A high-efficiency defluoridation agent and its application

A chemical and efficient technology, applied in the fields of flocculation/sedimentation water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. and other problems, to achieve the effect of improving the reaction speed, good sedimentation efficiency, and fast fluorine removal speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

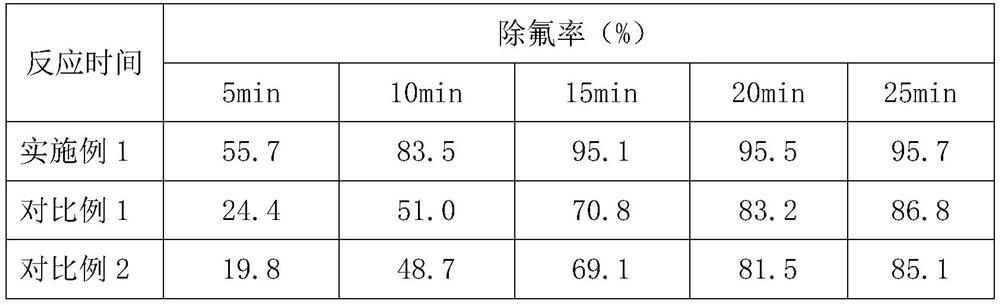

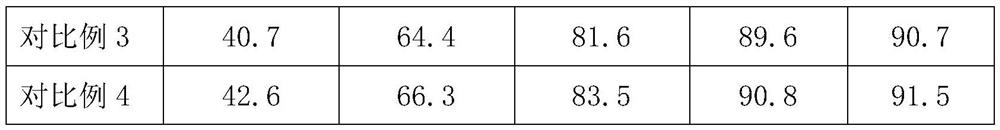

Examples

Embodiment 1

[0026] A high-efficiency fluorine-removing agent is composed of the following components by mass fraction: polyferric chloride 8%, polyferric sulfate 16%, polyaluminum sulfate 16%, polyaluminum ferric sulfate 16%, polyaluminum chloride 18%, tea leaves Iron 7%, modified fly ash 6%, modified zeolite 6%, calcium hydrogen phosphate 4%, activated silicic acid 3%.

[0027] Among them, polyferric chloride, polyferric sulfate, polyaluminum sulfate, polyaluminum ferric sulfate, polyaluminum chloride, calcium hydrogen phosphate, activated silicic acid are all commercially available products; Su Wan, Zhang Yong, Wu Qi.Adsorption performance and kinetics of iron in tea[J].Chemical World,2010,51(09):516-519+523+526.) Prepared;

[0028] The preparation steps of modified fly ash are as follows: mix fly ash and calcium hydroxide in a mass ratio of 1:0.3 and place them in a crucible, then burn them in a muffle furnace at 550°C for 2.5 hours, cool them to room temperature and grind them , and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com