Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Reduce flow pressure loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

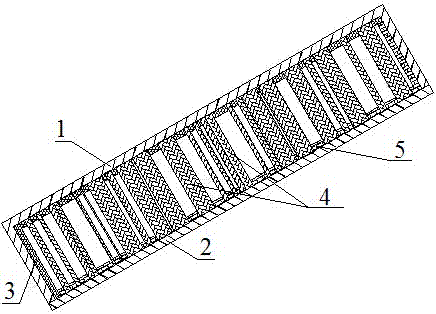

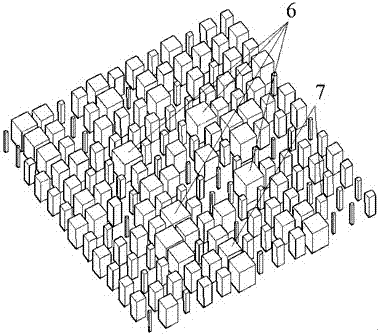

Reinforced heat transfer element of truncated cylindrical surface wing type vortex generator

InactiveCN101532798AReduce transportation energy consumptionEnhanced convective heat transferHeat transfer modificationTransportation energyEngineering

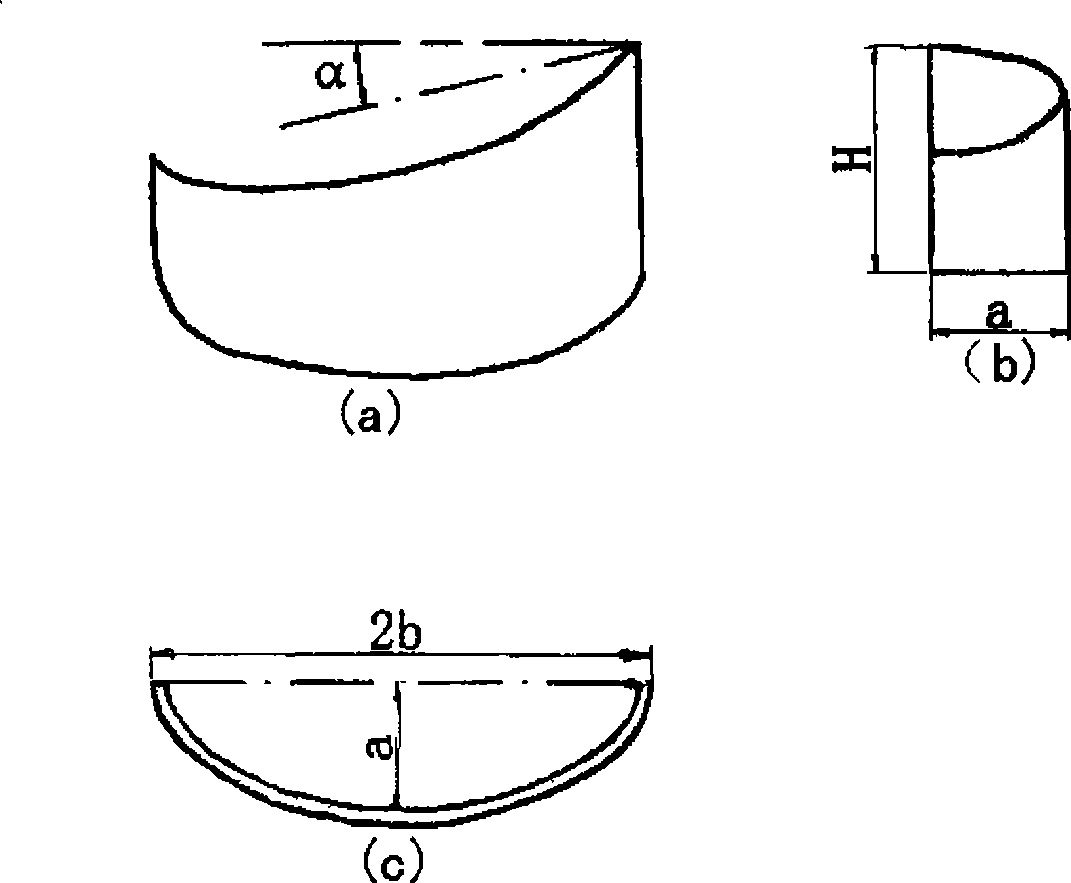

The invention discloses a reinforced heat transfer element of a truncated cylindrical surface wing type vortex generator, belonging to the field of heat transfer parts of heat exchanger. The vertical surface of a wing type vortex generator is bent into a semi cylindrical surface or a semi elliptic cylindrical surface to be arranged on a fin tube or a fin tube of a plate-fin heat exchanger or other passage flow heat exchanger plate surface in a certain incident flow impact angle and a certain array manner so as to induce the end longitudinal vortex and the root part horse shoe vortexes to couple to be thinned or destruct the boundary layer clinging to the wall face or reinforce the turbulence intensity to realize the passive reinforced heat exchange and improve the efficiency of the heat exchanger. In addition, due to the streamline surface, the shape resistance is reduced, thus lowering the flowing pressure loss and the fluid transportation energy consumption. The vortex generator can be manufactured by metal or other bendable molding materials, has the characteristics of simple manufacturing and convenient installation, and has extensive application prospect and promotion value in gas-liquid or gas-gas heat exchangers.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

A fluid separation device

InactiveCN1925902AEasy to modularizeReduce in quantityFuel cell auxillariesDispersed particle separationEngineeringSpiral flow

The present invention relates to a fluid separation device (10) for separating fluid, oil and oil spray from a gas. This fluid separation device (10) comprises a base carrier (21) in which fluid separator elements (20) in the form of flow-through tubes with worm-like segments (23) arranged therein, are integrated. The worm-like segments (23) at the same time form spiral flow paths (25) for the gas. They have a maximal length of half a pitch of the worm-like segment (23) so that the base carrier (21) together with the associated fluid separator elements (20) may be formed as one piece. Several base carriers may be arranged one after the other in a manner such that individual fluid separator elements of various base carriers form a common flow path for the gas.

Owner:REINZ DICHTUNGS

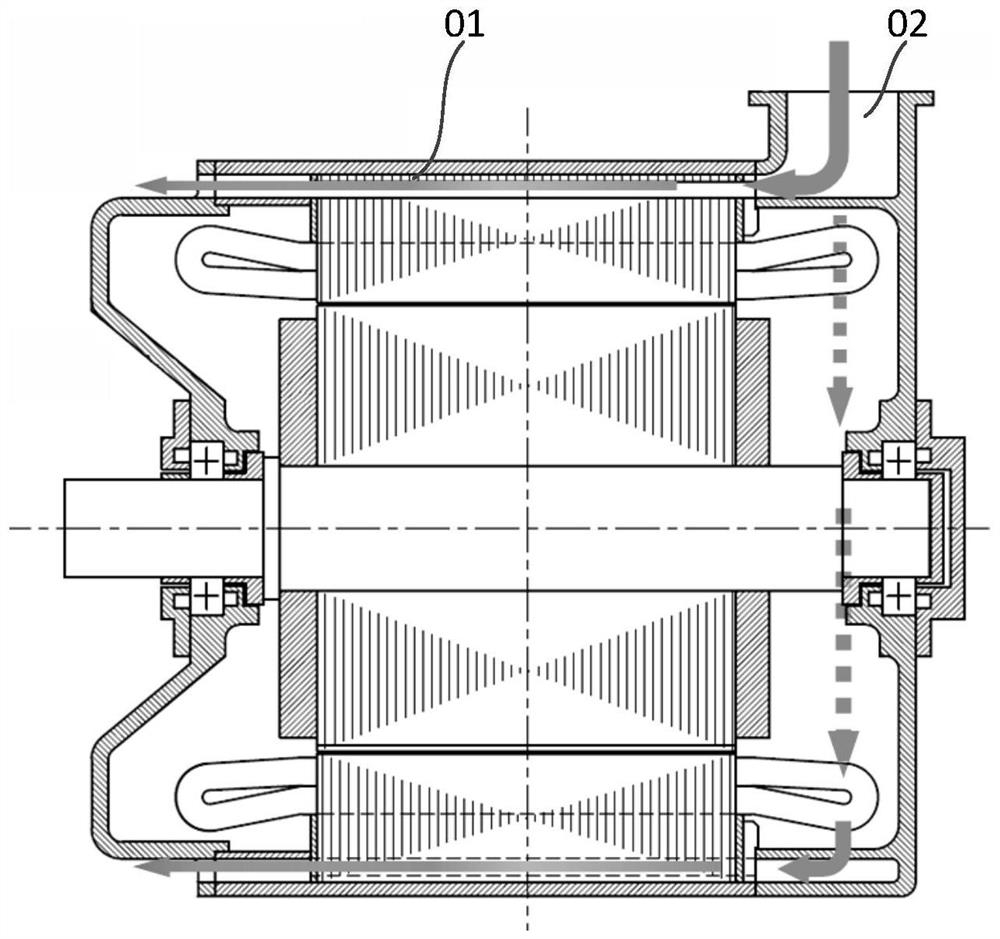

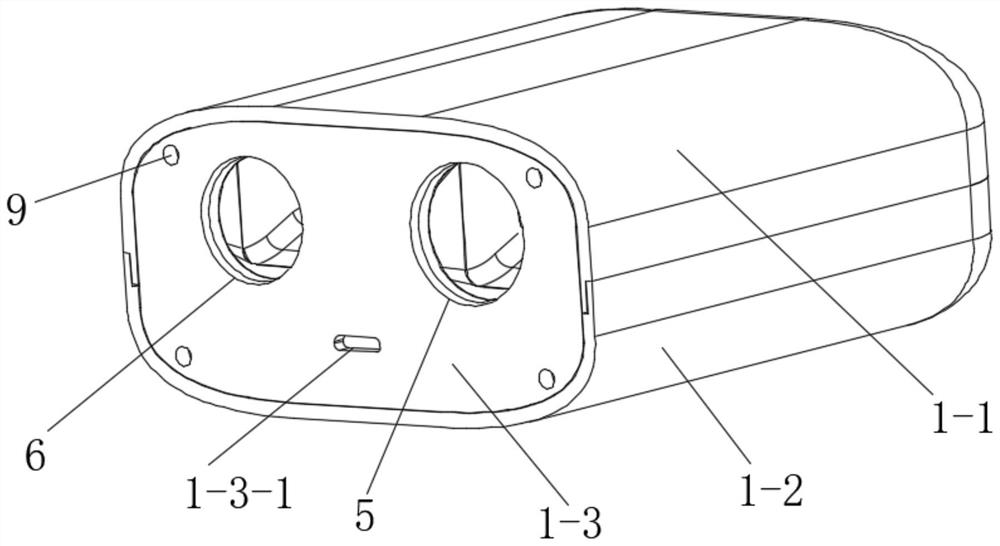

Power steering pump

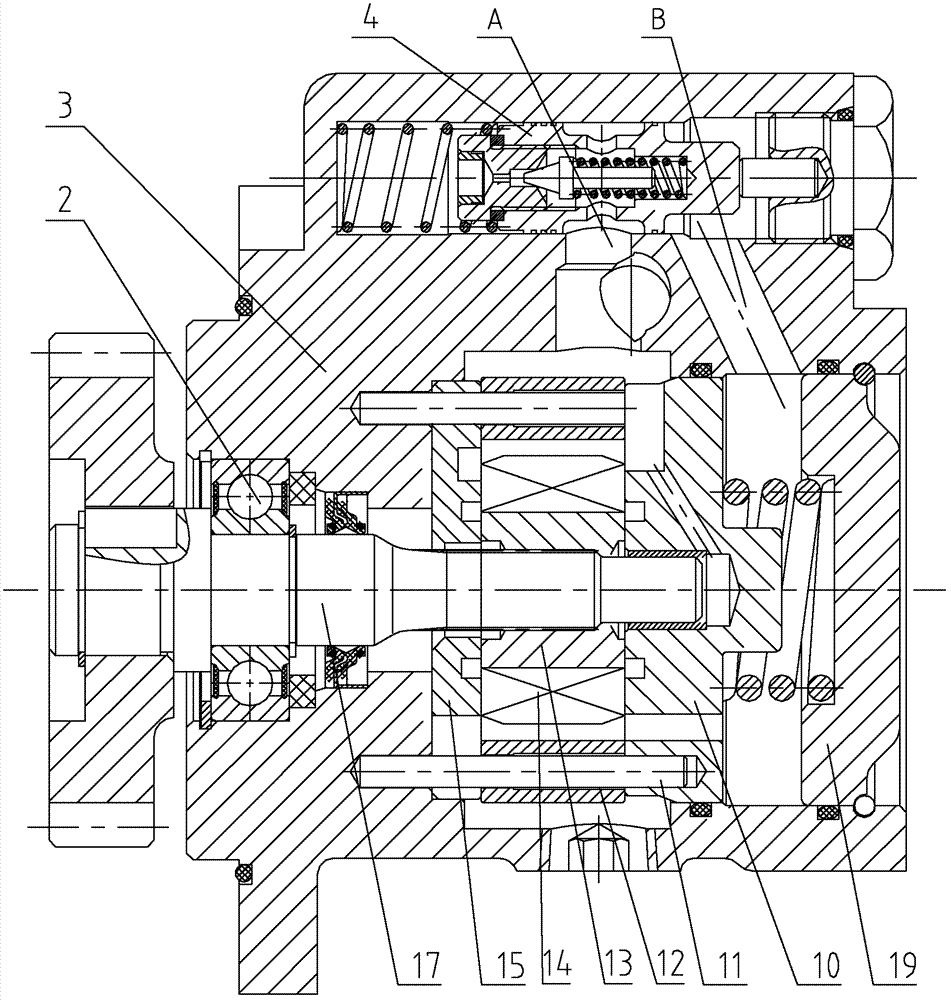

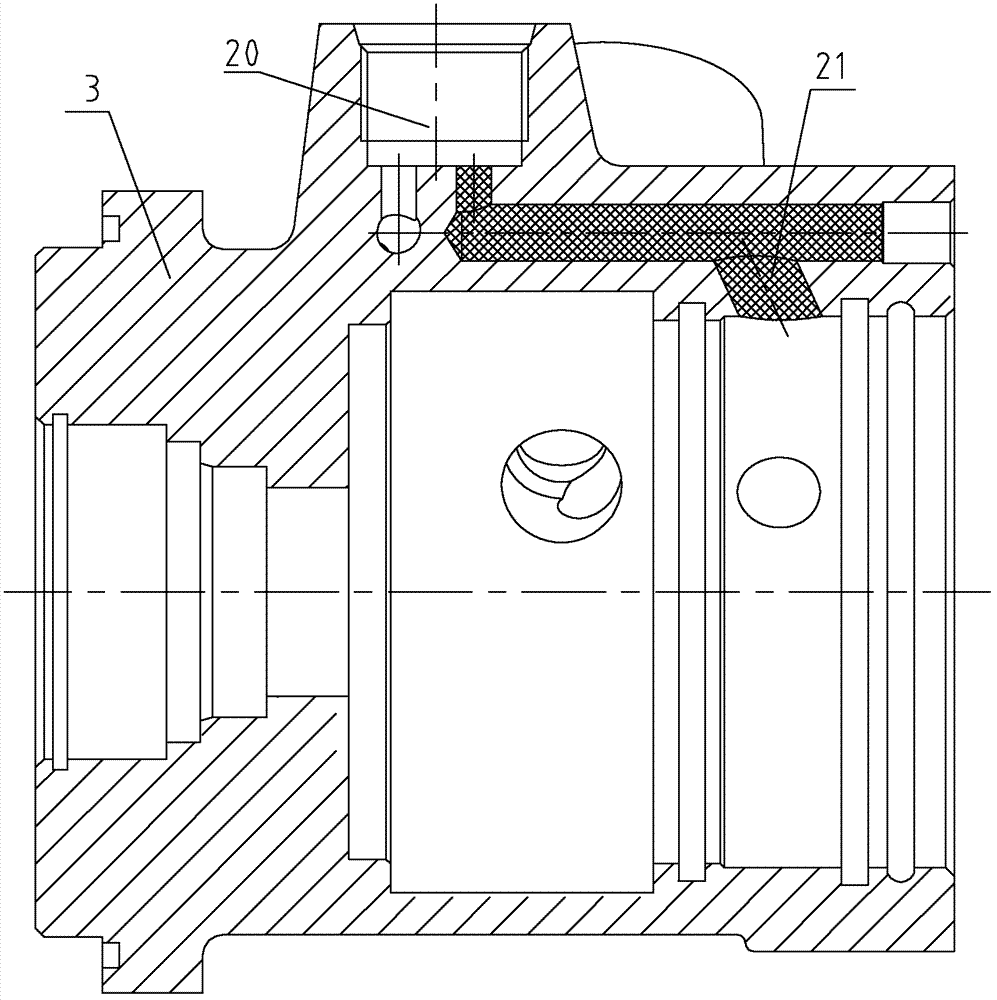

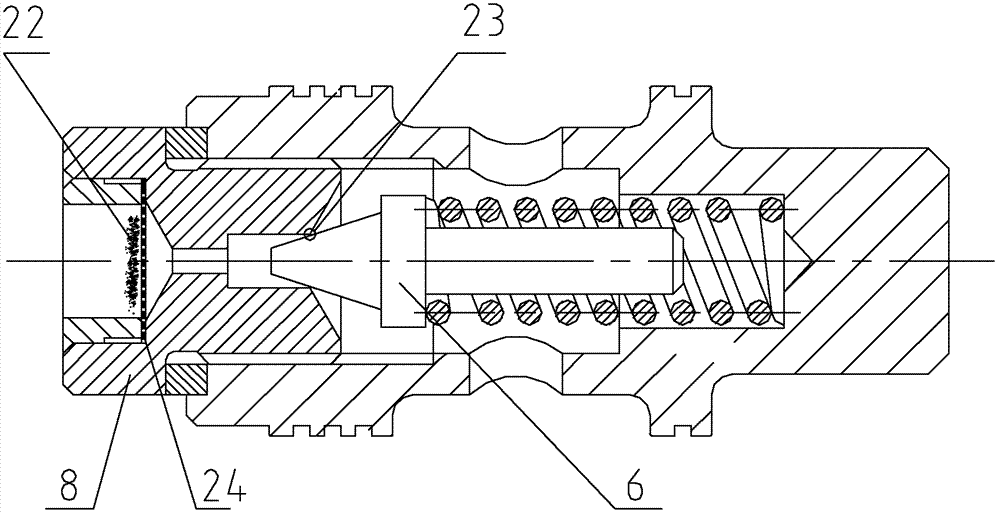

ActiveCN102536802AExtended service lifeImprove filtering effectSpecific fluid pumpsRotary piston pumpsSafety controlOil distribution

The invention discloses a power steering pump. The power steering pump is characterized in that a pump shaft is connected in series with a front oil distribution disc, a blade assembly and a front oil distribution disc into a whole so as to be installed in a pump body cavity, the front oil distribution disc and a front wall of the pump body cavity form an oil-out front cavity in an enclosed mode, and a pump body is provided with a valve hole on the side of an outer circle of the pump body cavity; the valve hole is communicated with the oil-out front cavity, the valve hole is internally provided with a flow safety control valve, and the oil-out front cavity is communicated with an oil outlet at the front of the pump body through a high-pressure oil channel; the outer circle of the blade assembly and an inner wall of the pump body cavity form a pump body back cavity in an enclosed mode, and the valve hole is communicated with the pump body back cavity through a return oil channel; and blades are driven by the pump shaft to rotate so as to finish an oil absorption and draining process, and the flow safety control valve controls oil mass discharged from the oil-out front cavity through the oil outlet to keep constant. The power steering pump provided by the invention has the advantage of shortening a high-pressure oil flow channel with smoothness in transition, reducing flow pressure loss, and avoiding that the power steering pump is failed due to serious heating because the flow channel in the traditional structure is long and bent by adopting a high pressure structure of the pump body front cavity.

