Engine piston connecting rod assembly

A technology for pistons, connecting rods and engines, which is applied to piston rods, engine components, machines/engines, etc. It can solve problems such as failure to meet engine requirements, poor lubrication of connecting rods, and damage to bearing bushes, so as to reduce the risk of less pad holding and reduce The effect of small surface pressure and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

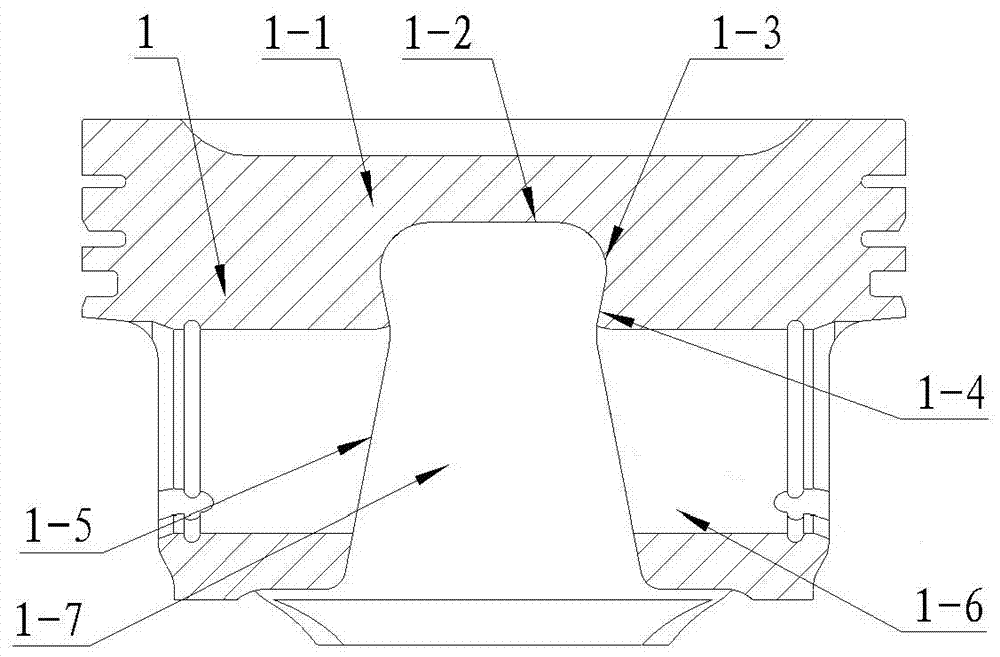

[0019] The piston connecting rod assembly 1 of the engine adopted in the present embodiment comprises a piston head 1-1 and a connecting rod 7 with an air ring 2, an air ring 3 and an oil ring 4, and the connecting rod 7 connects with the piston head 1 through the piston pin 5. -1 are connected together, and the movement of the piston pin 5 in the pin hole 1-6 is controlled by a snap ring. Connecting rod 7 comprises connecting rod small end 7-3, connecting rod large end 7-5, connecting rod large end 7-8 and connecting rod small end 7-3 and connecting portion 7-2 and being arranged on connecting rod large end 7-5. The bearing bush 8 in the hole seat.

[0020] The structure of the connecting rod 7 in this embodiment is as follows: the connecting rod small head 7-3 is a wedge-shaped structure, and a funnel is arranged on the top of the connecting rod small head 7-3 (that is, on the outer wall of the hole seat of the connecting rod small head 7-3) shaped oil return hole 7-1; an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com