Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Reduced opening torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

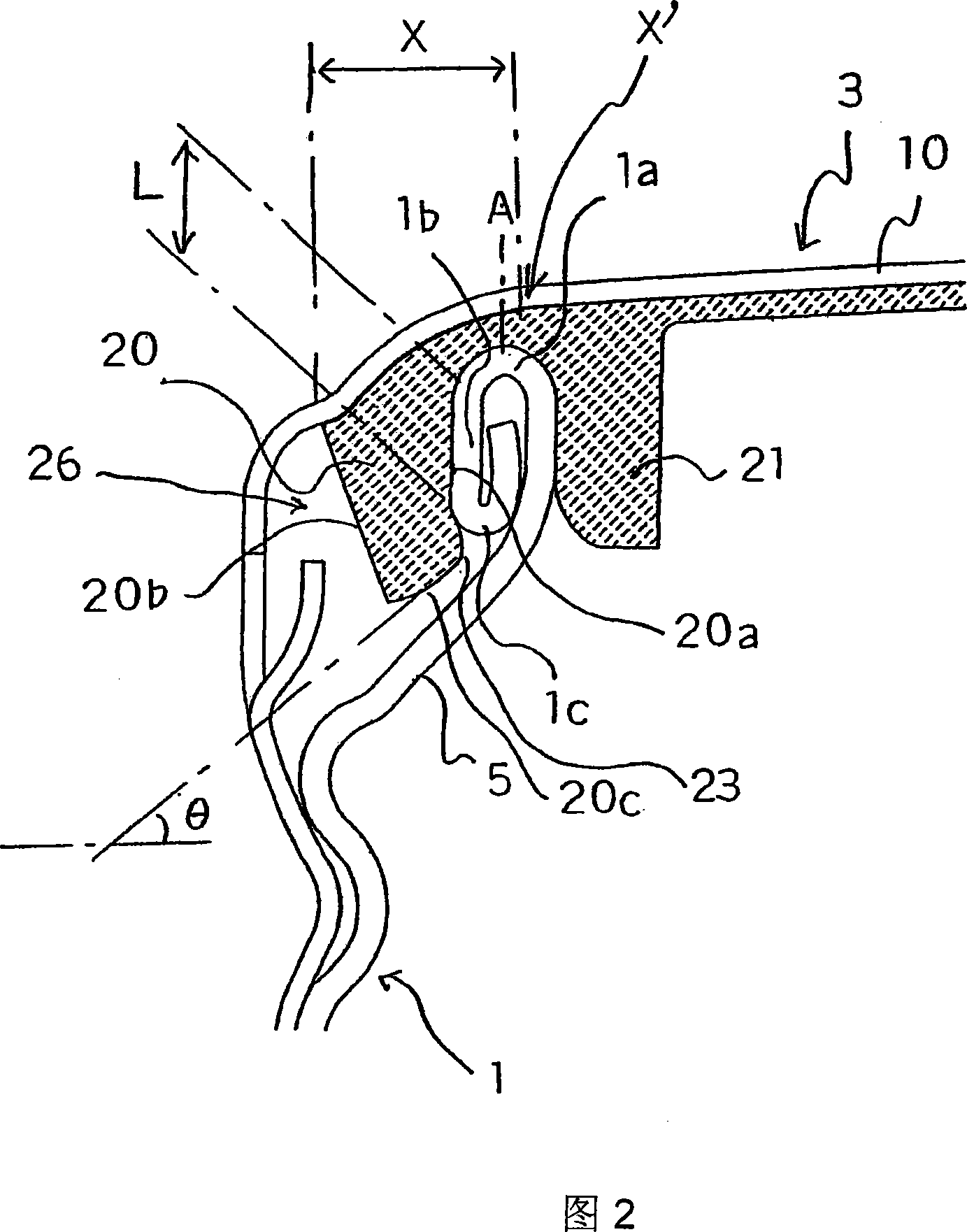

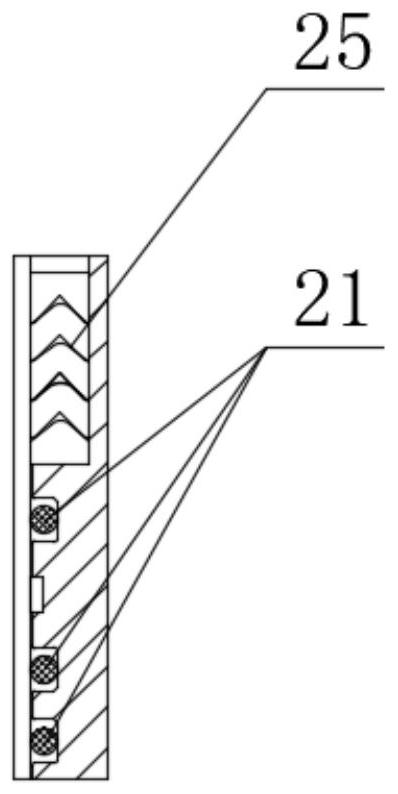

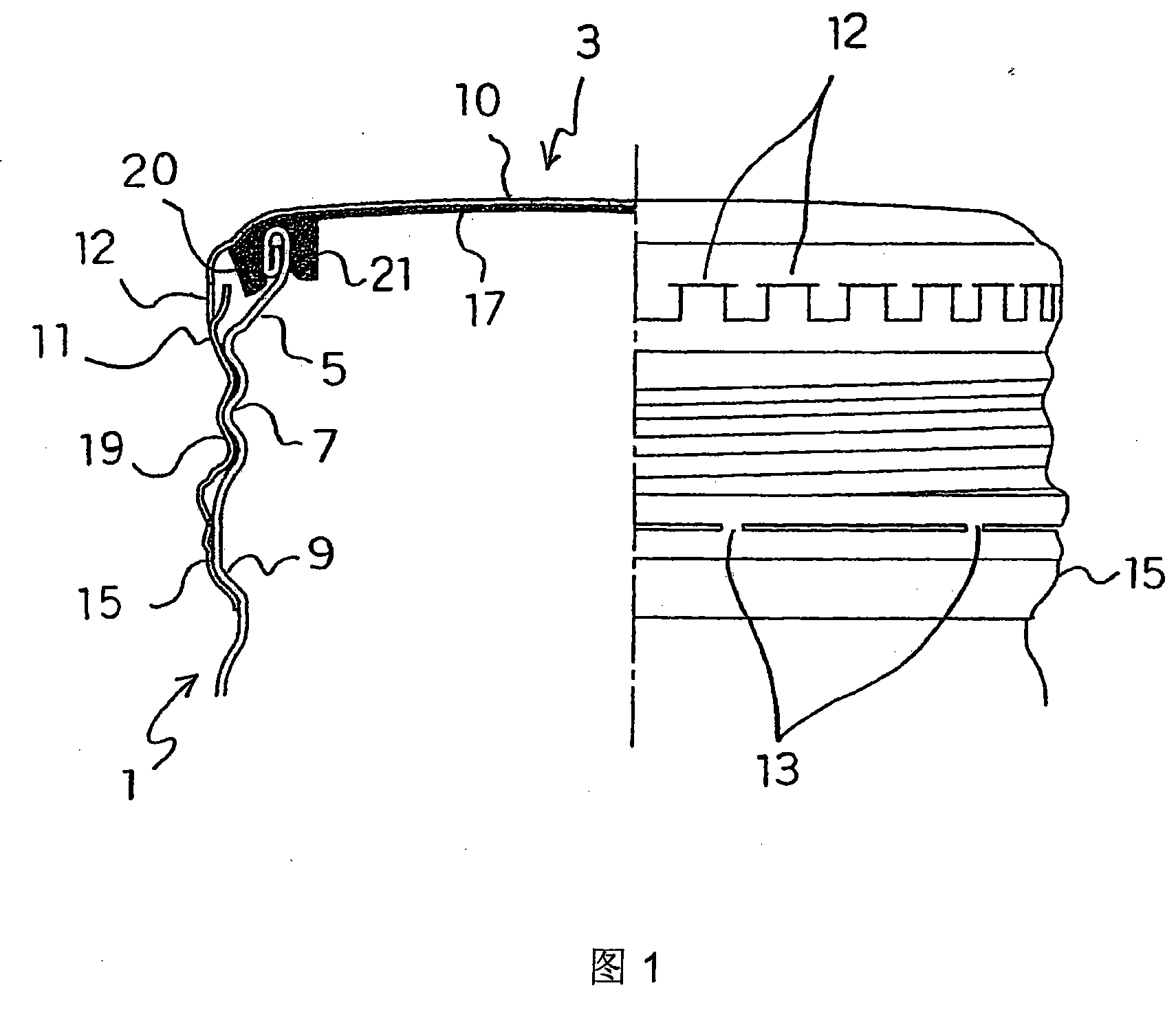

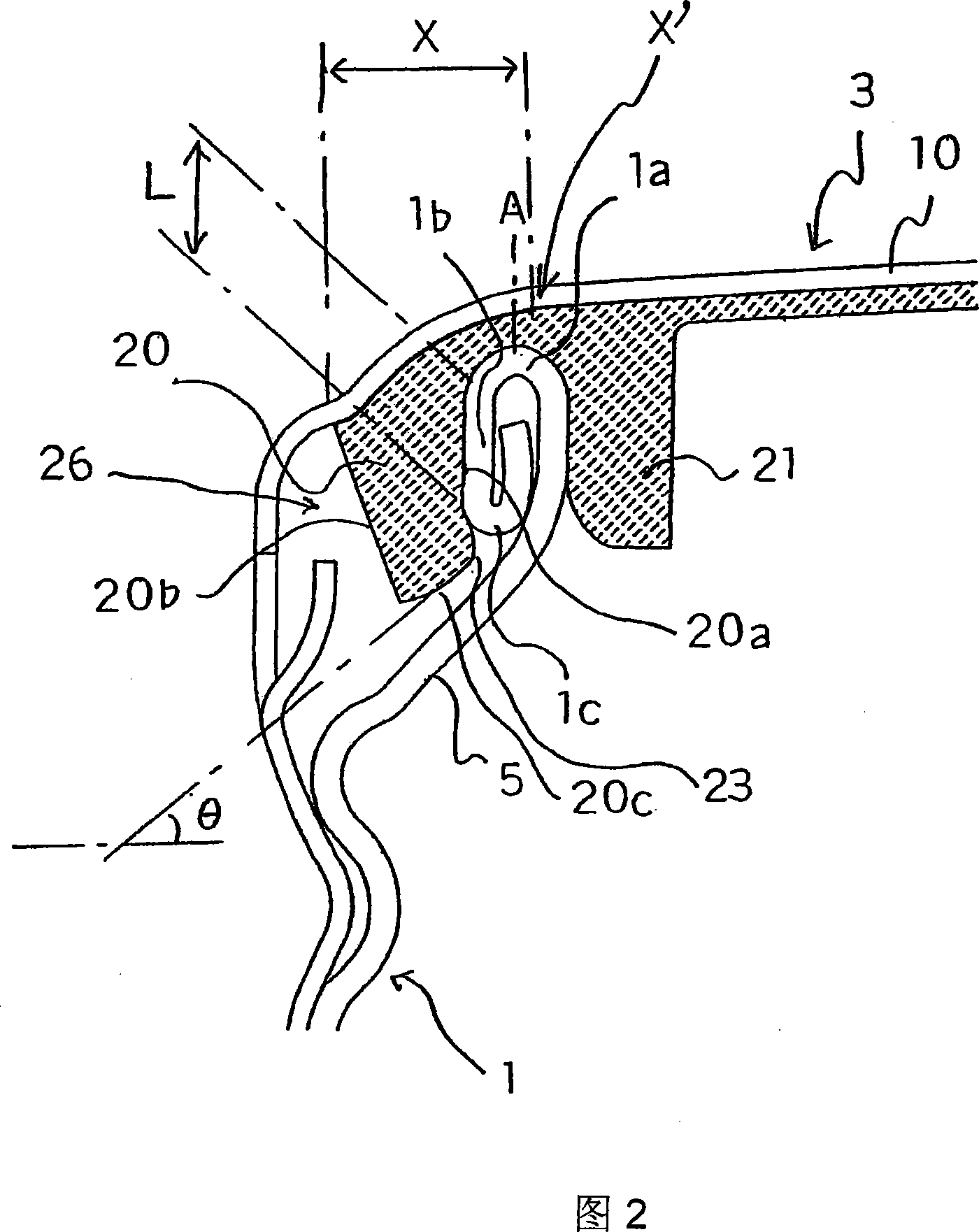

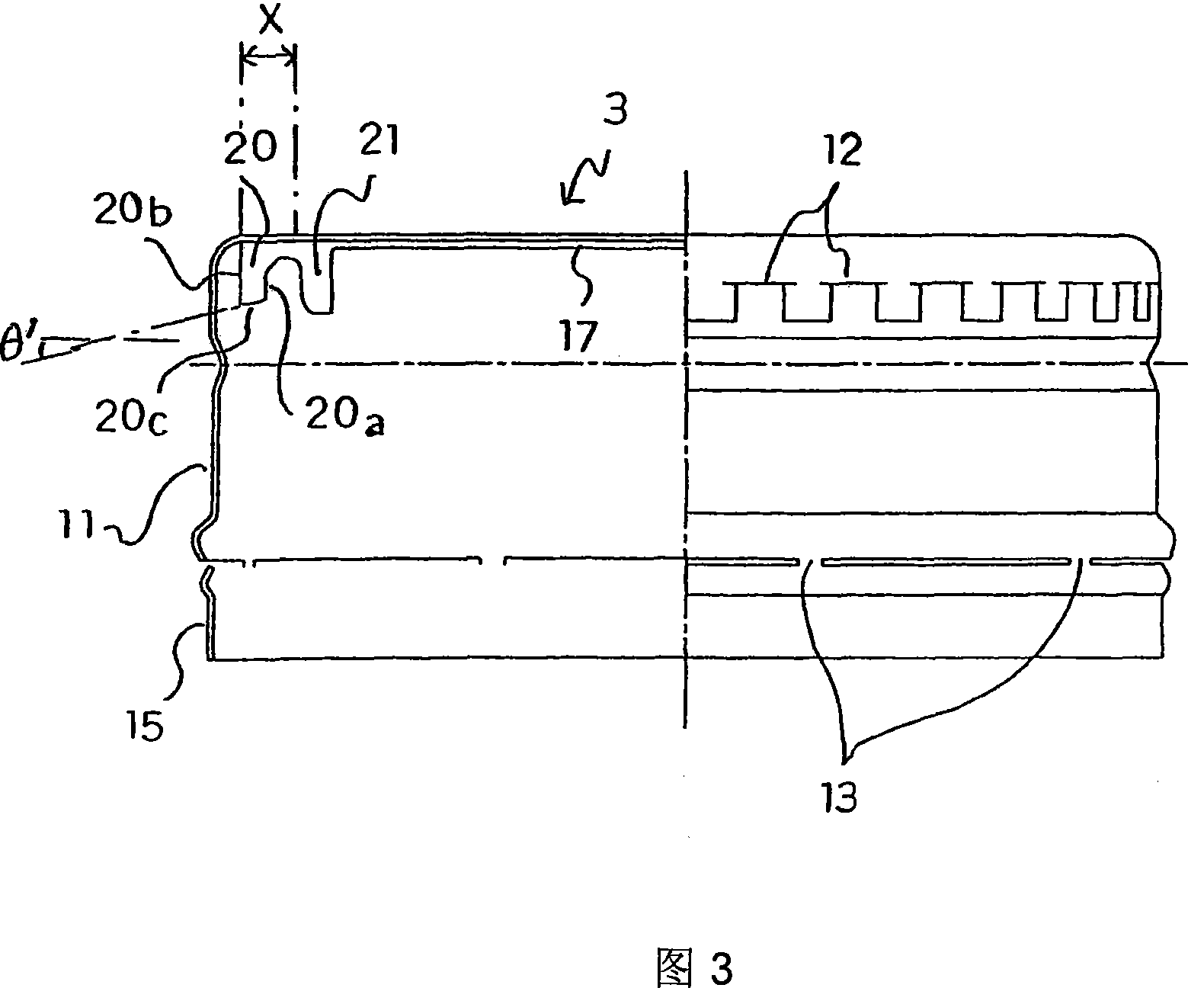

Metallic package

ActiveCN101148208ALarge rotation angleSeal Break PreventionCapsClosure capsEngineeringMechanical engineering

