Heavy-duty floating worktable

A worktable, floating technology, used in manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc., can solve problems such as increasing the pressure of the dry oil lubrication station, the press cannot continue to work, and the worktable is worn out. Achieve the effect of reducing wear, compact structure and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is further described below in conjunction with embodiment and accompanying drawing.

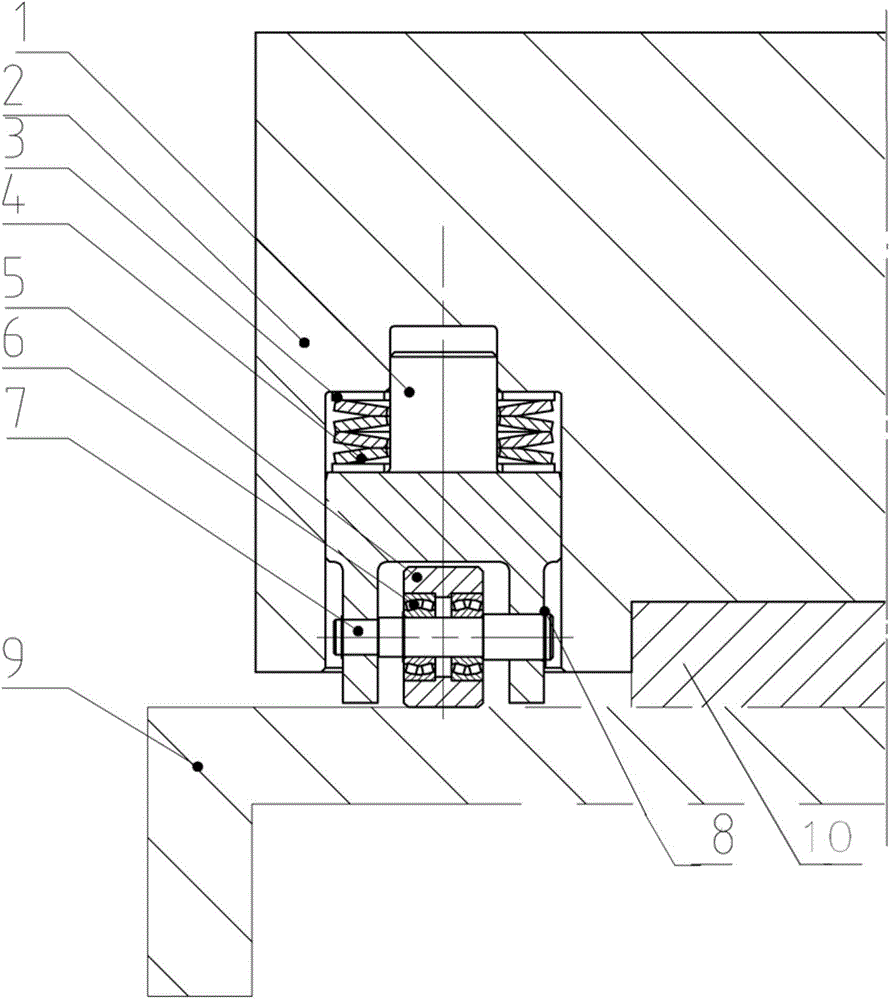

[0016] The embodiment is a heavy-duty floating workbench of a 10,000-ton free forging hydraulic press, which includes a workbench body 2, a lower beam 9, a slide plate 10 and floating rollers. The slide plate is placed on the lower beam 9, and there is no gap between the workbench body 2 and the slide plate. Seam fit, the floating idler includes pin 1, spring 4, wheel 5, bearing 6, shaft 7 and retaining ring 8, the lower part of pin 1 is a channel steel wheel seat, and the center position of the upper plane of the channel steel wheel seat There is a cylindrical pin, and a shaft hole is opened on the two vertical plates of the channel steel wheel seat. The shaft 7 is installed on the two vertical plates of the channel steel wheel seat through the retaining ring 8, and the wheel is installed in the groove of the shaft through the bearing 6. Between the two vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com