Nanofiltration-Forward Osmosis Combined System Using Commercial Nanofiltration Membrane and Forward Osmosis Membrane and Its Application

A technology of forward osmosis membrane and nanofiltration membrane, which is applied in the field of nanofiltration-forward osmosis combined system, can solve the problems of external energy consumption hindering the wide application of pressure membrane technology and pollution, so as to improve water treatment efficiency, high operation degree and reduce The effect of flushing water volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

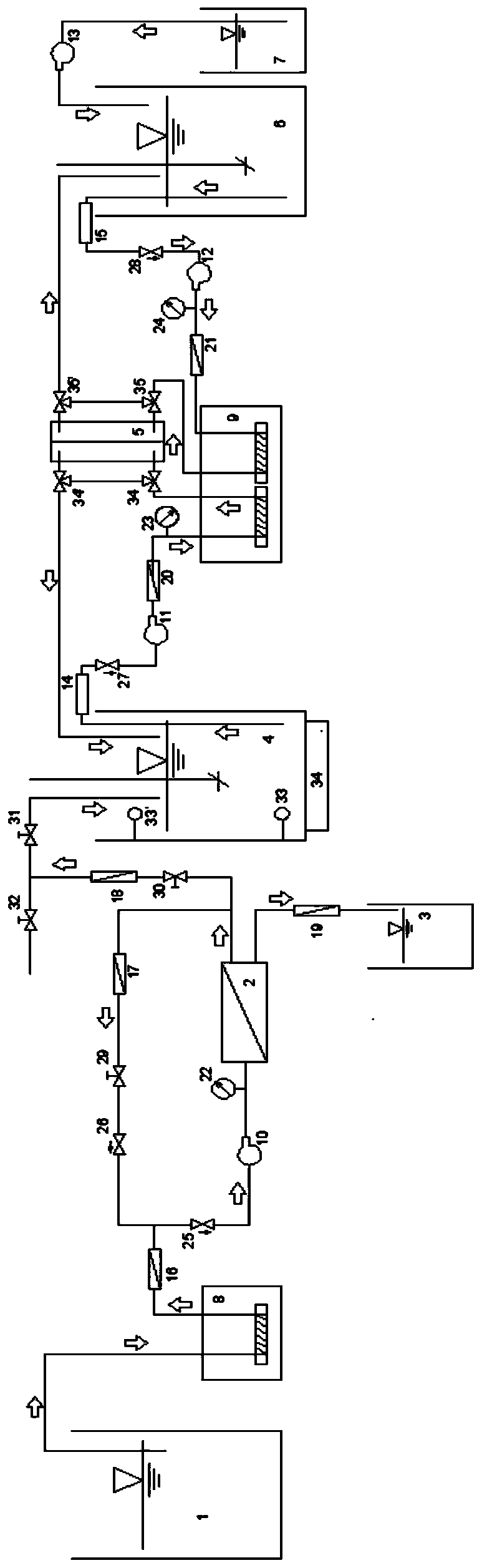

[0021] First of all, choose NF-90 nanofiltration membrane and commercial ES (or NW) forward osmosis membrane, both of which are flat membranes, assemble nanofiltration and forward osmosis module components according to requirements, and use two sets of fully automatic electronic control equipment. The computer display screen sets the pressure or flow of each pump, the operating parameters and time of the subsystem. The nanofiltration-forward osmosis combined process technology mainly consists of the following five stages. The present invention uses nanofiltration as the main treatment process, forward osmosis as the auxiliary system, and the nanofiltration concentrated water is partially refluxed and partially discharged into the forward osmosis system as the raw material liquid, so as to achieve the purpose of removing soluble organic matter in slightly polluted raw water. The nanofiltration-forward osmosis combined process for removing dissolved organic matter in slightly po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com