Owner:JAPAN CROWN CORK CO LTD

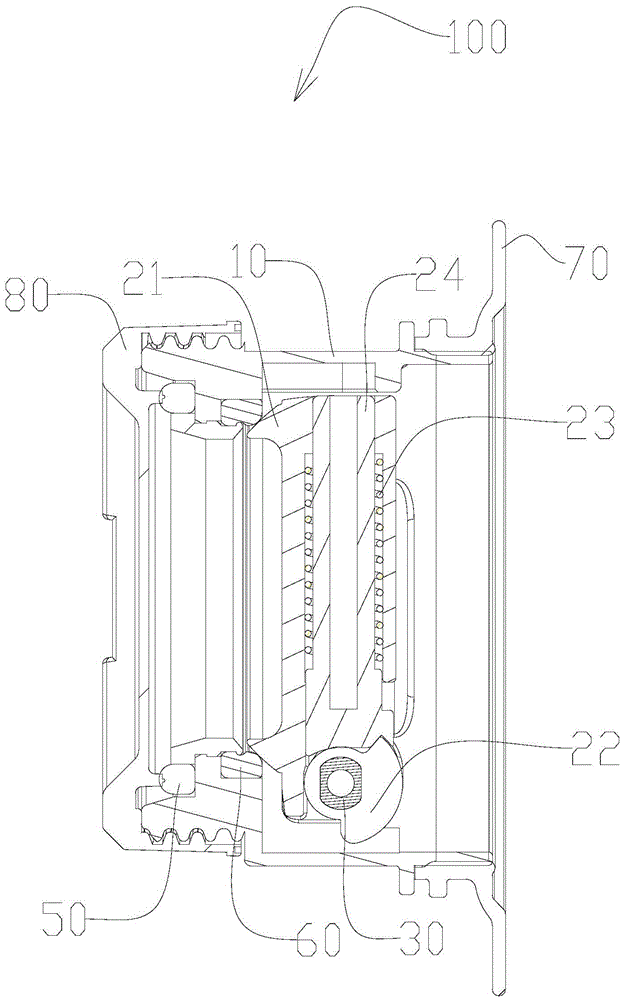

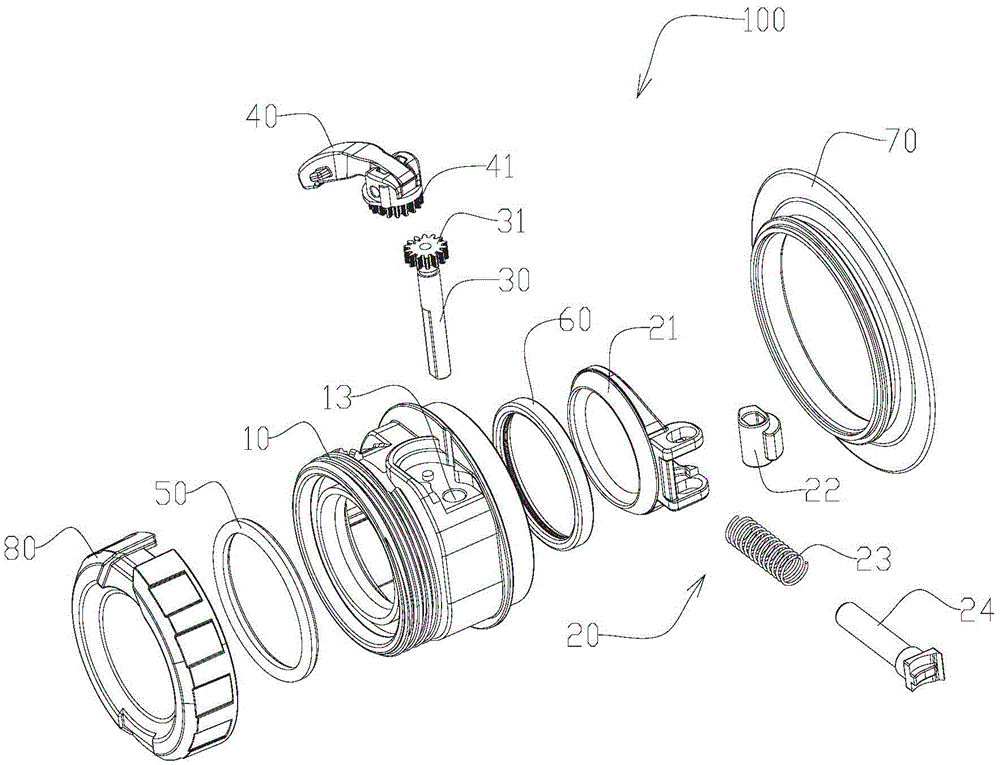

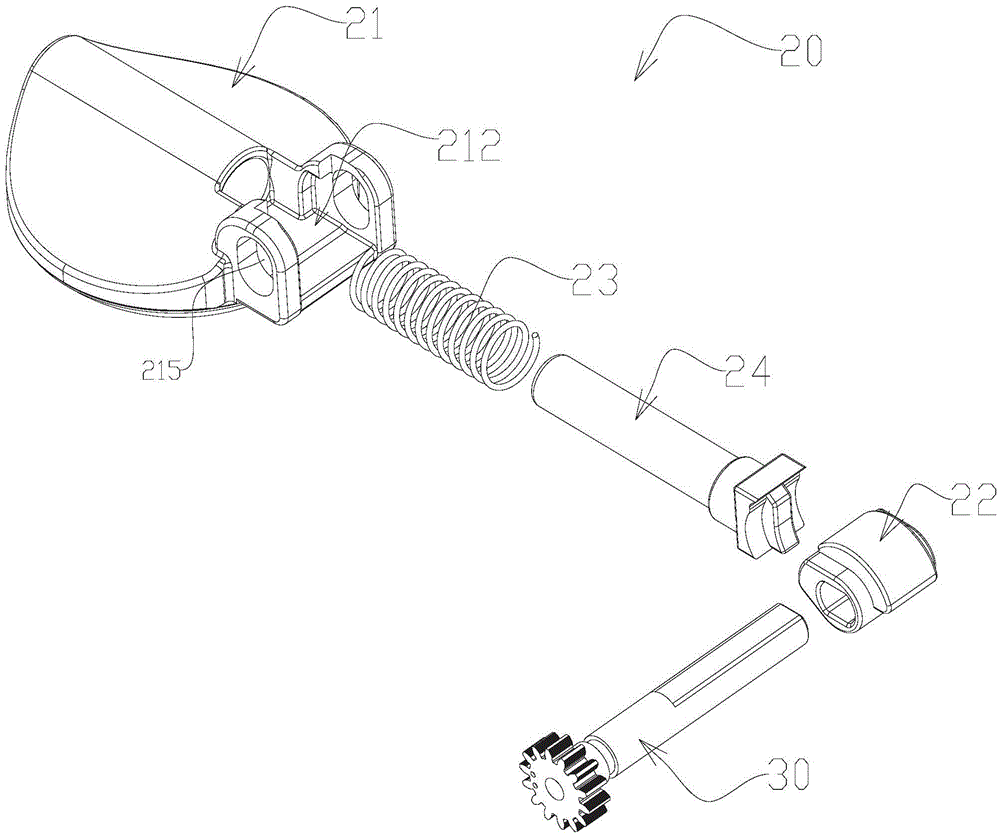

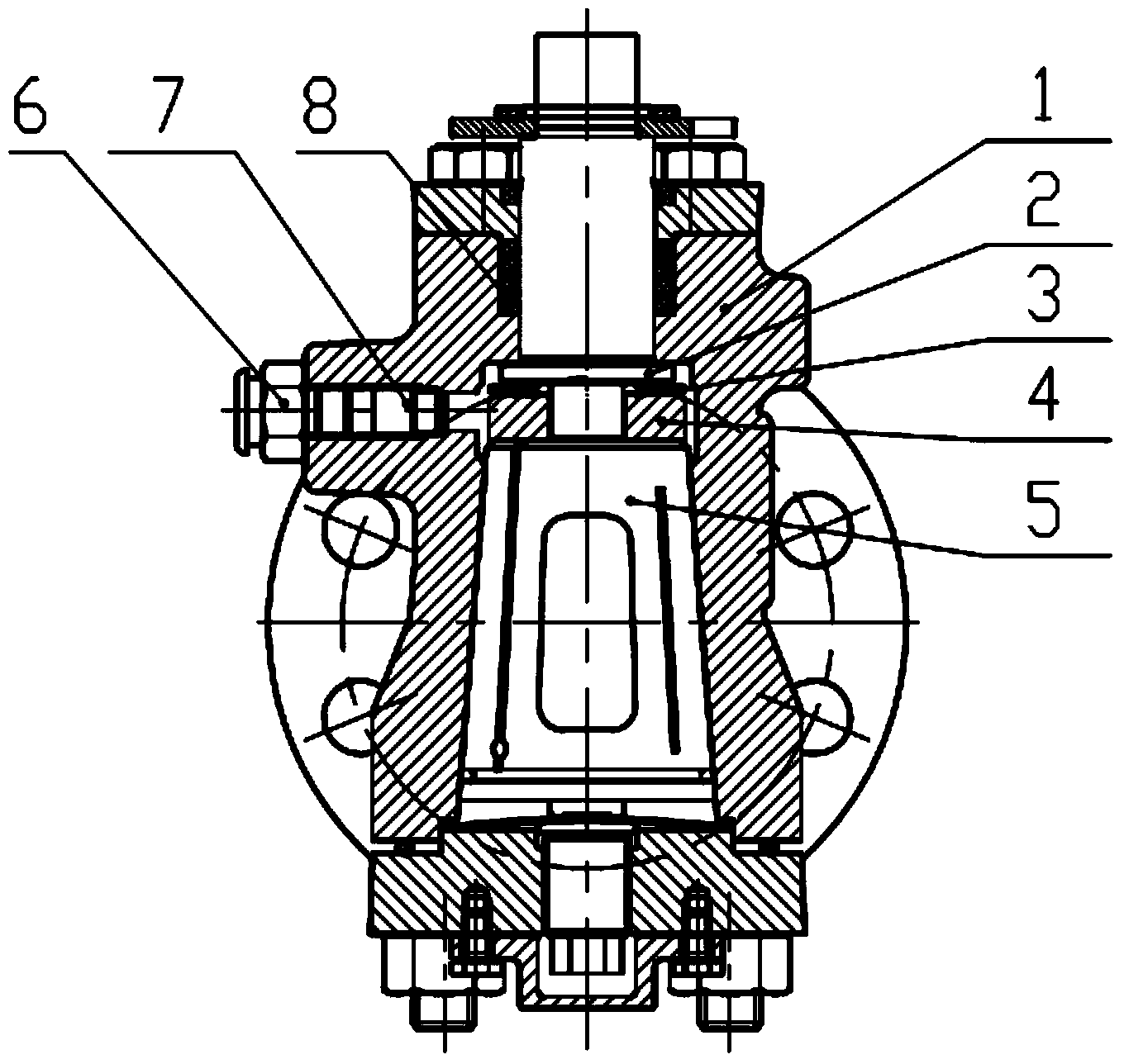

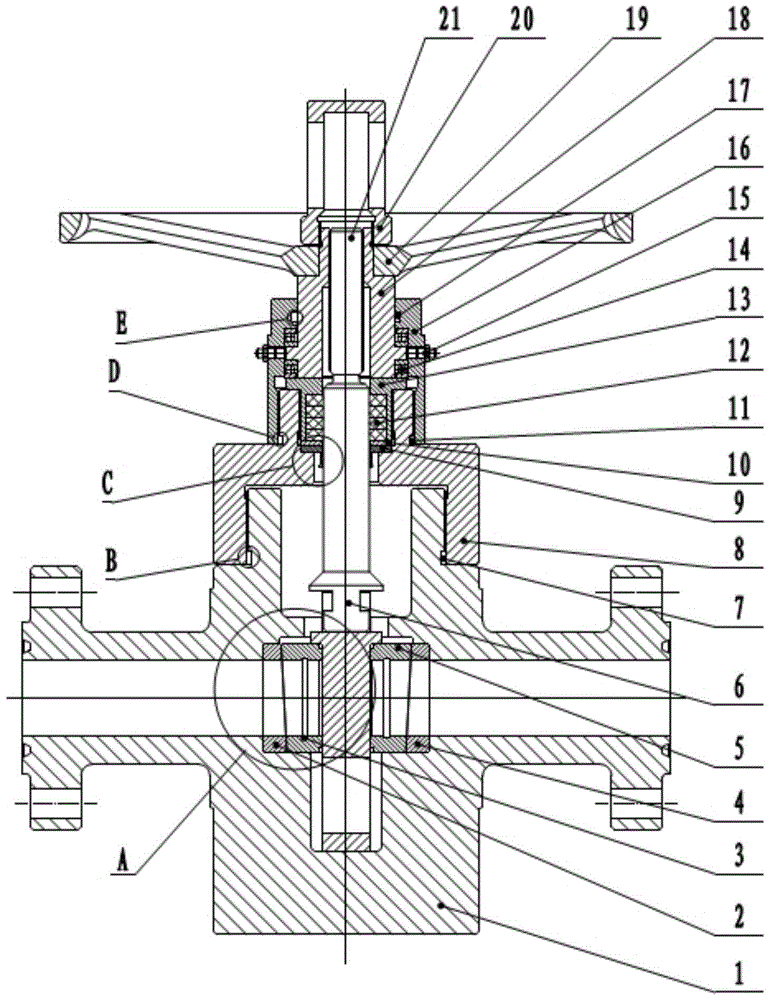

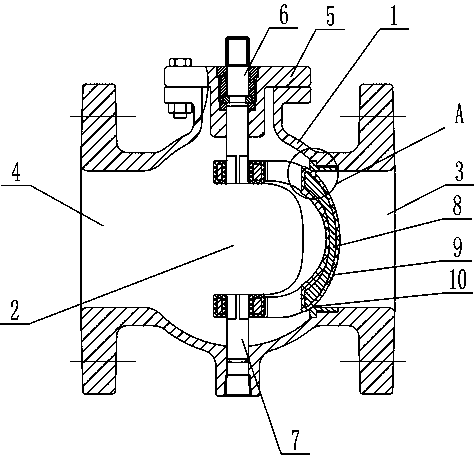

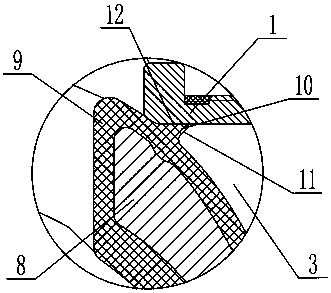

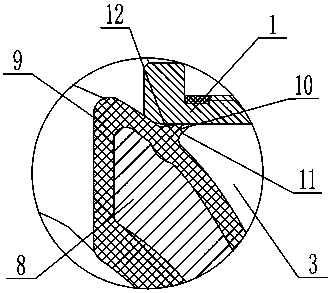

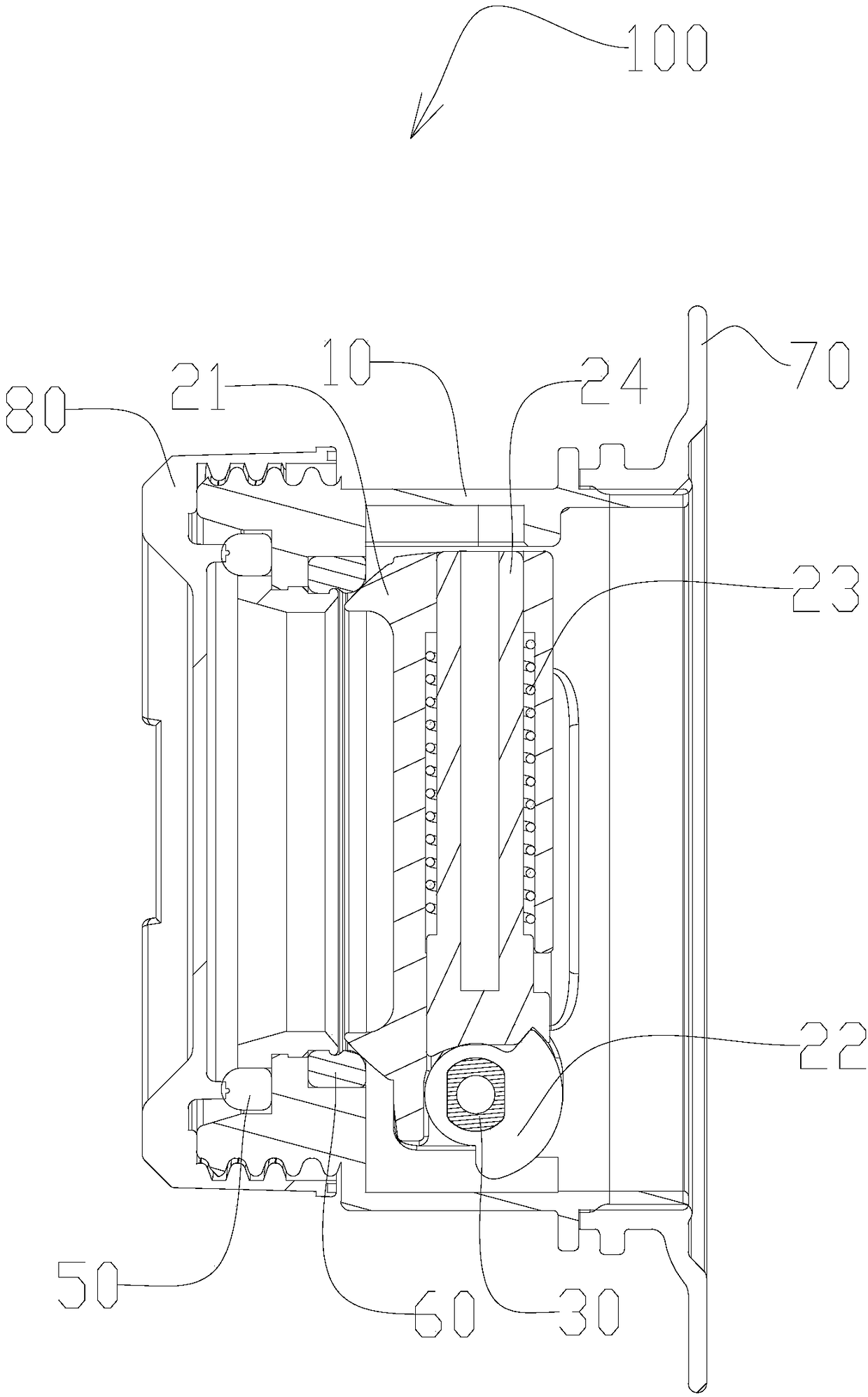

Valve

ActiveCN105805321ASimple structureImprove space utilizationOperating means/releasing devices for valvesLift valveManufacturing technologyEngineering

The invention discloses a valve. The valve comprises a valve body, a valve rod, a valve base and a valve core assembly; the valve core assembly is mounted in the valve body and comprises a valve core, the valve core is hinged to the valve body, and the valve core assembly further comprises a drive part, a positioning part and an elastic part; and the positioning part of the valve core assembly is mounted in the valve element in a relatively-moving manner, the elastic part is mounted between the positioning part and the valve element, and due to the engaging and disengaging matching relation between the riving part and the positioning part, the valve has three transmission relations in the closing process. The three transmission relations include the first transmission relation, the second transmission relation and the third transmission relation. According to the first transmission relation, the driving part and the positioning part are matched to form relative rest; according to the second transmission relation, the driving part extrudes the positioning part to enable the positioning part to do relative motion relative to the valve element; and according to the third transmission relation, the second transmission relation of the driving part and the positioning part is switched into the third transmission relation of the driving part and the valve element. The valve has the beneficial effects of being few in part, good in manufacturing technology, simple in structure, high in space utilization rate and the like.

