Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Reduce collision speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

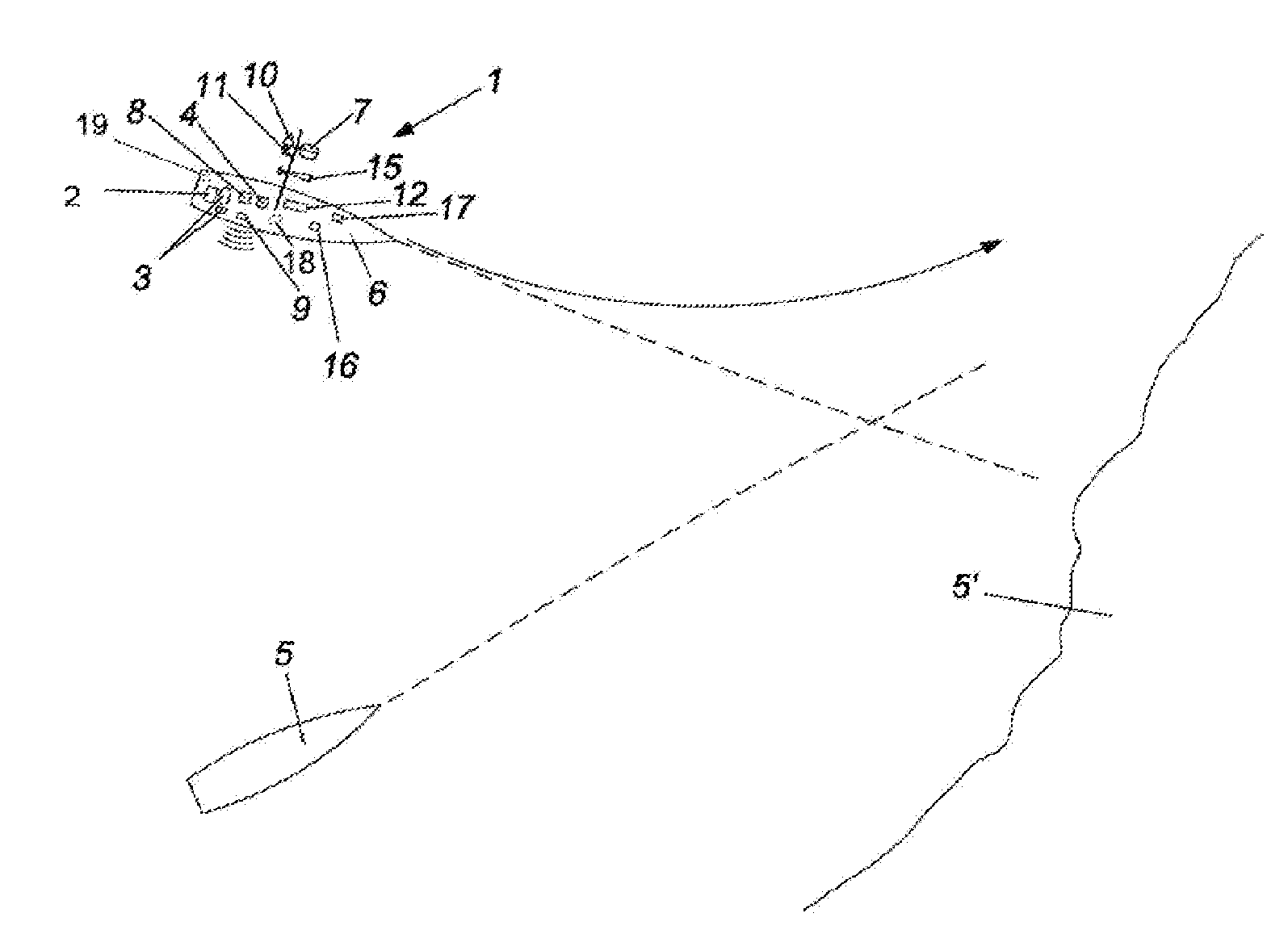

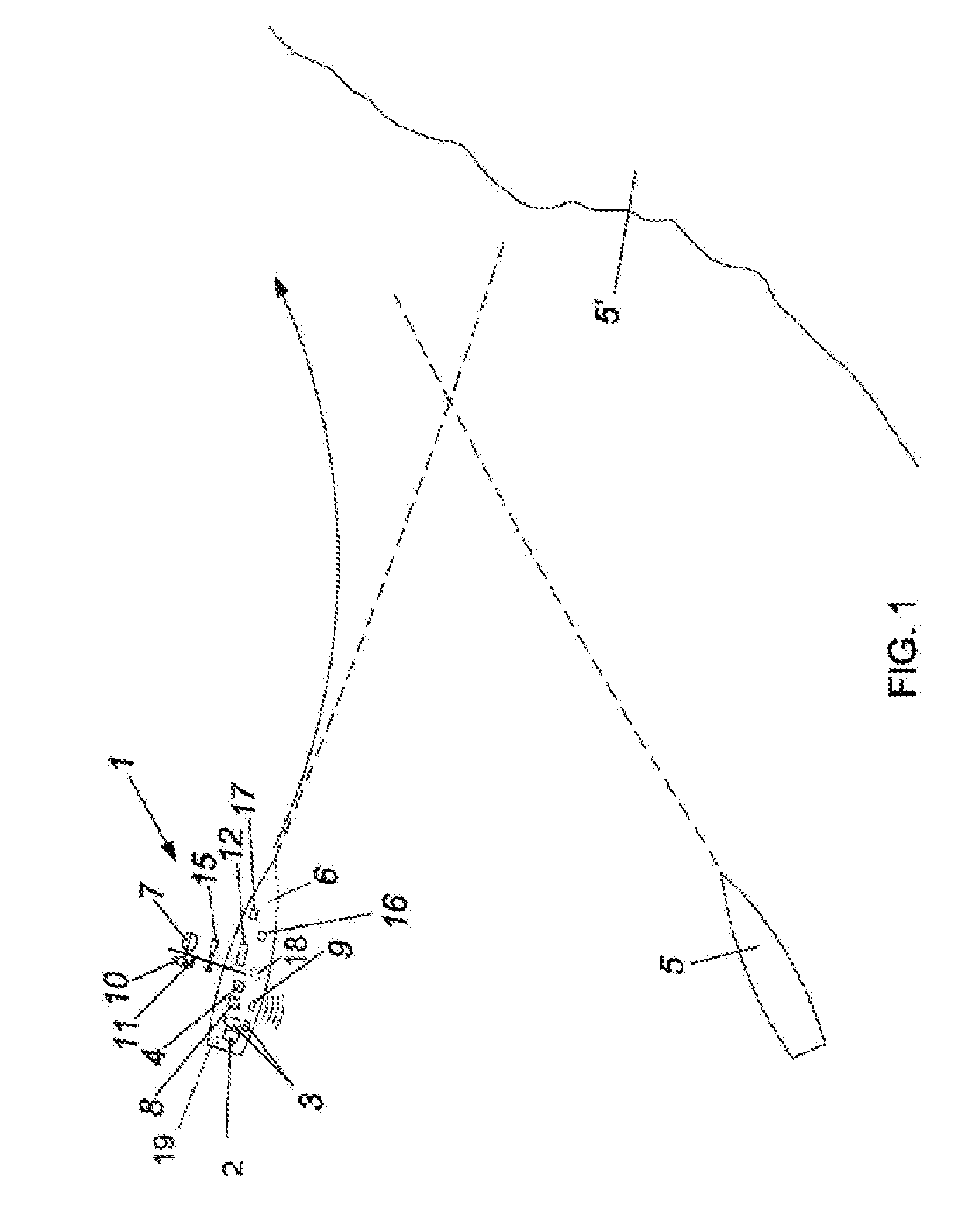

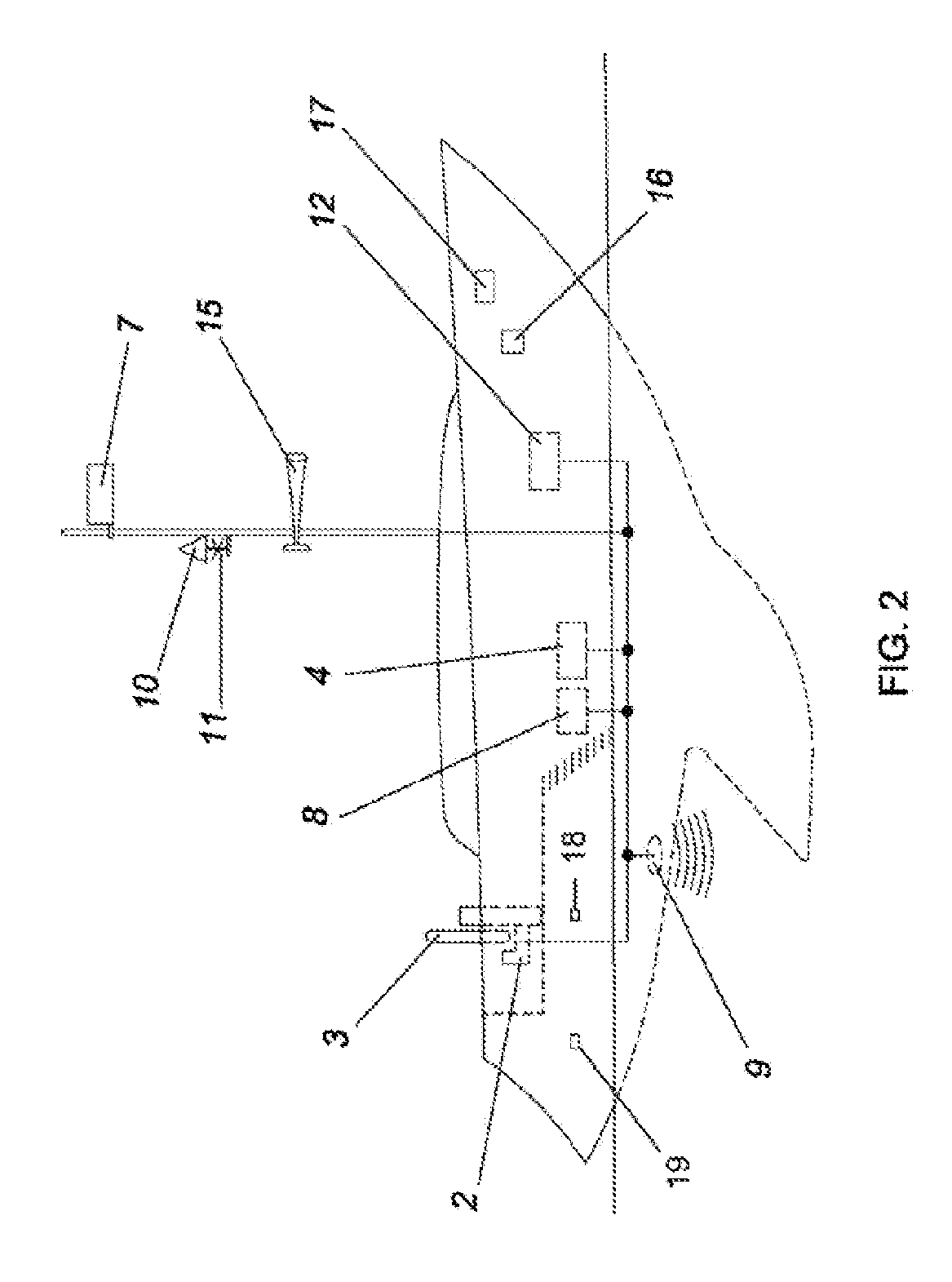

Evasive autopilot system for vessels

InactiveUS20110022316A1Reduce collision speedAvoid collisionSteering ruddersSteering initiationsSteering wheelRadar

The present disclosure relates to an autopilot device (2) which actuates, at least, on the course controls (3) of the bearing vessel (6), and which comprises an electronic evasion module (4) capable of generating evasive manoeuvre orders for the autopilot device (2) in the event of taking a collision course; as well as a radar (7) connected to said an electronic evasion module (4) in order to detect the existence of obstacles (5, 5′) which generate collision courses, as well as comprising a laser telemeter (16) and an AIS system (17), to support the radar (7), and means of detecting (18) the turning degrees of the steering wheel, as well as sensors (19) that measure the revolutions of the engine.

