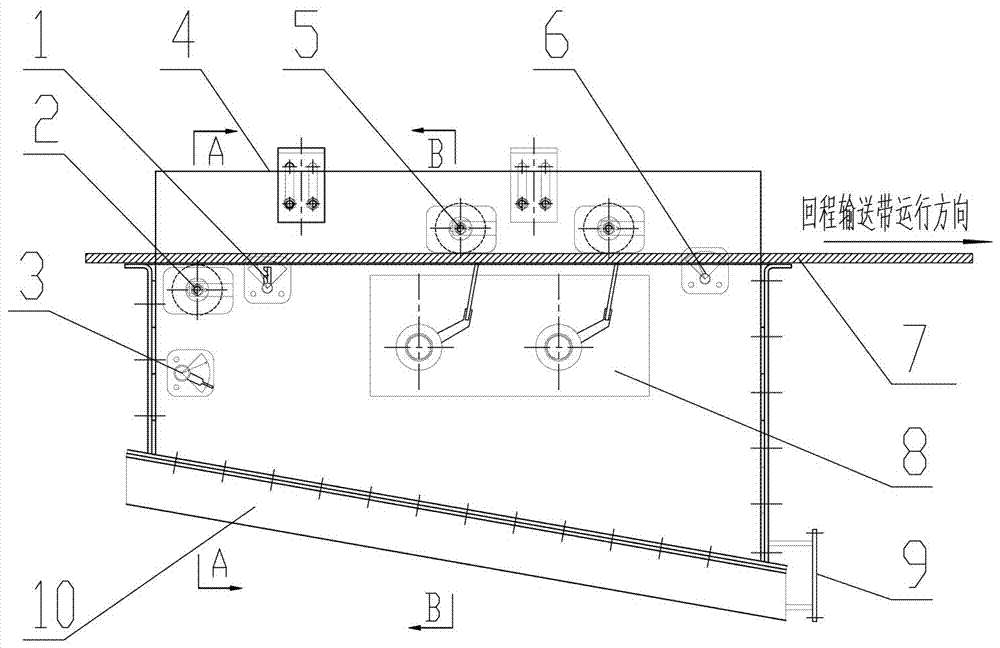

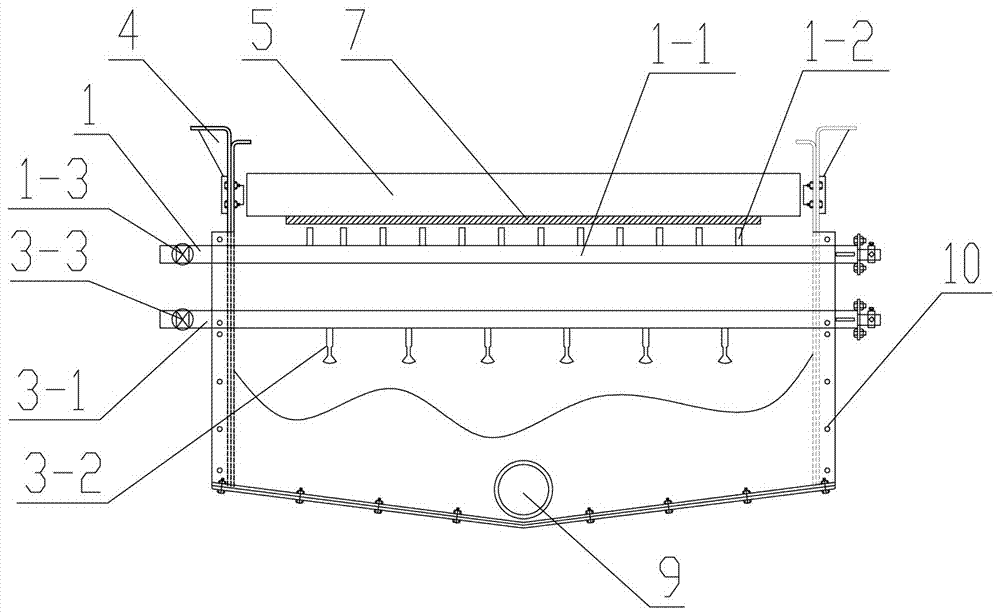

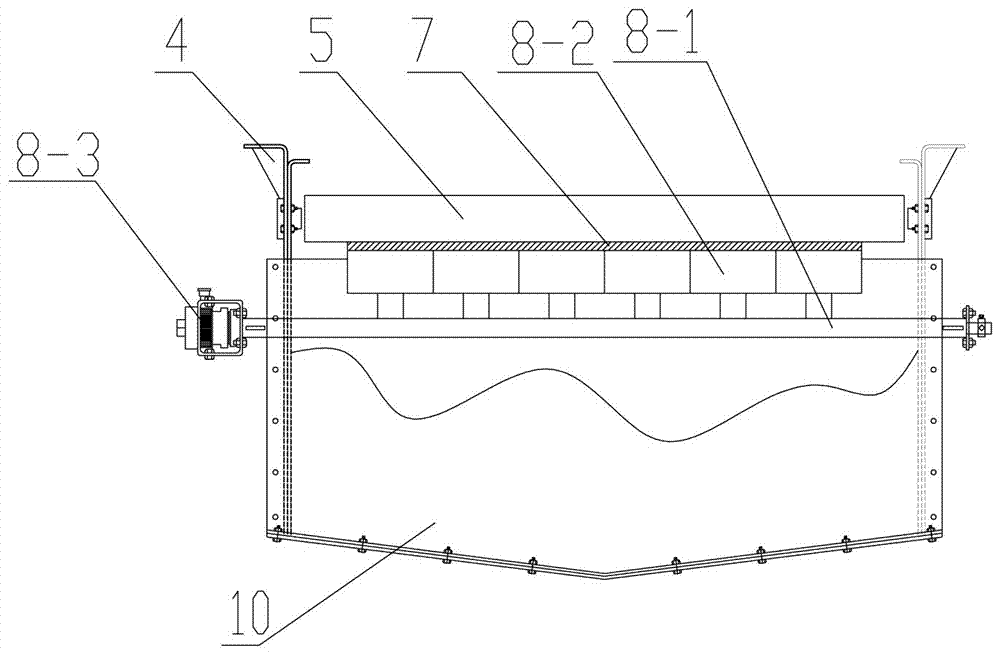

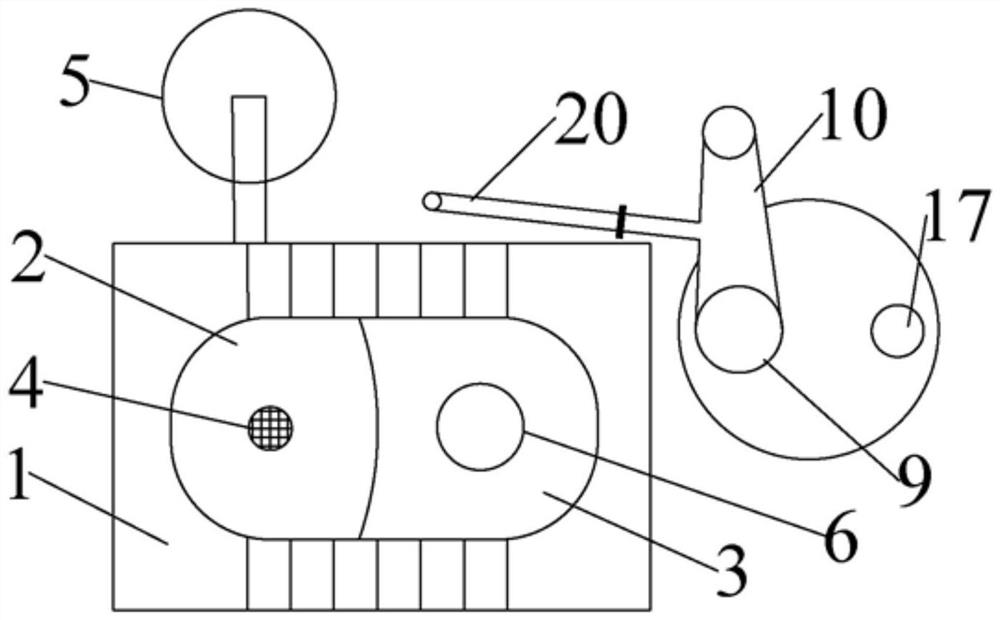

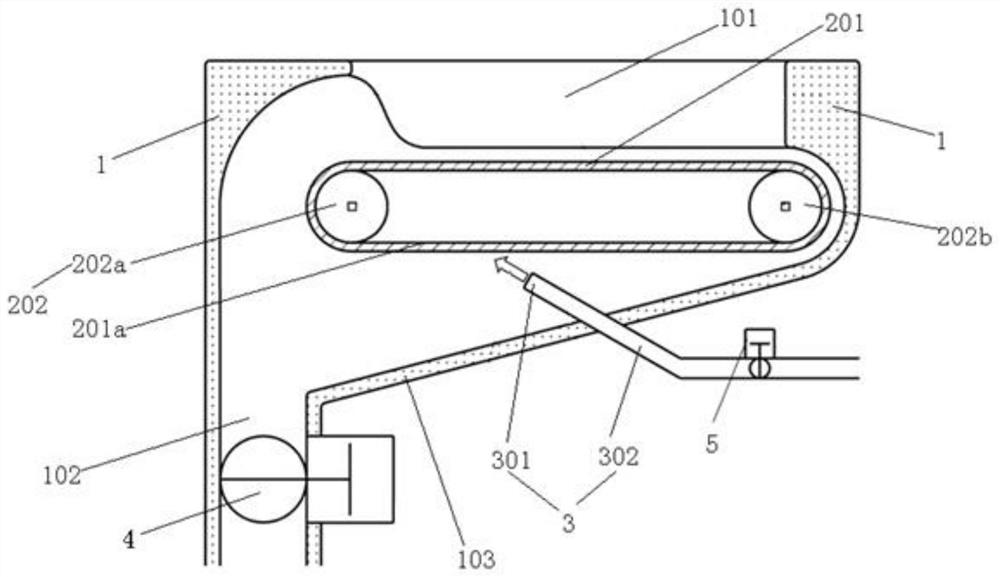

Conveying belt cleaning device for belt conveyer

The invention discloses a conveying belt cleaning device for a belt conveyer. The conveying belt cleaning device comprises a connection hanging bracket, a top water spraying system, an end part water spraying system, a compressed gas blowing-drying system, a carrier roller, a carrier roller rack, scraping knife systems, a mud collection box and the like. The conveying belt cleaning device disclosed by the invention is applicable to cleaning for a conveying belt of the belt conveyer, and in particular to an occasion with a high requirement on the cleanliness degree of the conveying belt of the belt conveyer and a high requirement on environmental protection. The device is installed on a return-stroke conveying belt of the belt conveyer, and on an inclined section or a horizontal section. A material adhesion force is reduced through the water spraying systems of the device, and materials adhered onto the conveying belt are effectively cleaned through the two scraping knife systems, so that material scattering of the belt conveyer on the way is reduced and even avoided, the environment of a plant is improved, and the workload of cleaners in the plant is reduced. The device has the advantages of being easy to install, low in member cost, easy to adjust, not provided with a drive component, convenient to maintain, long in service life, capable of prolonging the service life of the conveying belt, and the like.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

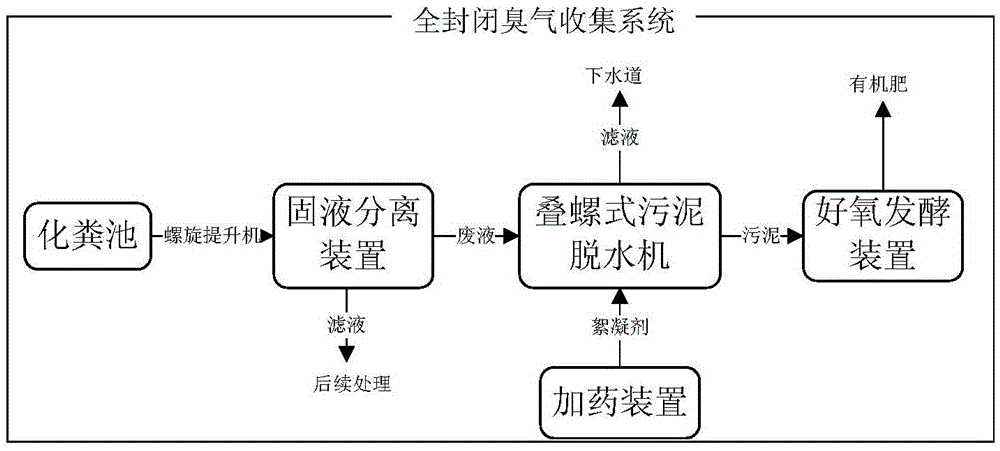

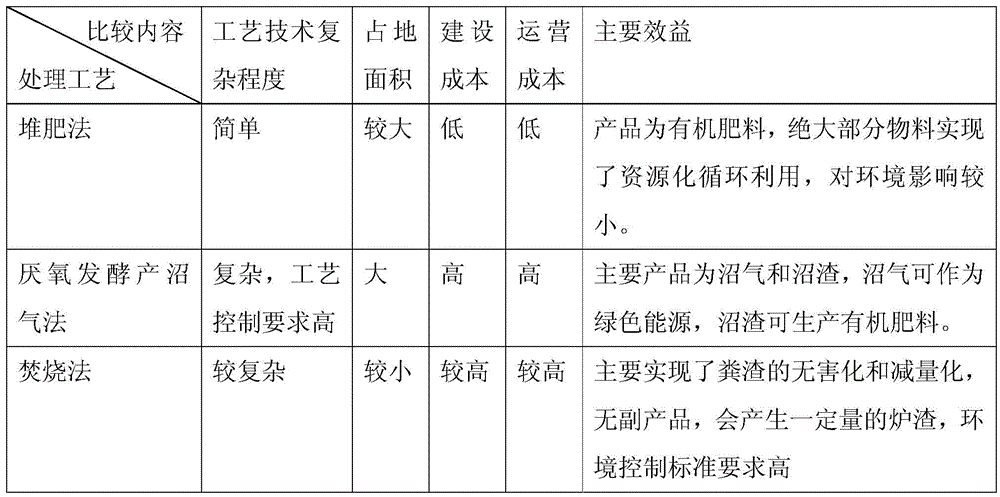

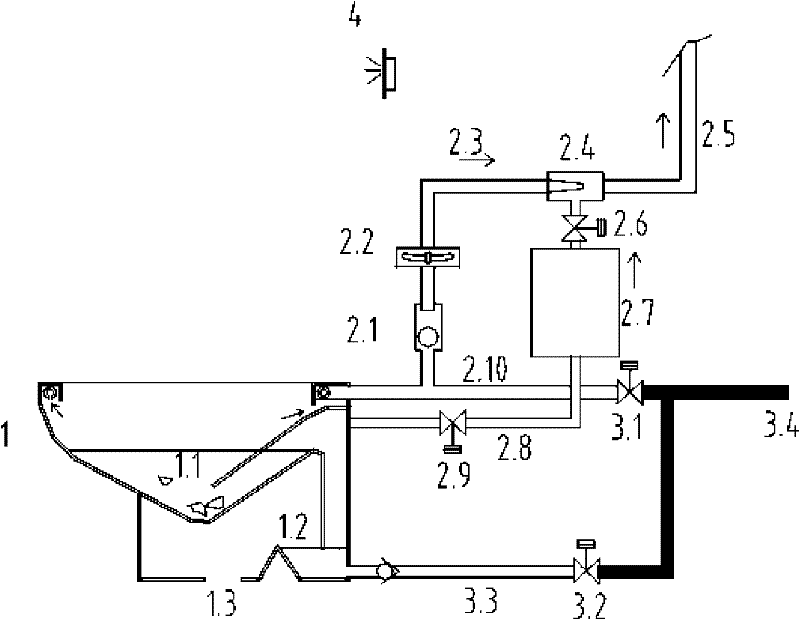

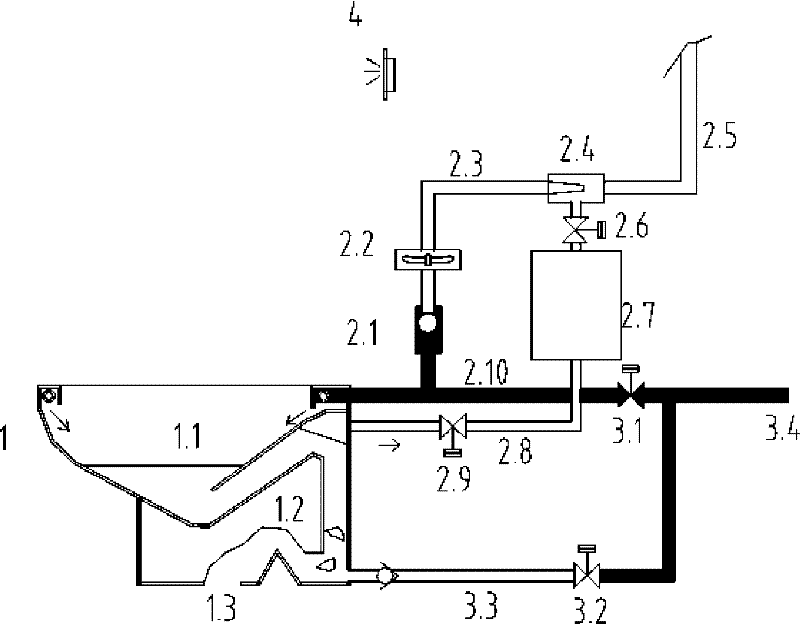

Night-soil on-site treatment system and treatment method thereof

InactiveCN105541062ASave cleaning workWon't cause cloggingSludge treatment by de-watering/drying/thickeningSludge processingSites treatmentEngineering

The invention provides a night-soil on-site treatment system. The night-soil on-site treatment system comprises a screw elevator, a solid-liquid separating device, an overlap-spiral type sludge dewatering machine, a chemicals dosing plant and an aerobic fermentation device; wherein the screw elevator, the solid-liquid separating device, the overlap-spiral type sludge dewatering machine and the aerobic fermentation device are connected in sequence, and the chemicals dosing plant and the overlap-spiral type sludge dewatering machine are connected. According to the night-soil on-site treatment system and a treatment method thereof, urban night-soil is separated by a new night-soil pumping mode and working procedures such as solid-liquid separation, screw press dewatering, small dynamic aerobic fermentation, chunks of waste are transported to a refuse transfer station as household refuse, wastewater is transported to a sewage treatment plant via a sewer for treatment, and sludge is subjected to harmless treatment on site, all pollutants are well treated, meanwhile refuse reclamation can be performed to produce an organic fertilizer, the recycling use of resources is realized, and aims of harmlessness, reclamation and reduction of the treatment of the urban night-soil are truly achieved.

Owner:SHENZHEN LONGJISHUN IND DEV

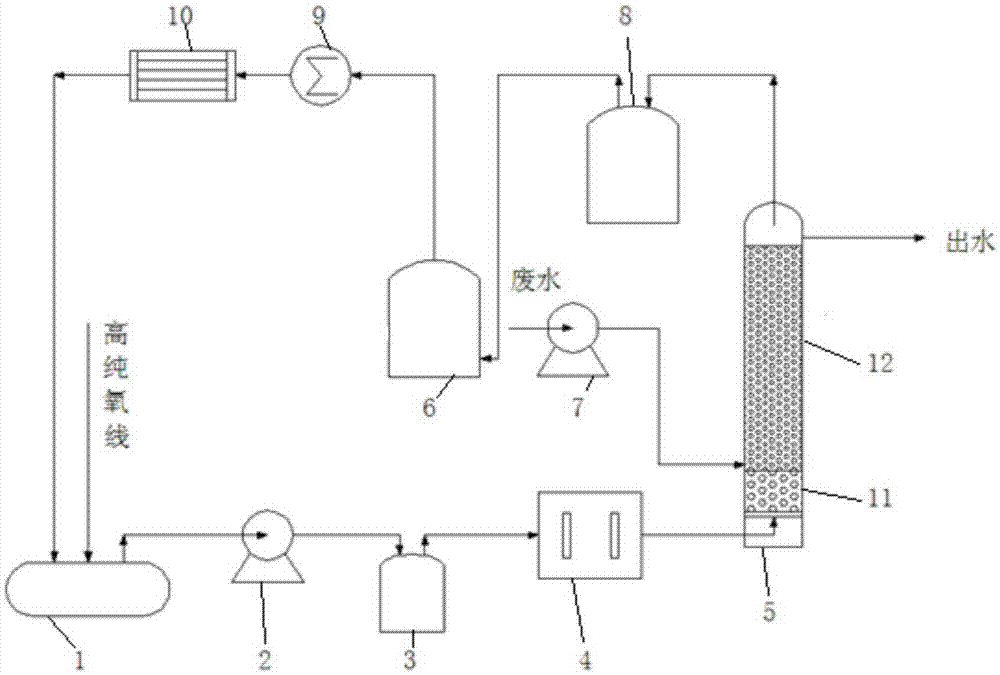

Treatment method and device of industrial wastewater

ActiveCN106865736ATake advantage ofIncrease profitCombination devicesGas treatmentIndustrial waste waterFiltration

The invention relates to a treatment method of industrial wastewater, wherein the method comprises the following specific technological process: high-salt and high-COD concentrated water enters an advanced oxidation reactor through a sewage pump, and the advanced oxidation reactor is internally provided with a special catalyst layer and a catalyst support layer from top to bottom successively, the catalyst support layer is internally filled with activated alumina based multi-phase catalyst with the particle size of 5-15 cm, and the specific catalyst layer is internally filled with a specific catalyst; the high-salt and high-COD concentrated water undergoes a full mixed reaction with ozone provided by a plasma generator in the advanced oxidation reactor, and effluent after the reaction is directly discharged to the outside; tail gas is treated successively through a gas-liquid separation tank, a pre-oxidation tank, an ozone annihilator / ozone destructor and a cold drying and filtration system, and then enters an oxygen storage tank; and the tail gas in the oxygen storage tank is pressurized and then passes through the plasma generator, and is supplied for the whole system to use in a new ozone form finally.