Owner:SHANGHAI HONGYAN RETURNABLE TRANSIT PACKAGINGS CO LTD

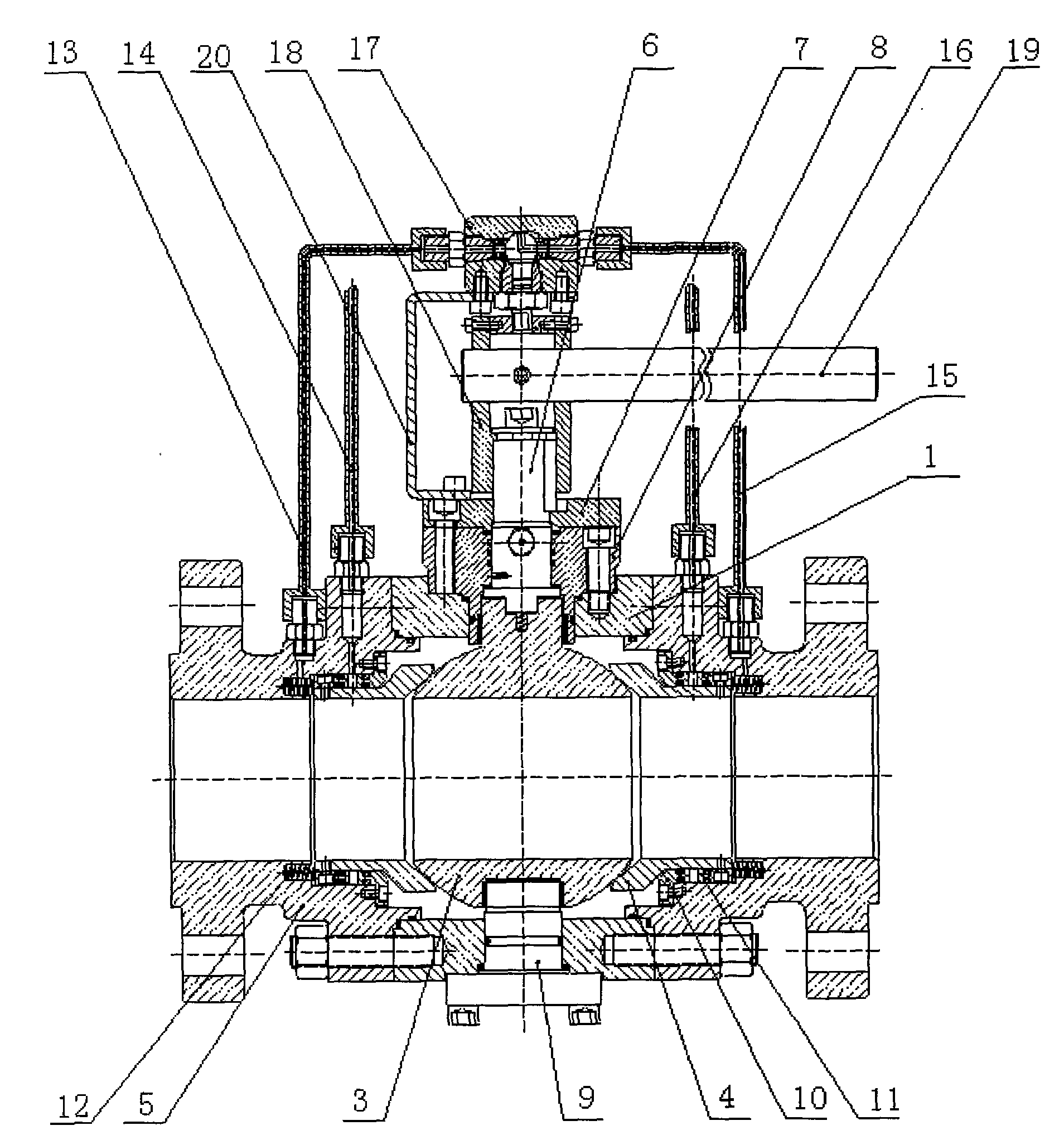

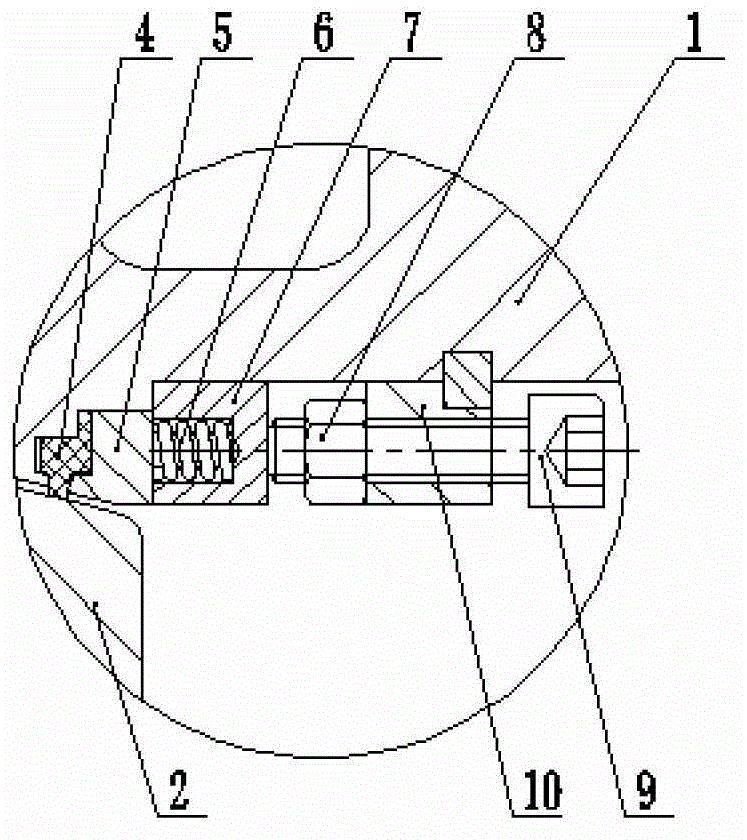

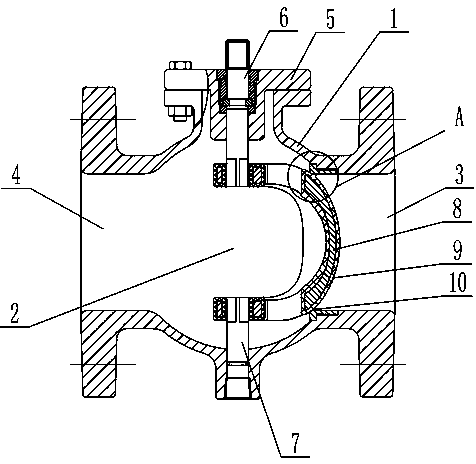

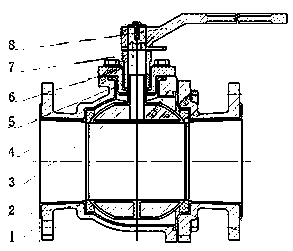

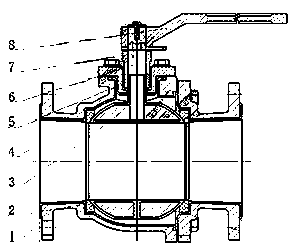

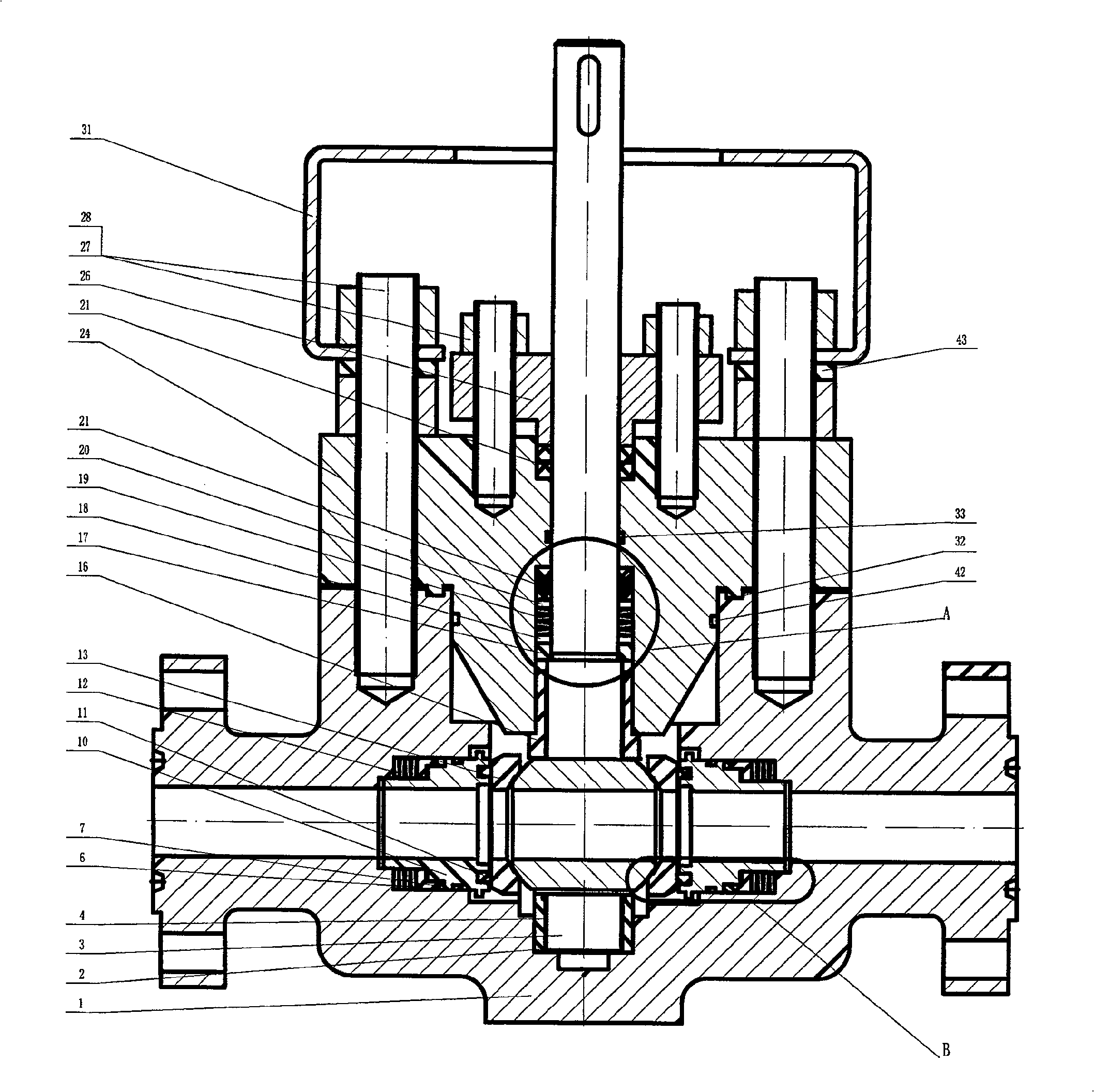

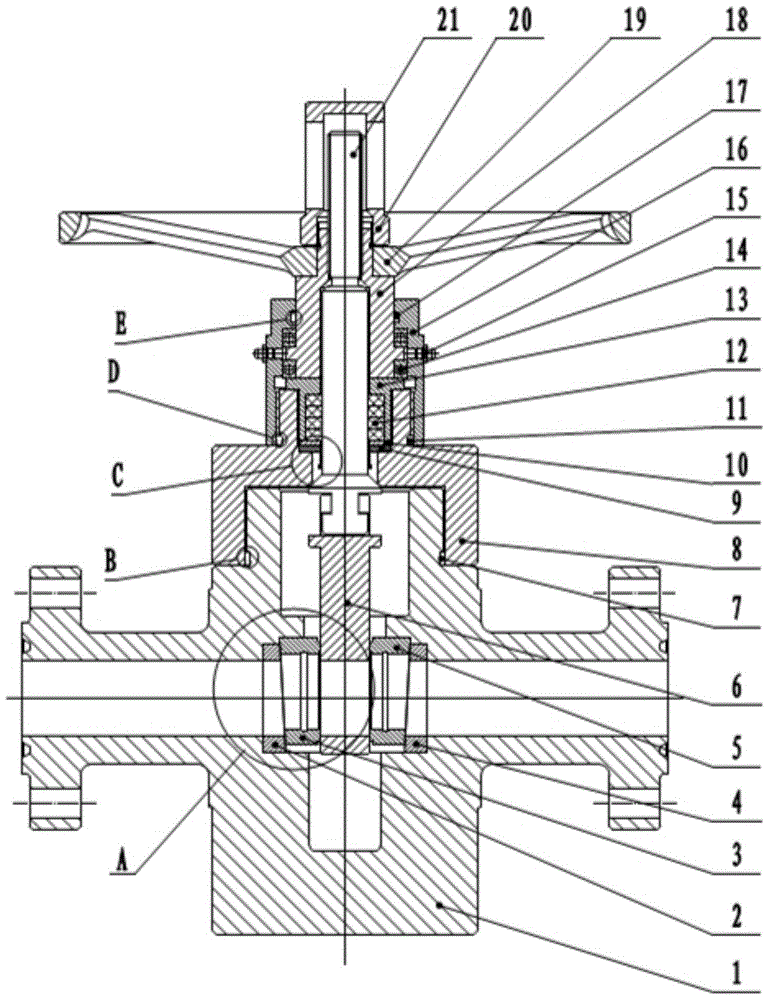

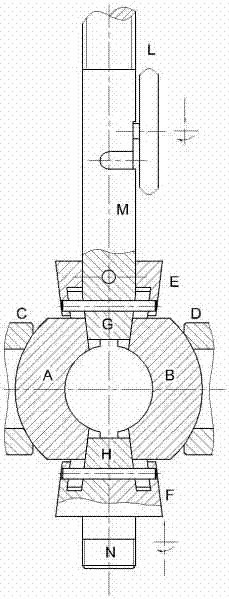

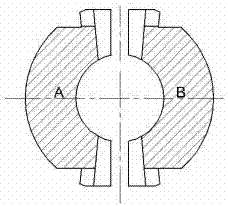

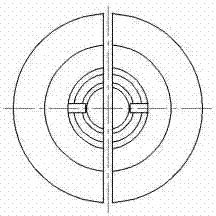

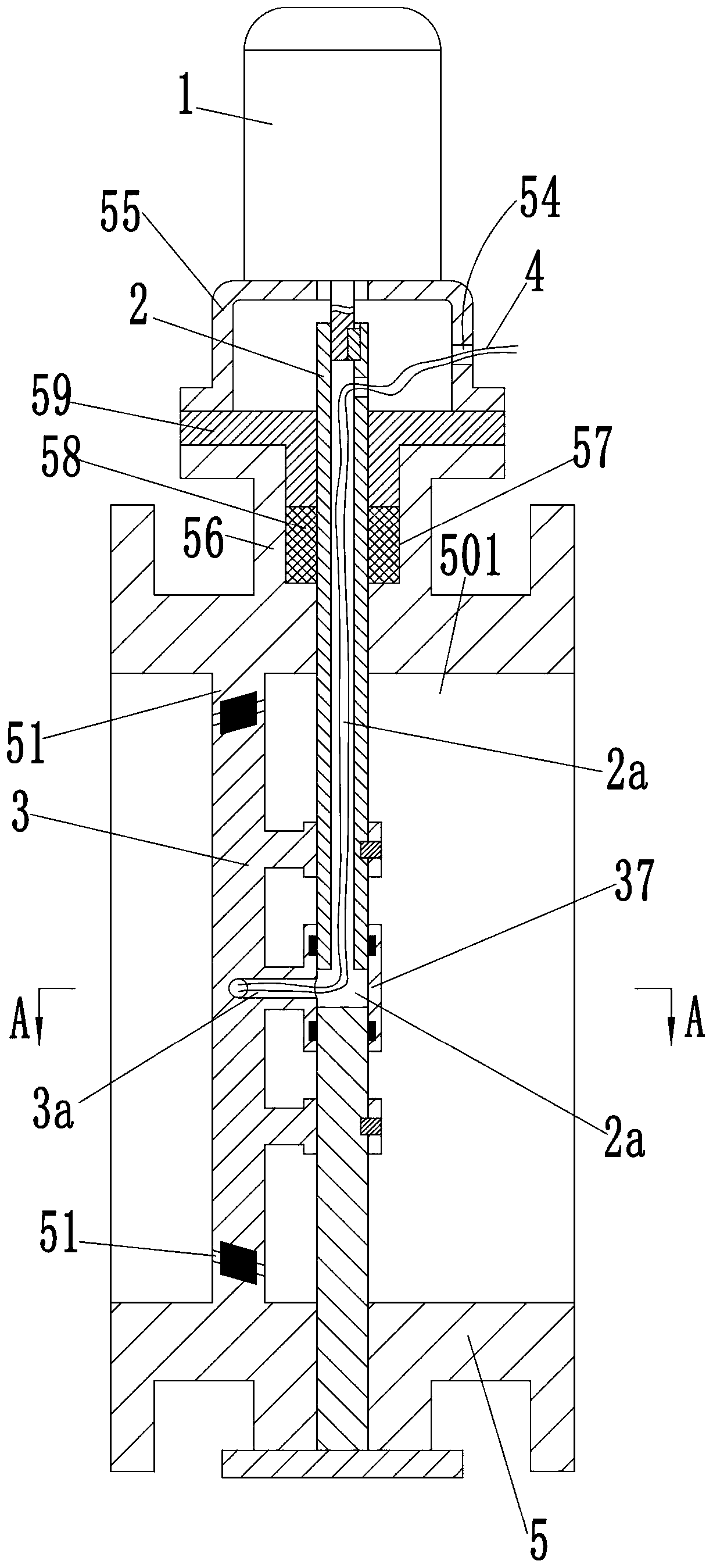

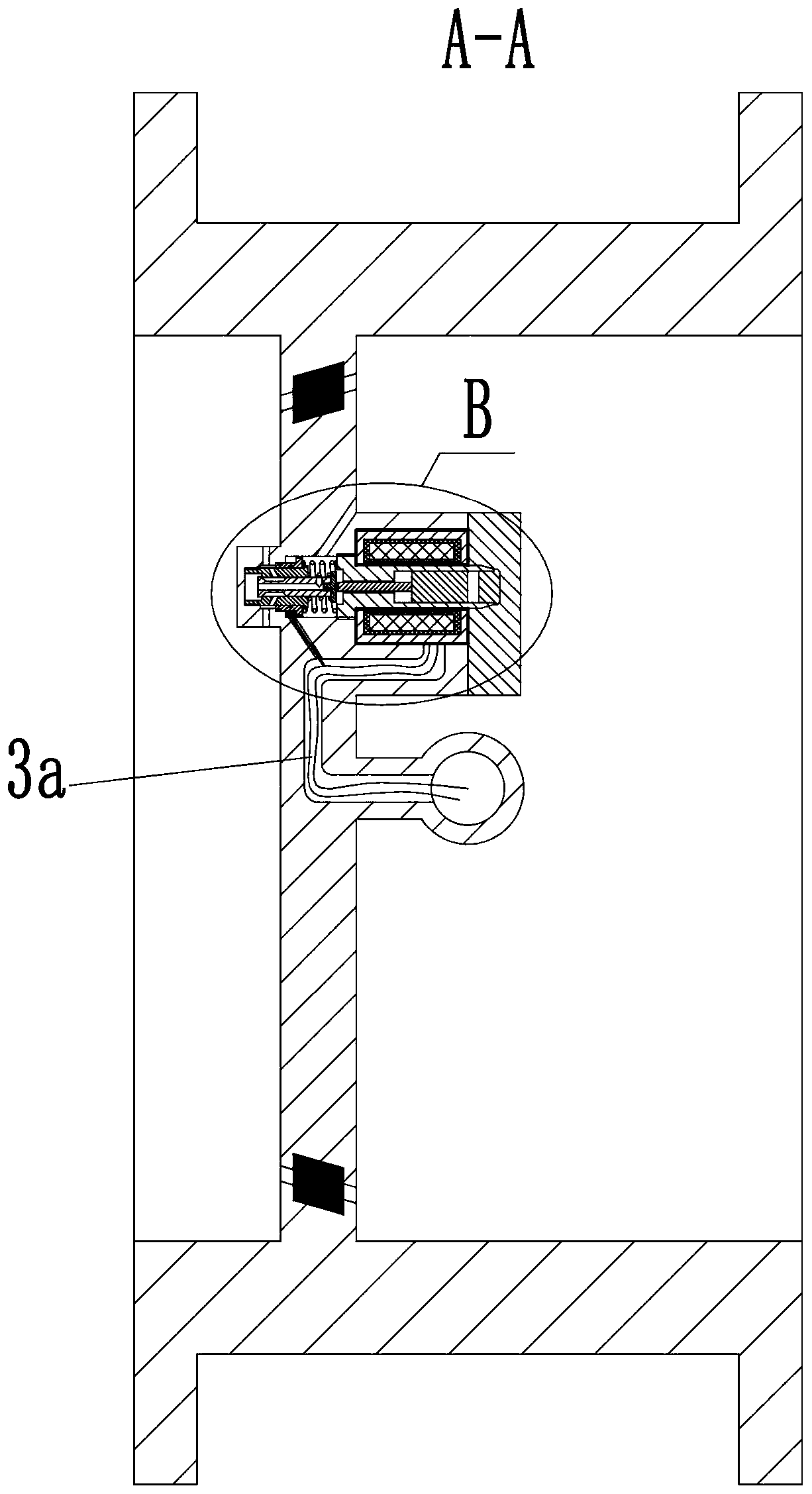

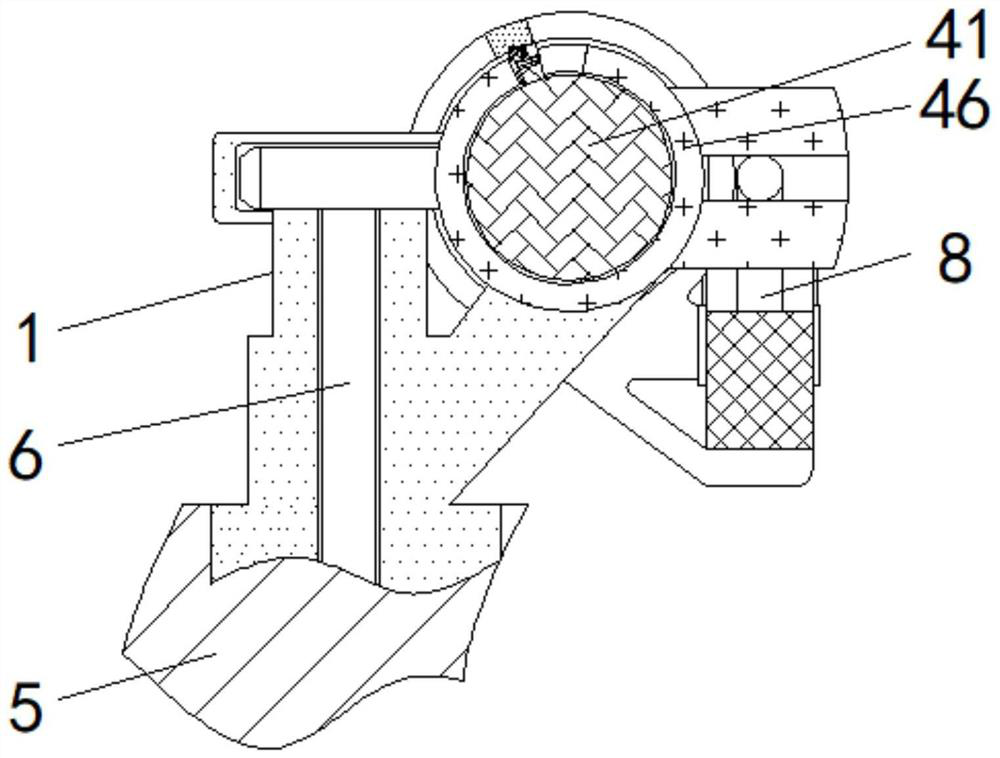

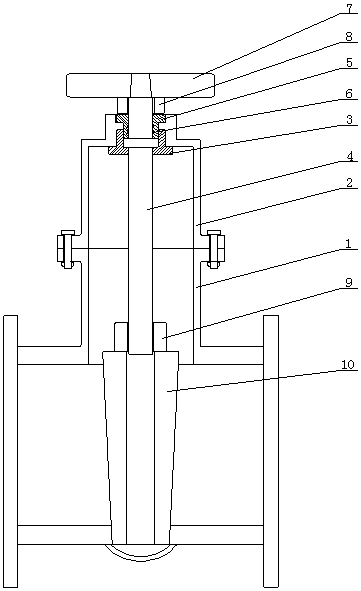

Pilot-operated type hard seal fixing ball valve

ActiveCN101629640AExtended service lifeReduced opening torquePlug valvesOperating means/releasing devices for valvesEngineeringPressure difference

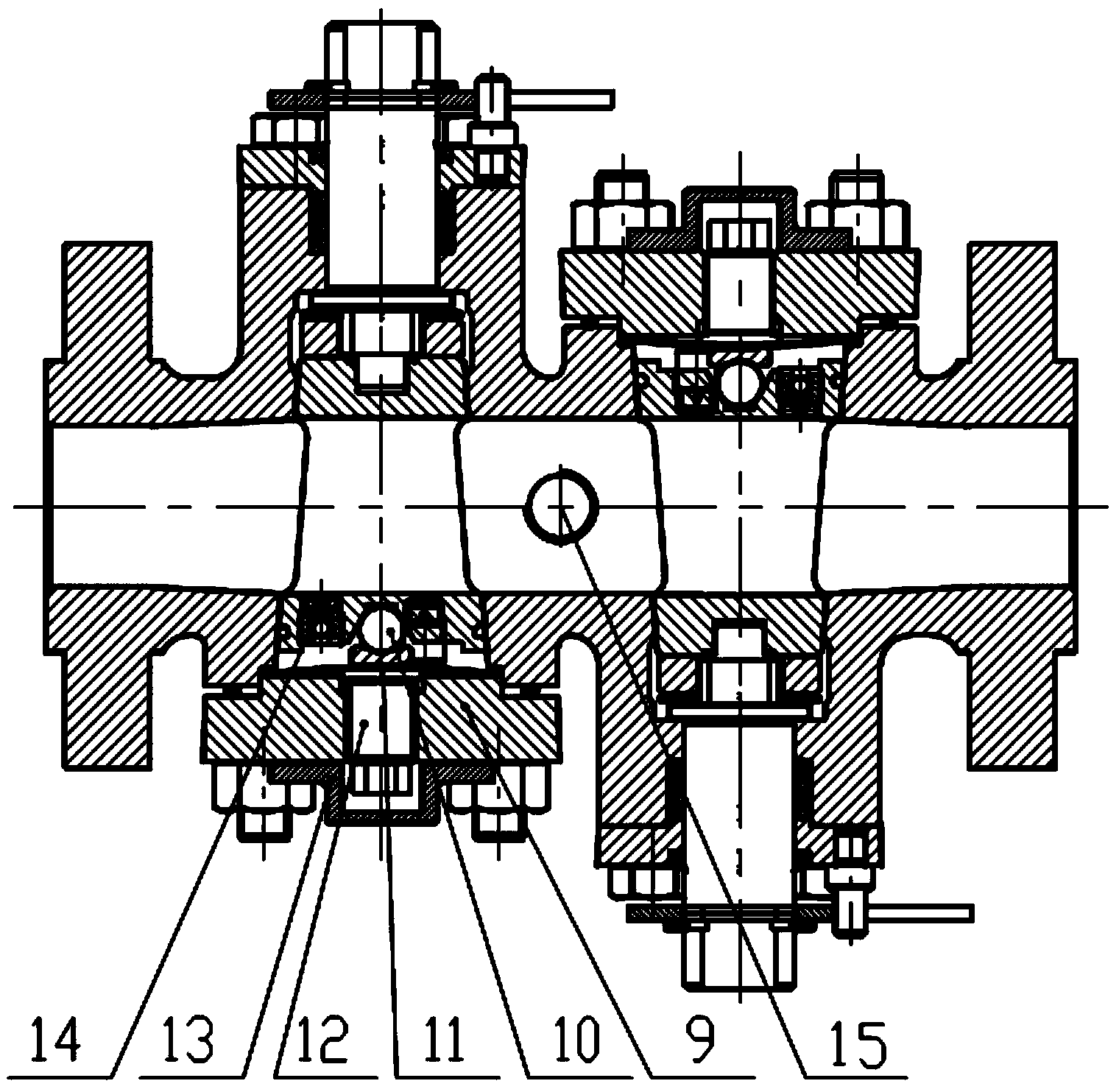

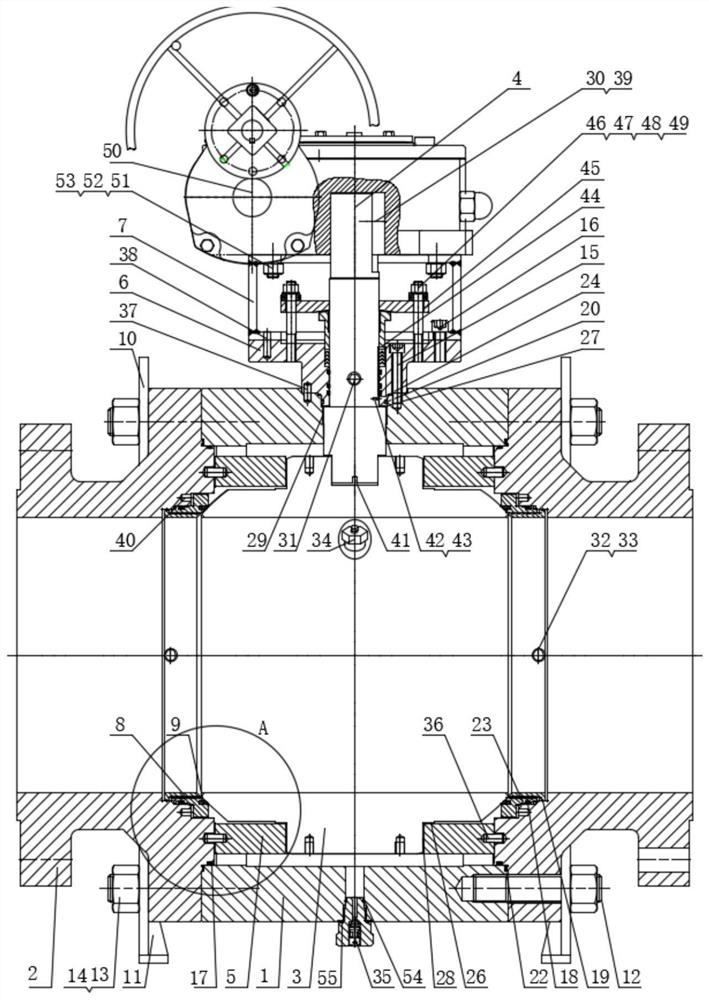

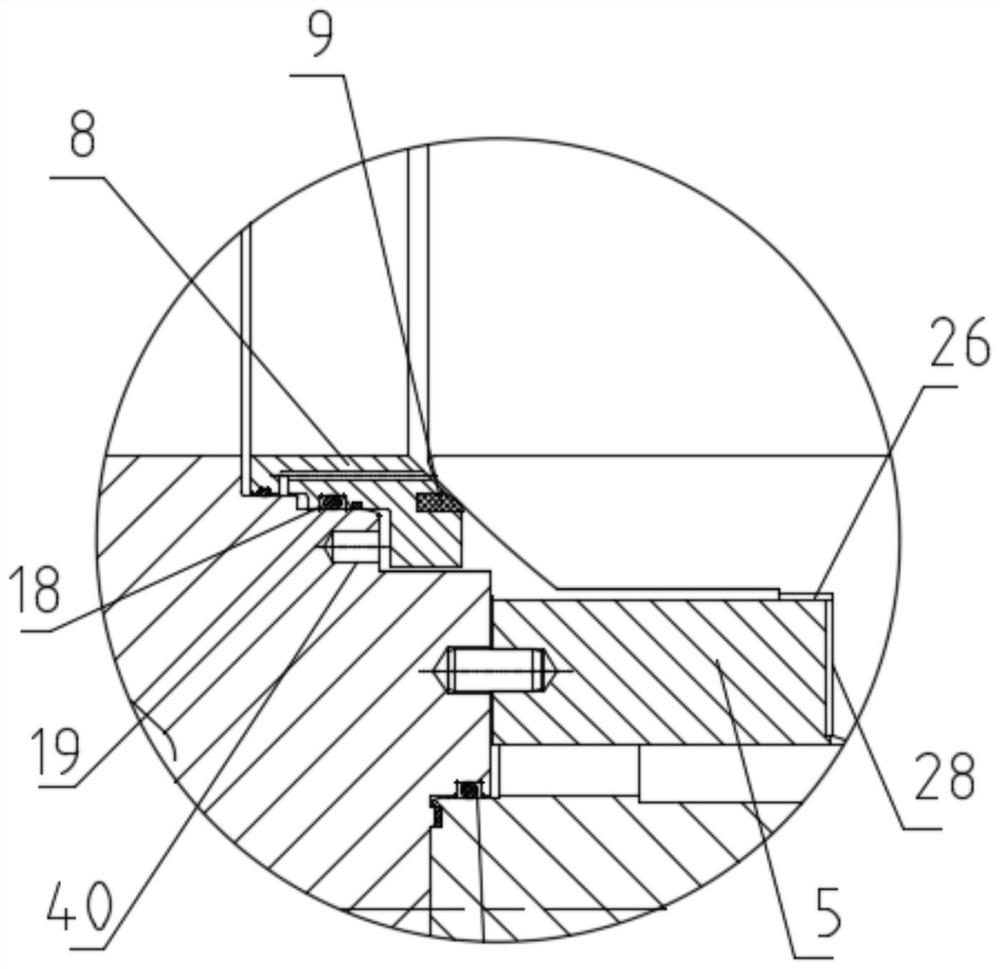

The invention discloses a pilot-operated type hard seal fixing ball valve which comprises a valve body, a ball body, a valve seat, a valve cover, a valve rod, a press cover, a filling press cover and a supporting shaft, wherein the ball body is arranged in the valve body; the valve rod passes through the upper part of the valve body and is connected with the ball body, and the valve rod is externally sleeved with the press cover and the filling press cover which are vertically arranged; the valve seat is arranged between the valve cover and the ball body; the supporting shaft passes through the lower part of the valve body and is connected with the ball body; two valve cover sealing rings and a valve seat spring are arranged between the valve cover and the valve seat; the valve cover, the valve seat and two valve seat sealing rings form a pressure difference cavity; the left side of the valve cover is provided with two left by-pass pipes, the right side is provided with two right by-pass pipes, and the left by-pass pipes and the right by-pass pipes are connected by control valves; the valve rod is also sleeved with a three-way handle head which is communicated with the control valves; and a handle steel pipe is arranged on the valve rod. The invention realizes that the valve seat can be automatically separated from a ball surface when the valve is turned on so as to greatly prolong the service life of the hard seal fixing ball valve and greatly reduce the turn-on torque of the valve.