Owner:BENDITO VALLORI JUAN MARIANO

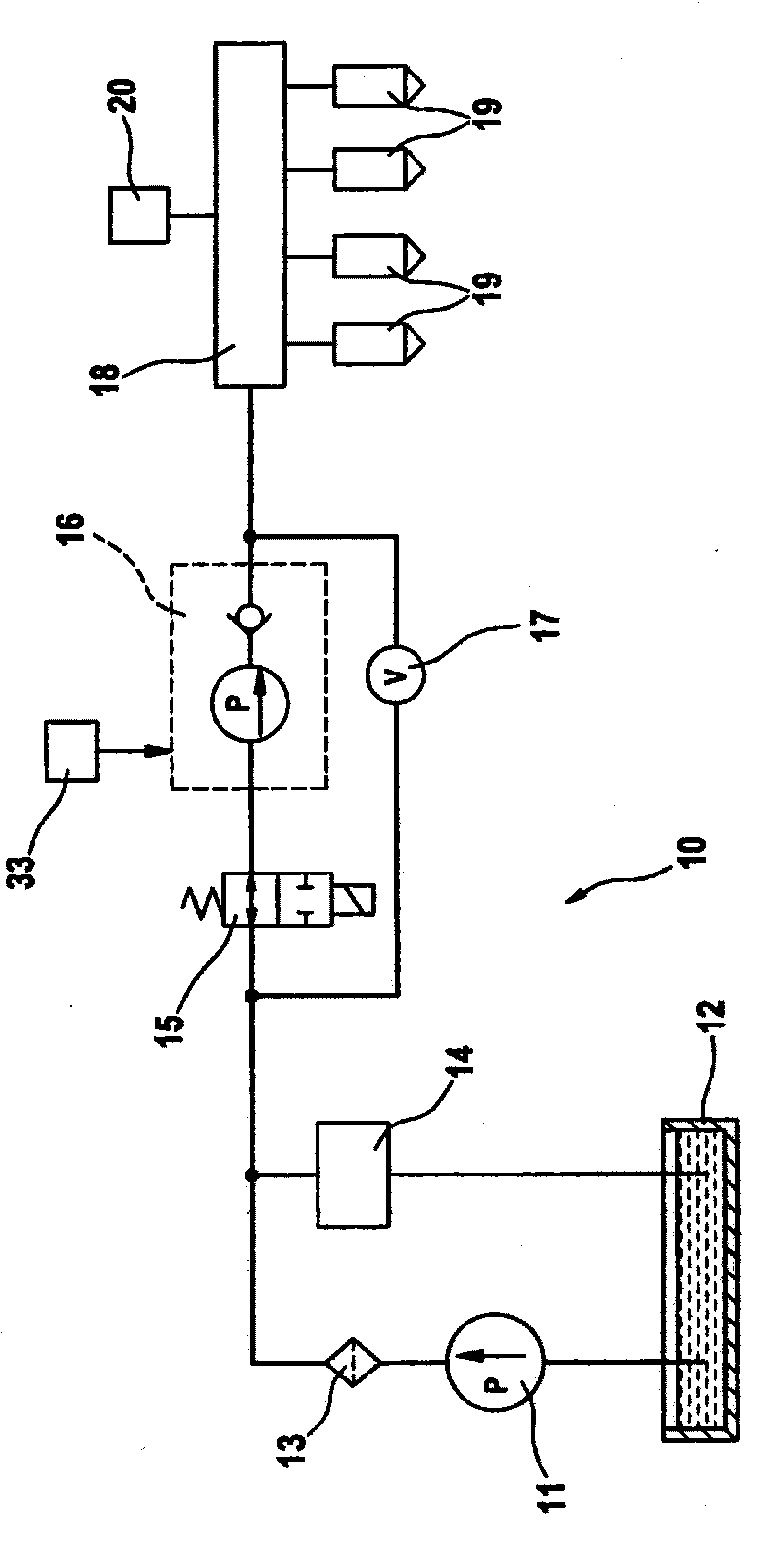

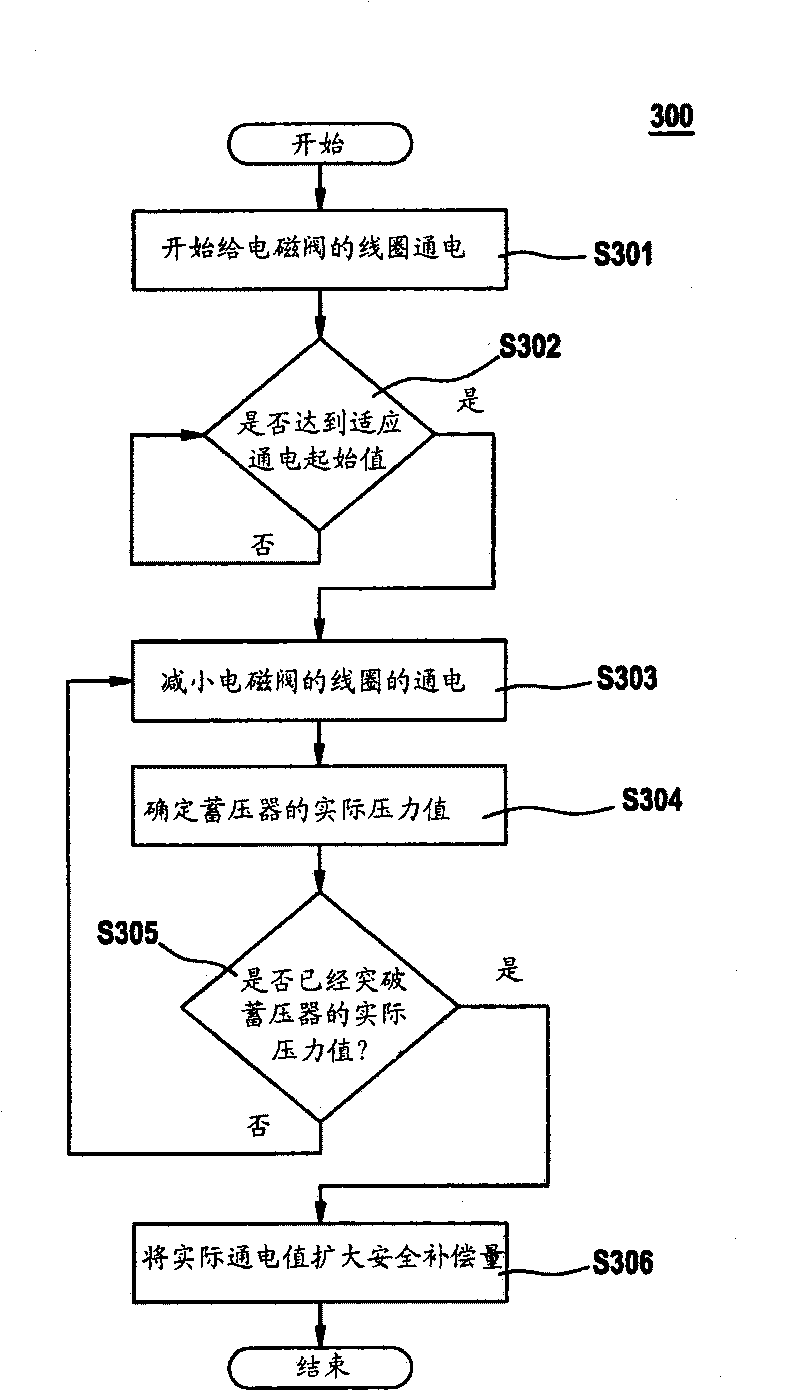

Method for controlling a solenoid valve of a quantity controller in an internal combustion engine

ActiveCN101765713ASmall volumnExpand the amount of safety compensationElectrical controlMachines/enginesPower flowSolenoid valve

The invention relates to a method for controlling a fuel injection system (10) of an internal combustion engine, the fuel injection system (10) comprising a high-pressure pump (16) associated with a quantity controlling valve (15) having a solenoid valve (22) electromagnetically actuatable by a coil (21) for supplying fuel, the quantity control valve (15) controlling the quantity of fuel supplied by the high-pressure pump (16) and the coil (21) of the solenoid valve (22) having a first current value applied thereto, in order to close the same for supplying fuel to the high-pressure pump (16), the first current value being reduced to a second current value when the solenoid valve is closing (22), such that the radiation of audible sound arising from the closing of the solenoid valve (22) is at least partially reduced.

Owner:ROBERT BOSCH GMBH

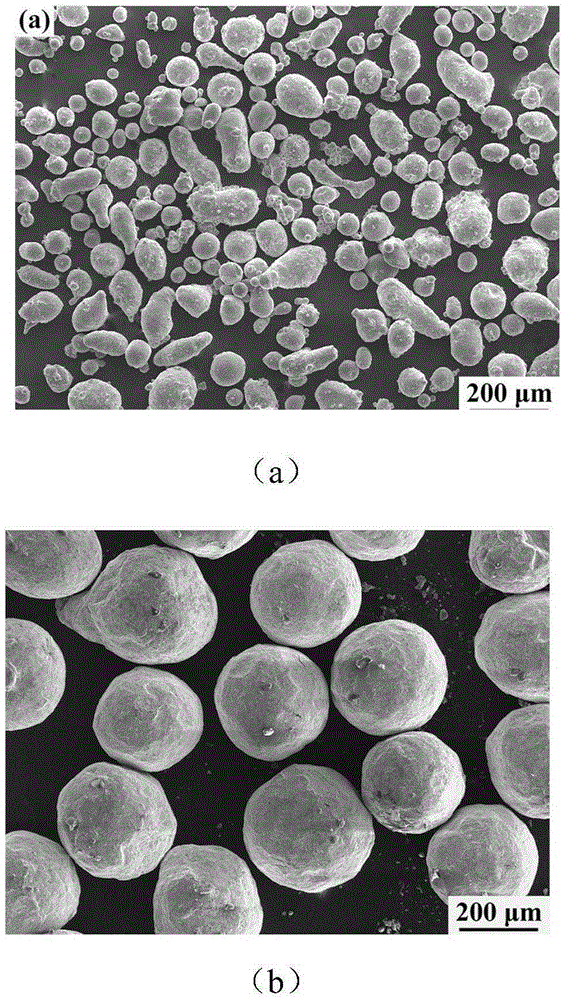

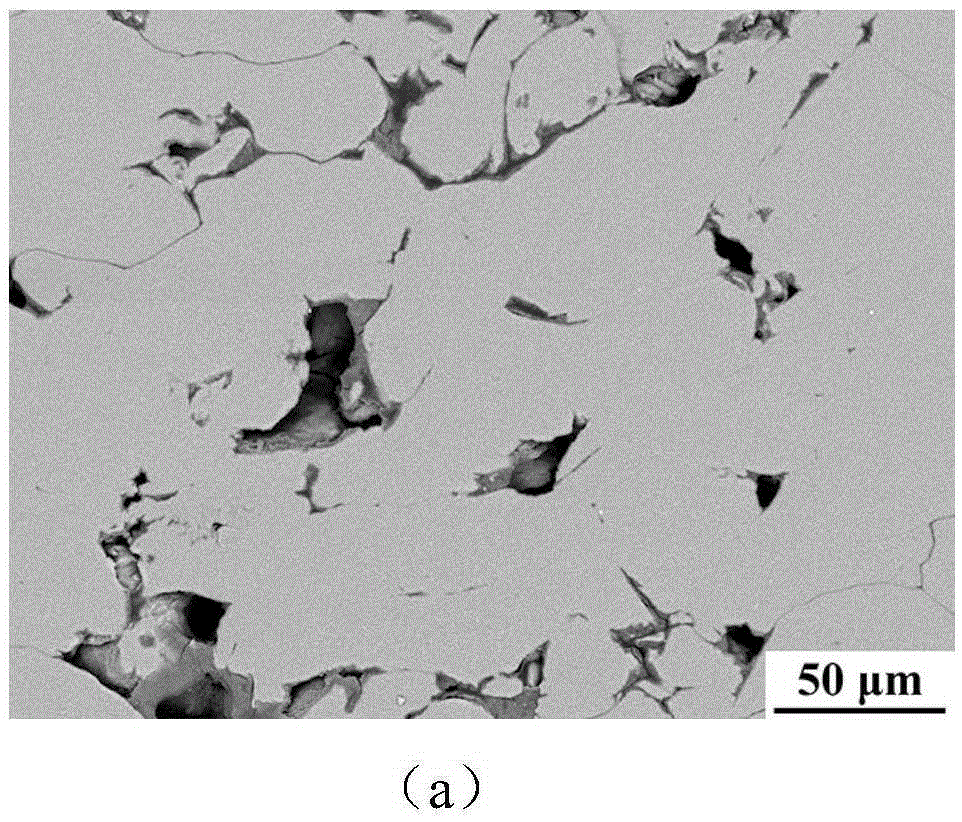

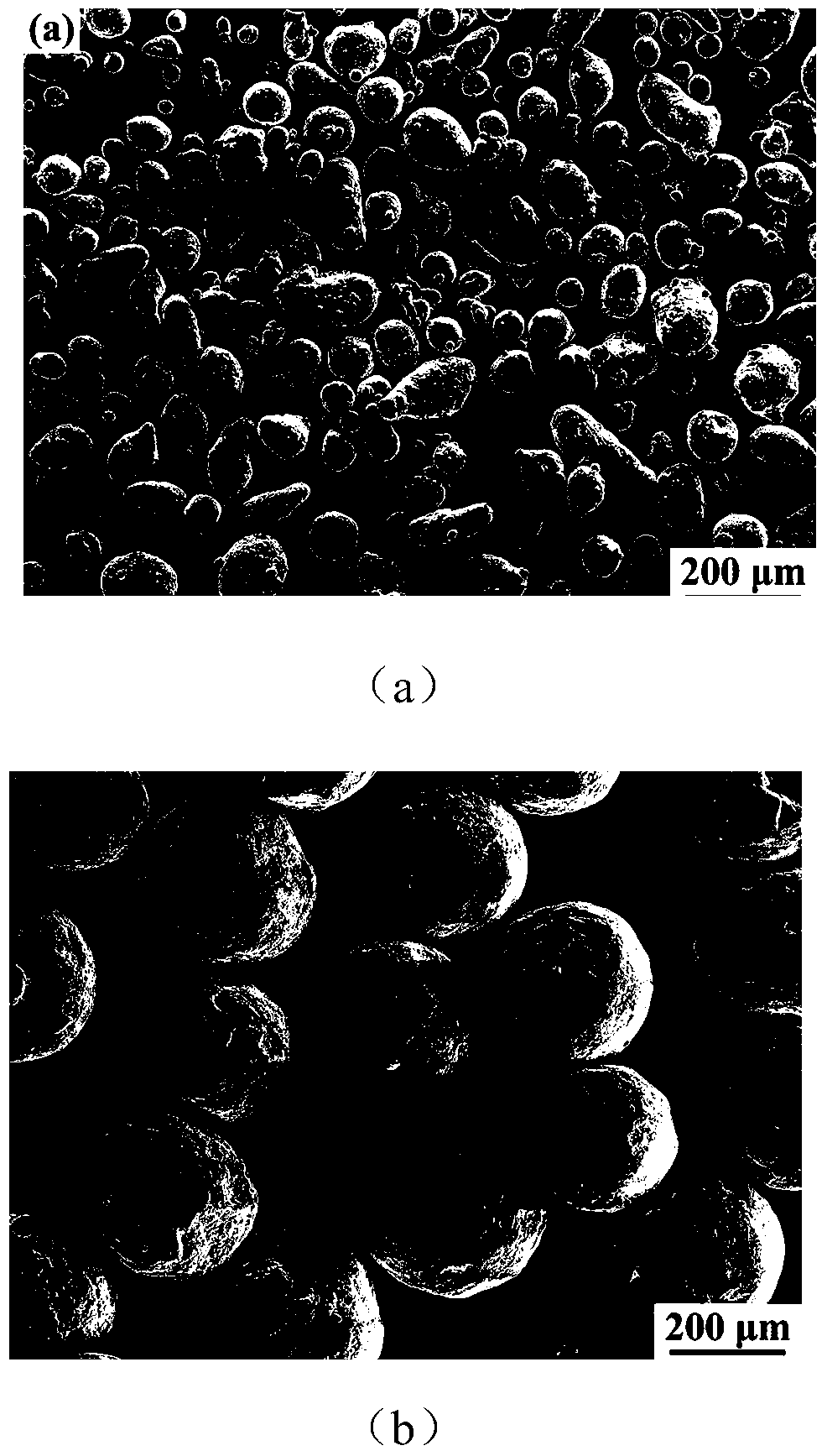

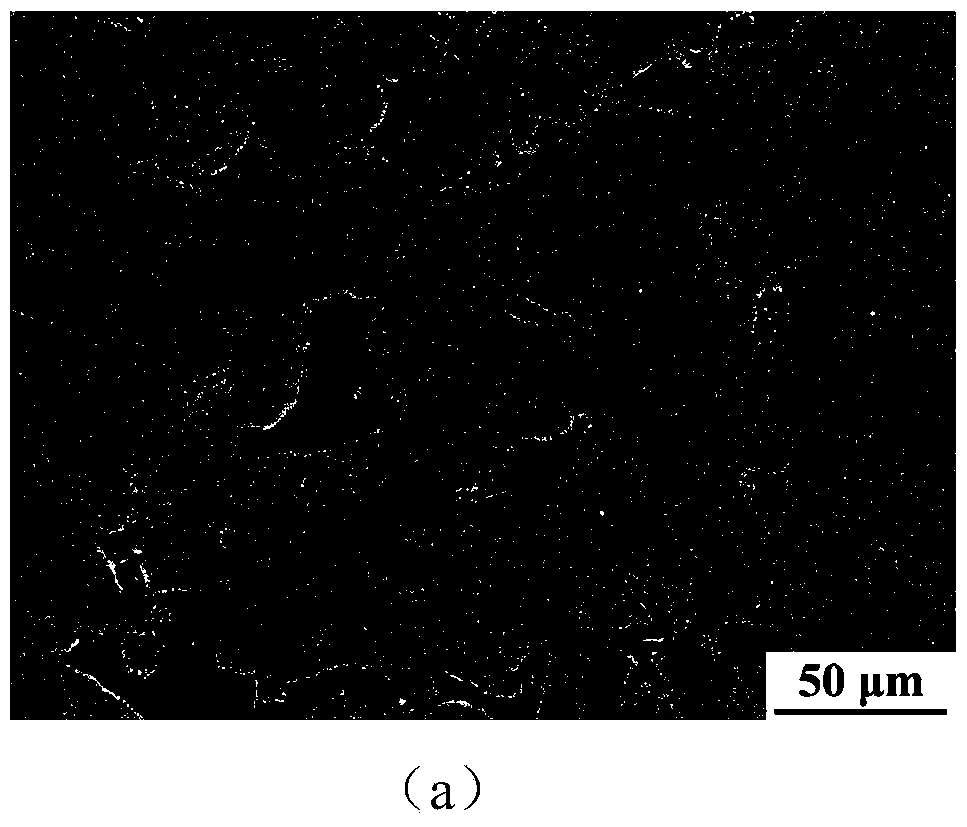

Cold spraying manufacturing method for anticorrosive aluminum base or zinc-aluminum base metal coating on magnesium alloy surface

ActiveCN105256307ADeposition will notImprove corrosion resistanceMolten spray coatingPressure inorganic powder coatingSurface engineeringDeposition temperature

The invention discloses a cold spraying manufacturing method for an anticorrosive aluminum base or a zinc-aluminum base metal coating on a magnesium alloy surface and belongs to the field of the material surface engineering technology and mechanical manufacturing. The method includes the following steps that firstly, aluminum base or zinc-aluminum base metal powder is mixed with hard metal powder so as to manufacture mixed powder for cold spraying; and secondly, a cold spraying process is adopted, the mixed powder is sprayed to a pretreated magnesium alloy matrix, and the anticorrosive aluminum base or zinc-aluminum base metal coating is manufactured on the surface of the magnesium alloy matrix. By the adoption of the method, the grain speed and the deposition temperature do not need to be remarkably improved, operation is easy, a sedimentary body manufactured through the method is more excellent in electric conductivity and thermal conductivity and higher in corrosion resistance, abrasion resistance and mechanical performance, and therefore the method can be widely applied for manufacturing coatings with high electric conductivity, thermal conductivity, corrosion resistance and abrasion resistance or workpieces with the high mechanical performance.