Owner:PETROCHINA CO LTD

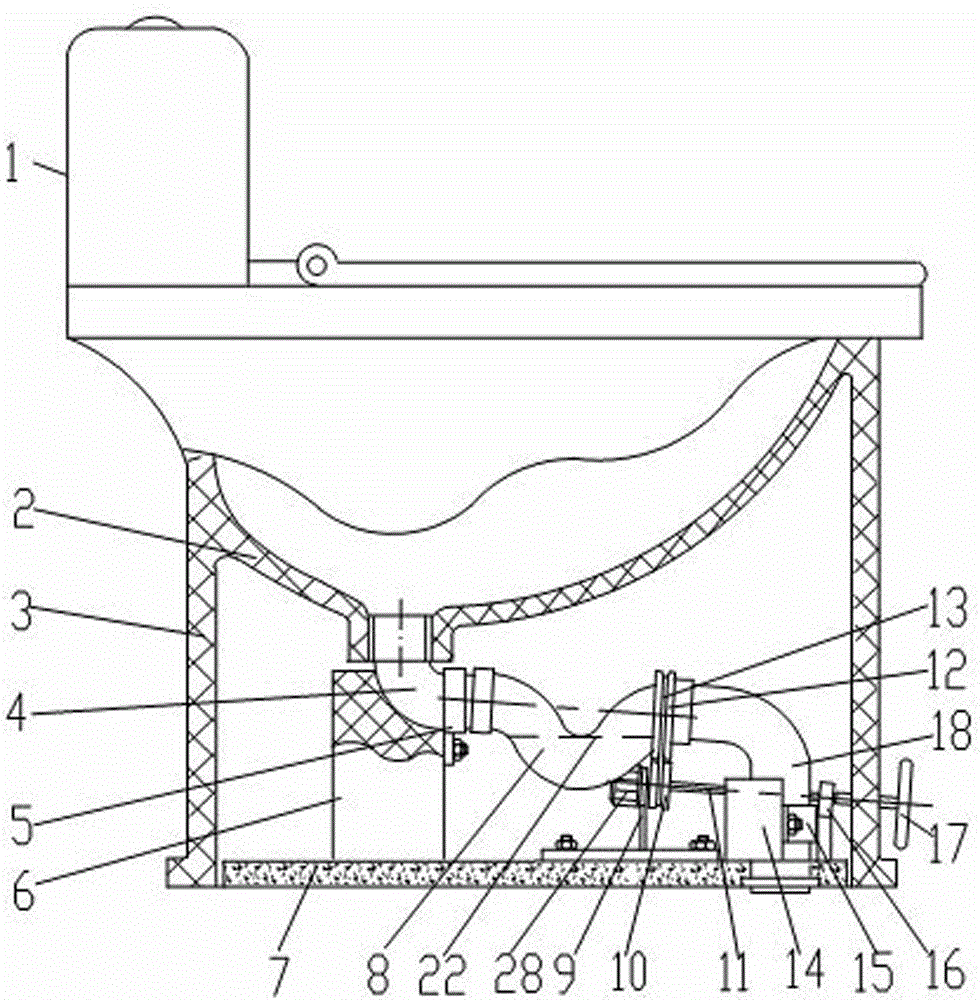

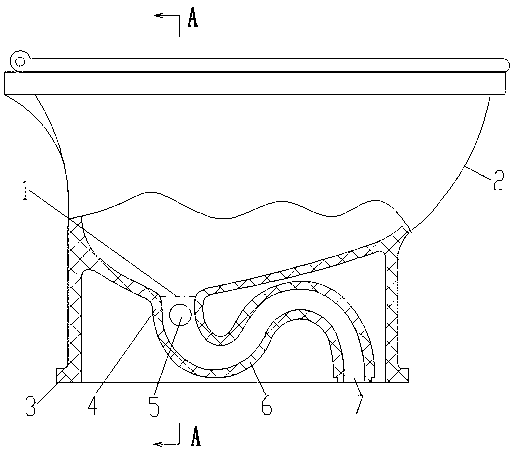

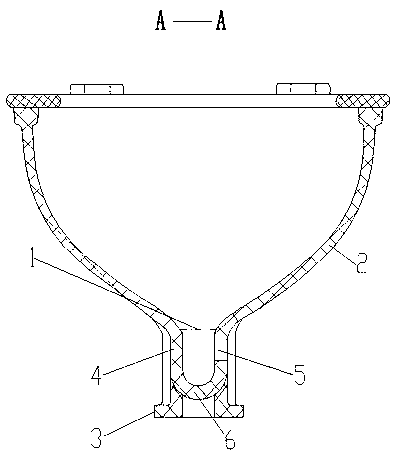

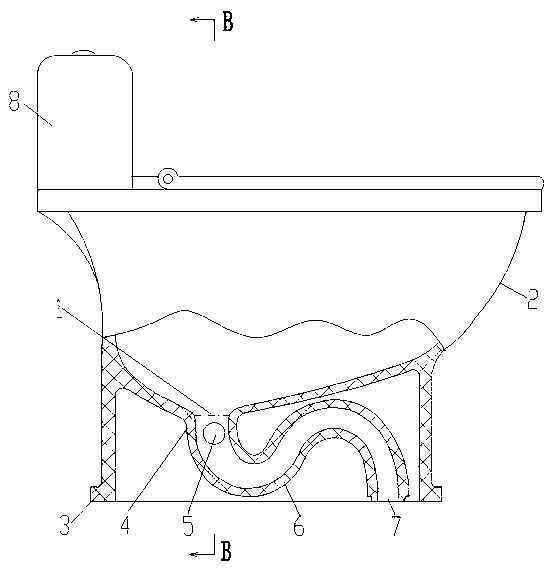

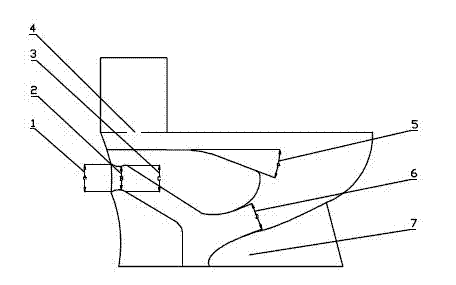

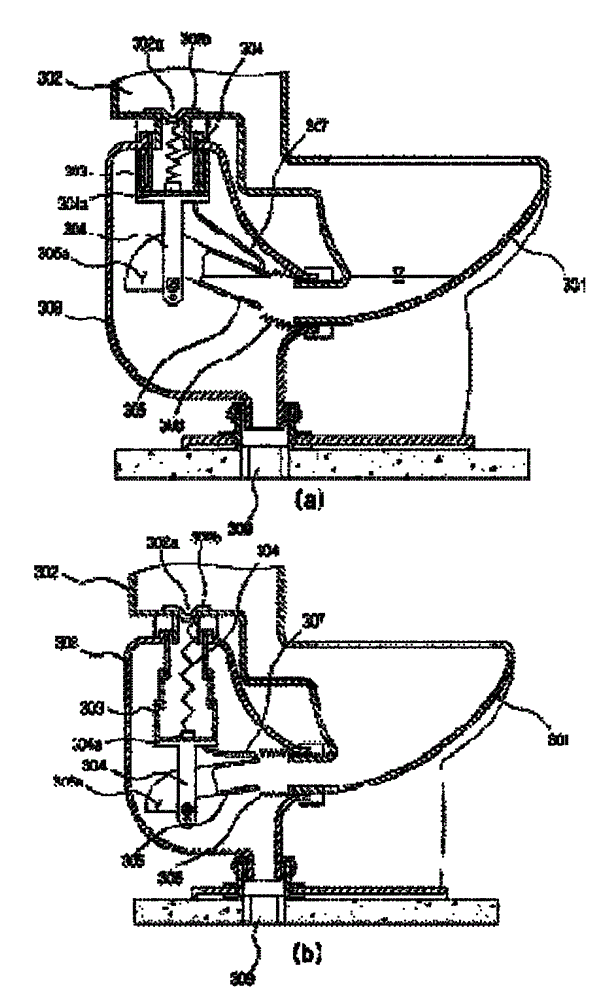

Water-saving discharging pipeline of pedestal pan

InactiveCN105113605AAvoid pollutionImprove the level of civilizationWater closetsWater useWater saving

The invention discloses a water-saving discharging pipeline of a pedestal pan. The water-saving discharging pipeline comprises a water inlet bend, a water sealing bend and a discharging bend. A water inlet of the water inlet bend is connected with a drain hole in the bottom of a pedestal pan bowl body, a water outlet of the discharging bend is connected with a sewer, and the center of a water outlet of the water inlet bend is higher than the center of a water inlet of the discharging bend. One end of the water sealing bend is connected with the water outlet of the water inlet bend in a sleeved mode, and the other end of the water sealing bend is connected with the water inlet of the discharging bend in a sleeved mode. The water sealing bend is provided with a swing device. The pedestal pan matched with the water-saving discharging pipeline is easy to operate, convenient to wash and high in discharging speed. Stinks can be prevented from polluting the air, the level of civilization of a toilet is improved, the amount of water used for flushing the toilet is greatly lowered, and thus an obvious energy-saving effect is achieved.

Owner:李武

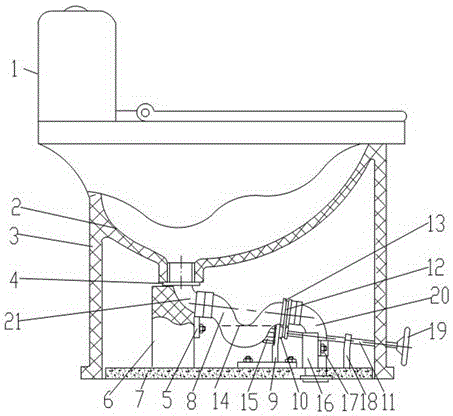

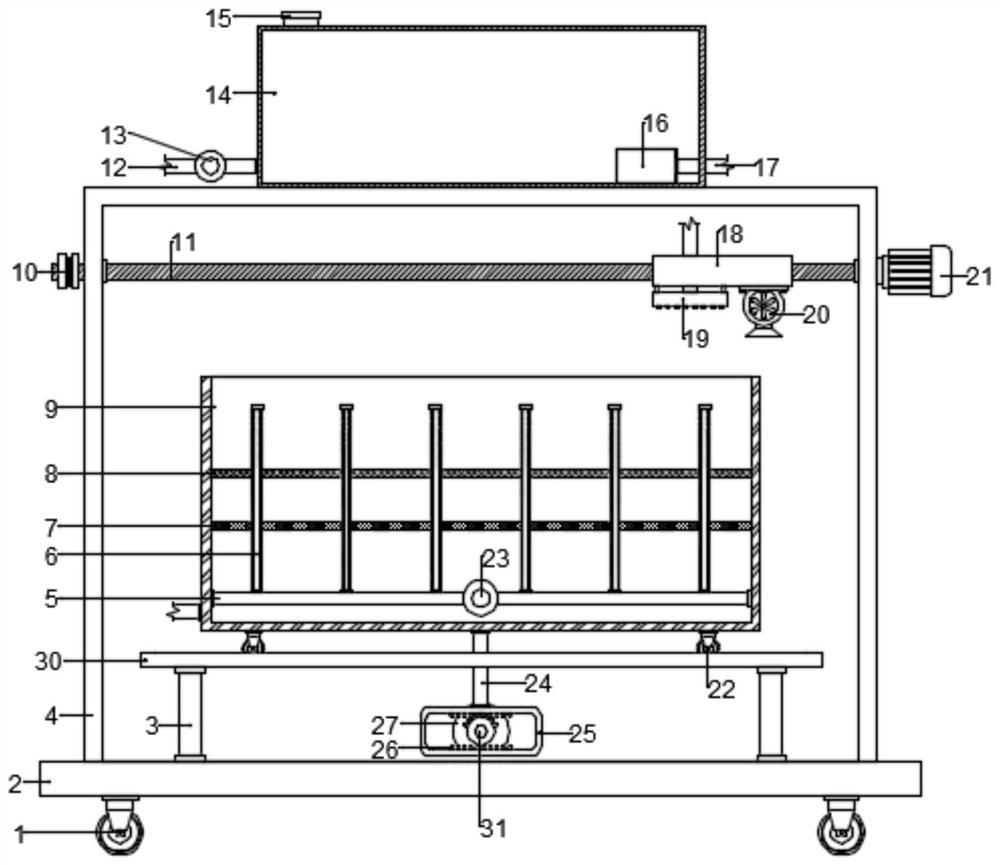

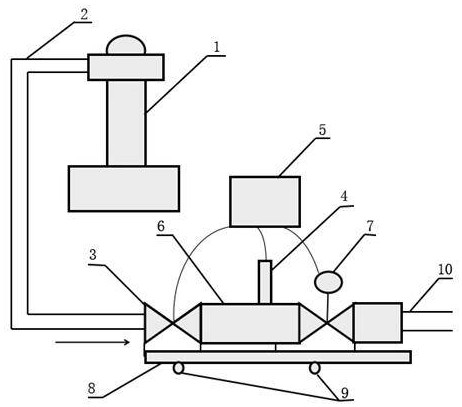

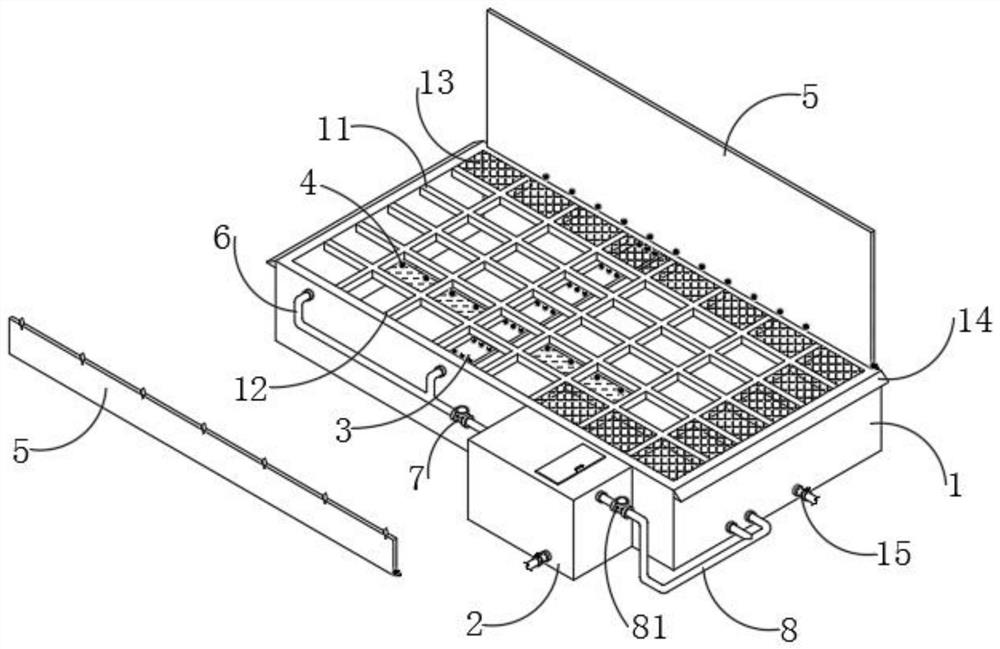

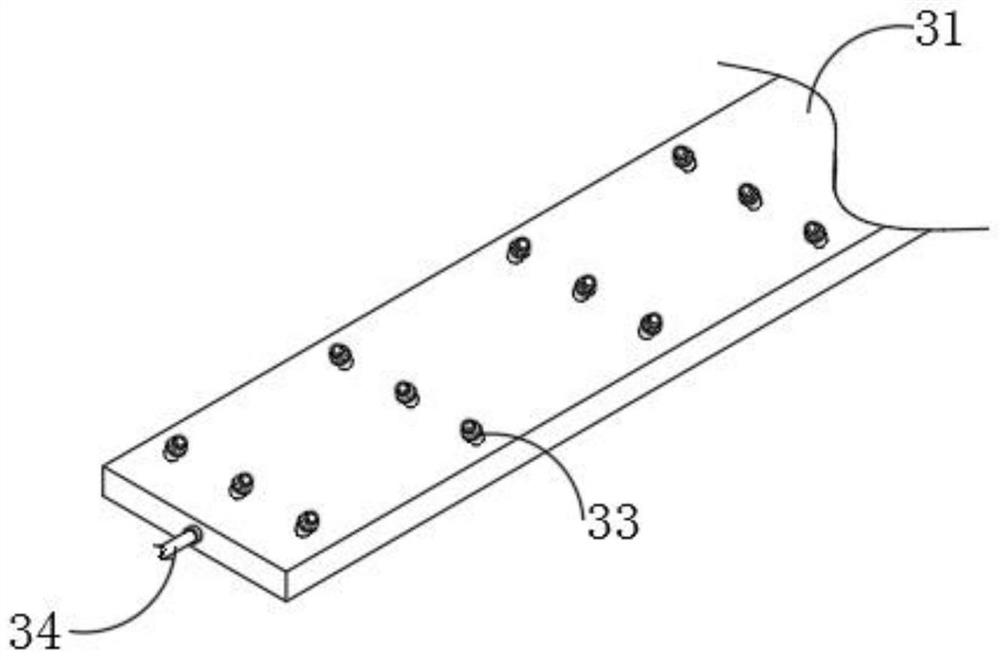

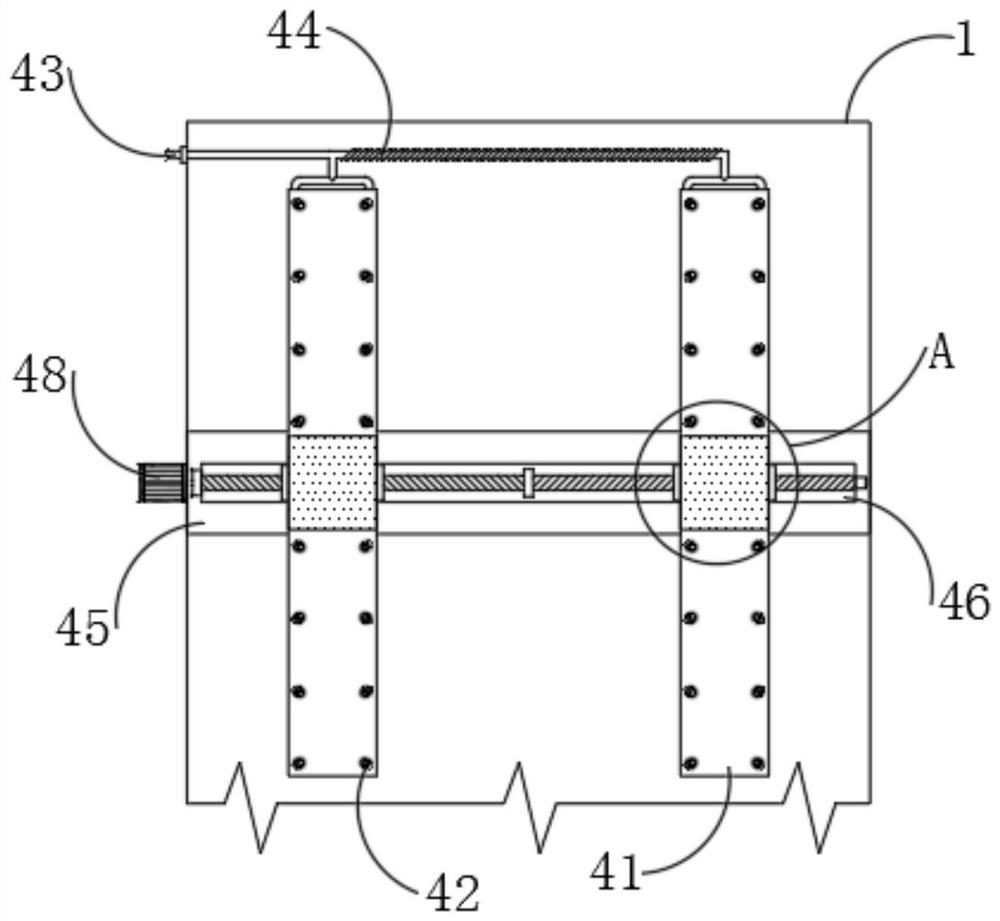

Mechanical arm production aluminum profile rinsing device

InactiveCN111921948AReduce flushing water consumptionReduce production processDrying gas arrangementsCleaning using liquidsWater storageWater use

The invention discloses a mechanical arm production aluminum profile rinsing device. The device comprises a base, a U-shaped plate and a bearing platform; the U-shaped plate is fixedly installed on the base; the bearing platform is fixedly installed above the base via a plurality of supporting rods; a rinsing box is movably arranged on the bearing platform; a main water guiding pipe is arranged atthe bottom of an inner cavity of the rinsing box; a plurality of branch water guiding pipe are equidistantly embedded on the main water guiding pipe; one end, away from the main water guiding pipe, of each branch water guiding pipe extends towards the upper part of the inner cavity of the rinsing box; two threaded rods are rotatably installed in the U-shaped plate via bearings in a front-and-backsymmetrical mode; a movable seat is arranged between the two threaded rods in a threaded penetration mode; a strip-type spraying nozzle is fixedly arranged at the bottom of the movable seat; and a water storage box is fixedly arranged at the top of the U-shaped plate. According to the device, while an aluminum profile is evenly rotated, the aluminum profile is rinsed from the upper part and the inner part, and the cleaning effect is better; through the arrangement of a dynamic balance water circulation system, the amount of water used for aluminum profile rinsing is greatly reduced; and the device has good economic benefits and practical significance.

