Double-wedge type double-ball-clack valve

A ball valve and wedge type technology, which is applied to valve devices, cocks including cut-off devices, engine components, etc., can solve problems such as poor sealing, mismatching of mating surfaces, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

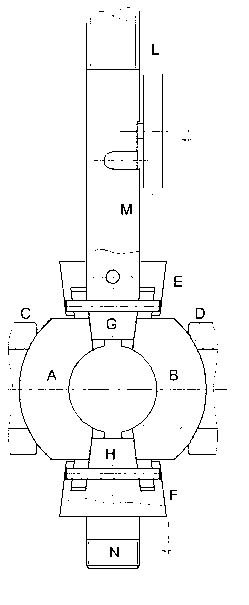

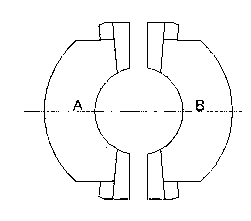

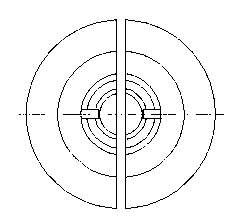

[0006] Embodiment 1, a kind of double-wedge double-ball disc valve of the present invention (see Figure 1-5 ), there is a valve body, a valve seat in the flow channel in the valve body, a bracket of the valve body, a ball corresponding to the valve seat C and D in the valve body, a valve stem M connected to the ball, and the valve stem passes through the seal of the valve body Extending to the top of the valve body, the screw at the upper end of the valve stem cooperates with the handwheel nut on the valve body bracket, the side of the valve stem has an L-shaped guide groove, and the bracket is fixed with a guide pin L whose end is inserted into the guide groove; its characteristics That is: the sphere is two left and right balls A, B, the upper part and the lower part between the two balls are the open upper conical space and the lower conical space, and the upper conical space and the lower conical space correspond to the upper and lower conical spaces. The upper end of the...

Embodiment 2

[0008] A kind of double-wedge type double-ball disc valve of the present invention, see attached Figure 5, there is a valve body (14), a valve cover (11) and a gasket (26) fixedly connected by bolts (25), the valve seat (16) of the flow channel in the valve body, and the valve body fixed by bolts (9) The bracket (8), the ball (15) corresponding to the valve seat in the valve body, the valve stem connected with the ball, the valve stem passes through the sealing ring (13) of the valve body to seal the packing (12), and the packing gland (10) passes through Bolts (24) and nuts (23) are connected to the valve cover and backlogged on the packing. The screw rod at the upper end of the valve stem cooperates with the nut (5) in the middle of the handwheel (2) on the valve body support (8). The stepped shaft at the lower end of the nut (5) is in dynamic fit with the bushing (4) of the bracket, a gasket (3) is clamped between the bushing and the handwheel, and the upper end of the nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com