Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Reduce face pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

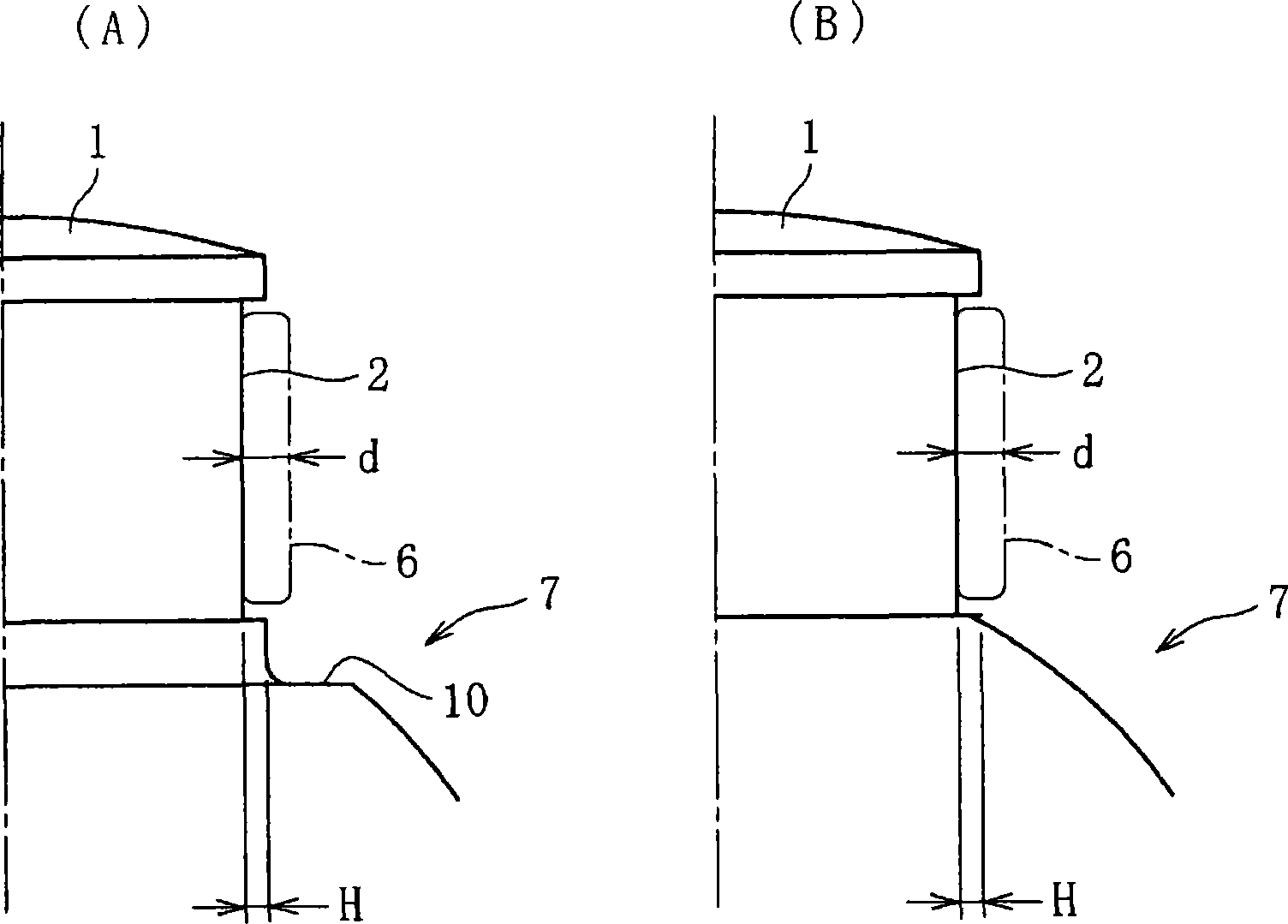

Metallic package

ActiveCN101148208ALarge rotation angleSeal Break PreventionCapsClosure capsEngineeringMechanical engineering