Owner:KUSN WEISA VALVE

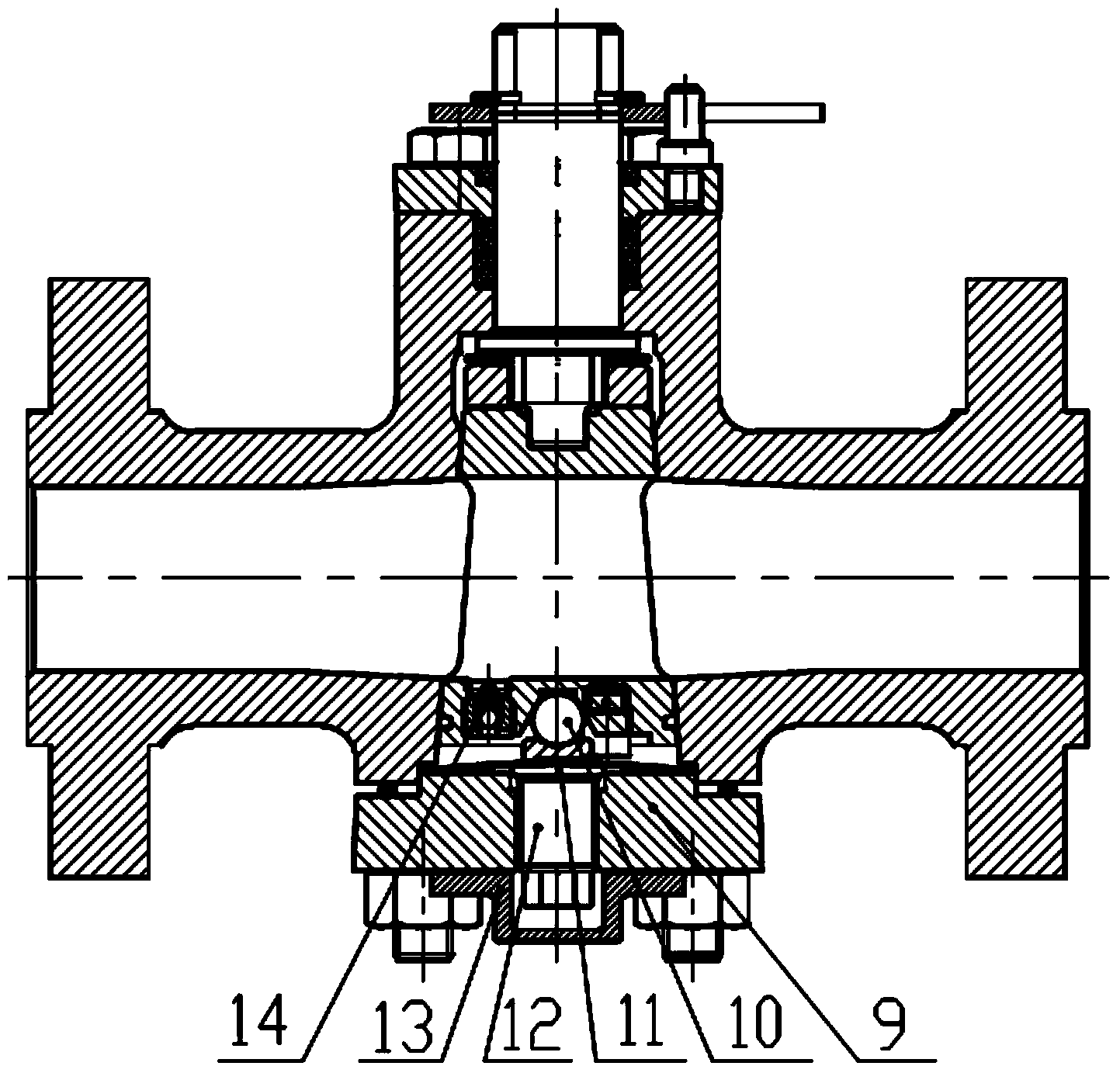

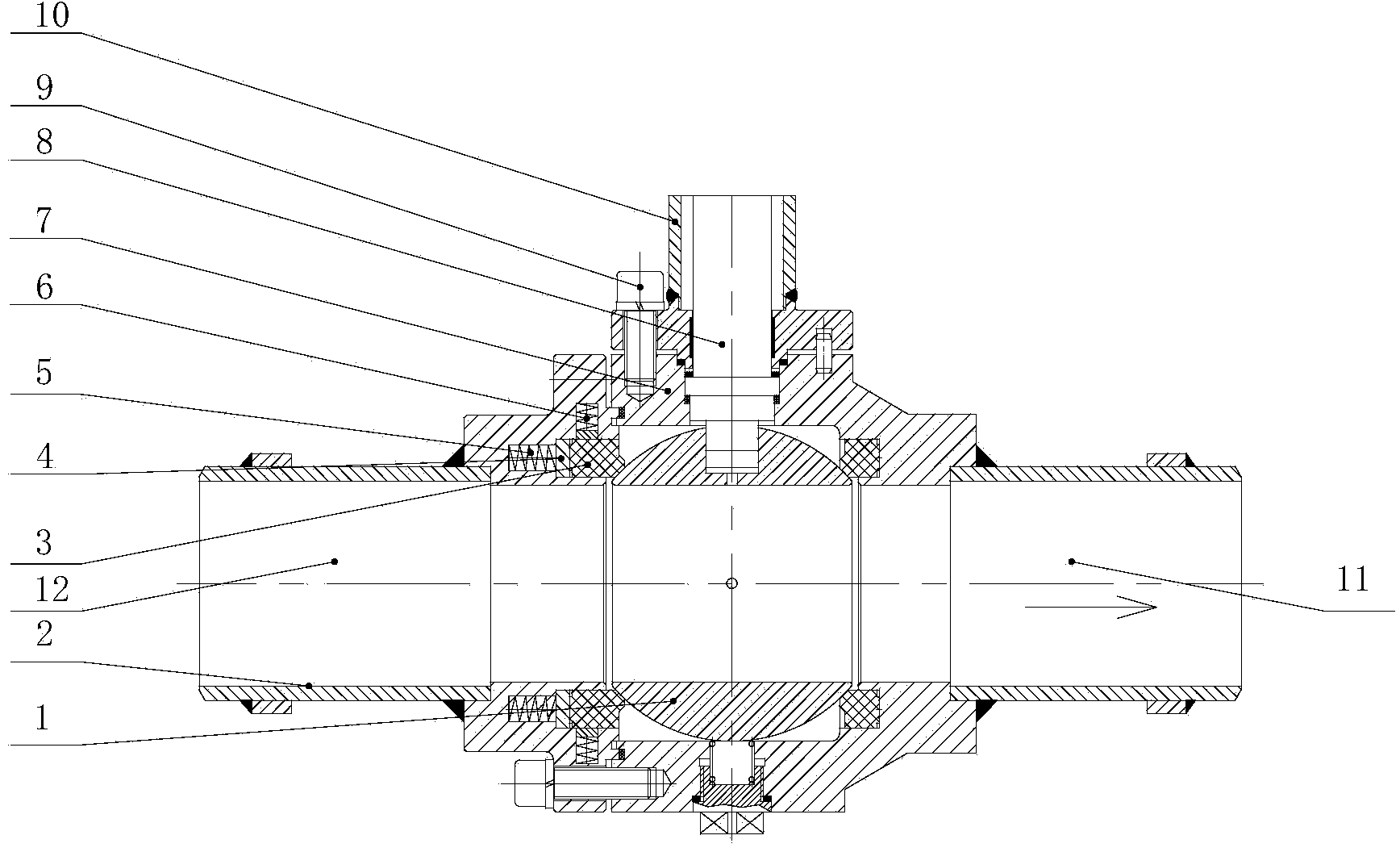

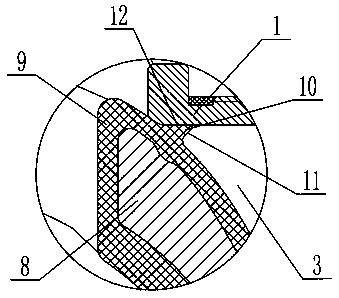

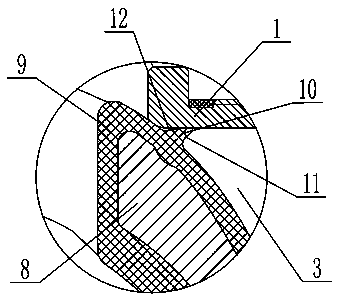

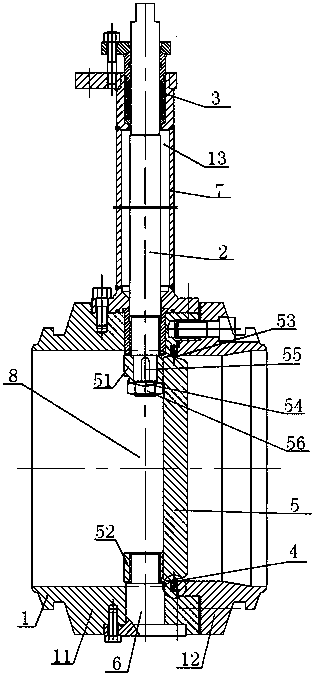

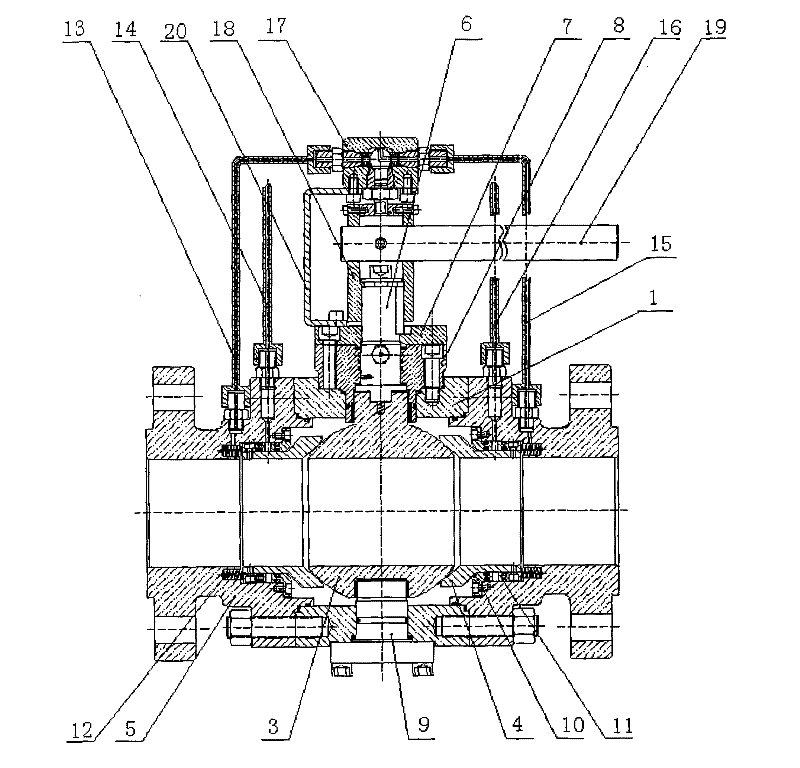

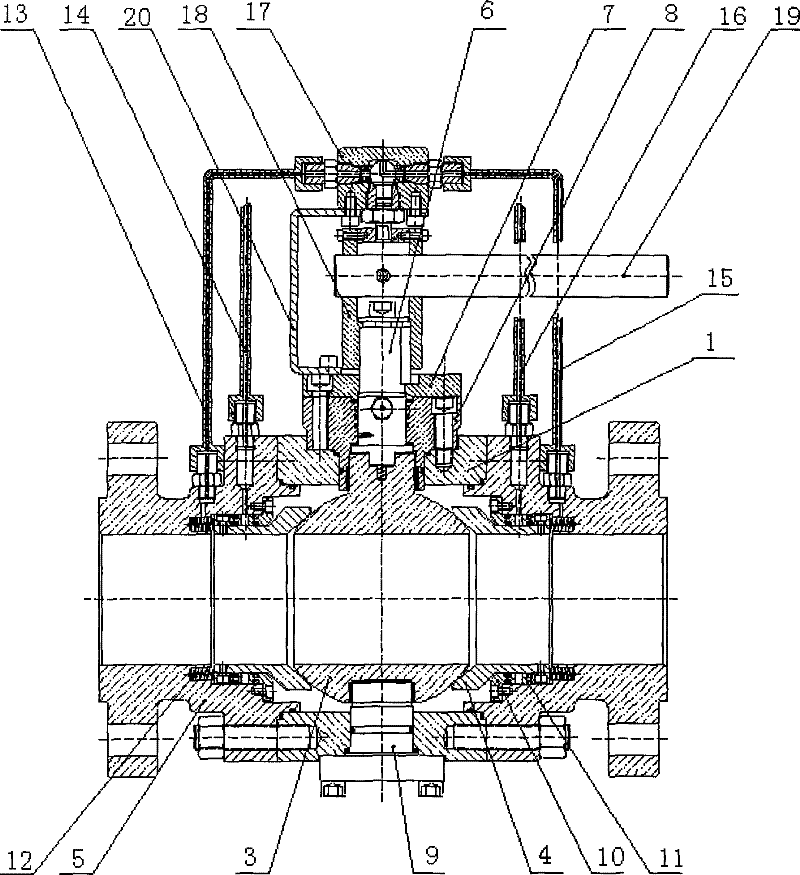

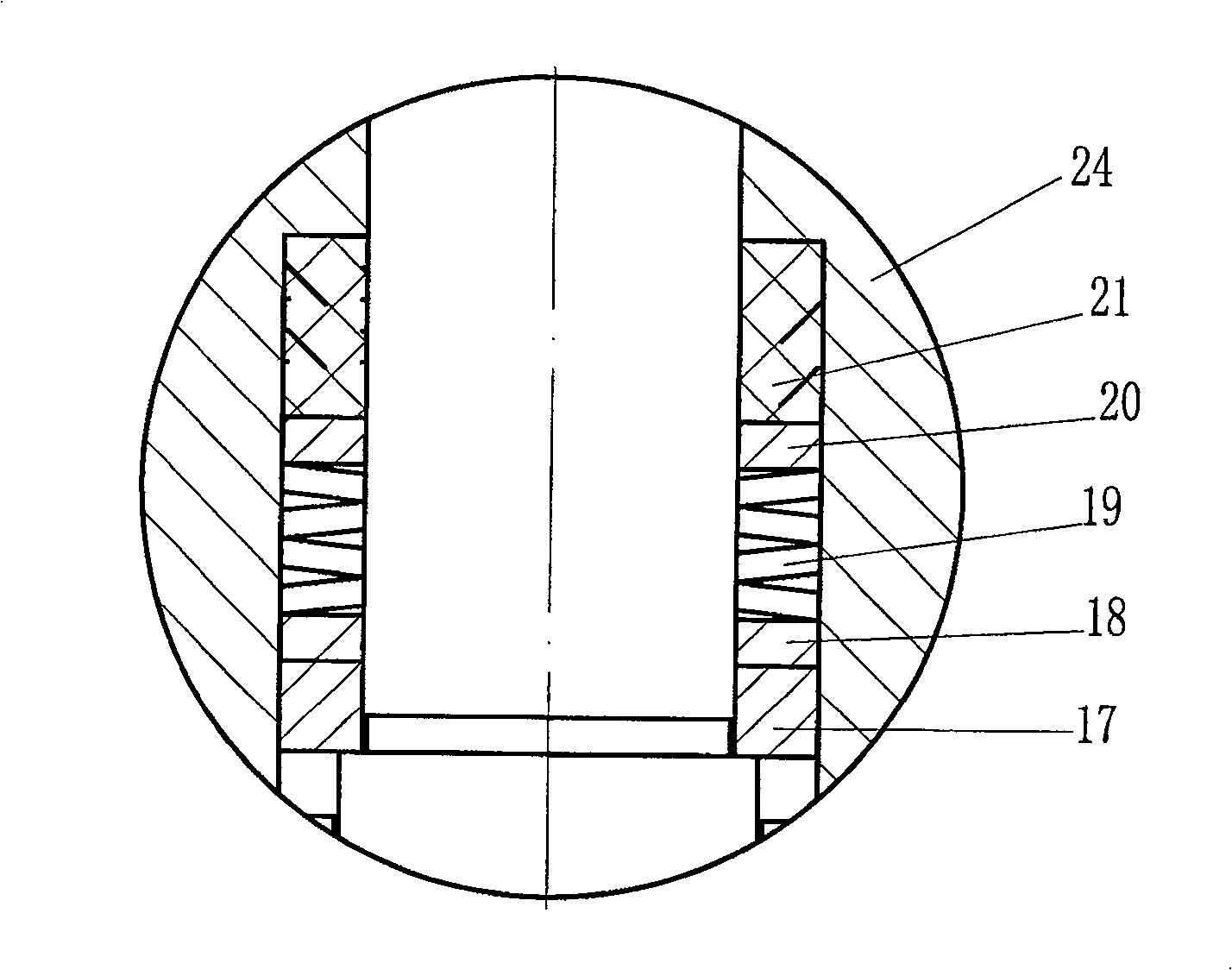

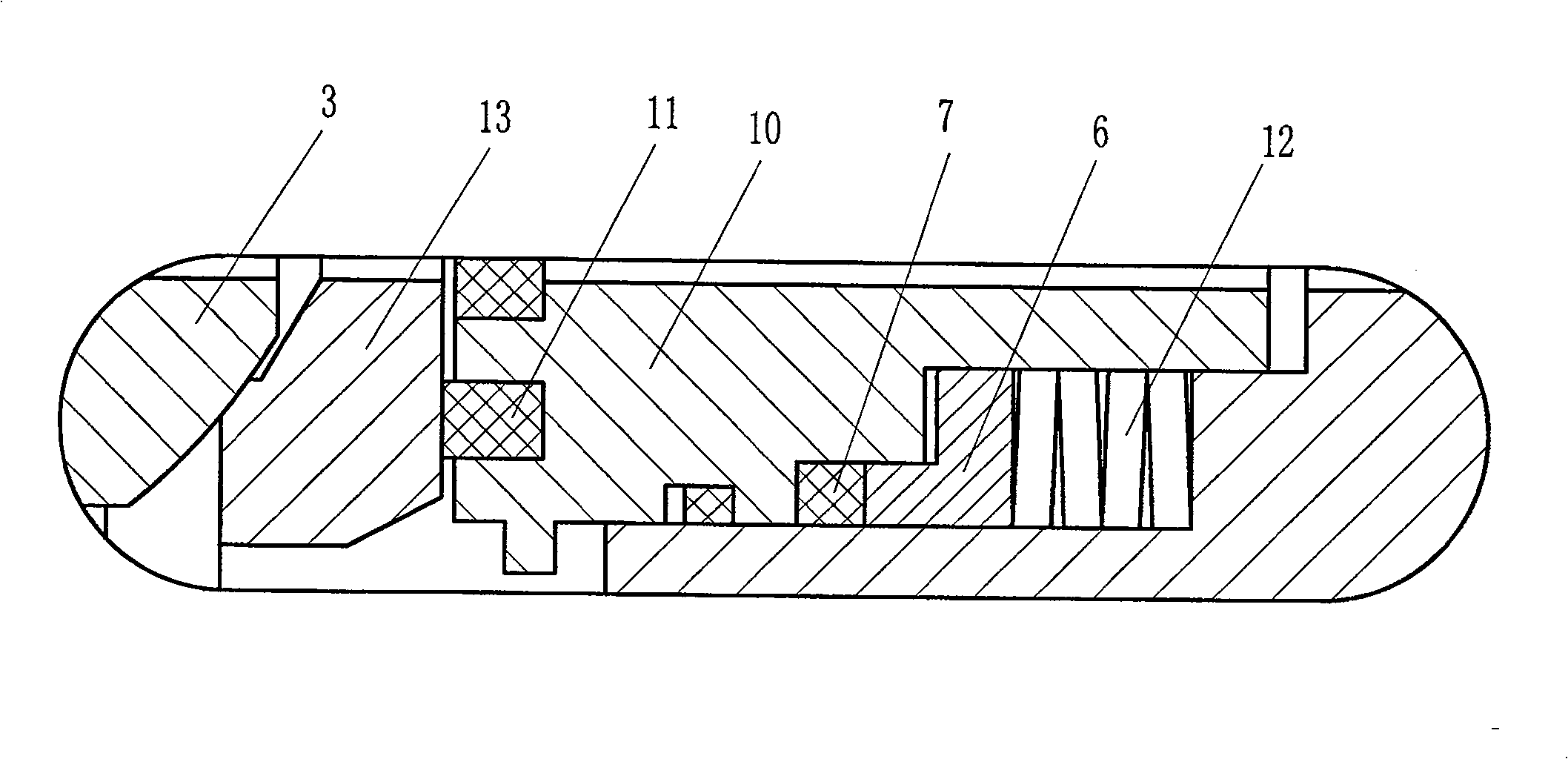

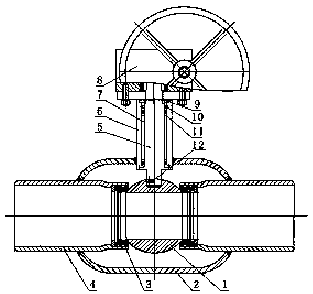

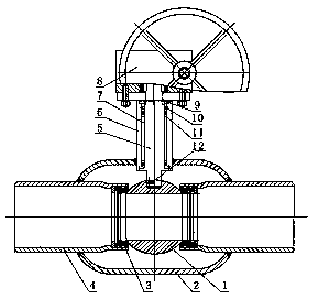

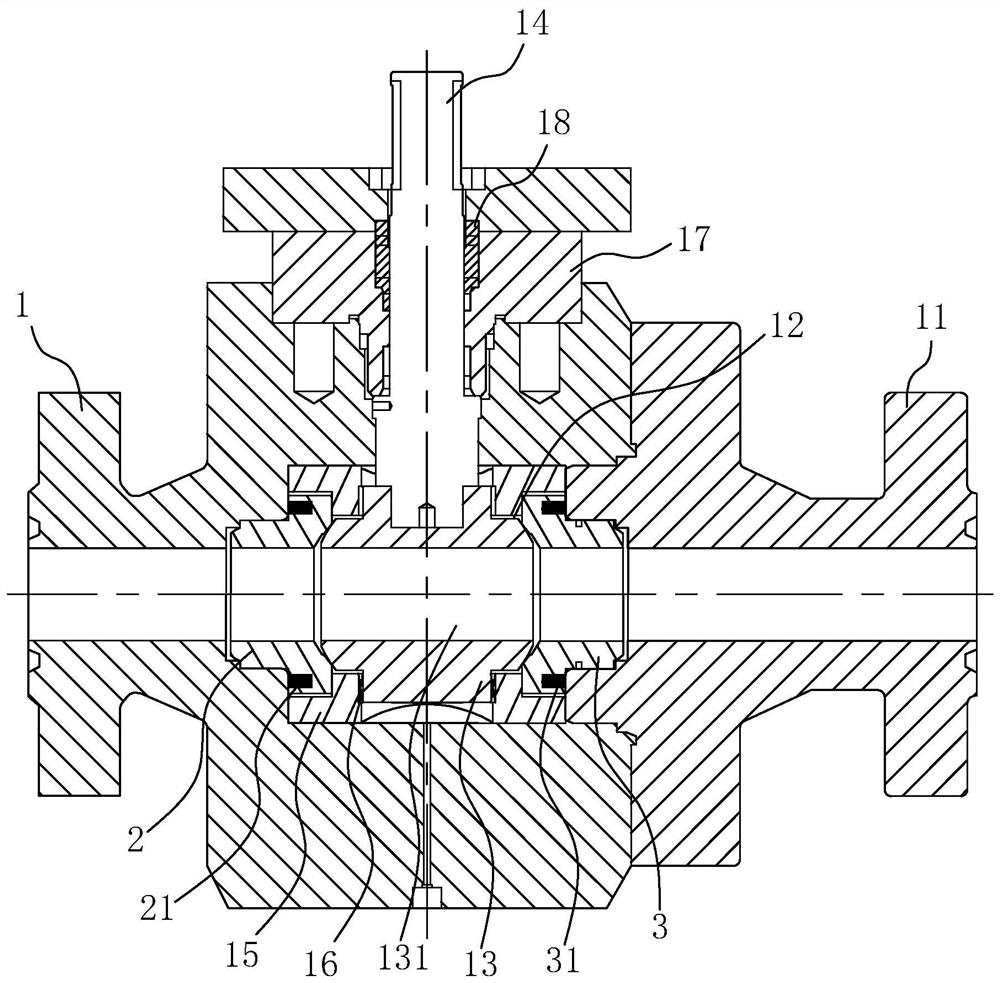

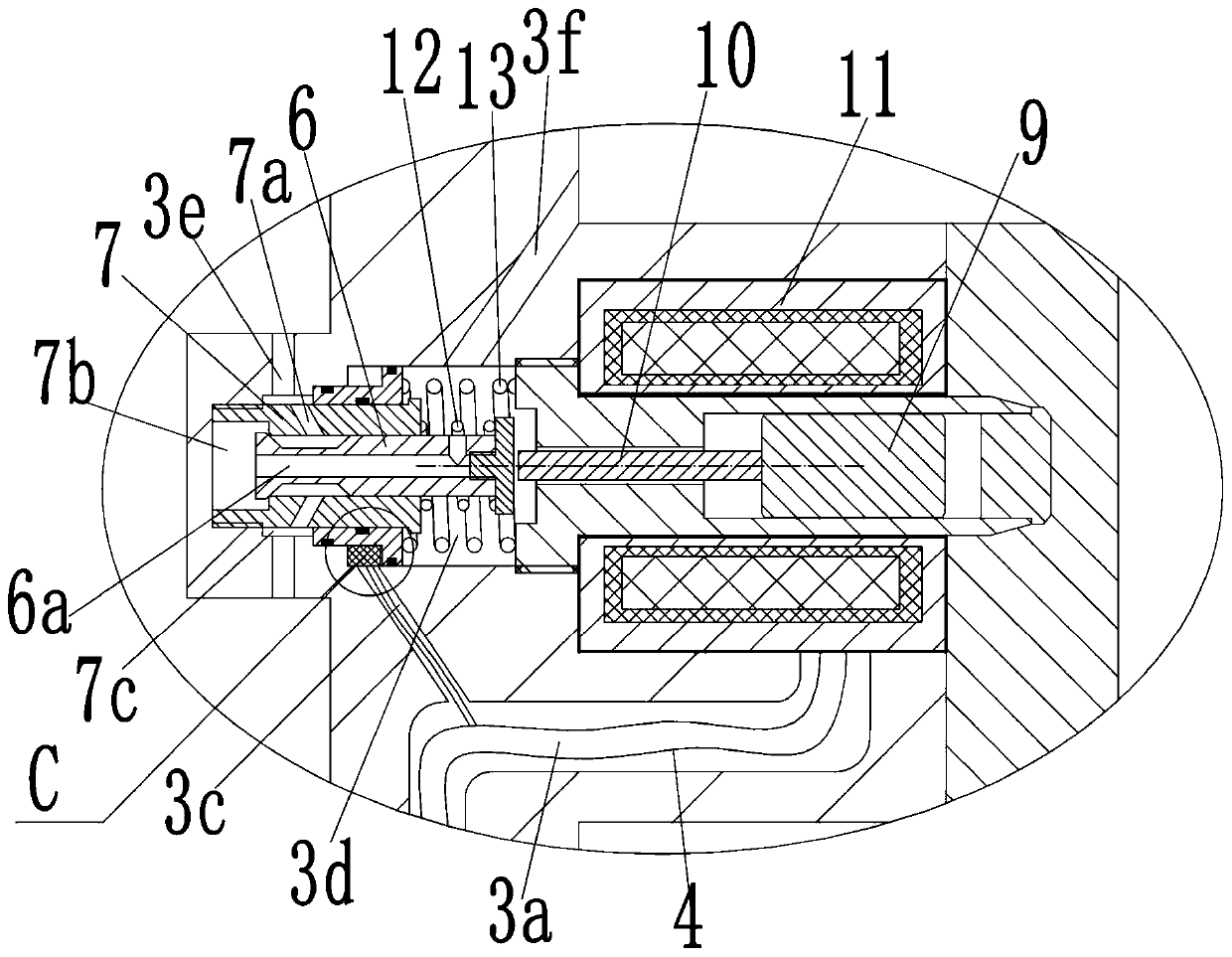

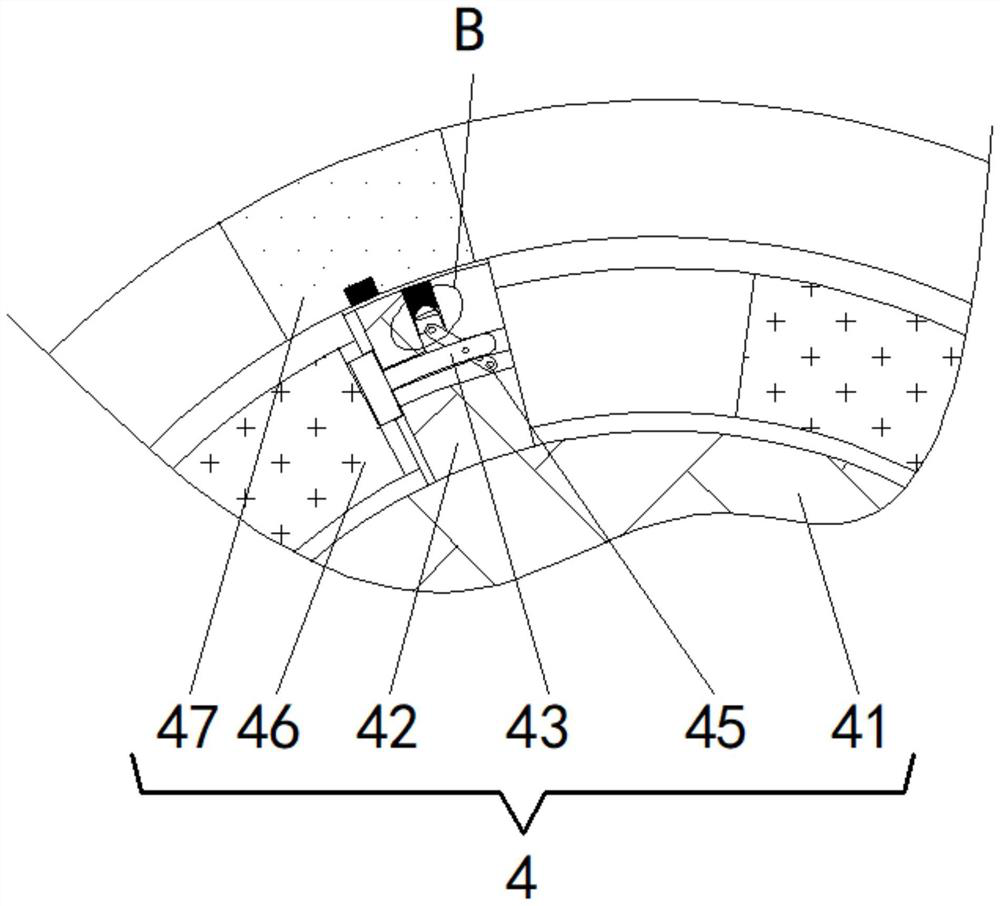

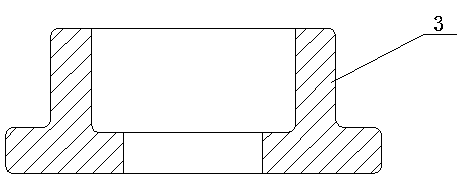

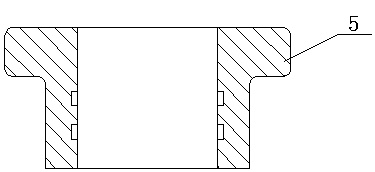

Integral top mounting type ultra-high pressure and ultra low temperature hard seal ball valve

ActiveCN101349354ALarge opening torqueGuaranteed sealing performanceSpindle sealingsPlug valvesUltra high pressureFilling materials

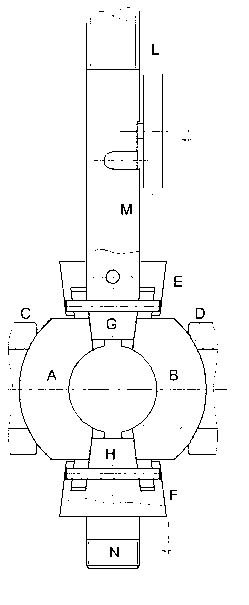

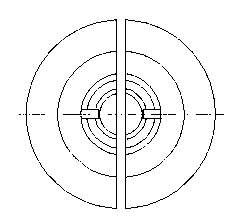

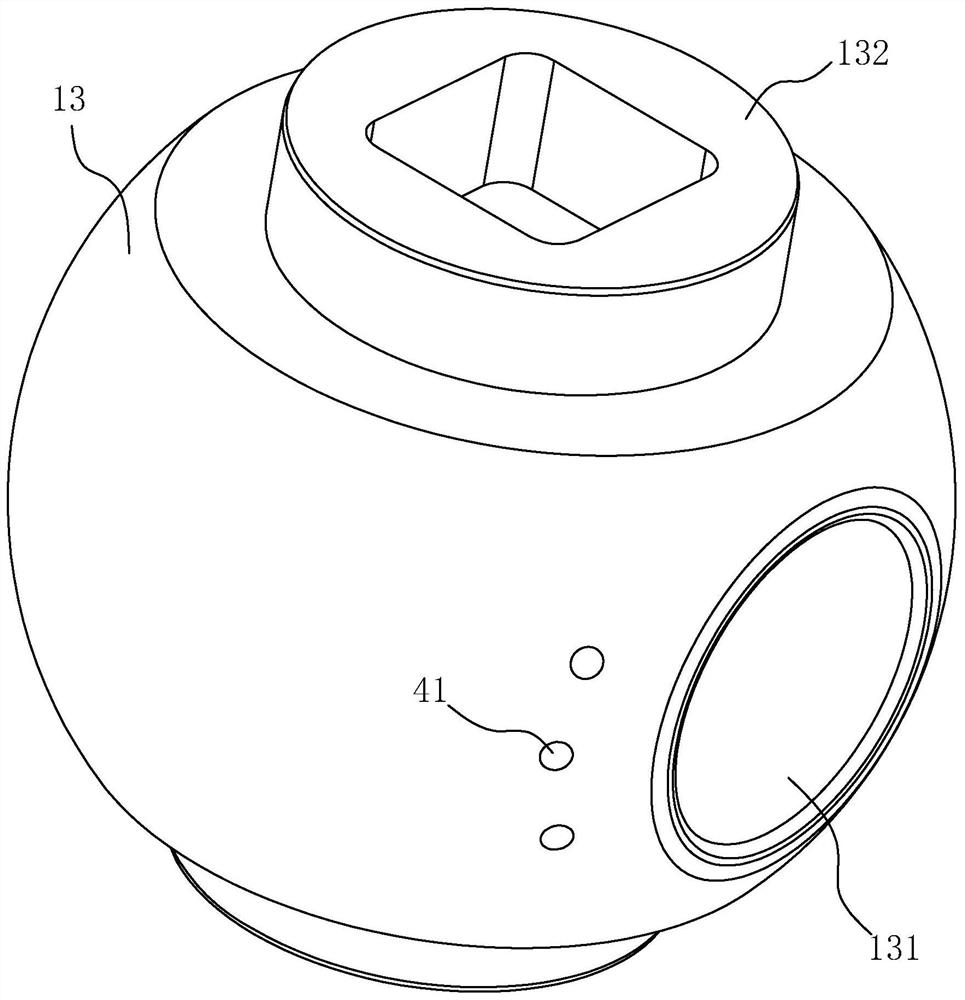

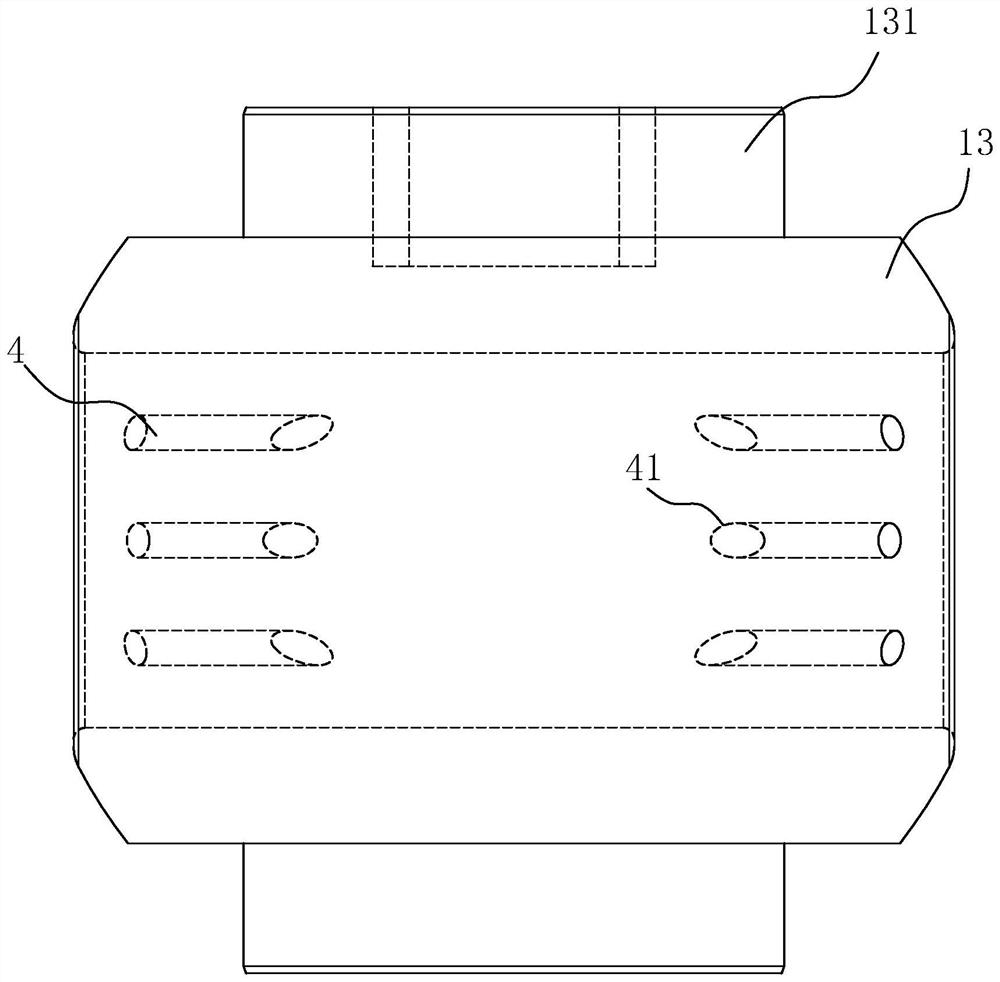

Disclosed is an internal top-mounting type super-high pressure super-low temperature hard sealing ball valve, which is mainly composed of a valve body (1), a valve cover (24), a ball body with a handle (3), a valve seat (13), a rear valve seat (10), a valve rod bearing seat (16) and the like. The ball body with a handle (3) placed in the valve body (1) penetrates through the center of the valve cover (24), and the ball body with a handle (3) is enabled to rotate 90 degrees by an external force to realize the opening and the closing of pipes. The sphere sealing is realized by that two sides of the ball body with a handle (3) hold the rear valve seat (10) and the valve seat (13), and a valve seat spring (12) elastically pushes and presses the ball body with a handle (3). The sealing of a valve rod employs a unique three-ply sealing structure of a self-sealing preloading device, which can guarantee sealing under low pressure, and under the action of high pressure, medium pressure action realizes self-sealing for a bearing ring (17), thereby avoiding that filling material sealing needs the high-strength pressure, and the torque becomes extremely large when the valve rod is opened.

Owner:JIANGSU JIULONG VALVE MFG

Pressure balance type inverted cock valve

The invention discloses a pressure balance type inverted cock valve which comprises a valve body, a cock, a valve rod and padding. The cock is an inverted conical cock with the lower end being larger than the upper end. The cock is arranged in an inner cavity of the valve body, the valve rod drives the cock to rotate, a sealing face of the cock is a conical face, the valve rod is connected with the cock through a cross connector, a cylindrical spring or a belleville spring is arranged between the valve rod and the cock, the lower end of the valve body is fixedly provided with a valve cover, and the valve cover is provided with an adjustment shaft. The lower end of the adjustment shaft penetrates out of the valve cover, and the upper end of the adjustment shaft abuts against the cock. the lower end of the cock is provided with a first check valve, a sealing grease groove is formed in the sealing face of the cock, an oil storage tank is arranged in the valve body, the oil storage tank of the valve body is communicated with the sealing grease groove of the cock, and an oil filling valve communicated with the oil storage tank is arranged outside the valve body. The pressure balance type inverted cock valve can be used under high temperature, high pressure and severe work conditions, and has the advantages of being reliable in sealing, small in operation torque, long in service life, and the like.

Owner:WOTAI VALVE KUSN

Automatic compensation butterfly valve

The invention relates to an automatic compensation butterfly valve which comprises a valve body, a valve rod, a butterfly plate and a valve seat sealing ring. A horizontal medium channel is arranged in the valve body, the valve rod is longitudinally arranged in the valve body, and one side of the valve rod in the valve body is fixedly provided with the butterfly plate which rotates under the driving of the valve rod. The valve seat sealing ring is coaxially arranged on the inner wall of the medium channel on one side, where the butterfly plate is arranged, of the valve body, and the valve seat sealing ring is sealed with the butterfly plate in a rubbing mode. The valve seat sealing ring is arranged on the valve body through an elastic compensation device, fixing seats are fixedly arranged between the inner wall of the valve body on the valve seat sealing ring side and the valve seat sealing ring horizontally at intervals. The fixing seats are horizontally provided with screws which are arranged on the fixing seats through guide regulation by nuts, the screws butt against a spring seat horizontally, and the spring seat butts against a pressing ring horizontally. The pressing ring horizontally butts against the valve seat sealing ring. The automatic compensation butterfly valve is simple in structure, scientific in design, reliable in sealing performance, long in service life, small in opening torque, and suitable for various occasions.