Owner:QUANXING MACHINING GRP

Power steering pump

ActiveCN102536802BExtended service lifeImprove filtering effectSpecific fluid pumpsRotary piston pumpsEngineeringHigh pressure

Owner:QUANXING MACHINING GRP

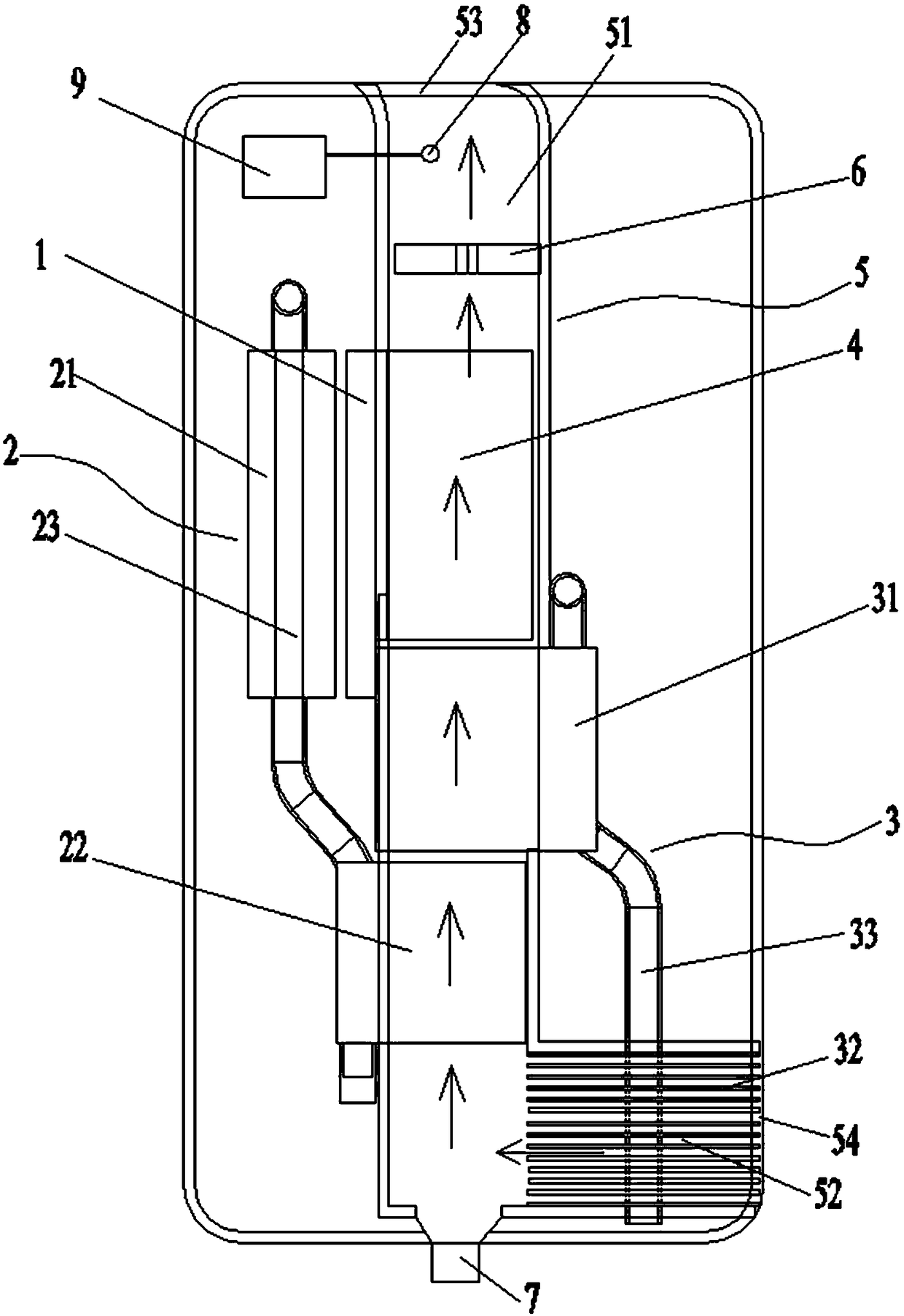

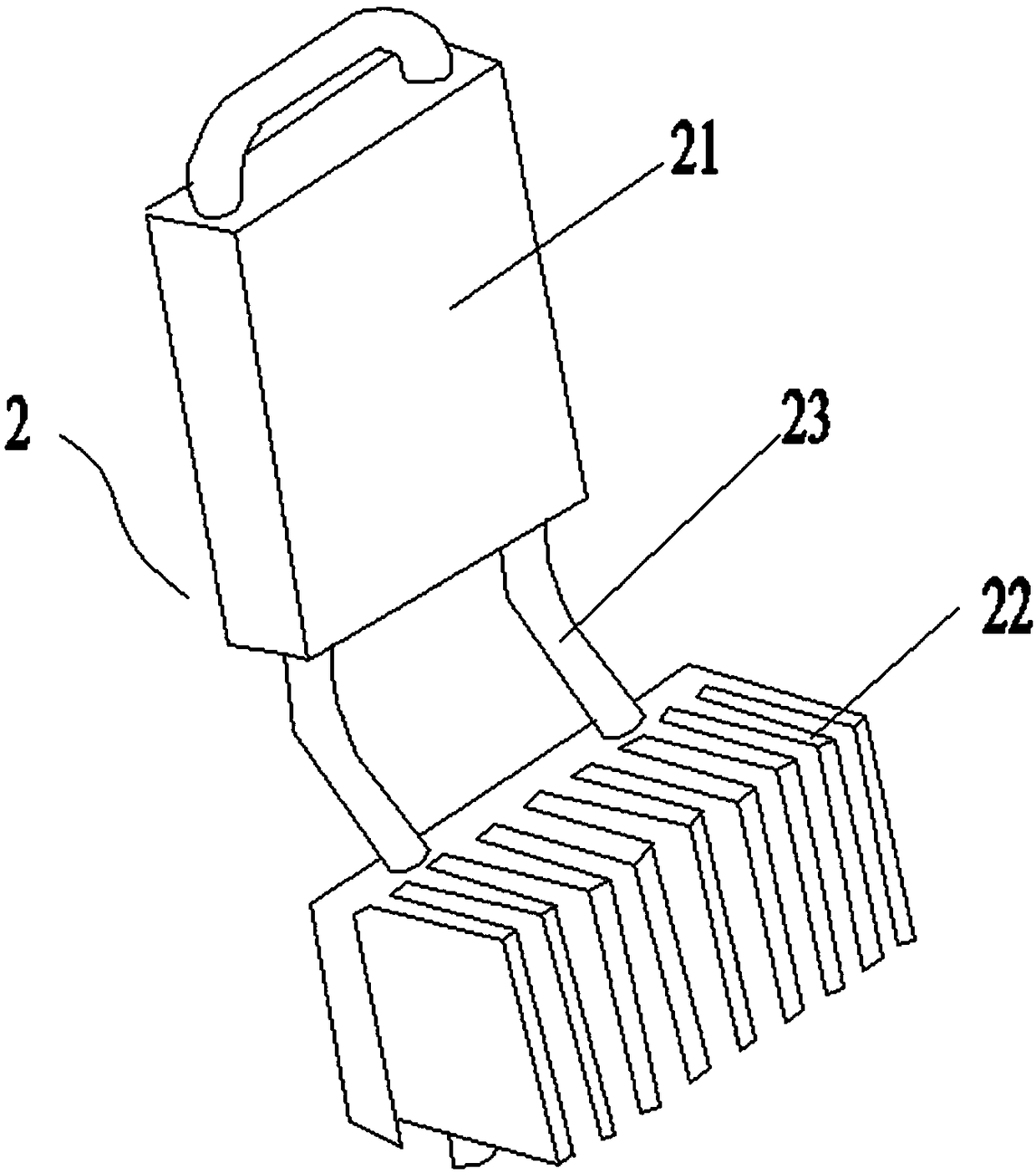

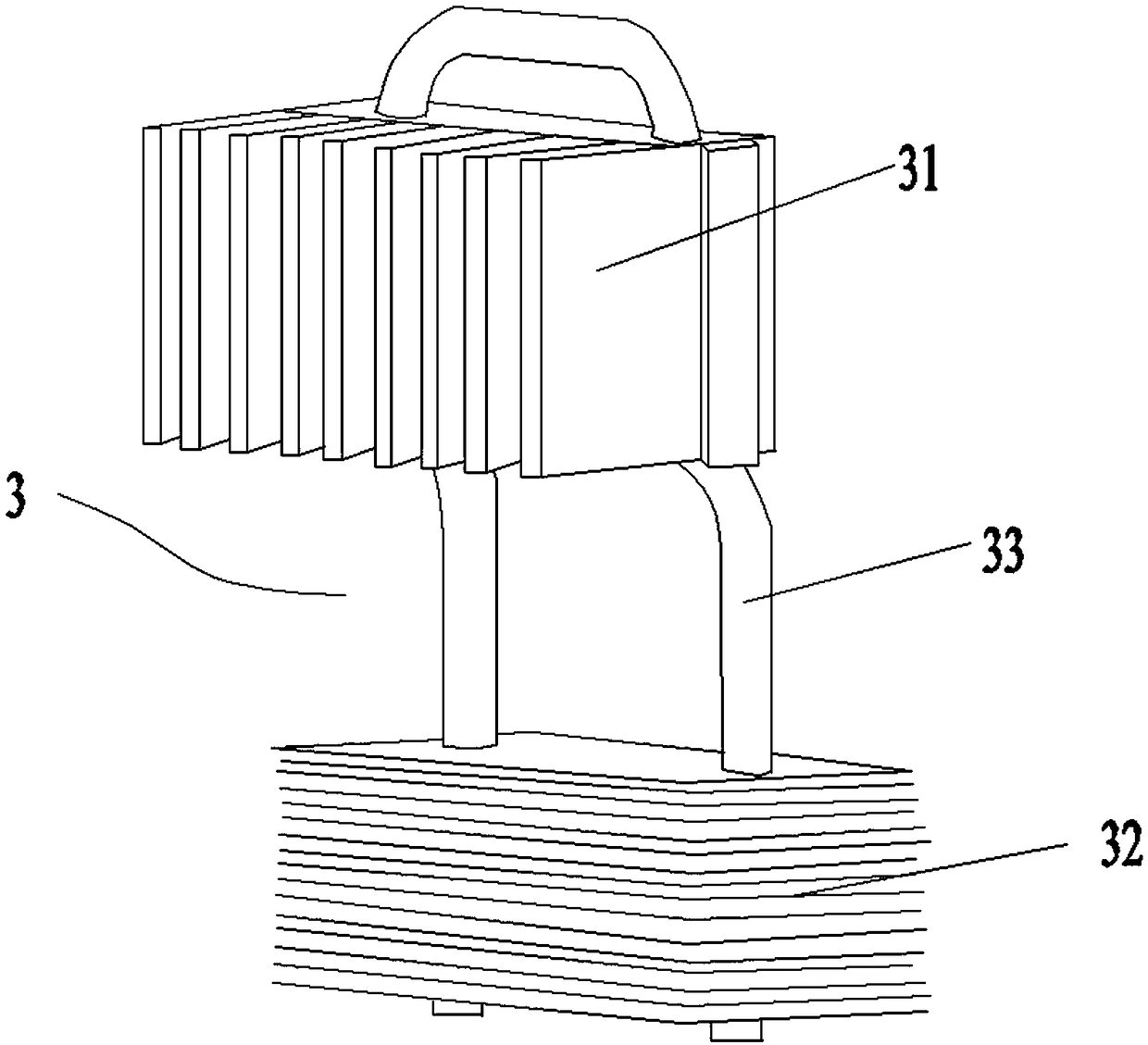

Semiconductor refrigeration dehumidifier and dehumidification method thereof

PendingCN108758882AImprove dehumidification efficiencySimple structural designMechanical apparatusSpace heating and ventilation detailsEngineeringCooling capacity

The invention provides a double-heat-pipe semiconductor refrigeration dehumidifier and a dehumidification method of the double-heat-pipe semiconductor refrigeration dehumidifier. The double-heat-pipesemiconductor refrigeration dehumidifier comprises a semiconductor refrigeration sheet, a first heat transfer device, a second heat transfer device, a third heat transfer device, an air flue, an exhaust fan and a water outlet. Heat exchange and dehumidification of air are performed through the arrangement of the three heat transfer devices, and the first heat transfer device can transfer the cooling capacity of the cold face of the semiconductor refrigeration sheet and performs secondary cooling on the air in an air-discharging channel through the absorbed cooling capacity of the cold face ofthe semiconductor refrigeration sheet. The third heat transfer device can transfer the heat of the hot face of the semiconductor refrigeration sheet and performs secondary heating on the air in the air-discharging channel, the air passes through the cold face for heat exchange in advance and then passes through the hot face for heat exchange without changing the direction, structural design of theair flue is simplified, the flowing pressure loss of the air in the air flue is reduced, and the dehumidification efficiency of the whole dehumidifier is improved.