Owner:JAPAN CROWN CORK CO LTD

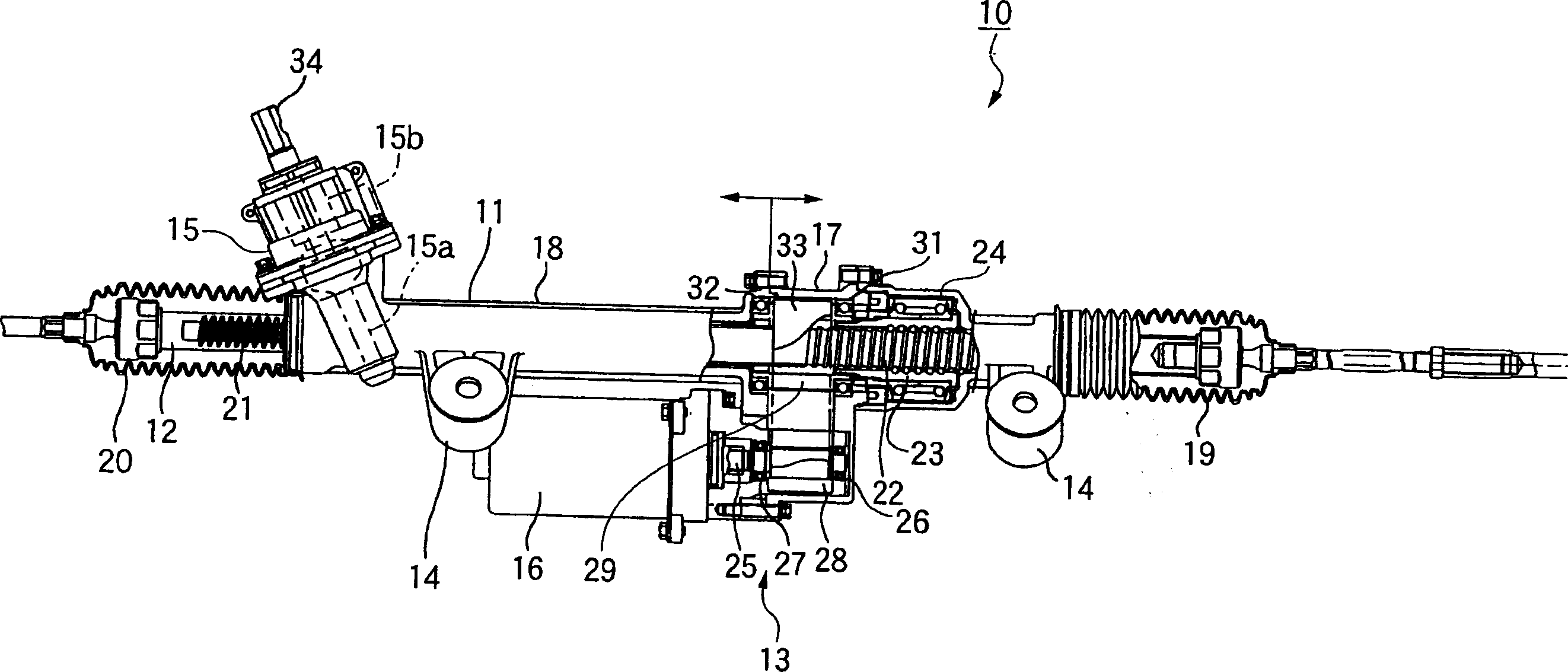

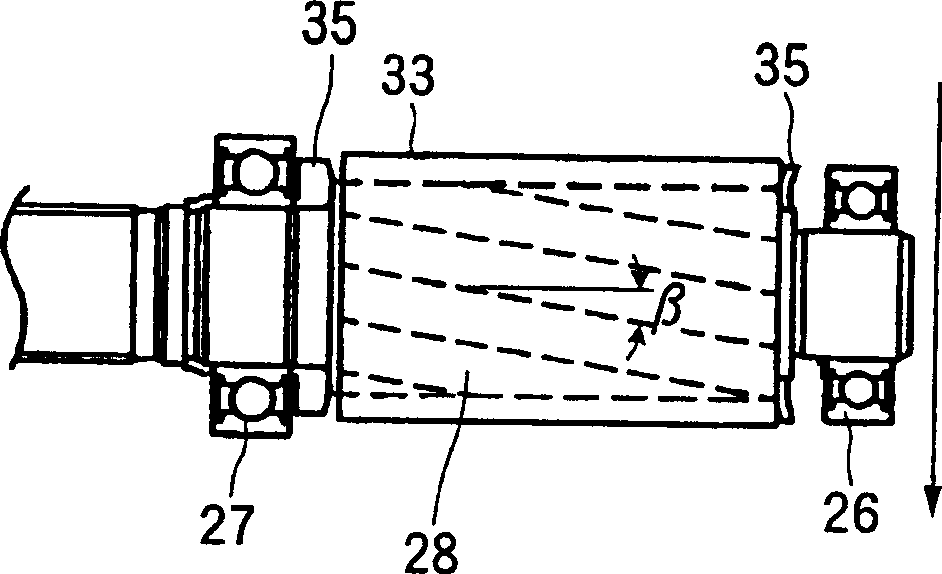

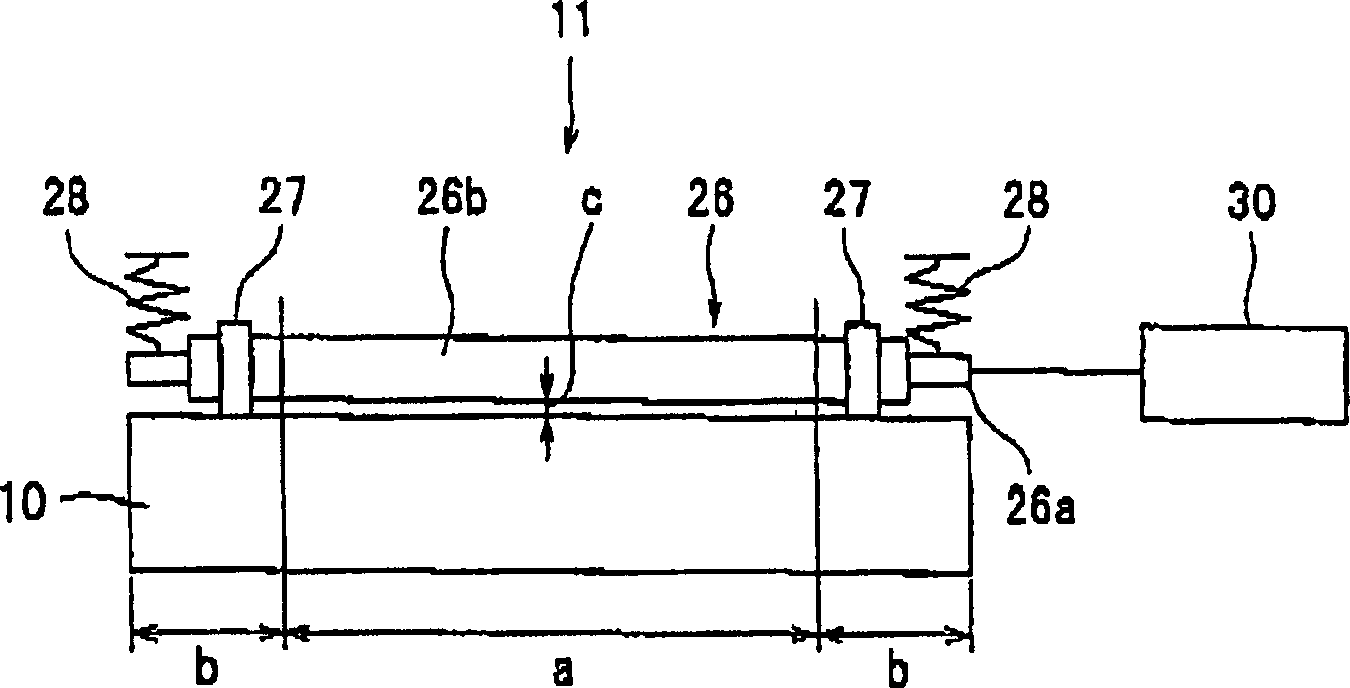

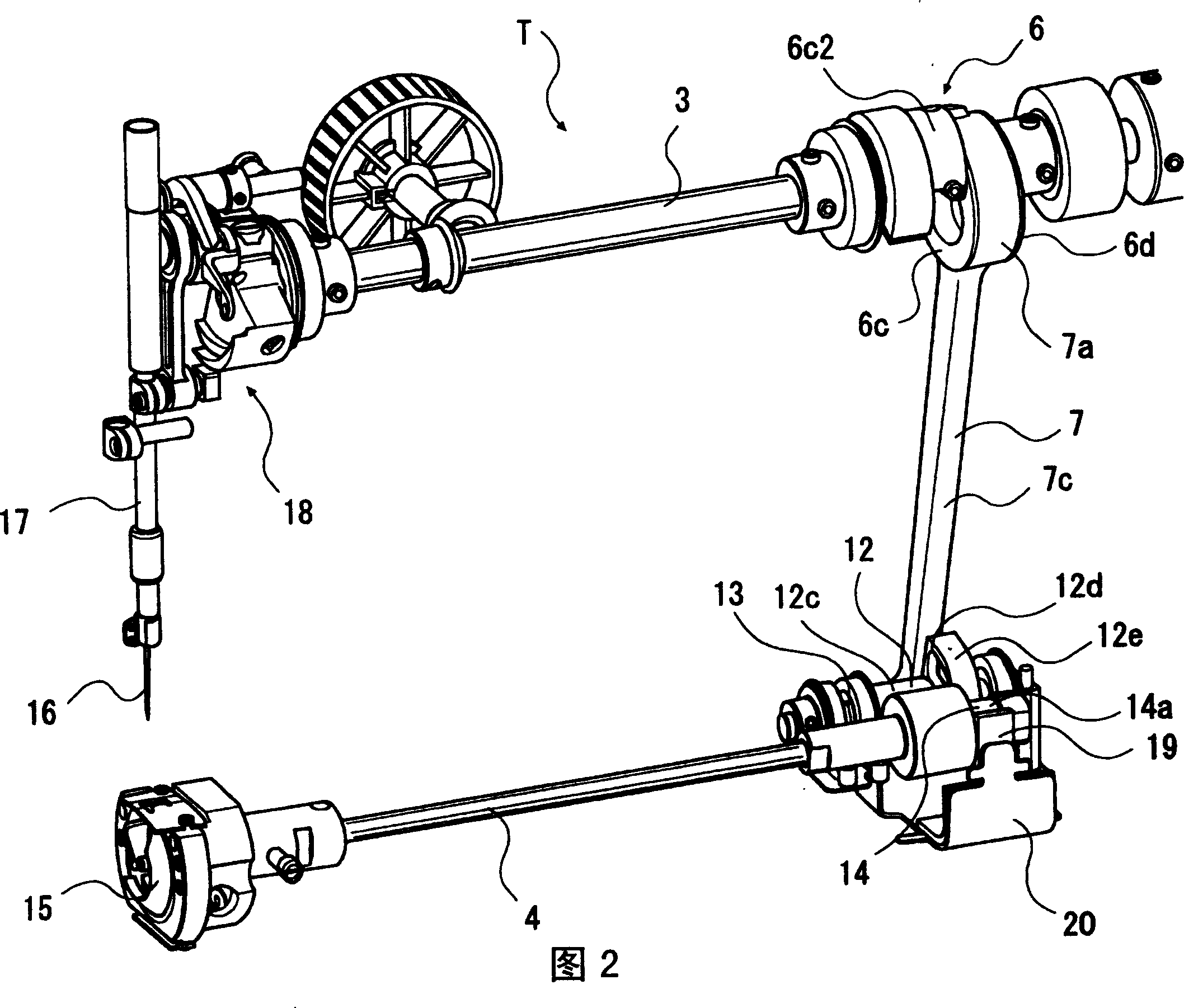

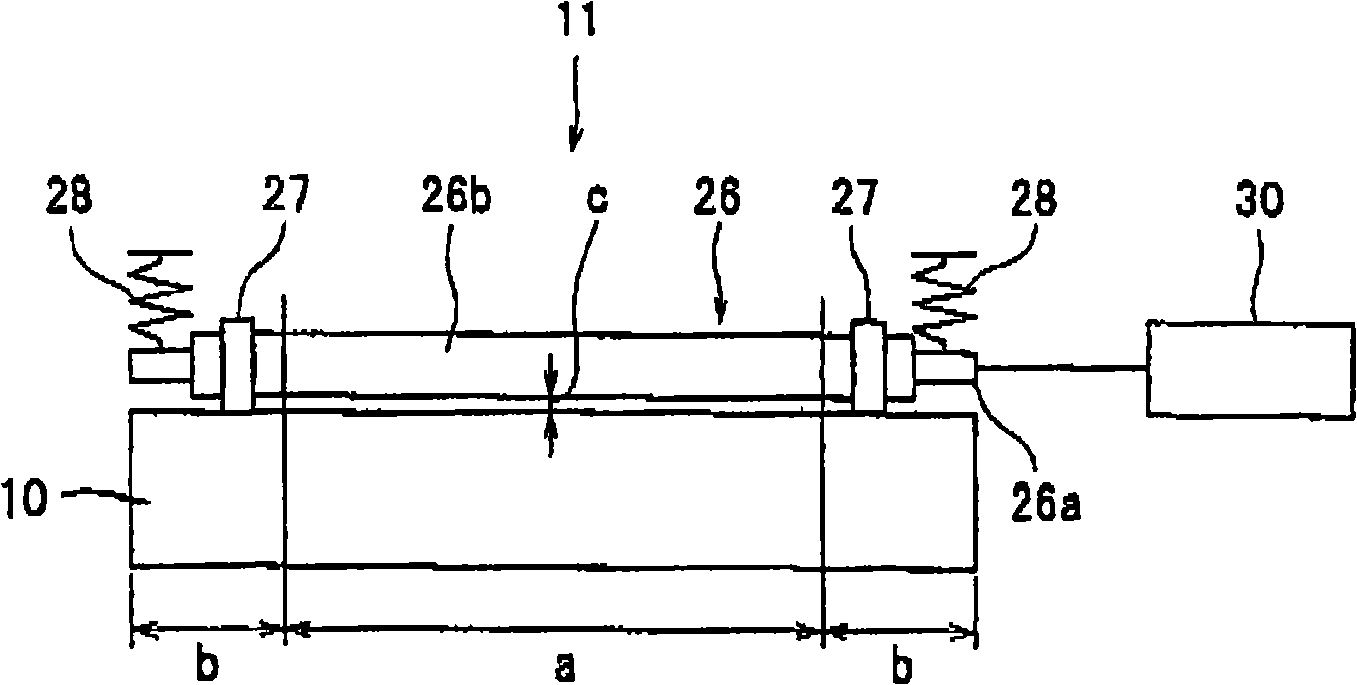

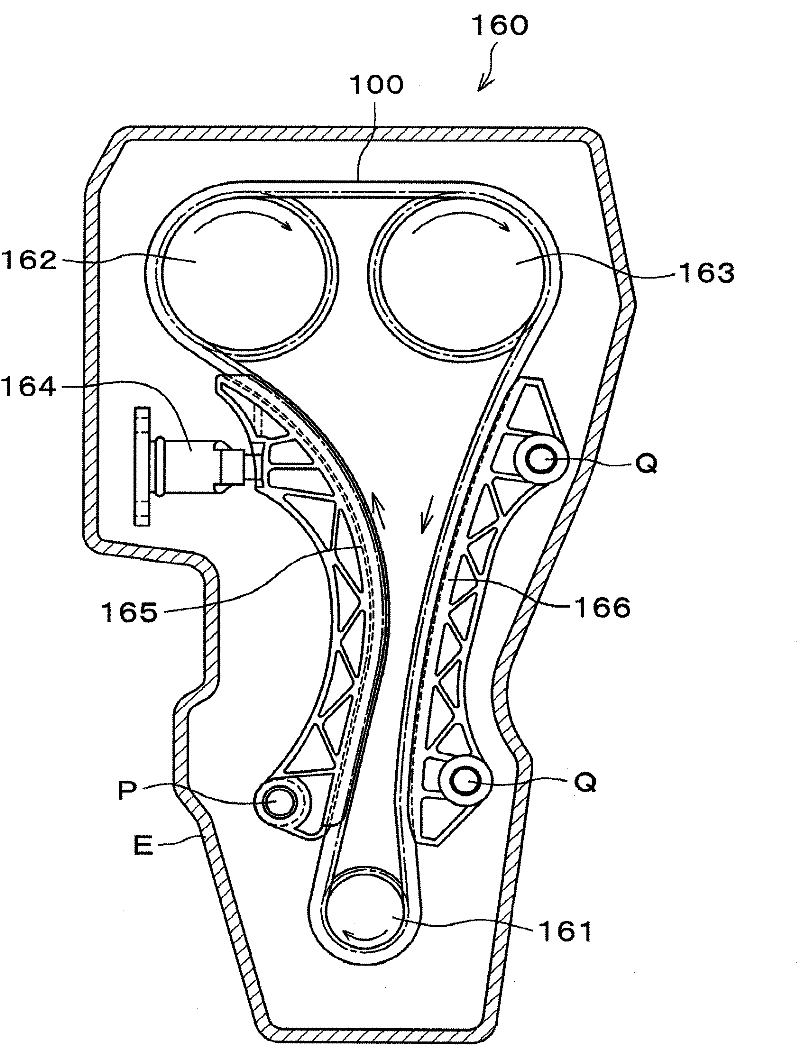

Belt speed reducer for electric power steering device and electric power steering device

InactiveCN1784332AReduce fricative noiseReduce face pressureElectrical steeringPower steeringEngineering

A belt deceleration device for an electric power steering device, comprising: a driving pulley with a first helical tooth, a driven pulley with a second helical tooth, a driving belt with a third helical tooth, at the twist angle of each helical tooth Between β and the coefficient of friction μ between the first or second helical teeth and the third helical teeth, a relationship of tan β<μ is maintained. In addition, in the electric power steering device, the backlash adjustment between the gears meshing in the speed reduction device, or the adjustment of the belt tension of the speed reduction device is performed.

Owner:NSK LTD +1

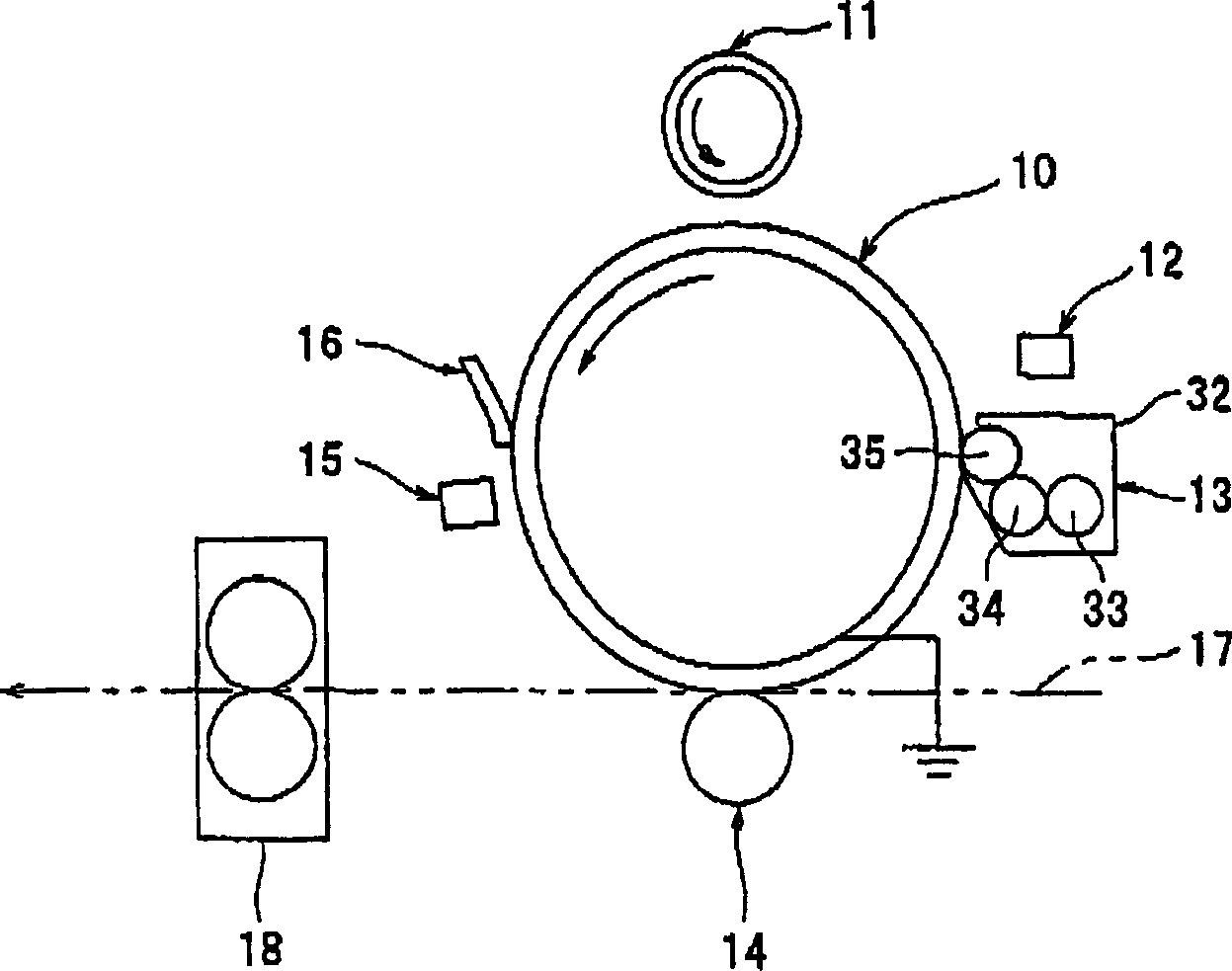

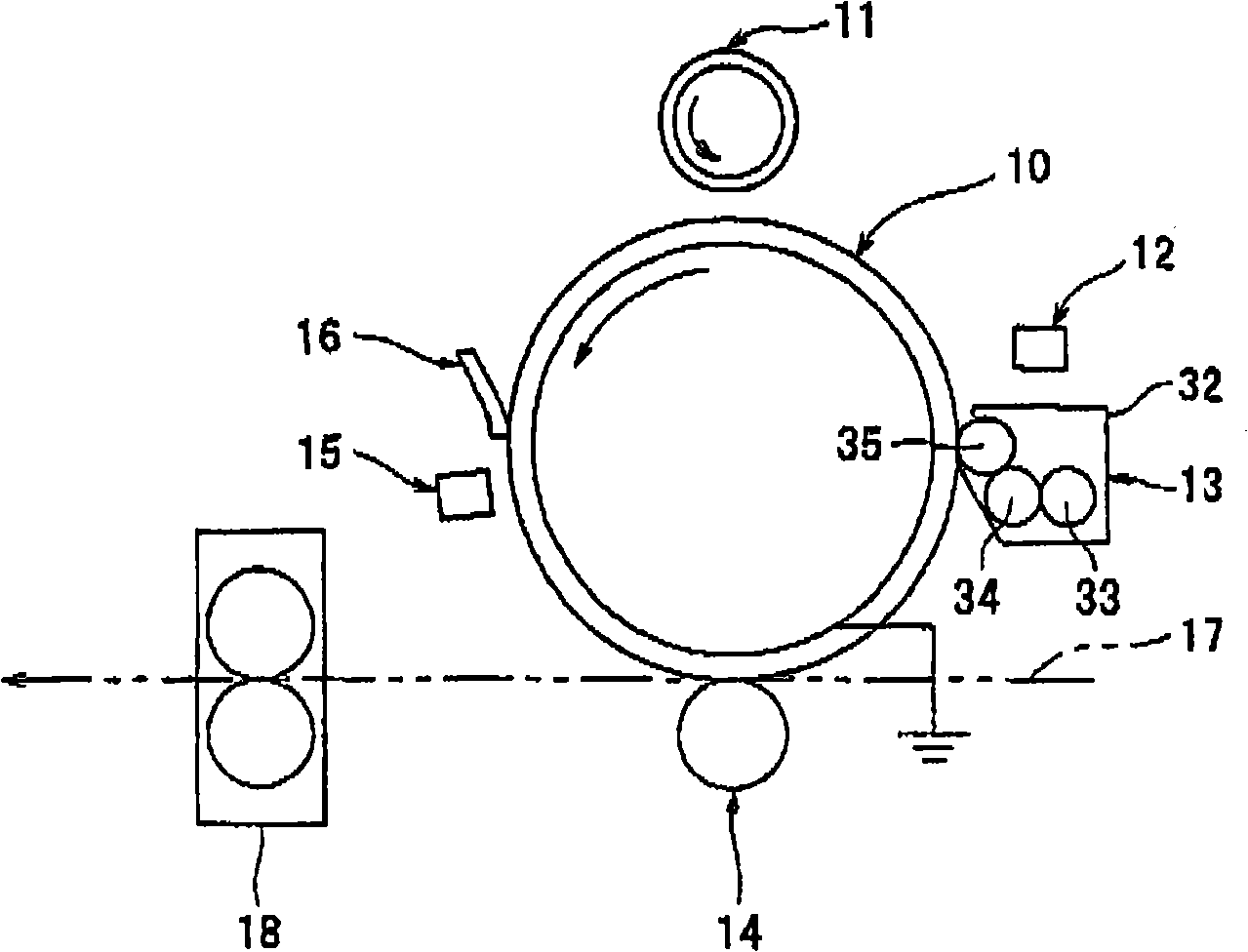

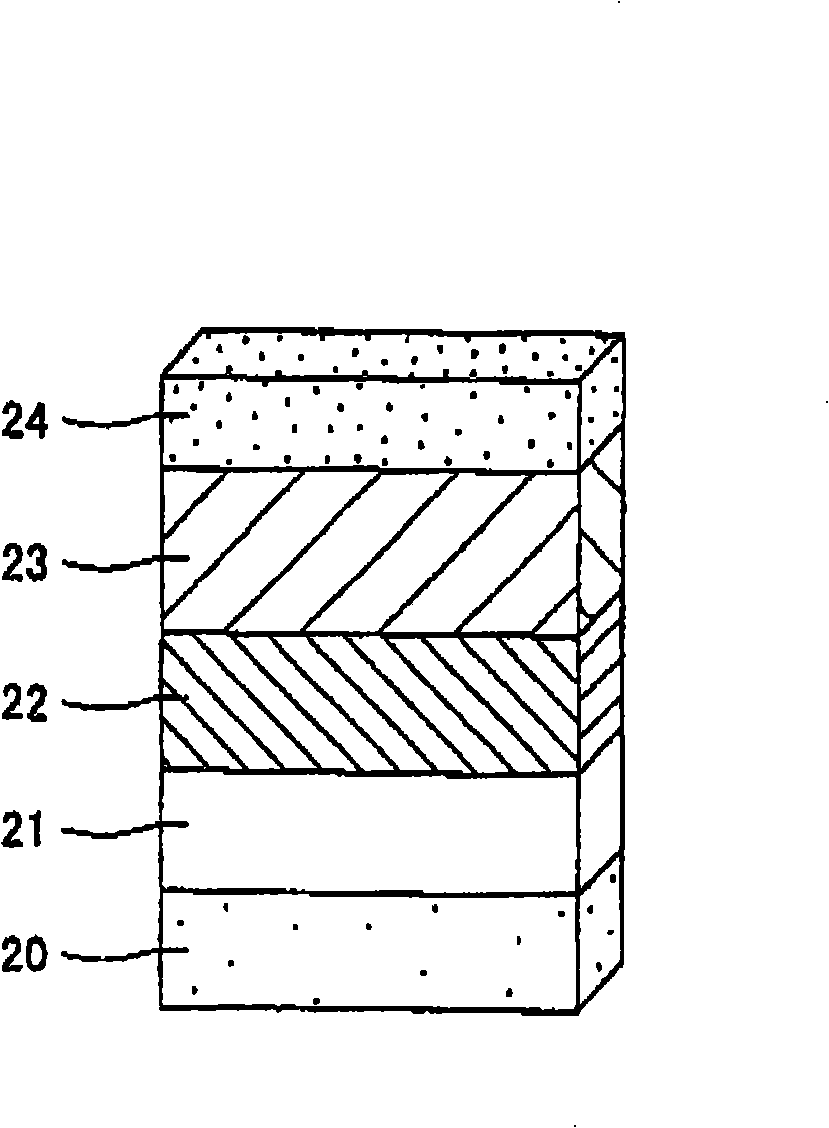

Cleaning device, process cartridge, and image forming apparatus

ActiveCN1770041ANo reduction in contact widthIncrease line pressureElectrography/magnetographyBand shapeImage formation