Owner:TIANJIN BAILIZHANFA GRP

Low-temperature spherical valve

The invention discloses a low-temperature spherical valve which comprises a main valve body, a side valve body, a sphere, a valve cover assembly and a valve rod, wherein the main valve is provided with an outlet channel and a sphere mounting chamber; the side valve body is provided with an inlet channel; the sphere is mounted in the sphere mounting chamber; the side valve body is fixed on the main valve body and covers the sphere; the side valve body is provided with a plurality of spring mounting holes extending in the direction that a medium flows, and a circular caulking groove; the spring mounting holes are communicated with the caulking groove; a compensation spring and a gasket are mounted in each spring mounting hole; a sphere gasket is mounted in the caulking groove and is in extrusion seal fit with the sphere; the sphere and the sphere mounting cavity are sealed through the sphere gasket; the valve cover assembly is fixed on the main valve body; the valve rod penetrates through the valve cover assembly and is fixedly connected with the sphere. The low-temperature spherical valve increases the balancing force to the sphere gasket, still has favorable sealing performance when the sphere gasket is subjected to low-temperature shrinkage distortion, and thus is suitable for being used in pipelines of low-temperature media.

Owner:ZHANGJIAGANG FURUI SPECIAL EQUIP CO LTD

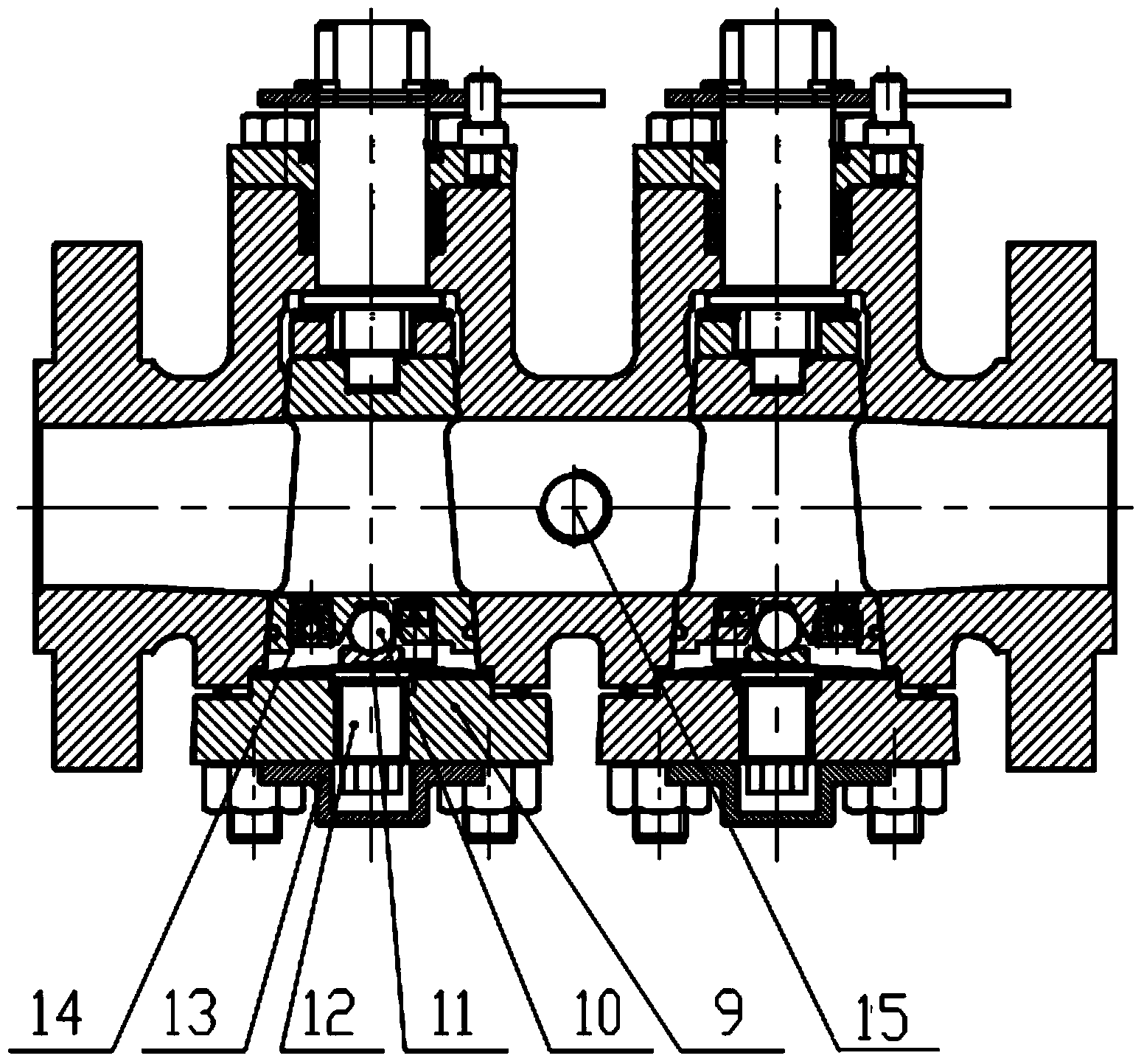

Double block and bleed pressure balance type inverted plug valve

The invention discloses a double block and bleed pressure balance type inverted plug valve which comprises a valve body, plug cocks, valve rods and filler. The plug cocks are arranged in the inner cavity of the valve body, the valve rods drive the plug cocks to rotate, the sealing faces of the plug cocks are conical surfaces, one valve body is arranged, the two plug cocks are connected in series, a safety relief valve is arranged in a valve body middle cavity between the two plug cocks, the plug cocks are inverted conical valve plugs, the ends, connected with the valve rods, of the conical valve plugs are smaller than the other ends of the conical valve plugs, the valve rods are connected with the plug cocks through cross connectors, cylindrical springs or belleville springs are arranged between the valve rods and the plug cocks, valve covers are fixed to the lower end of the valve body, an adjusting shaft is arranged on each valve cover, the lower ends of the adjusting shafts stretch out of the valve covers, and the upper ends of the adjusting shafts abut against the plug cocks. The double block and bleed pressure balance type inverted plug valve has the DBB function, can be used at high temperature and high pressure and under severe working conditions, and has the advantages of being reliable in sealing, small in operating torque, long in service life and the like.

Owner:WOTAI VALVE KUSN

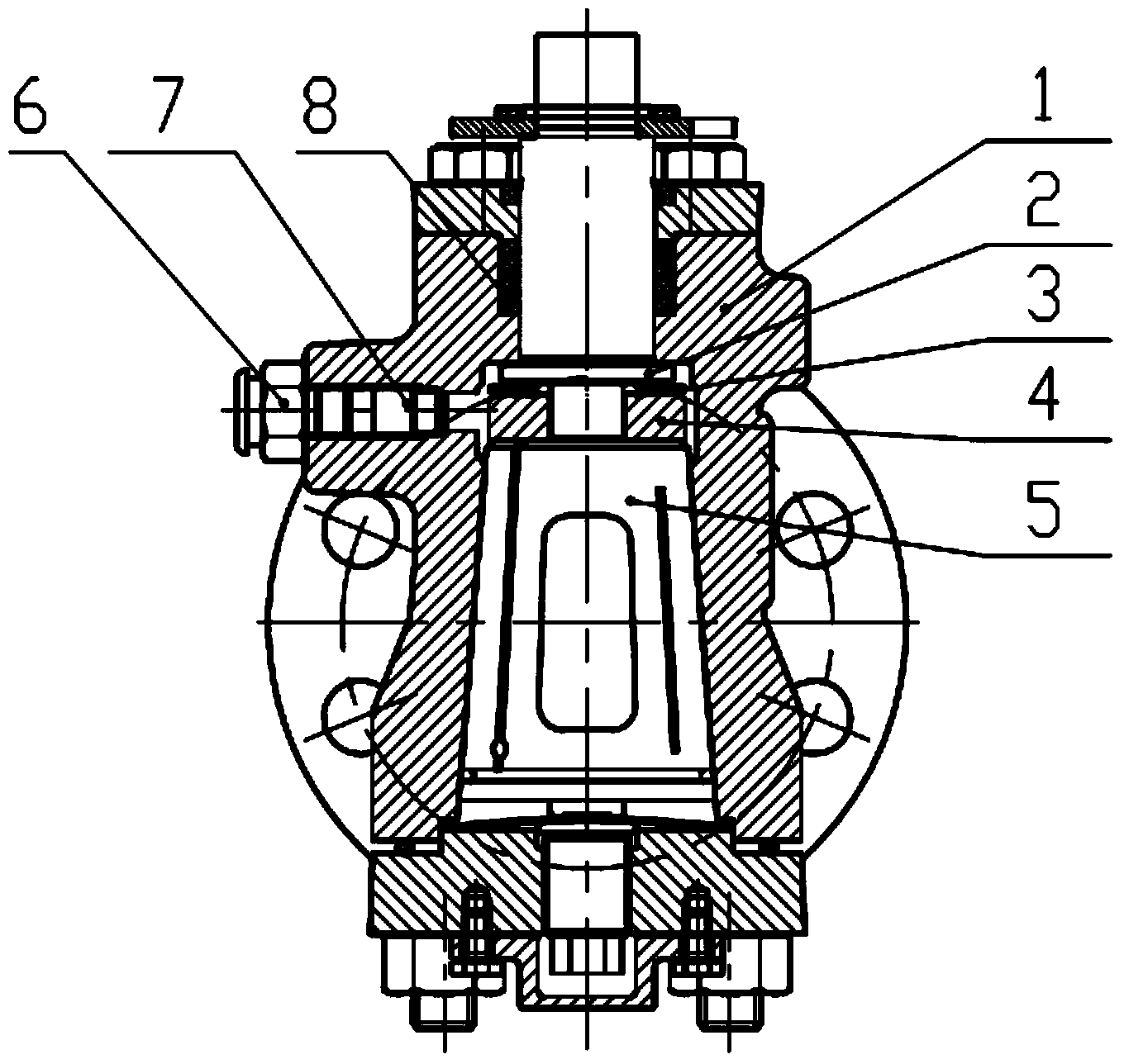

Double-wedge type double-ball-clack valve

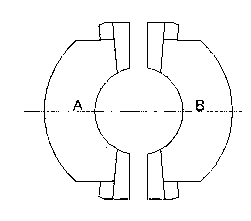

The invention discloses a double-wedge type double-ball-clack valve. A sphere of the double-wedge type double-ball-clack valve is enabled to open and close through a method of exerting external force without rotation, and partial stress, friction and abrasion are avoided and reduced. The double-wedge type double-ball-clack valve comprises a valve body, a valve seat, a support of the valve body, the sphere and a valve rod, wherein the valve seat is arranged in a flow passage in the valve body, the sphere corresponds to the valve seat and is arranged in the valve body, and the valve rod is connected with the sphere. The valve rod penetrates through gland packing of the valve body. A threaded rod at the upper end of the valve body is matched with a hand wheel nut on the support of the valve body. An L-shaped guide groove is formed in the side face of the valve rod. The support of the valve body is provided with a guide pin in a fixed mode, wherein the end portion of the guide pin is inserted into the guide groove. The double-wedge type double-ball-clack valve is characterized in that the sphere is composed of a left ball clack and a right ball clack, an upper portion between the two ball clacks is open upper taper space, a lower portion between the two ball clacks is open lower taper space, an upper wedge sphere is arranged in the upper taper space, a lower wedge sphere is arranged in the lower taper space, the upper wedge sphere corresponds to the lower wedge sphere, the upper end of the upper wedge sphere is fixedly connected with the lower end of the valve body, the lower end of the lower wedge sphere is connected with the valve body, an extending pin is arranged at the upper end of the upper wedge sphere or the lower end of the valve rod, and two ends of the extending pin are respectively arranged in horizontal grooves which are reserved at two upper ends of the two ball clacks.