Owner:AUX AIR CONDITIONING LTD BY SHARE LTD

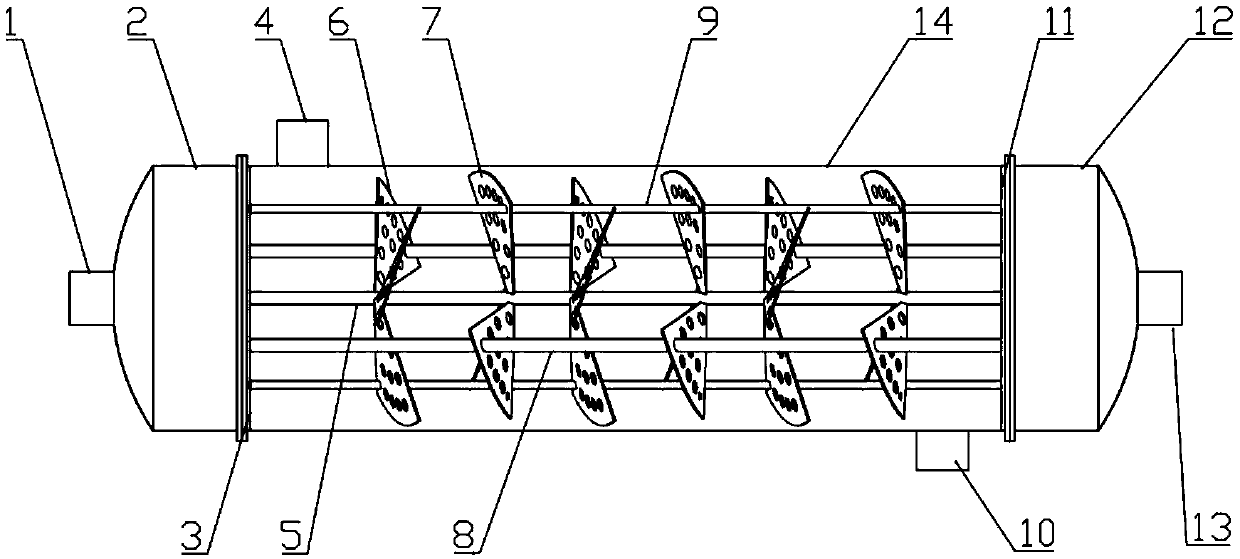

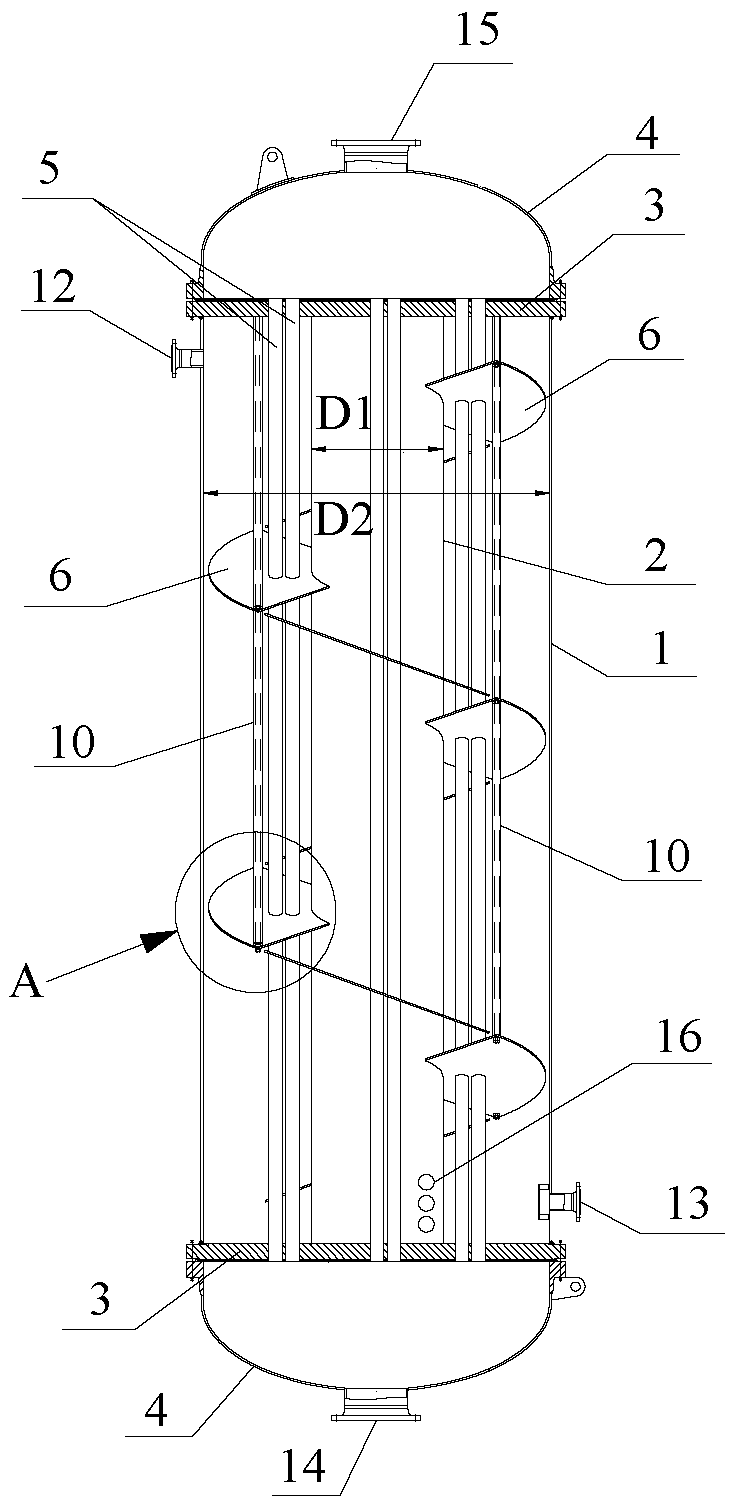

Spiral lattice plate shell-and-tube heat exchanger

InactiveCN109579573AReduce flow pressure lossReduce consumptionHeat exchanger casingsStationary tubular conduit assembliesShell and tube heat exchangerPlate heat exchanger

The invention relates to a spiral lattice plate shell-and-tube heat exchanger comprising a shell, a central pipe, six pull rods, two tube plates located at the two ends of the shell separately, a heatexchange tube bundle, a plurality of spacer tubes and a plurality of groups of spiral lattice baffles located between the central tube and the shell; the tube plates are connected with seal heads, and one seal head is provided with a drain hole and a tube side inlet; the other seal head communicates with a tube side outlet; and the spiral lattice baffles are composed of two groups of spiral lattice plates of which the rotation directions are different. The shell side fluid flows out from gaps of first group of the baffles, and flows longitudinally; the fluid is disturbed in a small spiral flow form when meeting the second group of the baffles; and in this process, pressure drop of the shell side is reduced through the longitudinal flow form, and the disturbance of the shell side fluid isenhanced through the spiral flow form. Through the spiral lattice baffle structure mode adopted by the heat exchanger, the shell-and-tube heat exchanger can be more compact, and the heat exchange efficiency is improved; the flow resistance is reduced, and the vibration of the heat exchange tube bundle and fouling deposits of the shell side are reduced; and the service life of the shell-and-tube heat exchanger is prolonged.