Owner:熊祥

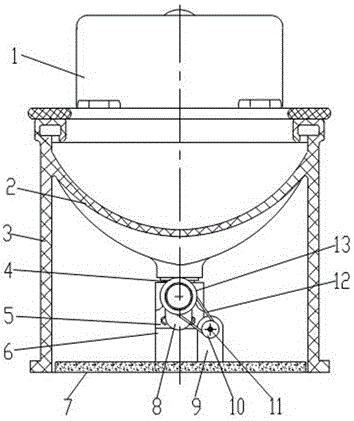

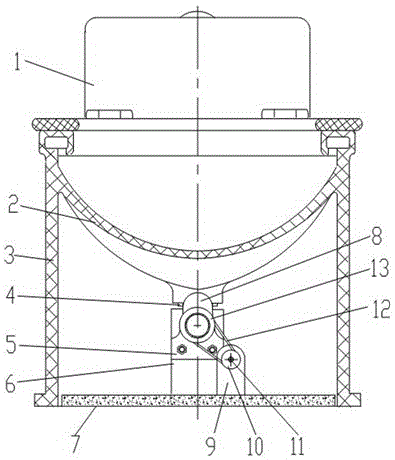

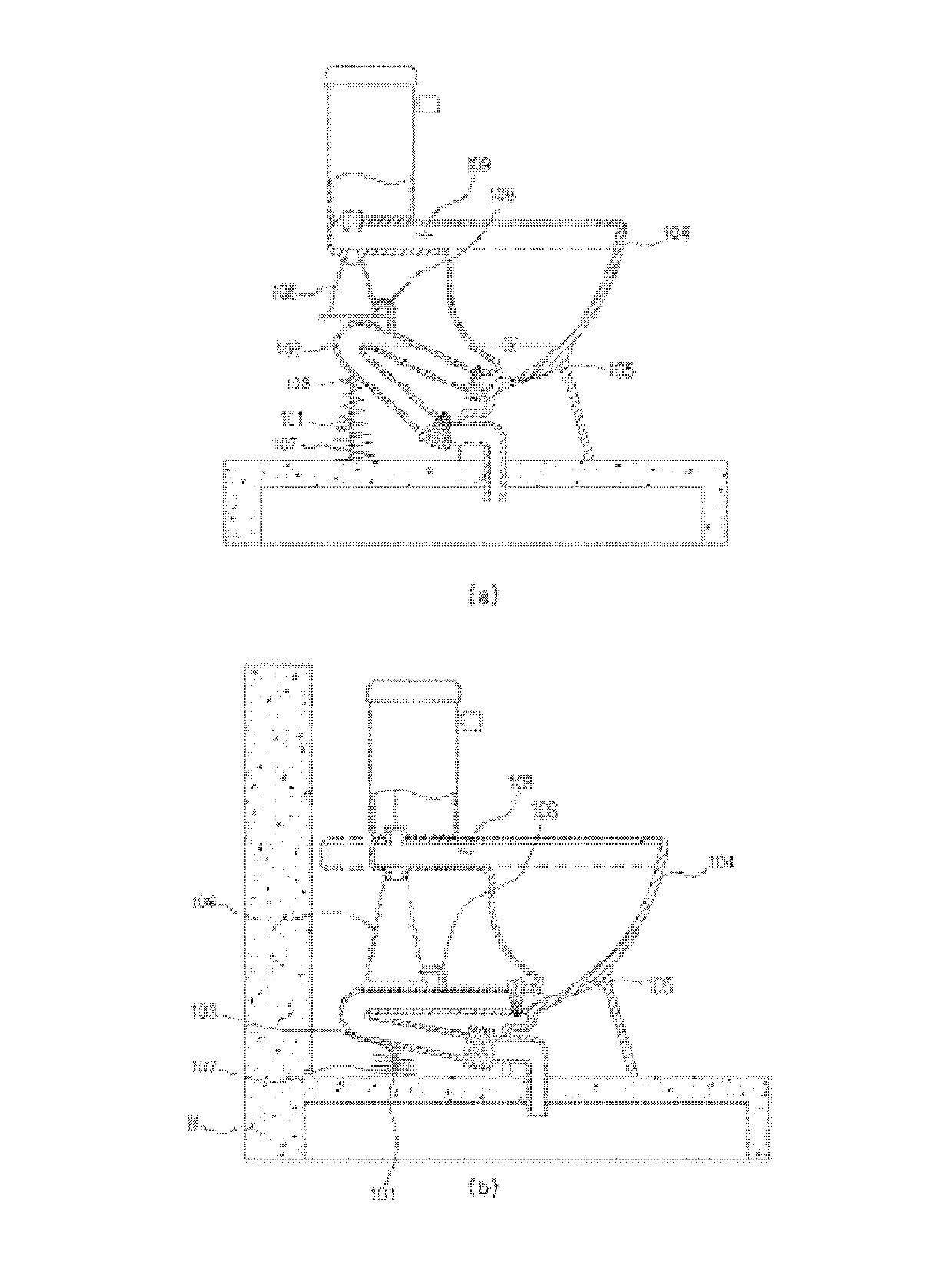

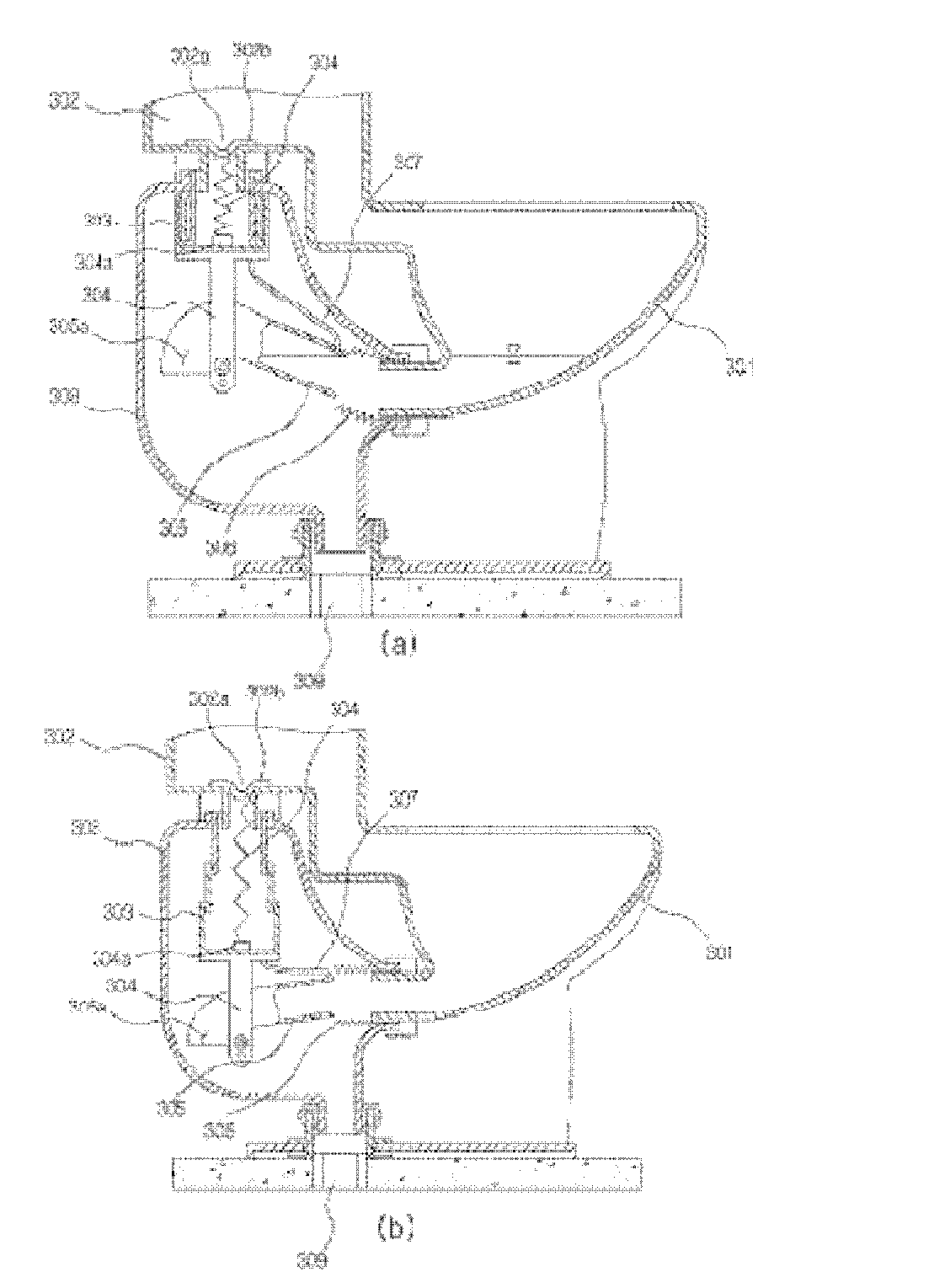

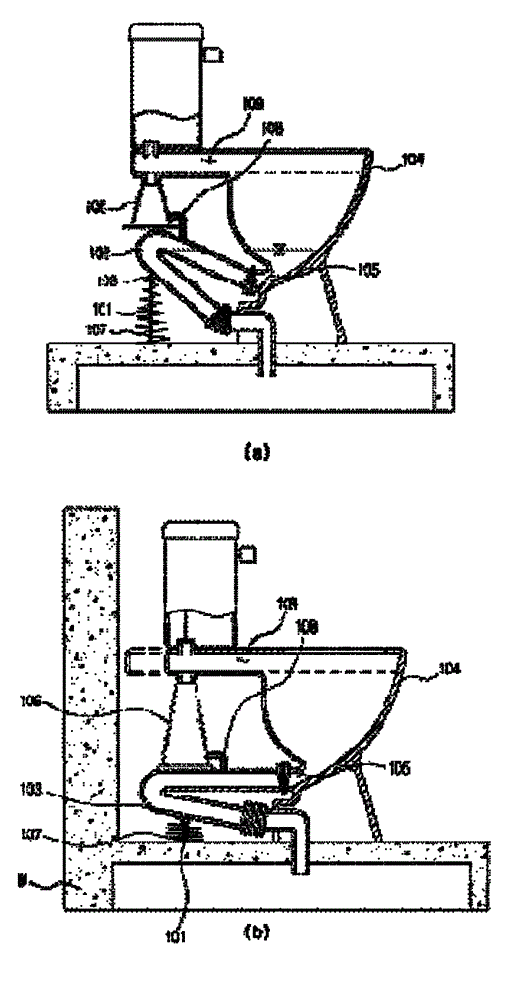

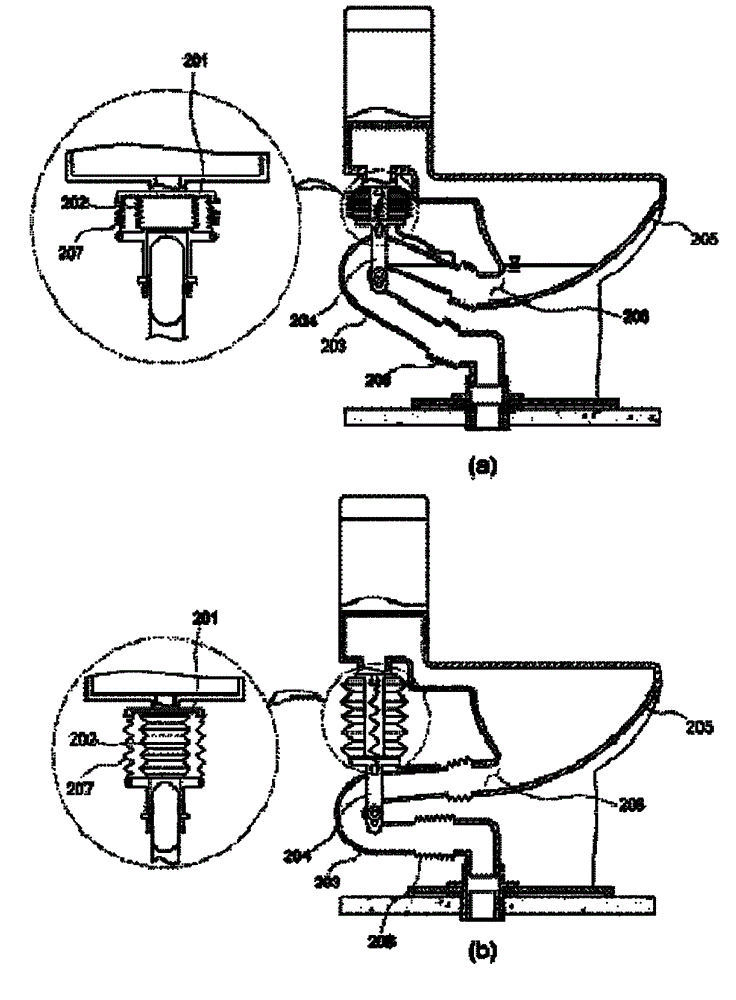

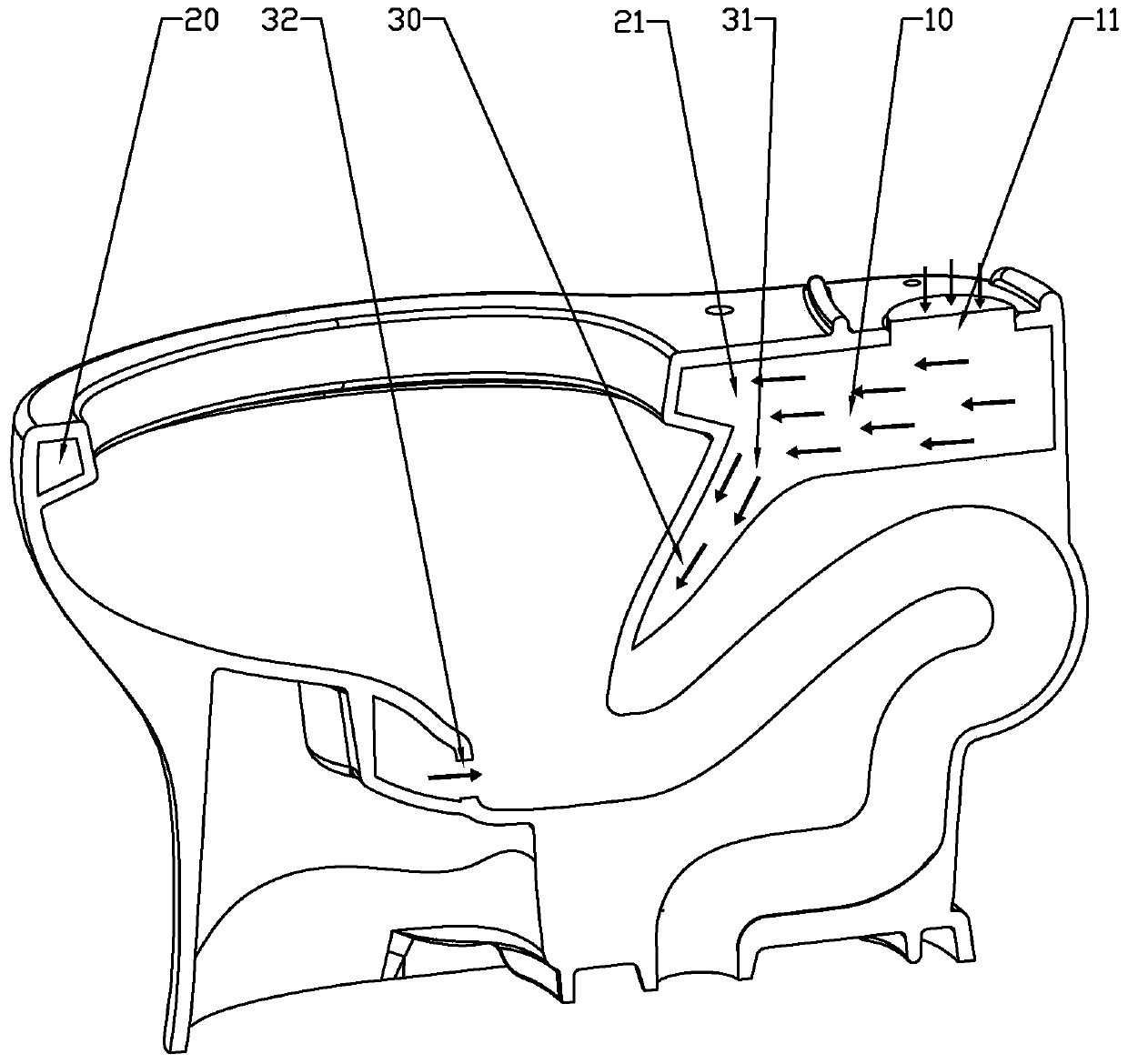

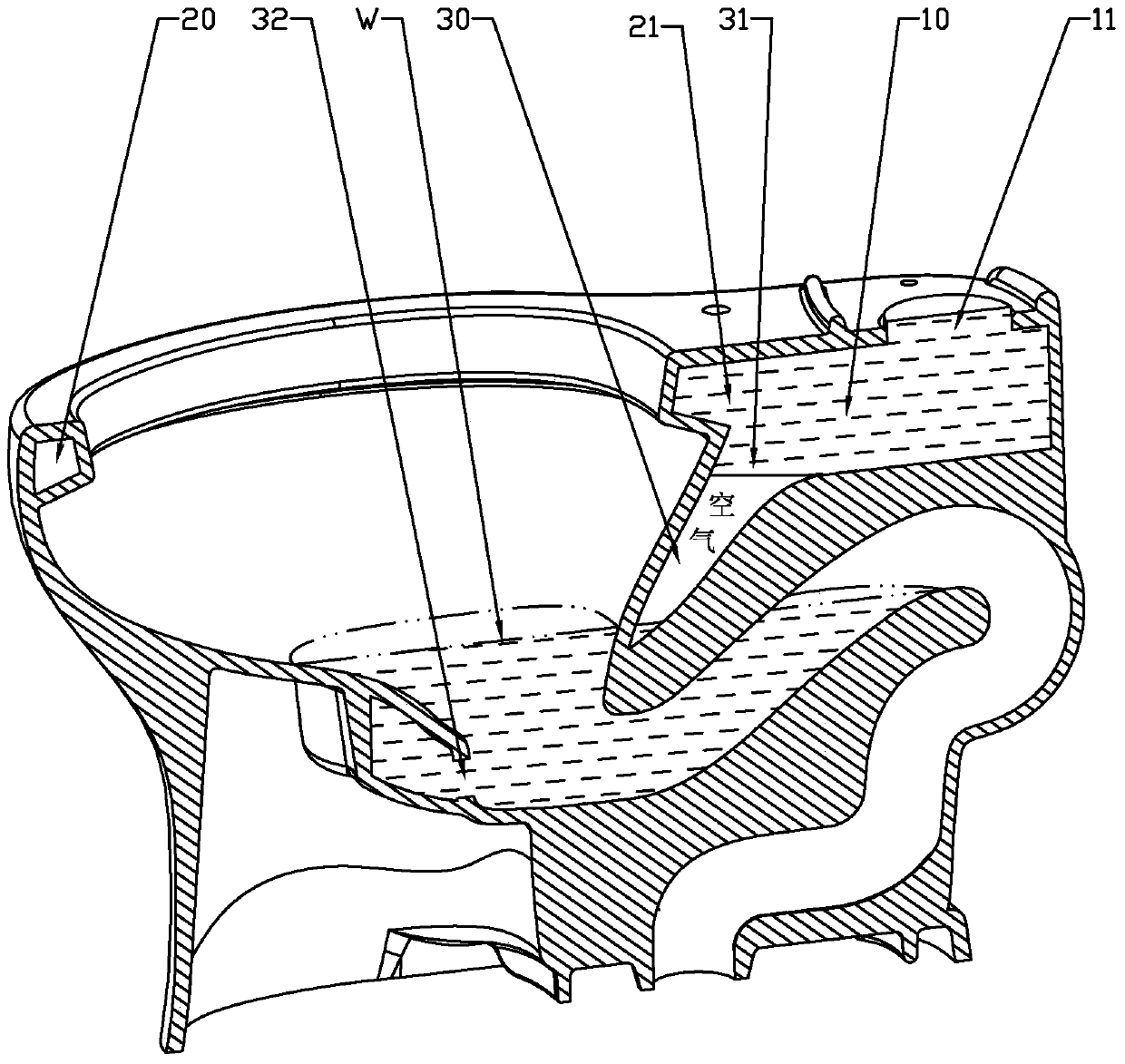

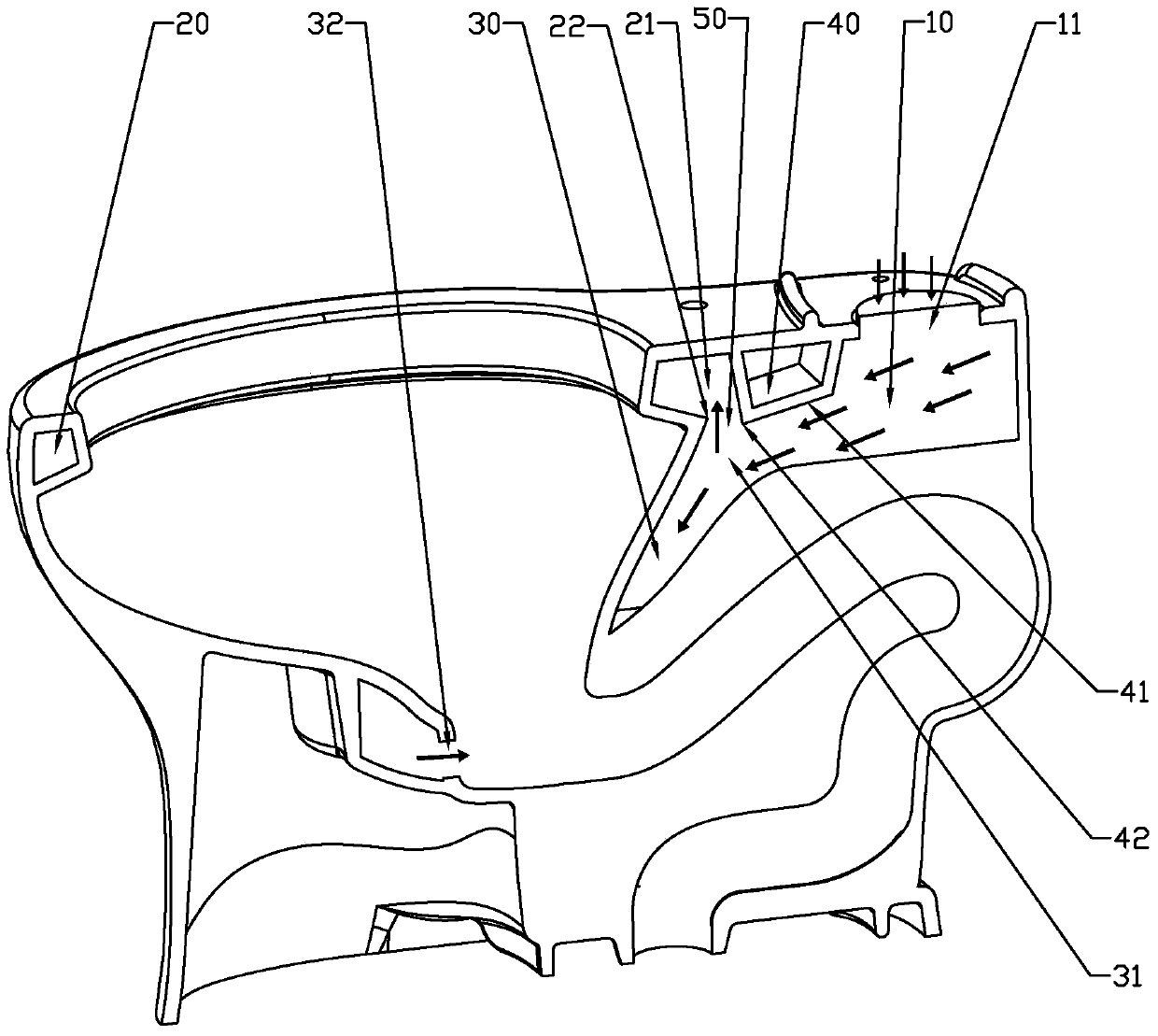

Variable, double, straight-line piping type of water-saving toilet

InactiveCN102713098AImprove flushing efficiencyLow costUrinalsWater closetsWater savingWater discharge

The variable, double, straight-line piping type of water-saving toilet of the present invention comprises: a main toilet body (10) having a bowl (11), a cistern (12), a water-supply pathway (13) connected to the rear of the bowl (11) from the cistern (12), and a cover part (14) which covers the lower part of the cistern (12) and the rear of the bowl (11) and is adapted to guide foul water discharged from the bowl (11) to a floor pipe (15); a variable, double, straight-line pipe (20) incorporating an inner pipe (21) of which one end is connected via a flexible tube (25) to the discharge port (13a) of the bowl (11), an outer pipe (22) which receives part of the inner pipe (21) on the inside thereof and which is equipped with spring-securing parts (22a) on the outside surface on two sides, and a connecting part (23) which forms a receiving space (23a) where cleaning water is received between the inner pipe (21) and the outer pipe (22), the pipe (20) being adapted so as to discharge the foul water and the cleaning water in the bowl (11) by rotating downward under its own weight due to the inflow of cleaning water into the receiving space (23a) because of the increase in cleaning water flowing into the bowl (11) during foul-water discharge; two brackets (30) which are secured either vertically or horizontally on both sides of the rear wall (11b) of the bowl (11), and are equipped with spring-fastening parts (31); and tension springs (40) which exhibit a resilient restoring force such that the variable, double, straight-line pipe (20) rotates upwards after foul-water discharge.

