Thick oil thermal recovery single gate slab gate valve

A technology of heavy oil thermal recovery and slab gate valve, applied in sliding valves, valve details, valve devices, etc., can solve the problems of filling into the corrugated spring groove, corrugated spring failure, high viscosity of heavy oil, etc., to reduce the opening torque, reliable Sealing performance, effect of good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

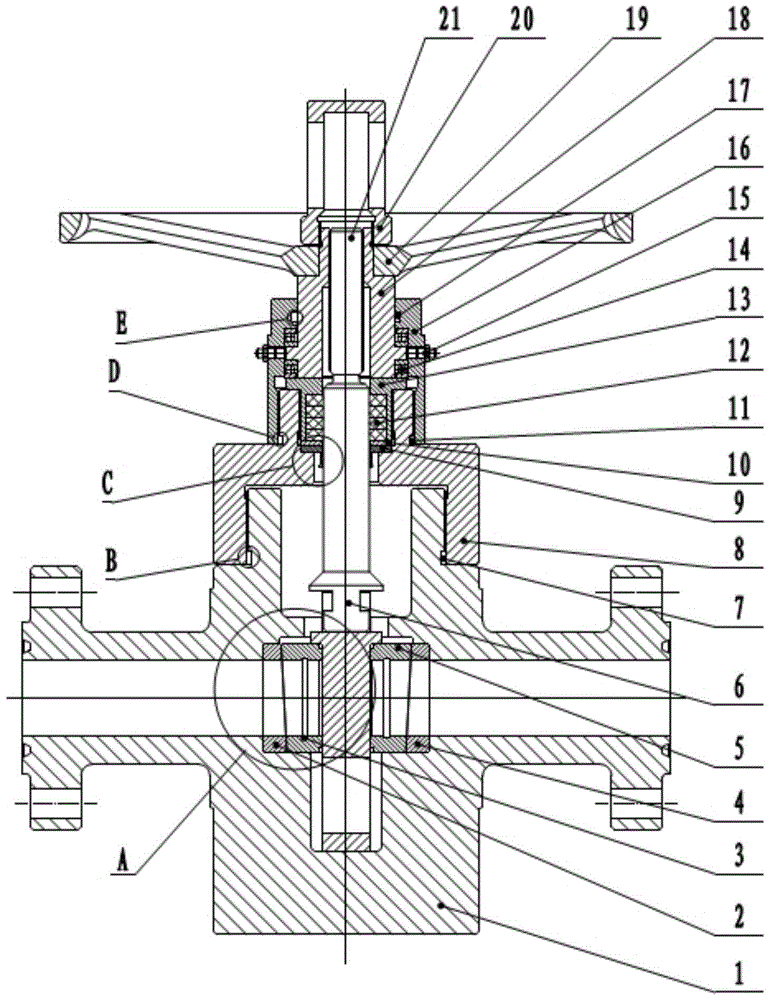

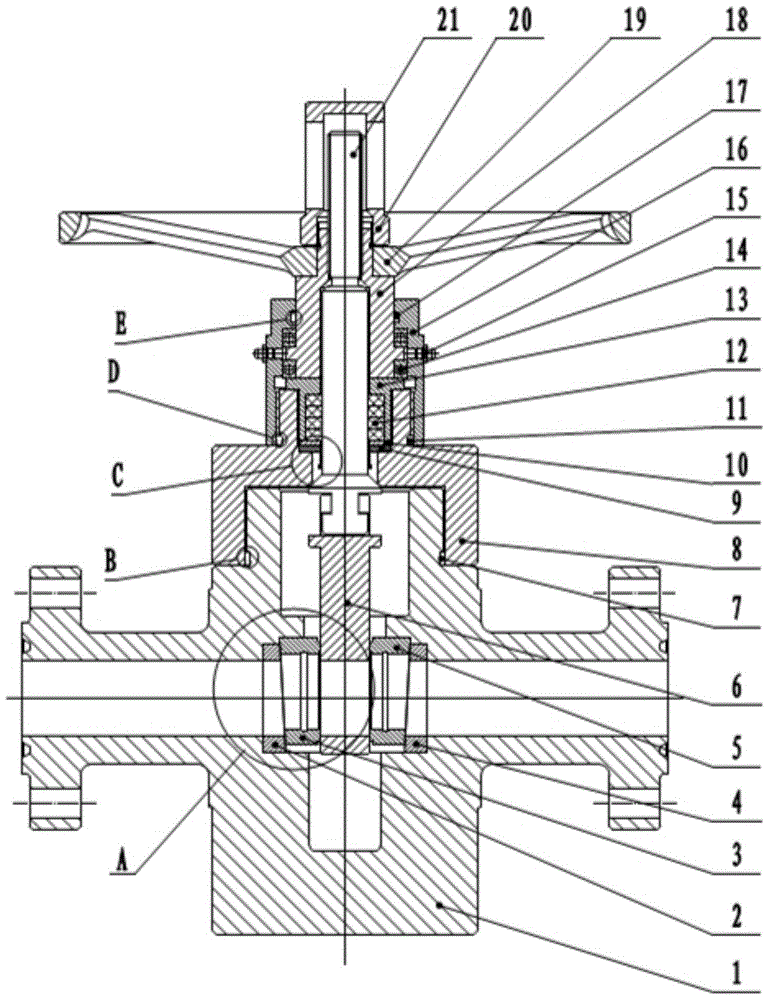

[0024] An embodiment of the present invention is described below with reference to the accompanying drawings.

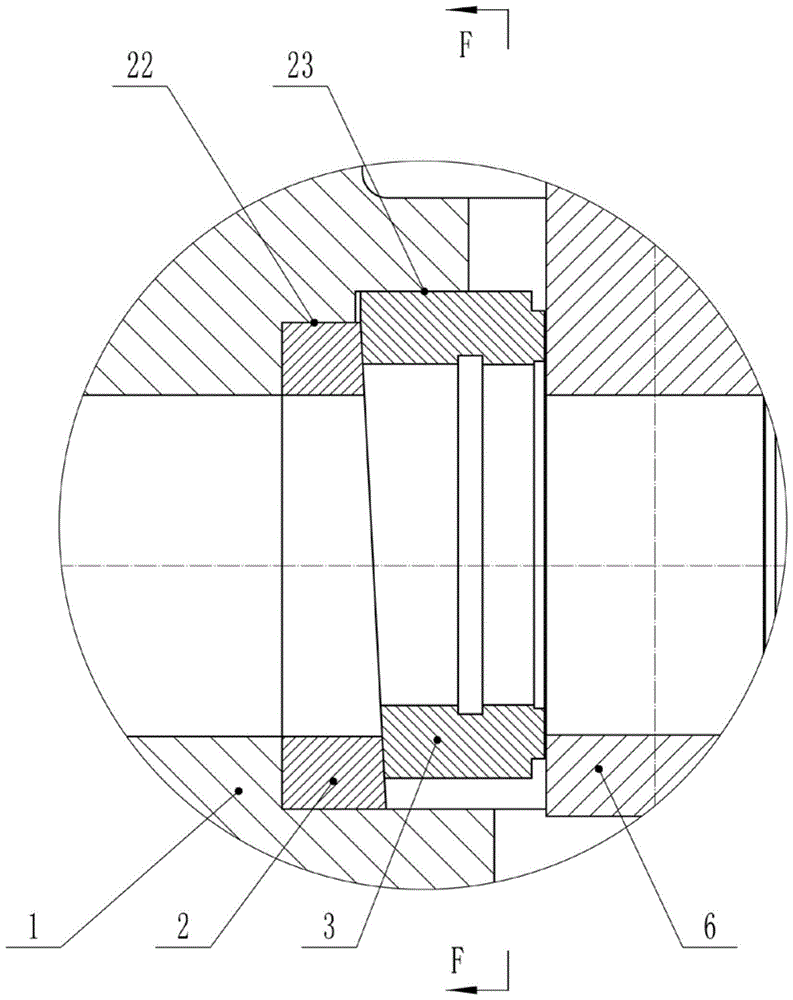

[0025] as attached figure 1 , 2 As shown, the heavy oil thermal recovery single gate plate gate valve includes a valve body 1, a left static valve seat 2, a left movable valve seat 3, a right static valve seat 4, a right movable valve seat 5, a valve plate 6, and a valve stem 21; There are upper channel, middle channel and lower cavity in the valve body 1 from top to bottom; image 3 Shown, be shaped on left step hole and right step hole symmetrically at the two ends of middle channel, the small hole of two step holes is a circular hole 22, and the big hole of step hole is a long hole 23, and the upper end of long hole 23 And the lower end is a circular arc with the same radius as the circular hole 22, and the middle part of the elongated hole is a rectangle with the same radius as the upper and lower arcs; and the lower end of the elongated hole 23 is on the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com