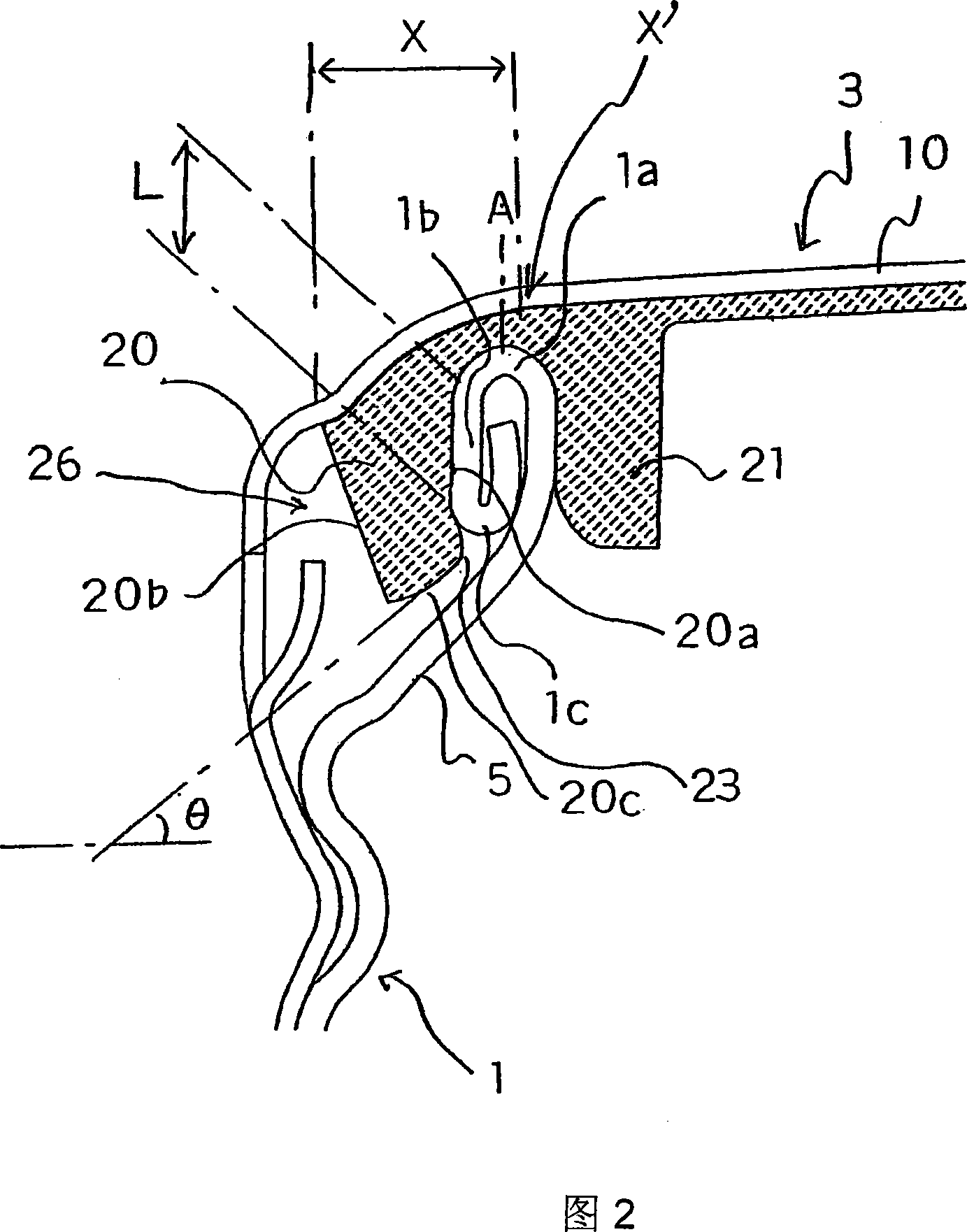

In cleaning devices, process cartridges and image forming devices, a cleaning structure with low linear pressure and high surface pressure can be obtained by specifying the material, shape and support structure of the cleaning blade. Press the front end corners of the elastic cleaning blade (38) supported by the so-called sheet holder, that is, the supporting member (37), on the roller-shaped and belt-shaped image carrier (10), and remove the residue remaining on the image carrier after image transfer. body toner. In such a cleaning device (16), the angle (θ) forming the front end corner line portion (36) of the cleaning blade is formed as an obtuse angle, and the front end corner line portion is formed at a surface pressure greater than or equal to 2.0 g / mm2. Press on the image carrier. The so-called surface pressure refers to the value obtained by dividing the total load applied to the cleaning blade by the contact area of the cleaning blade with respect to the member to be cleaned.

Owner:RICOH KK

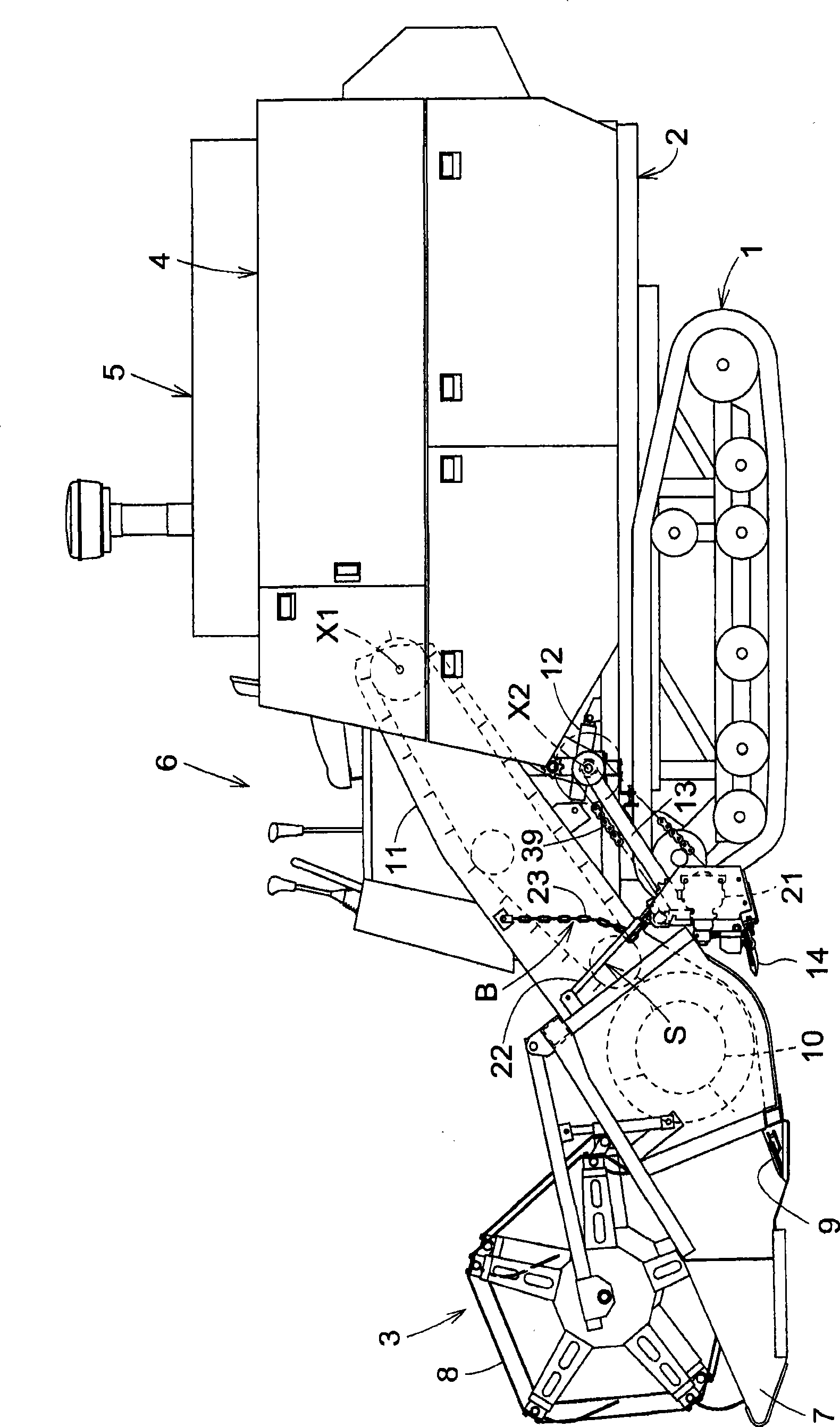

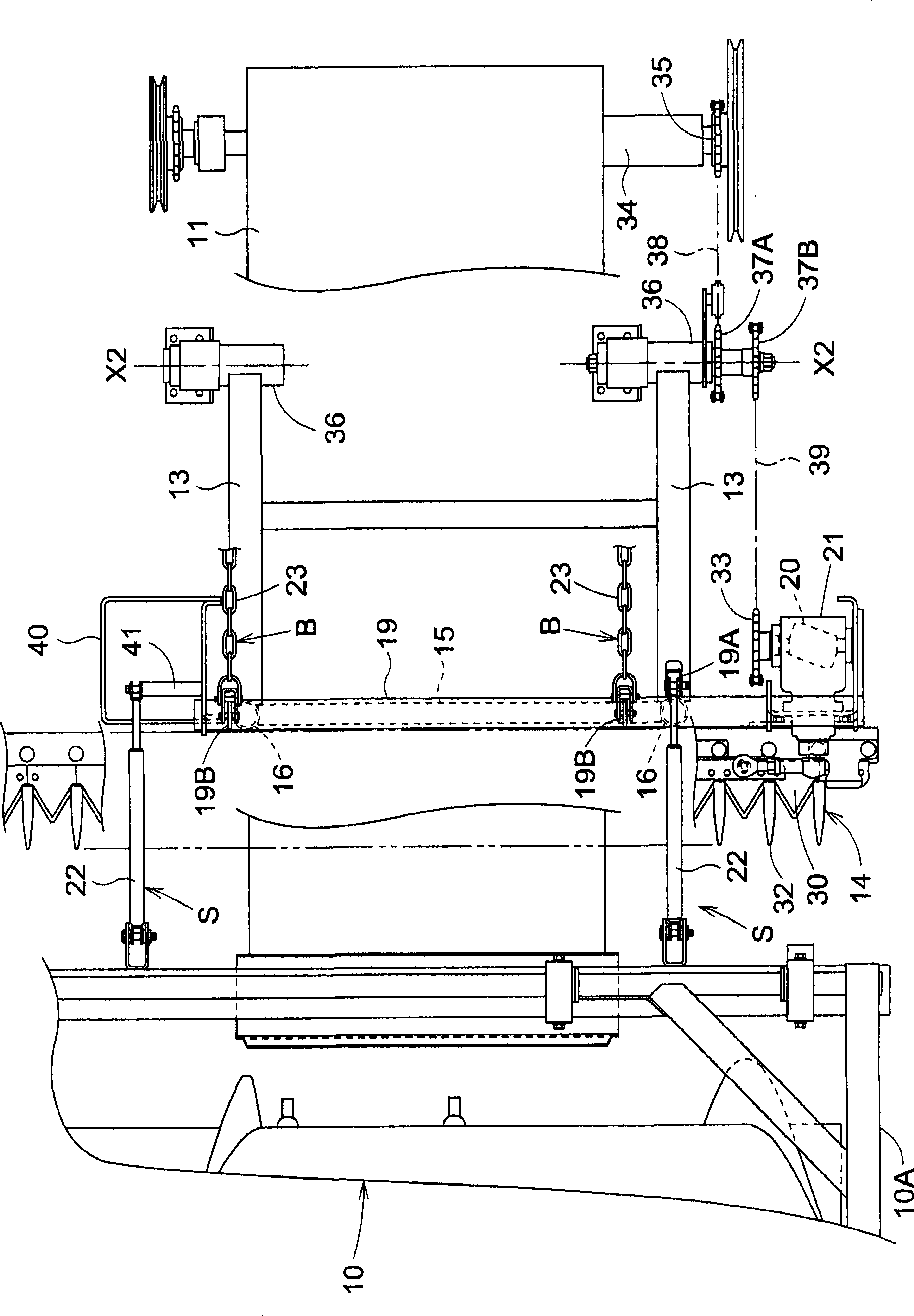

Combine harvester

ActiveCN101507387AAchieve simplicityReduced parts countMowersAgricultural undercarriagesPre treatmentCombine harvester

The invention provides a reaping pre-treatment configuration of combine harvester capable of maintaining the good degree of reaping work of the main and assistant cutting devices and causing the strain height of the remained strains to be accordant by improving the assistant cutting device. An assistant cutting device (14) acting for the vertical straws on the position lower than the main cutting device (9) for reaping the vertical straws is provided. The assistant cutting device (14) is freely supported by a lifting frame (13). The assistant cutting device (14) and the main cutting device (13) are formed that, under the situation of cutting the height adjustment and operating the work, the assistant cutting device (14) is maintained at the state of free of linking with the lifting action of the main cutting device (9), during rotating, the assistant cutting device (14) is linked with the lifting action of the main cutting device (9).