Owner:李钟寅 +1

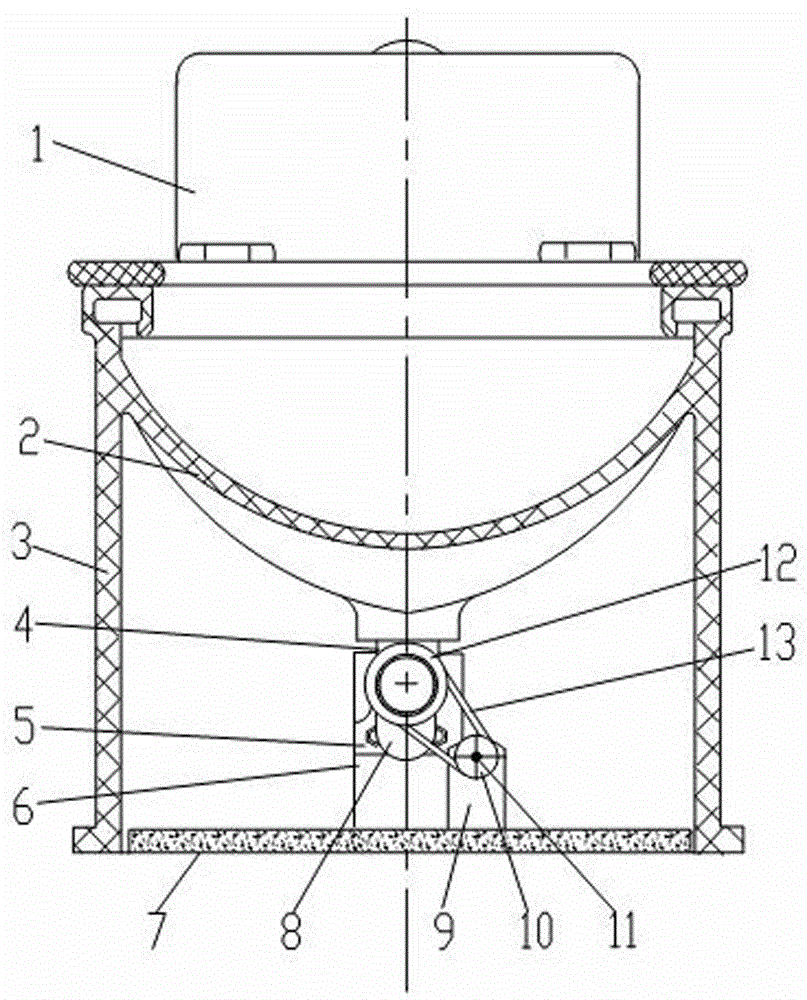

Toilet bowl discharge pipeline

The invention discloses a toilet bowl discharge pipeline and belongs to the technical field of water-saving toilet bowls. The toilet bowl discharge pipeline comprises a flushing elbow, a water seal elbow and a discharge elbow. A water inlet of the flushing elbow is communicated with a drain hole in the bottom of a toilet bowl body, a water outlet of the discharge elbow is communicated with a sewer, and the center of a water outlet of the flushing elbow is higher than the center of a water inlet of the discharge elbow. One end of the water seal elbow is in sleeving connection with the water outlet of the flushing elbow, and the other end of the water seal elbow is in sleeving connection with the water inlet of the discharge elbow. When a toilet bowl matched with the toilet bowl discharge pipeline is used, due to the fact that the center of the water outlet of the flushing elbow is higher than the center of the water inlet of the discharge elbow, the water seal elbow swings, sewage is automatically discharged into the sewer based on the gravity, the water seal elbow swings again to return to the original position after water flushing, and a water seal can be formed with a little amount of stored water. The resistance of flushing water can be reduced through the discharge pipeline, complete flushing can be achieved with a little of water, the amount of the toilet flushing water is greatly reduced, and an obvious water saving effect is achieved.

Owner:李武

Nanofiltration-forward osmosis combined system adopting commercial nanofiltration membrane and forward osmosis membrane and application of nanofiltration-forward osmosis combined system

InactiveCN107596920AImprove processing efficiencyLight pollutionSemi-permeable membranesWater contaminantsFrequency changerWater baths

The invention relates to a nanofiltration-forward osmosis combined system adopting a commercial nanofiltration membrane and a forward osmosis membrane and application of the nanofiltration-forward osmosis combined system. A nanofiltration system adopts cross flow filtration, water passes from the two sides of the membrane, the filtration pressure and the circular flow are regulated through a frequency converter of a gear pump, and a PLC (Programmable Logic Controller) controls the whole. The quantity of reflux of concentrated water is controlled through the regulation of a valve so as to achieve different recovery rates. The effluent of nanofiltration fresh water is measured by a mass flowmeter controlled by the PLC, the result is stored in a PLC storage unit, so that the flux of infiltration water is recorded and acquired. The nanofiltration water inlet temperature is controlled by a water bath and keeps consistent with the temperature of a forward osmosis system, and the concentratedwater of the nanofiltration system flows out to a raw material solution tank of the forward osmosis system. A raw material solution is placed on a balance connected to a computer, and the change of the mass within the time interval set in advance is transmitted into the computer. The temperatures of the raw materials solution and a driving liquid are controlled through the water bath and keep consistent with the temperature of the nanofiltration system. The design flow of the system is 60 L / h, and the removal rate of dissolved organic matters is more than 90%. The membrane is replaced at regular intervals. The system is cleaned at regular intervals.

Owner:TONGJI UNIV

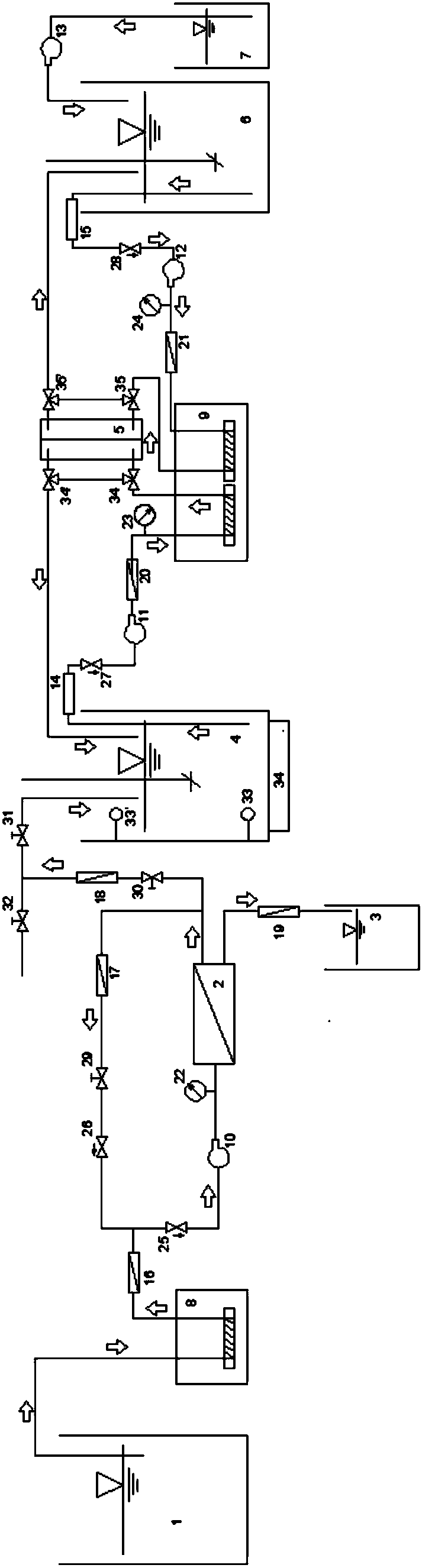

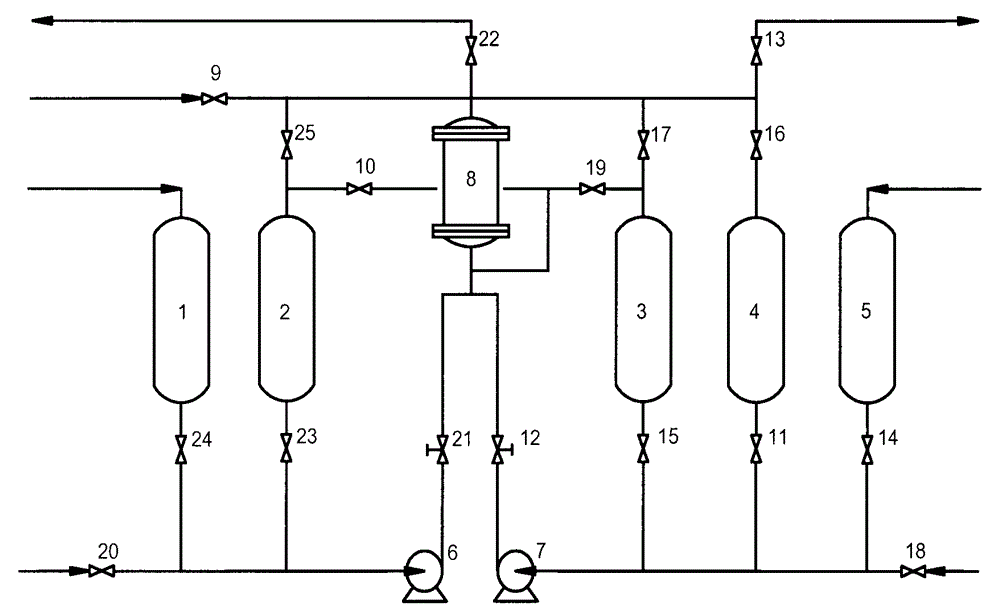

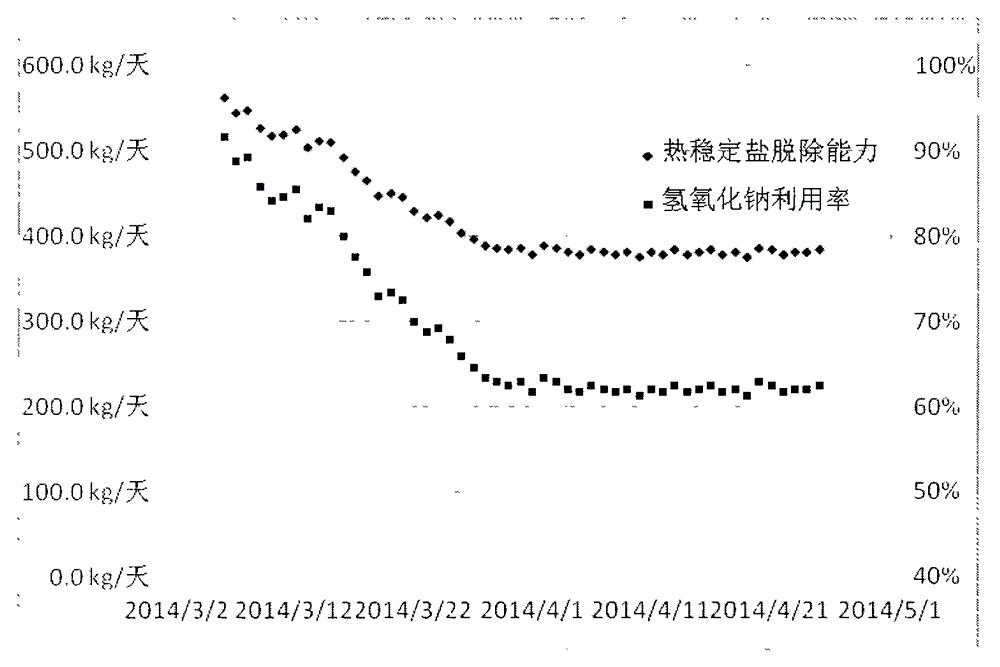

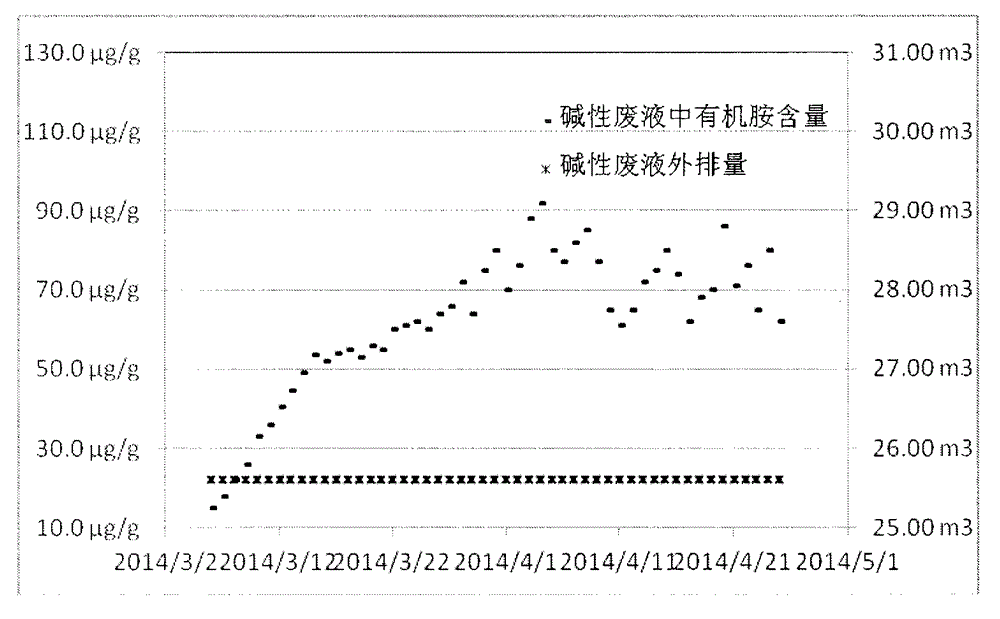

Resin bed thermal stabilization salt removing method

ActiveCN105366766AReduce dosageIncrease profitIon-exchanger regenerationWater/sewage treatment by ion-exchangeWater rinsingRinse water

The invention discloses a resin bed thermal stabilization salt removing technology to overcome the defects that regenerant consumption is large, washing water consumption is large and drained waste liquid amount is large in the prior art. The method comprises the steps of resin bed purging and emptying (through purging amine), resin bed preregeneration, resin bed regeneration, alkali recovery, recycle washing after regeneration, deep washing after regeneration, resin bed purging and emptying (through purging alkali), thermal stabilization salt removal, amine-containing water washing, lateral line extraction and washing and amine recovery. By the adoption of the technology, the good resin exchange, regeneration and washing effects can be obtained through a small amount of washing water and regeneration agent, so that according to the resin bed device, the consumption of the regeneration agent and salt removing water is reduced, and the drained waste liquid amount is greatly reduced.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

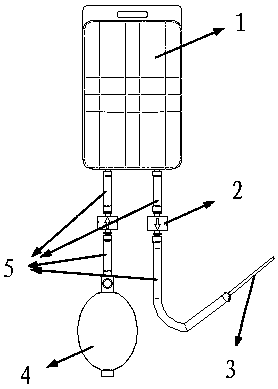

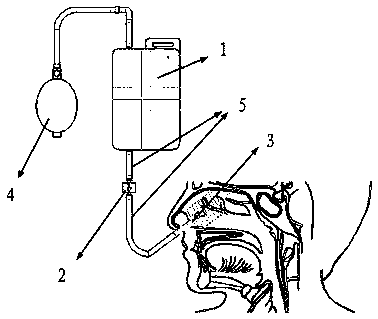

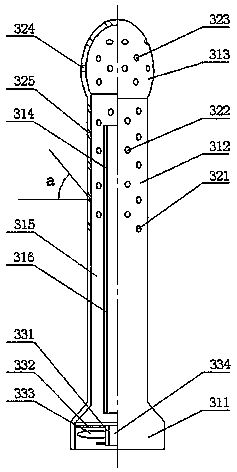

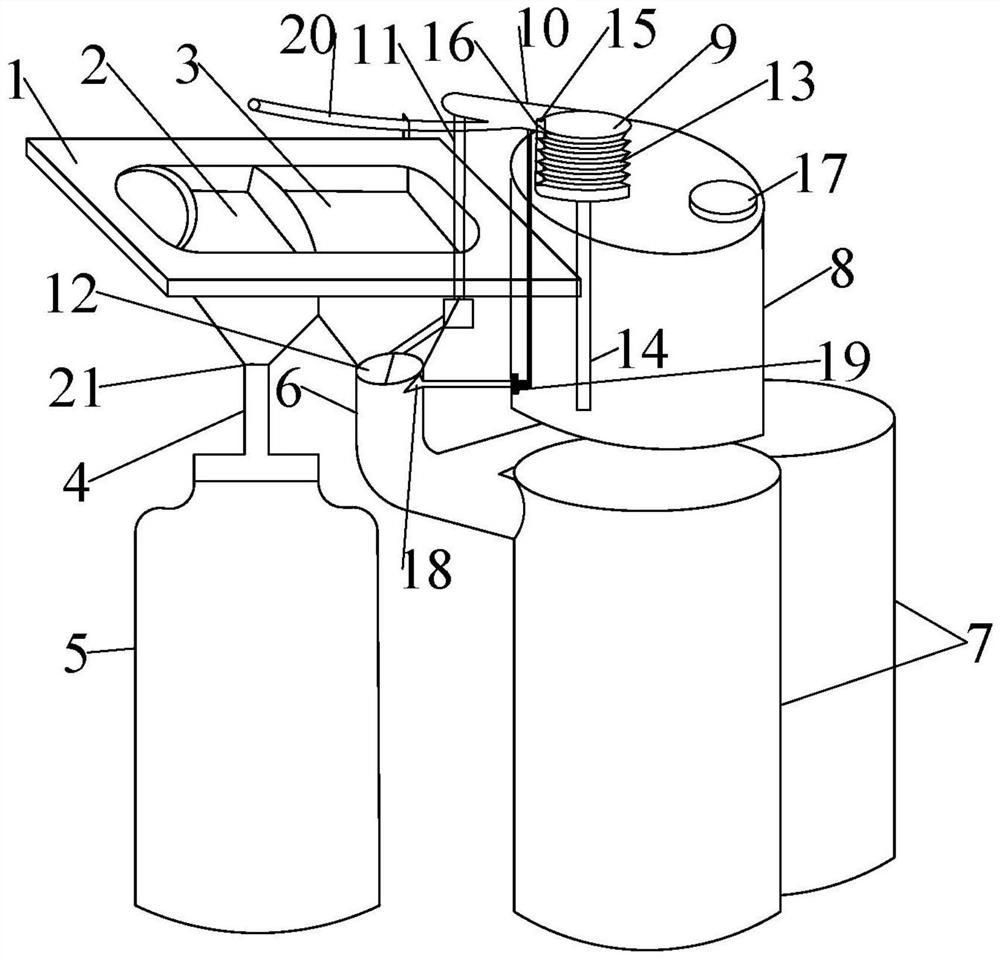

Spiral-flow type nasal cavity cleaning instrument

InactiveCN108542756AImprove effective utilizationIncrease flushing areaBathing devicesNasal cavityMedical equipment

The invention relates to a spiral-flow type nasal cavity cleaning instrument. The instrument comprises a vessel, a spray pipe and an air inflation device, wherein a water outlet of the vessel is connected with a water inlet of the spray pipe through a water delivery pipe, the side wall of the spray pipe is provided with a plurality of nozzles, an air outlet of the air inflation device is connectedwith an air inlet of the vessel through an air delivery pipe, a distribution area of the nozzles in the side wall of the spray pipe comprises all pipe walls within a section of distance on the frontportion of the spray pipe, the front end of the spray pipe is a head of the spray pipe, the head of the spray pipe is provided with a plurality of nozzles, the tail portion of the spray pipe is internally provided with a spiral flow diversion propulsion device used for forming spiral flow, when fluid flows forward, a pipe body of the spray pipe is driven to rotate relative to a fixing seat, the spray pipe is internally provided with a coaxial inner pipe, and the inner pipe is located between the spiral flow diversion propulsion device and the head of the spray pipe in the axial direction. Thespiral-flow type nasal cavity cleaning instrument has the advantages that the flushing effect of the cleaning instrument is good, the area is large, the use is convenient, the cleaning instrument is mainly used for cleaning the nasal cavity and can be used as a daily sanitary product and medical equipment.

Owner:BEIJING M&B ELECTRONIC INSTR CO LTD

Vacuum-assisted toilet

ActiveCN101691777BGuarantee the quality of water sealReduce water consumptionWater closetsFlushing devicesVacuum assistedSewage

The invention relates to a vacuum-assisted toilet, which adopts assisting vacuum for flushing so as to save water and deodor. The toilet comprises an exhaust fan which is started when a person uses the toilet to allow a gas injector arranged on an exhaust pipe to work. On one hand, the exhaust fan exhausts the odor in a washing room and particularly exhausts the odor given off by excrement discharged from a human body into a toilet basin at any time through the flushing in the toilet basin to reduce odor; and on the other hand, and gas at the position of the exhaust opening of the exhaust fanserves as a working medium to directly drive the gas injector arranged in the exhaust pipe to generate certain vacuum in an sewage pipe of the toilet, so that when the person leaves, the toile discharges the excrement under the actions of the pressure of flushing water, the self gravity of the excrement and the vacuum in the sewage pipe. Under the action of the vacuum, water consumption is reduced and an aim of saving water is fulfilled.

