Double block and bleed pressure balance type inverted plug valve

A balanced plug valve technology, which is applied in the direction of plugs including cut-off devices, valve devices, engine components, etc., can solve the problems of low valve safety, difficult release of medium pressure, easy wear of sealing slides, etc., to avoid High temperature jamming phenomenon, reducing opening torque, and protecting the effect of sealing surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] Embodiment: please refer to the accompanying drawings, and the present invention will be further elaborated.

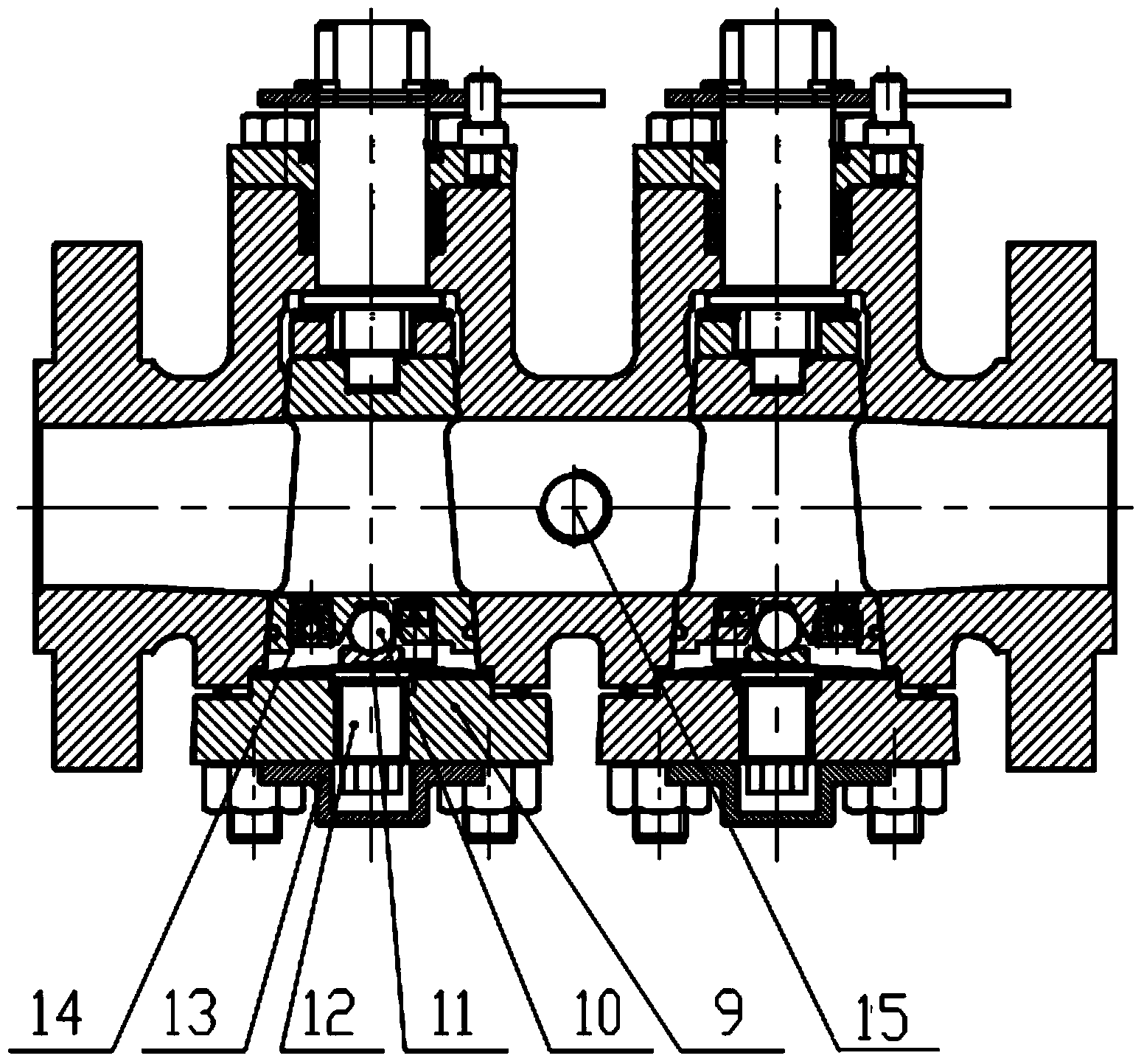

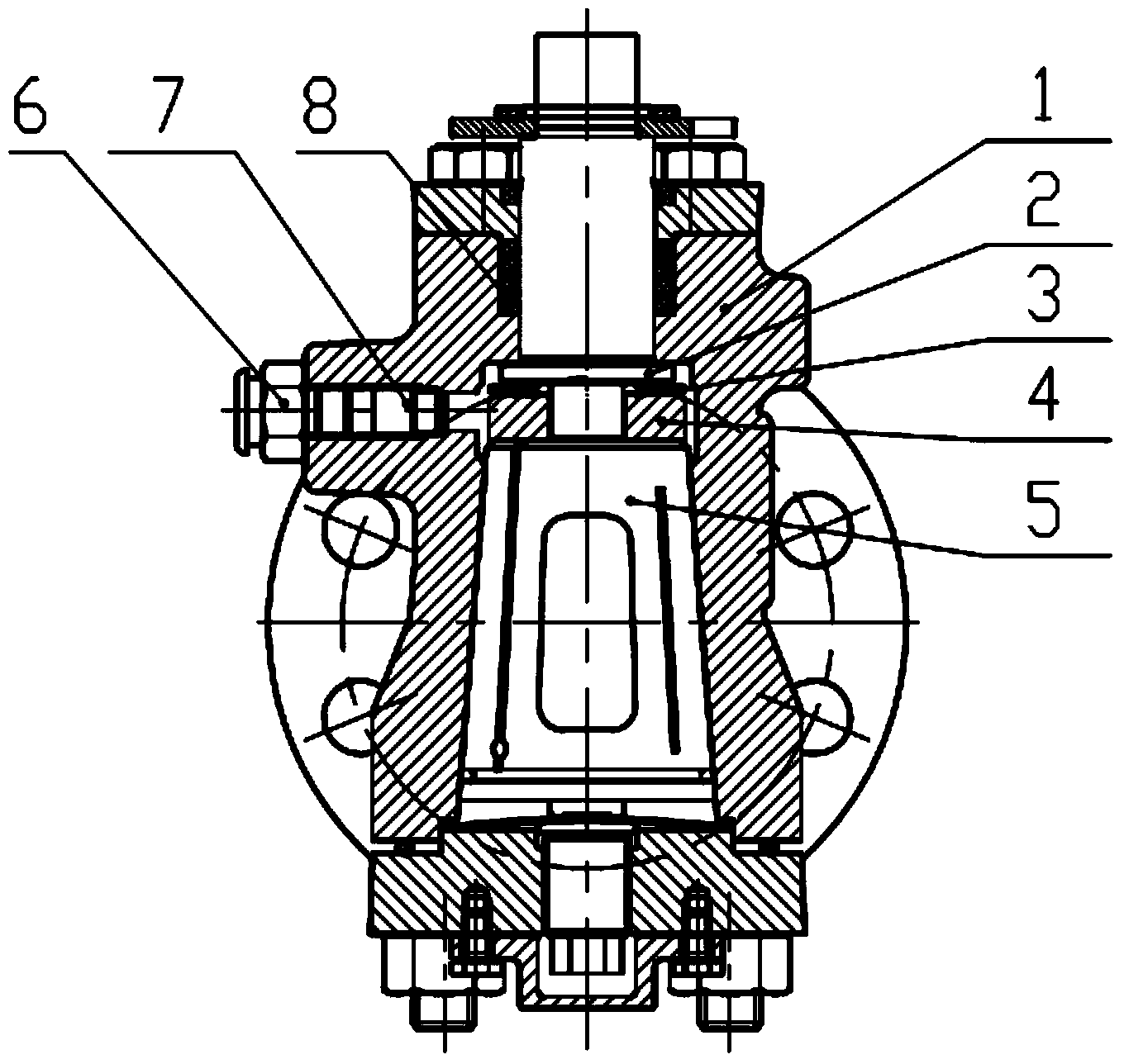

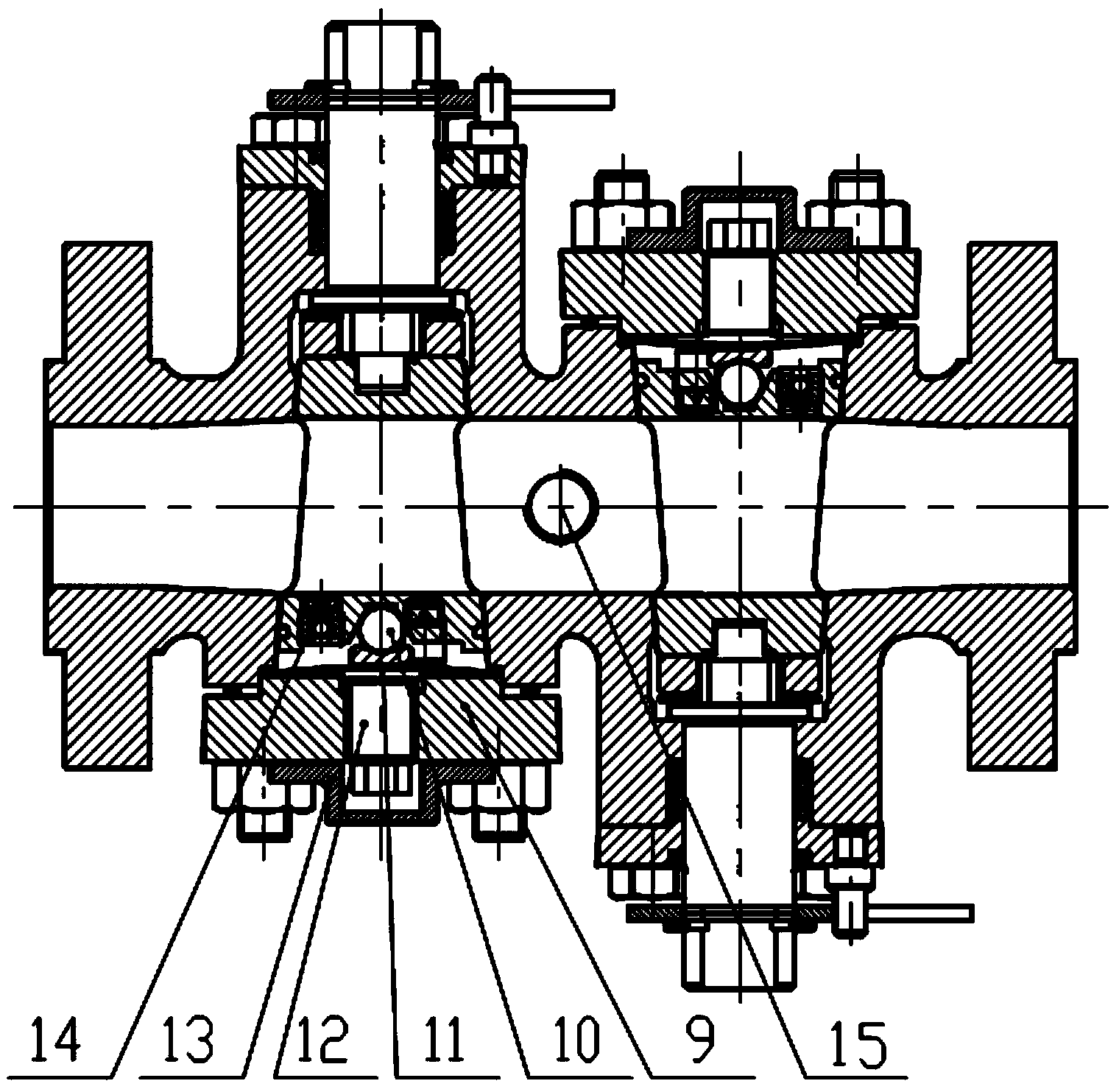

[0047] Such as figure 1 , figure 2 and image 3 As shown, the present invention provides a double-close and double-break pressure-balanced inverted plug valve with reliable sealing and preventing the plug from being stuck. It includes valve body 1, valve stem 2, butterfly spring 3, cross connector 4, cock 5, oil filling valve 6, second check valve 7, packing 8, valve cover 9, ball 10, sealing diaphragm 11, adjustment Shaft 12, adjusting shaft gland 13, second check valve 14 and other important parts. According to the form of the cock flow hole, it can be divided into conventional straight type or Venturi type. There are many types of materials for the valve body and internal parts, a wide range of applications, and suitable for various media. The cock of the present invention is an inverted tapered valve plug whose one end connected to the valve stem is sma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com