Dustproof thin film assembly accepting container

A technology of dust-proof film components and storage containers, which is applied in the direction of instruments, electrical components, and originals for photomechanical processing, etc., which can solve the problems that the vibration and impact of the dust-proof film component frame cannot be fully absorbed, and save cleaning work , reduce manufacturing costs, and use high-value effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

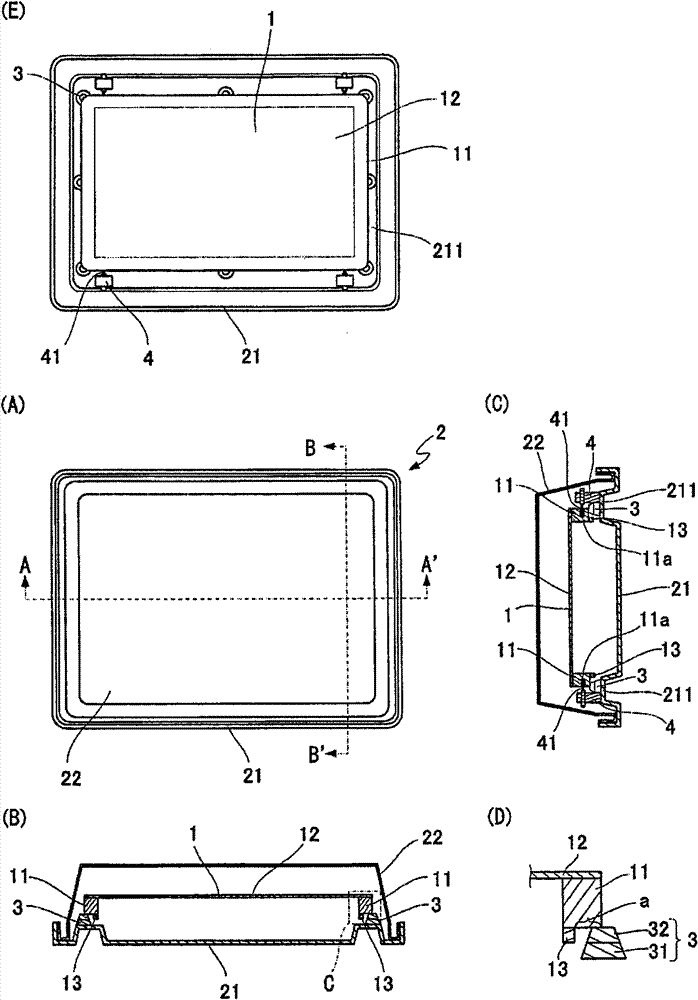

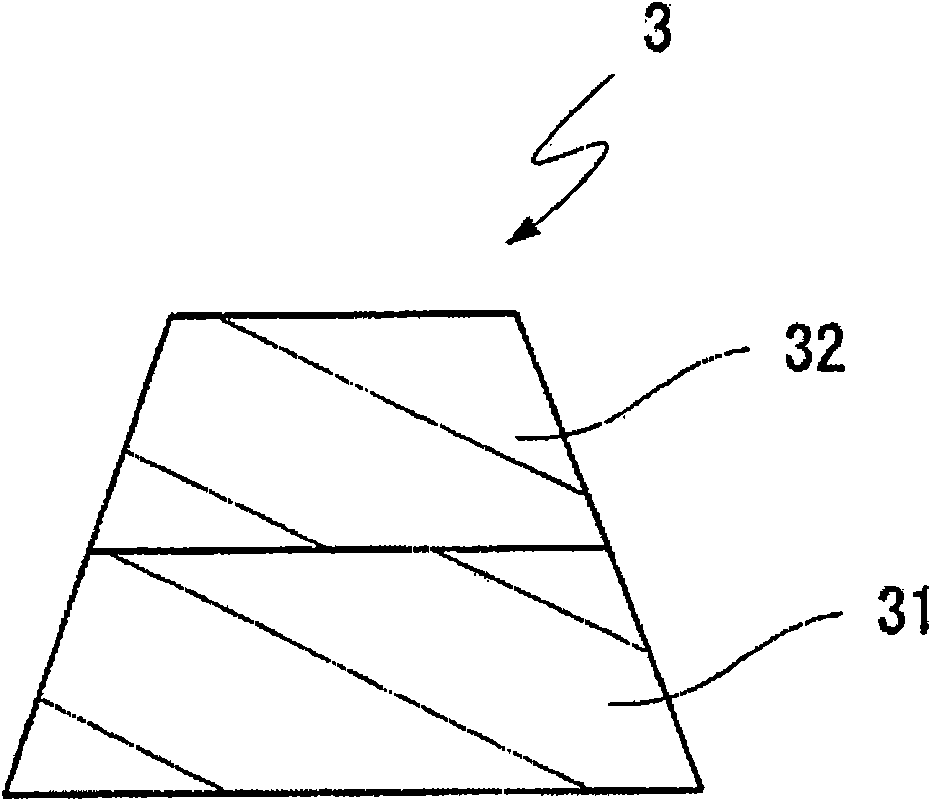

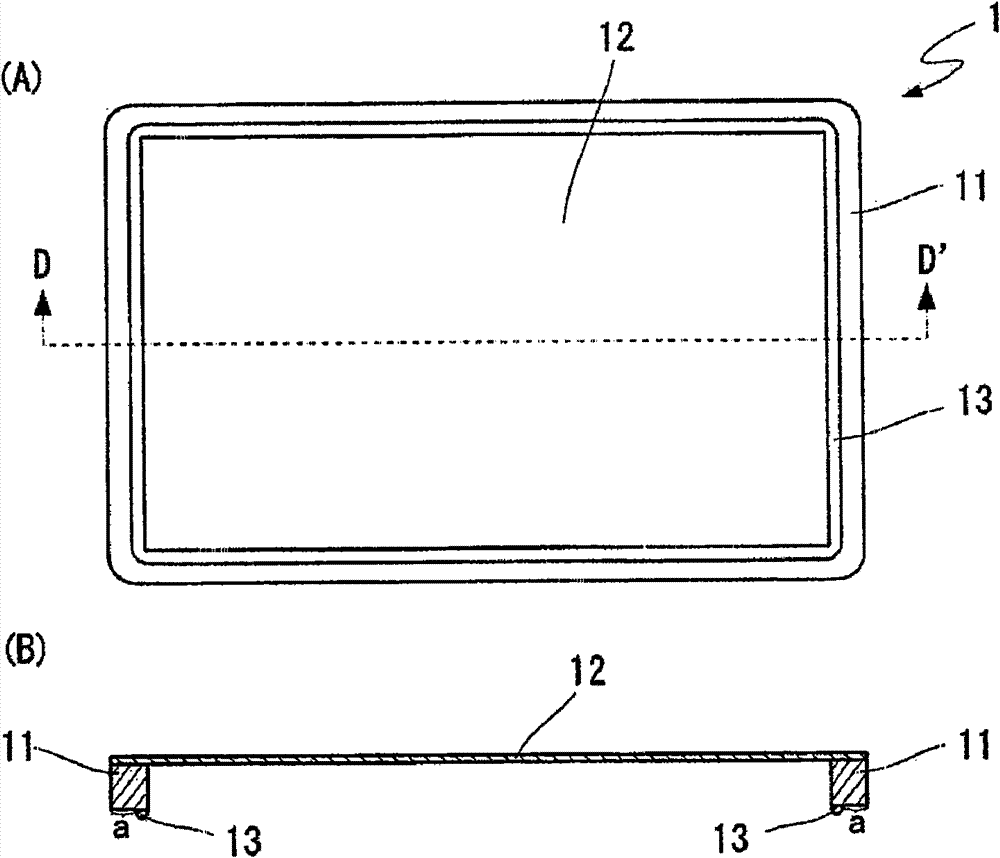

[0074] made as image 3 The pellicle assembly 1 is shown. That is, a 5000 series aluminum alloy is cut into a pellicle frame 11 with a long side external dimension of 1600mm, a short side external dimension of 1500mm, a height of 5.8mm, and a width of 13mm by machining, and black alumite is applied to the surface. deal with. Non-through holes 11 a into which pins 41 of the holding mechanism 4 can be inserted are provided at four predetermined positions on the outer surface of the pellicle frame 11 . The pellicle frame was washed with pure water, and after drying, a silicone adhesive diluted with toluene (manufactured by Shin-Etsu Chemical Co., Ltd., product name: X) was applied with a vertical 3-axis dispenser. -40-3122) as the adhesive layer 13. In addition, the cross-sectional shape of the pressure-sensitive adhesive layer 13 was a semicircle with a width of 4 mm and a height of 1.5 mm. At this time, the width of the pellicle frame was 13 mm, and since the adhesive layer...

Embodiment 2

[0080] Polycarbonate is used for the base part of the pellicle frame support body, and silicone rubber is used for the buffer part (manufactured by Shin-Etsu Chemical Co., Ltd., product name: KE-1950-10, hardness: 10 measured with a rubber hardness tester TYPEA), Shaped by profile molding, except for this, the pellicle storage container was made in the same manner as in Example 1, and the pellicle was fixed and stored.

Embodiment 3

[0082] ABS is used for the base part of the pellicle frame support body, and PS-(PE / PP / PB) copolymer (manufactured by KURARAY PLASTICS Co., Ltd., product name: Septon KC-623, hardness: TYPE rubber hardness tester is used for the cushioning part) The measurement of A is 80), and it is shaped by profile molding. In addition, the dust-proof film assembly storage container is made in the same manner as in Example 1, and the dust-proof film assembly is fixed and stored.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com