Owner:XI AN JIAOTONG UNIV

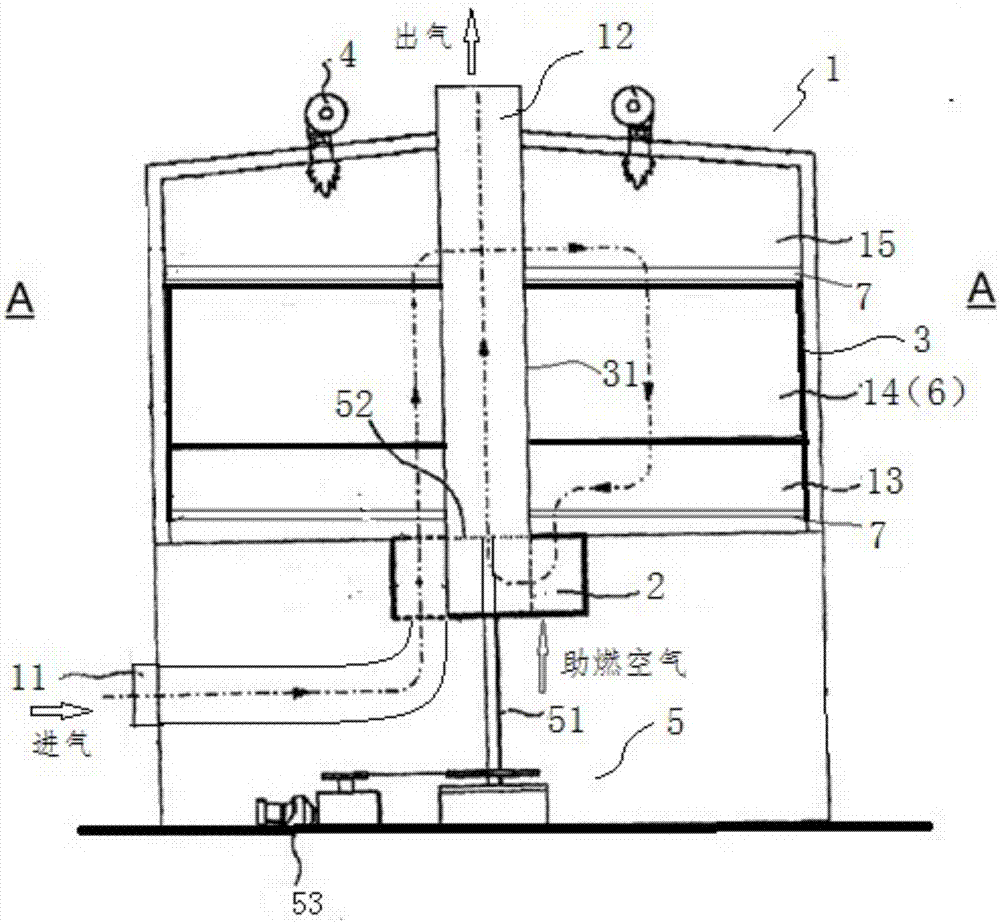

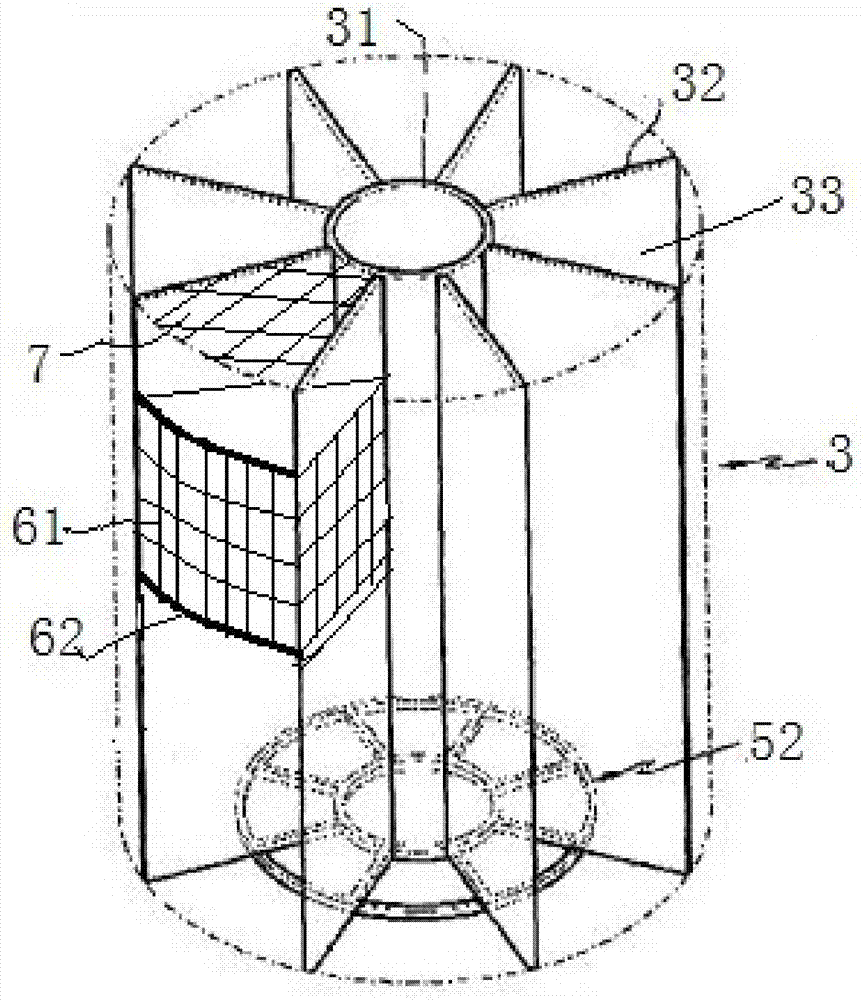

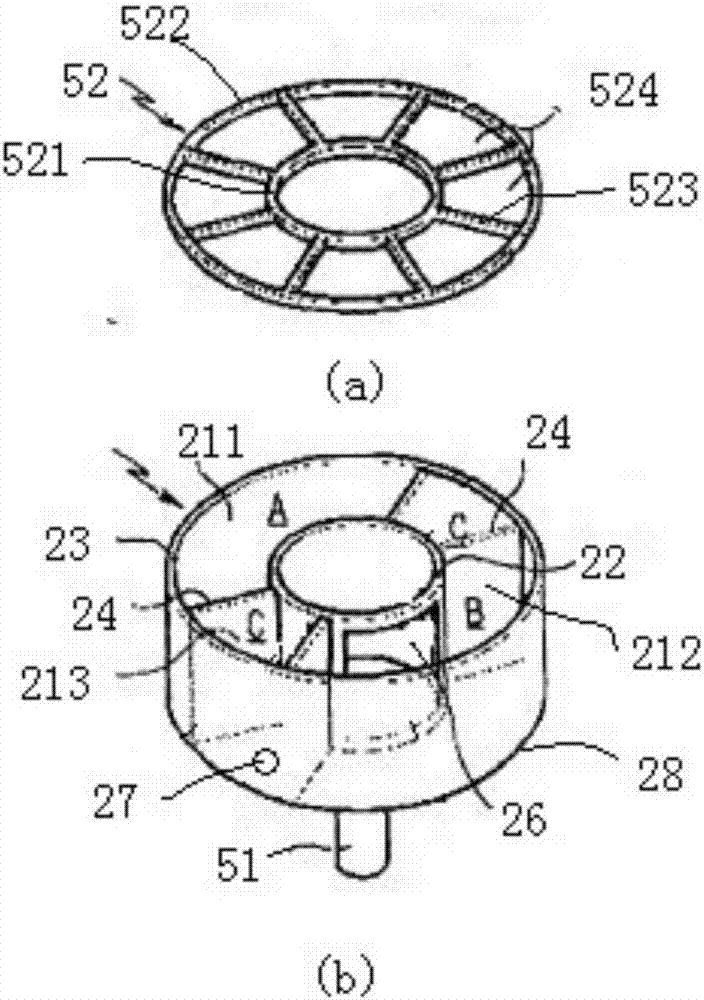

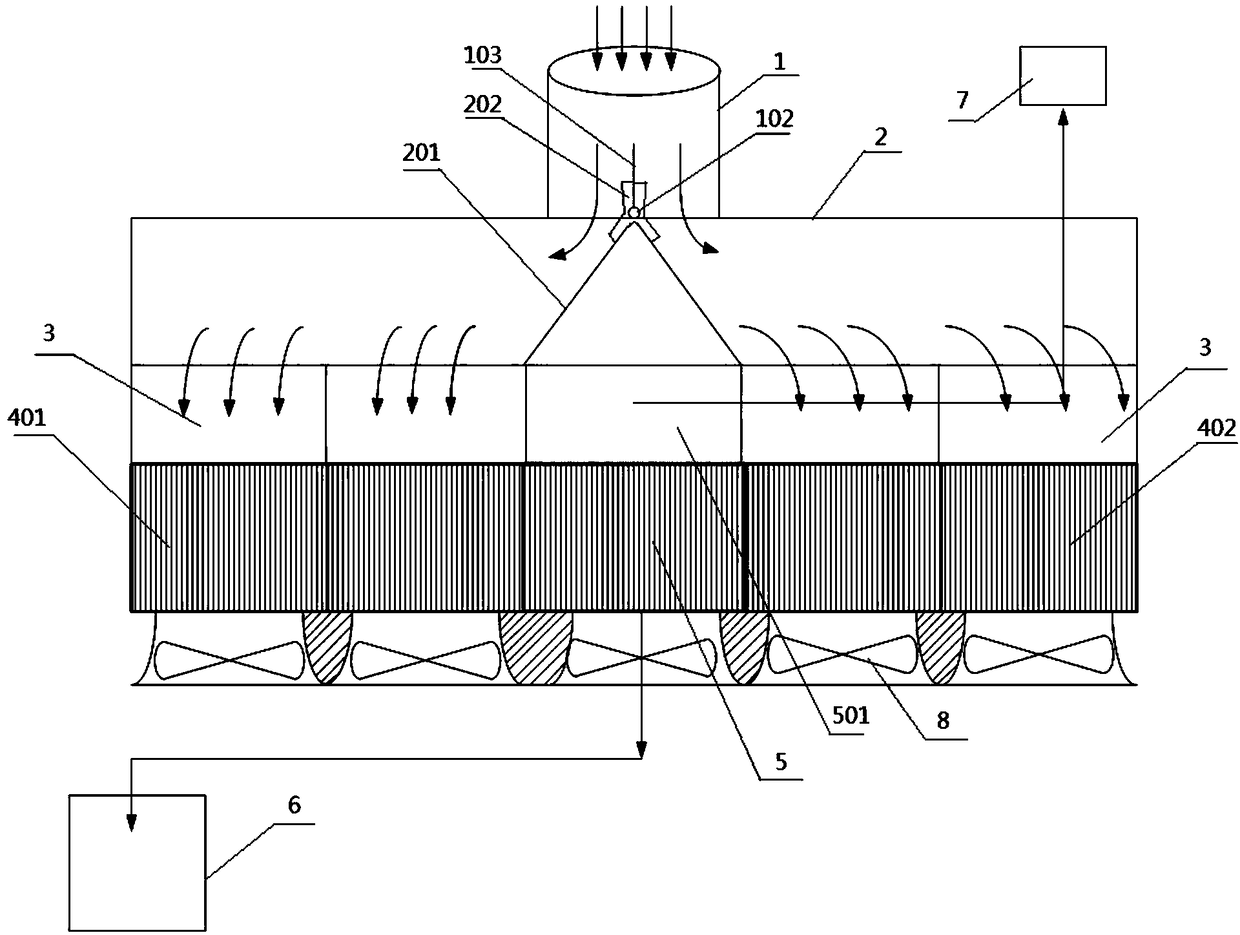

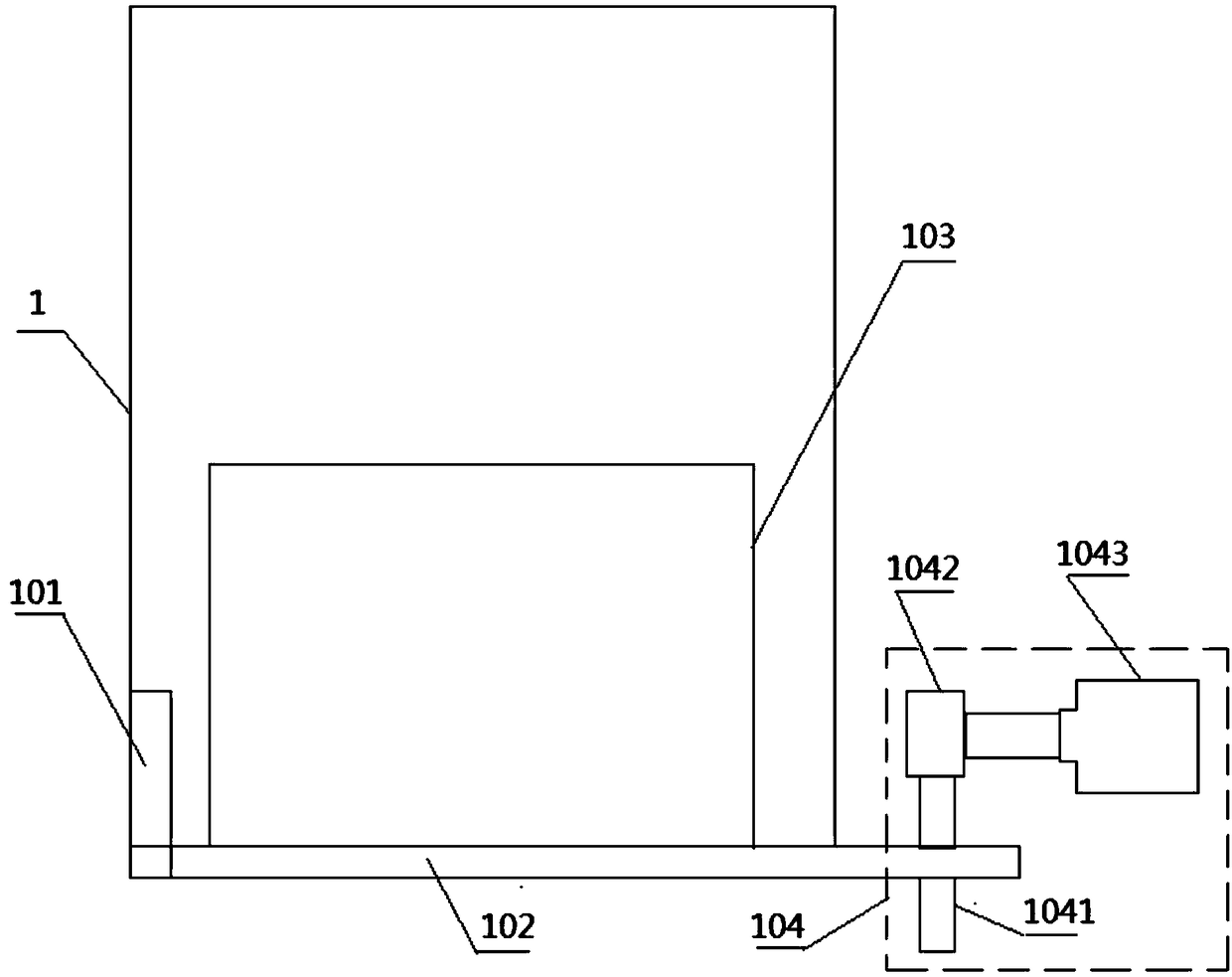

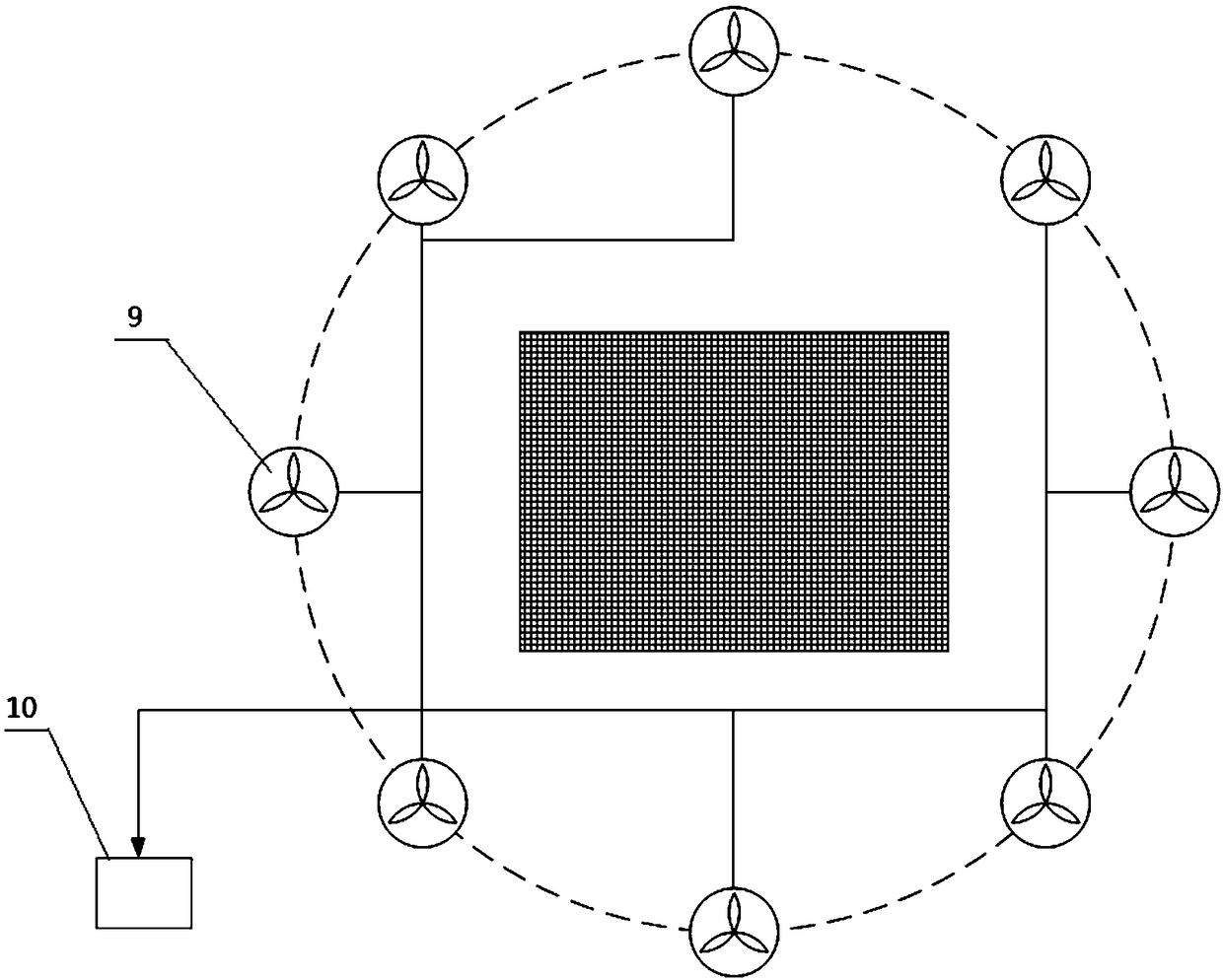

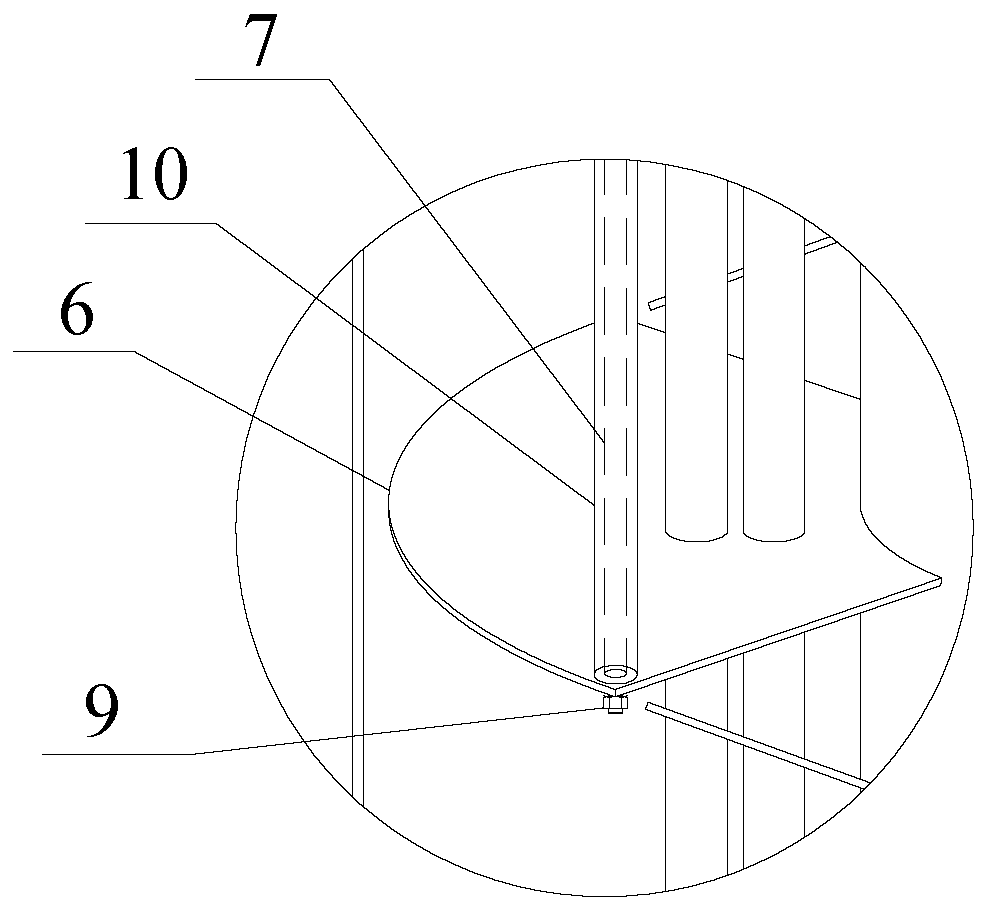

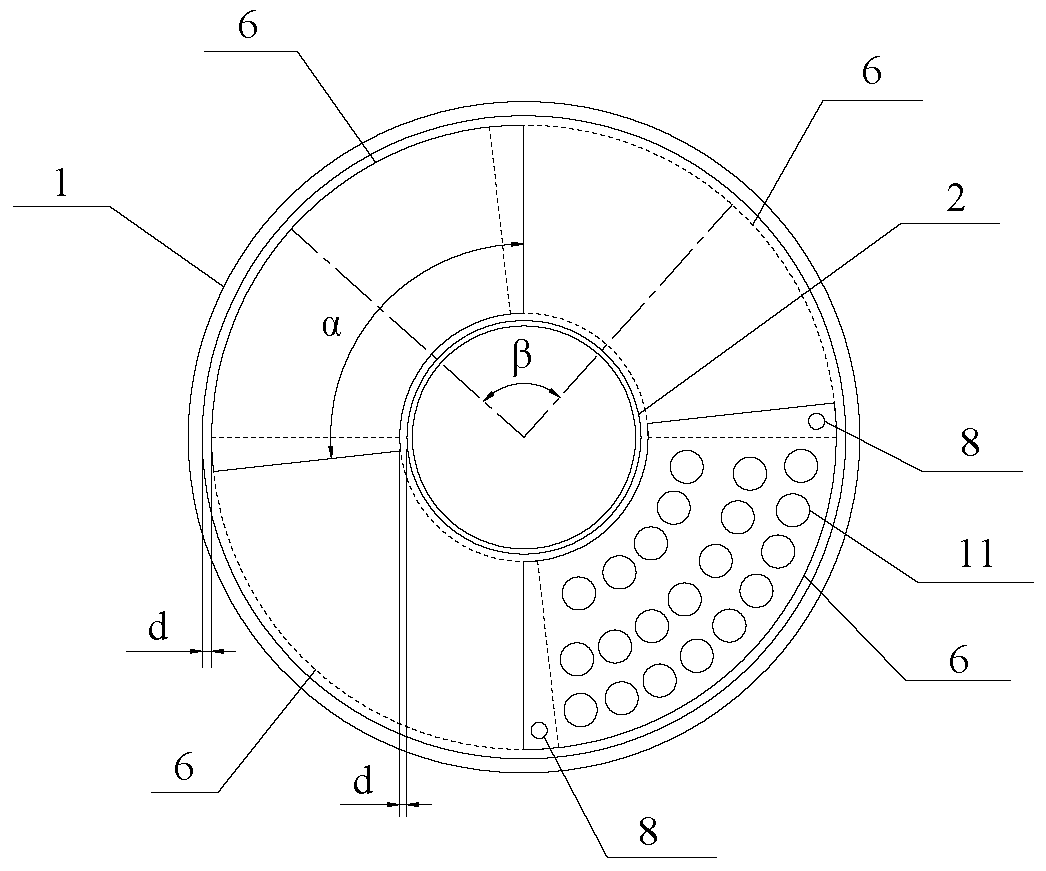

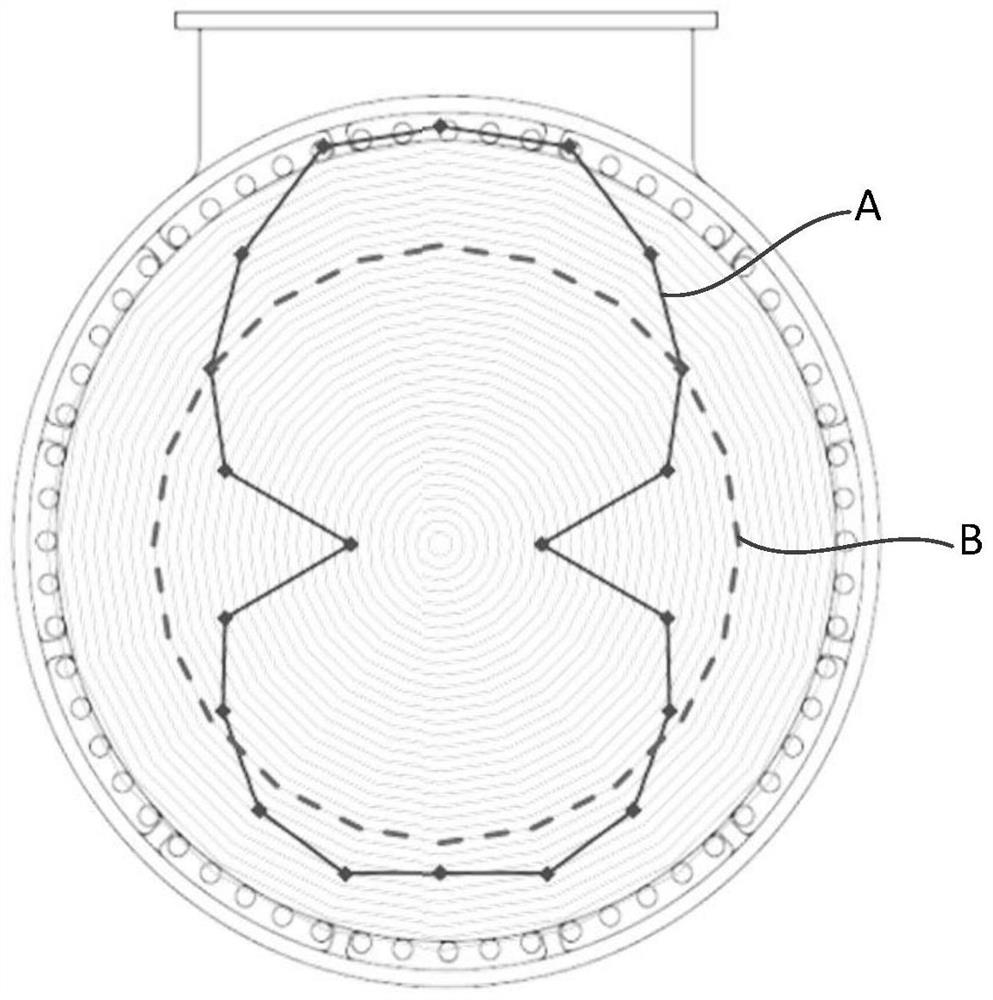

Multi-chamber heat accumulating type oxidation furnace

The invention discloses a multi-chamber heat accumulating type oxidation furnace. The multi-chamber heat accumulating type oxidation furnace comprises an oxidation furnace body, an air inlet pipeline,an exhausting pipeline, a gas distribution device, a division device, an combustion-supporting device and a rotary device, wherein the division device is located inside the oxidation furnace body andis used for dividing the oxidation furnace body into a reaction chamber and a gas distribution chamber; the gas distribution chamber is divided into a plurality of mutually independent fan-shaped division chambers by a plurality of division plates; the gas distribution device is of an internal and external double-layer barrel structure and comprises an air inlet area A, an air outlet area B and at least two combustion-supporting air areas C; the air inlet area A and the air outlet area B are spaced by the combustion-supporting air areas C; the rotary device drives the division device to rotate together; and the volume of the air outlet area B is larger than that of the air inlet area A. The multi-chamber heat accumulating type oxidation furnace has the beneficial effects that the pressureloss of the whole device can be reduced, the continuous operation of the device is ensured, the working efficiency of the multi-chamber heat accumulating type oxidation furnace is improved, and energy sources are saved.