Owner:XUZHEN NEW ENERGY TECH (SHANGHAI) CO LTD

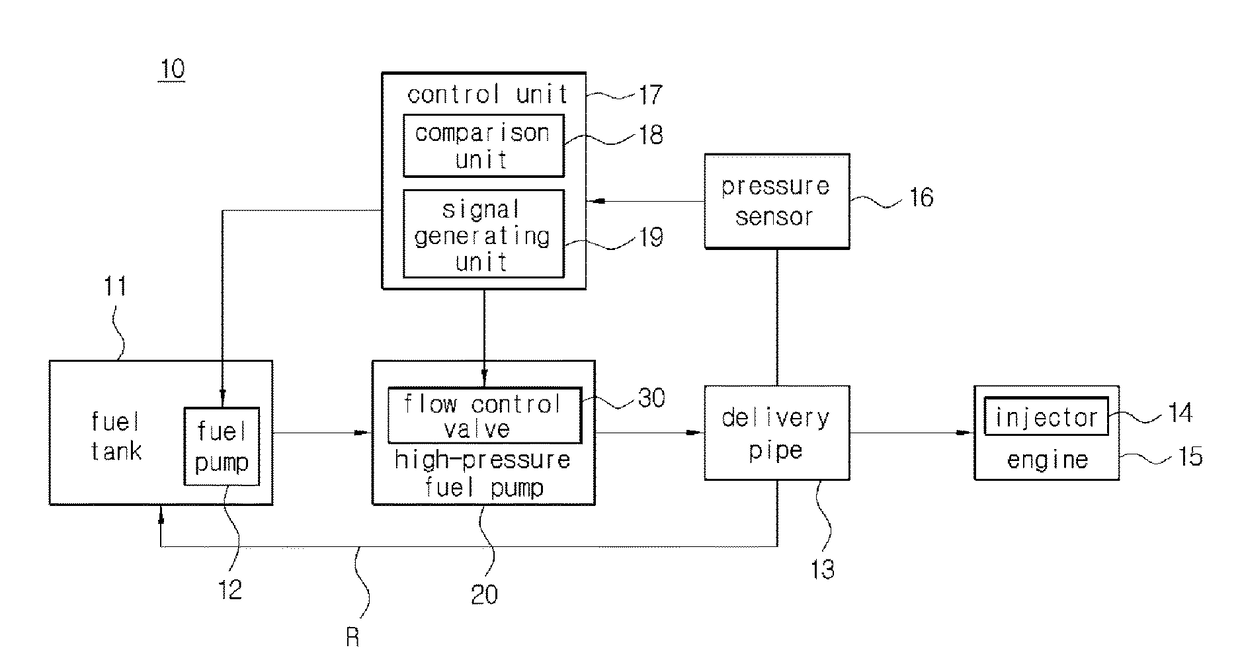

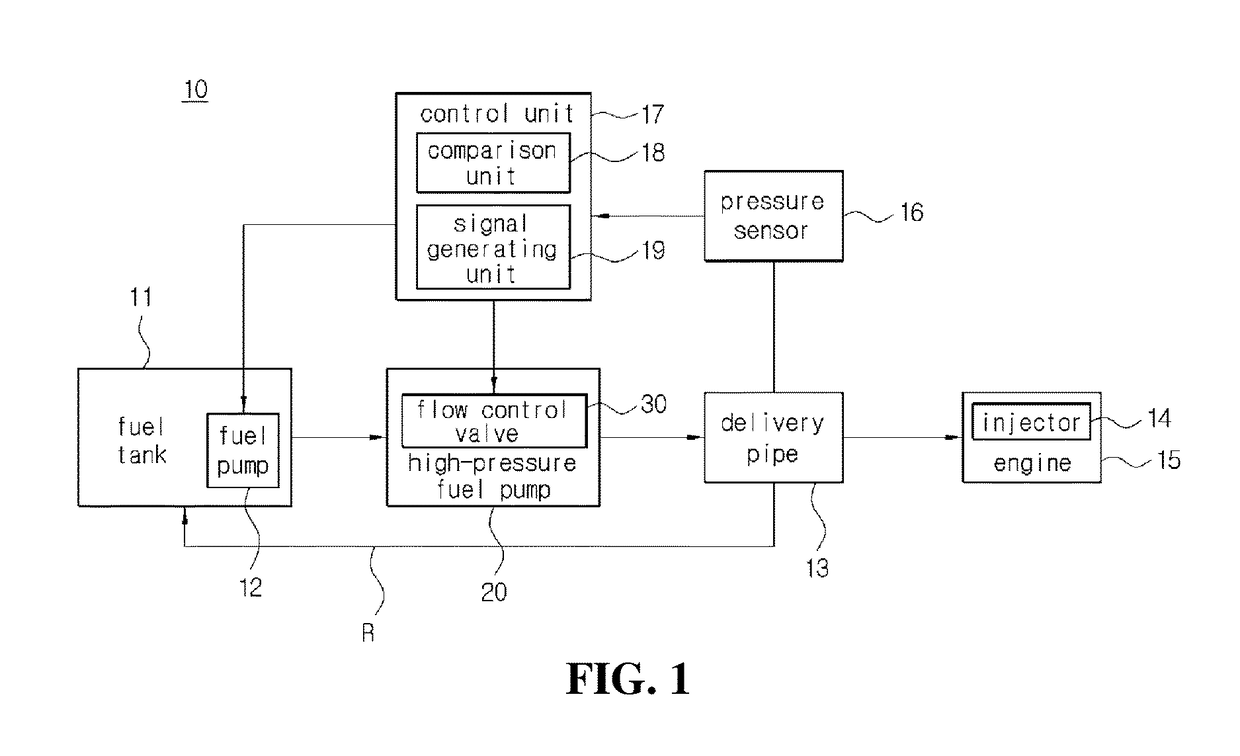

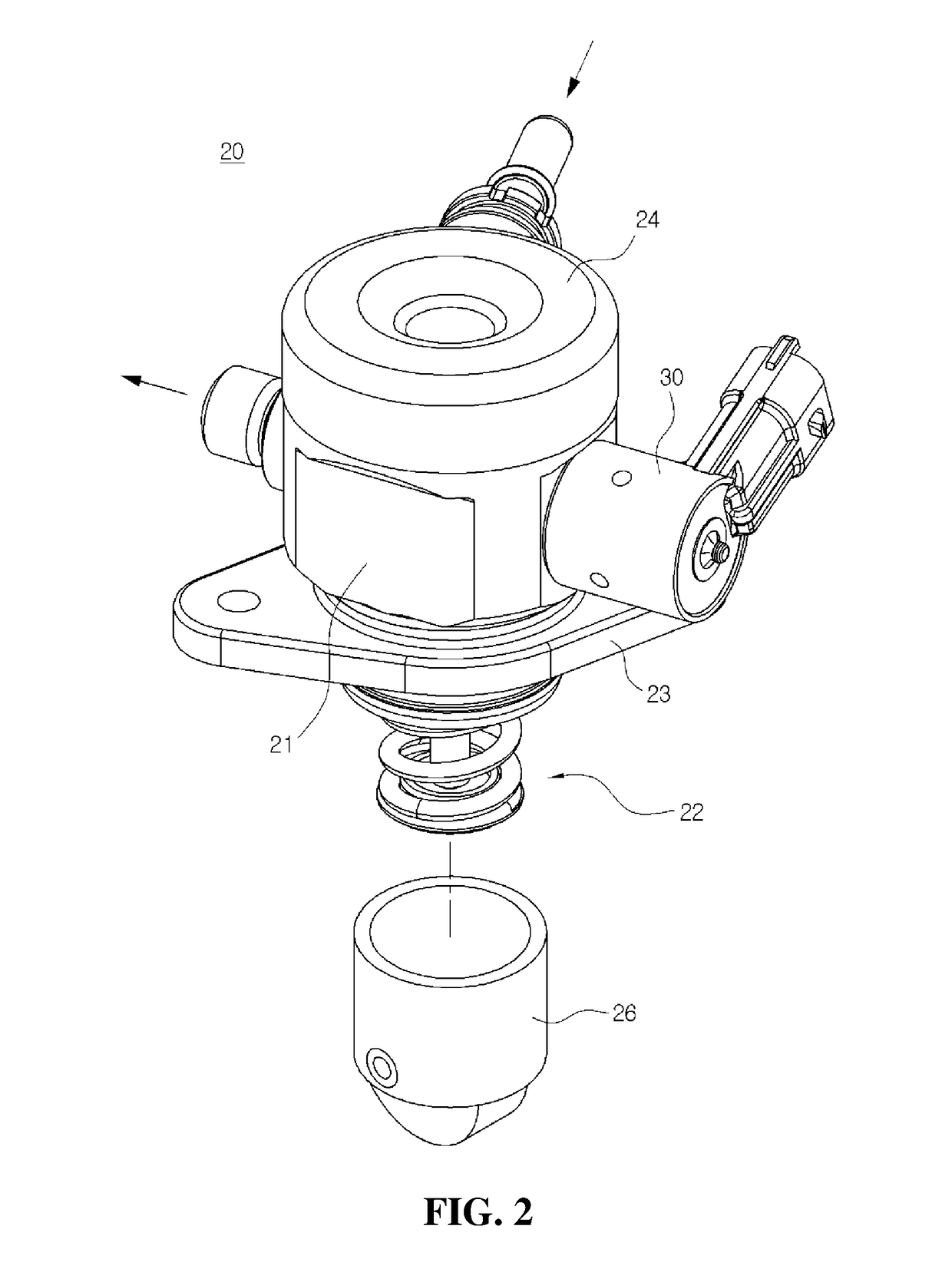

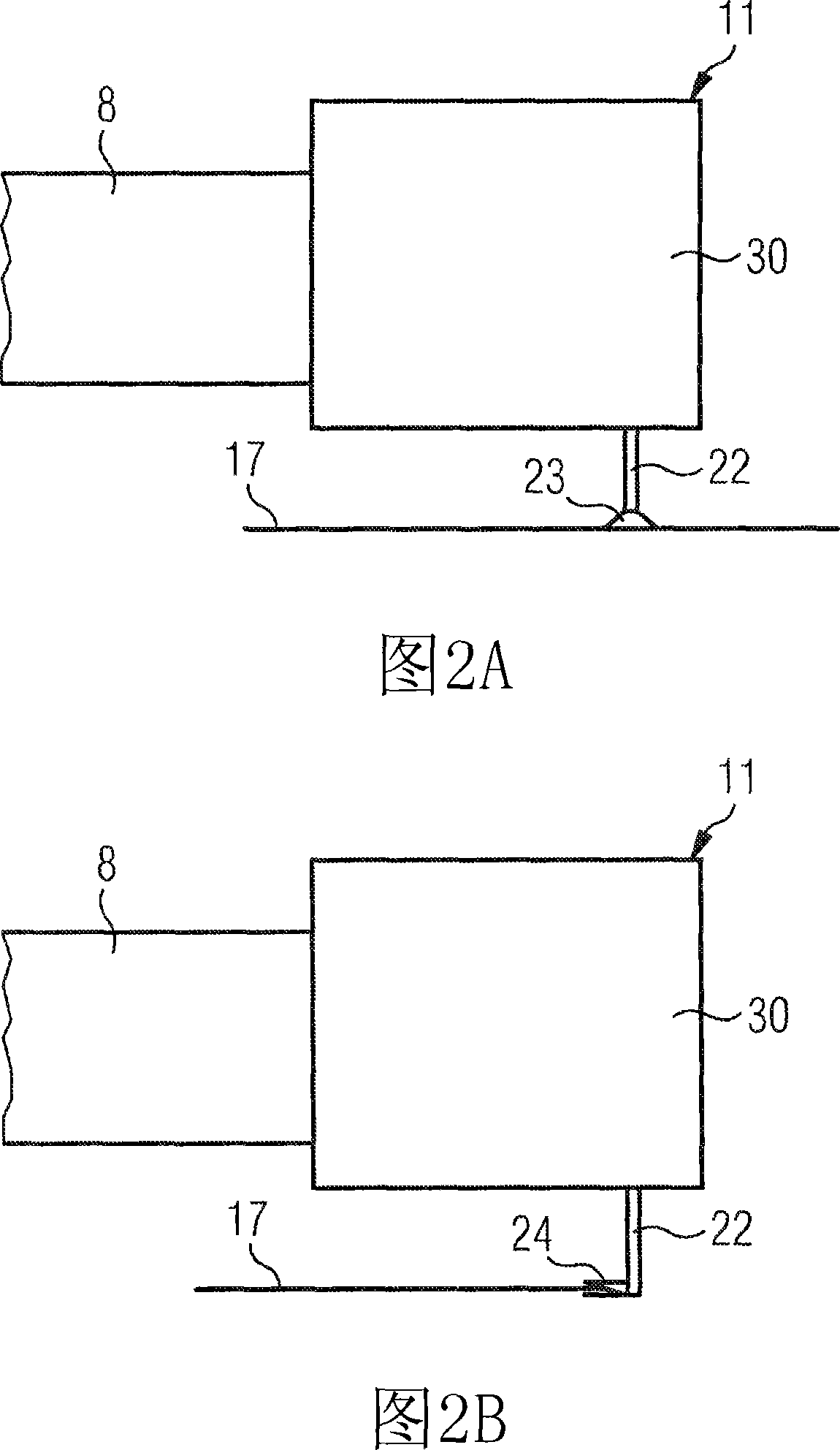

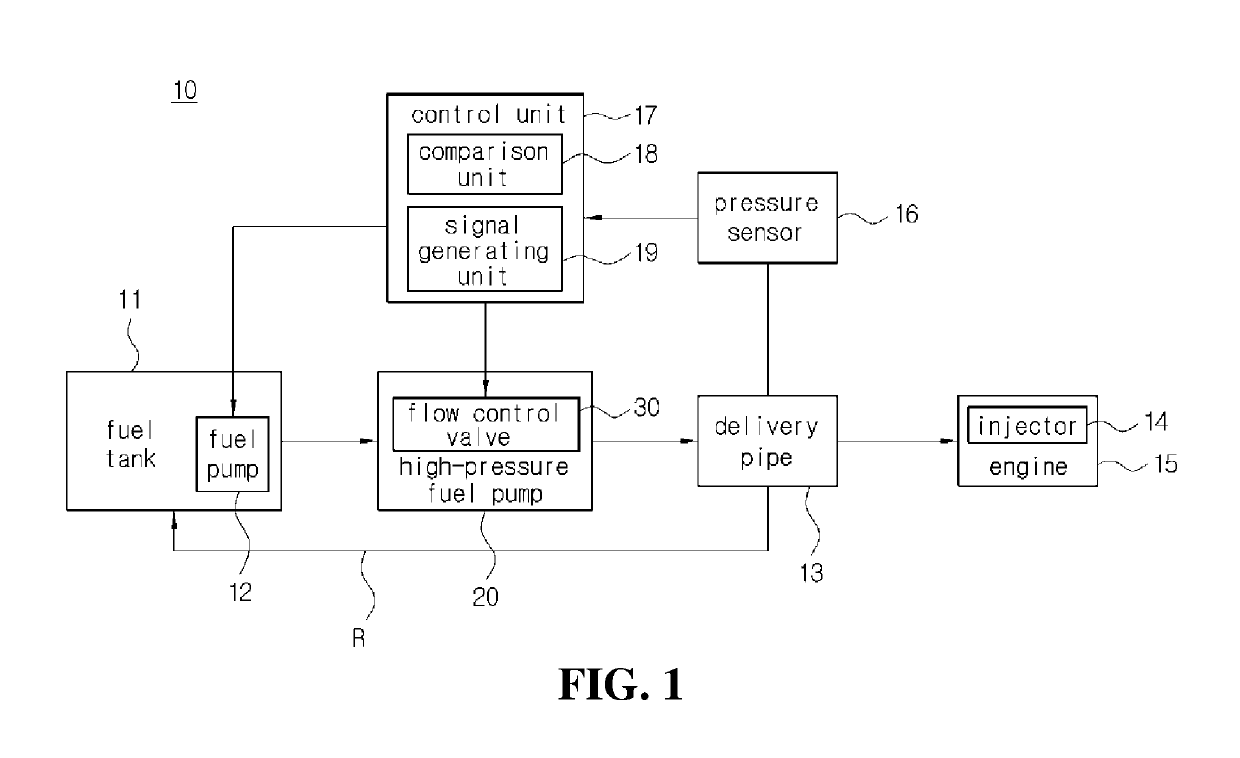

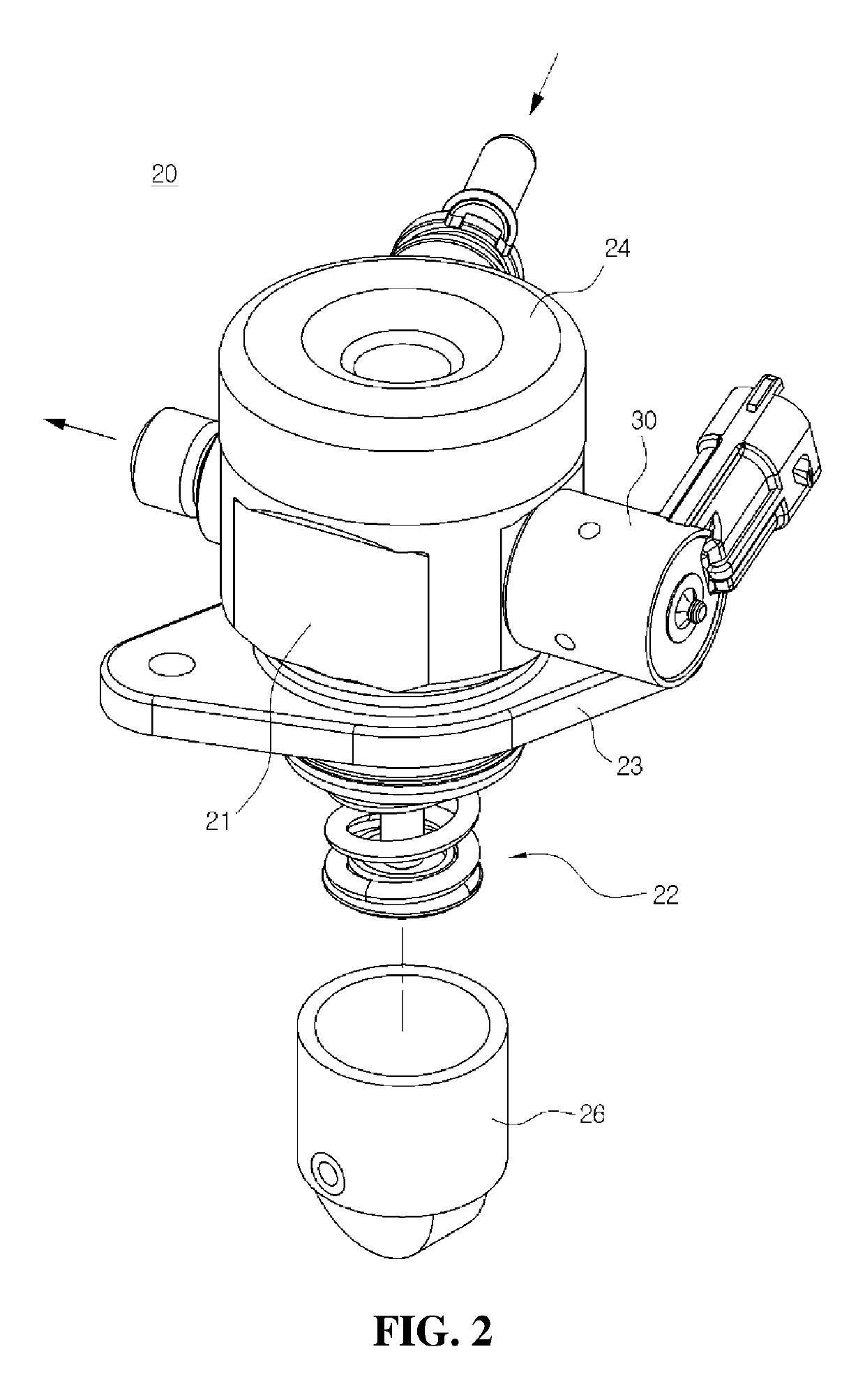

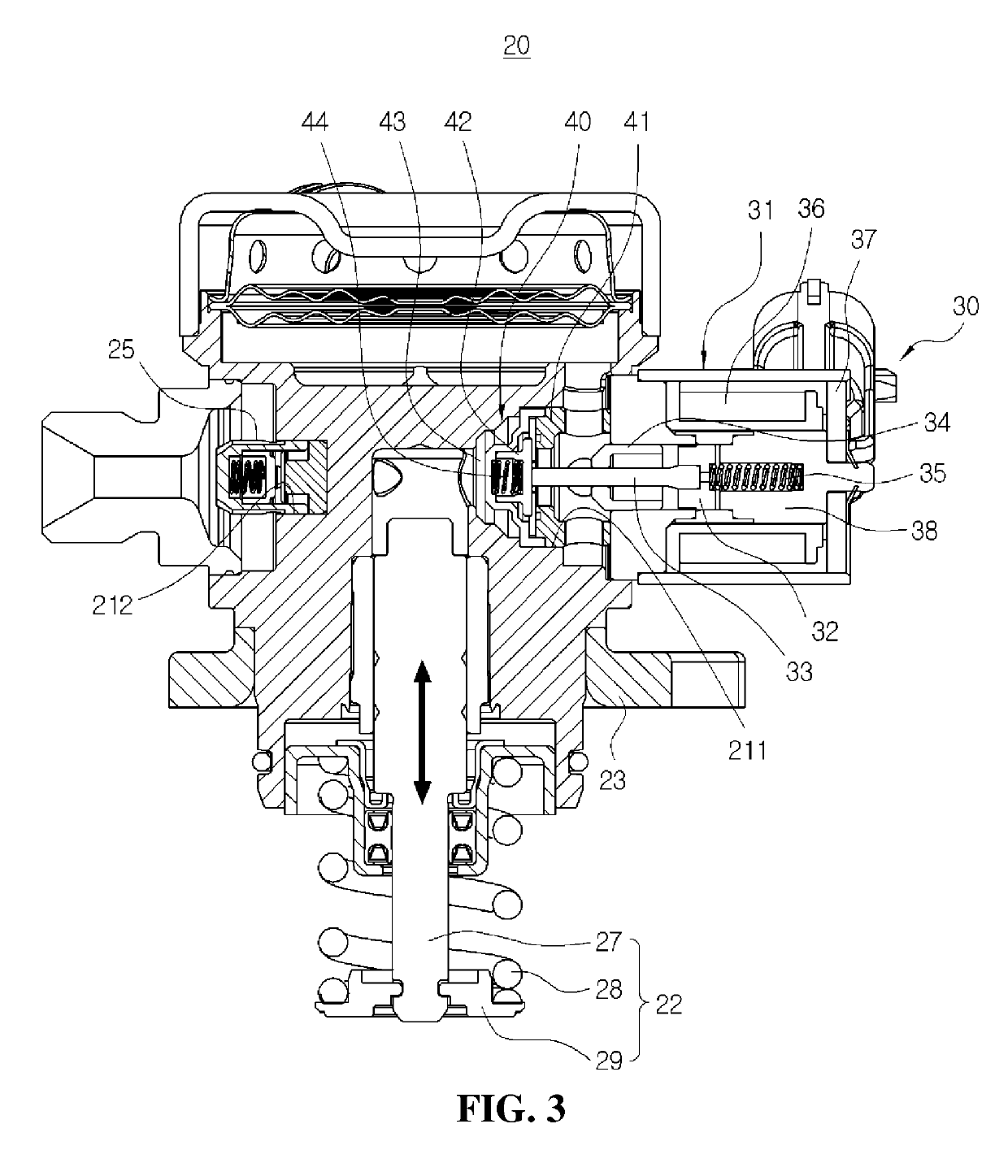

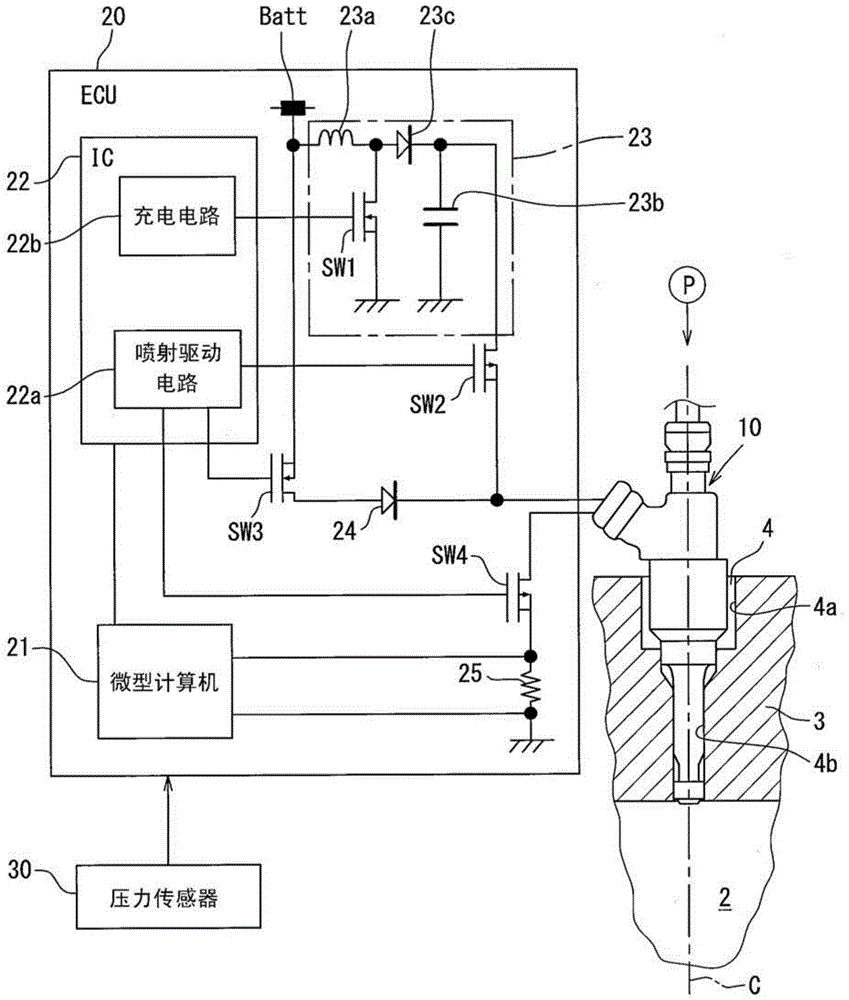

Apparatus and method for controlling flow control valve for high pressure fuel pump

ActiveUS20170292468A1Operation speed decreaseReduce noiseElectrical controlEngine testingControl flowElectricity

An apparatus and a method for controlling a flow control valve for a high-pressure fuel pump include: a pressure sensor for fuel in a delivery pipe; a control unit for controlling an operation of a flow control valve by controlling a current applied to a coil; a power switching unit for supplying or blocking driving power supplied to the flow control valve based on a control signal of the control unit; and a current adjustment unit electrically connected / disconnected with the flow control valve by the power switching unit to reduce a current supplied to the flow control valve when the current adjustment unit is connected with the flow control valve. Therefore, a noise and a vibration by collision between the plunger and the core upon closing the flow control valve may be attenuated by adjusting a current amount applied to the coil.

