Fluorine removal method and application of lithium-ion battery positive electrode material leachate

A lithium-ion battery and cathode material technology, applied in the field of defluorination of lithium-ion battery cathode material leaching solution, recovery of nickel, cobalt and manganese in lithium-ion battery cathode materials, can solve the problems of Ni, Co, Mn loss and low cost, and achieve The effect of reducing the amount of addition, low cost, and short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

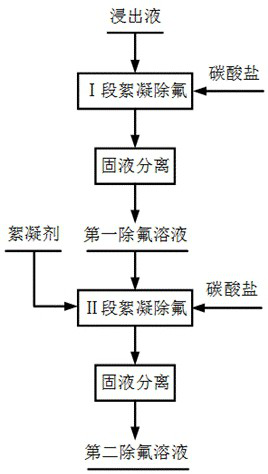

[0051] The method for removing fluorine of the lithium-ion battery cathode material leaching solution provided in this embodiment is as follows: figure 1 As shown, it specifically includes the following steps:

[0052] (a) Water and waste LiNi with a mass ratio of 4:1 x co y mn z o 2 Lithium battery positive electrode materials are mixed to obtain a pulp; concentrated sulfuric acid is added to the pulp, and after mixing evenly, hydrogen peroxide is slowly added to it to perform a reductive acid leaching reaction. After the reaction is completed, the solid-liquid separation is obtained to obtain a leachate;

[0053] (b) Take 500mL of the leaching solution obtained in step (a), and slowly add CaCO with a mass concentration of 20% to it 3 For the dispersion liquid, adjust the pH of the mixed material to 5, carry out flocculation and precipitation at 55°C, and separate the solid and liquid after reacting for 1 hour to obtain 506 mL of the first defluorination solution;

[005...

Embodiment 2

[0060] The method for removing fluorine from the lithium-ion battery cathode material leachate provided in this embodiment comprises the following steps:

[0061] (a) Mix water with a mass ratio of 2:1 and the positive electrode material of the spent lithium nickelate battery to obtain a pulp; add concentrated hydrochloric acid to the pulp, mix well, and then slowly add hydrogen peroxide to it to carry out reductive acid leaching reaction , after the reaction is completed, the solid-liquid separation is obtained to obtain the leachate;

[0062] (b) Take 500mL of the leaching solution obtained in step (a), and slowly add NiCO with a mass concentration of 15% to it 3 Dispersion solution, adjust the pH of the mixed material to 4, carry out flocculation and precipitation at 550°C, and separate the solid and liquid after reacting for 1 hour to obtain 498mL of the first defluorination solution;

[0063] (c) Take 250mL of the first defluoridation solution obtained in step (b) and 0....

Embodiment 3

[0069] The method for removing fluorine from the lithium-ion battery cathode material leachate provided in this embodiment comprises the following steps:

[0070] (a) Water and waste LiNi with a mass ratio of 4:1 x co y mn z o 2 Lithium battery cathode materials are mixed to obtain ore pulp; acetic acid is added to the ore pulp, and after mixing evenly, hydrogen peroxide is slowly added to it to carry out reductive acid leaching reaction, and solid-liquid separation is obtained after the reaction is completed to obtain leachate;

[0071] (b) Take 500mL of the leaching solution obtained in step (a), and slowly add MnCO with a mass concentration of 20% 3 For the dispersion, adjust the pH of the mixed material to 5, carry out flocculation and precipitation at 55°C, and separate the solid and liquid after reacting for 1 hour to obtain 502 mL of the first defluorination solution;

[0072] (c) Mix 250mL of the first defluoridation solution obtained in step (b) with 1.09g of alum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com