Owner:KUBOTA LTD

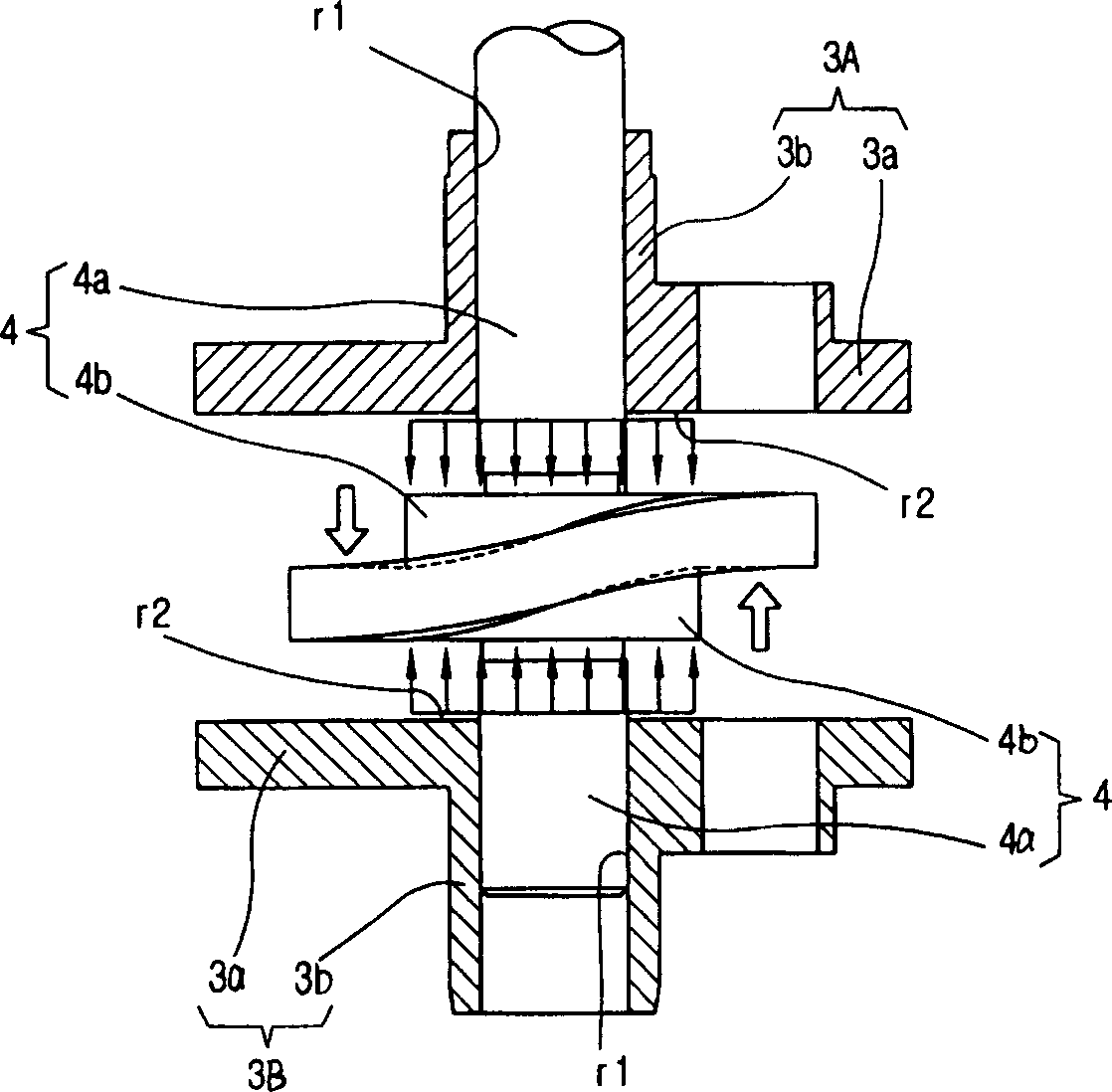

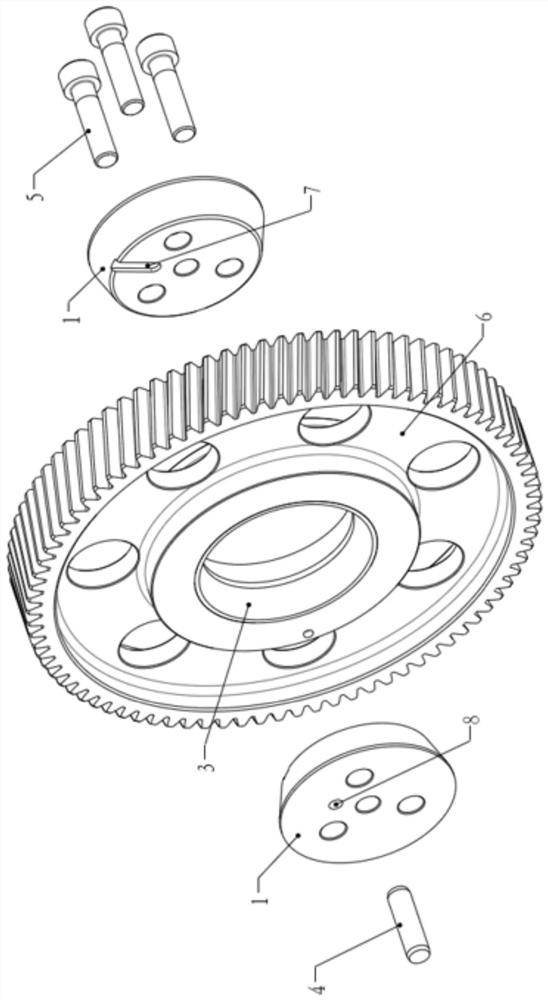

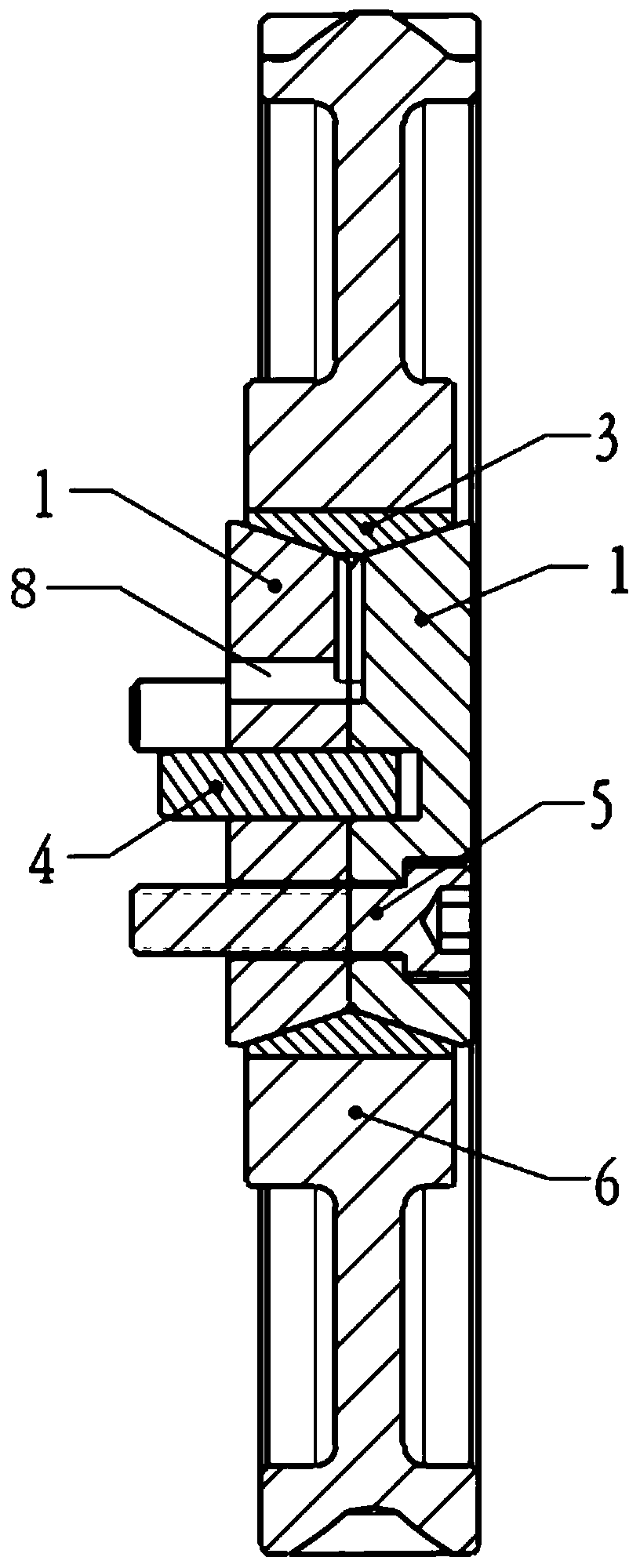

Power transmission mechanism of sewing machine

InactiveCN1521297AAchieve lightweightReduce face pressureLubrication/cooling devicesSewing-machine control devicesGear wheelEngineering

In the power transmission mechanism T of a sewing machine provided with a crank rod, a first gear and a second gear for dynamically connecting an upper shaft for vertically moving a sewing needle 16 and a lower shaft for swinging a shuttle, a grease holding member impregnated with grease is brought into contact with at least one of the first gear and the second gear and the grease is applied to the respective gear.

Owner:JUKI CORP

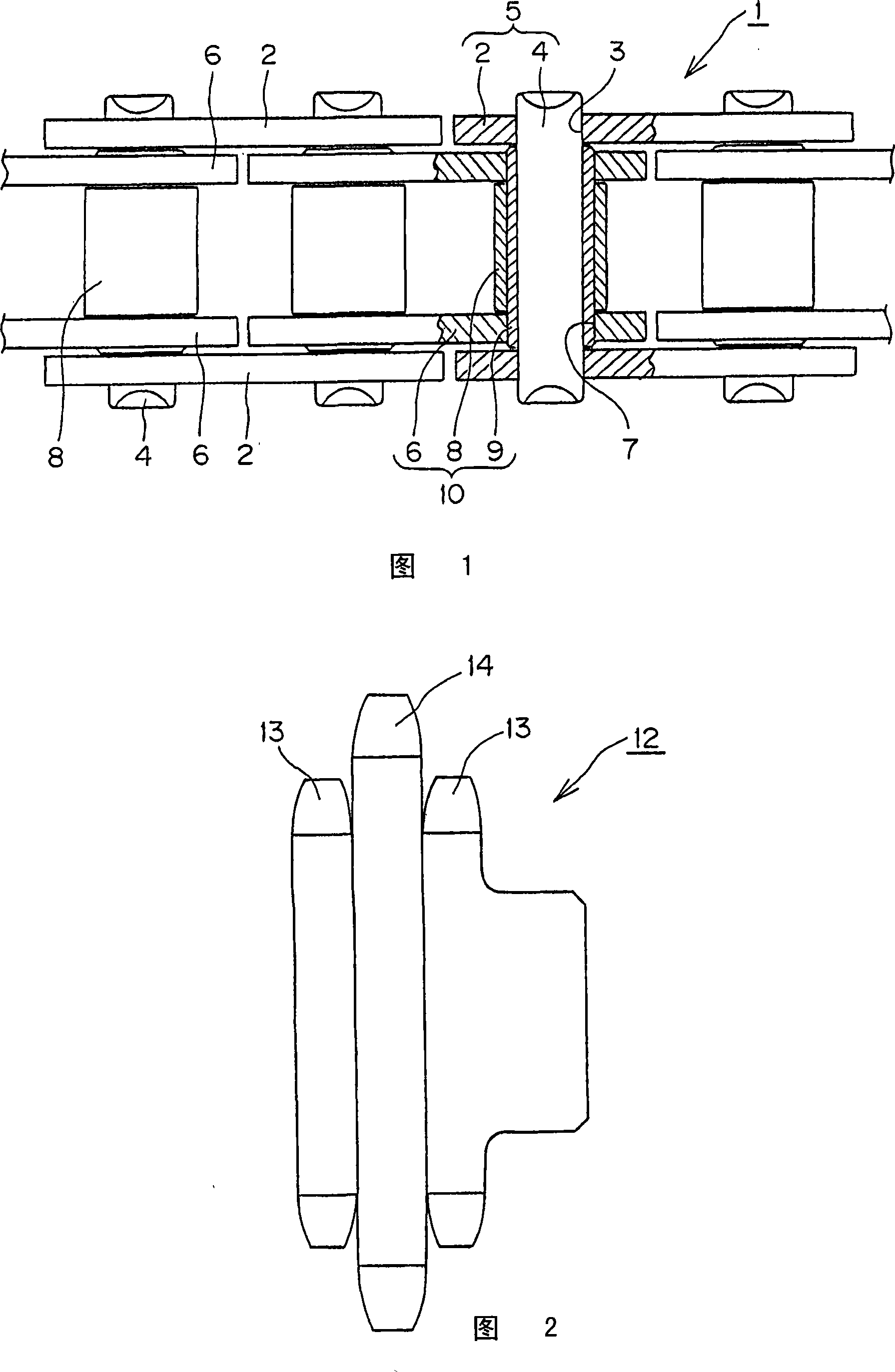

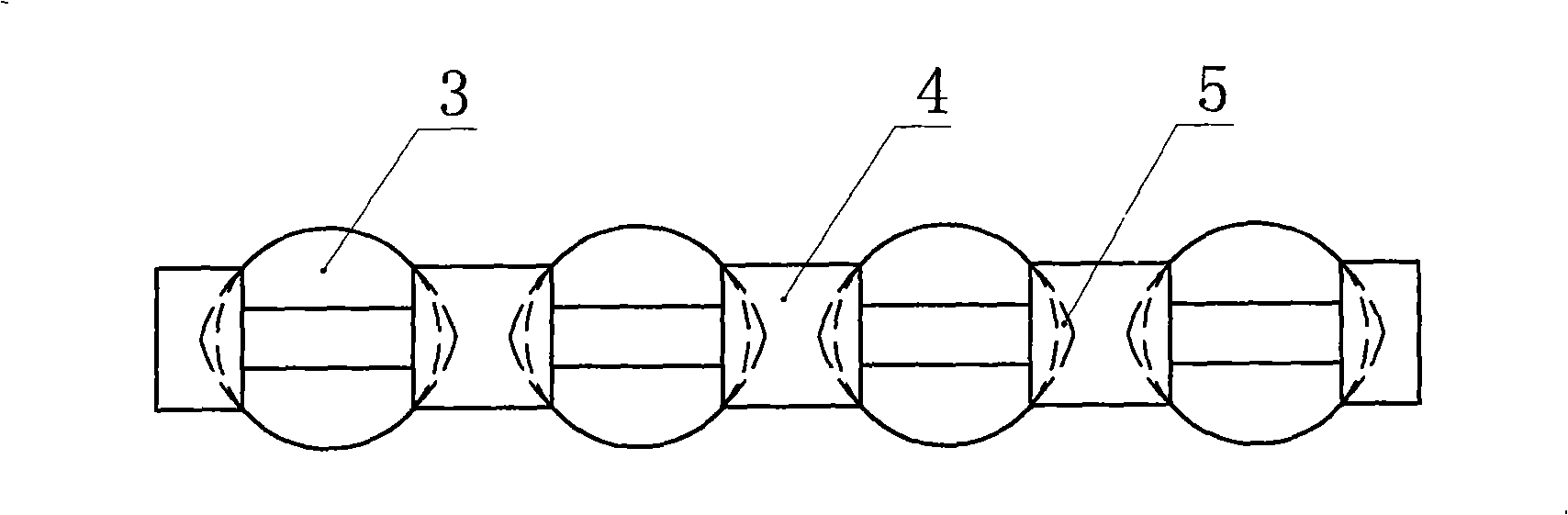

Chain transmission device

ActiveCN101165368ASmooth bending movementInhibits wear extensionGearingDriving chainsRoller chainEngineering

The invention provides a chain transmission, which exhibits the advantages of a silent chain as well as those of a roller chain, which can avoid wear elongation and reduction of strength, and which also achieves noise reduction and weight reduction. A hybrid chain comprises a chain having toothed link plates 2, 6, located on either sides of bushings 9, wherein the toothed link plates mesh 2, 6, with first 13 and second sets 13 of teeth on a sprocket while the bushings 9 engage a third set 14 of teeth on the sprocket located between the first and second sets. The bushings ideally have rollers 10 mounted thereon. When meshing with the sprocket, a rear flank 11a of a tooth of a link plate 2, 6 engages the forward flank of a sprocket tooth 13. Once the rollers / bushings 8 become seated between the teeth of the third set 14, the flank of the link plate is spaced away (clearance) from the sprocket tooth. Each link plate may have a single tooth, or possibly two teeth. All sets of teeth of the sprocket may have the same angular pitch, with the middle set shifted by half the pitch angle.

Owner:TSUBAKIMOTO CHAIN CO

Tripod constant velocity universal joint

The invention relates to a tripod constant velocity universal joint in which only journal surfaces of leg shafts can restrain the position of needle rollers relative to the axial direction. In the tripod constant velocity universal joint, a groove (2) capable of receiving the needle rollers (6) and functioning as a rolling surface for the needle rollers (6) is formed on the outer peripheral surface of a leg shaft (1) in the circumferential direction of the leg shaft. A semisolid or solid lubricant having the consistency number 0, 1, or 2 assists the needle rollers (6) to be retained and aligned in the groove (2).

