Night-soil on-site treatment system and treatment method thereof

The technology of a treatment system and treatment method is applied in the field of feces on-site treatment system and its treatment to achieve the effects of remote operation, reduction of flushing water consumption, and odor-free treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

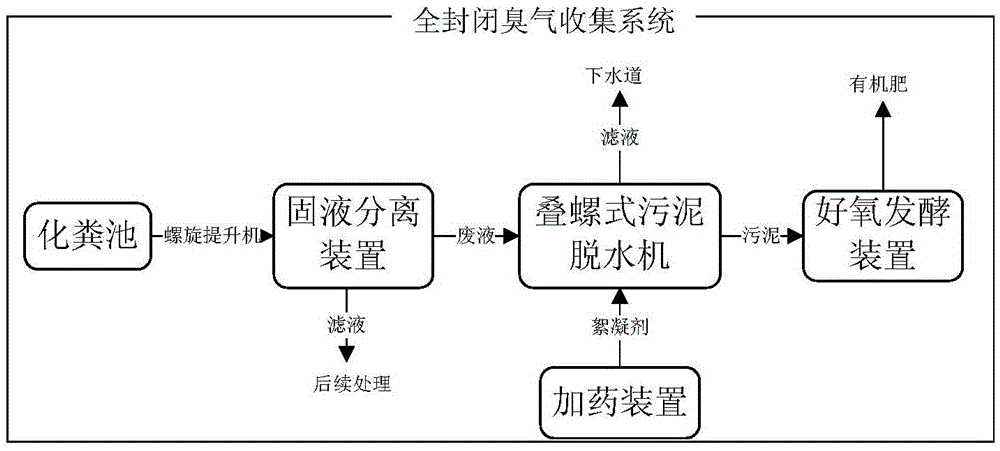

[0042] This embodiment provides an in-situ feces treatment system, the system includes a screw elevator, a solid-liquid separation device, a screw-type sludge dehydrator, a dosing device and an aerobic fermentation device; the screw elevator, solid The liquid separation device, the screw stacking sludge dehydrator and the aerobic fermentation device are connected in sequence, and the dosing device is connected with the screw stacking sludge dewatering machine.

[0043] The solid-liquid separation device is an integrated solid-liquid separation machine, which is directly placed on the septic tank.

[0044] The system includes an odor collection system, which is used to collect and centralize the entire system for odor collection.

[0045] The rotating speed of the screw shaft in the screw-stacking sludge dewatering machine in the system is 2-5 r / min.

[0046] The system is a fully enclosed processing system.

Embodiment 2

[0048] Adopt the system described in embodiment 1 to carry out feces on-the-spot processing, its processing flow is as follows figure 1 shown.

[0049] Put the screw elevator in the septic tank, use the screw elevator to lift the feces into the solid-liquid separation device, separate the waste residue and waste liquid, and the separated waste residue will be landfilled or incinerated, and the separated waste liquid will be stored in In the buffer tank, the sewage is pumped to the stacked screw sludge dewatering machine for screw extrusion dehydration treatment. The rotation speed of the screw shaft is 3r / min. During the screw extrusion dehydration process, flocculant is added to it through the dosing device Polyacrylamide, the dosage of flocculant is 1.5g of flocculant per liter of liquid, the filtrate produced by screw extrusion dehydration is discharged, and the sludge obtained by screw extrusion dehydration has a water content of <70wt%. Send it to an aerobic fermentation...

Embodiment 3

[0052] The system described in Example 1 was used to process feces on site. During the treatment process, except that the rotation speed of the screw shaft was 2r / min, and the dosage of flocculant was 1g of flocculant per liter of liquid, other steps were the same as those in Example 1. 2 is the same.

[0053] The number of coliform bacteria in the finally prepared organic fertilizer is less than or equal to 100 / g, the death rate of roundworm eggs is 95%, and the water content is less than or equal to 30wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com