Owner:NANJING CEEP TECH

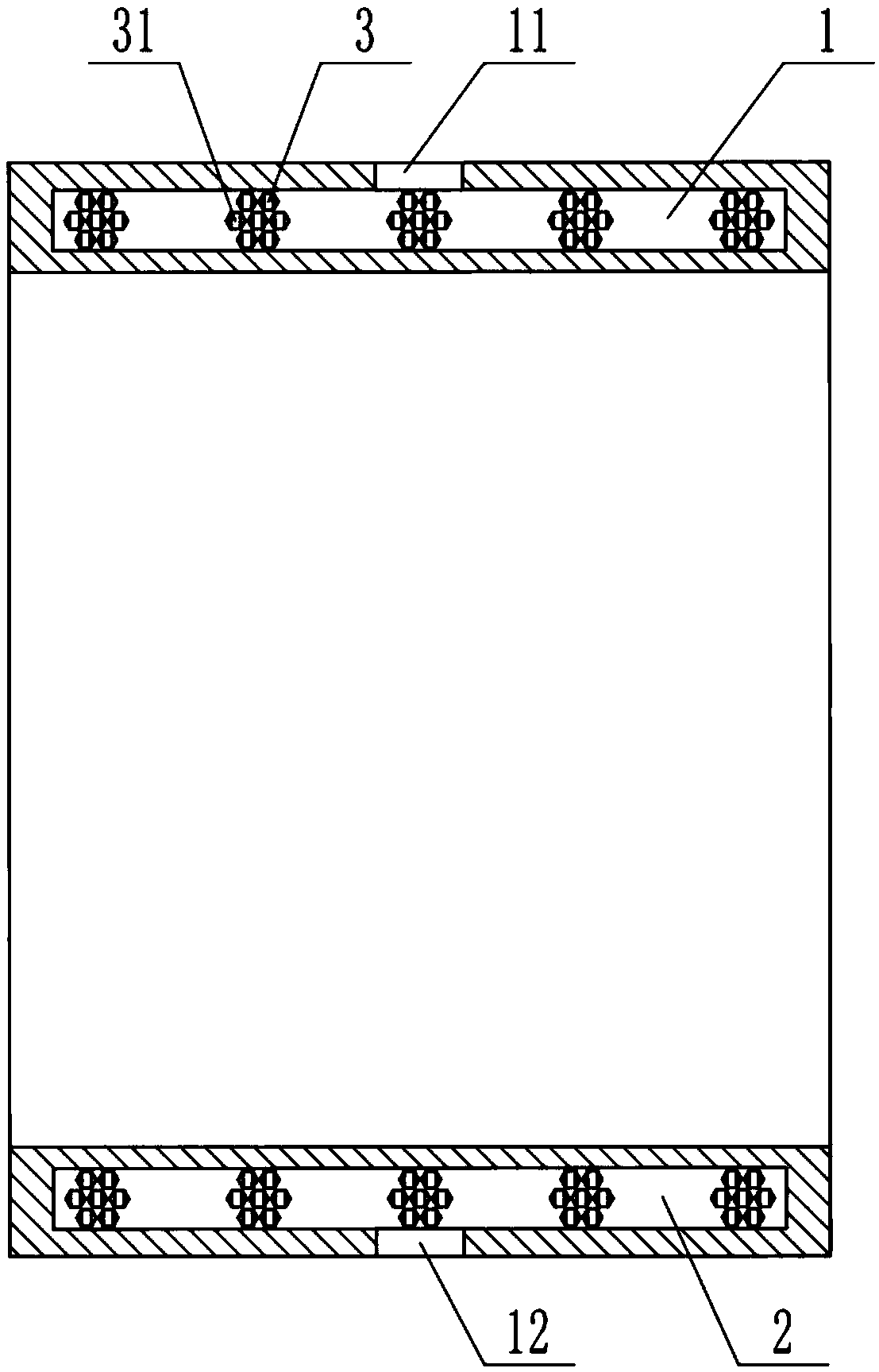

Spindle system cooling jacket and spindle system

PendingCN109590804AShorten flow lengthReduce flow pressure lossLarge fixed membersMaintainance and safety accessoriesEngineeringCooling fluid

The invention relates to the field of spindle systems, and provides a spindle system cooling jacket and a spindle system. The spindle system cooling jacket comprises a jacket body; the jacket body isinternally provided with a water inlet runner, a water outlet runner and a plurality of cooling runner sets; and the multiple cooling runner sets are arranged in the jacket body at intervals, the twoends of the cooling runner sets are connected with the water inlet runner and the water outlet runner, the cooling runner sets comprise a plurality of cooling runners, and the cooling runners communicate with the water inlet runner and the water outlet runner. The spindle system cooling jacket can simultaneously cool a spindle through the multiple cooling runners of the multiple cooling runner sets, the heat dissipation efficiency is high, by arranging the water inlet runner, cooling liquid is injected into the multiple cooling runner sets at the same time, the flowing length of the cooling liquid is decreased, and the flowing pressure loss of the cooling liquid is reduced.

Owner:QUZHOU UNIV

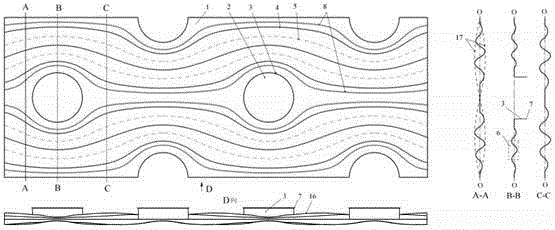

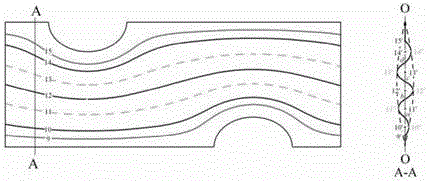

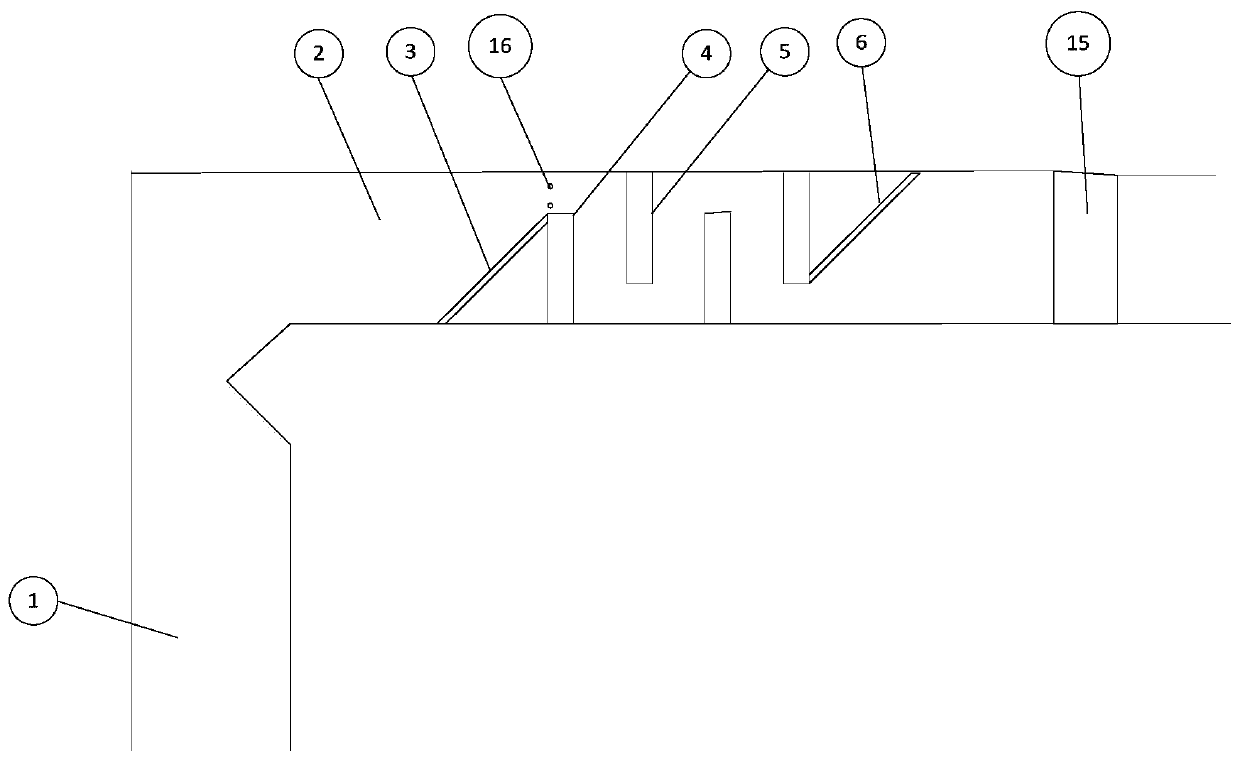

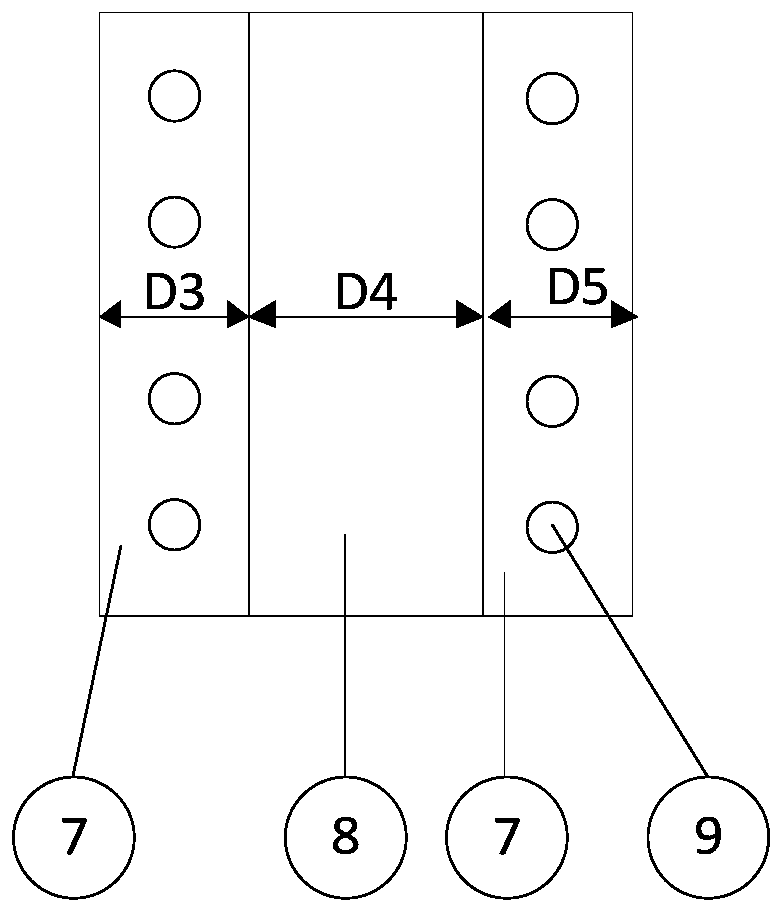

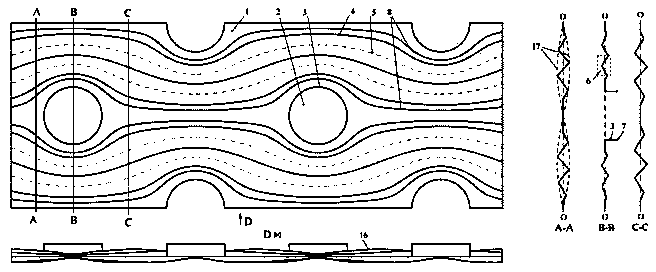

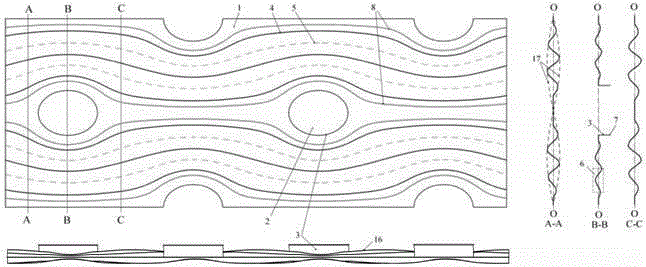

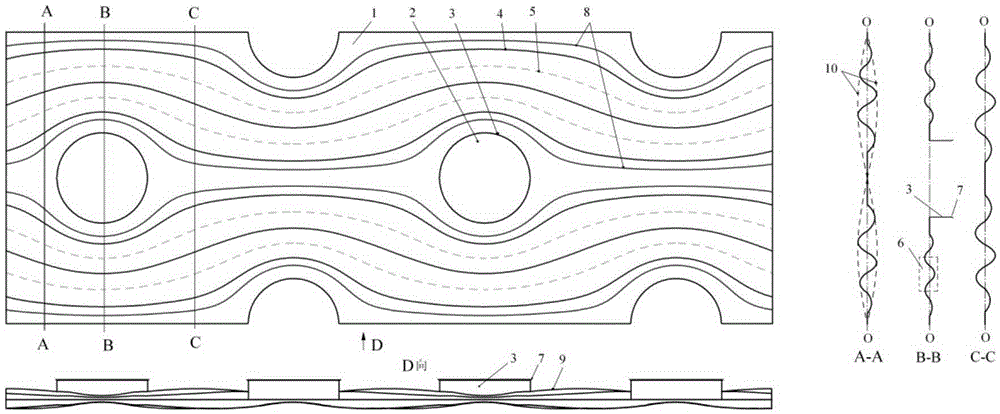

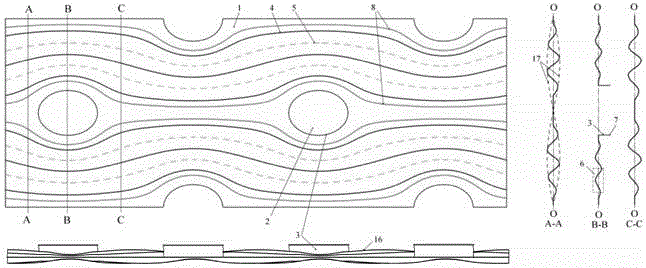

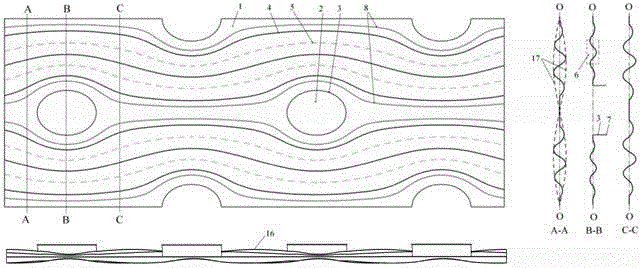

Streamline type variable wave amplitude parabolic corrugated fin of circular tube fin type heat exchanger

ActiveCN104142085AIncrease surface areaImprove heat transfer effectLaminated elementsTubular elementsLongitudinal waveEngineering

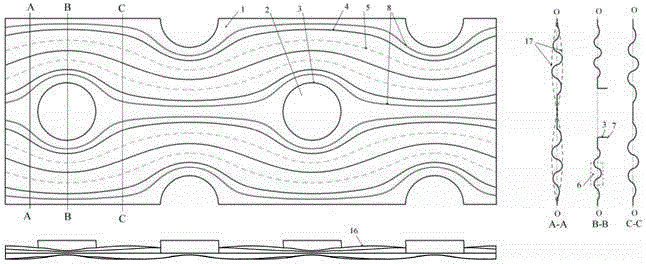

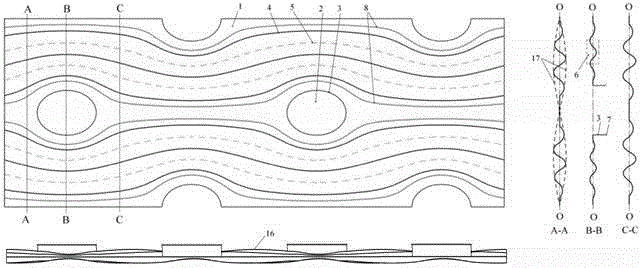

The invention discloses a streamline type variable wave amplitude parabolic corrugated fin of a circular tube fin type heat exchanger. Integral streamline type convex ripples 4 with the parabolic cross sections and integral streamline type concave ripples 5 with the parabolic cross sections are extruded on the fin from an airflow inlet to an outlet according to the needs of fin surface expanding and fluid flowing guiding. The same trough and wave crest connecting line is a streamline in which backflow does not occur on a pipe tail of a tube fin type heat exchanger plain film fin side channel corresponding to the fin 1 along the pipe axial center cross section. The convex ripples 4 and the concave ripples 5 change with an appropriate waveform 16 along the longitudinal wave amplitude, and the wave amplitude envelopes corrugated trough and wave crest change in the transverse direction with an appropriate waveform 17. According to the parabolic streamline type corrugated fin, the flowing streamline of the fluid can be effectively improved, flowing resistance is reduced, the surface area of the fin is increased through the convex / concave ripples on the surface of the fin, the heat transfer resistance is reduced, and the overall heat exchanging capacity of the fin is improved.

Owner:LANZHOU JIAOTONG UNIV

Flue structure for SNCR (selective non-catalytic reduction) denitration of flue gas of pulverized coal boiler and heating of sludge drying heat-conducting oil

PendingCN111425874ASimplify the heating systemWell mixedSludge treatment by de-watering/drying/thickeningGas treatmentSludgeFlue gas

The invention provides a flue structure for SNCR (selective non-catalytic reduction) denitration of flue gas of a pulverized coal boiler and heating of sludge drying heat-conducting oil. An SNCR denitration device is arranged in a proper area in a flue of the pulverized coal boiler, so that the flue gas carrying a reducing agent can be fully mixed when flowing through the SNCR denitration device,and ideal denitration efficiency is achieved. A heat-conducting oil heater pipeline is embedded in a basic mechanism unit, so that a heat-conducting oil heating system is simplified, and part of heatenergy in high-temperature flue gas is obtained for drying of municipal sludge. The whole design structure is simple, the concentration of NOx in the flue gas in front of an SCR device is greatly reduced, energy in the flue gas is obtained with the simple structure for drying of the municipal sludge, and better economic benefits and social benefits can be obtained in two aspects of pollutant emission reduction and municipal waste utilization.

