Pilot-operated type hard seal fixing ball valve

A fixed ball valve, hard sealing technology, applied in valve details, valve device, valve operation/release device and other directions, can solve the problems of shortening valve service life, ball and valve seat wear, strain, etc., to reduce the opening torque, The effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

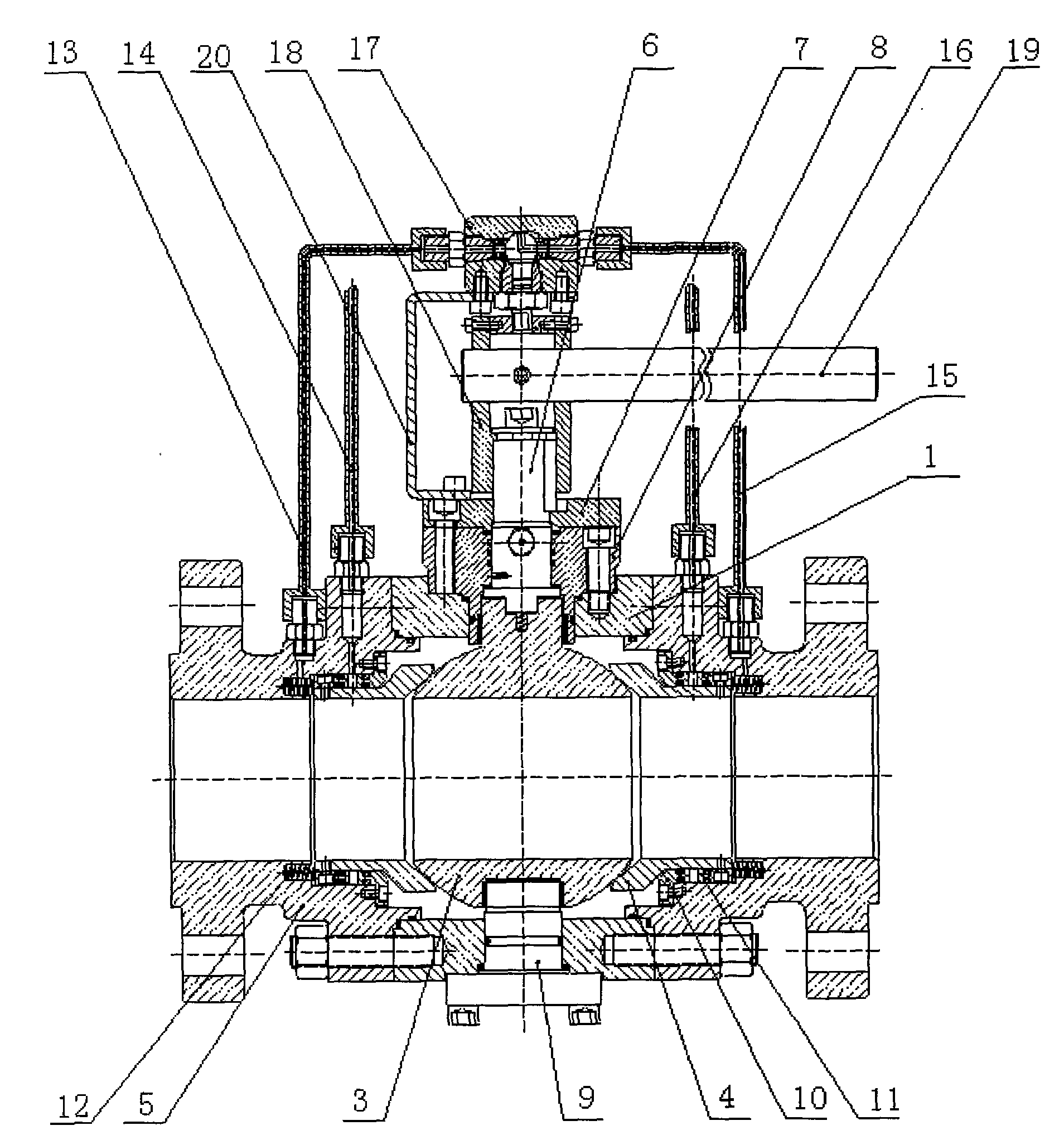

[0017] figure 1 It is a structural schematic diagram of an embodiment of the present invention.

[0018] Such as figure 1 Shown: a pilot-operated hard-sealed fixed ball valve, including a valve body 1, a ball 3, a valve seat 4, a valve cover 5, a valve stem 6, a gland 7, a packing gland 8, and a support shaft 9, wherein the ball 3 is set on Inside the valve body 1, the valve stem 6 passes through the upper part of the valve body 1 and is connected to the ball 3. The valve stem 6 is covered with a gland 7 and a packing gland 8. The gland 7 is located on the packing gland 8. The valve cap 5 and A valve seat 4 is arranged between the spheres 3, and the support shaft 9 passes through the lower part of the valve body 1 and is connected with the sphere 3. A valve cover sealing ring 10, a valve seat sealing ring 11 and a valve cover 5 are arranged between the valve seat 4. Valve seat spring 12, wherein, valve cover 5, valve seat 4, valve seat sealing ring one 10 and valve seat seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com