Low-temperature welding double-eccentric aluminum butterfly valve

A low-temperature welding, double eccentric technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of leakage, leakage at the joint between pipeline and valve, different material shrinkage rate, etc., to improve the flow capacity and reduce the rotation start. The effect of closing torque and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in combination with principle diagrams and specific operation examples.

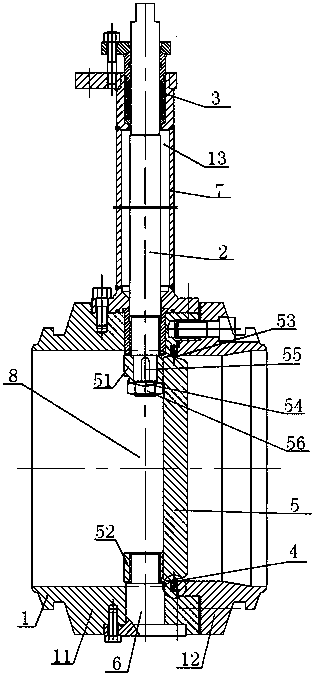

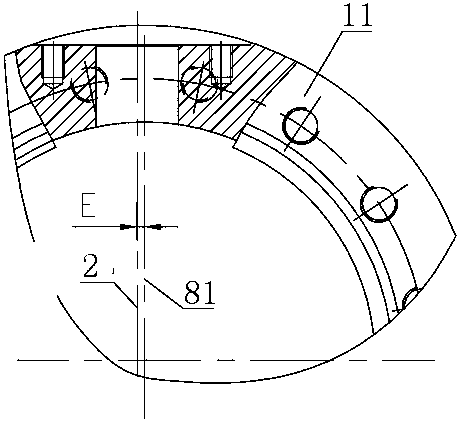

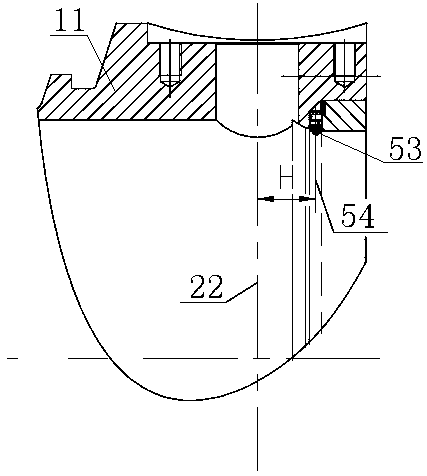

[0037] Such as figure 1 As shown in , a low-temperature welded double eccentric aluminum butterfly valve includes a valve body 1, a valve stem 2, a valve disc 5 and a pipe hole 8. The pipe hole 8 is a cavity formed between the valve body 1 and the valve disc 5.

[0038] In one example of the present invention, the valve body 1 is composed of a left valve body 11 and a right valve body 12, the right valve body 12 is placed in the left valve body 11, and the right valve body 12 is inserted into the left valve body by hexagon socket screws 11, the valve body 1 is a valve body with a welded structure, and the welding groove of the valve body 1 is consistent with the welding groove of the pipeline, so that the valve body 1 can be directly welded to the pipeline, and can also be welded on the welded groove There is a groove (not marked in the figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com