Integral top mounting type ultra-high pressure and ultra low temperature hard seal ball valve

A hard-sealing, top-loading technology, applied in shaft seals, valve details, valve devices, etc., can solve problems affecting production and use, ball valve sealing, strength and valve torque problems, to ensure sealing performance and avoid casting defects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

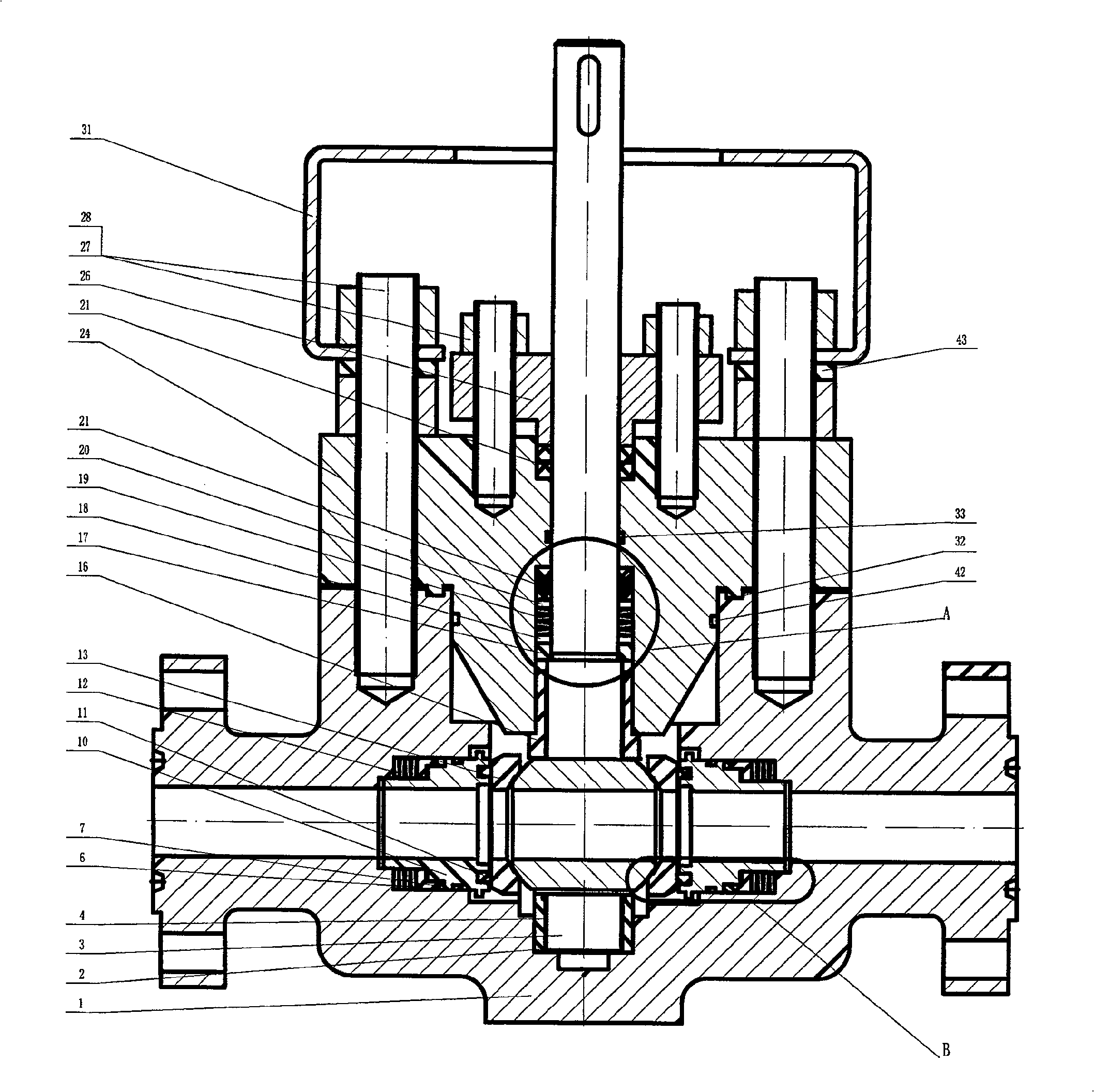

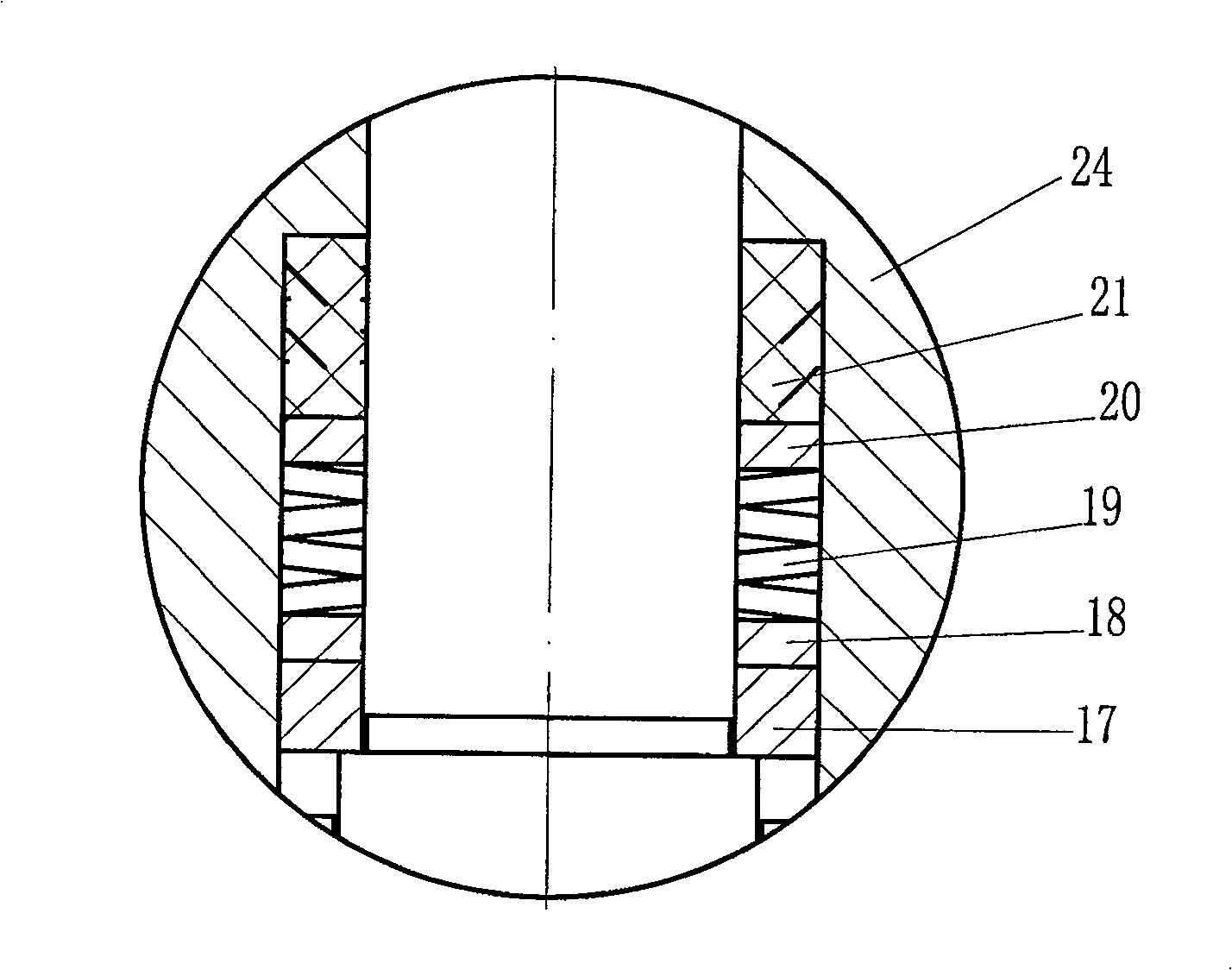

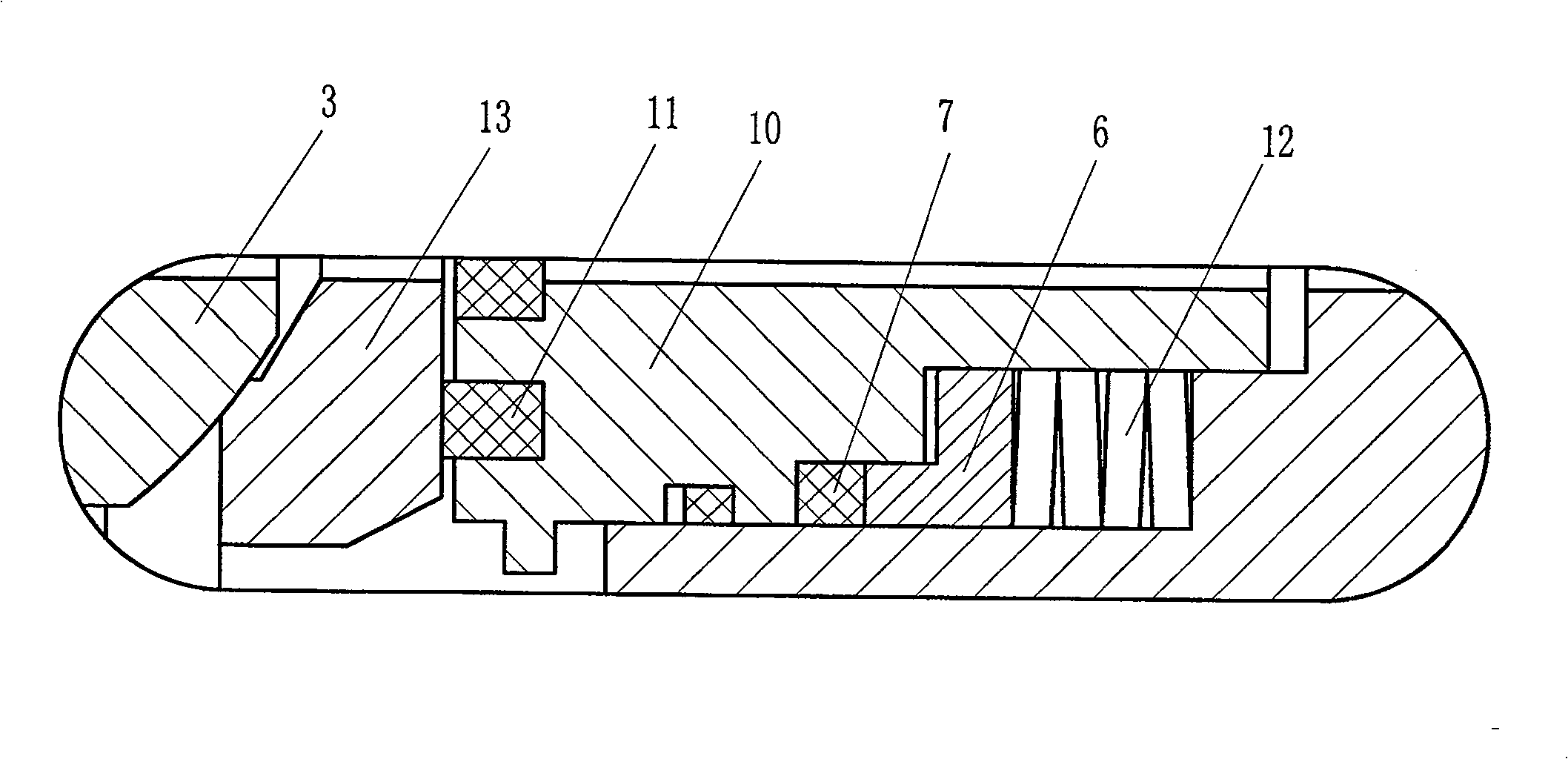

[0025] Attached below Figure 1-3 To describe in detail the structure of the integral top-mounted ultra-high pressure, ultra-low temperature hard-sealed ball valve. In order to illustrate the structure of the valve, the direction in which the valve stem protrudes is upward, and the opposite direction is downward; the handle sphere in the center of the ball valve is the inside of the valve, and the direction away from the handle sphere is outward.

[0026] figure 1 A structural cross-sectional view of an integral top-entry ultra-high pressure, ultra-low temperature hard-sealed ball valve is shown. The hard-sealed ball valve has a built-in handle ball 3 in the center of the valve body 1, and the upper part of the ball handle passes through the valve stem bearing seat 16, the pressure bearing ring 17, the thrust bearing 18, the butterfly spring 19, the bearing ring 20, the sealing packing 21, the Chinese method Lan gasket 32 and valve cover 24; at the same time, symmetrical v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com