Owner:DALIAN DAYANG VALVE RES & DEV CO LTD

Self-sealing eccentric half-ball valve

The invention discloses a self-sealing eccentric half-ball valve which comprises a valve body, wherein a liquid inlet cavity is arranged in the valve body; one end of the valve body is provided with a water inlet communicated with the liquid inlet cavity, and the other end is provided with a water outlet communicated with the liquid inlet cavity; the top of the valve body is connected with a valve cap; the valve cap is connected with a main valve shaft; the bottom of the valve body is provided with an auxiliary valve shaft; a half ball valve plate connected to the main valve shaft and auxiliary valve shaft is arranged in the liquid inlet cavity; the surface of the half-ball valve plate is coated with an elastic sealing layer; the elastic sealing layer of the sealing surface of the half-ball valve plate and the inner port position of the water inlet form a contact fit to form an axial sealing pair capable of implementing axial sealing; and the elastic sealing layer on the sealing surface of the half-ball valve plate and the wall of the water inlet form a contact fit to form a radial sealing pair with radial self-sealing effect. The self-sealing eccentric half-ball valve has the dual effects of axial sealing and radial sealing, can not easily cause seepage or leakage, and has the advantages of small opening torque and longer service life.

Owner:AQUA CASTING INC

Butterfly valve

PendingCN109386620ASimple preparation processSimple structureOperating means/releasing devices for valvesLift valveEngineeringButterfly valve

The invention discloses a butterfly valve. The butterfly valve comprises a valve body, an inner valve seat, a valve core, a valve rod and at least one positioning ring. The valve body has an inlet endand an outlet end and an axial passage communicating the inlet end and the outlet end. The valve body is provided with a valve rod mounting hole along the radial direction, between the inlet end andthe outlet end. And a valve seat mounting part is arranged in the valve body, at a position corresponding to the valve rod mounting hole. The inner valve seat is fixedly arranged on the valve seat mounting part and is a cylindrical piece, and the side wall of the inner valve seat is provided with a radial through hole corresponding to the valve rod mounting hole. The valve core is a plate-shaped element and is installed in the inner valve seat, wherein a through hole in the radial direction is formed in the plate-shaped element. The valve rod sequentially passes through the valve rod mountinghole, the through hole of the inner valve seat and the through hole of the valve core; the positioning ring is arranged in the valve body, on the axial side surface of the inner valve seat and forms asealing connection with the inner valve seat. The butterfly valve has good sealing performance.

Owner:SHANGHAI HONGYAN RETURNABLE TRANSIT PACKAGINGS CO LTD

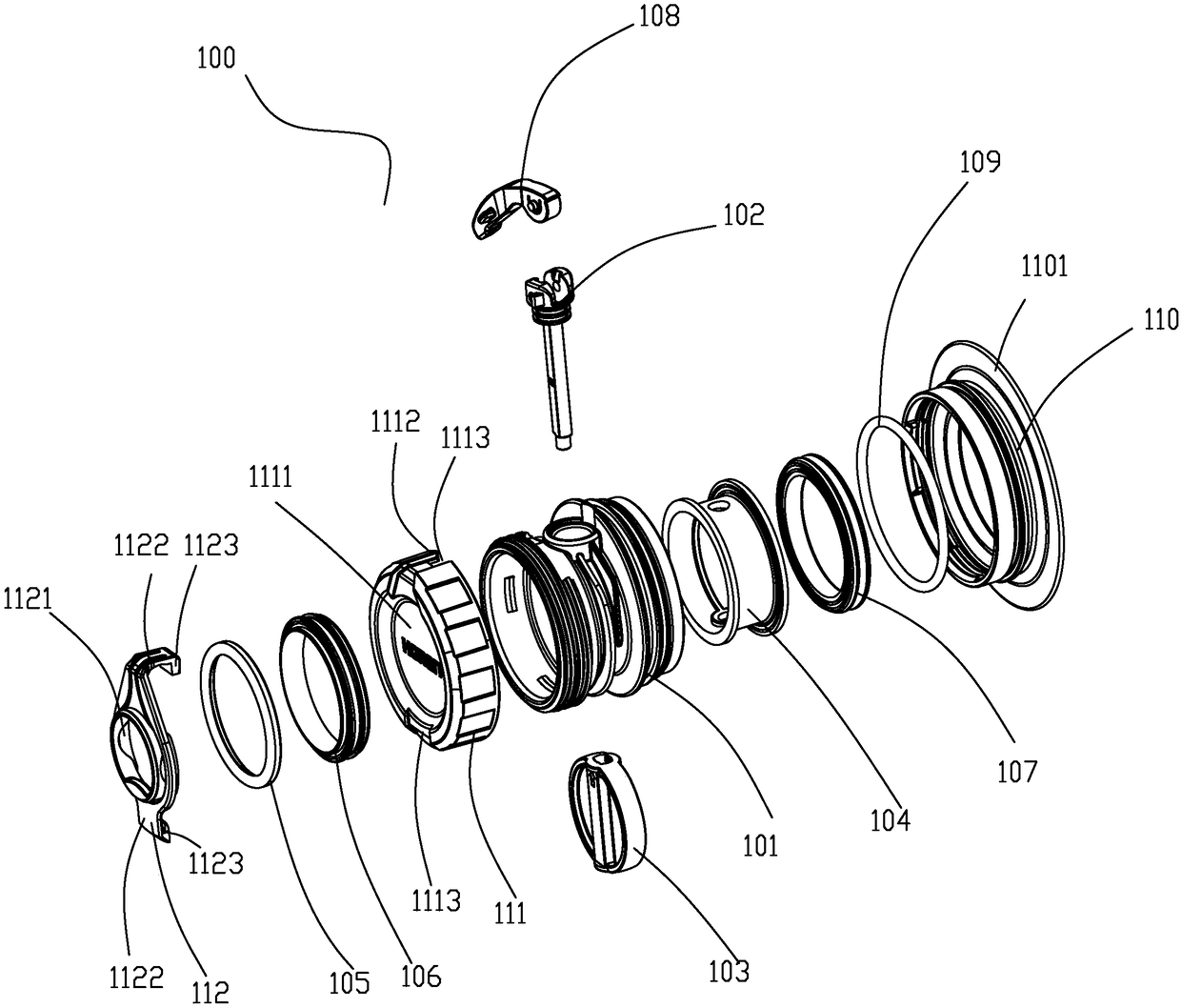

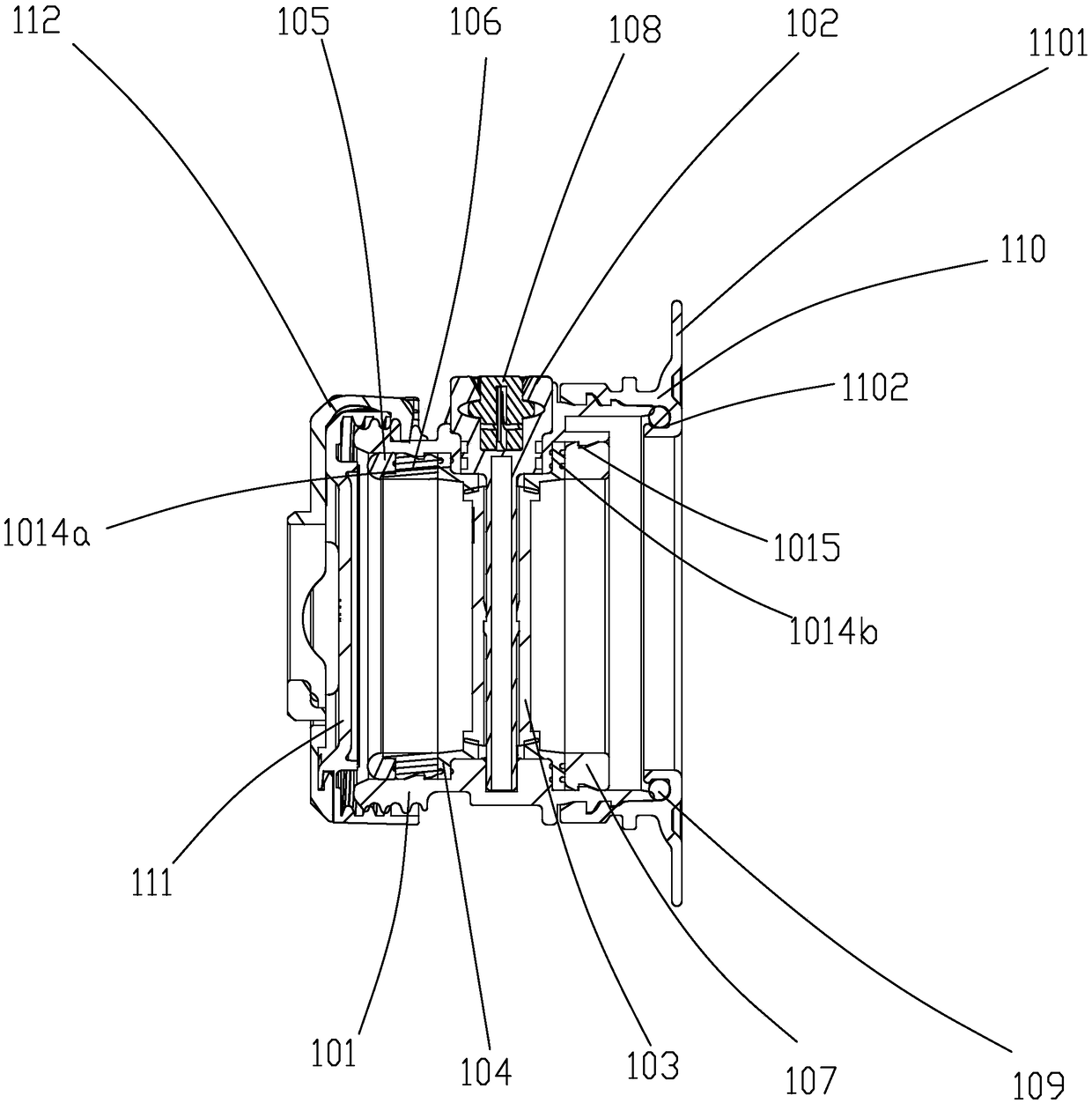

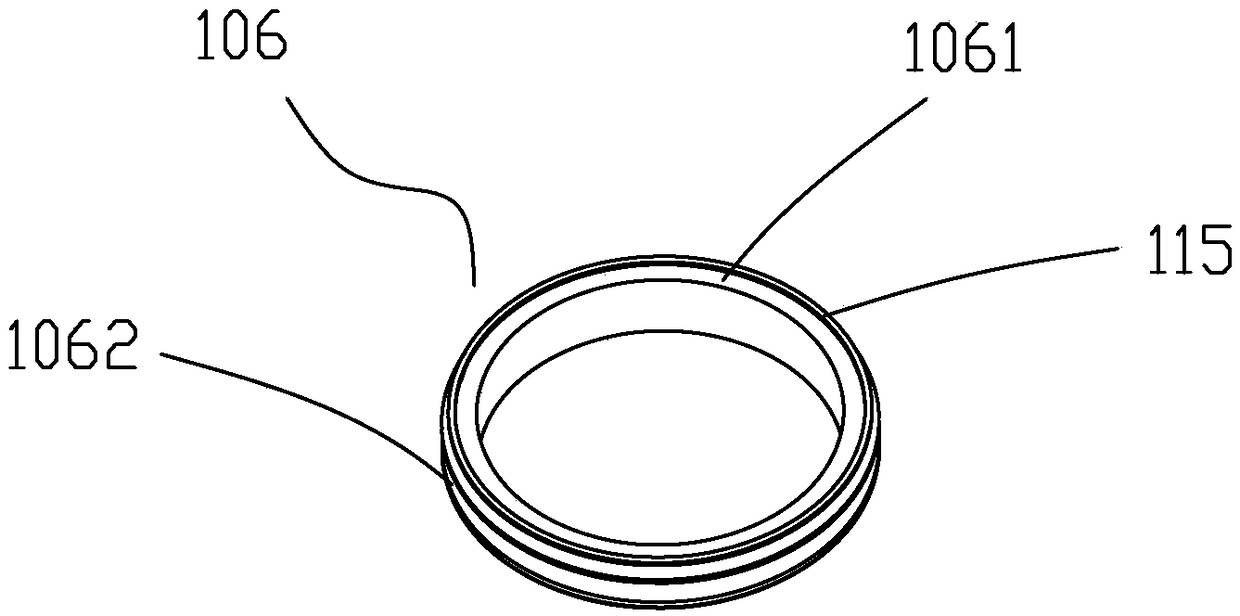

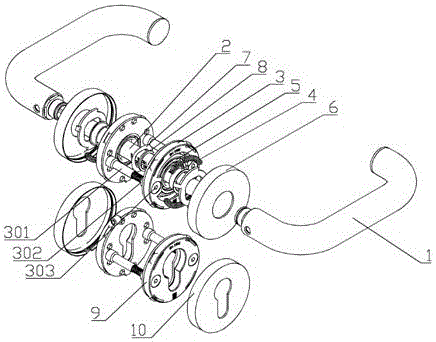

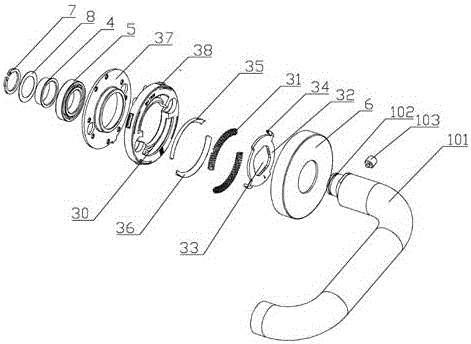

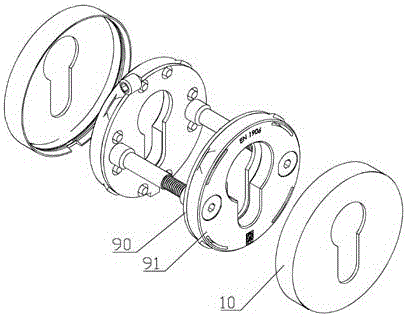

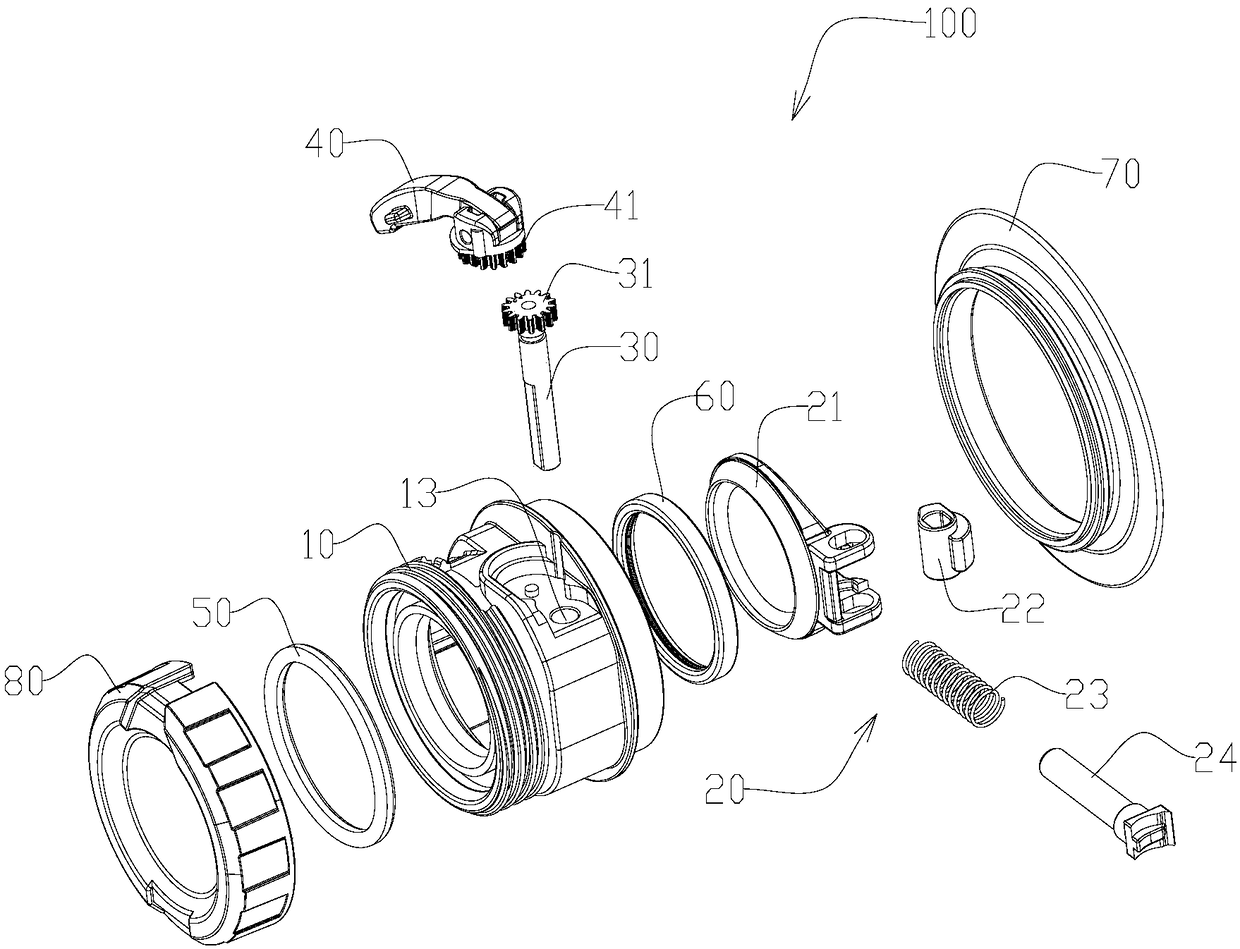

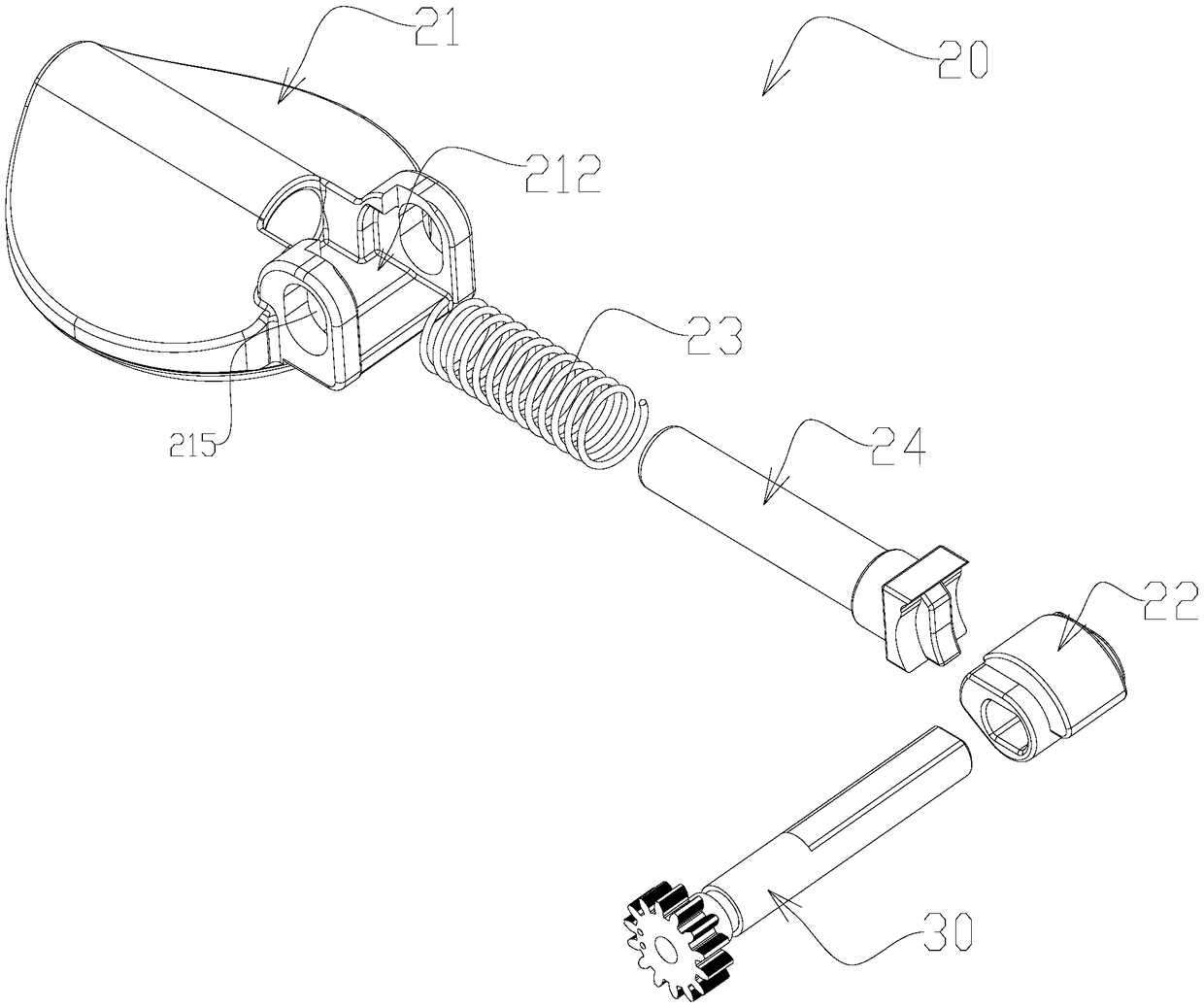

A profile door lock handle assembly

ActiveCN104265071BSolve the stuck phenomenonSmall adjustment spaceHandle fastenersBall bearingMechanical engineering

The invention discloses a profile door lock handle assembly and aims to provide a profile door lock handle assembly with simple structure, low installation requirements, convenient use, small opening torque, high safety performance and long service life. The profile door lock handle assembly includes a handle body, a square bolt connected to the handle body, and a fixing seat sleeved on the handle body, and the fixing seat is rotatably matched with the handle body through a bearing device. The bearing device includes sliding bearings and ball bearings arranged sequentially from the inside to the outside, the sliding bearings are sleeved on the handle body, the inner ring of the ball bearings is sleeved on the sliding bearings and connected to the Compatible with sliding bearings. The invention can be widely used in the field of profile doors.

