Filler ball valve

A packing ball and ball valve technology applied in the field of packing ball valves to achieve the effects of low friction, stable operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

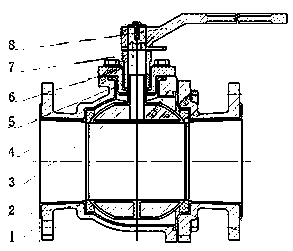

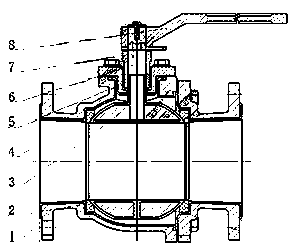

[0008] A packing ball valve, the ball valve includes a valve body 1, a valve seat 2, a ball 3, an inner liner 4, a packing 5, a valve stem 6, a gland 7 and a handle 8, and the valve seat 2 is arranged at the bottom of the ball valve end, the valve body 1 is set on the valve seat 2, the ball 3 is set in the valve body 1, the inner liner 4 is set on the upper part of the ball 3, and the gland 7 is set on the valve body 1 upper part, the valve stem 6 is set in the gland 7, one end of the valve stem 6 is connected to the handle 8, and the other end is connected to the ball 3, the outer side of the valve stem 6 is provided with a packing 5, so The filler 5 described above is an anti-corrosion and acid-resistant material.

[0009] The above embodiments are only used to illustrate the present invention rather than limit the technical scheme described in the present invention; therefore, although the present description has described the present invention in detail with reference to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com