Owner:JIANGSU CRRC ENVIRONMENT CO LTD

Nanofiltration-Forward Osmosis Combined System Using Commercial Nanofiltration Membrane and Forward Osmosis Membrane and Its Application

ActiveCN107486018BImprove processing efficiencyLight pollutionWater treatment parameter controlSpecific water treatment objectivesWater bathsSystems design

Owner:TONGJI UNIV

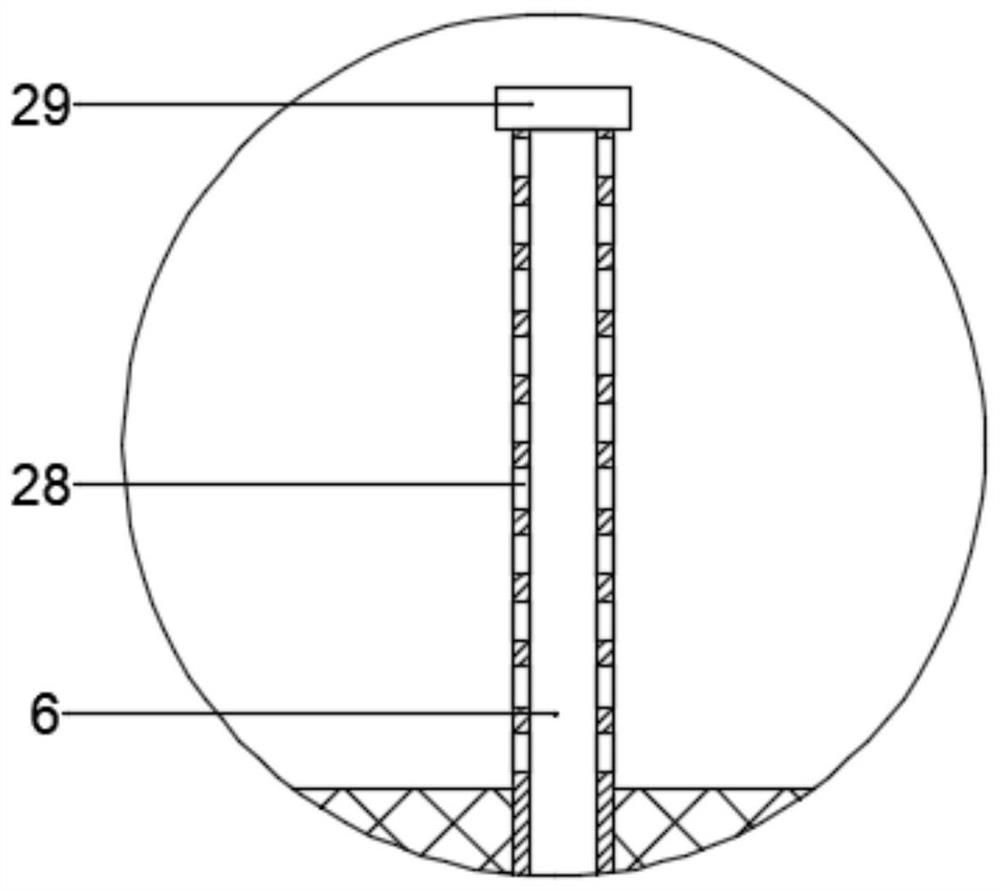

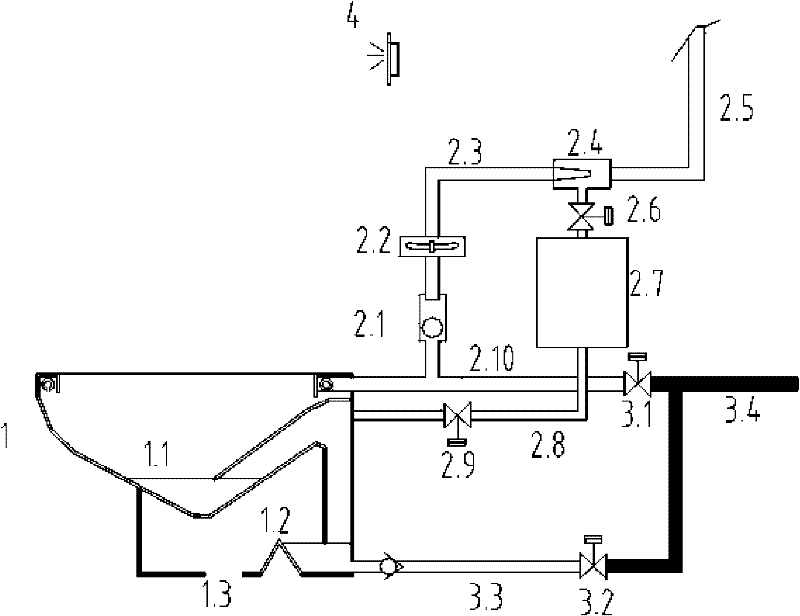

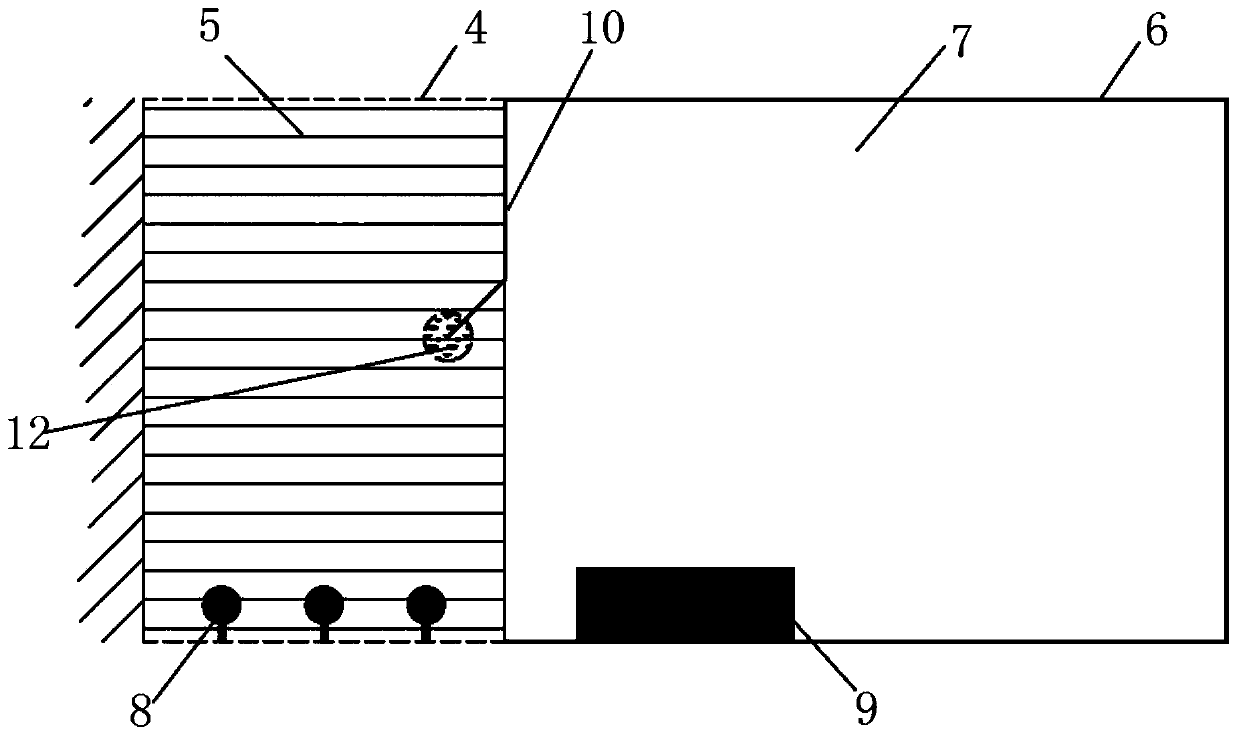

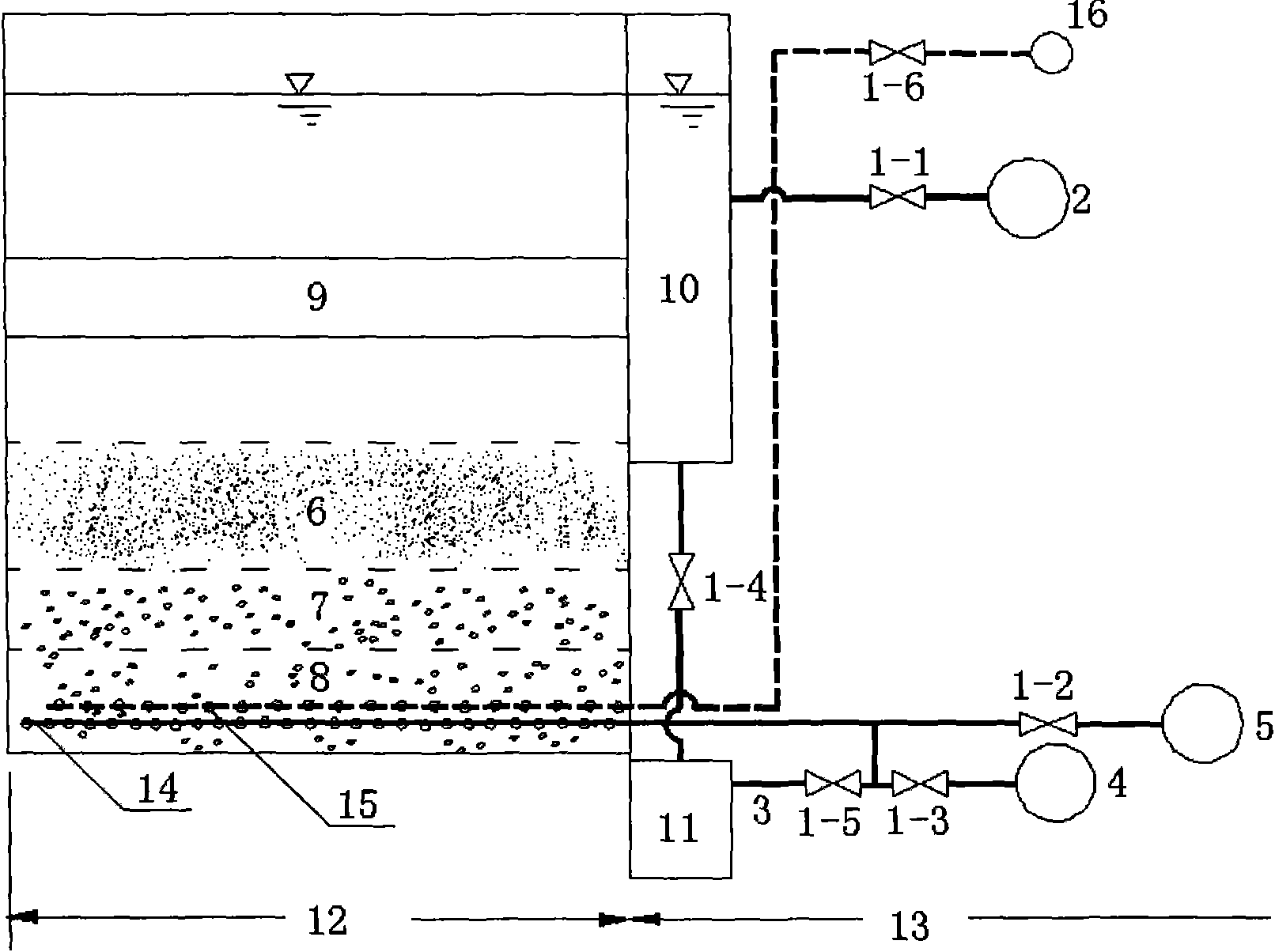

Municipal pipeline tail end drainage control device

InactiveCN113502877AReduce flushing water consumptionImprove washing effectService pipe systemsWater mainsAutomatic controlStream flow

The invention relates to the technical field of municipal pipeline operation, in particular to a municipal pipeline tail end drainage control device. The device comprises a fire hydrant (1), a water inlet connecting pipe (2), an electromagnetic valve (3), a main pipe (6) and an electromagnetic flowmeter (7) which are sequentially connected; a turbidity sensor (4) is mounted on the main pipe (6); the electromagnetic valve (3), the turbidity sensor (4) and the electromagnetic flowmeter (7) are all connected with a PLC automatic control system (5); and the tail end of the main pipe (6) is connected with a drainage pipe (10). The device can realize automatic control and record changes of parameters such as turbidity, flow, time and the like in the municipal water supply pipeline tail end flushing drainage process, is used for finely managing the municipal pipeline tail end drainage process, saves the drainage quantity, improves the drainage efficiency, and improves the water quality of a water supply pipeline.

Owner:SHANGHAI MUNICIPAL WATER RESOURCES DEV & UTILIZATION NAT ENG CENT

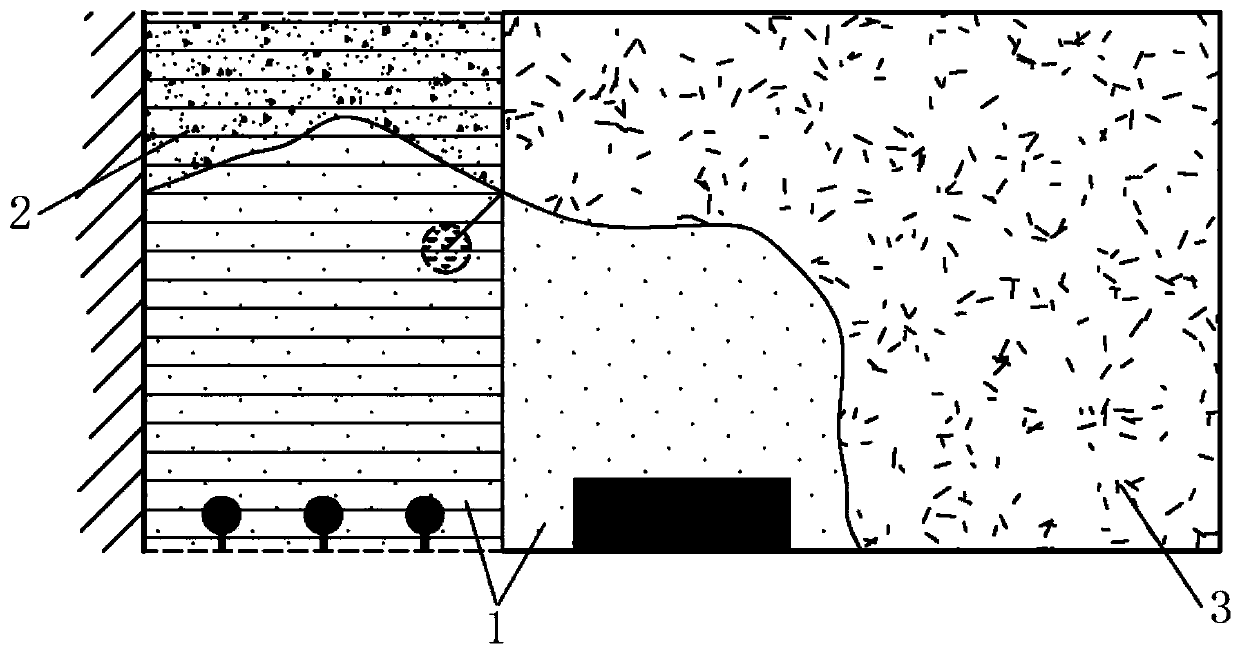

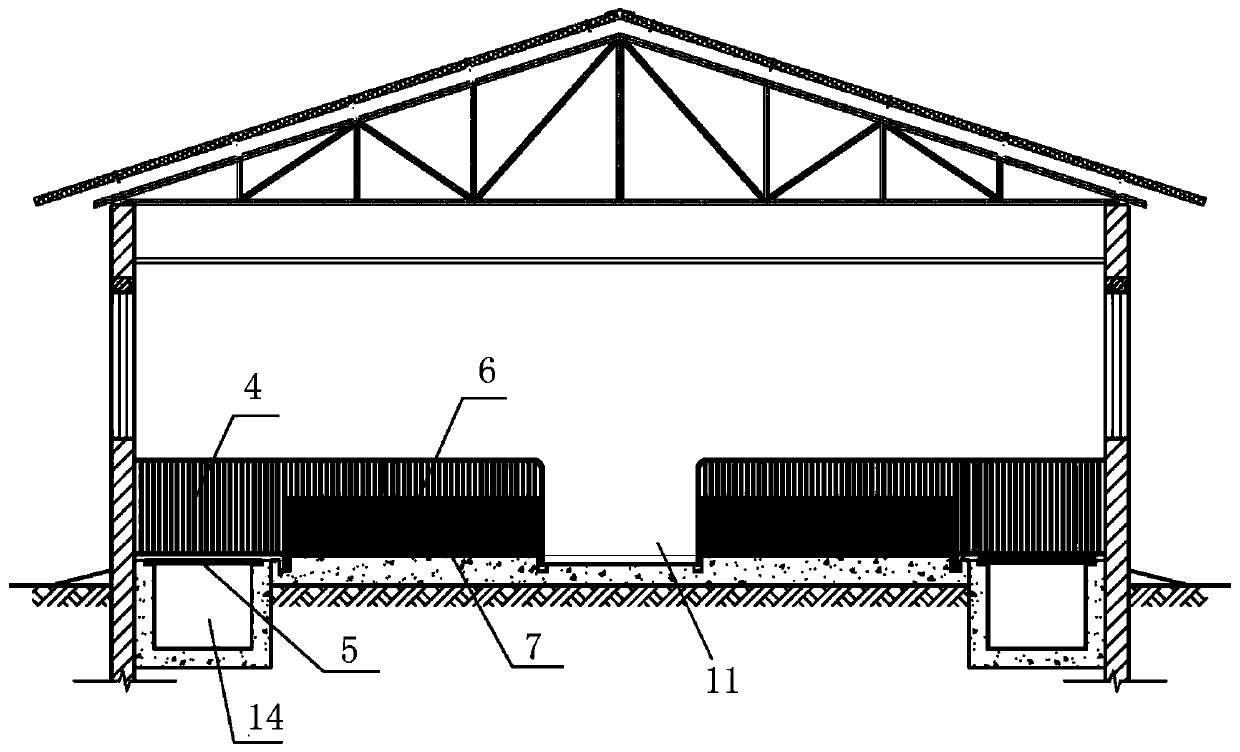

Clean welfare-oriented group rearing pigpen and space layout method

PendingCN110313407AReduce frictionWon't scratchAnimal watering devicesAnimal feeding devicesFecesPig breeding

The invention belongs to the technical field of animal husbandry engineering, and relates to a clean welfare-oriented group rearing pigpen and a space layout method. An open fence is arranged on the outer side of an excretion area and an activity area corresponding to the excretion area, a leakage floor is installed at the bottoms of the excretion area and the activity area, a semi-closed fence isarranged on the outer side of a rest area and an activity area corresponding to the rest area, and a solid floor is arranged at the bottoms of the rest area and the activity area; a water fountain isfixedly arranged on the leakage floor of one activity area, and a feeding device is fixedly arranged on the solid floor of the other activity area; an avoiding wall is fixedly arranged at the joint of the excretion area and the rest area, a feces and urine ditch is arranged below the leakage floor, and the area of the leakage floor is half of the area of the solid floor; longitudinal pigpen unitsare arranged like mirror images, the excretion areas of transverse pigpen units are opposite, and a walkway is reserved between the excretion areas of the adjacent pigpen units. According to the group rearing pigpen, the cleanliness of the pigpen can be improved, abnormal behaviors can be reduced, the production efficiency is improved, and the cleaning property, welfare orientation and high efficiency of live pig breeding can be realized.

Owner:CHONGQING ACAD OF ANIMAL SCI

Source separation water-saving sanitary toilet

InactiveCN112575868ABarrier contactPrevent escapeWater closetsFlushing devicesWater savingMechanical engineering

The invention provides a source separation water-saving sanitary toilet, and belongs to the technical field of sanitary facilities. The toilet comprises a squatting pan, a urine storage barrel, a double-pit alternating septic tank and a multifunctional flushing tank, the multifunctional flushing tank is arranged on the rear side of the squatting pan, and the urine storage barrel and the double-pitalternating septic tank are connected to the lower portion of the squatting pan; the squatting pan comprises a urinal and an excrement hopper which are separated front and back, a pressing type watersuction pump is arranged on the multifunctional flushing tank, the pressing face of the pressing type water suction pump is connected with an improved crank connecting rod, the lower portion of the improved crank connecting rod is connected with an excrement hopper outlet overturning partition plate, and a flushing spray head is arranged at the bottom of the left side of the multifunctional flushing tank and directly faces the overturning partition plate; And a movable sealing valve is arranged at the water inlet of the valve body and is connected to the pressing surface through a rod. The toilet is simple in structure, free of power consumption, water-saving, sanitary and low in installation and maintenance cost, and conforms to the use habits of users.