Owner:MOTONIC

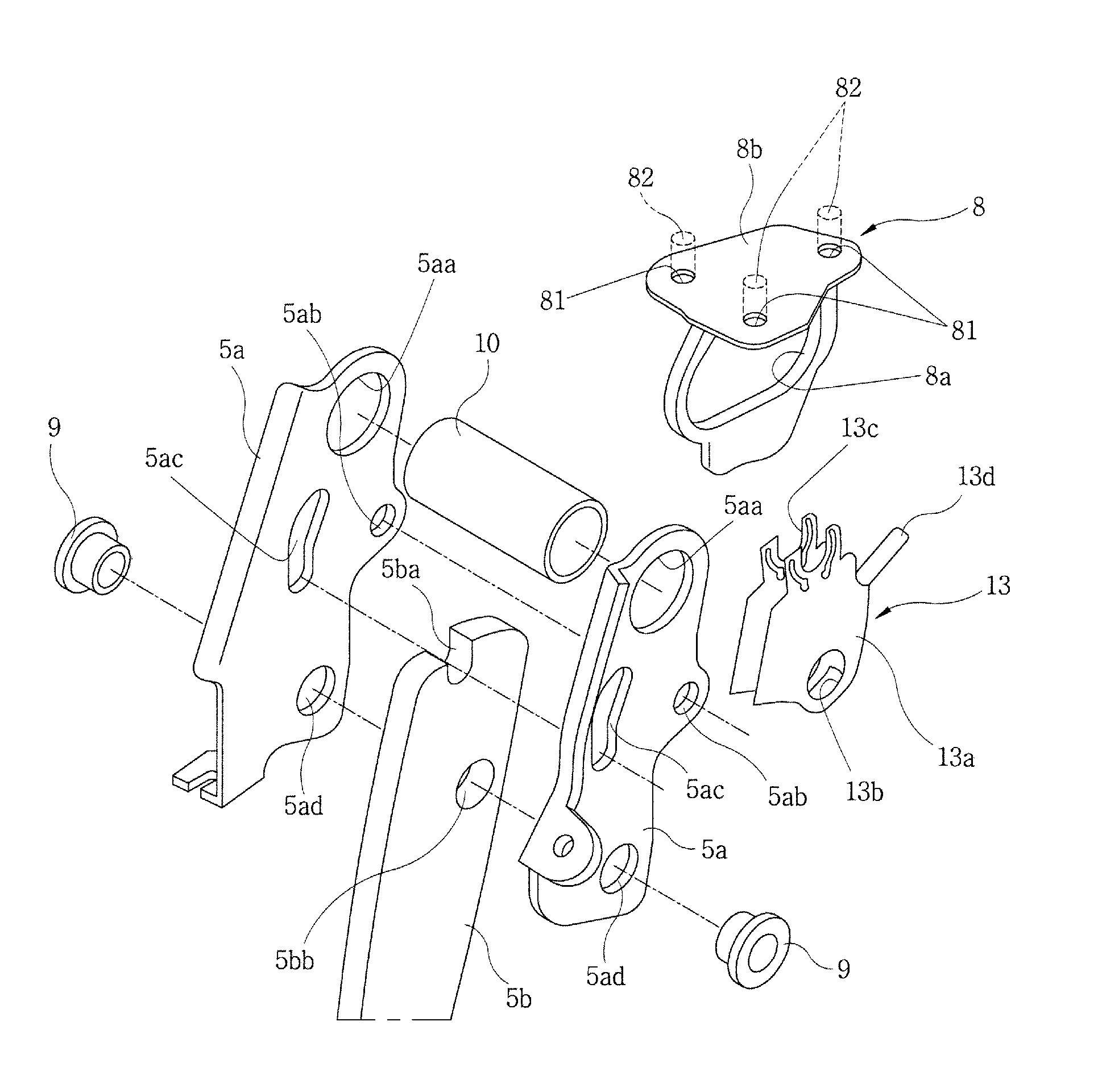

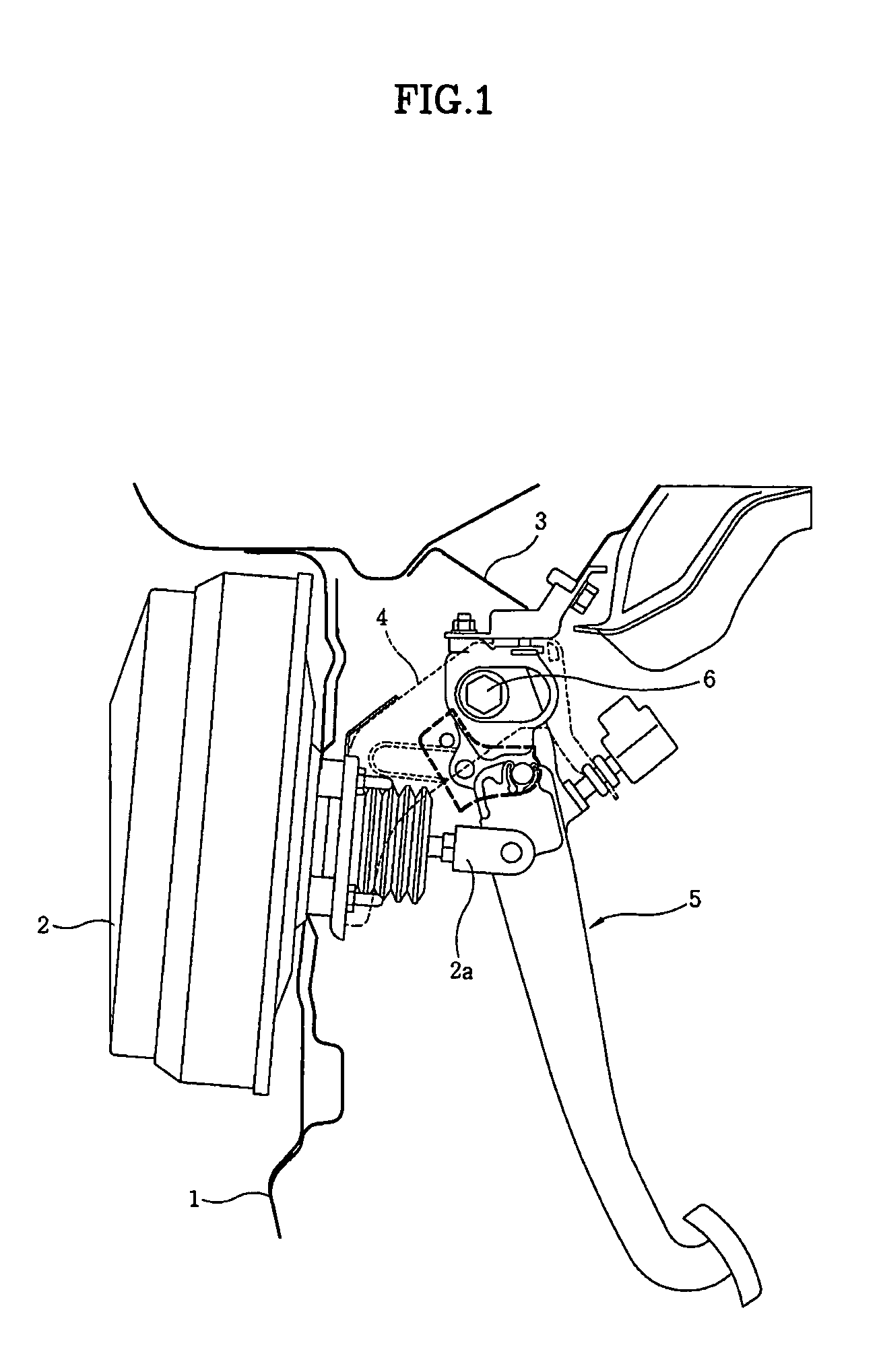

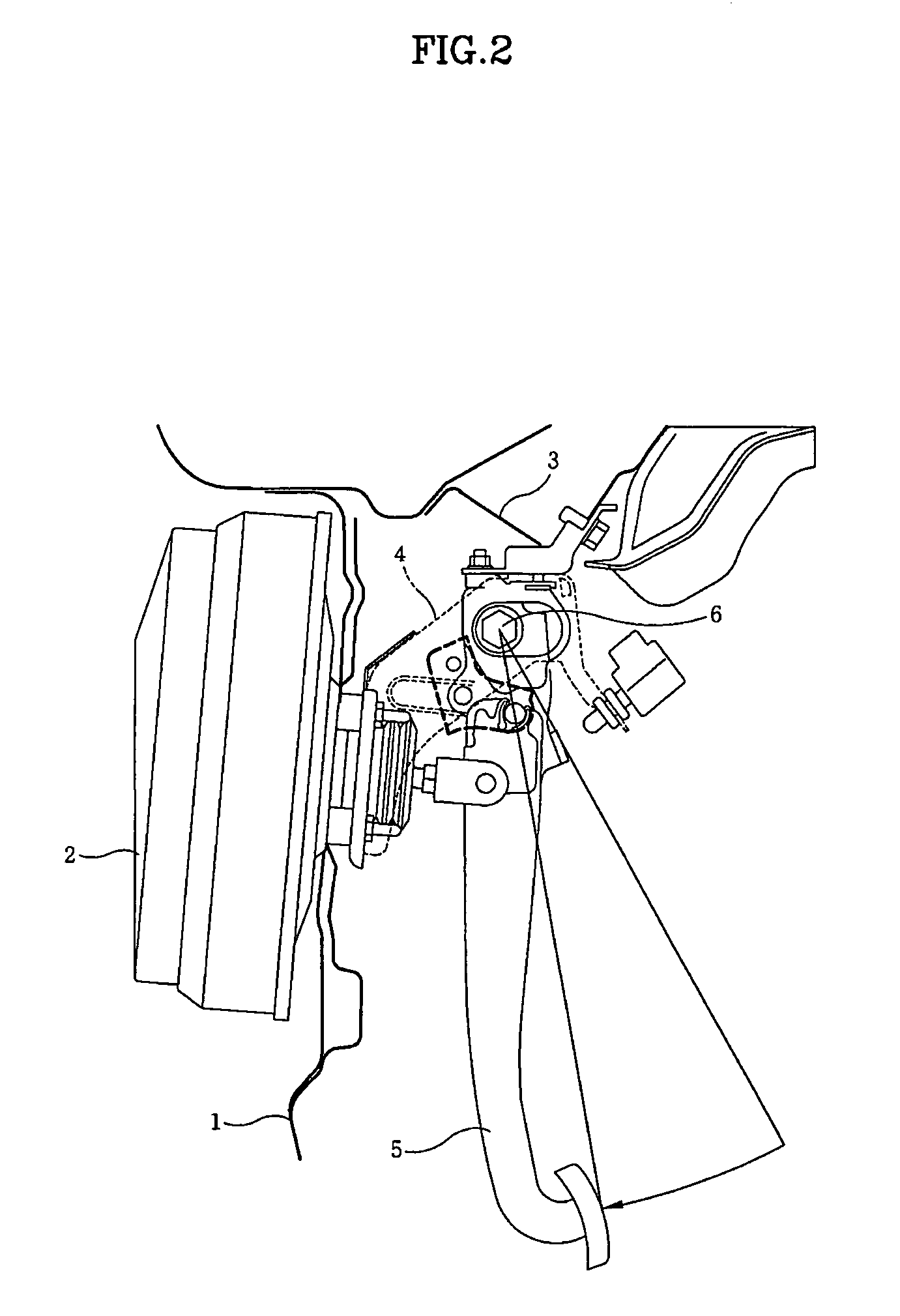

Shock absorbing device for brake pedals

ActiveUS7665387B2Reduce collision speedMinimize injuryControlling membersMechanical apparatusEngineeringFootplate