Owner:NTN CORP

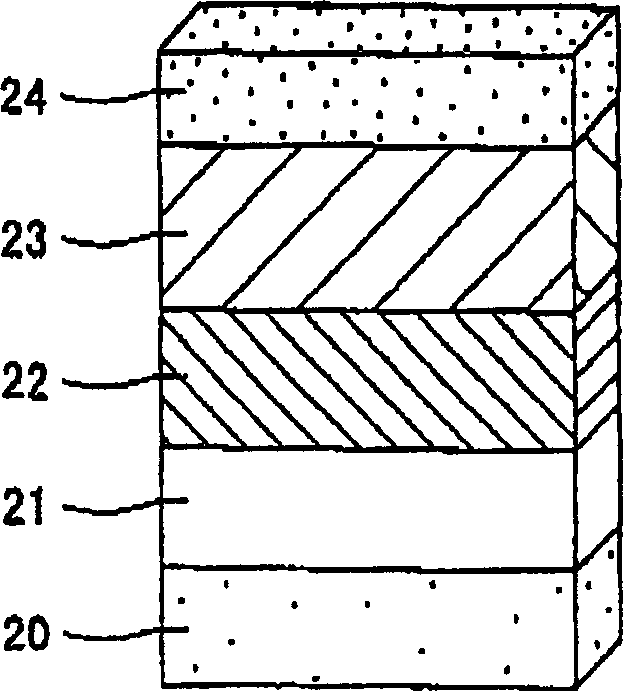

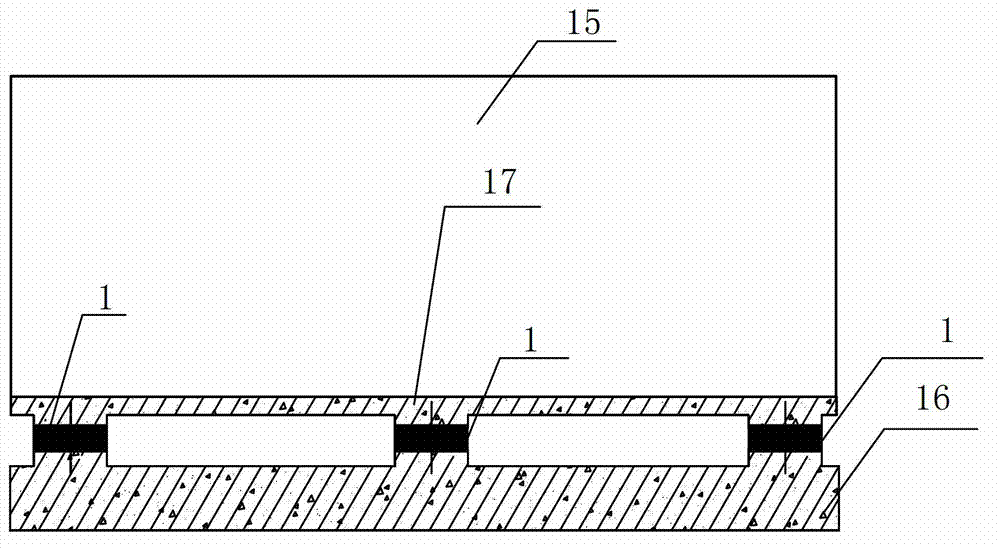

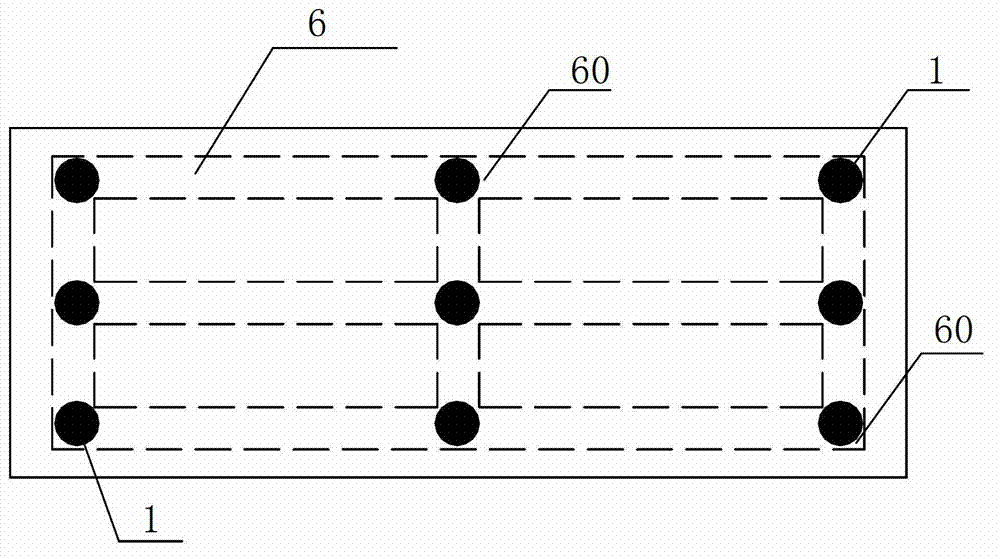

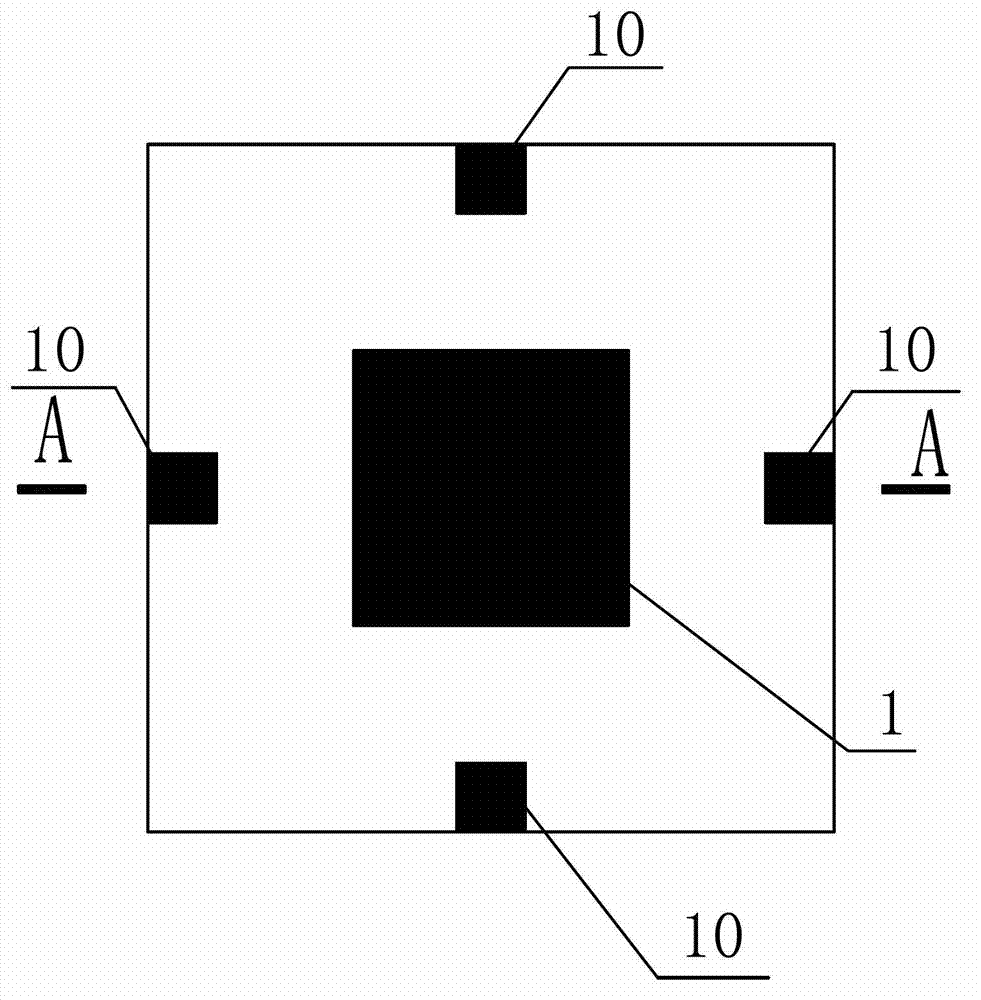

Earthquake-isolation energy dissipator for ultra-high-voltage converter transformer

ActiveCN103195854AImprove shock absorptionLow costRubber-like material springsShock absorbersSocial benefitsTransformer

The invention discloses an earthquake-isolation energy dissipator for an ultra-high-voltage converter transformer. The earthquake-isolation energy dissipator comprises a plurality of earthquake-isolation supports, steel plates and thin rubbers which are arranged horizontally are arranged on the earthquake-isolation supports from top to bottom at intervals, and central holes are arranged at centers of the earthquake-isolation supports and provided with lead cores inside. The earthquake-isolation energy dissipator is characterized by further being provided with a squared foundation valve plate composed by steel beams, an upper connecting plate and a lower connecting plate, wherein the plurality of earthquake-isolation supports are installed at steel beam nodes of the foundation valve plate, the upper connecting plate and the lower connecting plate are parallel, and the upper and lower surfaces of the earthquake-isolation supports are connected with the centers of the upper connecting plate and the lower connecting plate respectively. According to the earthquake-isolation energy dissipator, the stability is guaranteed, simultaneously, the horizontal stiffness is small, the earthquake-isolation damping effect can be improved, soft limiting and anti-falling functions are provided, the safety of the earthquake-isolation energy dissipator under the action of earthquakes can be guaranteed, when the earthquake-isolation fails, a certain damping effect is also provided, and the safety function is provided in case of failure. The earthquake-isolation energy dissipator is low in construction cost, simple in construction and provided with good social benefits.

Owner:CENT SOUTHERN CHINA ELECTRIC POWER DESIGN INST CHINA POWER ENG CONSULTING GROUP CORP

Cleaning device, process cartridge, and image forming apparatus

ActiveCN101339396ANo reduction in contact widthIncrease line pressureElectrographic process apparatusBand shapeImage transfer

A low linear pressure and high surface pressure cleaning structure by specifying the material, shape and support structure of a cleaning blade in a cleaning device, a process cartridge and an image forming apparatus is obtained. A tip portion of an elastic cleaning blade 38 supported by a support member 37 which is a so-called blade holder is pressed against a drum-shaped or belt-like image bearing member 10 to remove a residual toner remaining on the image bearing member after image transfer. In such a cleaning device 16, an angle [theta] forming a front edge portion 36 of the cleaning blade is made obtuse and the front edge portion is pressed against the image bearing member at a surface pressure of 2.0g / mm<2> or larger. The surface pressure is a value given by dividing total load applied on the cleaning blade by a contact area of the cleaning blade to the image bearing member.

Owner:RICOH KK

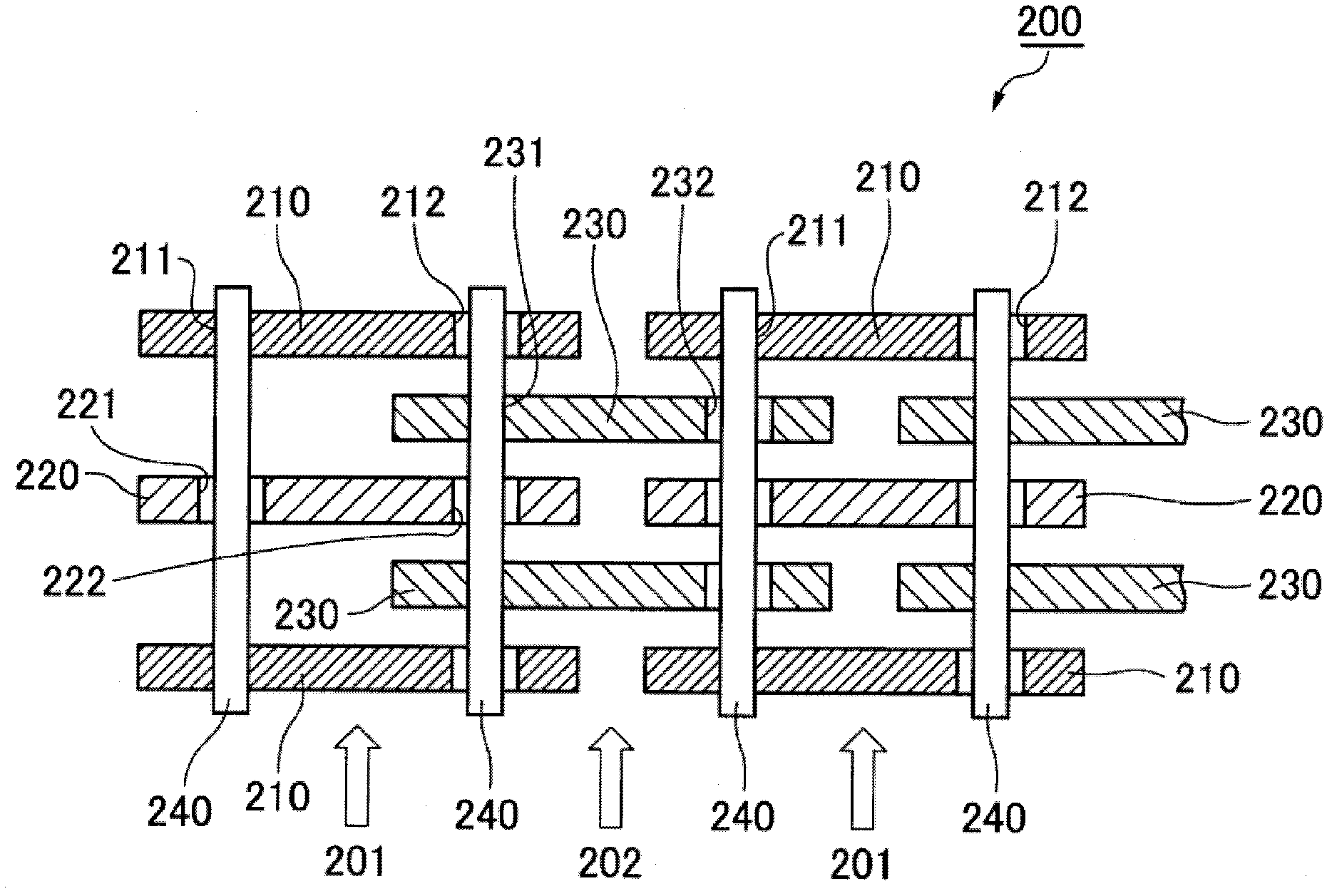

Chain

The invention provides a chain which can control manufacturing and assembling cost, and inhibit the wear increasing, heating and noise due to the repetitive deformation of a connecting pin and a guide link plate, and improve durability. As a tension force does not concentrated on a specific link plate, the strength of resisting tension force of an integral chain can be increased. For each guide link row, a pair of pins is provided for connecting the guide link rows (101) and non-guide link rows (102) in articulating relationship. The first connecting pin extends into first holes (111, 121, 131) of each of the guide plates of its guide link row and into and through the second hole of each link plate of an adjacent non-guide link row. The second connecting pin extends into second holes (112, 122, 132) of each of the guide plates extends into and through a first hole of each link plate of an adjacent non-guide link row. The connecting pins fit tightly into each first hole into which it extends and fits loosely in each second hole into which it extends.

Owner:TSUBAKIMOTO CHAIN CO

Chain transmission device

Owner:TSUBAKIMOTO CHAIN CO

Engine piston connecting rod assembly

InactiveCN107152350AReduce weightReduce face pressureMachines/enginesPistonsMechanical engineeringLarge head

The invention discloses an engine piston connecting rod assembly, and relates to the field of engine pistons. The engine piston connecting rod assembly adopts a wedge connecting rod structure and an inner cavity matched with the wedge structure, the stress area is increased, the face pressure of a movable piston hole and the piston head breaking risk are reduced, a lining ring is additionally arranged on the small end of a connecting rod, the lubricating amount and the lubricating area are increased, the wear between the connecting rod and the piston head is reduced, an oil way is added on the connecting portion of a connecting rod small end and a connecting rod large end, through the structure, the weight of the connecting rod is reduced, the lubricating oil can be sufficiently used, a bearing bush arranged on the connecting rod large end is lubricated, a positioning groove of the connecting rod large end is used, moving of the bearing bush is controlled, and risks of uneven bearing bush stress and bearing bush missing are reduced.

Owner:BRILLIANCE AUTO

Connecting rod for internal combustion engine

InactiveCN105465159AReduce face pressureConnecting rod bearingsConnecting rodsExternal combustion engineEngineering

Owner:HONDA MOTOR CO LTD

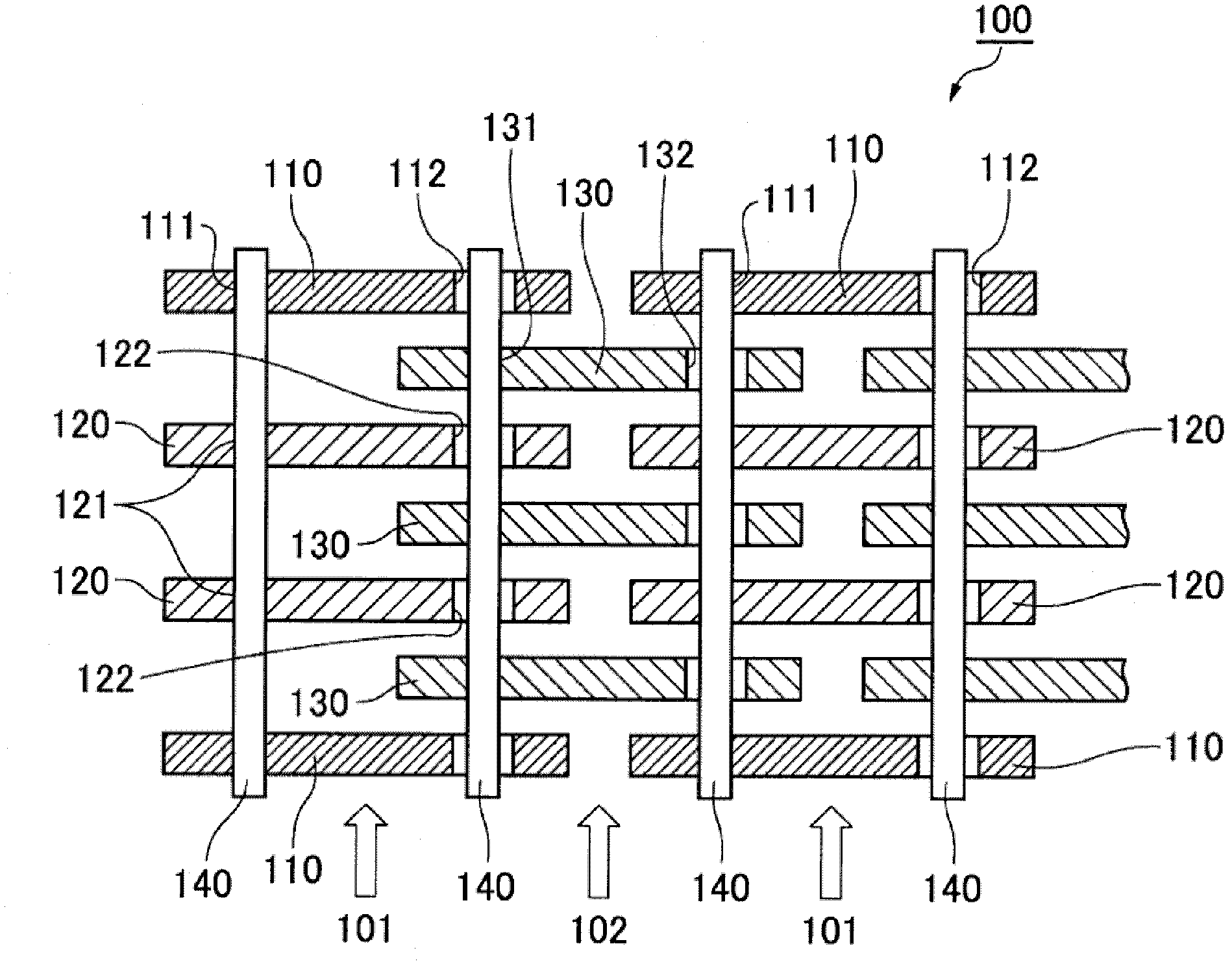

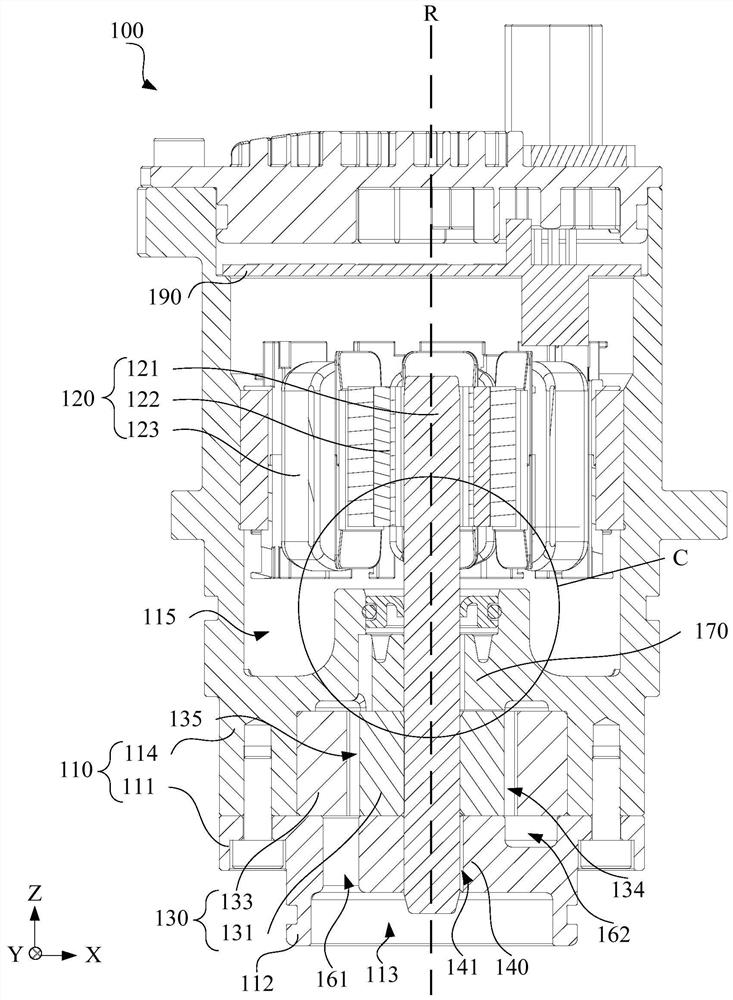

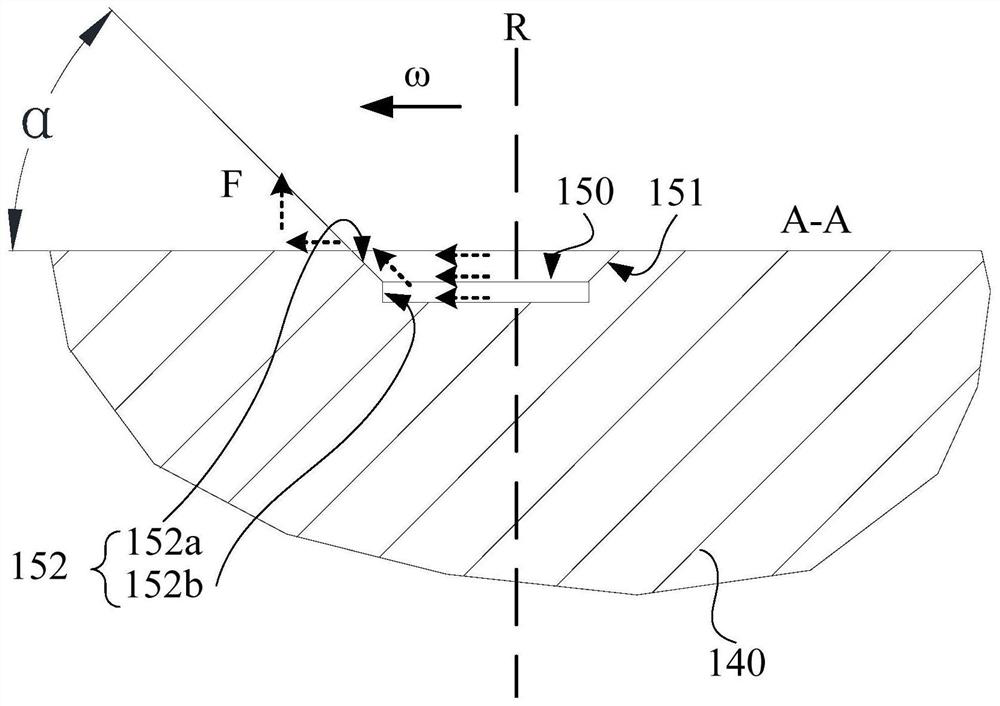

Chain

InactiveCN102235461AReduced sliding contact areaReduce resistanceChain linksDriving chainsEngineeringEquidistant