Owner:茵科门控(珠海保税区)有限公司

Low-temperature welding double-eccentric aluminum butterfly valve

InactiveCN103375596AEasy to fold and replaceExtended service lifeSpindle sealingsLift valveEngineeringButterfly valve

The invention discloses a low-temperature welding double-eccentric aluminum butterfly valve which comprises a valve body, a valve rod, a valve flap and a pipeline hole. The pipeline hole is a cavity formed between the valve body and the valve flap. The valve body comprises a left valve body and a right valve body which are fixedly integrated. The valve rod is disposed in a shaft hole of the left valve body. A first central axis of the valve rod deviates the central line of the pipeline hole to form a first eccentric structure. A valve seat is disposed between the left valve body and the right valve body. The valve flap is hermitically connected with the valve seat, and the contact face of the valve seat and the valve flap is a seal face. One end of the valve flap is fixed at the bottom end of the valve rod, and the other end thereof is located on a cylinder of the left valve body. The center of the seal face deviates a second central axis of the valve rod to form a second eccentric structure. By welding and the double-eccentric structure, opening torque of the valve flap can be reduced, abrasion can be lowered, and service life of the valve seat can be prolonged.

Owner:维士威(上海)控制阀门有限公司

Filler ball valve

The invention relates to a filler ball valve. The ball valve comprises a valve body, a valve seat, a ball body, an inner lining, a filler, a valve rod, a press cover and a handle, wherein the valve seat is arranged at the bottom end of the ball valve; the valve body is arranged on the valve seat; the ball body is arranged in the valve body; the inner lining is arranged at the upper part of the ball body; the press cover is arranged at the upper part of the valve body; the valve rod is arranged in the press cover; the handle is connected to one end of the valve rod, and the other end of the valve rod is connected to the ball body; and the filler is arranged on the outer side of the valve rod, and is anti-corrosion acid resistance materials. The filler ball valve disclosed by the invention is simple in structure, good in sealing property, convenient to open and close, low in friction, low in opening torque, stable in operation, low in production cost and long in service life, and sealingsurfaces can be self-cleaned.

Owner:李伟彦

Pilot-operated type hard seal fixing ball valve

ActiveCN101629640BExtended service lifeReduced opening torquePlug valvesOperating means/releasing devices for valvesEngineeringPressure difference

The invention discloses a pilot-operated type hard seal fixing ball valve which comprises a valve body, a ball body, a valve seat, a valve cover, a valve rod, a press cover, a filling press cover and a supporting shaft, wherein the ball body is arranged in the valve body; the valve rod passes through the upper part of the valve body and is connected with the ball body, and the valve rod is externally sleeved with the press cover and the filling press cover which are vertically arranged; the valve seat is arranged between the valve cover and the ball body; the supporting shaft passes through the lower part of the valve body and is connected with the ball body; two valve cover sealing rings and a valve seat spring are arranged between the valve cover and the valve seat; the valve cover, thevalve seat and two valve seat sealing rings form a pressure difference cavity; the left side of the valve cover is provided with two left by-pass pipes, the right side is provided with two right by-pass pipes, and the left by-pass pipes and the right by-pass pipes are connected by control valves; the valve rod is also sleeved with a three-way handle head which is communicated with the control valves; and a handle steel pipe is arranged on the valve rod. The invention realizes that the valve seat can be automatically separated from a ball surface when the valve is turned on so as to greatly prolong the service life of the hard seal fixing ball valve and greatly reduce the turn-on torque of the valve.

Owner:KUSN WEISA VALVE

Integral top mounting type ultra-high pressure and ultra low temperature hard seal ball valve

ActiveCN100529487CGuaranteed tightnessSealing specific pressure is smallSpindle sealingsPlug valvesUltra high pressureSpring force

An integral top-mounted ultra-high pressure ultra-low temperature hard-sealed ball valve, the ball valve is mainly composed of a valve body (1), a valve cover (24), a handle ball (3), a valve seat (13), a rear valve seat (10) and a valve Rod bearing seat (16) etc. are formed. Placed inside the valve body (1) and passing through the handle ball (3) at the center of the valve cover (24), the handle ball (3) is rotated 90 degrees by external force to realize the opening and closing of the pipeline. The sealing is to hold the symmetrical rear valve seat (10) and valve seat (13) on both sides of the handle sphere (3), and push and hold the handle sphere (3) with the elastic force of the valve seat butterfly spring (12) to realize the spherical surface seal. The sealing of the valve stem adopts a unique self-sealing pre-tightening device triple sealing structure, which can ensure the sealing under low pressure conditions, and under the action of high pressure, the medium pressure acts on the pressure bearing ring (17) to achieve self-sealing, thereby avoiding the need for packing seals With high pressure, the valve stem opening torque becomes very large.

Owner:JIANGSU JIULONG VALVE MFG

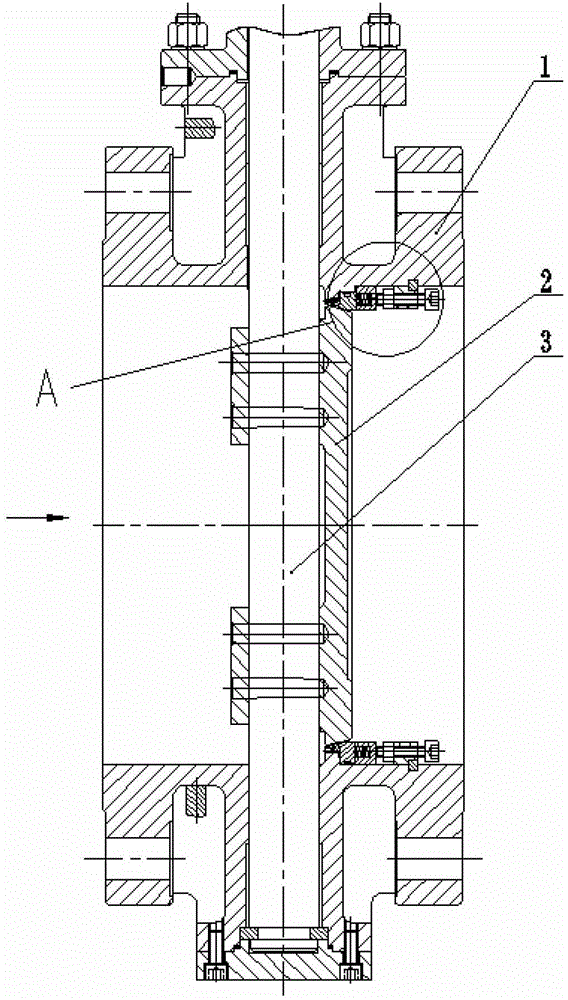

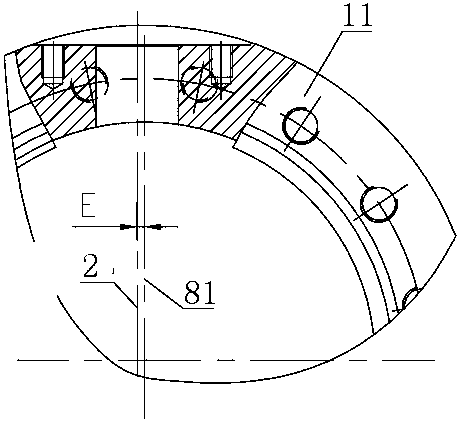

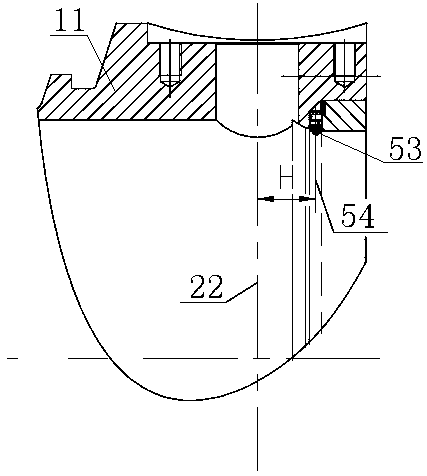

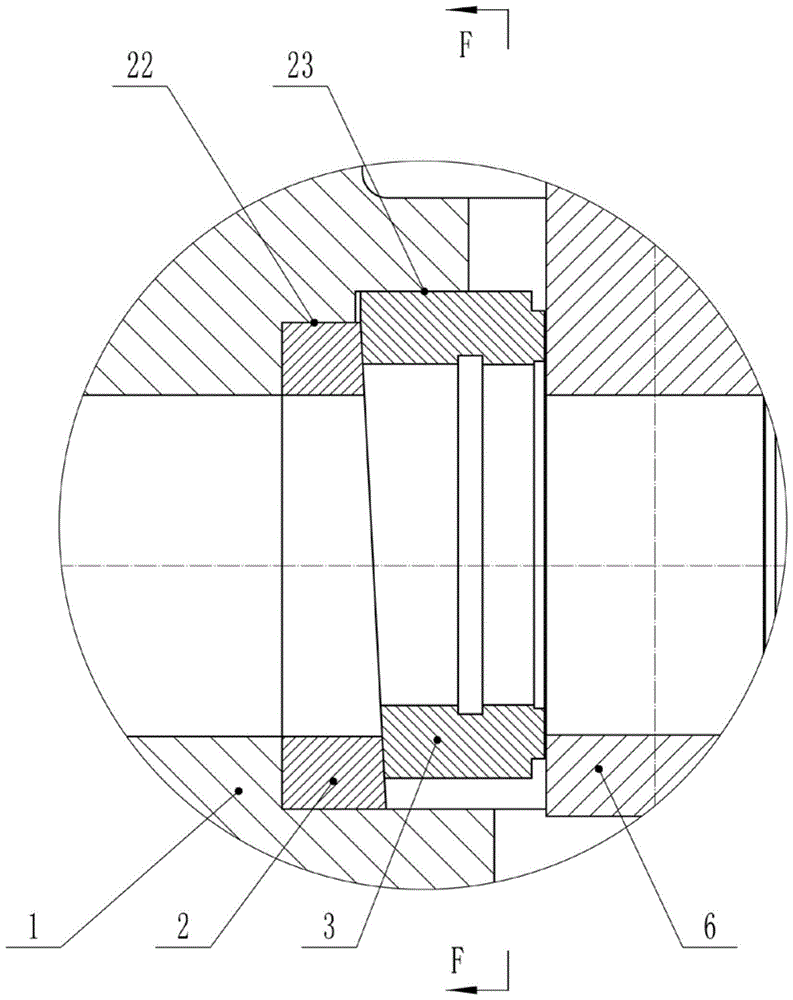

Thick oil thermal recovery single gate slab gate valve

InactiveCN103867740BImprove sealingReduced opening torqueSpindle sealingsSlide valveEngineeringViscosity

The invention provides a thick oil thermal recovery single disc flat gate valve. A left step hole and a right step hole are symmetrically formed in the two ends of a passage arranged in a valve body 1 of the thick oil thermal recovery single disc flat gate valve, in addition, the outer step hole is larger, the inner step hole is smaller, the smaller hole is a round hole 22, the larger hole is a slotted hole 23, a left static valve seat 2 is in a circular ring shape and is arranged in the round hole 22 of the left step hole, a left movable valve seat 3 is in a circular ring shape and is arranged in the slotted hole 23 of the left step hole, a right static valve seat 4 is in a circular ring shape and is arranged in the round hole 22 of the right step hole, a right movable valve seat 5 is in a circular ring shape and is arranged in the slotted hole 23 of the right step hole, and in addition, contact surfaces of the left static valve seat 2 and the left movable valve seat 3 and the contact surfaces of the right static valve seat 4 and the right movable valve seat 5 are respectively inclined surfaces. A valve plate 6 is inserted and arranged between the left movable valve seat 3 and the right movable valve seat 5, and when the valve plate 6 downwards moves, the left movable valve seat 3 and the right movable valve seat 5 are driven to downwards move for realizing the sealing. The work requirements of the single disc flat gate valve at high temperature and at high viscosity are met.

Owner:赵永刚

Floating ball valve

The invention relates to a floating ball valve. The ball valve comprises a ball body, a valve body, a valve seat, a joint, a valve rod, a shaft sleeve, a wear-resistant sheet, a motor, a gasket, a sealing ring, a wear-resistant layer and a spring, wherein the valve body and the valve seat are connected with each other, the ball body is arranged on the valve seat, the joint is connected to the valve seat, the valve rod is vertically placed, one end of the valve rod is connected with the spring and is connected to the ball body, the other end of the valve rod is connected to the motor, the wear-resistant sheet and the wear-resistant layer are arranged on the outer side of the valve rod, and the shaft sleeve is arranged outside the wear-resistant layer. The floating ball valve has the advantages that the structure is simple, the sealing performance is good, the sealing surface is self-cleaned, opening and closing are convenient, friction is small, the opening torque is small, operation isstable, the production cost is low, and the service life is long.

Owner:李伟彦

Double wedge double ball disc valve

The invention discloses a double-wedge type double-ball disc valve, which is a valve that makes the ball open and close without applying external force through rotation transmission, and avoids and reduces local force, friction and wear. It has a valve body, a The valve seat of the flow channel in the body, the bracket of the valve body, the ball corresponding to the valve seat in the valve body, the valve stem connected with the ball, the valve stem passes through the sealing packing of the valve body, the screw on the upper end of the valve stem and the valve body bracket The handwheel nut is matched, the side of the valve stem has an L-shaped guide groove, and the bracket is fixed with a guide pin whose end is inserted into the guide groove; it is characterized in that: the ball is two left and right balls, and the upper part between the two balls The upper and lower parts are open upper and lower conical spaces, and the upper and lower conical spaces correspond to an upper wedge sphere and a lower wedge sphere. The upper end of the upper wedge sphere is fixedly connected with the lower end of the stem, and the lower wedge sphere The lower end is connected with the valve body, and the upper end of the upper wedge sphere or the lower end of the valve stem also has a protruding pin, and the two ends of the pin are respectively located in the transverse grooves left on the upper ends of the two ball discs.

Owner:DALIAN DAYANG VALVE RES & DEV CO LTD

Pilot middle cavity balance pressure-type ultrahigh pressure ball valve for oil and gas production equipment

PendingCN112923094AExtended service lifeIncrease design pressurePlug valvesUltra high pressureEngineering

The invention relates to a pilot middle cavity balance pressure-type ultrahigh pressure ball valve for oil and gas production equipment. The pilot middle cavity balance pressure-type ultrahigh pressure ball valve comprises a main valve body, a first sealing valve seat, a second sealing valve seat and a pressure relief structure, wherein an auxiliary valve body is arranged at one side of the main valve body; a mounting cavity is formed in the main valve body; a valve ball is rotationally connected to the interior of the mounting cavity; a flow guide channel is formed in the middle of the valve ball; the first sealing valve seat and the second sealing valve seat are movably connected to the main valve body and oppositely arranged at two sides of the valve ball; and the pressure relief structure is arranged on the valve ball and is used for guiding a high-pressure medium to the mounting cavity to form a pressure balance state after the valve ball rotates to be opened at a preset angle. Due to the arrangement of the pressure relief structure, when the valve ball is rotated until the pressure relief structure corresponds to the flow guide channel, the high-pressure medium firstly enters the pressure relief structure to communicate with the mounting cavity, and at the moment, the pressure between the mounting cavity and the auxiliary valve body is balanced, so that quick opening and quick pressure relief are realized, the opening torque is reduced, the pressure relief stroke is shortened, damage to the sealing surface in the opening process is reduced, and the service life of the ball valve is prolonged.

Owner:SUZHOU DOUSON VALVE CO LTD

Three-piece forged steel soft sealing fixed ball valve

PendingCN114135690AImprove sealingReduced opening torquePlug valvesOperating means/releasing devices for valvesMaterials scienceValve seat

The invention provides a three-piece forged steel soft sealing fixed ball valve which comprises a valve body, valve covers arranged on the two sides of the valve body, a ball body in the valve body and a valve rod arranged on the outer side of the ball body and perpendicular to the axis of the valve body, a metal valve seat is arranged between the valve covers and the ball body, and the metal valve seat and the valve covers are in stepped contact. A plurality of valve seat springs are evenly arranged between the metal valve seat and the valve cover, and a soft valve seat is arranged between the metal valve seat and the ball body. By means of the mode, the problem that an existing three-piece type forged steel soft sealing fixed ball valve is poor in sealing performance is solved.

Owner:SUZHOU SIP STARD VALVE

Electric butterfly valve

InactiveCN111207237AExtended service lifeReduce torqueOperating means/releasing devices for valvesElectric machineEngineering

The invention discloses an electric butterfly valve, which comprises a valve body. The valve body is internally provided with a channel penetrating through from left to right; a baffle plate is arranged on the inner side wall of the channel, and is provided with a valve port; the valve body is internally and rotatably connected with a rotating shaft, and the rotating shaft is fixedly provided witha flap plate; the outer side of the valve body is fixedly provided with a motor; the flap plate is provided with a first valve hole and a second valve hole, the second valve hole is internally and fixedly provided with a valve sleeve, and a magnetic guide sleeve is fixedly arranged on the opening of the right end of the first valve hole; the valve sleeve is internally provided with a sliding holepenetrating through from left to right; the sliding hole is internally and slidably connected with a valve core; a spring seat is fixedly arranged at the right end of the valve core, and the valve core is connected with a first spring in a sleeved mode; the right end of the magnetic guide sleeve is slidably connected with a moving iron, and the magnetic guide sleeve is provided with a push rod; acoil is arranged at the side face of the outer circumference of the magnetic guide sleeve; before the electric butterfly valve is opened, mediums at the two ends of the butterfly valve are in communication in advance to reduce a pressure difference between the two sides, and thus power of the motor does not increase suddenly when the flap plate is controlled to rotate.

Owner:邵延荣

Industrial steam intelligent control electric butterfly valve

PendingCN114811071AReduced opening torqueImprove sealingOperating means/releasing devices for valvesLift valveRubber ringEngineering

The invention relates to the technical field of butterfly valves, and discloses an industrial steam intelligent control electric butterfly valve which comprises a valve body, an electromagnetic ring is embedded in the inner wall of the valve body, a sealing mechanism is fixedly installed on the inner wall of the valve body and comprises a valve seat, and a rubber ring is fixedly connected to the inner wall of the valve seat. The periphery of the rubber ring is fixedly sleeved with a metal soft ring, the left end of the valve seat is slidably connected with a magnetic ring in an inserted mode, the rear end of the valve body is movably connected with an adjusting mechanism, the adjusting mechanism comprises a worm, and the periphery of the worm is fixedly connected with an electric block. According to the industrial steam intelligent control electric butterfly valve, when the valve plate is closed, high pressure on the steam side is used for automatically providing high extrusion force between the rubber ring and the valve plate, and when the valve plate is opened, the rubber ring is controlled in advance to automatically reduce the extrusion force; therefore, the sealing abrasion is effectively reduced, the subsequent sealing quality is ensured, and the overall use stability of the valve is effectively improved.

Owner:JIANGSU YUANYANG VALVE INTELLIGENT CONTROL CO LTD

Self-sealing eccentric hemispherical valve

The invention discloses a self-sealing eccentric half-ball valve which comprises a valve body, wherein a liquid inlet cavity is arranged in the valve body; one end of the valve body is provided with a water inlet communicated with the liquid inlet cavity, and the other end is provided with a water outlet communicated with the liquid inlet cavity; the top of the valve body is connected with a valve cap; the valve cap is connected with a main valve shaft; the bottom of the valve body is provided with an auxiliary valve shaft; a half ball valve plate connected to the main valve shaft and auxiliary valve shaft is arranged in the liquid inlet cavity; the surface of the half-ball valve plate is coated with an elastic sealing layer; the elastic sealing layer of the sealing surface of the half-ball valve plate and the inner port position of the water inlet form a contact fit to form an axial sealing pair capable of implementing axial sealing; and the elastic sealing layer on the sealing surface of the half-ball valve plate and the wall of the water inlet form a contact fit to form a radial sealing pair with radial self-sealing effect. The self-sealing eccentric half-ball valve has the dual effects of axial sealing and radial sealing, can not easily cause seepage or leakage, and has the advantages of small opening torque and longer service life.