Owner:HYUNDAI MOTOR CO LTD

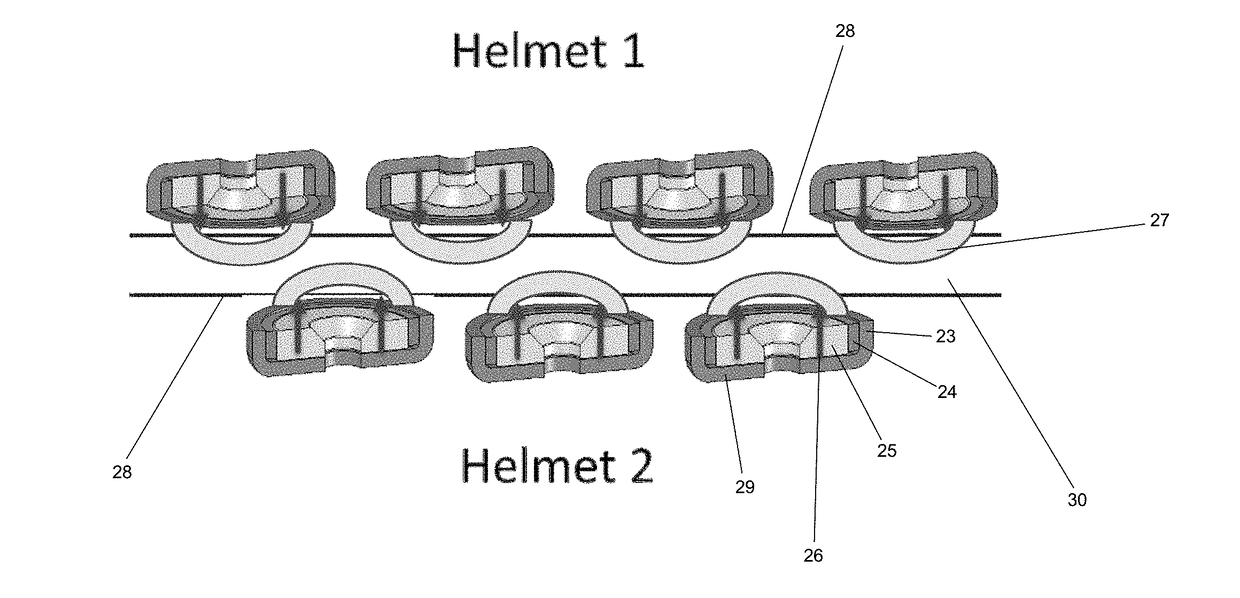

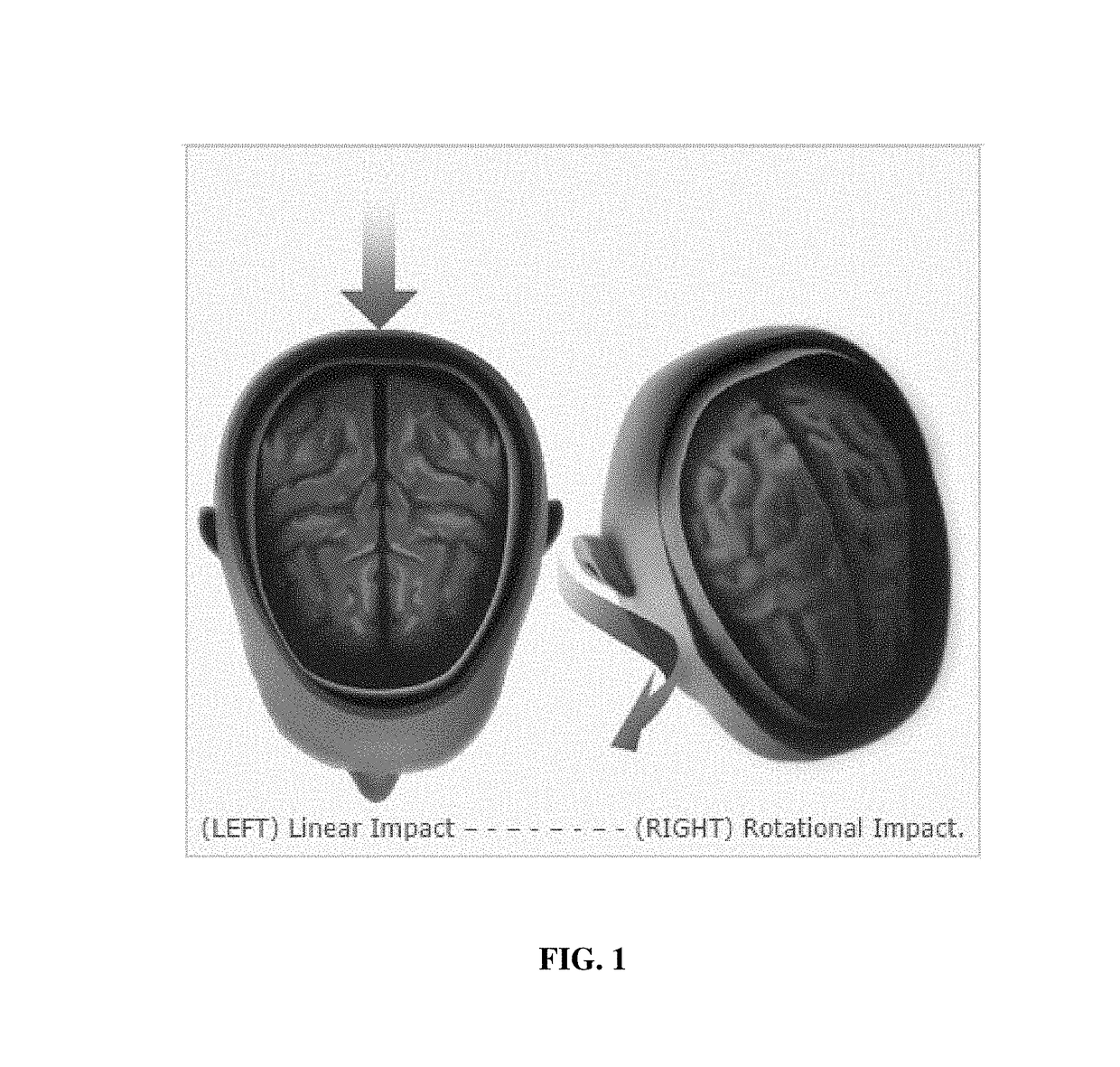

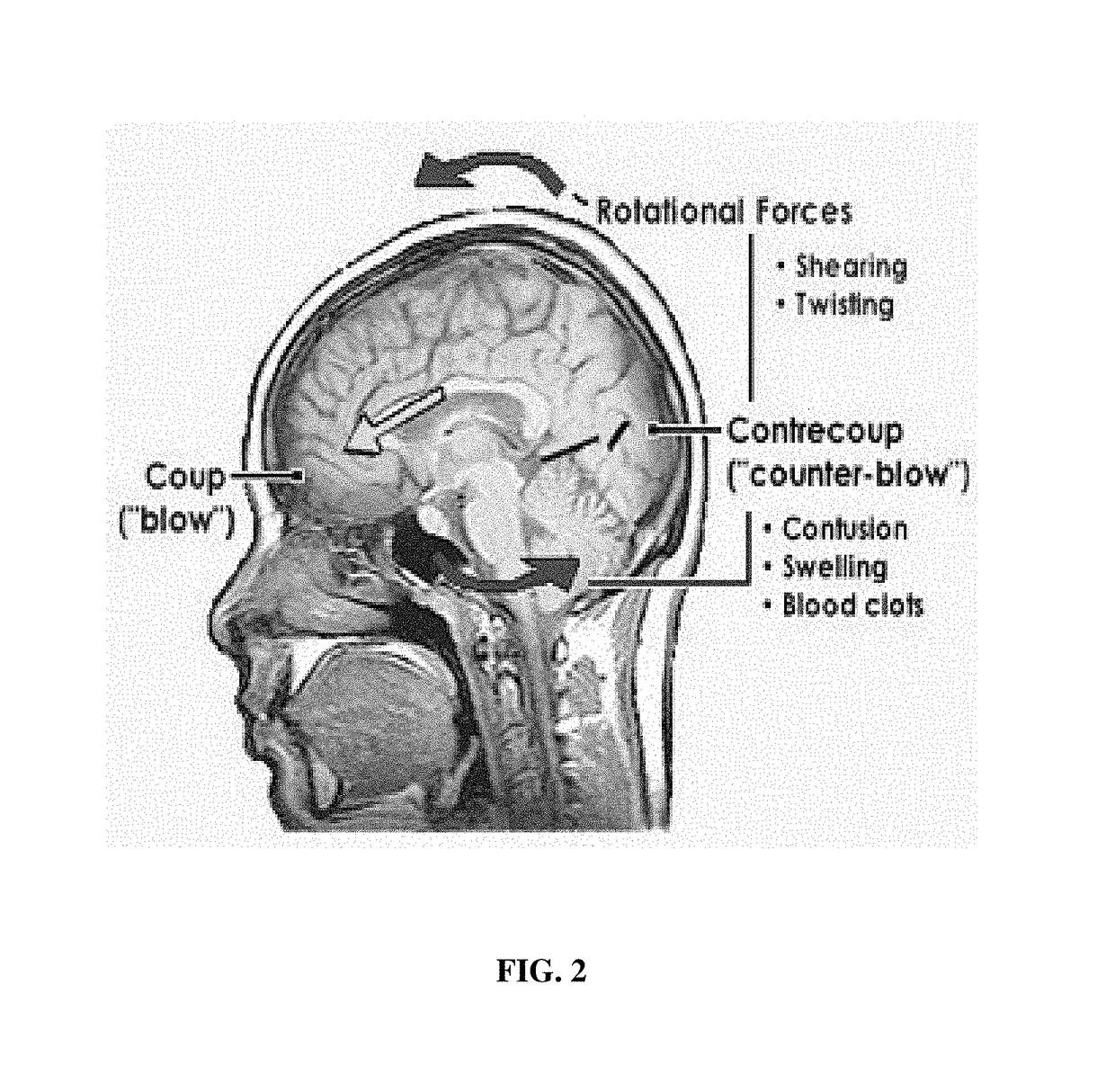

Magnetic football helmet to reduce concussion injuries

Helmets which harness magnetic forces to reduce the force of impact collisions to helmets during contact sports, thus reducing the likelihood that athletes sustain a physical injury such as a traumatic brain injury and / or a neck injury, are described. The helmets incorporate strong magnets into the shell such that a repulsive magnetic force is generated between opposing helmets, thus reducing impact forces. Each helmet includes a protective shell and at least one magnet which is arranged or configured to provide for a spatially modulated magnetic array.

Owner:VIRGINIA COMMONWEALTH UNIV

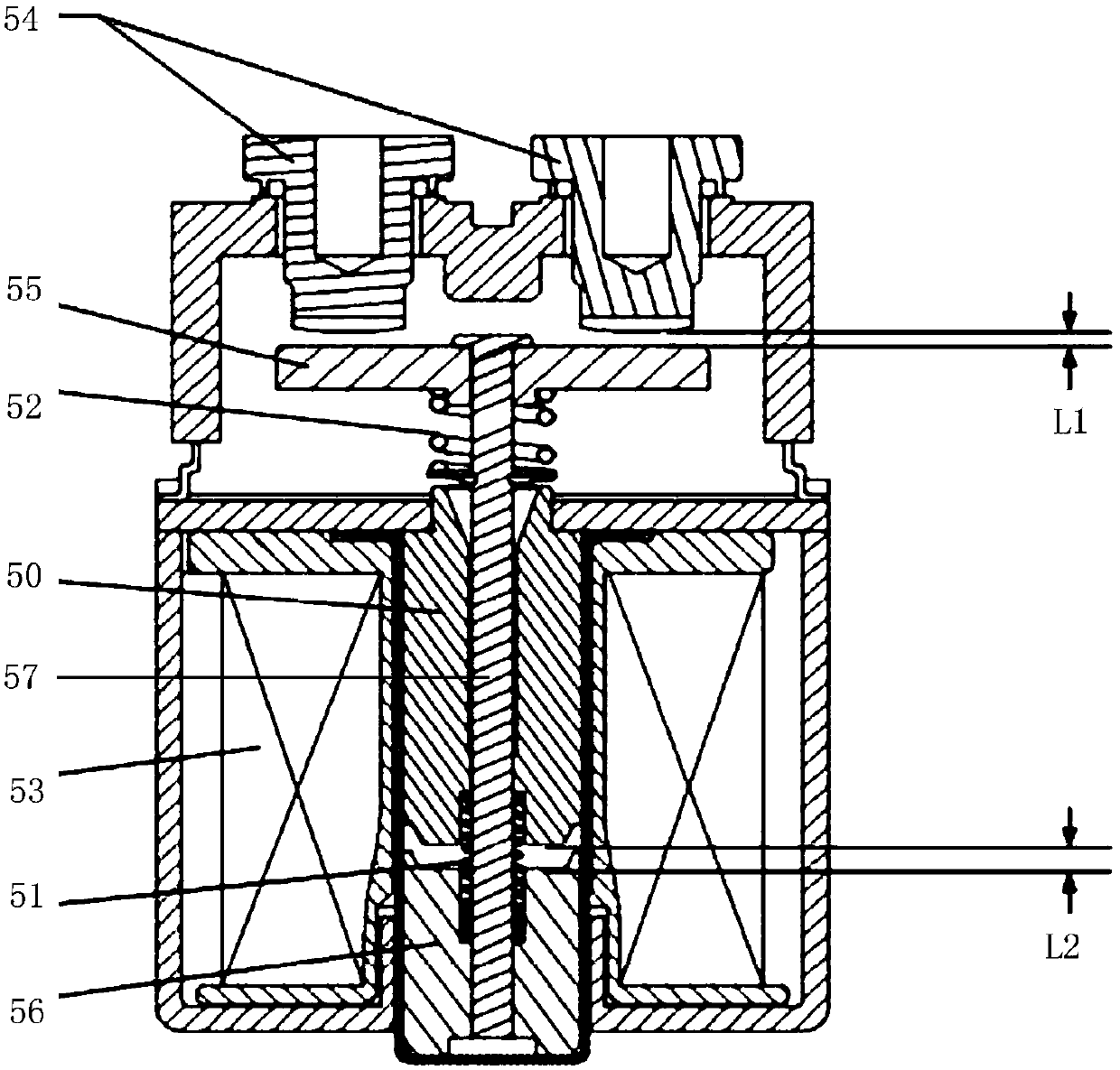

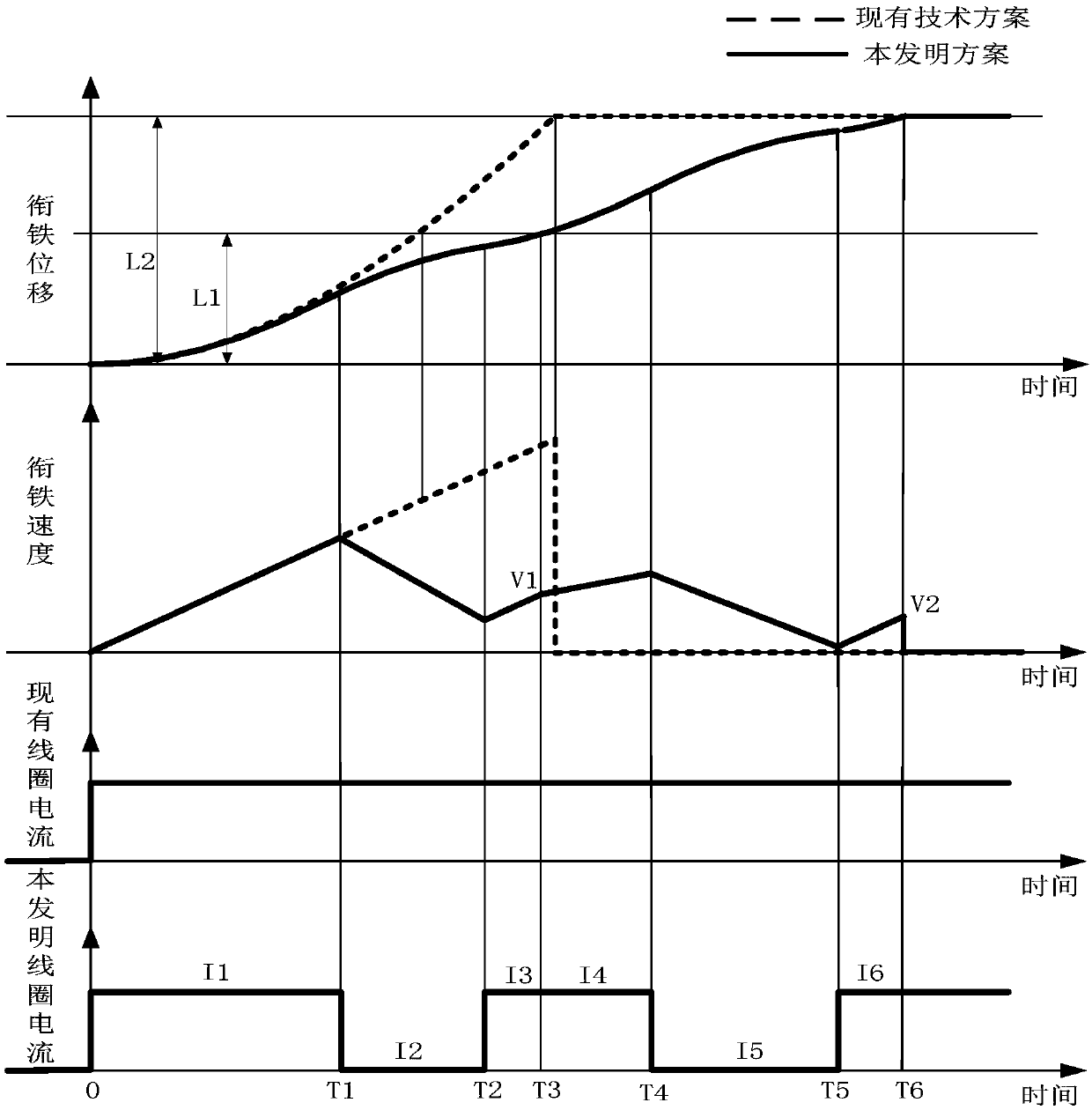

Method and device for suppressing noise of electromagnetic relay and computer-readable storage medium

ActiveCN110299264ASuppress noiseReduce sizeElectromagnetic relay detailsPower flowElectrical current

The invention discloses a method and device for suppressing the noise of an electromagnetic relay and a computer-readable storage medium. The method comprises a step of energizing a coil of an electromagnetic relay to control the movement of an armature of the electromagnetic relay such that a movable contact and a static contact of the electromagnetic relay gradually approach when the electromagnetic relay needs to be closed, and a step of starting to reduce the current such that the movement speed of the armature is lower than a preset first speed value when the movable contact and the static contact are in contact when the time reaches a preset first time T1. According to the invention, the generation of noise of the electromagnetic relay during the closing process can be effectively suppressed by controlling the working current of the electromagnetic relay in the closing process.

Owner:GAC AION NEW ENERGY AUTOMOBILE CO LTD

Cam mechanism having forced-valve-opening/closing cams and cam-profile setting method

InactiveUS20080110425A1Reduce collision speedMinimize unwanted sound noiseValve drivesMetal-working apparatusValve openingCam

No-load valve lift correction curves of opening and closing cams are set by offsetting no-load curve sections of basic valve lift curves of the cams in such directions as to increase a clearance between the curves, and they are connected with remaining sections of the curves to provide normal valve lift curves of the cams. Cam profiles of the cams are set on the basis of such normal valve lift curves. The cam profiles are set so that an ultimate speed difference between jumping and landing speeds of a follower on an ultimate valve speed curve determined from ultimate valve lift curves, having first and second shift sections where the follower shifts from the opening cam to the closing cam and from the closing cam to the opening cam, is smaller than a basic speed difference between jumping and landing speeds on a basic valve speed curve.