The invention provides a chain which enables to effectively reduce sliding contact resistance and wear of the parts that come into sliding contact. The chain (100) comprises multiple link plates (110), (120) which, with front and rear pin holes, are rotatably interconnected and are slidingly contacted by a guide member (150). The edge (121) of at least one link plate (120) that comes into sliding contact forms a convex curvature with continuous curvatures in the direction the chain is extended. Meanwhile, the apex (123) of the edge (121) of the convex curvature is located at a position equidistant from centers of the front and rear pin holes. The convex edge (121) has different curvatures on front and rear sides of the apex.

Owner:TSUBAKIMOTO CHAIN CO

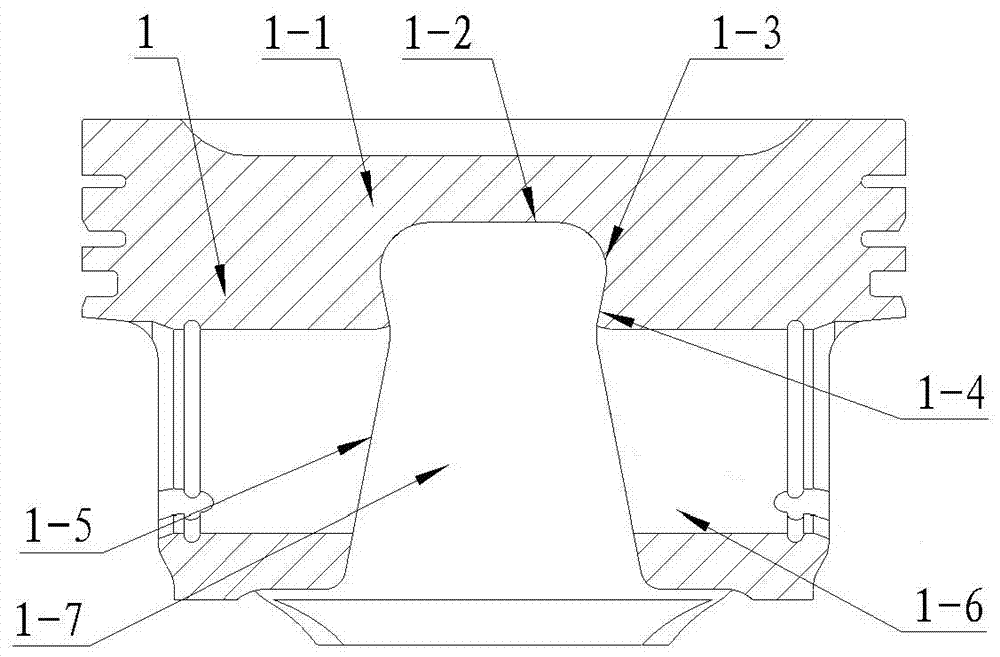

Face pressure reducer of closed compressor

InactiveCN1532417AReduce face pressureAvoid wear and tearRotary piston pumpsRotary piston liquid enginesAerospace engineeringEngineering

The face pressure reducer of closed compressor includes cylinder, rotation shaft, upper and lower bearing boards, partition board, guide board and spring for guide board. Technologically, the present invention features that at least one notched pressure exhausting spigot is set on the thrust bearing side of each bearing board axially supporting the rotation shaft or one thrust side of the rotation shaft corresponding to the thrust bearing side of each bearing board, and the pressure exhausting spigot has certain volume to hold compressed gas. The present invention can reduce face pressure acting on the thrust bearing of bearing board or on the thrust bearing of the rotation shaft and prevent the wear of the two parts.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

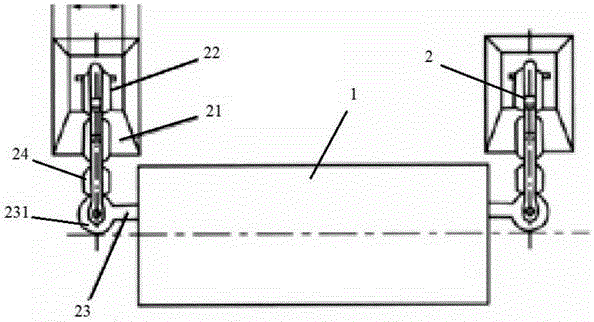

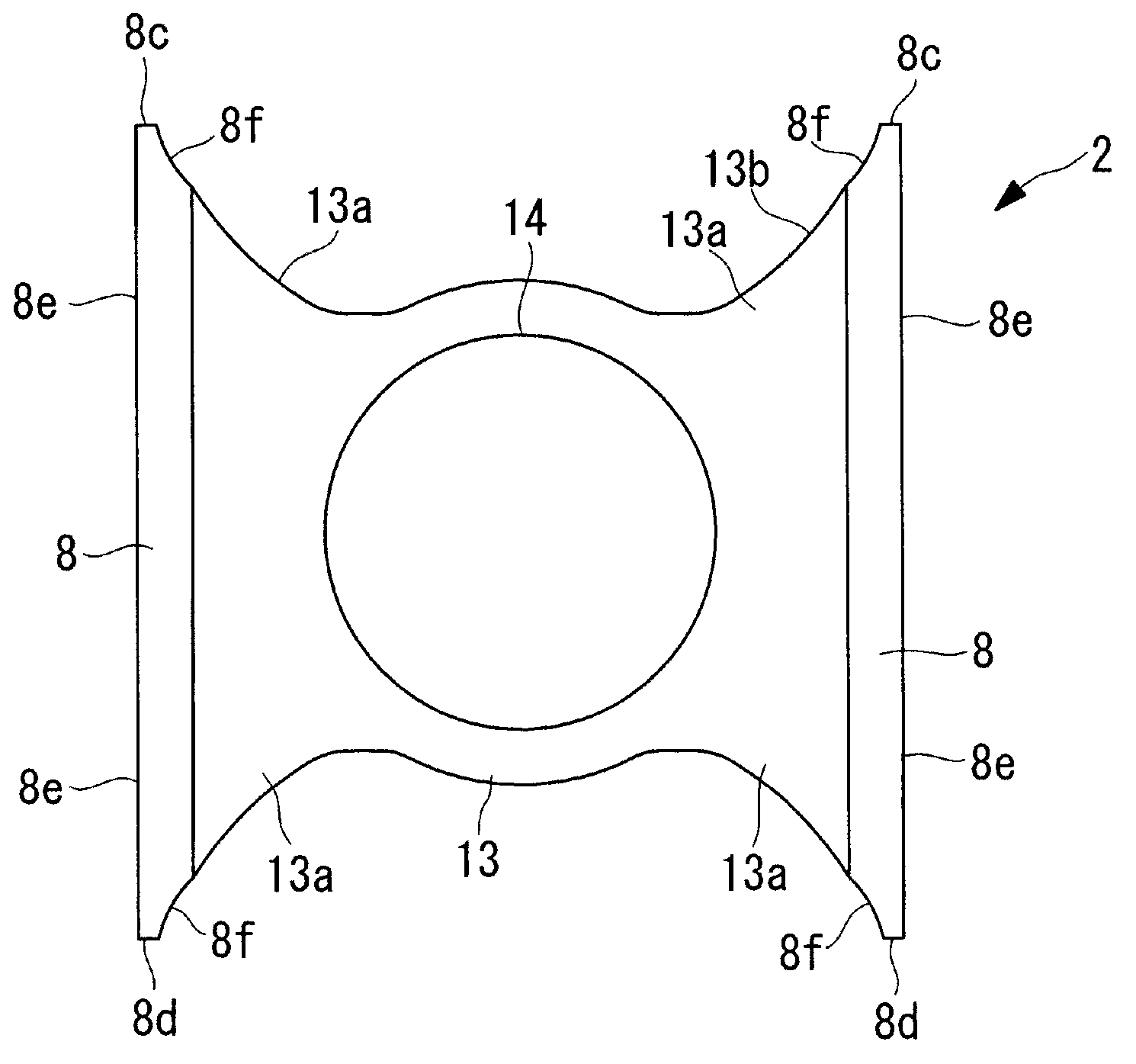

Cylindrical fender

InactiveCN106314716ASmall reaction forceReduce face pressureVessel cleaningClimate change adaptationEnergy absorptionSurface pressure

The invention discloses a cylindrical fender. The cylindrical fender comprises a fender body and suspension devices connected to two sides of the fender body, wherein the fender body is provided with a main body part of which the section is ring-shaped, and a hollow cavity body is formed in the axial direction of the main body part; and each suspension device comprises a base, a clamping ring fixed to the base, a steel roll arranged on the hollow cavity in a penetrating manner, and a chain connected to the clamping ring and the steel roll. The cylindrical fender disclosed by the invention has the advantages that the cylindrical fender is low in reaction force, low in surface pressure, and reasonable in energy absorption quantity; the cylindrical fender is simple in shapes and convenient to mount, repair and maintain; the cylindrical fender is free from the influence of sizes of ships and sizes of docks, and wide in purposes; the cylindrical fender is high in adaptability to rolling and pitching of ship berthing; and the cylindrical fender can be used as a suspension type defence device for various ships and various docks.