Owner:UNIV OF SCI & TECH BEIJING

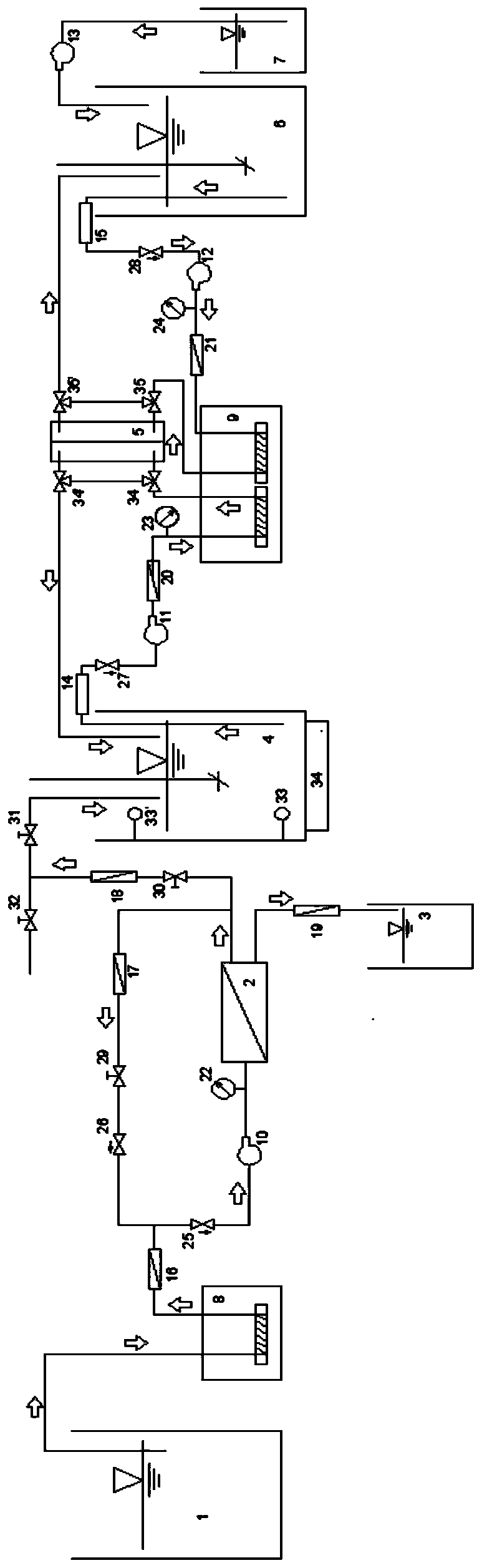

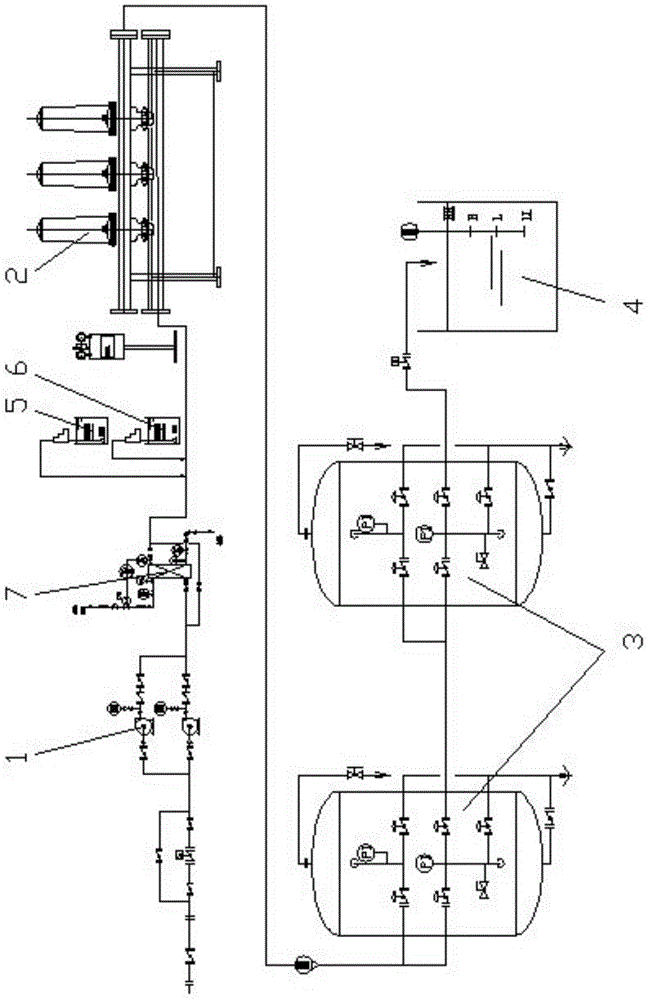

Water treatment system for circulating cooling water of cement production system

InactiveCN104445723AEliminate electrostatic repulsionGood effectTreatment involving filtrationMultistage water/sewage treatmentWater treatment systemThree stage

The invention discloses a water treatment system for circulating cooling water of a cement production system. The water treatment system comprises a raw water pump, a self-cleaning filter, a quartz sand filter and a circulation pond which are sequentially connected with one another along a water flow direction, wherein a chemical dosing system is also arranged between the self-cleaning filter and the raw water pump, and comprises a PAC adding system and a PAM adding system. According to the water treatment system, PAC and PAM are respectively fed to water through the chemical dosing system, so that colloidal particles are solidified and precipitated; a three-stage filtering system is formed through the self-cleaning filter and the quartz sand filter; impurities such as colloid and suspended solids in water can be thoroughly removed; the purity of circulating water is high; and long-term stable working of an equipment cooling system can be ensured.

Owner:重庆中科过滤设备制造有限公司

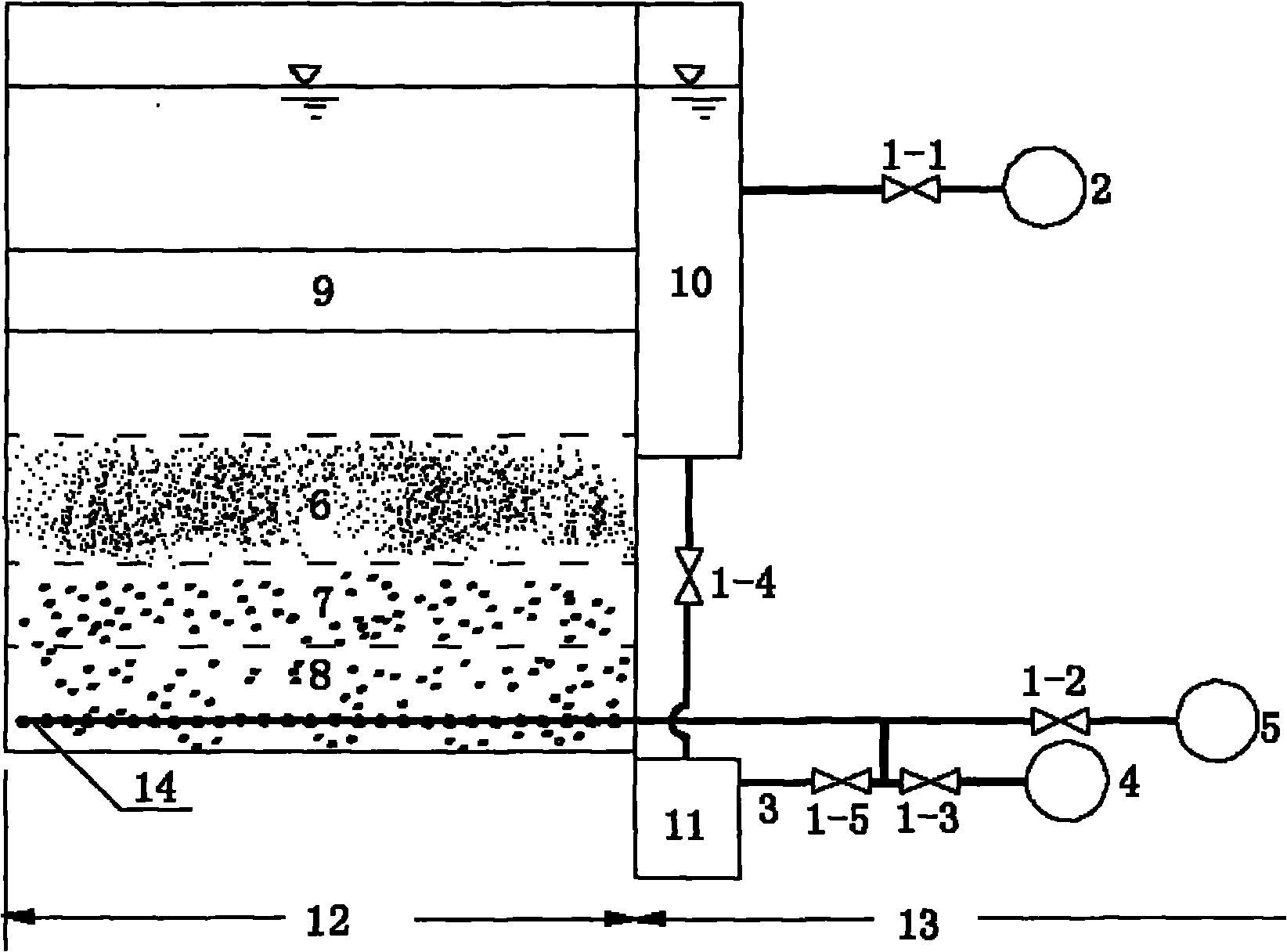

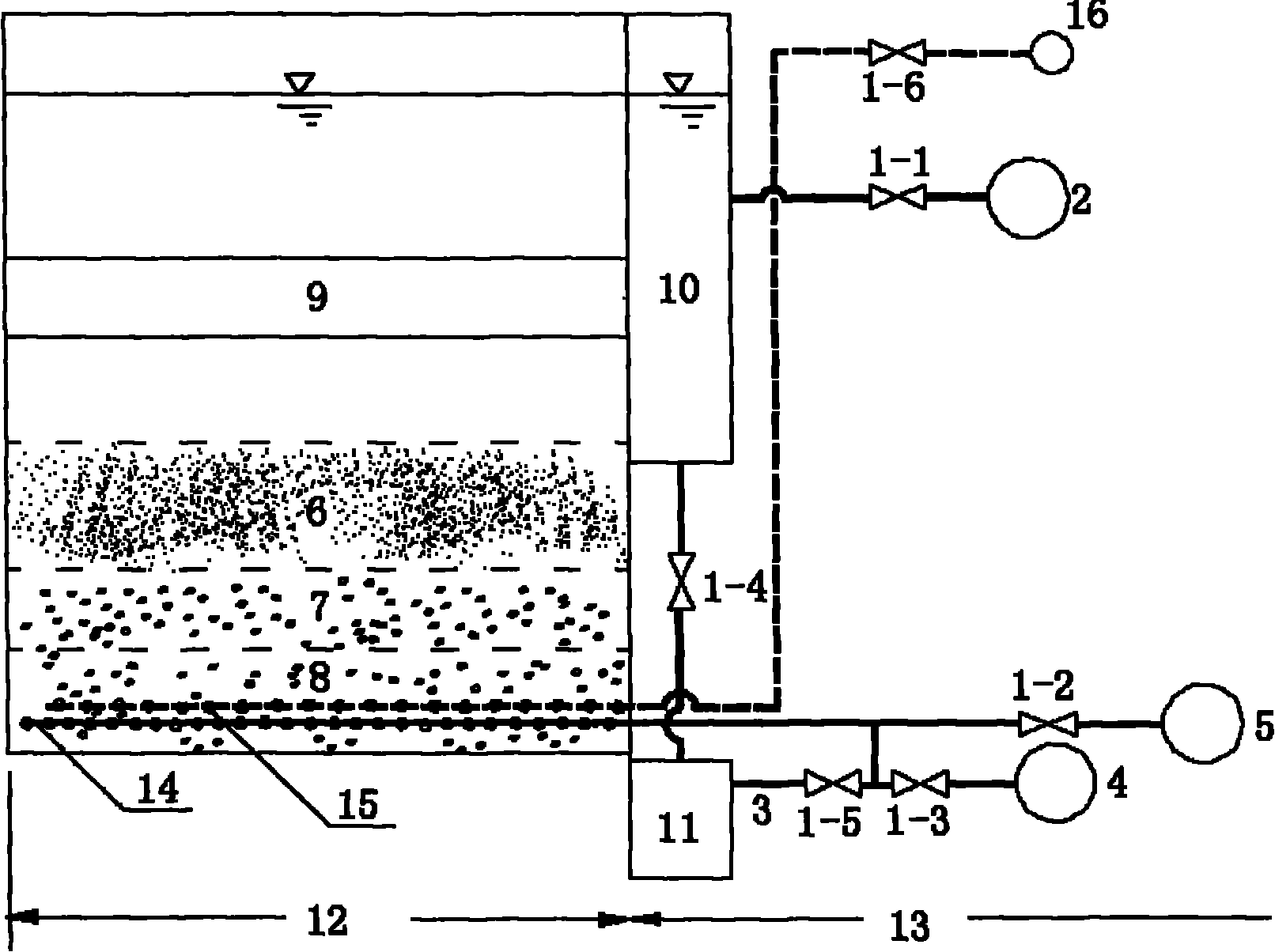

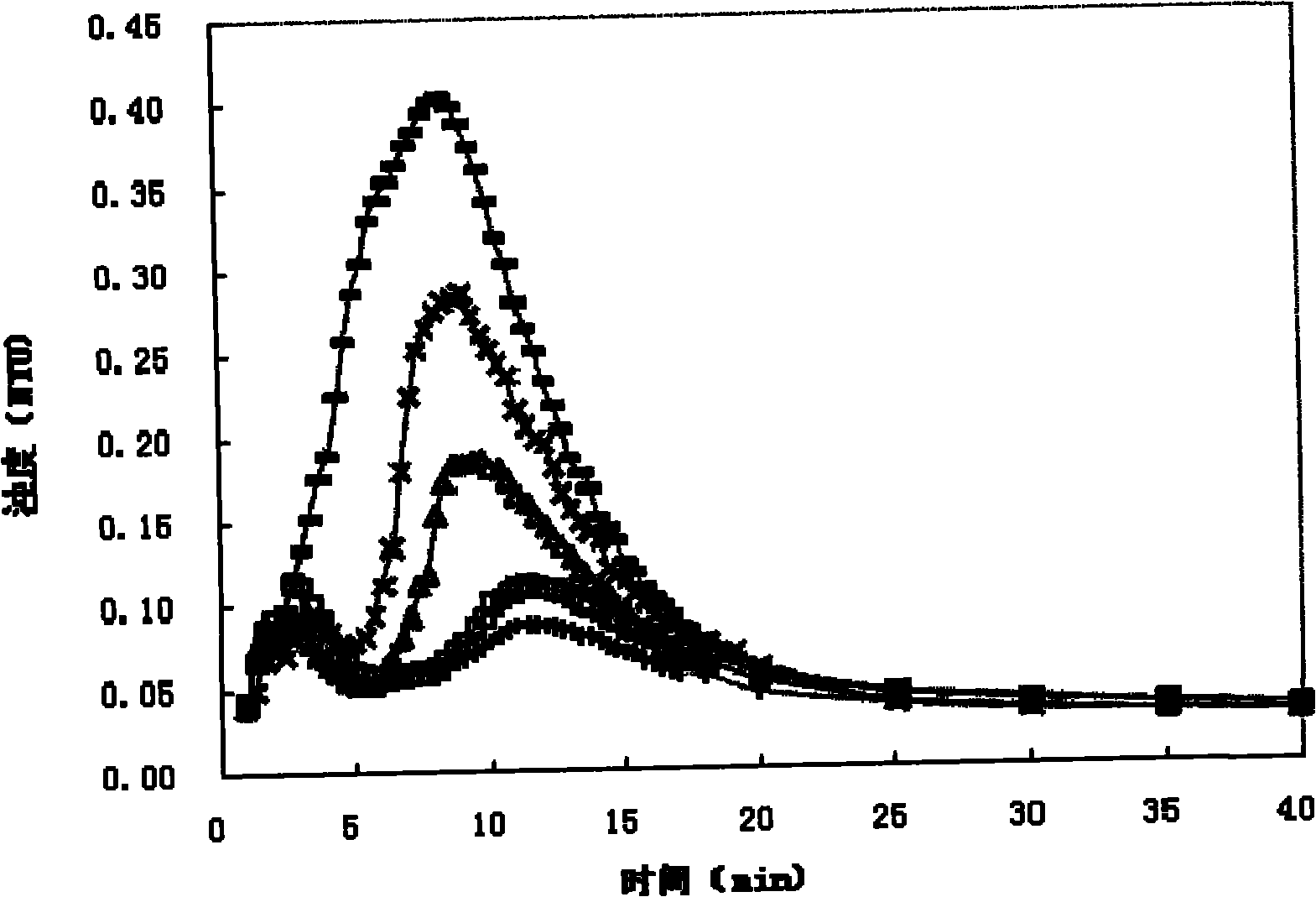

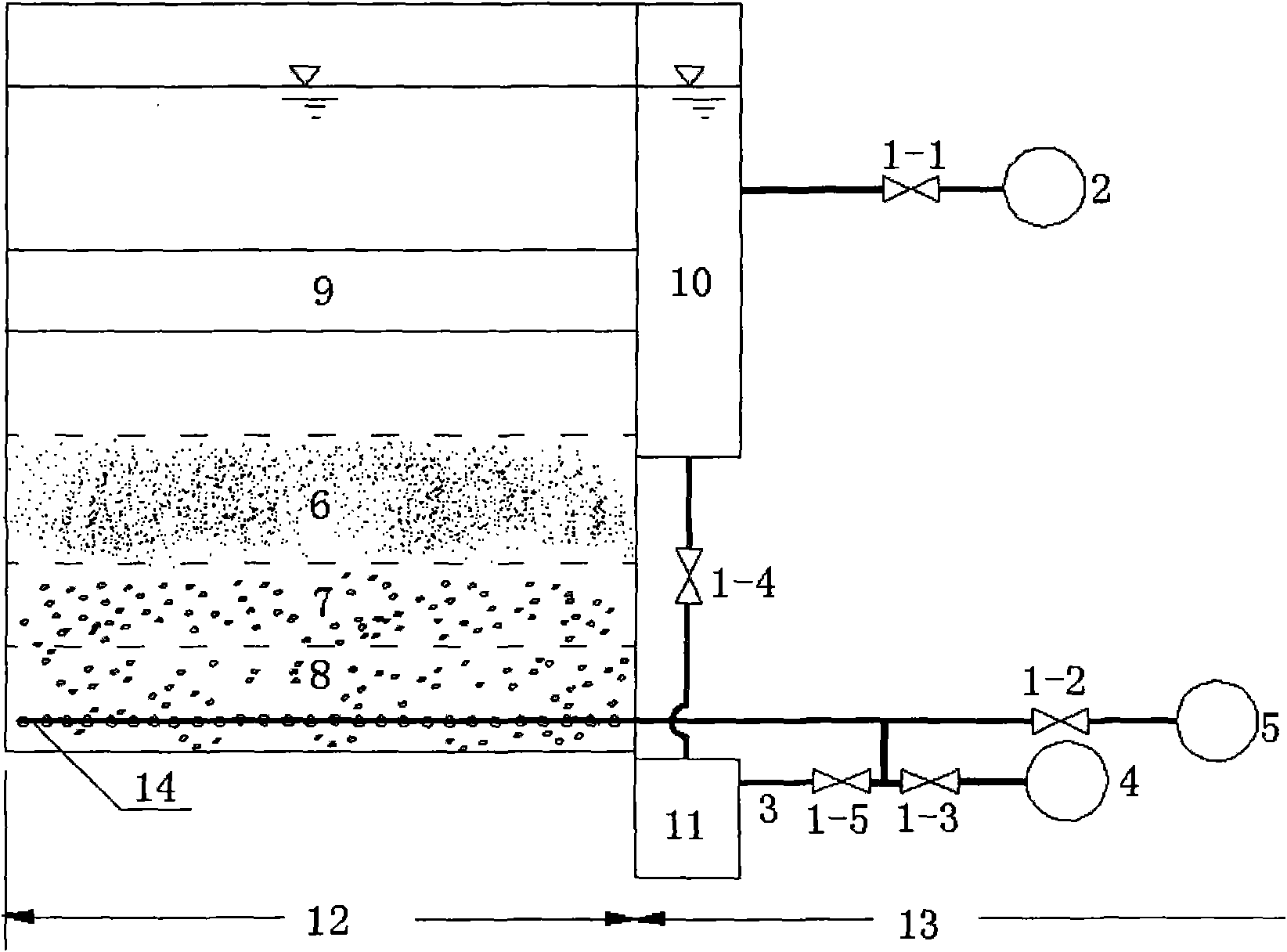

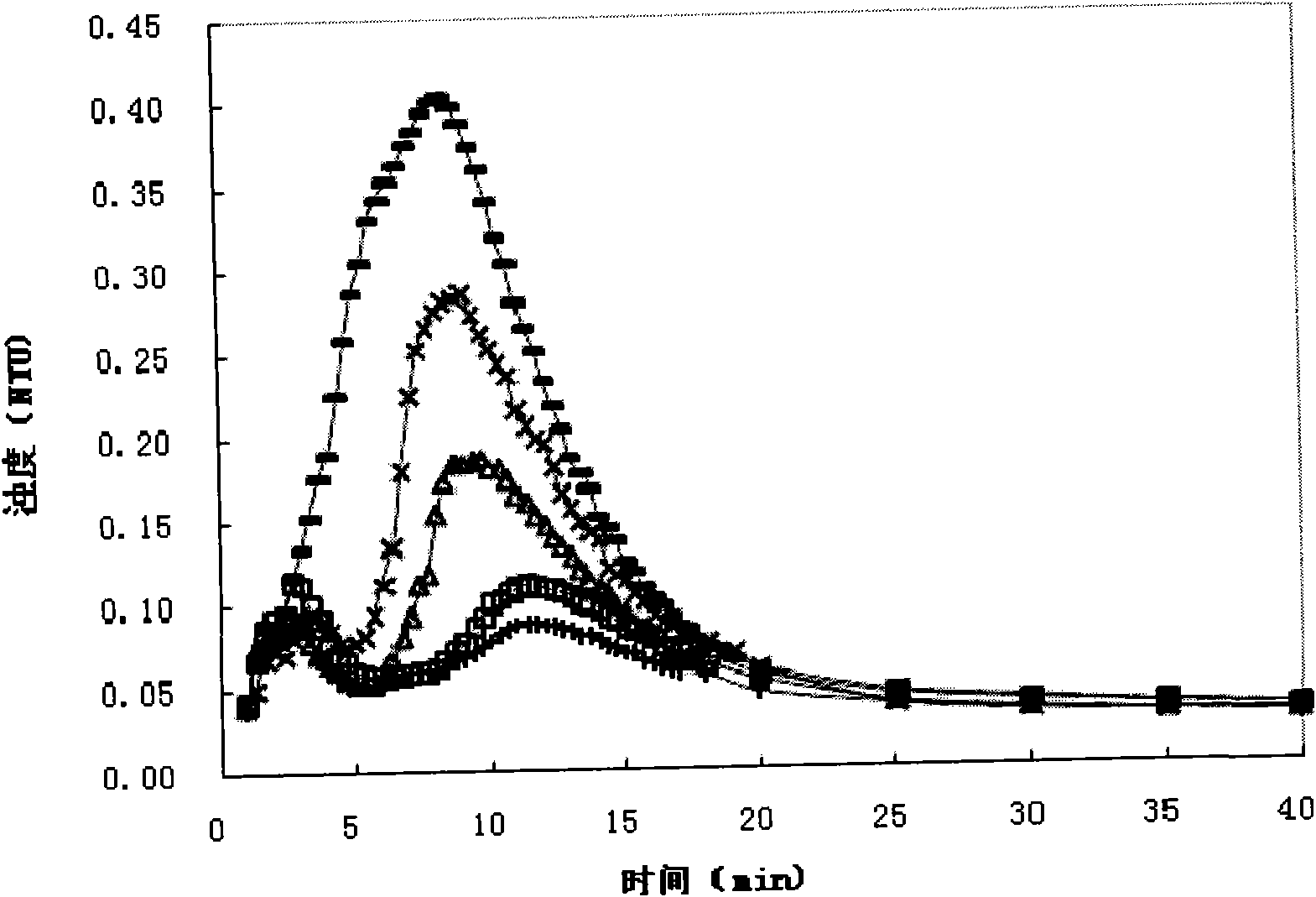

Method for controlling turbidity of initial filter water in quick filter tank after backwashing and micro-expansion washing

InactiveCN102179079AAdding Turbidity Control MethodsEasy to operateWater/sewage treatmentLoose filtering material filtersParticulatesWash water

The invention discloses a method for controlling turbidity of initial filter water in a quick filter tank after backwashing and micro-expansion washing, and belongs to the technical field of filtration in drinking water treatment. The method is characterized in that: after the backwashing of the filter tank, wash water is not immediately cut off completely, and micro-expansion washing for 1 to 7 minutes is carried out; the filter layer expansibility of the micro-expansion washing is 3 to 5 percent, the washing duration depends on the inflow turbidity and filtration rate when the filter tank is operated; when the inflow turbidity of the filter tank is 1 to 3 number of transfer units (NTU) and the filtration rate is 6 to 10m / h, the micro-expansion washing is kept for 1 to 3 minutes; and when the inflow turbidity of the filter tank is more than 3NTU and the filtration rate is more than 10m / h, the micro-expansion washing is kept for more than 3 minutes and less than 7 minutes. The principle is that: the pore structure of the washed filter material layer is improved through the micro-expansion washing, and residual particles are further removed, so that the turbidity of the initial filter water is reduced.