Owner:HONDA MOTOR CO LTD

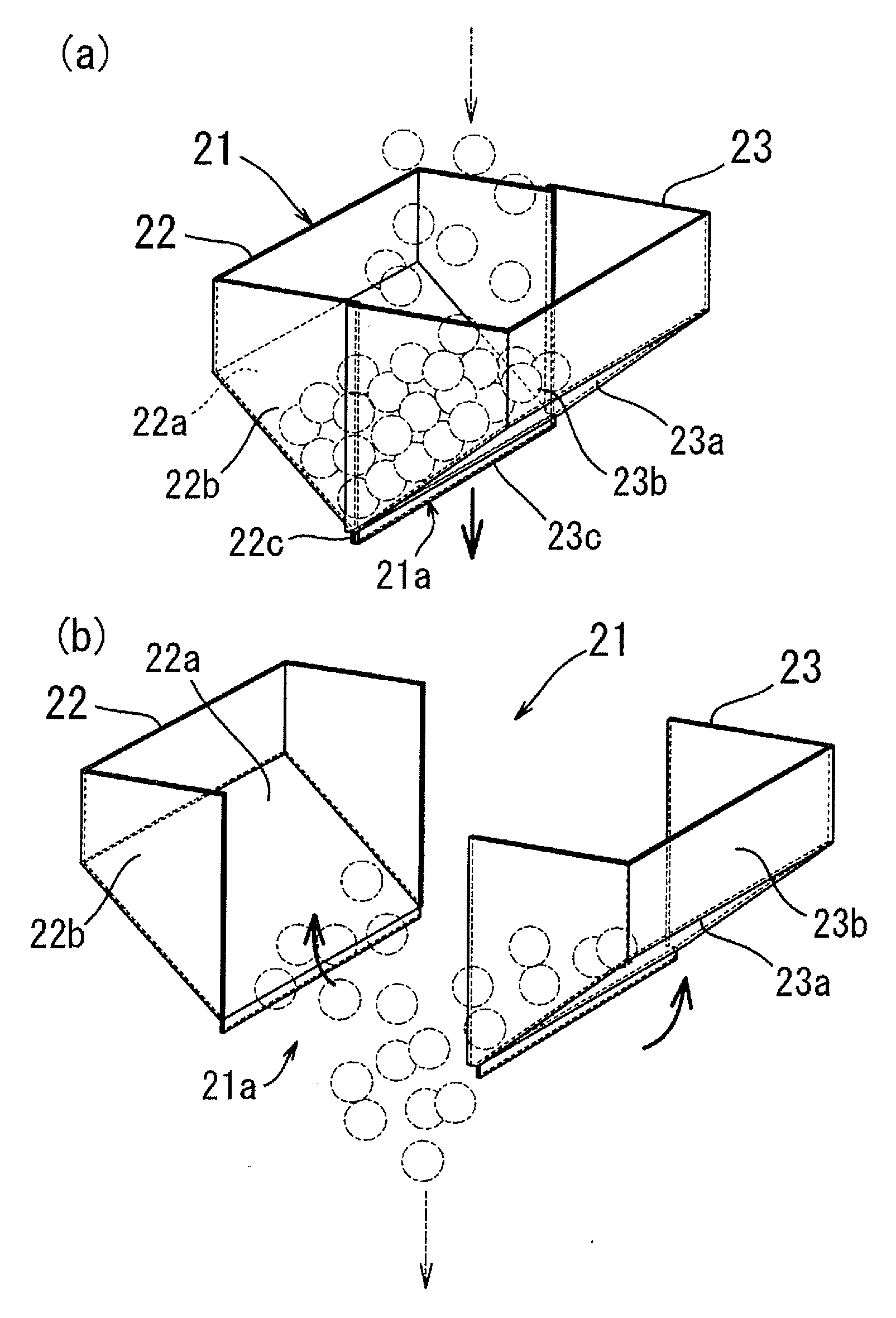

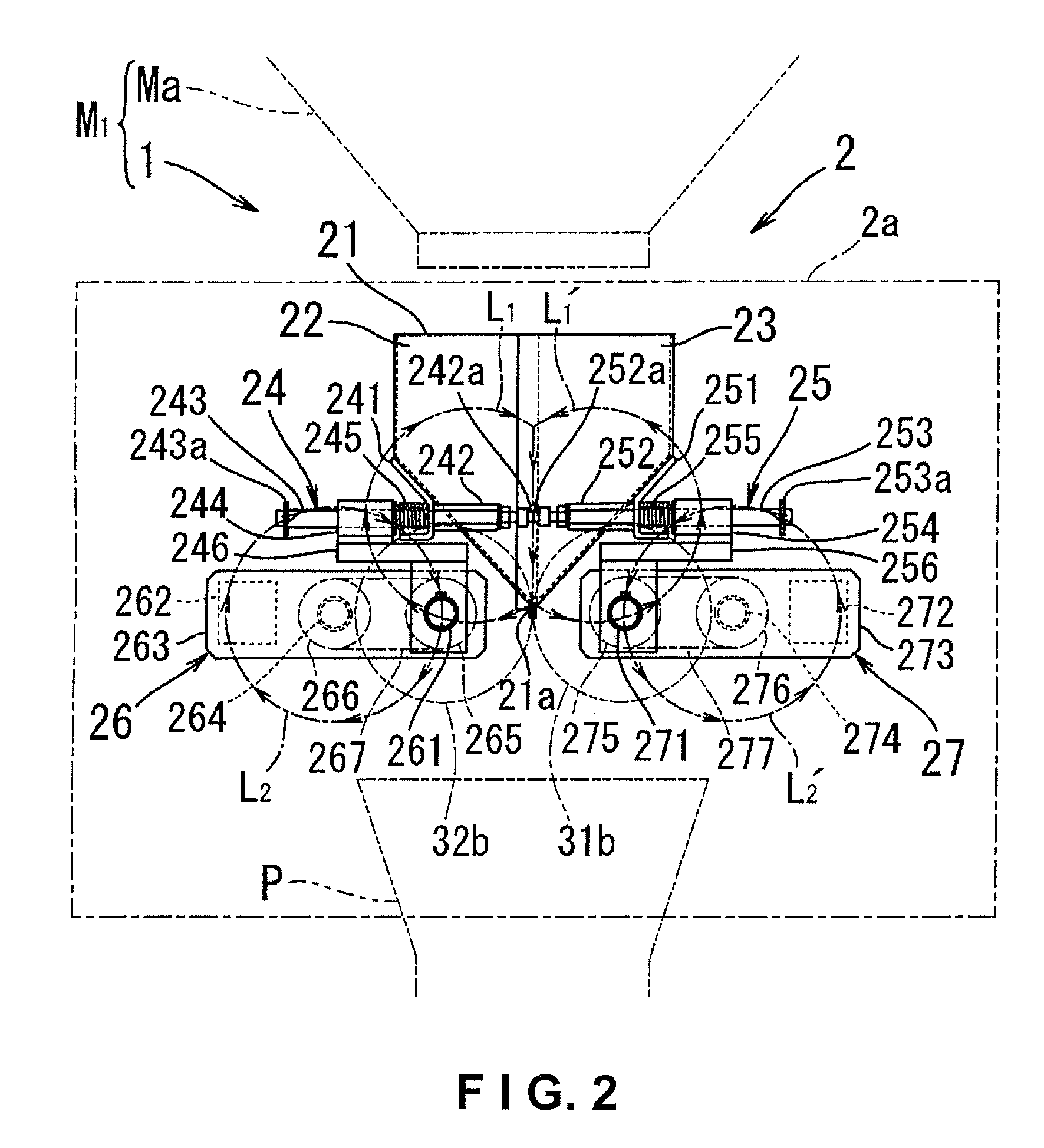

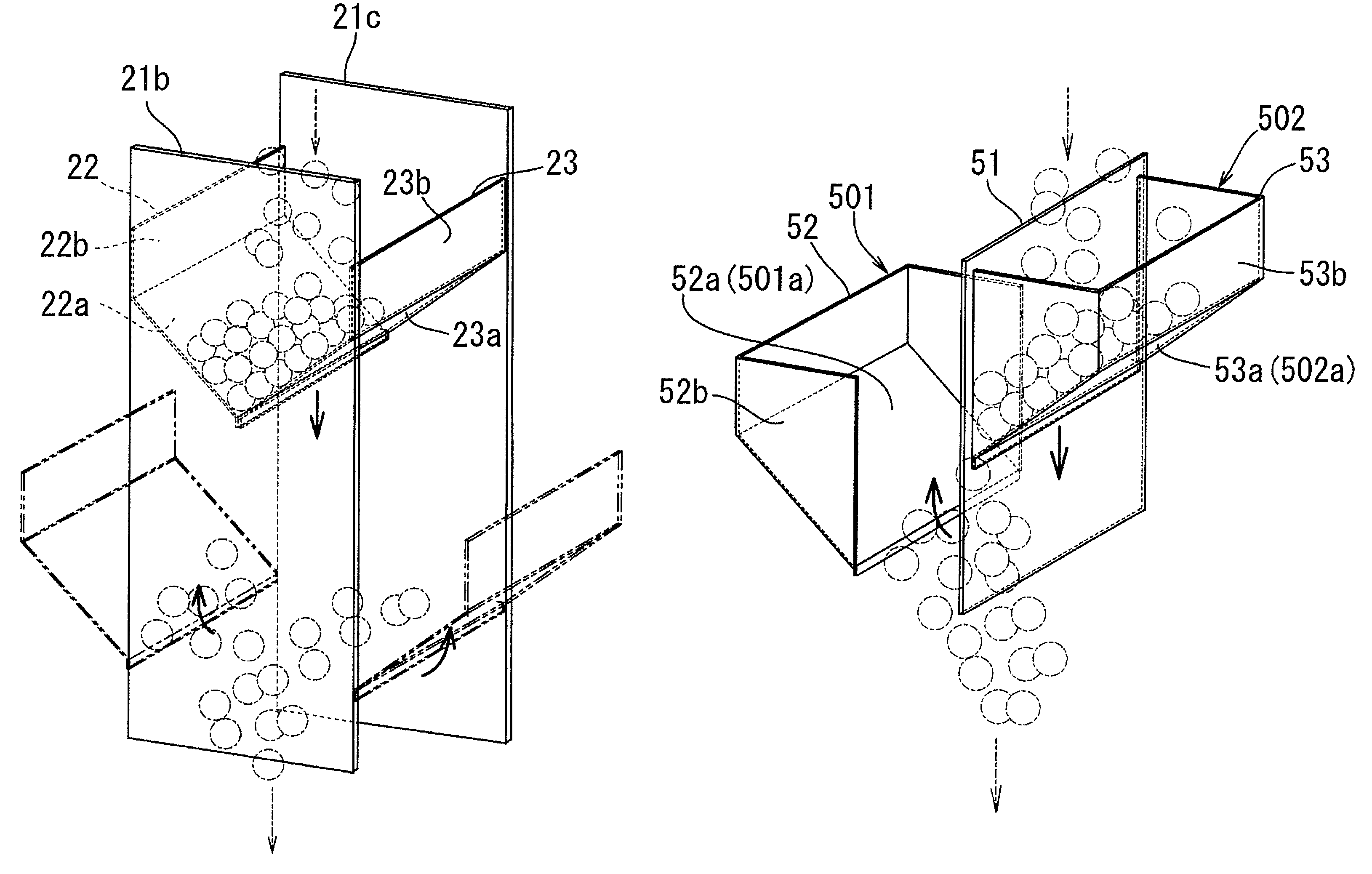

Article transfer device, and packaging device and weighing device equipped therewith

InactiveUS20100223886A1Small physical burdenHigh speedConveyorsSolid materialEngineeringMechanical engineering

Owner:ISHIDA CO LTD

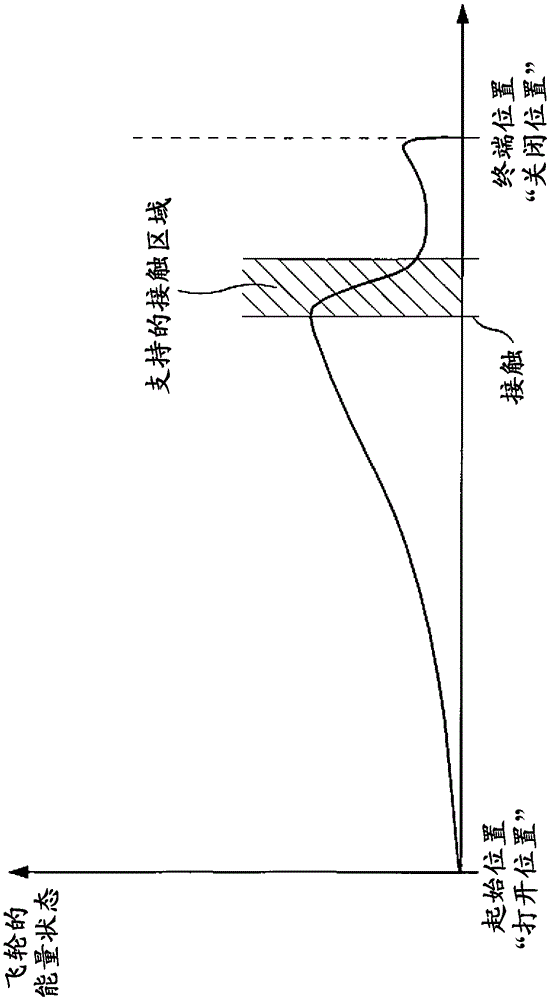

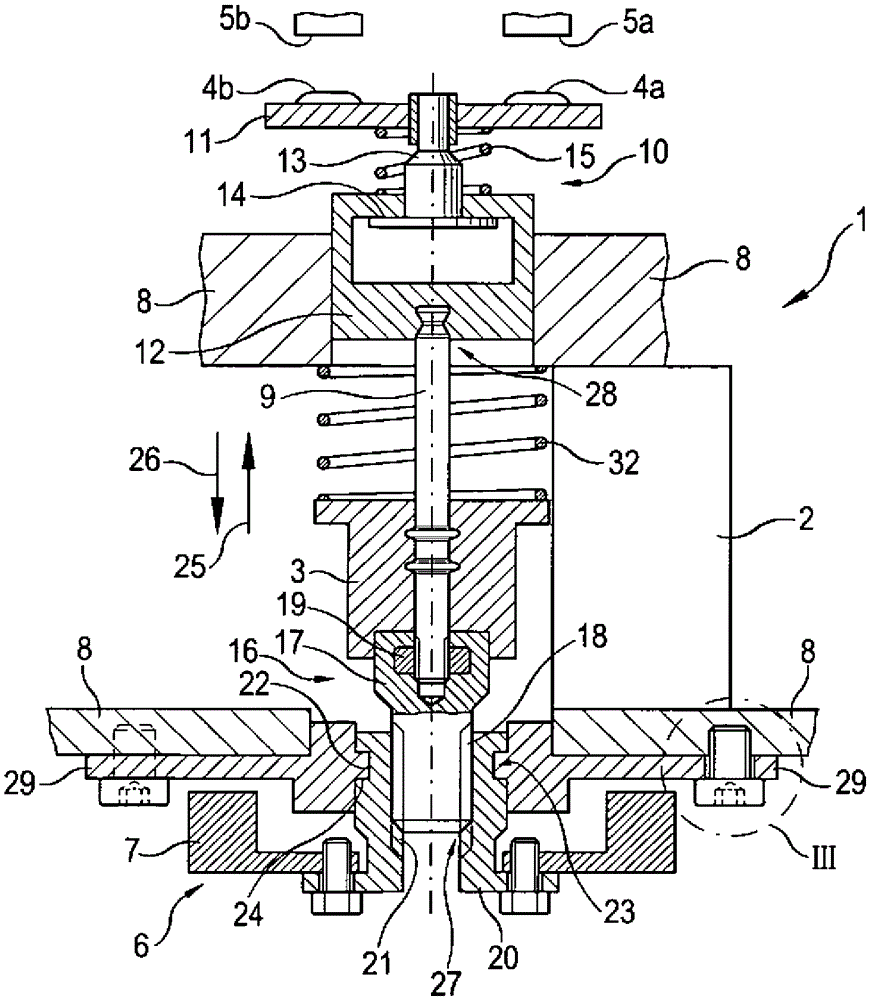

Electrical contactor with flywheel drive and method for switching an electrical contactor on and off

InactiveCN103890889AReduce collision speedReduced risk of wear and tearContact driving mechanismsSwitch power arrangementsContactorFlywheel

The invention relates to an electrical contactor 1, particularly for use in railways, having a stator 2 and an armature 3, said armature 3 being connected to a contact region 4a, 4b and being movable from a first to a second position during a switch-on and / or a switch-off process of the contactor, wherein the contact region 4a, 4b is connected in at least one of said positions to a counter-contact region 5a, 5b for closing an electrical circuit, wherein a pushing device 6 is connected to the armature, which pushing device can be rotated relative to the armature 3, wherein the pushing device 6 pushes the armature 3, during the movement from the first to the second position of the switch-on and / or switch-off process at least at times in a supporting manner. The invention also relates to a method for switching on and / or off an electrical contactor 1, comprising the following steps: moving an armature 3 by activating and / or deactivating a stator; accelerating a rotation of a pushing device 6, said pushing device 6 being connected to the armature 3; and transferring at least a portion of the kinetic movement energy of the pushing device 3 to the armature 3, in a phase of the switch-on and / or switch-off process, in which a contact region 4a, 4b connected to the armature 3 comes into contact with and out of contact with a counter contact region 5a, 5b to support the armature movement.