Owner:HUANENG POWER INT INC +2

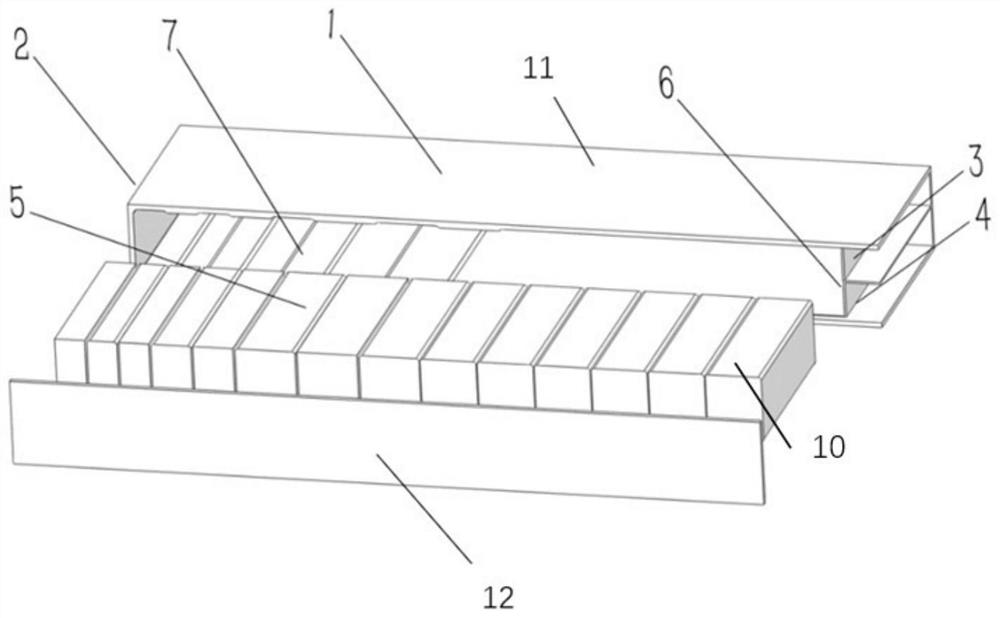

Direct air-cooling system for optimization of flow distribution of steam

InactiveCN108731495AHigh outputImprove efficiencySteam/vapor condensersAnti freezingAir cooling system

The invention discloses a direct air-cooling system for optimization of flow distribution of steam. The system comprises a vertically-arranged steam introducing pipe. The lower end of the steam introducing pipe communicates with a horizontally-arranged steam distributing pipe. The lower end of the steam distributing pipe communicates with multiple buffer covers. The lower end of each buffer covercorrespondingly communicates with a group of forward-flow area pipe bundles. Each forward-flow area pipe bundle comprises a windward-side pipe bundle and a leeward-side pipe bundle. An adverse flow area pipe bundle is arranged in the middle between each windward-side pipe bundle and each leeward-side pipe bundle. A flow guide board is arranged in the steam introducing pipe and swing leftwards andrightwards in the steam introducing pipe. An inverted-V-shaped baffle board is arranged in the steam distributing pipe. According to the actual demand, distribution of steam flow in the steam distributing pipe is adjusted such that steam-side thermal load matches air-side air quantity. Therefore, the heat exchange capability of the system is increased. Meanwhile, distribution of steam flow is controlled according to wind speed and wind direction of the environment. Therefore, optimization and matching of thermal load in the air-cooling system is realized. Therefore, an anti-freezing and over-summer capability of the system is enhanced.

Owner:DATANG GANSU POWER GENERATION

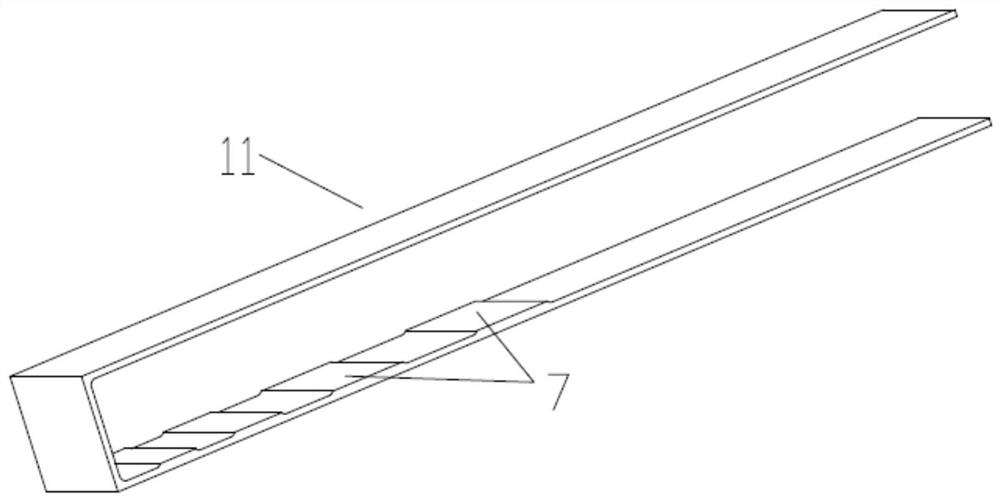

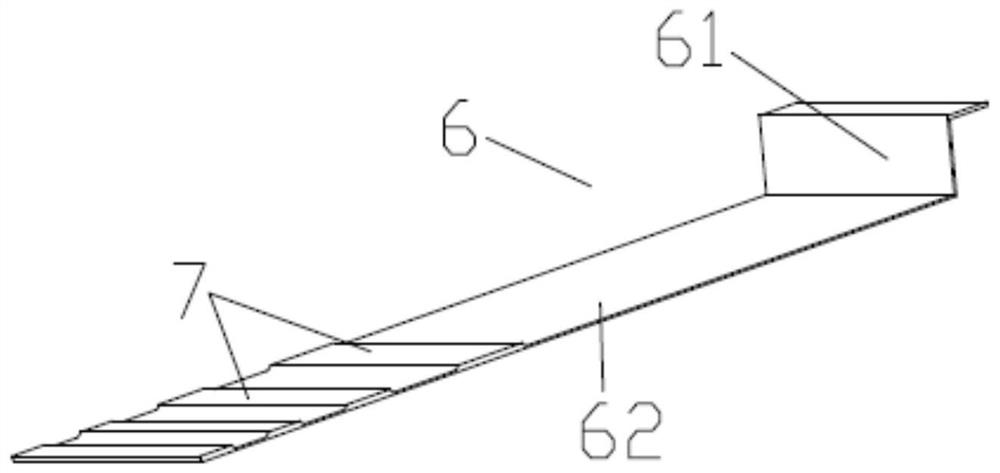

Enhanced heat transfer element of oblique truncated cylindrical wing vortex generator

InactiveCN101532798BReduce transportation energy consumptionEnhanced convective heat transferHeat transfer modificationEnhanced heat transferElliptic cylinder

The invention discloses an intensified heat transfer element for a vortex generator with oblique truncated cylindrical fins, which belongs to the field of heat transfer components of heat exchangers. It is to bend the facade of the airfoil vortex generator into a semi-cylindrical or semi-elliptical cylindrical form, and arrange it on the finned tube or the fin of the plate-fin heat exchanger or other channel flow heat exchange at a certain angle of attack and array. On the surface of the plate, the longitudinal vortex at the end is induced and the horseshoe vortex at the root is coupled to thin or destroy the boundary layer close to the wall or increase the turbulence intensity to achieve passive enhanced heat transfer and improve the efficiency of the heat exchanger. In addition, it is important that due to its streamlined surface, the shape resistance is reduced, thereby reducing the flow pressure loss and reducing the energy consumption of fluid transportation. This kind of vortex generator can be processed by metal or other flexible forming materials, has the characteristics of simple manufacture and convenient installation, and has broad application prospects and popularization value in gas-liquid or gas-gas heat exchangers.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

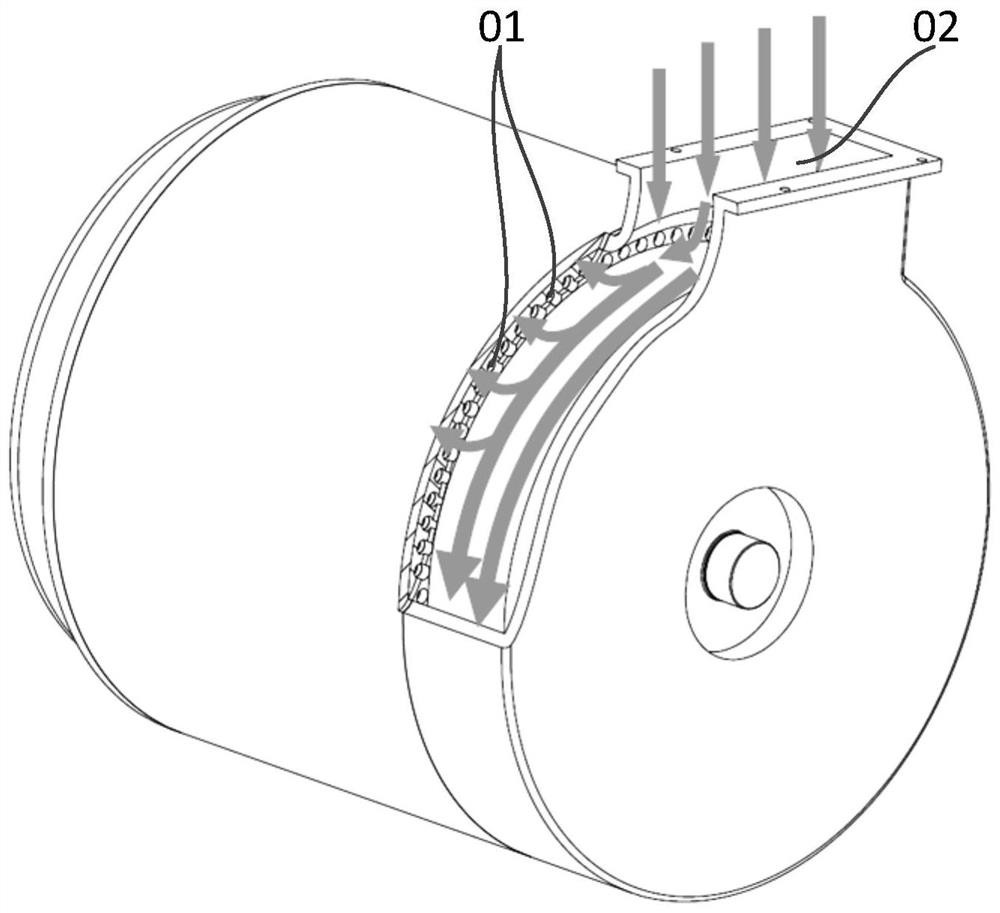

Spallation neutron target with mixed cooling flow channel

PendingCN113079618AExtended service lifeReduce working fluid flowDirect voltage acceleratorsNuclear targetsThermodynamicsHeat flow

The invention provides a spallation neutron target with a mixed cooling flow channel. The spallation neutron target has a serial cooling flow channel and a parallel cooling flow channel communicated with each other at the same time is provided, aims at thermal deposition of a target body, and takes an internal cooling flow channel as an optimization object. The spallation neutron target comprises a target container and a target body installed in the target container, and a target window is arranged on the front end face, right facing the proton beam bombardment direction, of the target container; the target body is formed by fixedly connecting a plurality of target piece single bodies in a stacked mode, a single serial cooling flow channel is formed by gaps between the target pieces close to the target window direction and the upper inner wall and the lower inner wall of the target container, a parallel cooling flow channel is formed by gaps between connecting faces between every two adjacent connected target pieces far away from the target window direction, and a serial cooling flow channel and the parallel cooling flow channel are communicated with each other. The overall flow of a working medium in the overall target structure is low, high-flow-rate heat dissipation is achieved in a high-heat-flow area of the target body through serial flow, flow resistance is reduced in a low-heat-flow area through parallel flow, efficient cooling and stable flowing are achieved, and therefore the service life of the target body is prolonged.

Owner:CHINA SPALLATION NEUTRON SOURCE SCI CENT +1

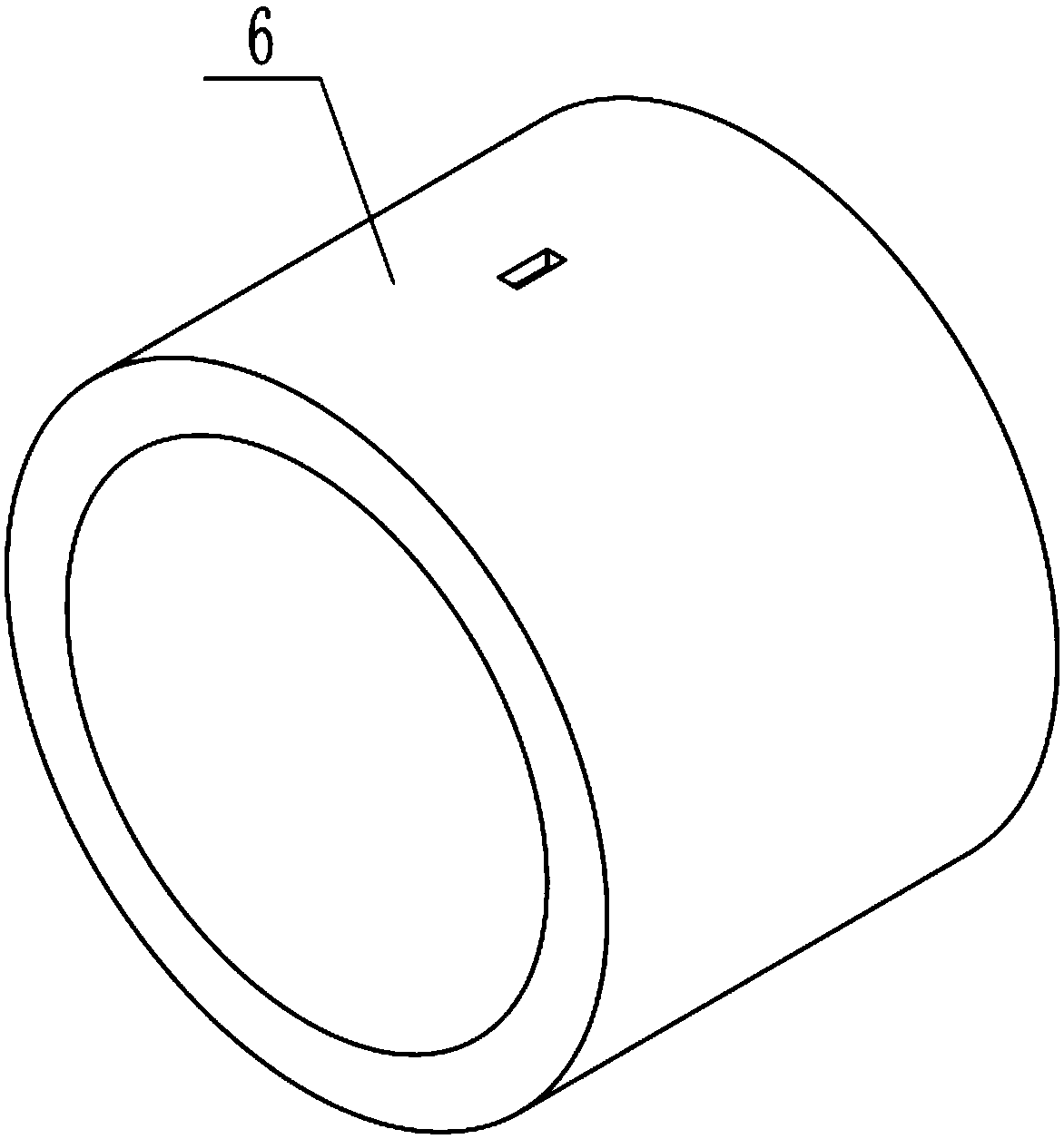

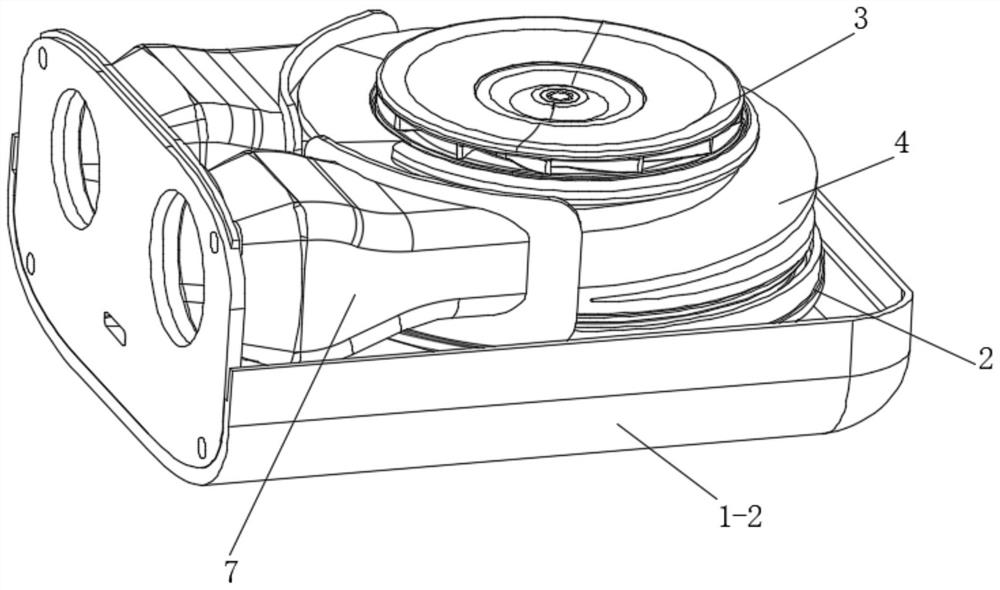

Compact ultrathin water pump

PendingCN113107864AReduce axial sizeImprove compactnessPump componentsPump installationsWater storageImpeller

The invention discloses a compact ultrathin water pump which comprises a water pump body. The water pump body comprises a top cover, a pump shell and a base assembly. An impeller assembly is arranged in the pump shell, and a stator assembly is arranged on the base assembly. A water inlet connector is arranged on one side of the pump shell, and a water outlet connector is arranged on the other side of the pump shell. A first cavity is formed between the top cover and the pump shell, the first cavity comprises an annular water storage chamber separately arranged on the side face of the pump shell and an annular suction chamber arranged on the pump shell and communicated with the annular water storage chamber, and the water inlet connector is communicated with the annular water storage chamber. A second cavity is formed between the pump shell and the base assembly, an annular water pumping chamber is arranged on the outer side of the second cavity, the impeller assembly is arranged in the middle of the second cavity, the annular suction chamber is communicated with the annular water pumping chamber, and the annular water pumping chamber is communicated with the water outlet connector. The axial size of the water pump is obviously reduced, a water tank is integrated into the design of the water pump, and the compactness of the water pump is improved.

