Flue structure for SNCR (selective non-catalytic reduction) denitration of flue gas of pulverized coal boiler and heating of sludge drying heat-conducting oil

A technology for sludge drying and pulverized coal boilers, which is used in dewatering/drying/concentrating sludge treatment, heat storage heaters, fluid heaters, etc. The problems of high cost and high construction cost can achieve the effect of simplifying the heat transfer oil heating system, improving economic and social benefits, and reducing the concentration of NOx.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

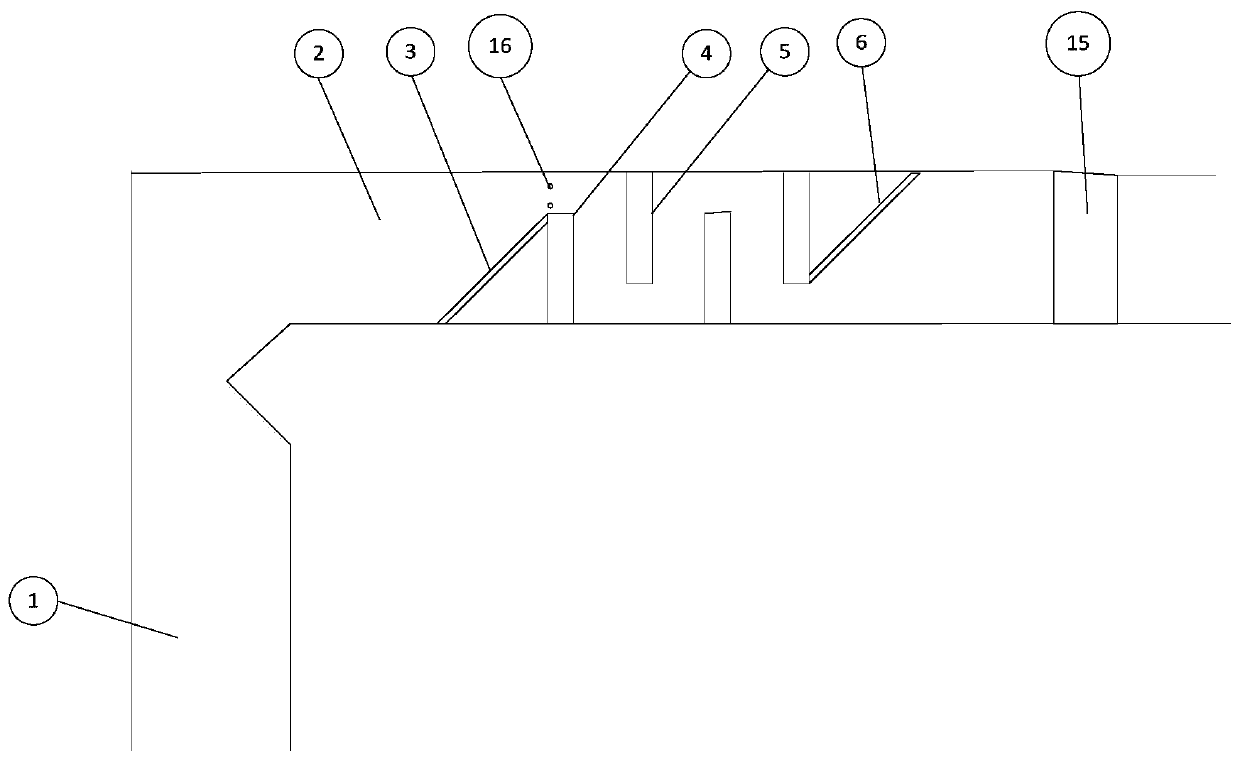

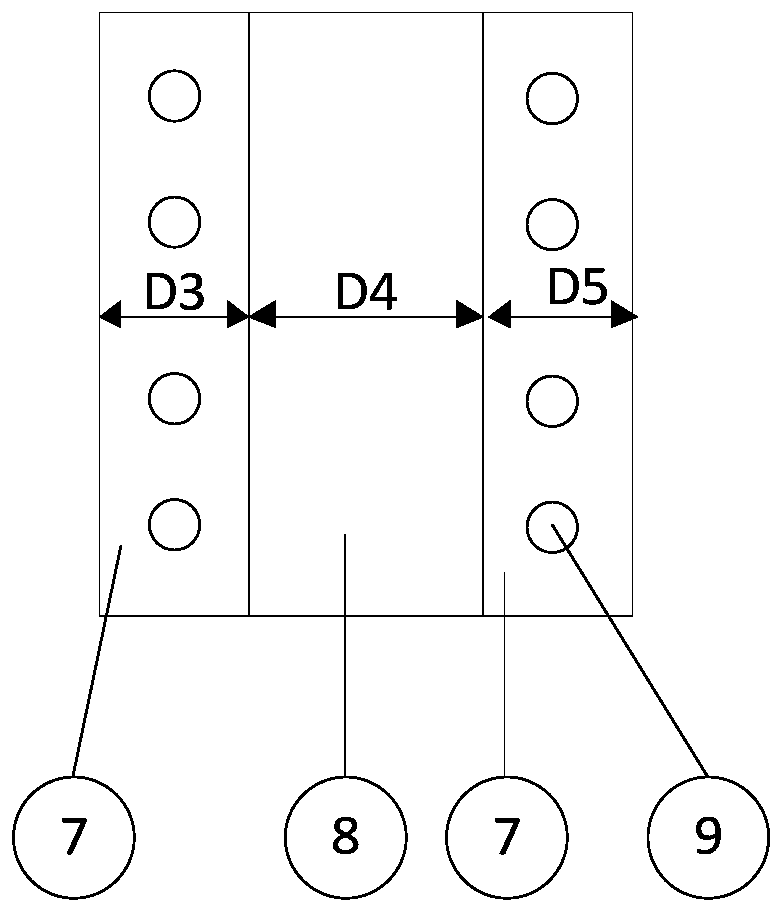

[0024] Such as Figure 1 to Figure 5 As shown, the present invention provides a flue structure for pulverized coal boiler flue gas SNCR denitration and heating sludge drying heat transfer oil, including pulverized coal boiler 1, flue 2, first inclined baffle plate 3, first Baffle 4, second baffle 5, second inclined baffle 6, refractory and wear-resistant material 7, heat-resistant steel plate structure 8, heat transfer oil heater pipe 9, control valve 10, heat transfer oil inlet header 11, heat conduction Oil outlet header 12, circulating pump 13, sludge dryer 14, SCR device 15 and spray gun 16, wherein the flue gas outlet of pulverized coal boiler 1 is connected to flue 2, and the flue gas outlet of said flue 2 is connected to There is a flue gas inlet for the SCR device 15 .

[0025] In the inner cavity of the flue 2, a first inclined baffle 3, a pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com