Electric butterfly valve

An electric butterfly valve and valve body technology, applied in valve details, valve devices, engine components, etc., can solve the problem of large torque of the butterfly valve, which is not conducive to the long-term use of the butterfly valve, and achieve the effects of reducing power, prolonging service life, and reducing opening torque.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

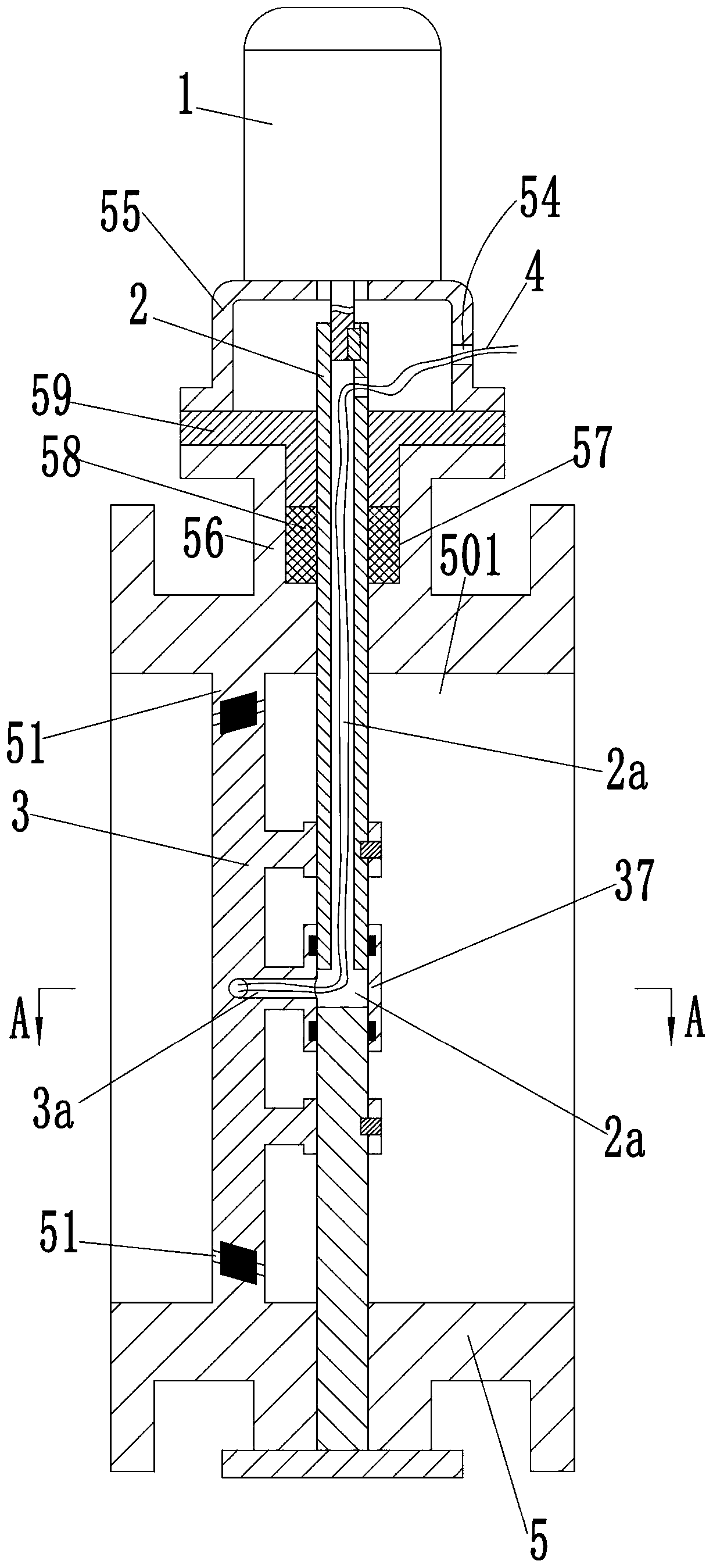

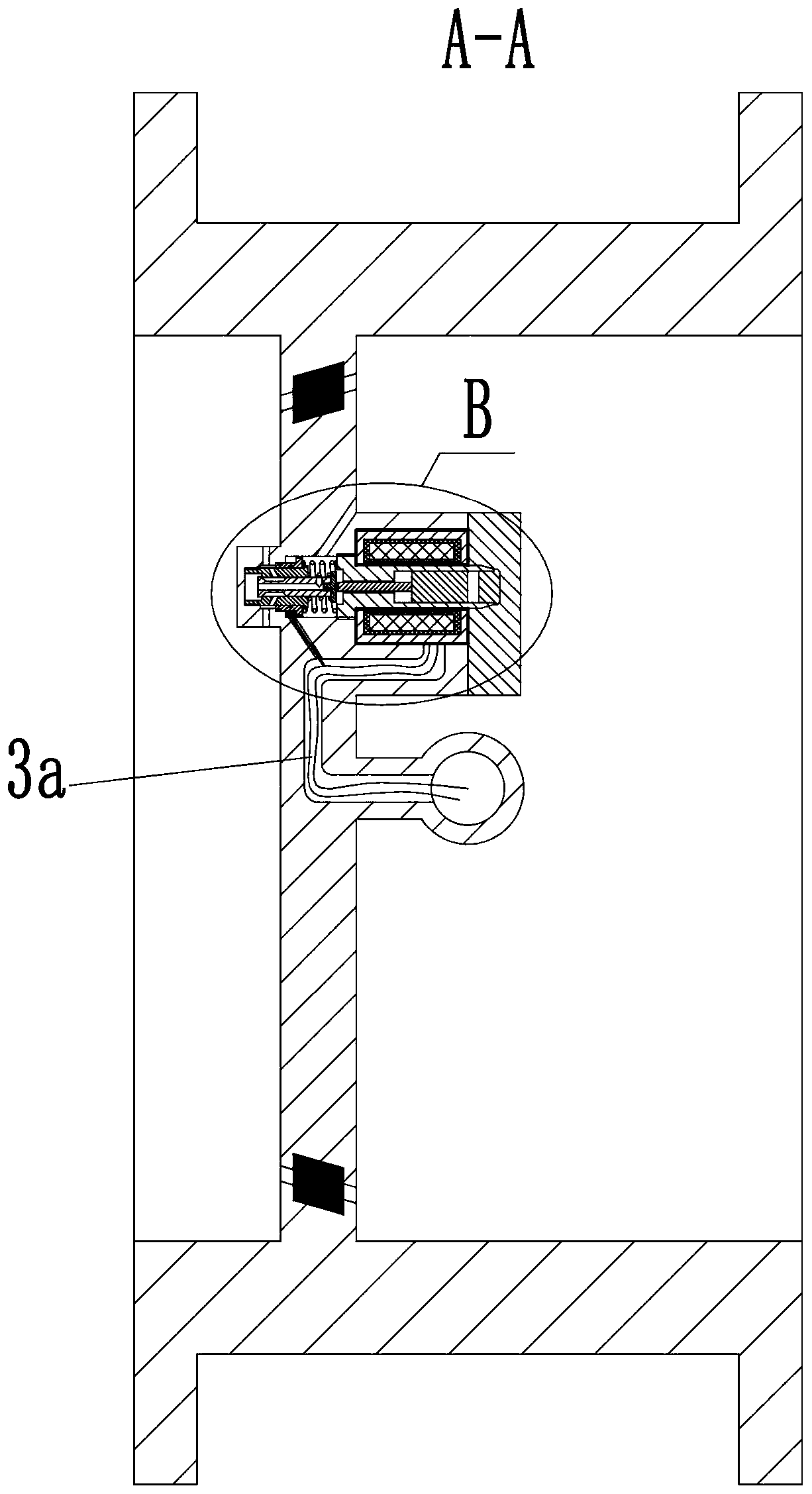

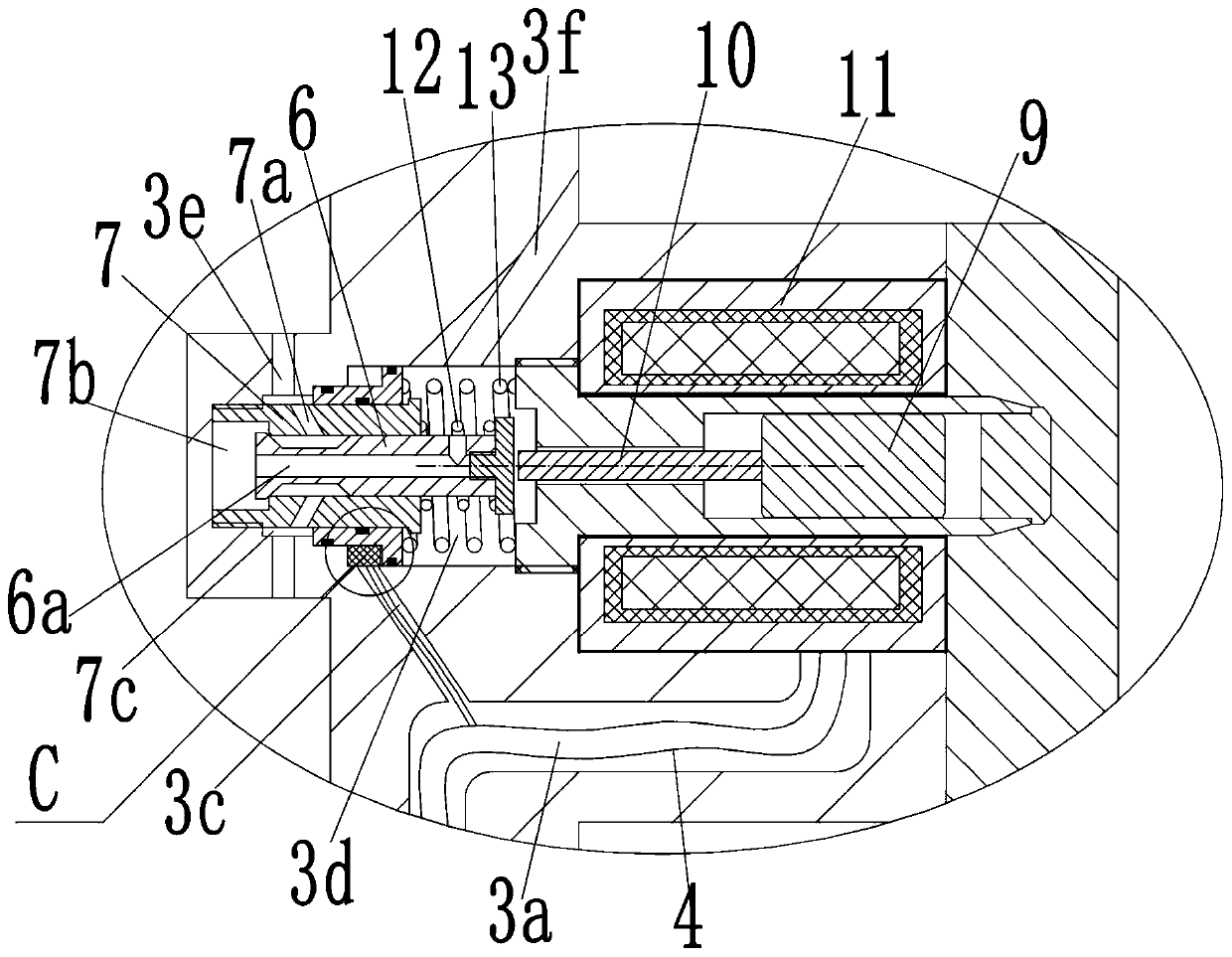

[0021] see Figure 1-5 As shown in the figure, an electric butterfly valve includes a valve body 5, and the valve body 5 is provided with a channel 501 penetrating left and right, the left end of the channel 501 is the inlet, and the right end is the outlet; baffle plate 51, the baffle plate 51 is provided with a valve port 52; the valve body 5 is rotatably connected with a rotating shaft 2, and the rotating shaft 2 is fixedly installed with a flap 3 for controlling the opening and closing of the valve port 52; the valve The outer side of the body 5 is fixedly installed with a motor 1 for driving the rotating shaft 2 to rotate; the right side of the flap 3 is provided with a first valve hole 31 and a second valve hole 32 in sequence to the left, and the flap 3 is provided with a There is a first through hole 3e for communicating the inlet and the second valve hole 32; a valve sleeve 7 is fixedly installed in the second valve hole 32, and a magnetic guide sleeve 91 is fixedly i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com