Owner:东莞市鸿盈电子科技有限公司

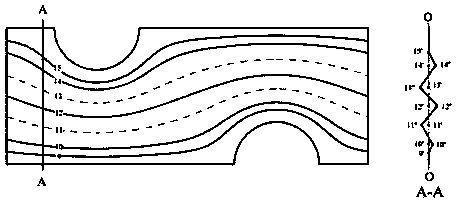

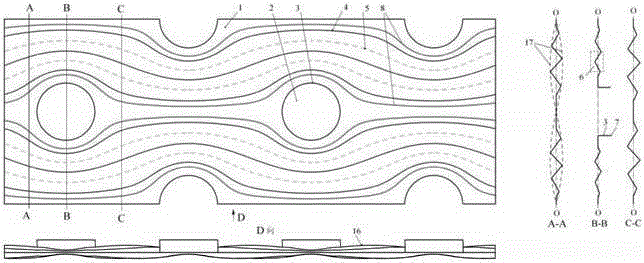

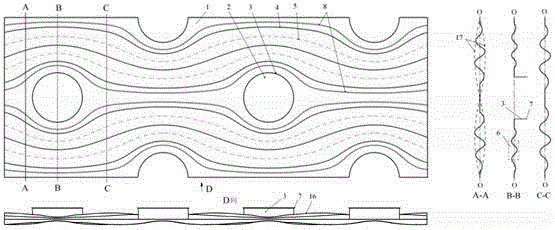

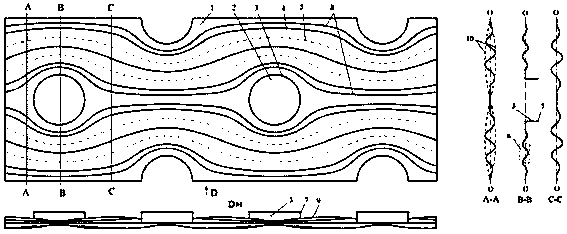

Streamline amplitude-variable folded-line-shaped corrugated fin of round tube fin type heat exchanger

ActiveCN104101243AIncrease surface areaImprove heat transfer effectTubular elementsHeat transmissionEngineering

Disclosed is a streamline amplitude-variable folded-line-shaped corrugated fin of a round tube fin type heat exchanger. According to the needs for expanding the fin surface and guiding fluid to flow, a streamline protrusive corrugation 4 and a recessed corrugation 5 with full sections shaped in folded lines are extruded from an air inlet and an air outlet in a fin. Connection lines among same troughs and crests are folded lines. The streamlines are streamlines without backflow at the tube tails, along an axial central section of a tube, of a lateral passage of a tube fin type heat exchanger plain fin which corresponds to a fin 1. The protrusive corrugation 4 and the recessed corrugation 5 vary along longitudinal amplitude in an appropriate waveform 16, and the amplitude varies transversely in a form of fitting an enveloped corrugation crest of a waveform 17. The streamline folded-line-shaped corrugated fin has the advantages that flowing streamline performance of the fluid can be improved effectively, flowing resistance is reduced, superficial area of the fin is enlarged by the protrusive / recessed corrugations on the fin surface, heat transmission resistance is reduced, and integral heat exchanging performance of the fin is improved.

Owner:LANZHOU JIAOTONG UNIV

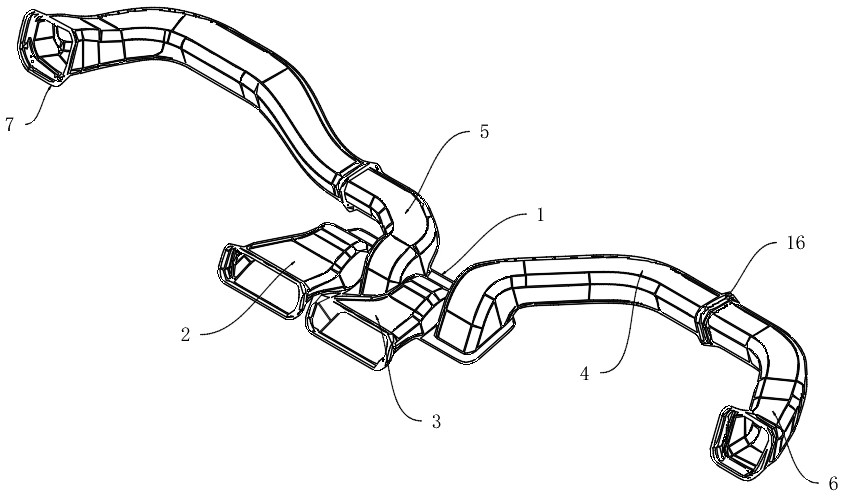

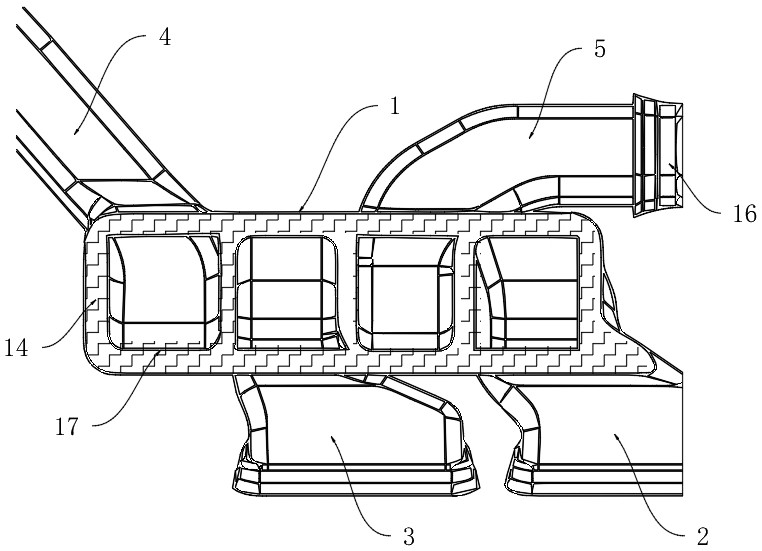

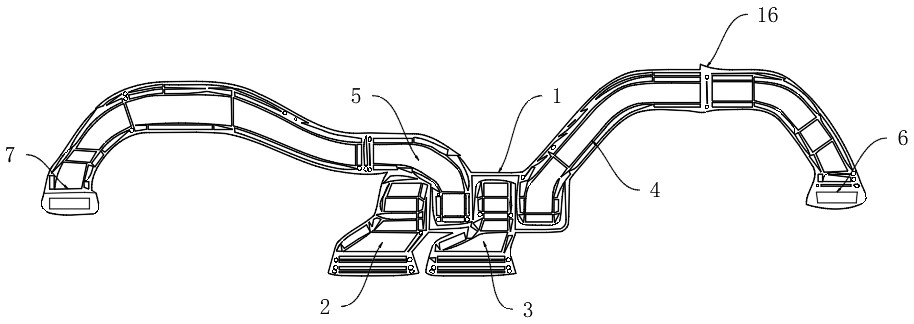

Air conditioner face blowing air pipe for pickup truck

PendingCN113682111AReduce design difficultyImprove design efficiencyAir-treating devicesVehicle heating/cooling devicesAir volumeEngineering

The invention discloses an air conditioner face blowing air pipe for a pickup truck, relates to the technical field of automobile refrigeration, and aims to solve problems that in the actual use of an existing air conditioner face blowing air pipe, a mixed flow transition section is generally connected to an outlet of an air conditioner box, air blown by an air conditioner is sent to different air outlets in four positions through different branches. Therefore, in the design process, in order to balance air volume distribution, a large amount of design optimization work needs to be conducted on different branch results and pipe type thicknesses, and large design errors always exist when the design target of air volume distribution is achieved. A first face blowing air pipe and a second face blowing air pipe are arranged at the upper end of an air pipe connecting piece, a first side face blowing air pipe is arranged on one side of the second face blowing air pipe, and a second side face blowing air pipe is arranged between the first face blowing air pipe and the second face blowing air pipe. A first side face blowing air pipe opening is formed in one end of the first side face blowing air pipe.

Owner:JIANGLING MOTORS

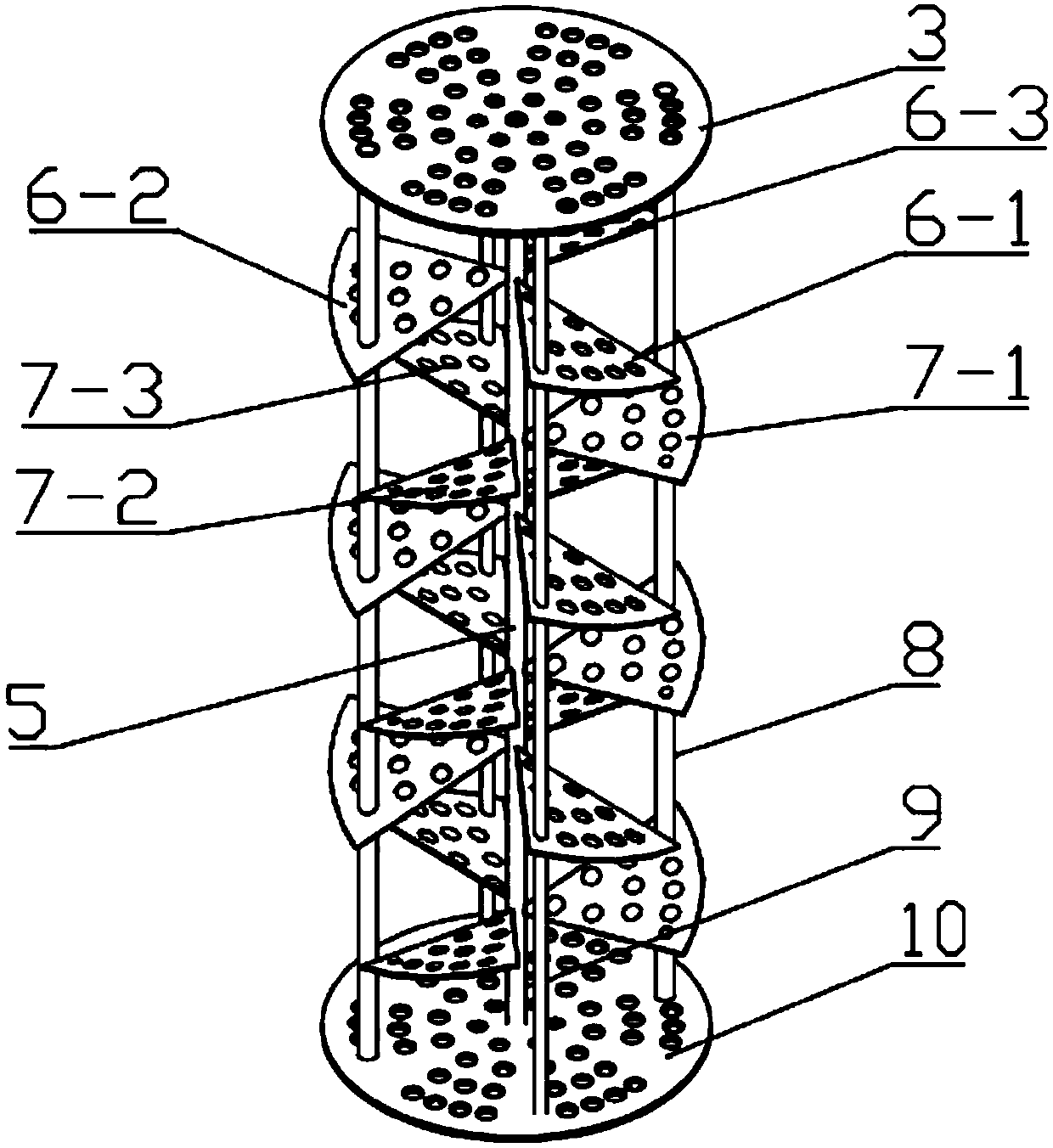

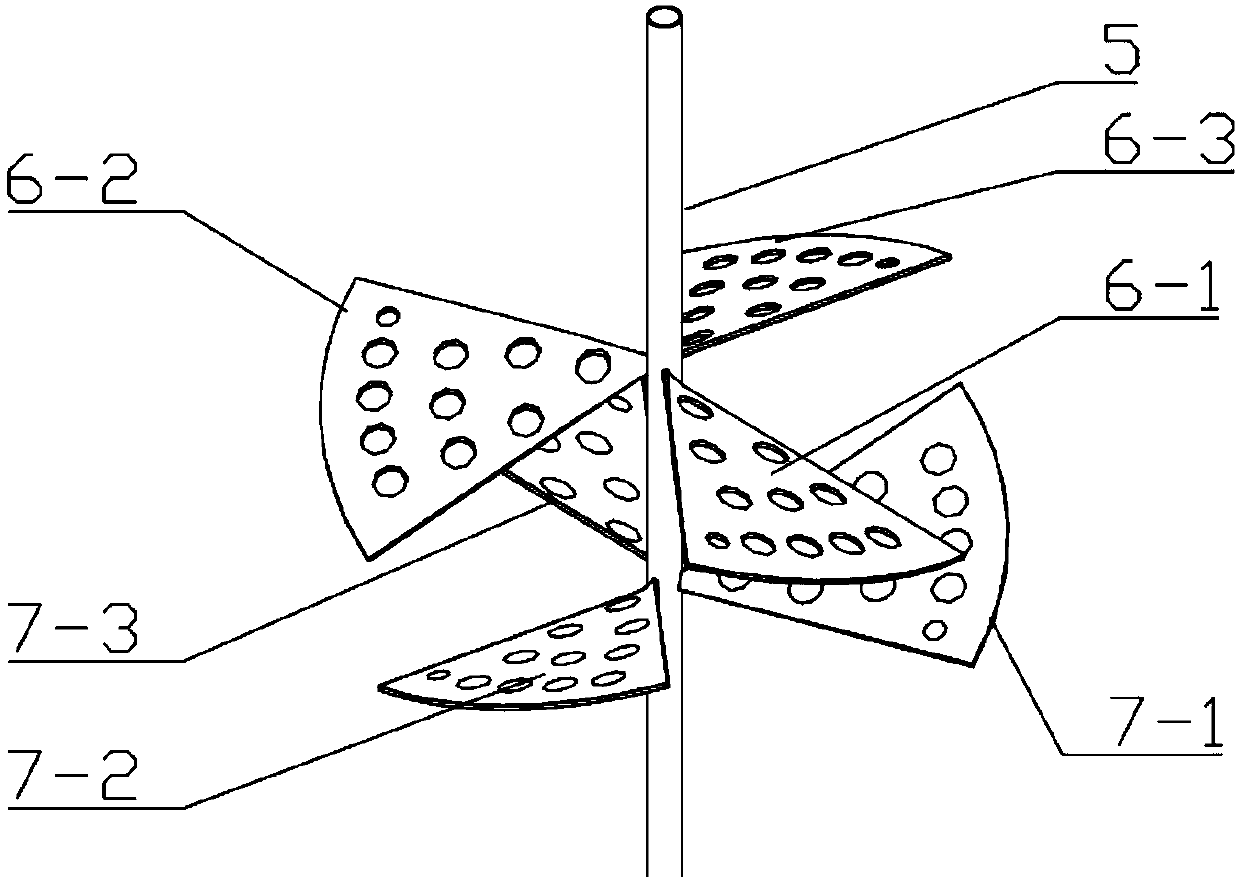

Discontinuous spiral baffle plate heat exchanger for cooling compressed air

PendingCN110906761AEasy to processGuaranteed heat exchange effectHeat exchanger casingsStationary tubular conduit assembliesPlate heat exchangerThermal efficiency

The invention provides a discontinuous spiral baffle plate heat exchanger for cooling compressed air, which can solve the problems that the existing spiral baffle plate heat exchanger has a flow leakage phenomenon, the heat exchange efficiency of a center area is low, and the machining difficulty is large. The heat exchanger comprises a cylindrical outer shell, tube plates are fixedly connected tothe two ends of the outer shell, a tube box is connected to the outer side of the tube plate, a spiral baffle plate and a heat exchange tube bundle are arranged in the outer shell in the axial direction, and the heat exchange tube bundle penetrates through the spiral baffle plate and the tube plate to be communicated with the tube box. The heat exchanger also comprises an inner shell which is coaxially arranged with the outer shell and is cylindrical, the two ends of the inner shell are fixedly connected with the two tube plates respectively, and the diameter ratio of the outer shell to the inner shell is 2:1-5:1; the spiral baffle plate is fixedly arranged between the outer shell and the inner shell, the spiral baffle plate is formed by spirally arranging at least four fan-shaped flat plates, and the edges of the axial projections of every two adjacent fan-shaped flat plates coincide with each other along the outer shell.