Owner:TSINGHUA UNIV

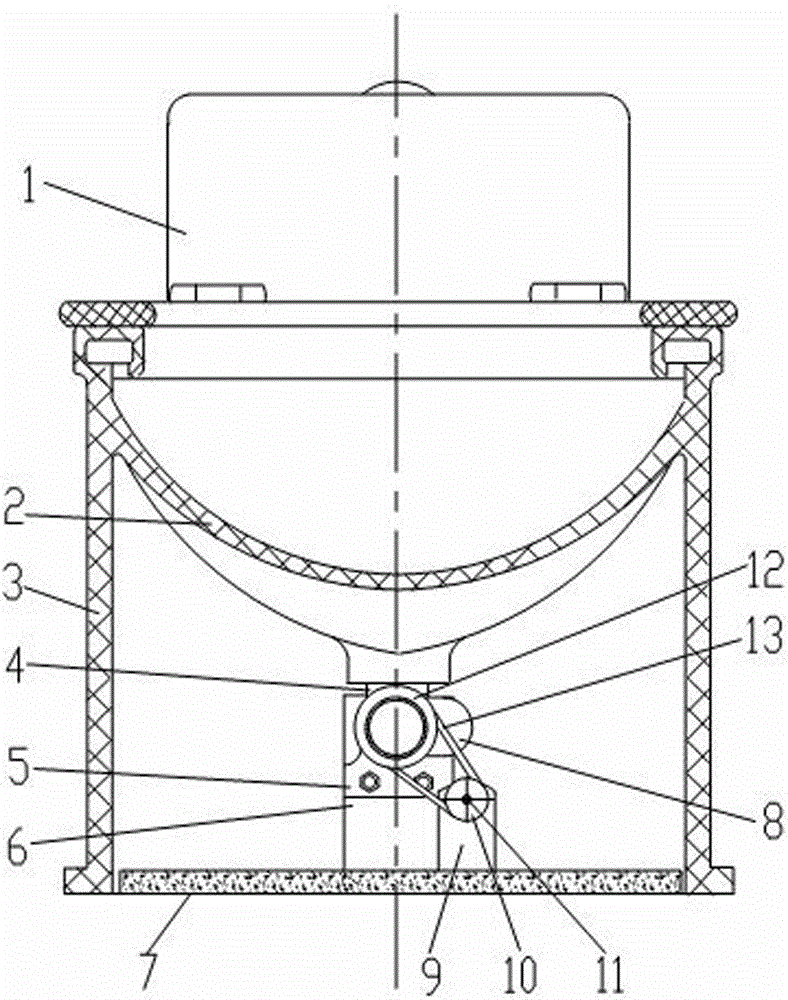

Water-saving toilet bowl

InactiveCN103276788AEasy to collect and reuseLower the altitudeWater closetsDomestic plumbingWater savingWater channel

The invention discloses a water-saving toilet bowl which comprises a basin and a discharge pipeline, wherein the bottom of the basin is communicated with the discharge pipeline. The water-saving toilet bowl is characterized in that a water inlet hole is formed in the wall of the discharge pipeline between the upper end face of an inlet of the discharge pipeline and the lower portion 200mm away from the inlet of the discharge pipeline. Another water inlet hole is formed in the wall of the discharge pipeline between the upper end face of the inlet of the discharge pipeline and the lower portion 160mm away from the inlet of the discharge pipeline, a third water inlet hole is formed in the wall of the discharge pipeline between the upper end face of the inlet of the discharge pipeline and the lower portion 120mm away from the inlet of the discharge pipeline, a flushing tank is arranged in the rear of the top end of the basin, an annular water channel is formed inside a convex edge at the top end of the basin, a discharge hole facing the inner wall of the basin is formed at the bottom of the annular water channel, and a water outlet of the flushing tank is communicated with the annular water channel. Waste water can transversely impact the discharge pipeline of the toilet bowl to flush the toilet bowl at the lowest position, the waste water is conveniently collected and recycled, energy is not consumed, and the toilet bowl is flushed by the flushing tank of the toilet bowl when no waste water is available.

Owner:李武

Filter tank

ActiveCN102580379BReduce lossesLower the altitudeStationary filtering element filtersWater useSludge

Owner:SHANGHAI TECHASE ENVIRONMENT PROTECTION

Toilet capable of exhausting air downwards

InactiveCN103046628AReduce flushing water consumptionWater closetsLavatory sanitoryHuman bodyWater saving

Owner:TIANJIN TEDA HOTEL CO LTD +3

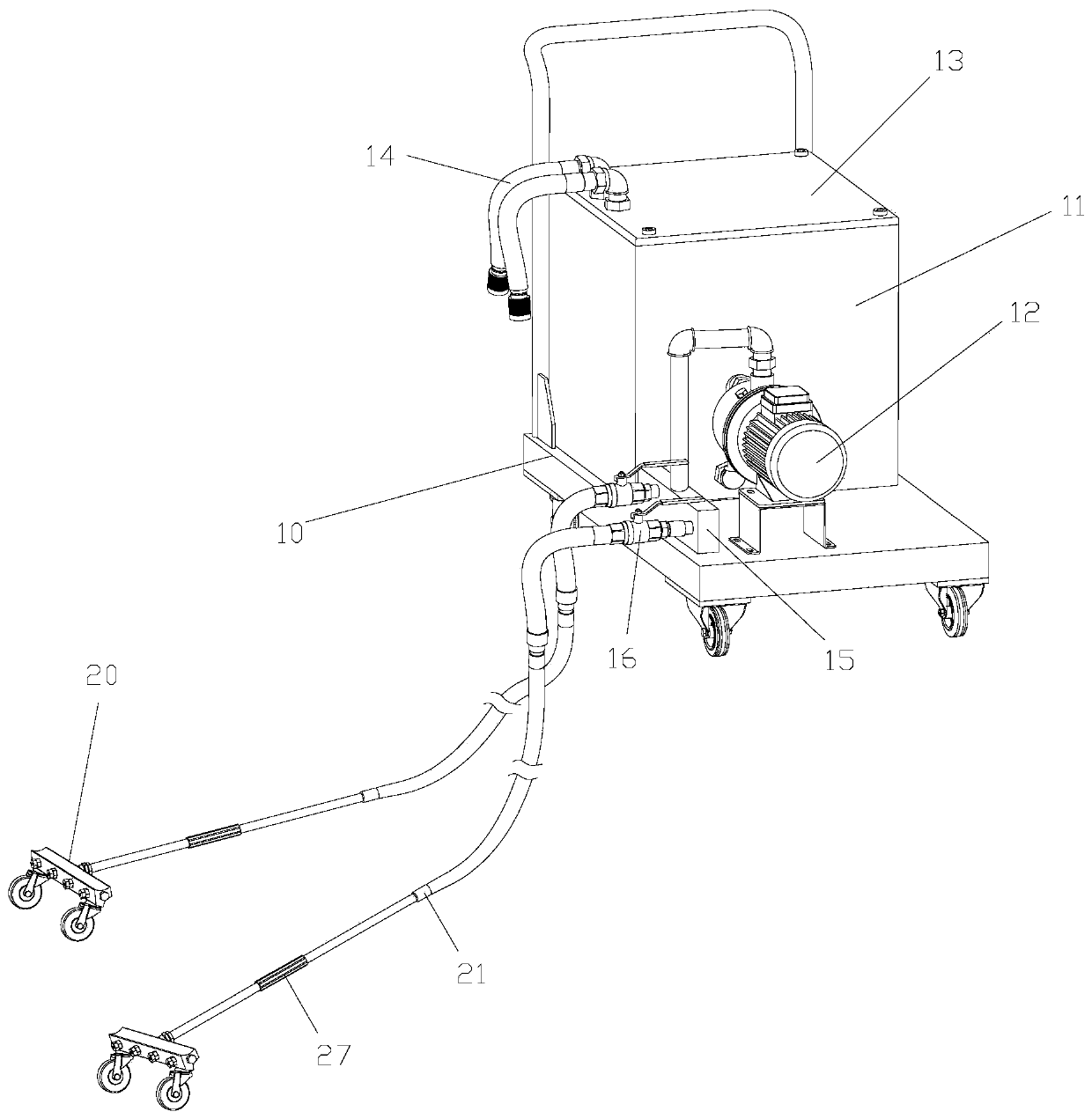

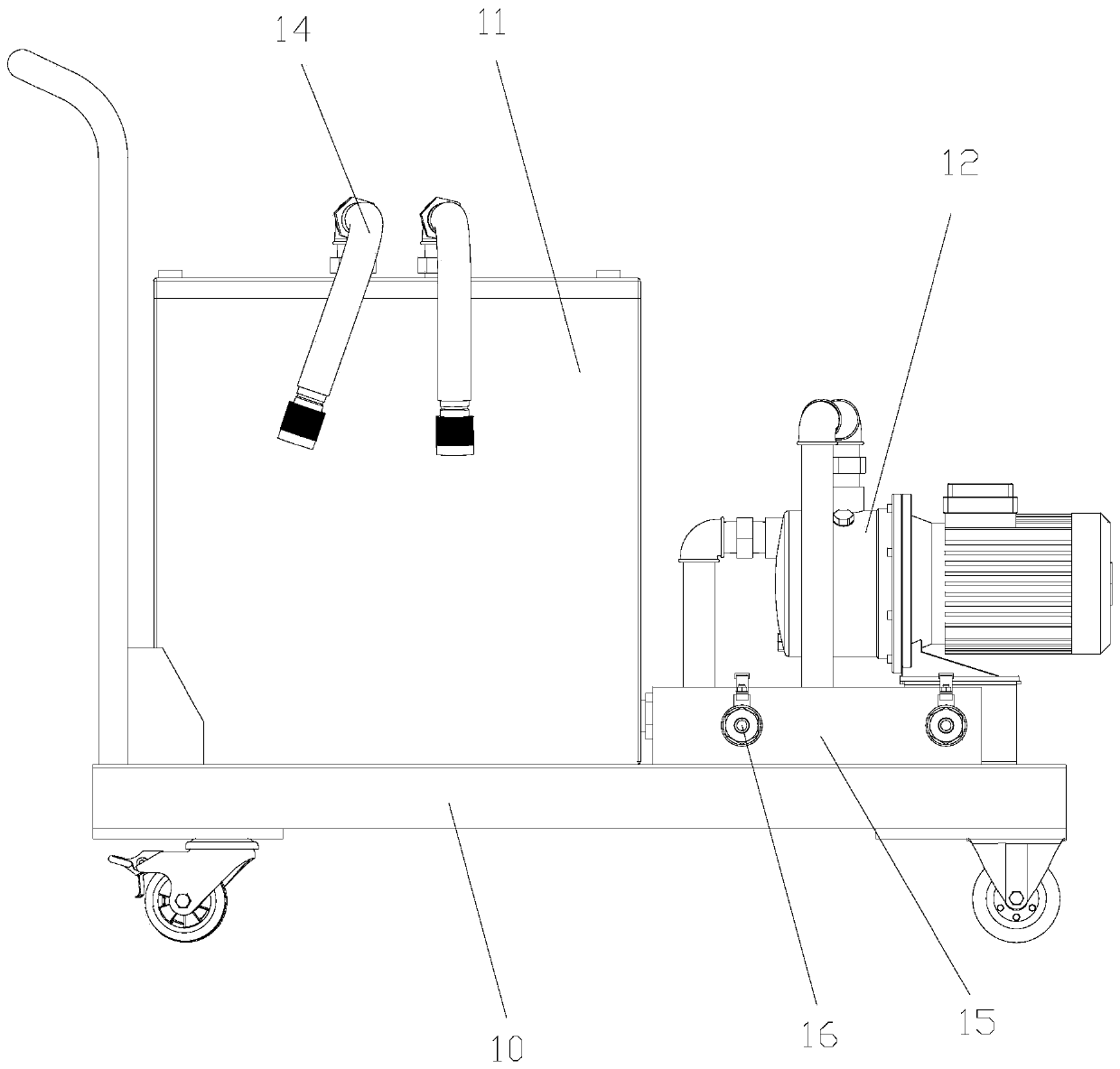

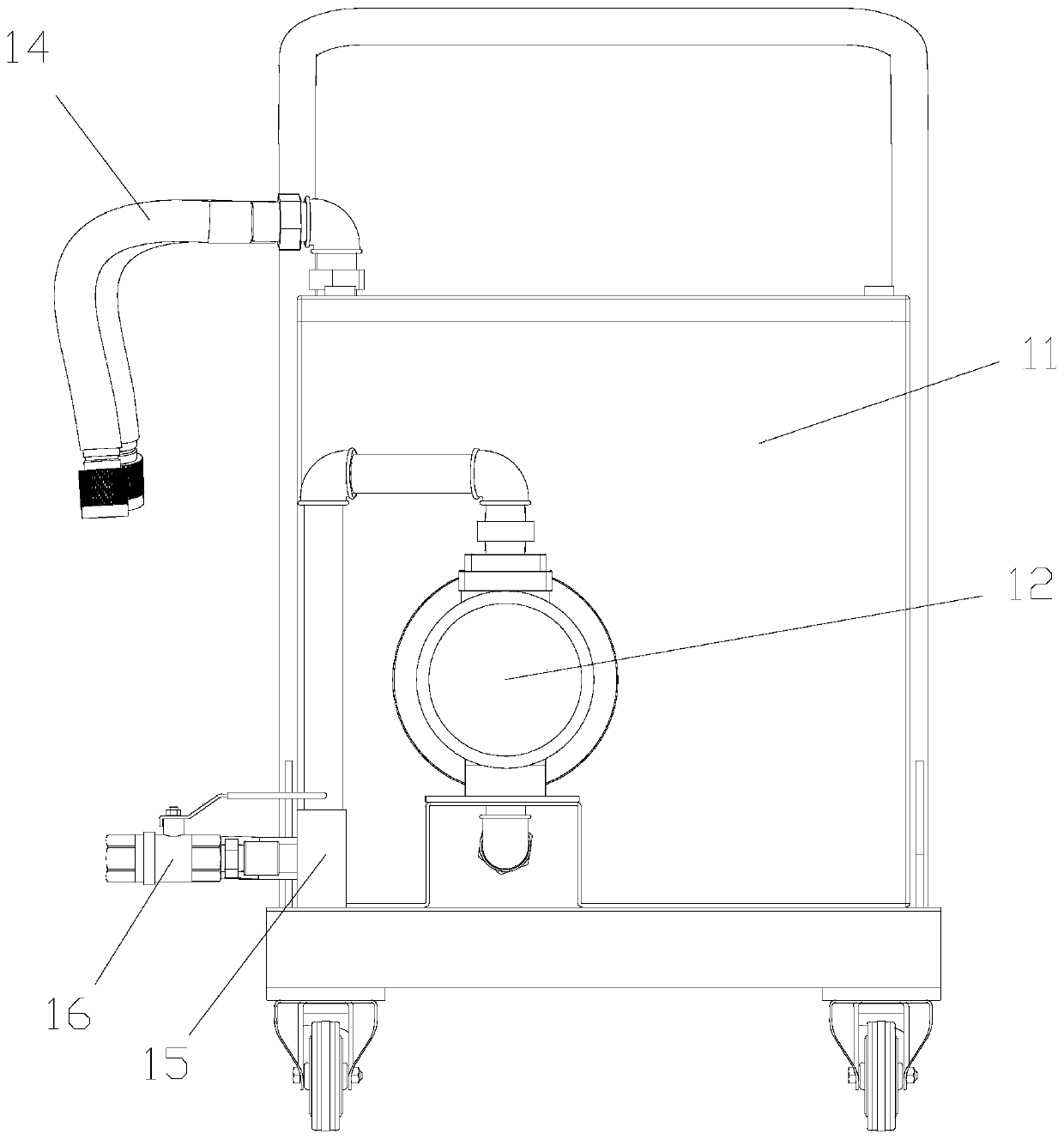

Lane washing machine

PendingCN110700171AMeet flushing requirementsReduce flushing water consumptionRoad cleaningWater flowProcess engineering

The invention relates to a lane washing machine which comprises a washing cart, a water tank and a booster pump are fixedly arranged on the washing cart, a water inlet of the booster pump is connectedwith the water tank through a pipeline, the water tank is provided with a detachable top cover, and a water inlet pipe opening is formed in the top cover. The lane washing machine also comprises a washing assembly which is connected to the water outlet of the booster pump through a pipeline, the washing assembly comprises a flow dividing device detachably connected with the pipeline, universal wheels used for supporting the washing assembly are connected to the lower portion of the flow dividing device, a plurality of spray heads are connected to the outer surface of the flow dividing devicein a threaded mode, and a flow dividing through cavity enabling water flow to be sprayed out of the spray heads is formed in the flow dividing device. The lane washing machine can efficiently wash thelane of highway sections, such as toll stations, etc., and is low in labor intensity and less in water consumption.

Owner:湖北交投宜昌高速公路运营管理有限公司

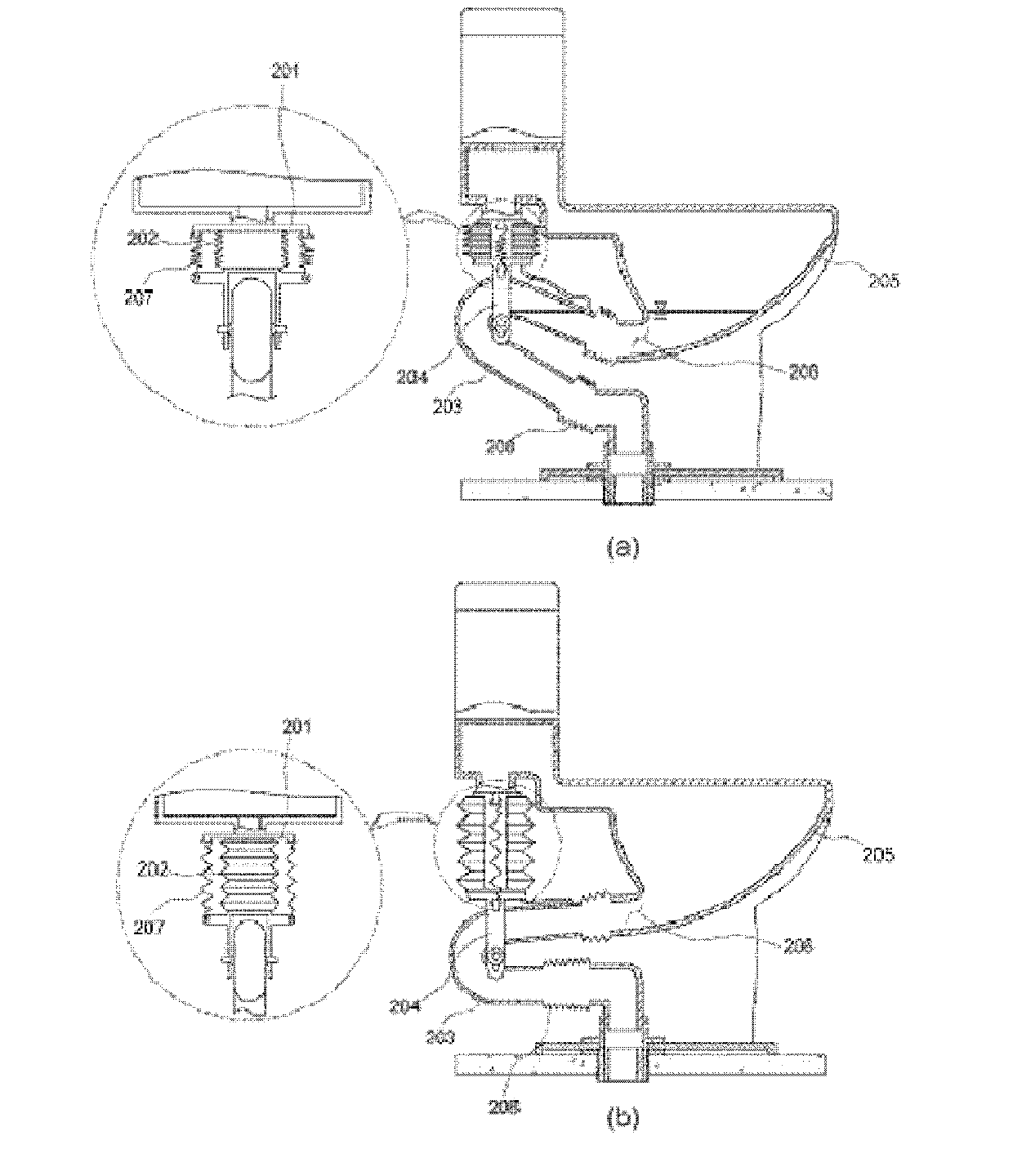

Variable, double, straight-line piping type of water-saving toilet

InactiveCN102713098BImprove flushing efficiencyLow costUrinalsWater closetsWater savingStraight tube

The variable, double, straight-line piping type of water-saving toilet of the present invention comprises: a main toilet body (10) having a bowl (11), a cistern (12), a water-supply pathway (13) connected to the rear of the bowl (11) from the cistern (12), and a cover part (14) which covers the lower part of the cistern (12) and the rear of the bowl (11) and is adapted to guide foul water discharged from the bowl (11) to a floor pipe (15); a variable, double, straight-line pipe (20) incorporating an inner pipe (21) of which one end is connected via a flexible tube (25) to the discharge port (13a) of the bowl (11), an outer pipe (22) which receives part of the inner pipe (21) on the inside thereof and which is equipped with spring-securing parts (22a) on the outside surface on two sides, and a connecting part (23) which forms a receiving space (23a) where cleaning water is received between the inner pipe (21) and the outer pipe (22), the pipe (20) being adapted so as to discharge the foul water and the cleaning water in the bowl (11) by rotating downward under its own weight due to the inflow of cleaning water into the receiving space (23a) because of the increase in cleaning water flowing into the bowl (11) during foul-water discharge; two brackets (30) which are secured either vertically or horizontally on both sides of the rear wall (11b) of the bowl (11), and are equipped with spring-fastening parts (31); and tension springs (40) which exhibit a resilient restoring force such that the variable, double, straight-line pipe (20) rotates upwards after foul-water discharge.