Owner:江苏沙源检测校准技术有限公司

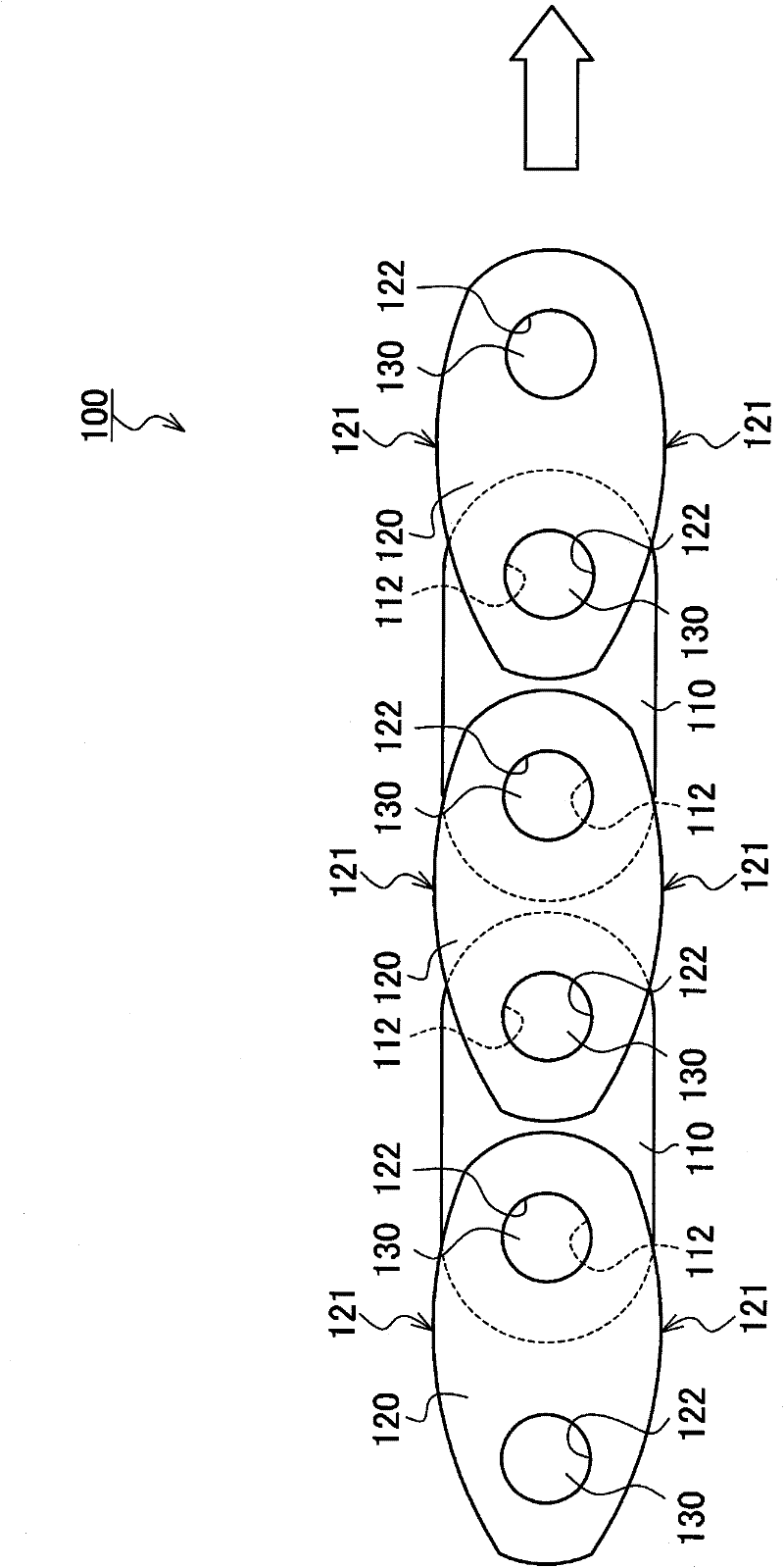

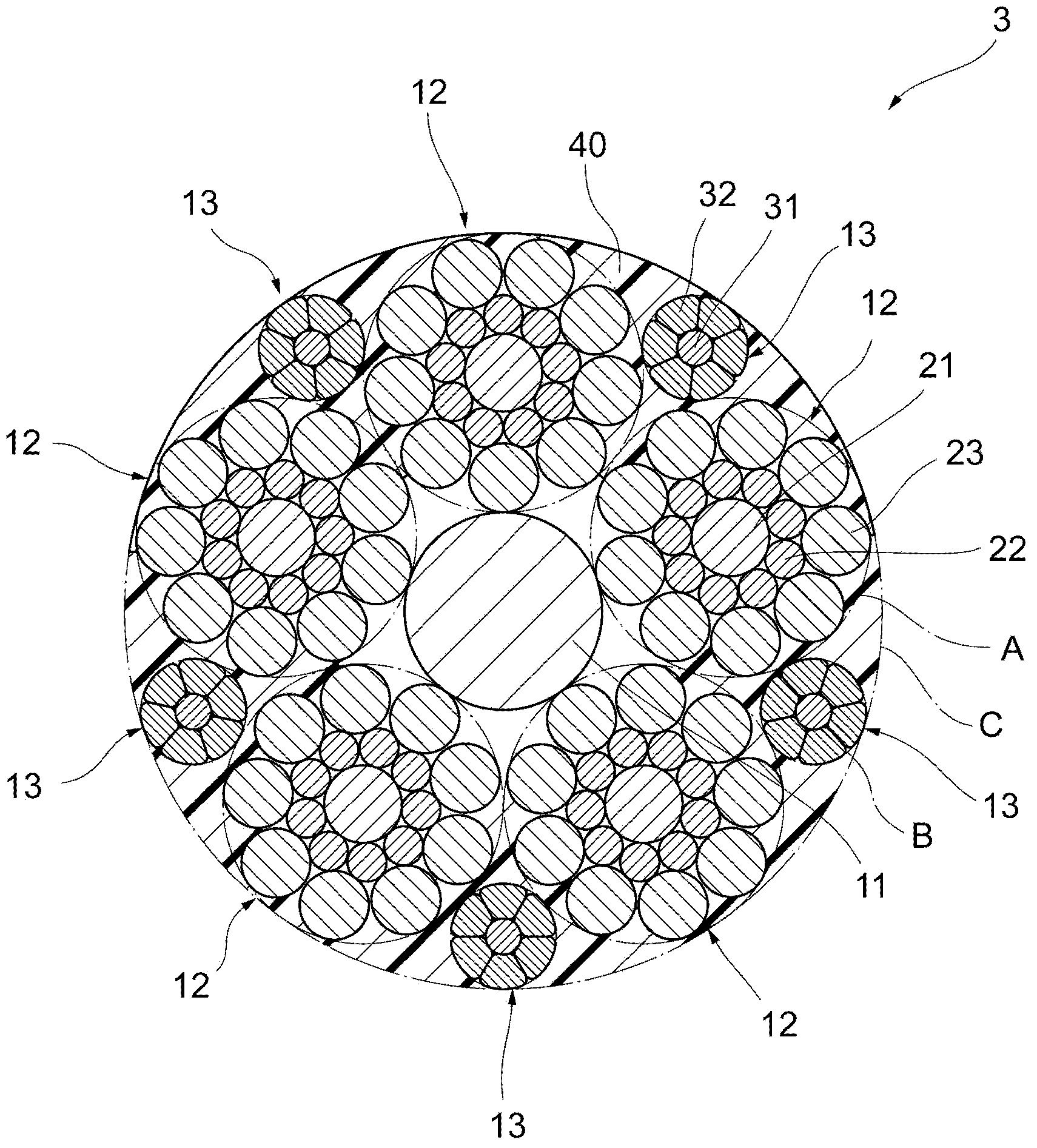

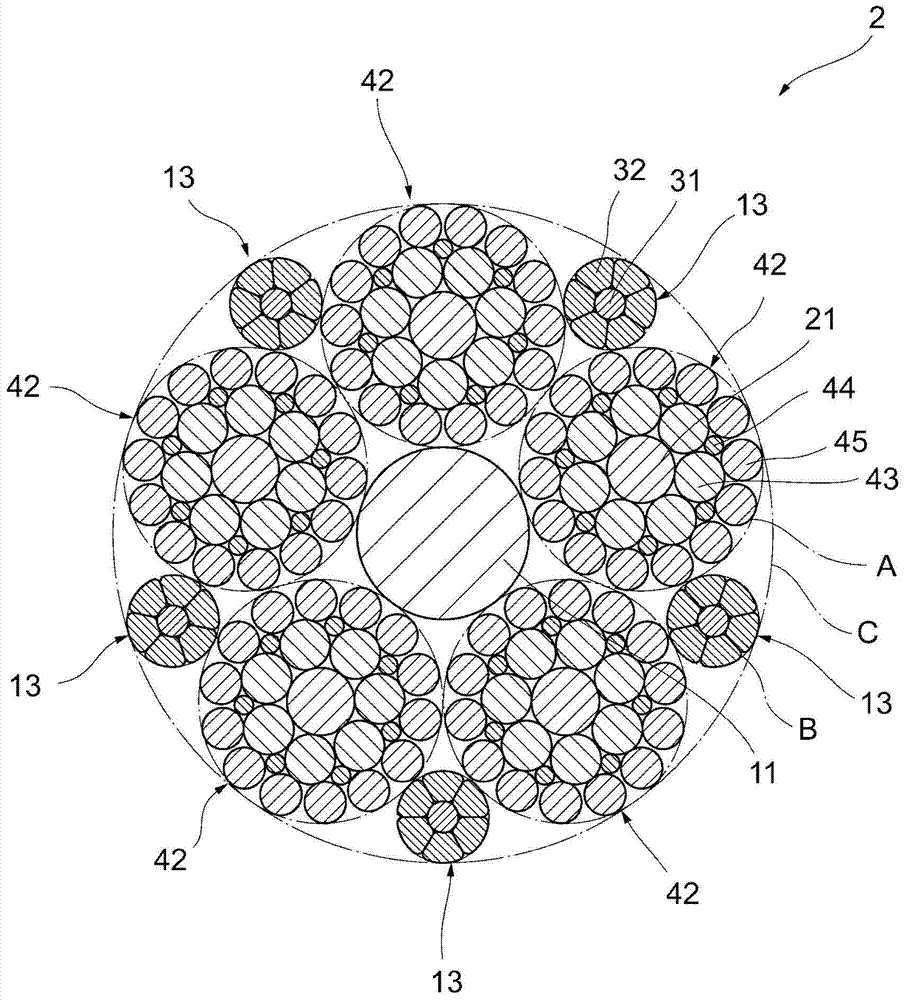

Mooring rope for elevator

ActiveCN104229594ASmall diameterExtended service lifeElevatorsTextile cablesElevator systemMiniaturization

The invention provides a mooring rope. Maintenance is convenient, the service life can be prolonged, the intensity can be raised, the diameter of the mooring rope is shortened, and therefore the mooring rope is suitable for miniaturization of an elevator system. The mooring rope comprises a core part (1), a plurality of side wires (12) arranged along the periphery of the core part (1), and auxiliary wires (13) arranged at the valley sections between adjacent side wires (12) at the outer side of the side wires (12). The side wires (12) are formed by a plurality of wires through twisting. The wires are formed by normal round wires. The auxiliary wires (13) are formed by a plurality of wires through twisting. The outer wires (32) are formed by special-shaped wires. The wires except the outer wires (32) are formed by normal round wires. The circumcircle (A) of each side wire (12) and the circumcircle (B) of each auxiliary wire (13) are internally tangent with the same circle approximately.

Owner:HITACHI LTD

Chain for use in automobile engine

ActiveCN101303062AReduce surface roughnessInhibition of fractureMachines/enginesDriving chainsChromium carbideSurface roughness

The invention provides a chain for automobile engine for enhancing the wearing extension function under the condition of the lubricating oil mixing the carbon black and inhibiting the abnormal abrasion caused by the break of the oil film. A chain for automobile engine is provided. Two ends of a cylindrical sleeve are respectively pressed in a sleeve hole in the inner board; the two ends of the pin embedded in the sleeve are pressed in the pin hole provided with a pair of outer board at the two outer sides of the inner board; the surface of the pin is covered by chrome carbide layer or vanadium carbide layer; the sleeve is formed by cold forging; the roughness of the surface of the pin is less than roughness of the surface of the sleeve; thereby the problem is solved.

Owner:TSUBAKIMOTO CHAIN CO

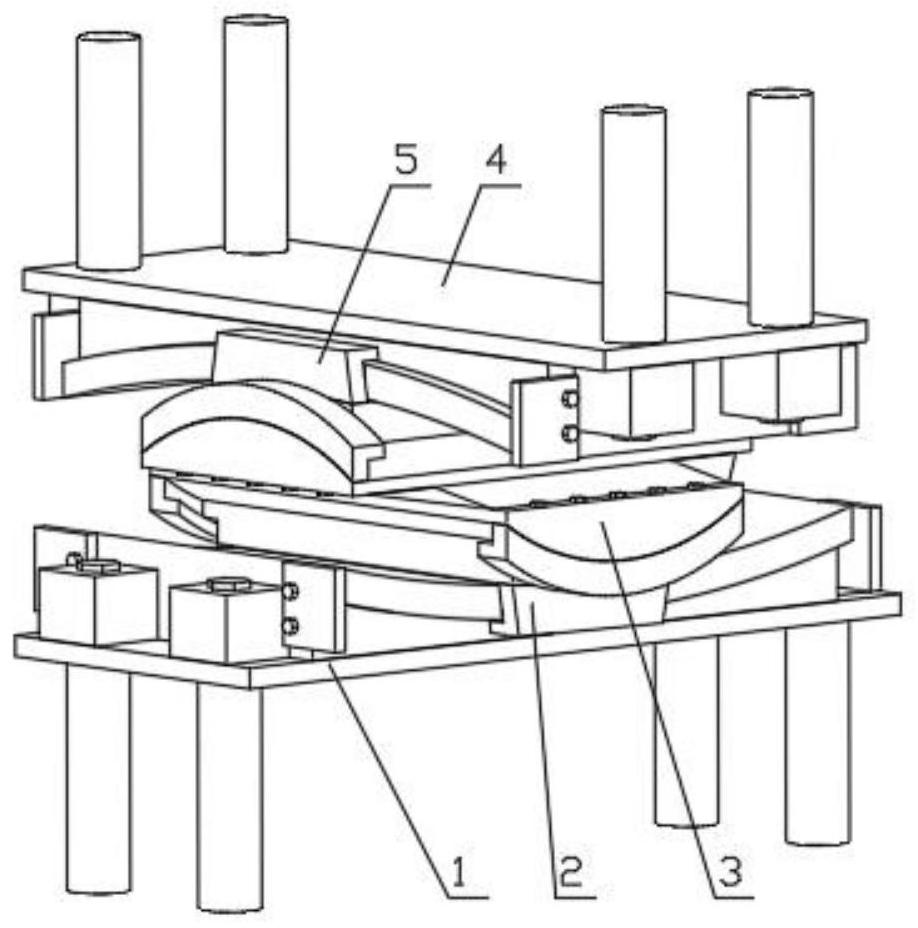

Carriage supporting device of traverse table of forging press

InactiveCN101829755BGuaranteed uptimeExtended service lifeForging/hammering/pressing machinesHardnessSurface pressure

The invention relates to carriage supporting device of a traverse table of a forging press, which relates to a forging press. The invention solves the problem that the surface pressure of contact part between the slideway and the carriage of the traverse table of the forging press is large to result in frequent damage, and improves the stability of the carriage when sliding. The carriage supporting device is characterized in that: the width of the slideway is not less than 0.3 meters, and the slideway is fixed on a bottom plate by bolt; an upper angle steel and a lower angle steel are vertically arranged from top to bottom; and the bottom plate is welded on the upper angle steel and the lower angle steel. The slideway is made from cast iron material with relatively low hardness.

Owner:TAIYUAN HEAVY IND

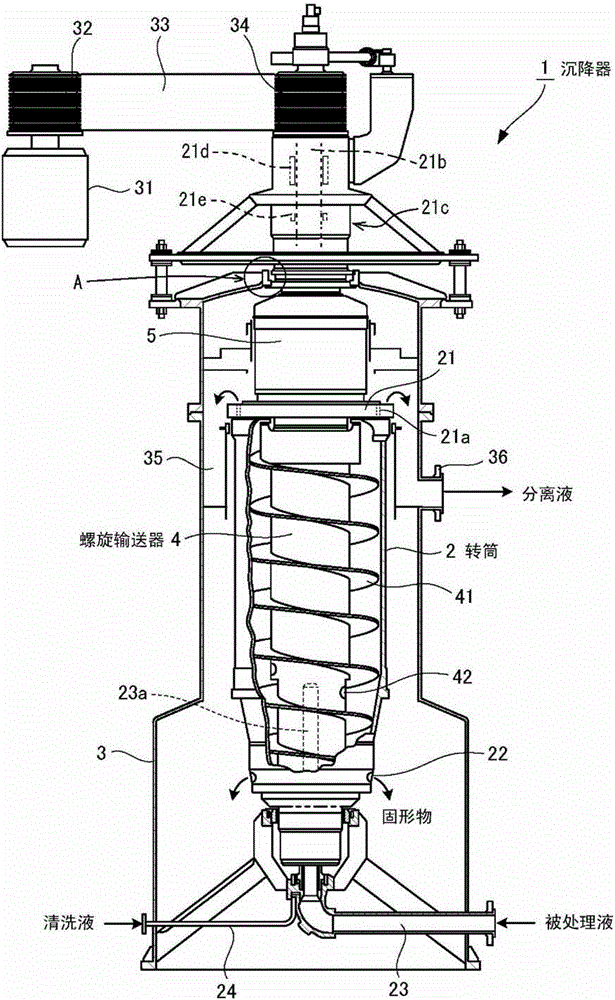

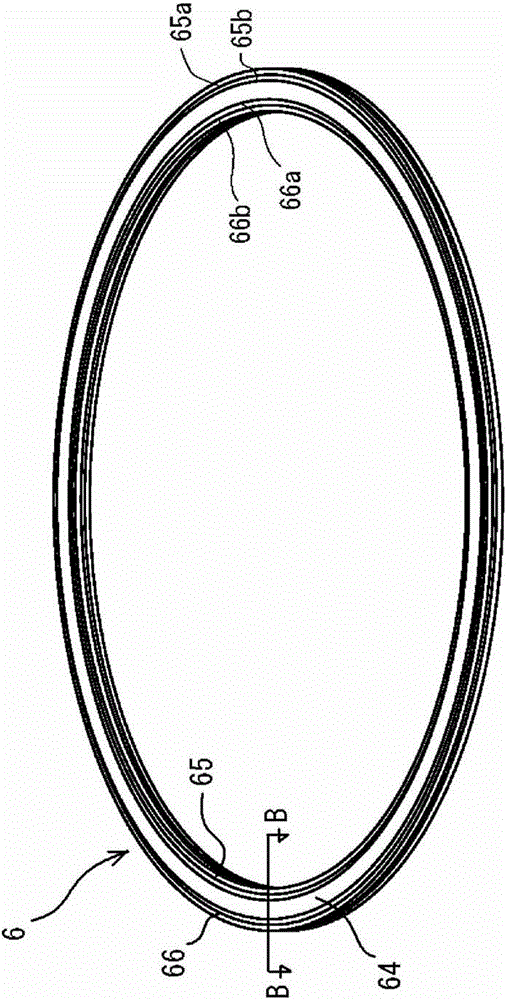

Sealing Mechanism for Rotary Handling Devices

ActiveCN103486271BImprove sealing propertiesReduced sealing propertiesEngine sealsRotary centrifugesAtmospherePressure vessel

The object of the present invention is to provide an improved sealing property when a ring-shaped sealing member seals a gap between an opening of a casing serving as a pressure vessel and a connection portion of a rotation processing mechanism, which extends through the opening. The sealing member a three-layer structure in which a layer of a fluorine-base resin material, a layer of a rubber-base resin material and a base fabric of a nylon-base material are deposited in that order from a side contact with an internal atmosphere within the casing and the cross sectional shape of the sealing member is designed to have a convexly curved center portion and the opposing portions on both side of the central portion, so that the sealing property at the opening of the casing where the connection portion of the rotation processing mechanism can be enhanced. In addition, the degradation of the sealing property due to any shakes (vibrations) which may occur during the rotational movement of the casing.

Owner:TOMOE ENGINEERING CO LTD

Low noise ball screw

InactiveCN101275652ANot easy to wearExtended service lifeGearingGear lubrication/coolingLow noiseBall screw

The invention discloses a ball screw with low noise, including a lead screw, a nut, a ball, wherein the lead screw is arranged with lead screw race, and the inner of the nut is provided with a nut inner worm race, characterized in that, the ball is embedded in the elastic separating chain, and the ball is arranged in sequence to form the chain rolling element and arranged in the lead screw and the nut internal thread race. The ball screw does not generate the friction to cause overheat between the balls with advanced precision, low noise, stable movement, long service life.

Owner:张国梁

Heavy-duty floating worktable

ActiveCN103691865BCompact structureEasy maintenanceForging/hammering/pressing machinesSlide plateEngineering

A heavy-duty floating worktable comprises a worktable body, a lower beam, a slide plate and a floating roller. The floating roller consists of a pin, a spring, a wheel, bearings and a shaft. A channel-steel wheel holder is arranged on the lower portion of the pin, a cylindrical pin is arranged at the center of the upper plane of the channel-steel wheel holder, the shaft is mounted on the channel-steel wheel holder, and the wheel is mounted on the shaft. Circular stepped holes are uniformly formed on the left and the right of each of the front and the back of the lower surface of the worktable body, the floating roller is mounted in the stepped holes of the lower surface of the worktable body, the spring is sleeved on the cylindrical pin between the upper plane of the channel-steel wheel holder of the pin and the bottom surface of the first stepped hole, and the wheel is tangent with the surface of the lower beam. The heavy-duty floating worktable has the advantages of compact structure and maintenance convenience. The floating roller balances 80% of dead weight of the worktable and reduces pressure for grease to flow into an oil groove on the slide plate, and thus service lives of lubricating elements are prolonged and service and maintenance cost are reduced. The residual weight of the worktable is enough to guarantee seamless fit of the worktable body and the slide plate.