Owner:WUXI HAIYUE BIOCHEM EQUIP

Round tube, tube and fin heat exchanger with streamlined variable-amplitude broken-line corrugated fins

ActiveCN104101243BIncrease surface areaImprove heat transfer effectTubular elementsHeat transmissionEngineering

Owner:LANZHOU JIAOTONG UNIV

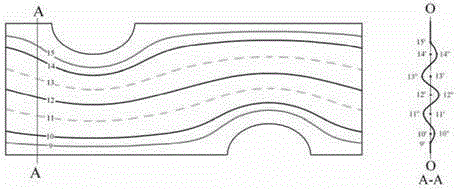

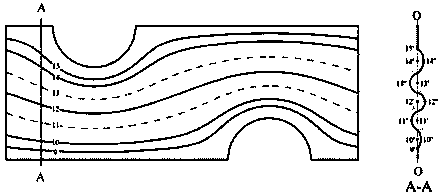

Round tube, tube and fin heat exchanger streamlined variable amplitude circular arc corrugated fins

ActiveCN104110986BIncrease surface areaImprove heat transfer effectTubular elementsLongitudinal waveEngineering

Disclosed is a streamline variable-amplitude arc-shaped wavy fin for round tube fin heat exchanger. According to needs of surfaces of extending fins and fluid flow guiding, streamline convex waves 4 and streamline concave waves 5 with integral cross sections in sine / cosine shapes are formed through extrusion on the fins from an air flow inlet to an outlet. Connection lines of the same wave troughs and wave crests are all streamlines. The streamlines are streamlines which enable backflow at tube ends to be avoided in a direction from the tube axis to central cross section in a side channel of a tube fin heat exchanger plate fin corresponding to the fins 1. The streamline convex waves 4 and the streamline concave waves 5 vary according to a needed waveform 16 along longitudinal wave amplitudes, and the wave amplitudes vary in a mode of a needed waveform 17 enveloping wave troughs and crests. The streamline arc-shaped wavy fin can effectively improve streamline of liquid flow, and reduces flow resistance; the convex / concave waves on the surface of the fin increase surface areas of the fin, therefore, the flow resistance is reduced and heat exchange capability of the fin is improved.

Owner:LANZHOU JIAOTONG UNIV

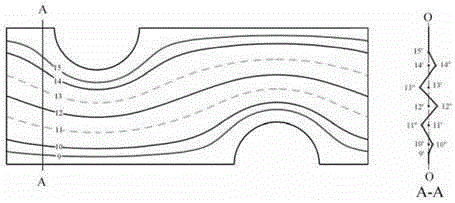

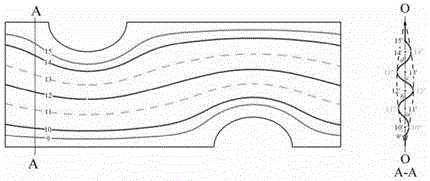

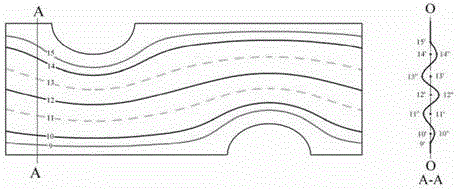

Elliptical tube-and-fin heat exchanger with streamlined variable-amplitude parabolic corrugated fins

ActiveCN104132574BIncrease surface areaImprove heat transfer effectTubular elementsEngineeringBackflow

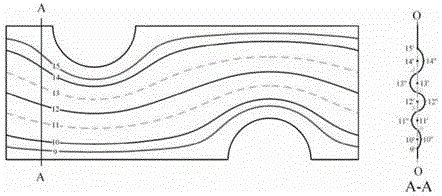

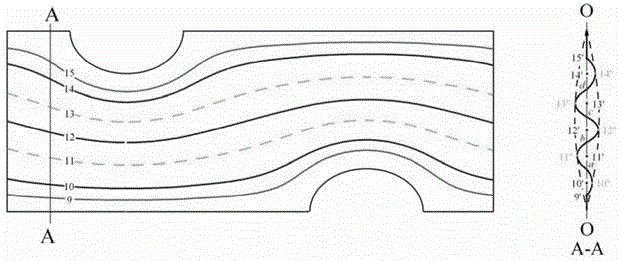

Provided is a streamlined variable amplitude parabolic corrugated fin of an oval tube fin heat exchanger. According to the needs for expanding the surface of the fin and guiding fluid to flow, streamlined convex ripples 4 and streamlined concave ripples 5 are extruded out on the fin from an airflow inlet to an airflow outlet, and the complete cross sections of the convex ripples 4 and the concave ripples 5 are parabolic. The connecting line of the same trough and the connecting line of the same wave peak are streamlines. According to the streamlines, backflow does not happen to a tube tail of a plain fin side channel of the tube fin heat exchanger corresponding to the fin 1 along the tube axial center section. The amplitude of the convex ripples 4 and the concave ripples 5 in the longitudinal direction needs the change of a waveform 14, and the amplitude in the transverse direction needs the change of an envelope ripple trough and peak of a waveform 15. The parabolic streamlined corrugated fin can effectively improve the streamline performance of flowing of fluid, flowing resistance is reduced, the area of the surface of the fin is increased through the convex / concave ripples on the surface of the fin, heat transfer resistance is reduced, and the overall heat exchange capacity of the fin is improved.

Owner:LANZHOU JIAOTONG UNIV

Elliptical tube-and-fin heat exchanger with streamlined variable-amplitude sine/cosine corrugated fins

ActiveCN104154804BIncrease surface areaImprove heat transfer effectHeat transfer modificationEngineeringPlate fin heat exchanger

Disclosed is a streamline variable-amplitude sine-cosine corrugated fin for an elliptical tube and fin heat exchanger. According to the requirements for expanding the surface of a fin and guiding flowing of fluid, from an air inlet to an air outlet, complete streamline convex corrugations 4 and concave corrugations 5, each which has a sine-cosine cross section, are made on the fin by stamping; a line of same trough and peak is a streamline, which allows no reflow to occur to the tail, which the fin 1 corresponds to, of a flat-fin side passage of the tube and fin heat exchanger along the tube axial center section. The longitudinal amplitude of the convex corrugations 4 and that of the concave corrugations 5 change in a moderate waveform 16; the transverse amplitudes change in a moderate waveform 17, including corrugation troughs and peaks. The streamline variable-amplitude sine-cosine corrugated fin has the advantages that flow streamline form of the fluid can be effectively improved, flow resistance is reduced, the surface convex / concave corrugations of the fin allow large fin surface area, heat transfer resistance is reduced, and heat exchange capability of the fin is improved.

Owner:LANZHOU JIAOTONG UNIV

Streamline variable-amplitude arc-shaped wavy fin for round tube fin heat exchanger

ActiveCN104110986AImprove heat transfer effectReduce flow pressure lossTubular elementsLongitudinal waveEngineering

Disclosed is a streamline variable-amplitude arc-shaped wavy fin for round tube fin heat exchanger. According to needs of surfaces of extending fins and fluid flow guiding, streamline convex waves 4 and streamline concave waves 5 with integral cross sections in sine / cosine shapes are formed through extrusion on the fins from an air flow inlet to an outlet. Connection lines of the same wave troughs and wave crests are all streamlines. The streamlines are streamlines which enable backflow at tube ends to be avoided in a direction from the tube axis to central cross section in a side channel of a tube fin heat exchanger plate fin corresponding to the fins 1. The streamline convex waves 4 and the streamline concave waves 5 vary according to a needed waveform 16 along longitudinal wave amplitudes, and the wave amplitudes vary in a mode of a needed waveform 17 enveloping wave troughs and crests. The streamline arc-shaped wavy fin can effectively improve streamline of liquid flow, and reduces flow resistance; the convex / concave waves on the surface of the fin increase surface areas of the fin, therefore, the flow resistance is reduced and heat exchange capability of the fin is improved.

Owner:LANZHOU JIAOTONG UNIV

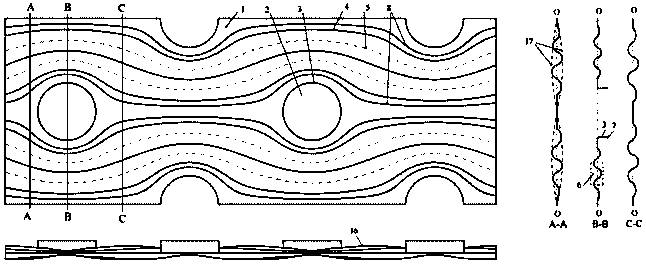

Round tube, tube and fin heat exchanger with streamlined variable amplitude corrugated fins

ActiveCN104110990BIncrease surface areaImprove heat transfer effectTubular elementsWall shearEngineering

Disclosed is a streamline variable-amplitude wavy fin for a round tube fin heat exchanger. Streamline convex waves 4 and streamline concave waves 5 which are arranged in a convex-concave interval mode are continuously stamped on fins 1 from an air flow inlet to an outlet according to streamline trends. Connection lines of the same wave troughs and wave crests are all streamlines. Wave amplitudes vary according to the needed waveform in a longitudinal direction. The amplitudes of transverse different waves vary in a mode of a needed waveform enveloping wave troughs and crests. The largest amplitude of convex waves 4 and concave waves 5 is 0.1-0.9 time the interval of the fins. The cross sections of the waves can be of any needed shape. The streamlines are streamlines which enable backflow at tube ends to be avoided in a direction from the tube axis to central cross section in a side channel of a tube fin heat exchanger plate fin corresponding to the fins 1. When liquid flows between the streamline wavy fins, part of the liquid flows in streamline channels formed by the convex waves and the concave waves, transverse changes and changes along the streamlines of the wave amplitudes reduce wall shear stress of flowing and pressure loss of flowing can be evidently reduced.

Owner:LANZHOU JIAOTONG UNIV

Round tube, tube and fin heat exchanger with streamlined variable amplitude parabolic corrugated fins

ActiveCN104142085BIncrease surface areaImprove heat transfer effectLaminated elementsTubular elementsLongitudinal waveWave shape

The invention discloses a streamline type variable wave amplitude parabolic corrugated fin of a circular tube fin type heat exchanger. Integral streamline type convex ripples 4 with the parabolic cross sections and integral streamline type concave ripples 5 with the parabolic cross sections are extruded on the fin from an airflow inlet to an outlet according to the needs of fin surface expanding and fluid flowing guiding. The same trough and wave crest connecting line is a streamline in which backflow does not occur on a pipe tail of a tube fin type heat exchanger plain film fin side channel corresponding to the fin 1 along the pipe axial center cross section. The convex ripples 4 and the concave ripples 5 change with an appropriate waveform 16 along the longitudinal wave amplitude, and the wave amplitude envelopes corrugated trough and wave crest change in the transverse direction with an appropriate waveform 17. According to the parabolic streamline type corrugated fin, the flowing streamline of the fluid can be effectively improved, flowing resistance is reduced, the surface area of the fin is increased through the convex / concave ripples on the surface of the fin, the heat transfer resistance is reduced, and the overall heat exchanging capacity of the fin is improved.

Owner:LANZHOU JIAOTONG UNIV

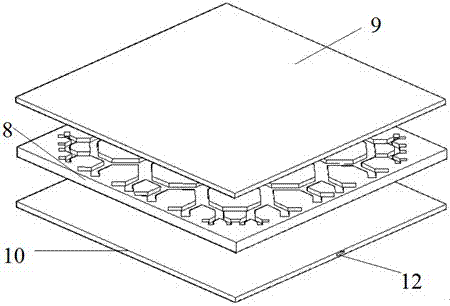

A deformation-resistant and pressure-resistant equal temperature plate

ActiveCN105280583BEnhanced resistance to deformation and pressure resistanceExtend your lifeSemiconductor/solid-state device detailsSolid-state devicesFractional Brownian motionInlet channel

Owner:安徽瀚程机械制造有限公司

Diffusion end cover and motor

PendingCN114389398AUniform cooling effectImprove uniformityMagnetic circuit stationary partsCooling/ventillation arrangementElectric machineCooling effect

The invention discloses a diffusion end cover which is used for being in fixed butt joint with a motor stator shell, a disc-shaped airflow channel is formed between the end face of an inner cover body and the end face of an outer cover body, the disc-shaped airflow channel is of a disc-shaped cavity structure, and the disc-shaped airflow channel provides diffusion space for inflow airflow. Airflow flowing in from the air inlet can enter the disc-shaped airflow channel, move in the circumferential direction and uniformly flow to all the ventilation holes, the internal airflow space is increased through the disc-shaped airflow channel, the static pressure of the airflow flowing into the disc-shaped airflow channel from the air inlet is increased, the flowing speed of a medium in the circumferential direction is effectively reduced, and the efficiency is improved. Meanwhile, the flow pressure loss is reduced, the flow resistance is reduced, and the cooling effect of each position in the circumferential direction of the motor is uniform and consistent. The motor provided by the invention can realize the same technical effect.

Owner:湖南中车尚驱电气有限公司

Streamline variable-amplitude wavy fin for round tube fin heat exchanger

ActiveCN104110990AIncrease surface areaImprove heat transfer effectTubular elementsWall shearWave shape

Disclosed is a streamline variable-amplitude wavy fin for a round tube fin heat exchanger. Streamline convex waves 4 and streamline concave waves 5 which are arranged in a convex-concave interval mode are continuously stamped on fins 1 from an air flow inlet to an outlet according to streamline trends. Connection lines of the same wave troughs and wave crests are all streamlines. Wave amplitudes vary according to the needed waveform in a longitudinal direction. The amplitudes of transverse different waves vary in a mode of a needed waveform enveloping wave troughs and crests. The largest amplitude of convex waves 4 and concave waves 5 is 0.1-0.9 time the interval of the fins. The cross sections of the waves can be of any needed shape. The streamlines are streamlines which enable backflow at tube ends to be avoided in a direction from the tube axis to central cross section in a side channel of a tube fin heat exchanger plate fin corresponding to the fins 1. When liquid flows between the streamline wavy fins, part of the liquid flows in streamline channels formed by the convex waves and the concave waves, transverse changes and changes along the streamlines of the wave amplitudes reduce wall shear stress of flowing and pressure loss of flowing can be evidently reduced.

Owner:LANZHOU JIAOTONG UNIV

Streamline variable-amplitude sine-cosine corrugated fin for elliptical tube and fin heat exchanger

ActiveCN104154804AImprove heat transfer effectReduce flow pressure lossHeat transfer modificationEngineeringHeat exchanger

Disclosed is a streamline variable-amplitude sine-cosine corrugated fin for an elliptical tube and fin heat exchanger. According to the requirements for expanding the surface of a fin and guiding flowing of fluid, from an air inlet to an air outlet, complete streamline convex corrugations 4 and concave corrugations 5, each which has a sine-cosine cross section, are made on the fin by stamping; a line of same trough and peak is a streamline, which allows no reflow to occur to the tail, which the fin 1 corresponds to, of a flat-fin side passage of the tube and fin heat exchanger along the tube axial center section. The longitudinal amplitude of the convex corrugations 4 and that of the concave corrugations 5 change in a moderate waveform 16; the transverse amplitudes change in a moderate waveform 17, including corrugation troughs and peaks. The streamline variable-amplitude sine-cosine corrugated fin has the advantages that flow streamline form of the fluid can be effectively improved, flow resistance is reduced, the surface convex / concave corrugations of the fin allow large fin surface area, heat transfer resistance is reduced, and heat exchange capability of the fin is improved.

Owner:LANZHOU JIAOTONG UNIV

Air source device and portable breathing machine

PendingCN114776610AReduce noisePromote the development of miniaturizationRespiratorsPump componentsElectric machineryEngineering

The invention discloses an air source device and a portable breathing machine, an air source assembly comprises a shell assembly and a motor assembly arranged in the shell assembly, an impeller assembly is fixedly installed at the output end of the motor assembly, an air duct assembly is arranged between the impeller assembly and the motor assembly, the air duct assembly is coaxially and fixedly installed on the motor assembly, and the air duct assembly is fixedly installed on the shell assembly. A gap is formed between the impeller and the impeller assembly; a first airflow channel and a second airflow channel which communicate with the impeller assembly are formed between the air duct assembly and the shell assembly, and an inlet of the first airflow channel and an outlet of the second airflow channel are distributed in the circumferential direction of the air duct assembly. The shell assembly is provided with an air source inlet and an air source outlet which are communicated with an inlet of the first airflow channel and an outlet of the second airflow channel respectively. The internal structure is highly integrated, miniaturization development of breathing machine equipment is better facilitated, meanwhile, through structural optimization, the air inlet direction and the air outlet direction are located on the same plane, and meanwhile air duct noise is greatly reduced.

Owner:杭州贝丰科技股份有限公司 +1

Streamlined variable amplitude parabolic corrugated fin of oval tube fin heat exchanger

ActiveCN104132574AImprove heat transfer effectReduce flow pressure lossTubular elementsEngineeringPlate fin heat exchanger

Provided is a streamlined variable amplitude parabolic corrugated fin of an oval tube fin heat exchanger. According to the needs for expanding the surface of the fin and guiding fluid to flow, streamlined convex ripples 4 and streamlined concave ripples 5 are extruded out on the fin from an airflow inlet to an airflow outlet, and the complete cross sections of the convex ripples 4 and the concave ripples 5 are parabolic. The connecting line of the same trough and the connecting line of the same wave peak are streamlines. According to the streamlines, backflow does not happen to a tube tail of a plain fin side channel of the tube fin heat exchanger corresponding to the fin 1 along the tube axial center section. The amplitude of the convex ripples 4 and the concave ripples 5 in the longitudinal direction needs the change of a waveform 14, and the amplitude in the transverse direction needs the change of an envelope ripple trough and peak of a waveform 15. The parabolic streamlined corrugated fin can effectively improve the streamline performance of flowing of fluid, flowing resistance is reduced, the area of the surface of the fin is increased through the convex / concave ripples on the surface of the fin, heat transfer resistance is reduced, and the overall heat exchange capacity of the fin is improved.

Owner:LANZHOU JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com