Water treatment system for circulating cooling water of cement production system

A technology of circulating cooling water and production system, applied in water/sludge/sewage treatment, water/sewage treatment, water/sewage multi-stage treatment, etc. Less rinsing water, high purity, and remarkable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

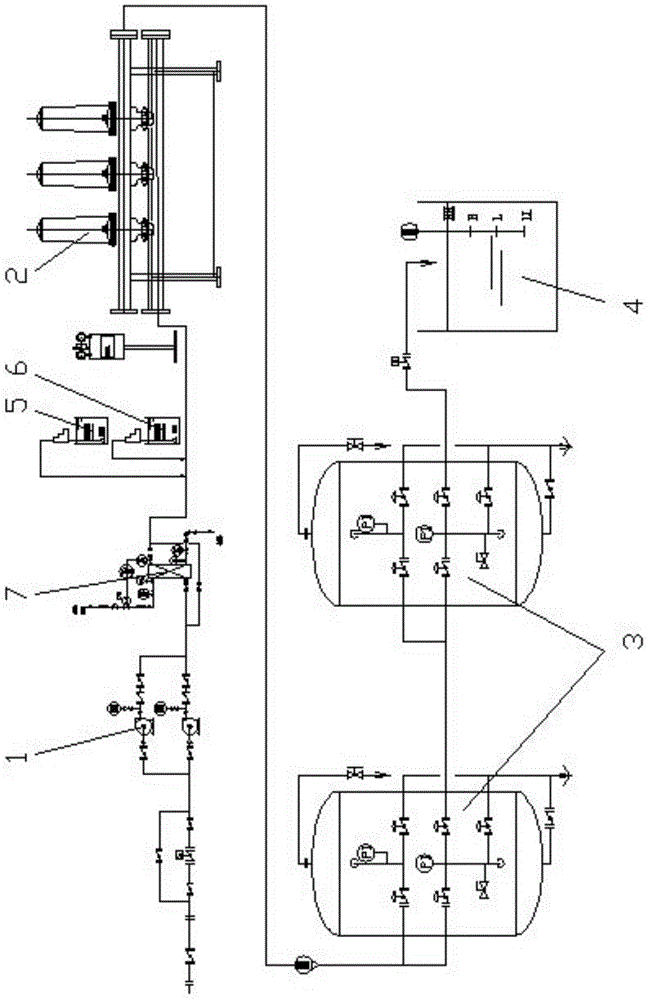

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0014] As shown in the figure, the circulating cooling water treatment system of the cement production system in this embodiment includes a raw water pump 1, a self-cleaning filter 2, a quartz sand filter 3 and a circulating water pool 4 connected sequentially along the water flow direction. A dosing system is also provided between the device and the raw water pump, and the dosing system includes a PAC adding system 5 and a PAM adding system 6 .

[0015] The circulating cooling water water treatment system of the cement production system in this embodiment, it adds PAC (basic aluminum chloride) and PAM (polyacrylamide) respectively to the water through the dosing system; after PAC is added, it can be mixed with tiny Colloids, suspended matter and even macromolecular organic matter collide and bond with each other, eliminating the electrostatic repulsion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com