Owner:AQUA CASTING INC

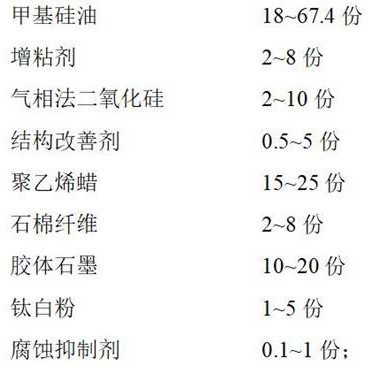

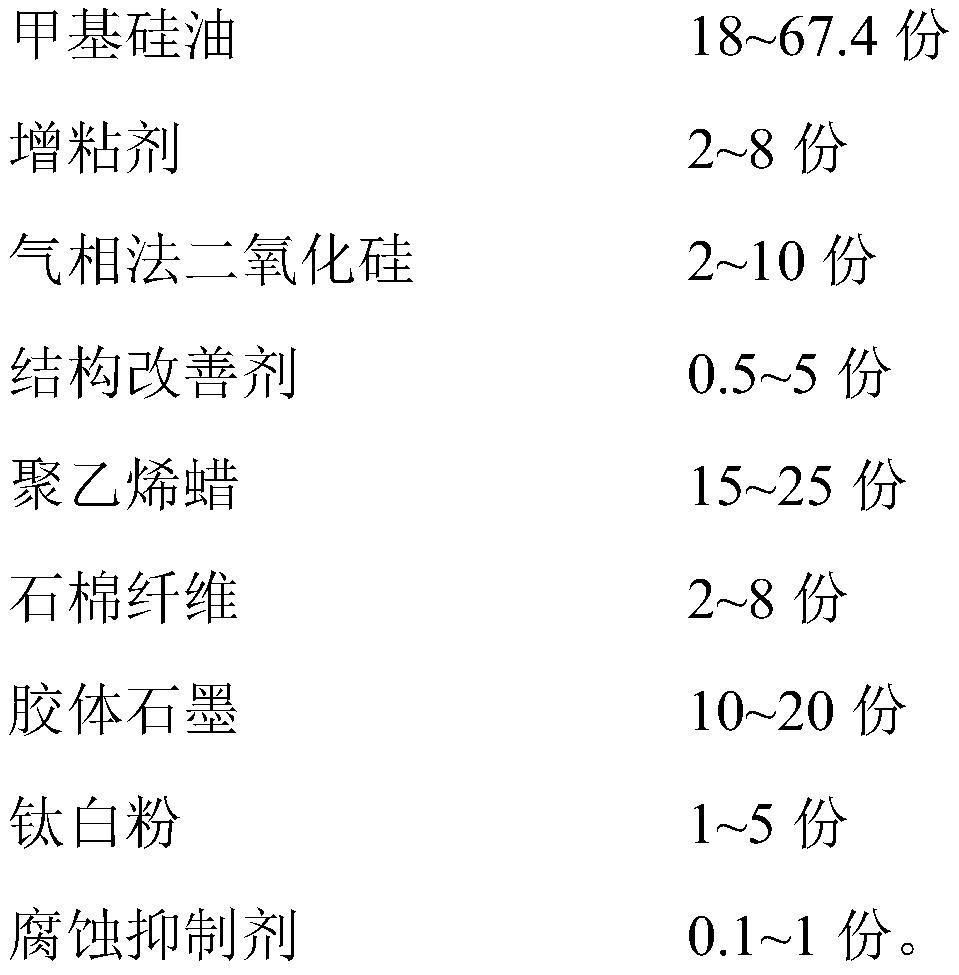

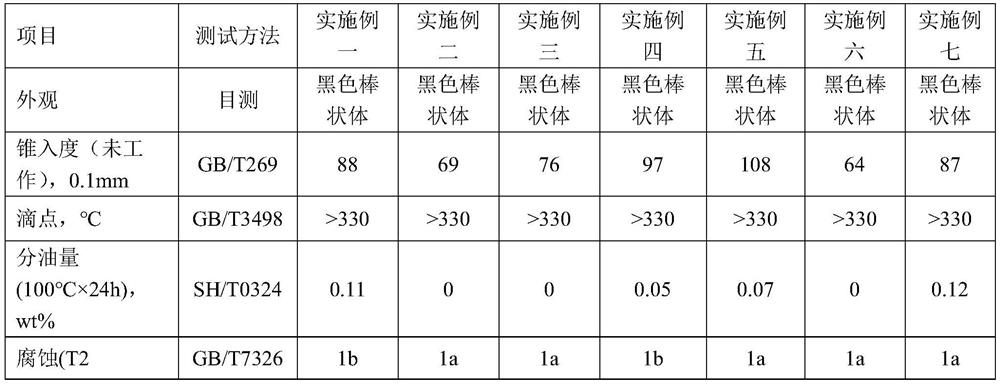

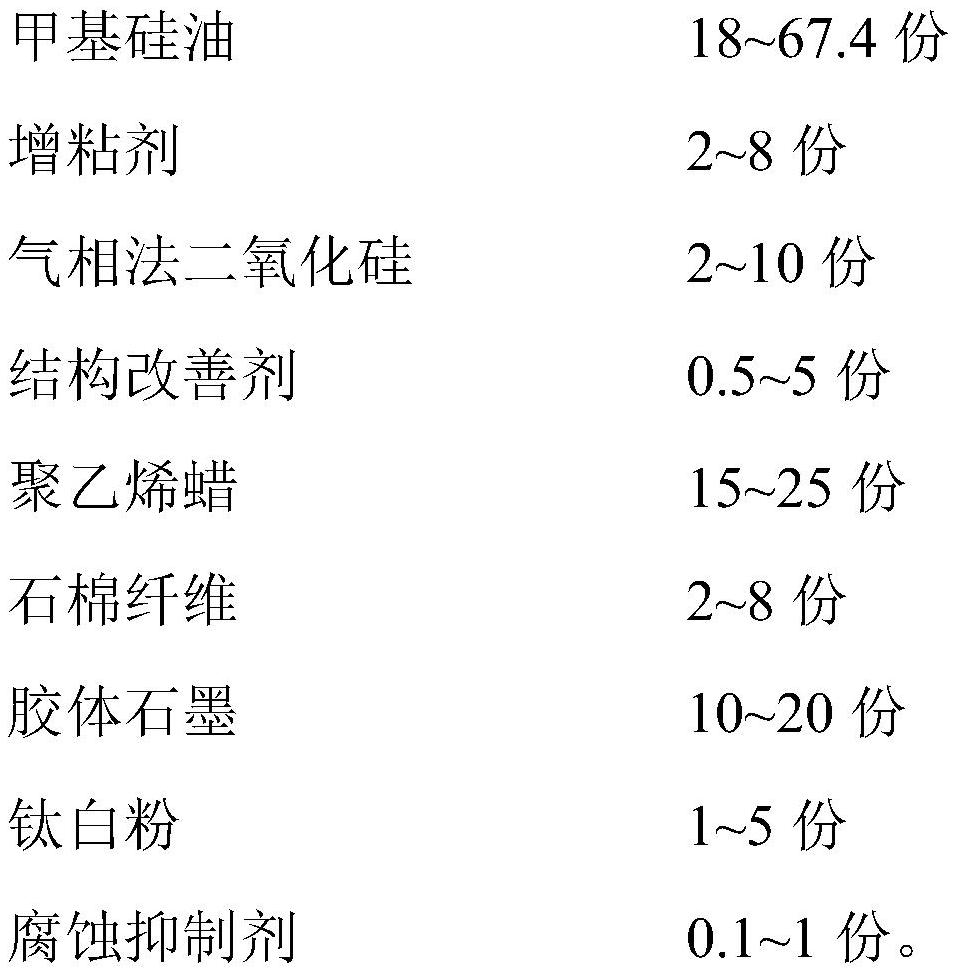

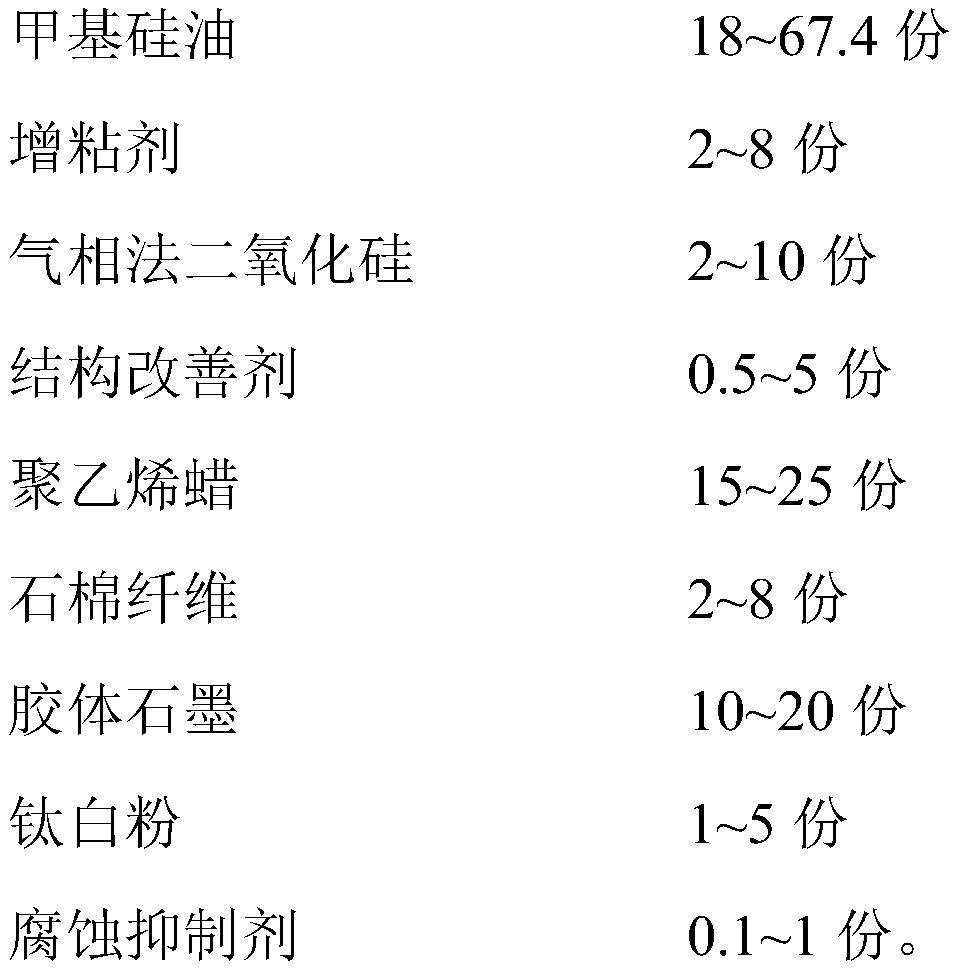

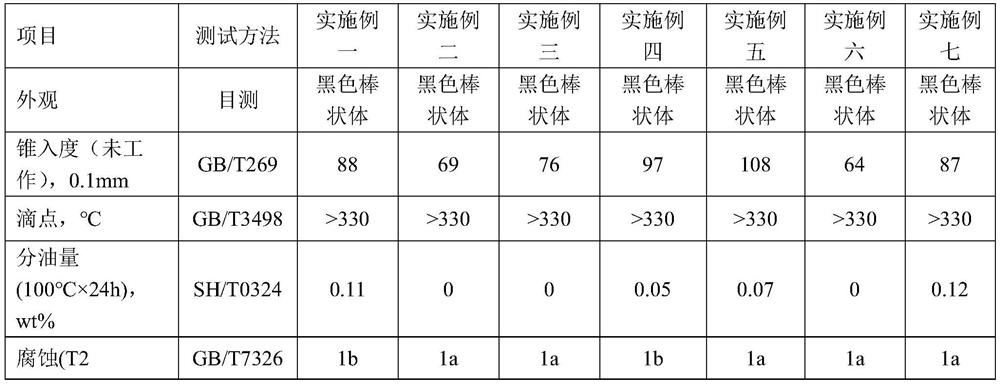

A kind of low temperature rod-shaped valve stem sealing grease composition and preparation method thereof

ActiveCN112552985BGood low temperatureImprove thermal stabilityLubricant compositionFiberPolymer science

The invention discloses a low-temperature rod-shaped valve stem sealant composition, comprising the following components in proportion by weight: 18-67.4 parts of methyl silicone oil, 2-8 parts of a tackifier, and 2-10 parts of fumed silica , 0.5 to 5 parts of structure improver, 15 to 25 parts of polyethylene wax, 2 to 8 parts of asbestos fiber, 10 to 20 parts of colloidal graphite, 1 to 5 parts of titanium dioxide, and 0.1 to 1 part of corrosion inhibitor. The invention also discloses a preparation method of the rod-shaped valve stem sealant composition. The present invention adopts fumed silica to thicken methyl silicone oil, and is matched with a stick-shaped valve stem sealant compound made of a tackifier, a solid lubricant, a molding agent and a corrosion inhibitor, and has excellent low-temperature performance, good High thermal stability and chemical stability, strong resistance to medium corrosion, excellent sealing, pressure resistance, adhesion and abrasion resistance, and non-toxic, non-stick, plastic, non-curing, arbitrary molding.

Owner:武汉博达特种润滑技术有限公司

valve

ActiveCN105805321BSimple structureImprove space utilizationOperating means/releasing devices for valvesLift valveRelative motionEngineering

The invention discloses a valve, which comprises a valve body, a valve stem, a valve seat and a valve core assembly. The valve core assembly is installed in the valve body and includes a valve core, the valve core is hinged to the valve body, and the valve core assembly further includes a driving part, a positioning part and an elastic part. Among them, the positioning part can be installed on the valve core in a relatively movable manner, the elastic part is installed between the positioning part and the valve core, and the coupling relationship between the driving part and the positioning part can make the valve have three transmission relationships during the closing process: the driving part Cooperate with the positioning part to form a relatively static first transmission relationship; the driving part squeezes the positioning part to make the positioning part perform a second transmission relationship relative to the valve core; the driving part and the positioning part are switched from the second transmission relationship to driving The third transmission relationship between the component and the spool. The valve of the invention has the beneficial effects of few parts, good manufacturing process, simple structure and high space utilization rate.

Owner:SHANGHAI HONGYAN RETURNABLE TRANSIT PACKAGINGS CO LTD

Quick-mounting gate valve of enamel sealing and with high performance

PendingCN109488777AReduced opening torqueLower the altitudeSpindle sealingsSlide valveEngineeringScrew thread

The invention provides a quick-mounting gate valve of enamel sealing and with high performance. The quick-mounting gate valve comprises a valve body, a valve cover, a copper nut, a valve rod, a locking nut, a hand wheel, and a wedge disc. Inorganic glass porcelain glaze is sprayed on the inner surface of the valve body. The valve cover is fixedly connected to the top of the valve body. The coppernut is in threaded connection with the inner top wall of the valve cover in an inserting mode. The valve rod extending into the valve body is movably inserted into the top of the valve cover and is located in the copper nut. The locking nut is inserted in the copper nut and is located outside the valve rod in a thread-connection mode. The copper nut and the locking nut are embedded in the valve cover. A traditional shaft sealing cover and other assemblies are omitted. Height of the gate valve is lowered. Copper alloy is adopted to the copper nut, and therefore opening torsion is reduced, the cost is saved, and disassembling is convenient. The porcelain glaze is sprayed on the surfaces of the valve body and the gate plate to prevent the gate valve from rusting and being corroded. Fluid resistance is reduced, the opening torsion of the valve is reduced, dust sticking and dust accumulating are reduced meanwhile, and the service life is prolonged.

Owner:ANHUI TONGDU FLOW TECH

Metallic package

ActiveCN101148208BLarge rotation angleSeal Break PreventionCapsClosure capsMechanical engineeringClose contact

Owner:JAPAN CROWN CORK CO LTD

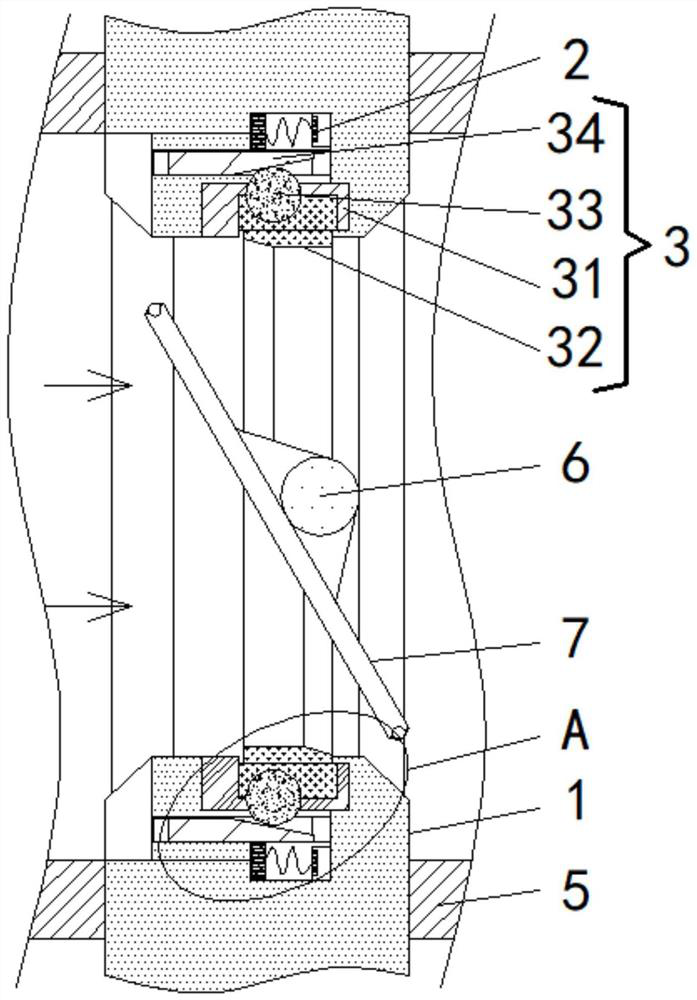

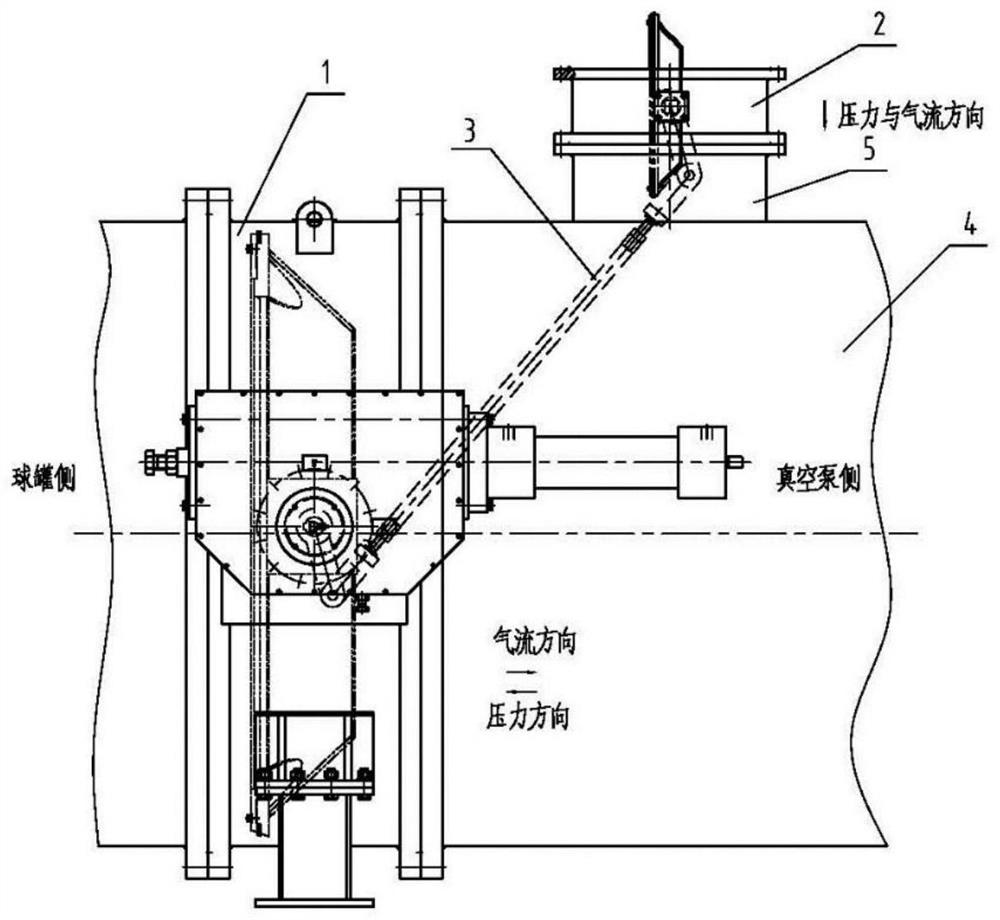

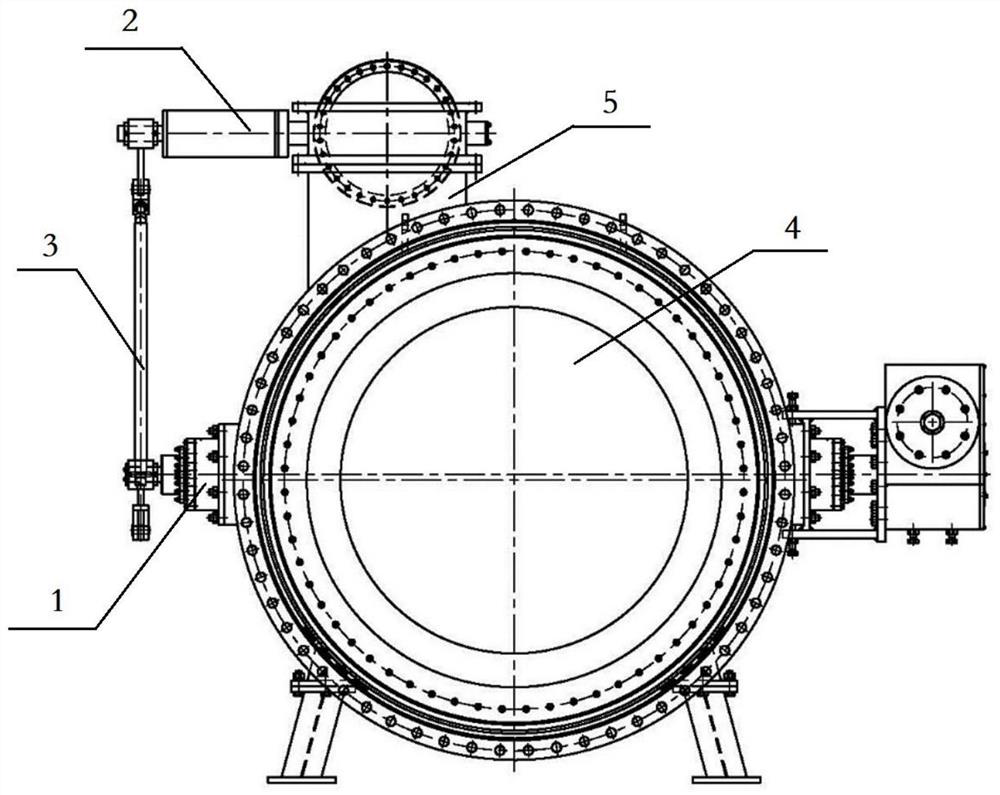

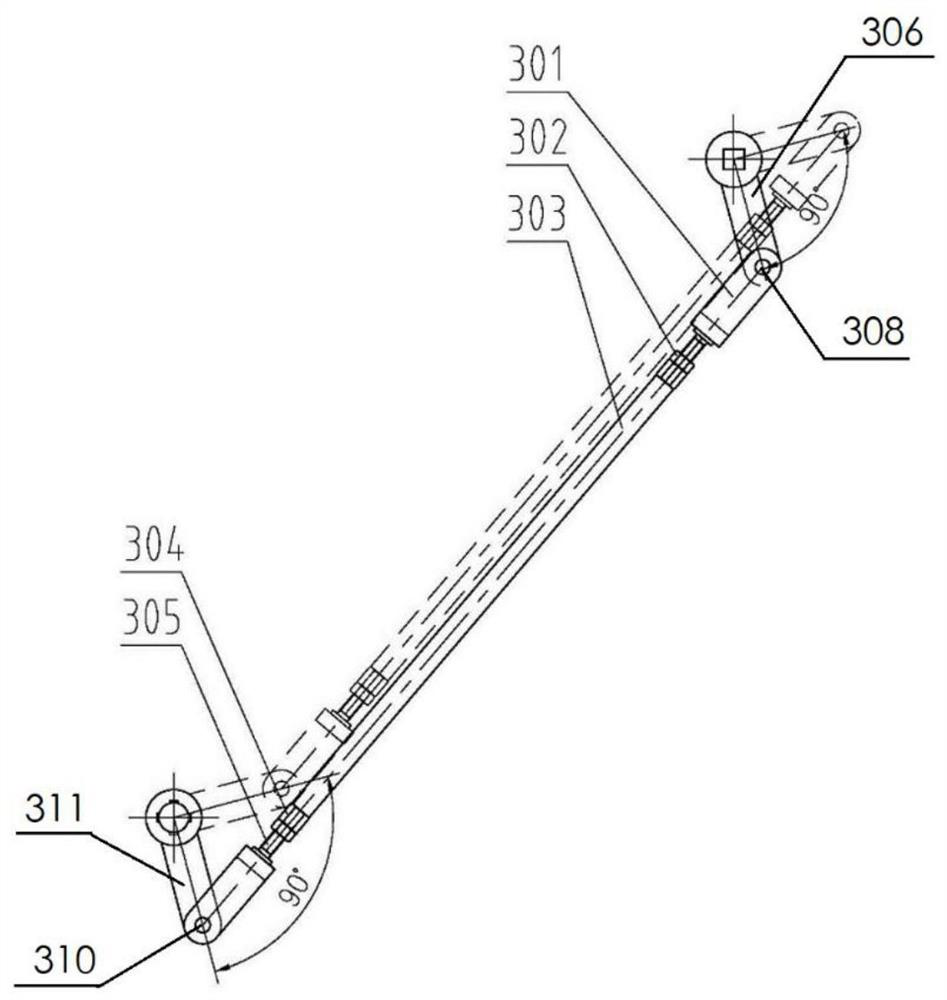

A Centrifugal Vacuum Pump Protection Device Used in Ultra-High Speed Wind Tunnel

ActiveCN111750140BImprove sealingExtended service lifeOperating means/releasing devices for valvesPump componentsUltra high speedEngineering

The invention discloses a centrifugal vacuum pump protection device used in an ultra-high-speed wind tunnel. The protection device includes auxiliary valves, linkages and branch pipelines; the branch pipelines are perpendicular to the main pipeline and located downstream of the main valve, the main valve is installed on the main pipeline, and the auxiliary valves are installed on the branch pipelines. The active end of the valve stem of the auxiliary valve is connected by a linkage; the degree of freedom of movement of the linkage is 90°, at the position of the main valve, when the apex angle of the linkage is 30°, the main valve opens and the auxiliary valve closes , when the top angle of the linkage mechanism is 150°, the main valve is closed and the auxiliary valve is opened. The protection device can avoid the "blind pumping" phenomenon of the centrifugal vacuum pump and protect the normal operation of the centrifugal vacuum pump.

Owner:中国空气动力研究与发展中心超高速空气动力研究所

Low-temperature rodlike valve rod sealing grease composition and preparation method thereof

ActiveCN112552985AGood low temperatureImprove thermal stabilityLubricant compositionFiberPolymer science

The invention discloses a low-temperature rodlike valve rod sealant composition which comprises the following components in parts by weight: 18-67.4 parts of methyl silicone oil, 2-8 parts of tackifier, 2-10 parts of fumed silica, 0.5-5 parts of structure improver, 15-25 parts of polyethylene wax, 2-8 parts of asbestos fiber, 10-20 parts of colloidal graphite, 1-5 parts of titanium dioxide and 0.1-1 part of corrosion inhibitor. The invention further discloses a preparation method of the rodlike valve rod sealant composition. According to the invention, fumed silica is adopted to thicken methylsilicone oil, and the tackifier, the solid lubricant, the forming agent and the corrosion inhibitor are matched to prepare the rodlike valve rod sealant compound, so that the rodlike valve rod sealant composition has excellent low-temperature performance, good thermal stability and chemical stability, strong medium erosion resistance, excellent sealing performance, compression resistance, adhesion and wear resistance, and is non-toxic, non-sticky, plastic, non-cured and randomly formed.

Owner:武汉博达特种润滑技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com