Owner:DALIAN DESIGN INST CO LTD CHINA FIRST HEAVY IND +1

Anti-drawing guide rail type friction pendulum support

ActiveCN114809313AOvercome the problem of being unable to resist pulling outImprove anti-overturn performanceProtective buildings/sheltersShock proofingInsulation layerStructural engineering

The invention discloses an anti-drawing guide rail type friction pendulum support. The invention relates to a guide rail type support, and belongs to the technical field of friction pendulum supports. The problem that a friction pendulum support can only be pressed is solved. Comprising a lower rail assembly, a lower sliding part, a middle connecting piece, an upper rail assembly and an upper sliding part, the lower sliding part and the upper sliding part are connected to the upper side and the lower side of the middle connecting piece respectively, the lower sliding part and the lower rail assembly slide in a matched mode, and the upper rail assembly and the upper sliding part slide in a matched mode. The problem that a traditional friction pendulum cannot resist drawing is solved, and the anti-overturning capacity of the shock insulation layer can be remarkably improved.

Owner:丰泽智能装备股份有限公司 +1

Worm gear mechanism

InactiveCN103930693AIncrease contact areaInhibit wearToothed gearingsPortable liftingEngineeringElectric motor

The invention provides a worm gear mechanism. The worm gear mechanism (44) is configured to comprise a worm (70) which is connected to an electric motor, and a worm wheel (80) engaged with the worm. In the worm wheel (80), at least a tooth flank (81a) is formed of a resin material. In the tooth flank (81a), an engagement recess (81dr), which is based on a the trajectory of a contact point being in contact with a tooth (71) of the worm (70) according to a rotation of the worm (70), is formed by injection molding only, together with the tooth flank, using a mold (100). The engagement recess (81dr) comprises a plurality of points (P1a-P9a) which are recessed the most in a the direction of a tooth of the tooth flank of the worm wheel correspondingly to the trajectory of the contact point with which the most convex portion of the tooth (71) of the worm (70) is in contact. A line (Loa) which connects the plurality of points intersects with respect to a tooth width center line (Ct) of the tooth flank (81a) of the worm wheel (80).

Owner:HONDA MOTOR CO LTD

Elevator Ropes

ActiveCN104229594BSmall diameterExtended service lifeElevatorsTextile cablesElevator systemEngineering

PROBLEM TO BE SOLVED: To provide wire rope maintained easily, having a long lifetime, high strength and a thin diameter, and suitable for compactification of an elevator system.SOLUTION: Wire rope comprises: a core 11; multiple side strands 12 arranged along external circumference of the core 11; and adjunct strands 13 provided to outside of the side strands 12 and in valleys between the side strands 12 neighboring each other. The side strands 12 are constructed by twisting multiple strands comprised of normal round wires. The adjunct strands 13 are constructed by twisting multiple strands, and external layer strands 32 are comprised of modified wires and the strands other than the external layer strands are comprised of normal round wires. Each circumcircle A of the side strand 12 and each circumcircle B of the adjunct strand touch an about equivalent circle internally.

Owner:HITACHI LTD

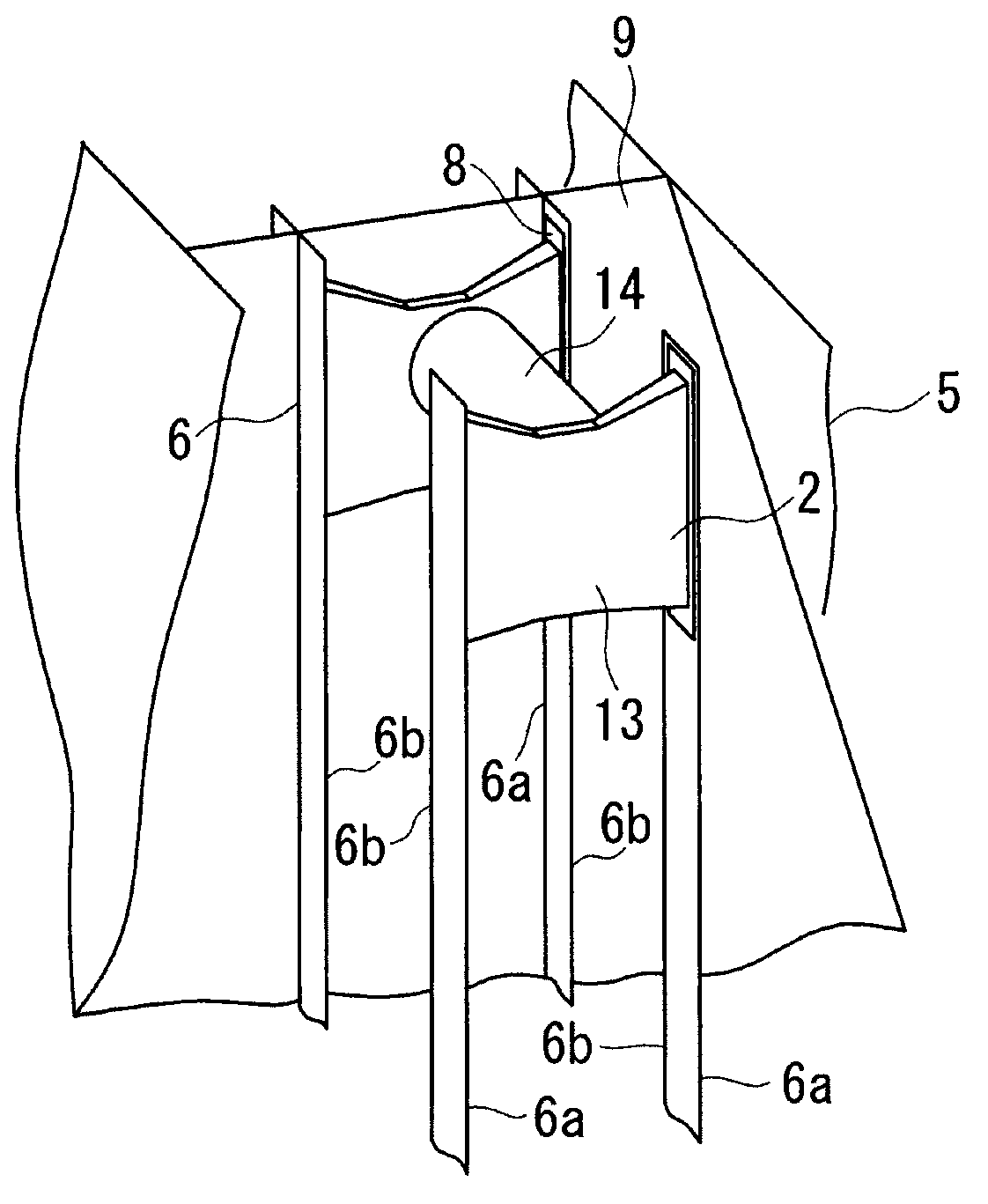

crosshead diesel engine crosshead

ActiveCN103249929BLow costReduce face pressureCrossheadsMachines/enginesReciprocating motionSlide plate

Owner:MITSUBISHI HEAVY IND LTD +1

A kind of idler gear device and engine

The invention relates to the technical field of idle gear shafts, and discloses an idle gear device and an engine. The idler gear device includes an idler gear with a central hole; a bearing bush is arranged in the central hole of the idler gear, and the central hole of the bearing bush includes two symmetrically arranged tapered holes. The large-diameter end of the tapered hole is located on the outside of the bearing bush; two idler gear shafts, the idler gear shafts are frustum-shaped, and the two idler gear shafts are respectively arranged in the tapered hole, and can be relatively The bearing bush rotates, and a lubricating gap is provided between the outer wall of the idler gear shaft and the inner wall of the tapered hole. The idler gear device of the present invention can bear axial force, prevent the idler gear shaft from moving axially, and the idler gear shaft and the bearing bush from eccentric wear, and improve the reliability of the idler gear device.

Owner:WEICHAI POWER CO LTD

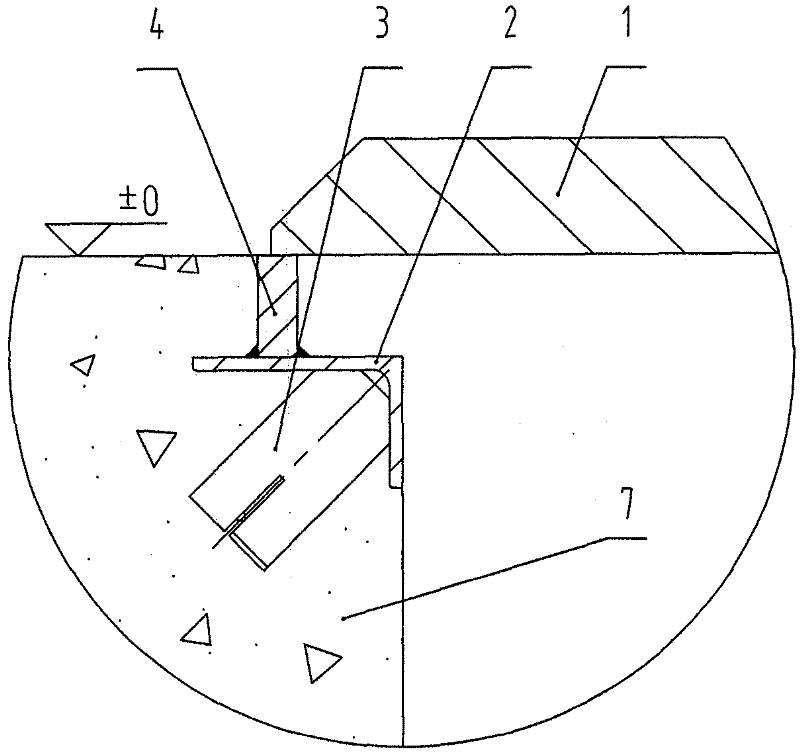

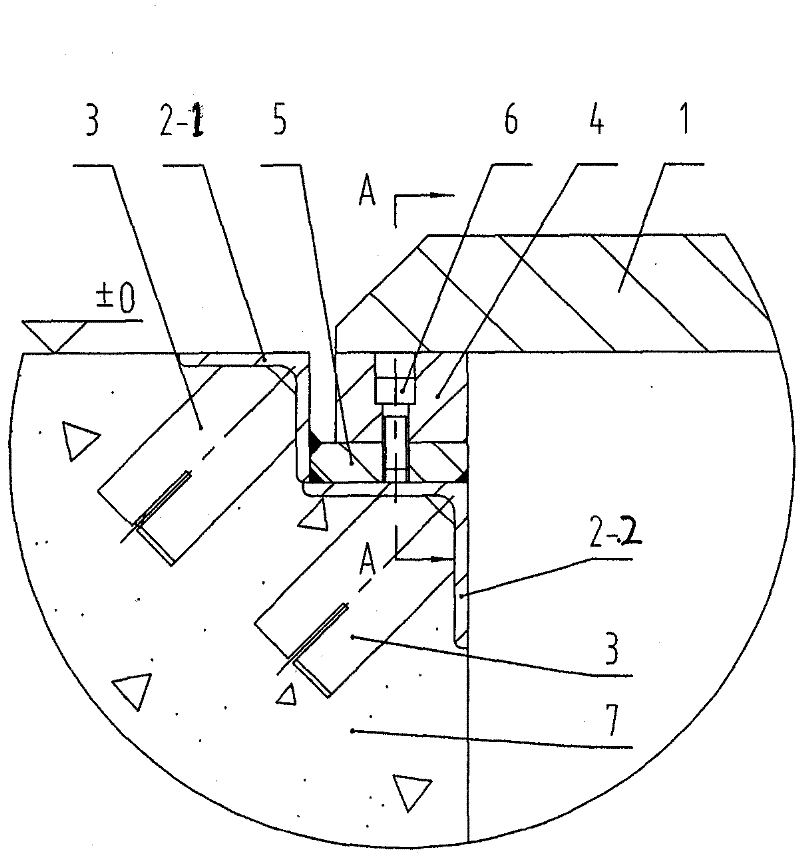

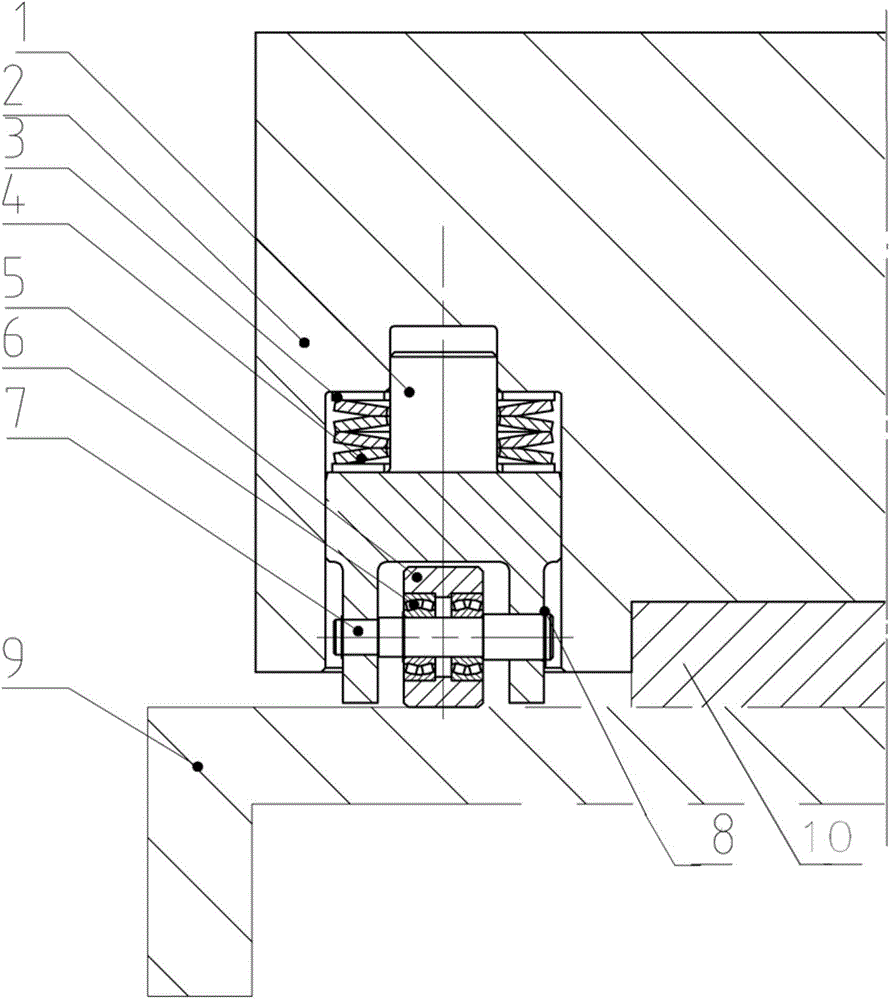

Cross head for cross head type diesel engine

ActiveCN103249929ALow costReduce face pressureCrossheadsMachines/enginesReciprocating motionSlide plate

A cross head for a cross head type diesel engine, provided with: a pin (14) for pivotably connecting one end of a piston rod and one end of a connecting rod; shoes (8) reciprocating while sliding relative to slide plates (6) raised from the affixed ends thereof, which are affixed to a framework, toward the free ends (6b) thereof; and connecting plates (13) for connecting the pin (14) and the shoes (8). The axis (C1) of each of the arm section (13a) of each of the connecting plates is offset to the inner end section (8b) side from the center of the corresponding shoe (8).

Owner:MITSUBISHI HEAVY IND LTD +1

Idle gear device and engine

ActiveCN111043279AStable structurePrevent axial movementShaftsPortable liftingAutomotive engineeringLubrication

The invention relates to the technical field of idle gear shafts, and discloses an idle gear device and an engine. The idle gear device comprises an idle gear, a bearing bush and two idle gear shafts.A center hole is formed in the idle gear. The bearing bush is arranged in the center hole of the idle gear. A center hole of the bearing bush comprises two conical holes symmetrically formed. The large-diameter ends of the conical holes are located outside the bearing bush. Each idle gear shaft is in a circular truncated cone shape. The two idle gear shafts are arranged in the conical holes correspondingly and can rotate relative to the bearing bush. A lubrication gap is formed between the outer wall of each idle gear shaft and the inner wall of the corresponding conical hole. The idle gear device can bear axial force and prevent axial movement of the idle gear shafts and eccentric wear of the idle gear shafts and the bearing bush, and reliability of the idle gear device is improved.

Owner:WEICHAI POWER CO LTD

Pump device and vehicle

PendingCN114135383ASimple structureImprove sealingPump componentsPump installationsElectric machineryControl theory

The invention provides a pump device and a vehicle. The pump device comprises a shell, a motor part, a pump part, a first bearing and a thrust lubrication groove. Wherein the shell is provided with a cavity; the motor part is arranged in the cavity and comprises a rotating shaft rotating around the central axis of the motor part. The pump part is arranged on the axial side of the motor part and makes contact with the rotating shaft, and the pump part can be driven by the rotating shaft to rotate. The first bearing is connected with the shell, sleeves the rotating shaft and is located on the side, away from the motor part, of the pump part. The thrust lubrication groove is formed in the end face, close to the pump part, of the first bearing and communicates with a shaft hole of the first bearing. Lubricating oil in the thrust lubricating groove can flow to the end face gap between the first bearing and the pump part, so that fluid lubrication is formed on the contact end faces of the first bearing and the pump part, the abrasion condition of the contact end faces of the pump part and the first bearing is greatly improved, power consumption is reduced, and in addition, operation noise of the pump device can be reduced.

Owner:ANHUI WELLING AUTO PARTS CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com