Owner:李钟寅 +1

Method for controlling turbidity of initial filter water in quick filter tank after backwashing and micro-expansion washing

InactiveCN102179079BReduce turbidityImprove turbidity indexWater/sewage treatmentLoose filtering material filtersParticulatesWash water

The invention discloses a method for controlling turbidity of initial filter water in a quick filter tank after backwashing and micro-expansion washing, and belongs to the technical field of filtration in drinking water treatment. The method is characterized in that: after the backwashing of the filter tank, wash water is not immediately cut off completely, and micro-expansion washing for 1 to 7 minutes is carried out; the filter layer expansibility of the micro-expansion washing is 3 to 5 percent, the washing duration depends on the inflow turbidity and filtration rate when the filter tank is operated; when the inflow turbidity of the filter tank is 1 to 3 number of transfer units (NTU) and the filtration rate is 6 to 10m / h, the micro-expansion washing is kept for 1 to 3 minutes; and when the inflow turbidity of the filter tank is more than 3NTU and the filtration rate is more than 10m / h, the micro-expansion washing is kept for more than 3 minutes and less than 7 minutes. The principle is that: the pore structure of the washed filter material layer is improved through the micro-expansion washing, and residual particles are further removed, so that the turbidity of the initial filter water is reduced.

Owner:TSINGHUA UNIV

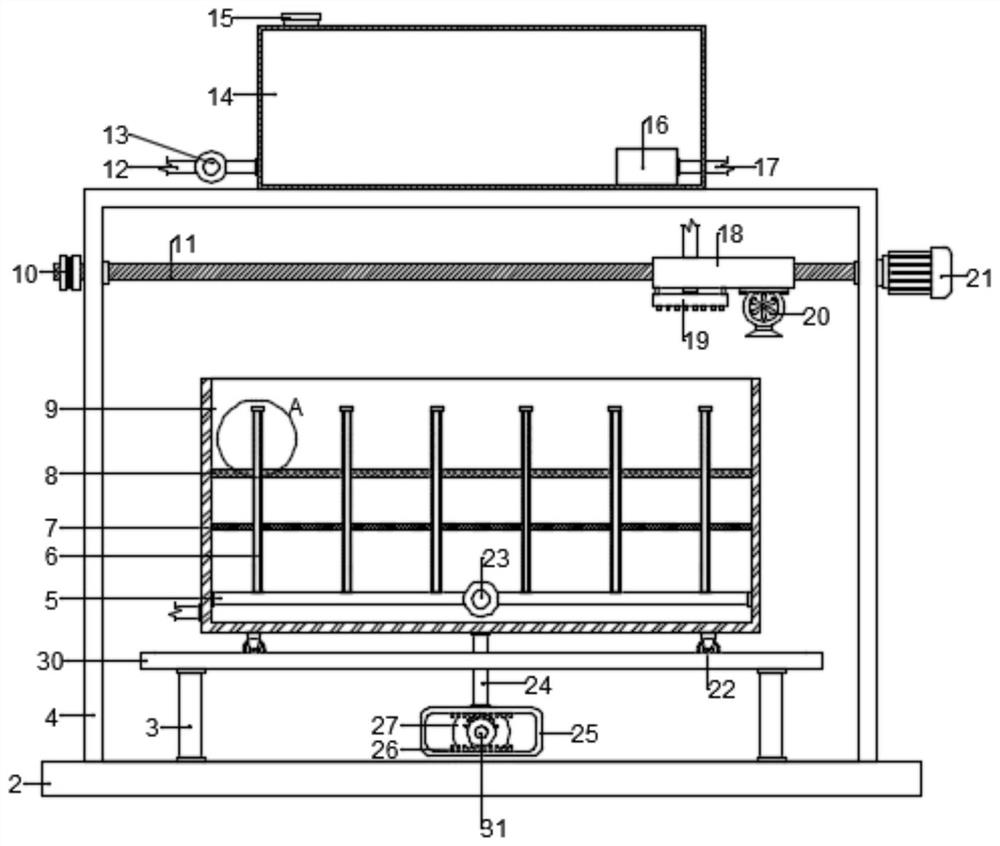

Energy-saving and efficient wheel washing machine capable of recycling sewage and using method thereof

PendingCN113715781AEfficient cleaningGood energy savingCleaning apparatus for vehicle exteriorsStationary filtering element filtersWater circulationSewage

The invention discloses an energy-saving efficient wheel washing machine capable of recycling sewage, which comprises a wheel washing water tank body, a supporting mechanism is arranged at the top of the wheel washing water tank body, a circulating water tank is arranged on one side of the wheel washing water tank body, a cleaning frame is arranged on the wheel washing water tank body, and the cleaning frame comprises a first cleaning frame, a second cleaning frame and a third cleaning frame. The first cleaning frame is arranged in the portion, below the supporting mechanism, of the wheel washing water tank body, the second cleaning frame is arranged in the portion, below the first cleaning frame, of the wheel washing water tank body, the first cleaning frame and the second cleaning frame are of a cross-shaped structure, and the third cleaning frame is arranged on the two opposite sides of the top of the wheel washing water tank body. By arranging a series of structures, segmented flushing operation of the wheel washing machine equipment on vehicle wheels and a chassis is achieved, segmented flushing can save the flushing water consumption of the equipment, the second cleaning frame meets the pertinence of wheels of different vehicle types, segmented flushing is higher in applicability, the flushing quality of the wheel washing machine is improved, cleaning is efficient, the energy-saving performance is better, and time and labor are saved.

Owner:安徽晶辉矿山科技有限公司

Paper pulping bleaching and waste water purification integration technology

InactiveCN101597871BHigh yieldShort production processPulp liquor regenerationPulp bleachingBlack liquorPulp and paper industry

A paper pulping bleaching and waste purification integration technology comprises two technology stages of paper pulping bleaching and waste water purification; wherein the paper pulping bleaching technology stage comprises: (1) slicing; (2) solution preparing; (3) initial reaction by adding enzyme and medicament; (4) deep reaction by adding medicament; (5) sieving, sedimentation and grinding; and (6) pulp washing, bleaching and stabilizing to obtain paper pulp finished product; and the waste water purification technology stage comprises: (1) purification, sedimentation and separation; and (2) concentration, drying and sediment recovery. The invention combines chemistry and biology, pulping and bleaching are completed in the same container in an integration way, neither chorine element isrequired nor black liquor is produced during pulping and bleaching, COD, BOD, SS and chrominance in pulping water are reduced to the utmost extent, waste water of pulping can be reused in pulp washing after purification treatment, and finally zero discharge or standard discharge of the whole waste water of pulping is realized.

Owner:XIAN TONGRUN BIOTECH

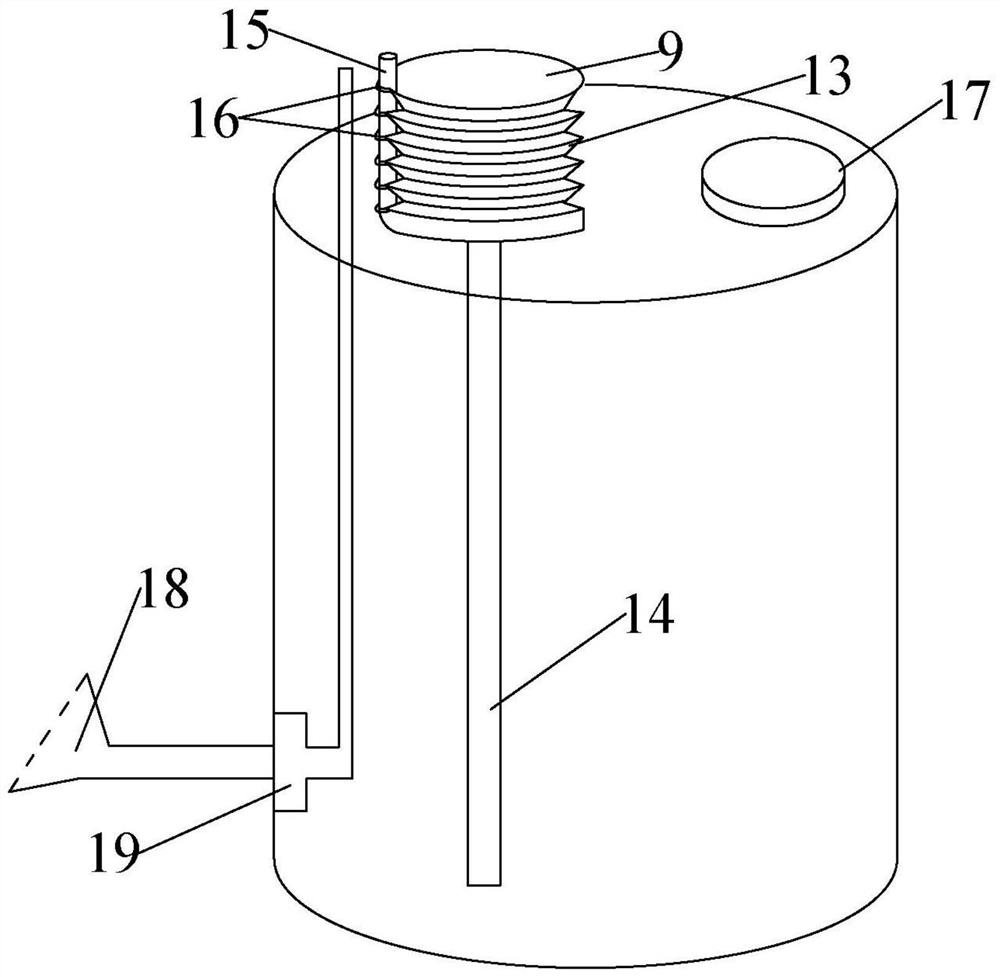

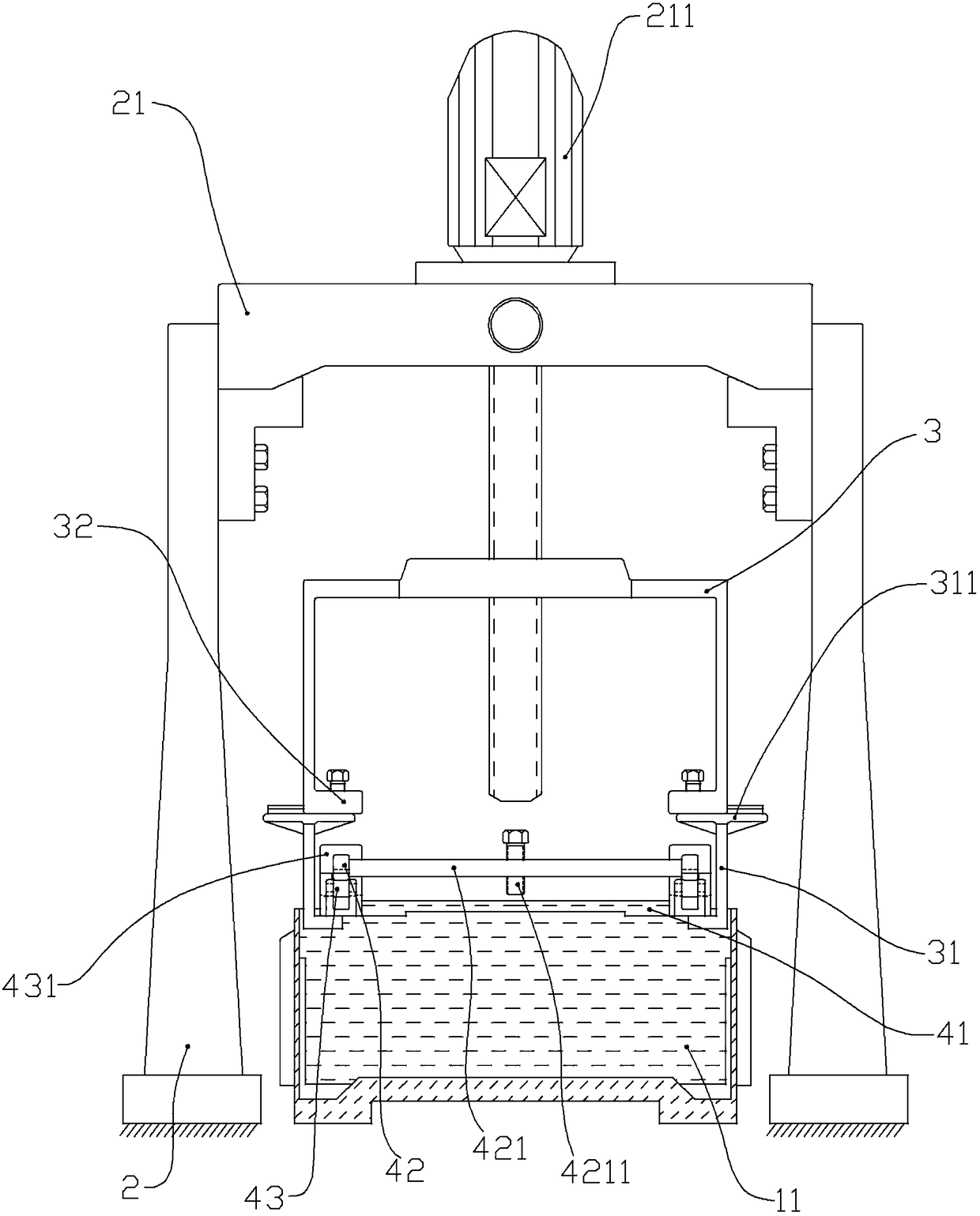

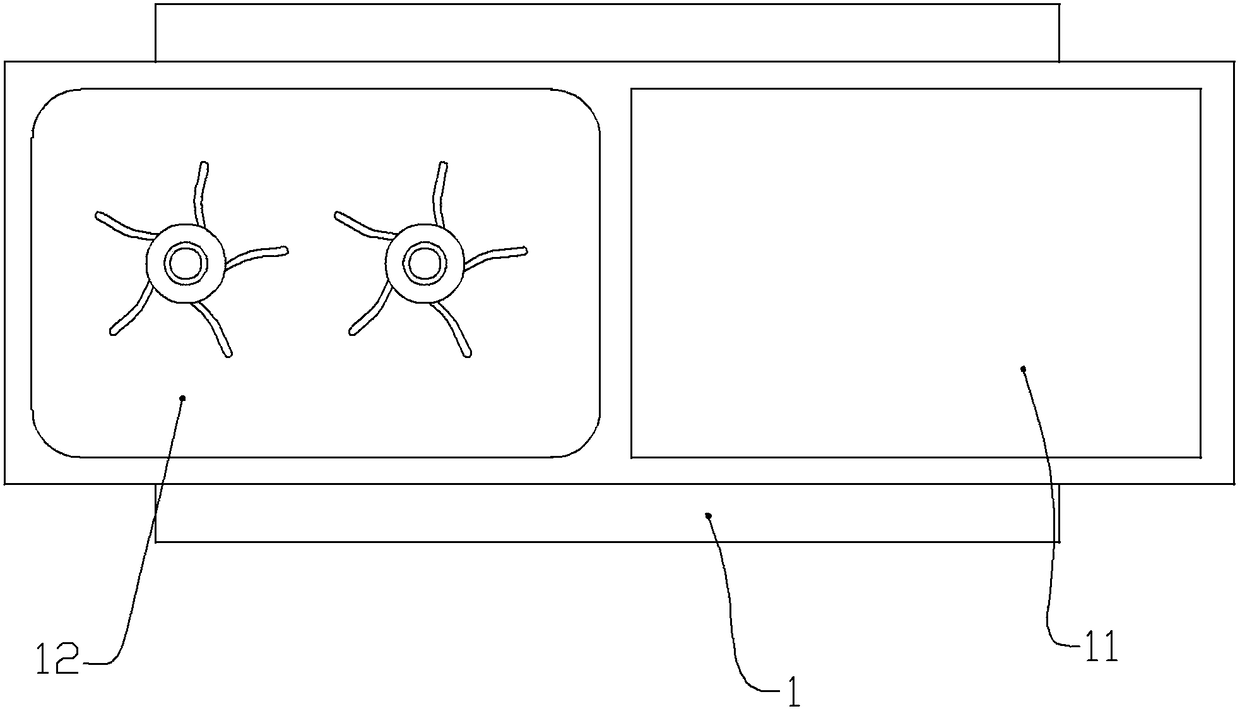

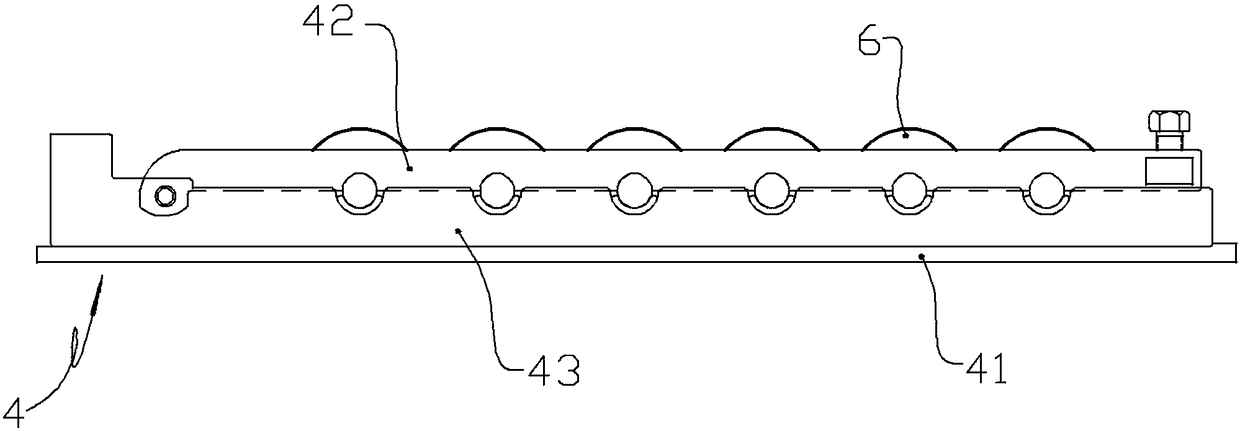

Device for cleaning replaced insulators

InactiveCN106076965BReduce work intensityImprove efficiencyCleaning using liquidsDrive motorEngineering

The invention provides a device for cleaning replaced insulators and belongs to the technical field of insulator cleaning in electric power facilities. A tank unit is arranged below a portal frame and comprises a cleaning tank and a flushing tank arranged in the front-back direction. A sliding block transmission mechanism is arranged at the upper end of the portal frame. A lifting driving motor provided with a lead screw is installed at the upper end of a sliding block. A U-shaped seat and the lead screw are matched to form a lead screw-sliding block transmission mechanism. Supporting arms are arranged at the two vertical arm ends of the U-shaped seat. A clamping set unit comprises a base plate, a static clamping plate fixed to the base plate, and a movable clamping plate correspondingly matched with the static clamping plate. The movable clamping plate is buckled on the static clamping plate through a movable structure. A fixing part is arranged between the movable clamping plate and the base plate, and the movable clamping plate and the base plate are fixedly connected through the fixing part. By the adoption of the device for cleaning the replaced insulators, batched concentrated cleaning can be conducted on the detached insulators, in the cleaning process, workers are mainly responsible for mounting and dismounting the insulators, the workers do not need to stay on the site all the time in the cleaning process, the working intensity of the workers can be relieved, and the cleaning operation efficiency is improved.

Owner:国网江西省电力有限公司九江供电分公司 +2

Toilet stool and control method thereof

InactiveCN112144625AReduce flushing water consumptionClean upWater closetsMechanical energy handlingFecesWater rinsing

The invention belongs to the field of bathroom accessories, and particularly discloses a toilet stool and a control method thereof. The toilet stool comprises a shell, a control module, a conveying assembly arranged in the shell and a water spraying assembly; the shell comprises a sewage inlet and a sewage outlet communicated with a drainage pipeline; the conveying assembly comprises a bearing part and a transmission part, the bearing part is used for receiving dirt falling from the dirt inlet, and the control module is used for controlling the transmission part to rotate to drive the bearingpart, so that the bearing part moves around the transmission part, and the dirt falls from the bearing part to enter the dirt outlet; and a water spraying port of the water spraying assembly faces thebearing surface of the bearing part. Most excrement such as faeces falls into a sewer line under the action of gravity through movement of the bearing part, only a small amount of water is needed forflushing, a small amount of residual excrement remains, the water consumption for flushing the toilet is reduced, meanwhile, the problem that the toilet cannot be flushed cleanly or even cannot be flushed is solved, and spreading of infectious viruses, bacteria and the like is prevented to a certain extent.

Owner:HUAZHONG UNIV OF SCI & TECH

A toilet flushing waterway structure and toilet seat with accelerated siphon

ActiveCN105525665BSpeed up dischargeReduce flushing water consumptionLavatory sanitoryWater useSiphon

The invention discloses a closestool washing water way structure capable of accelerating siphon and a toilet seat. The closestool washing water way structure comprises a common water way arranged in the toilet seat, a washing ring water way for providing water to a closestool washing ring, and a spray water way for providing water to a closestool spray hole, wherein the front end of the common water way is communicated with a water inlet of the toilet seat, the rear end of the common water way forms split-flows and is respectively communicated with an inlet end of the washing ring water way and an inlet end of the spray water way, the common water way is internally provided with a flow guide structure for preferentially guiding the water flow into the spray water way, so that most of the air in the spray water way enters the washing ring water way and is exhausted from a washing ring hole along the washing ring water way before washing is carried out, therefore, the influences of the air to the potential energy of the water flow is reduced, the exhausting speed of the air in the spray water way is improved, the early formation of spray siphon is facilitated, and the water use amount for washing is reduced.

Owner:XIAMEN R&T PLUMBING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com