Face pressure reducer of closed compressor

A compressor, airtight technology, used in mechanical equipment, machines/engines, rotary piston machines, etc., can solve the problems of low torque and wear of the rotating shaft 4, and achieve the goal of reducing surface pressure, reducing friction loss and improving efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

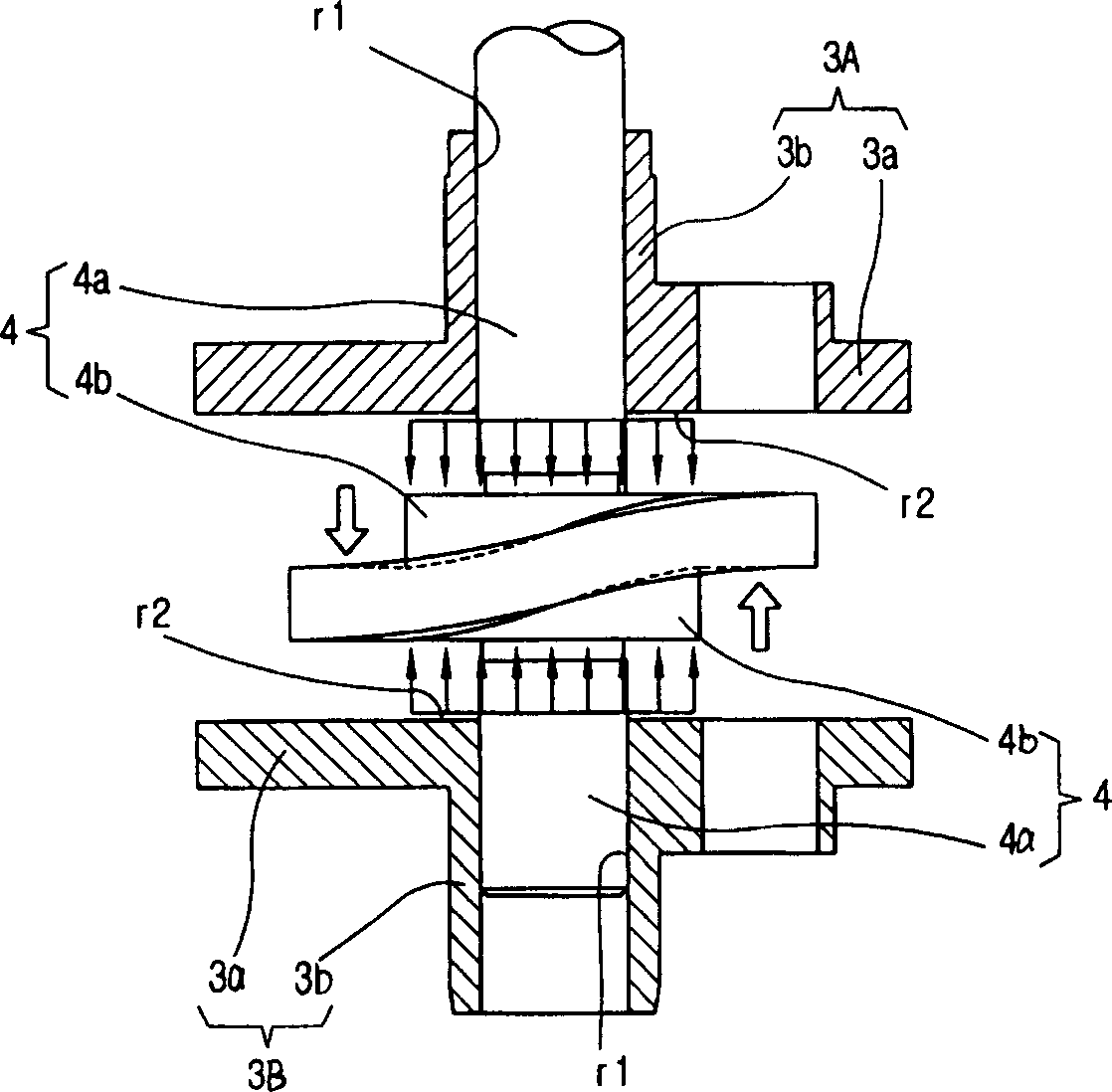

[0041] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, features and effects of the present invention will be described in detail as follows.

[0042] 10, 20. Upper and lower bearing plates

[0043] 11, 12. Thrust bearing (THRUST BEARING)

[0044] 11a, 21a. Pressure relief socket (POCKER)

[0045] 12. 22. Radial Bearing (RADIAL BEARING)

[0046] 30. Rotary shaft 31. Shaft

[0047] 32. Expansion Department

[0048] see Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 As shown, the compressor portion of the vane compressor of the present invention includes the following structure: cylinder 2, upper bearing plate 10, lower bearing plate 20, rotating shaft 30, partition plate 5, first guide plate 6A and the second guide plate 6B.

[0049] Above-mentioned cylinder 2 is fixed on casing ( figure 1 In the lower half of the prompt) 1, the above-mentioned cylinder 2 has an internal space for sucking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com