Low-temperature rodlike valve rod sealing grease composition and preparation method thereof

A composition and rod-shaped technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems that affect the rapid and sensitive opening and closing of blowout preventers and gate valves, are easily dissolved by oil and gas, diluted, and cannot meet the requirements of high temperature, etc. Achieve the effects of excellent chemical stability, excellent thermal stability, and excellent low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

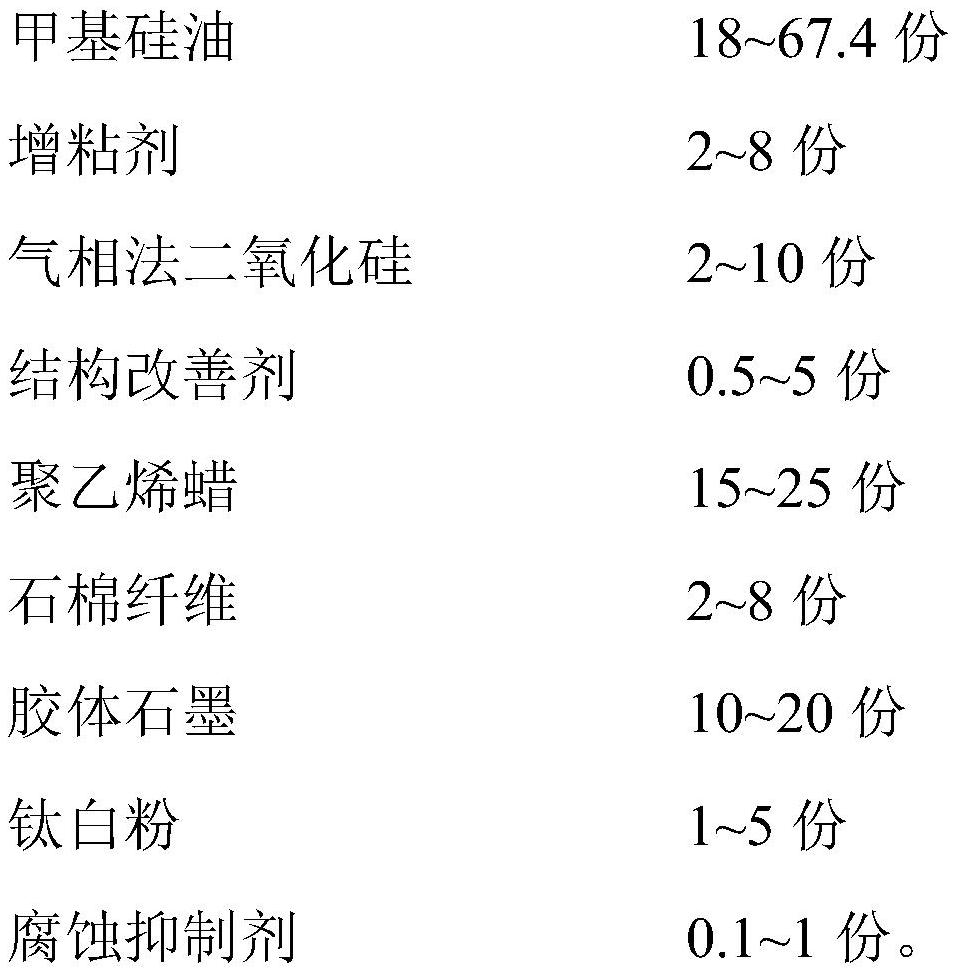

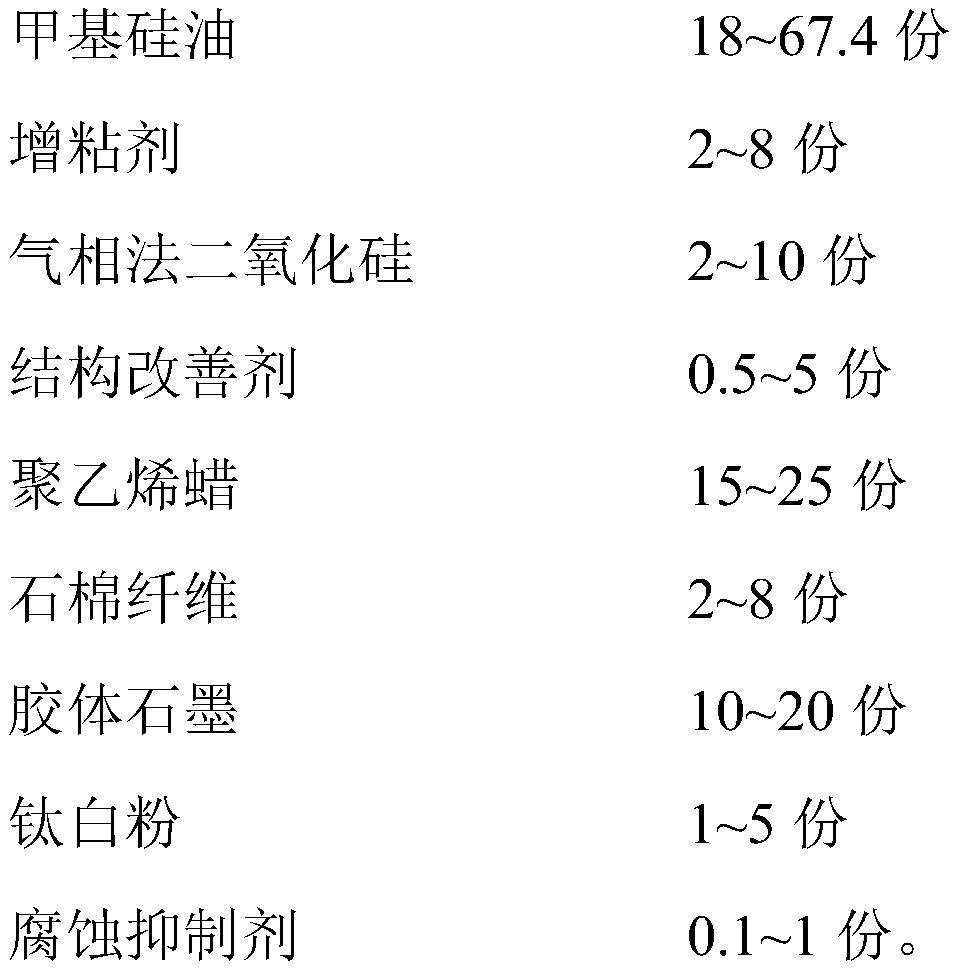

Method used

Image

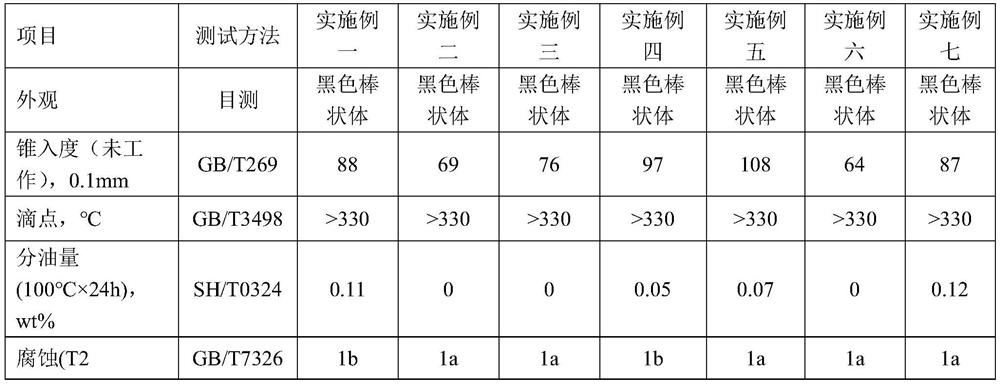

Examples

Embodiment 1

[0036] A low-temperature rod-shaped valve stem sealing grease composition, the preparation method of which is:

[0037] 1) Add 43.5 parts of methyl silicone oil (V25=15000mm 2 / s) and 5 parts of polymethyl methacrylate (V100=1050mm 2 / s) into the reaction kettle in turn, heated and stirred to 90±5°C, stirred at constant temperature for 30±5 minutes to make the system uniformly dispersed, then added 2 parts of diphenyldihydroxysilane, and continued to heat up to 160±5°C, Slowly add 6 parts of fumed hydrophilic silica (specific surface area=200m 2 / g), then 20 parts of polyethylene wax (V149=85mm 2 / s), stirring at constant temperature for 60±5 minutes.

[0038] 2) After the constant temperature is over, add 5 parts of asbestos fiber, 15 parts of colloidal graphite, 3 parts of titanium dioxide and 0.5 part of T706 in sequence, stir and disperse for 45±5 minutes, then discharge the material into the barrel, and immediately pass through three-roller grinding Grind it once by m...

Embodiment 2

[0041] A low-temperature rod-shaped valve stem sealing grease composition, the preparation method of which is:

[0042] 1) First, 36.7 parts of methyl silicone oil (V25 = 12500mm 2 / s), 5 parts of polymethyl methacrylate (V100=1980mm 2 / s) and 2 parts of low molecular weight polyisobutylene (V100=2870mm 2 / s) into the reaction kettle in turn, heated and stirred to 90±5°C, stirred at constant temperature for 30±5 minutes to make the system uniformly dispersed, then added 3 parts of octyltrimethoxysilane, and continued to heat up to 160±5°C, Slowly add 8 parts of fumed hydrophilic silica (specific surface area=150m 2 / g), then 22 parts of polyethylene wax (V149=97mm 2 / s), stirring at constant temperature for 60±5 minutes.

[0043] 2) After the constant temperature is over, add 6 parts of asbestos fiber, 12 parts of colloidal graphite, 5 parts of titanium dioxide and 0.3 part of T561 in sequence, stir and disperse for 45±5 minutes, then discharge the material into the barrel...

Embodiment 3

[0046] A low-temperature rod-shaped valve stem sealing grease composition, the preparation method of which is:

[0047] 1) Add 33.8 parts of methyl silicone oil (V25=9500mm 2 / s) and 8 parts of low molecular weight polyisobutylene (V100=1030mm 2 / s) into the reaction kettle in turn, heating and stirring to 90±5°C, stirring at constant temperature for 30±5 minutes to make the system uniformly dispersed, then adding 3 parts of diphenyldihydroxysilane, and continuing to heat up to 160±5°C, Slowly add 9 parts of fumed hydrophilic silica (specific surface area=260m 2 / g), then 16 parts of polyethylene wax (V149=55mm 2 / s), stirring at constant temperature for 60±5 minutes.

[0048] 2) After the constant temperature is over, add 8 parts of asbestos fiber, 20 parts of colloidal graphite, 2 parts of titanium dioxide and 0.2 part of T551 in sequence, stir and disperse for 45±5 minutes, then discharge the material into the barrel, and immediately pass through three-roller grinding G...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com