Owner:SCHALTBAU GMBH

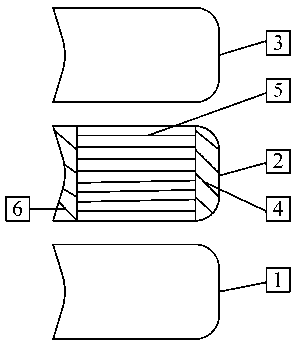

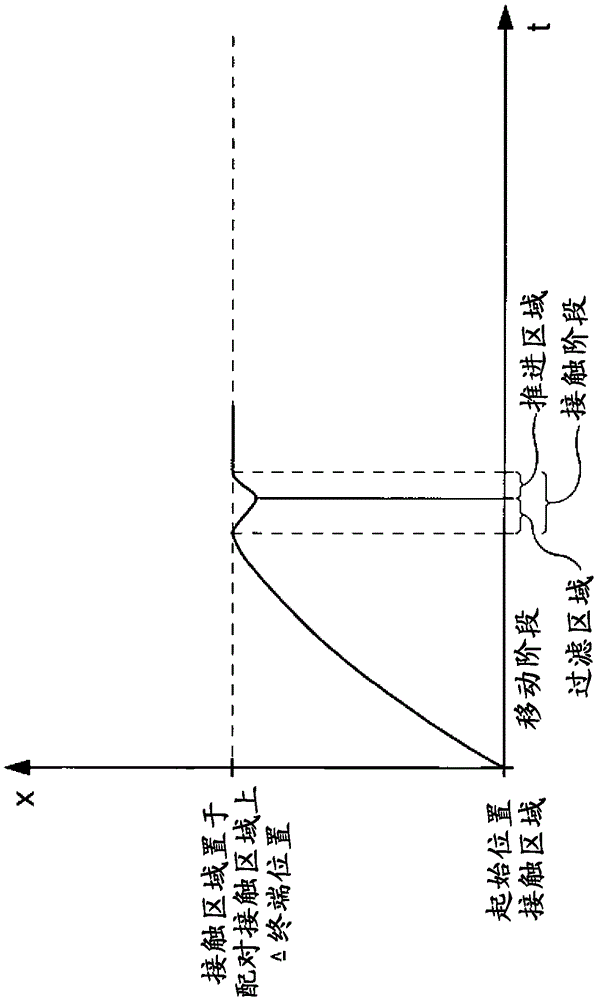

Method for picking semiconductor chips from a foil

InactiveCN1505122AReduce collision speedReduce shockSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor chipEngineering

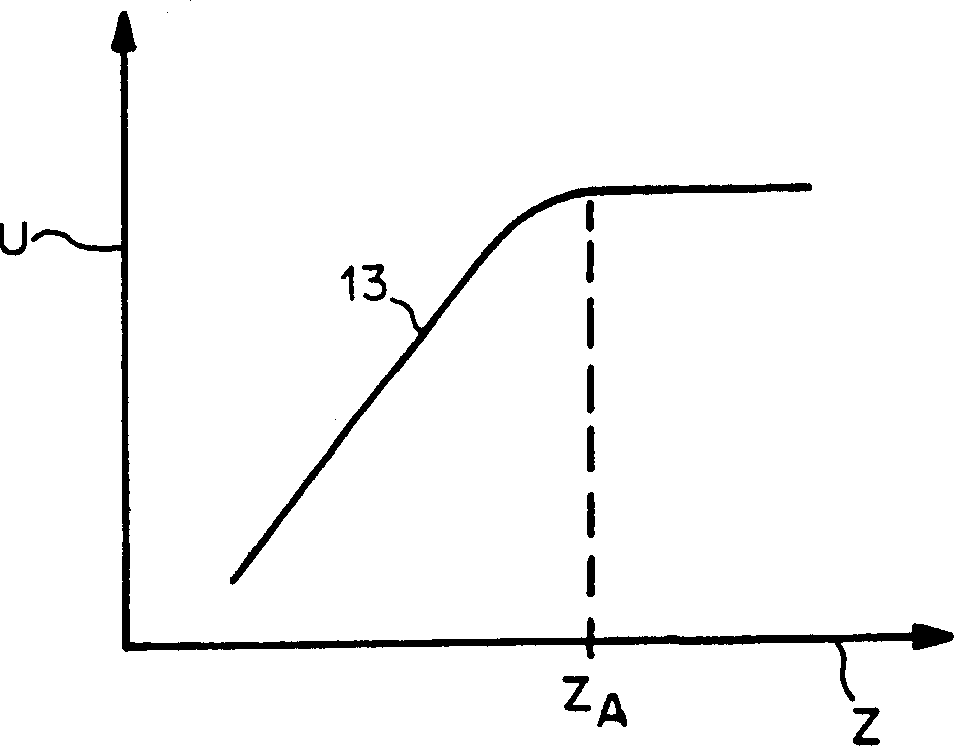

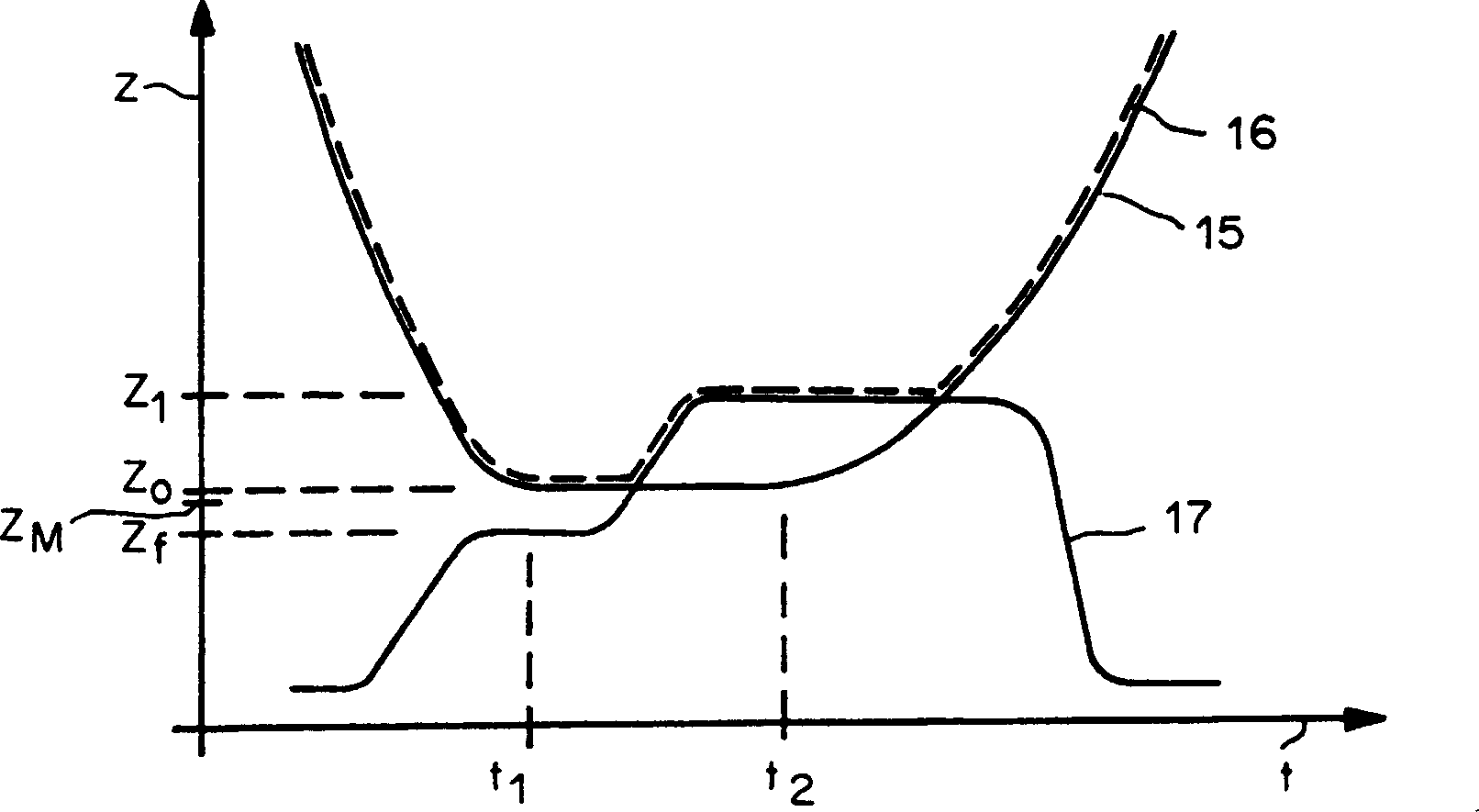

The picking of a semiconductor chip from a foil takes place by means of a chip gripper which bears on a bondhead and can be deflected in a predetermined direction and with the aid of a needle. An inductive sensor serves the precise measurement of the deflection of the chip gripper with reference to the bondhead. The pick process itself is characterised by the following steps: a) Lowering the chip gripper to a height z0, that is greater than an average height of the surface of the semiconductor chips so that the chip gripper does not yet touch the semiconductor chip, b) Raising the needle to a predetermined height z1, whereby the needle raises the semiconductor chip in order to bring the semiconductor chip into contact with the chip gripper and then to increase the height of the chip gripper, and c) Raising the chip gripper, whereby the semiconductor chip detaches itself from the needle.

Owner:ESEC TRADING

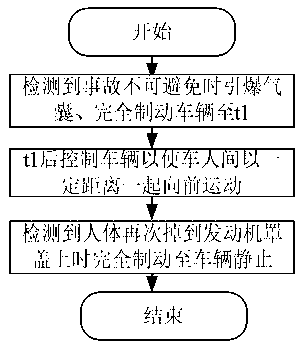

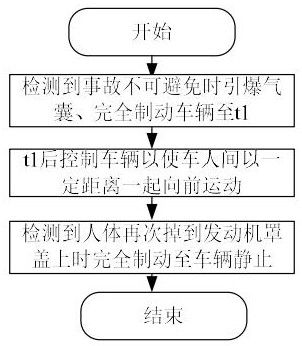

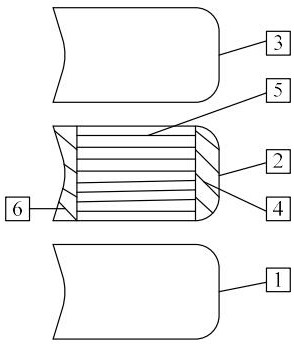

Engine cover for protecting pedestrians for intelligent automobile and working method of engine cover

ActiveCN109760621AReduce direct collision forceReduce collision speedPedestrian/occupant safety arrangementSuperstructure subunitsHuman bodyAirbag

Aiming at the fact that most of in existing research results, only human-vehicle collision damage is protected, the invention designs an engine cover for protecting human-vehicle and human-ground collision damage. The engine cover consists of a supporting layer, an air bag layer and a protective layer, wherein the air bag layer comprises three hedgehog-shaped air bags. When an accident is detectedto be unavoidable, the air bag layer is detonated and completely brakes until the head of a human body collides with a vehicle body for the first time, the speed of the vehicle is controlled to enable the rear edge of the engine cover to keep a certain distance from the chest of the human body and the engine cover and the human body move together, and when the human body collides with the enginecover again, the air bag layer completely brakes again until the human body is in a fixed state. The engine cover has the beneficial effects that by detonating the air bag layer, the hedgehog-shaped air bags cover a vehicle head so as to reduce human-vehicle direct collision force, and meanwhile, the ejection speed of a pedestrian is reduced by barb-shaped air columns; and the vehicle head catchesthe human body by moving the vehicle, and the falling speed of the human body is reduced by the air columns on the outer surfaces of the air bags to further consume potential energy and kinetic energy of the human body, so that human-ground collision speed is reduced, and human-vehicle collision protection and human-ground collision protection are realized simultaneously.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Article transfer device, and packaging device and weighing device equipped therewith

InactiveUS7861498B2Avoid cloggingIncrease speedConveyorsSolid materialEngineeringMechanical engineering

Owner:ISHIDA CO LTD

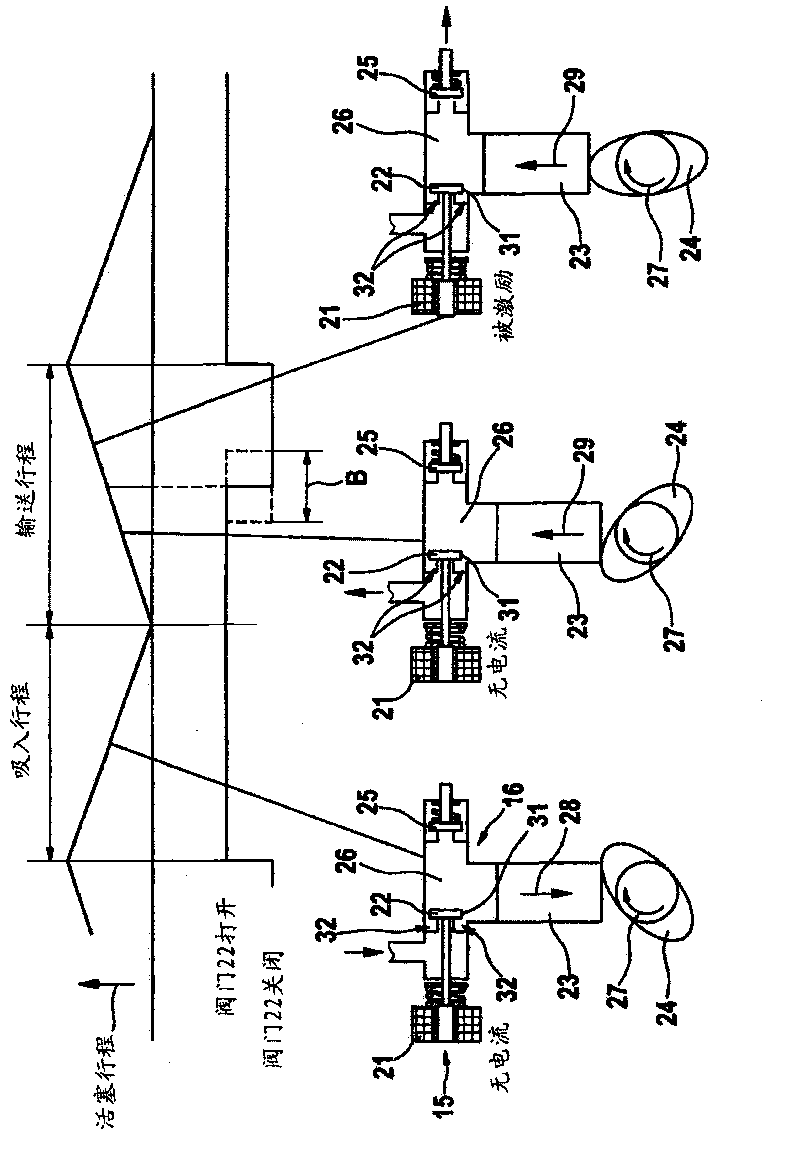

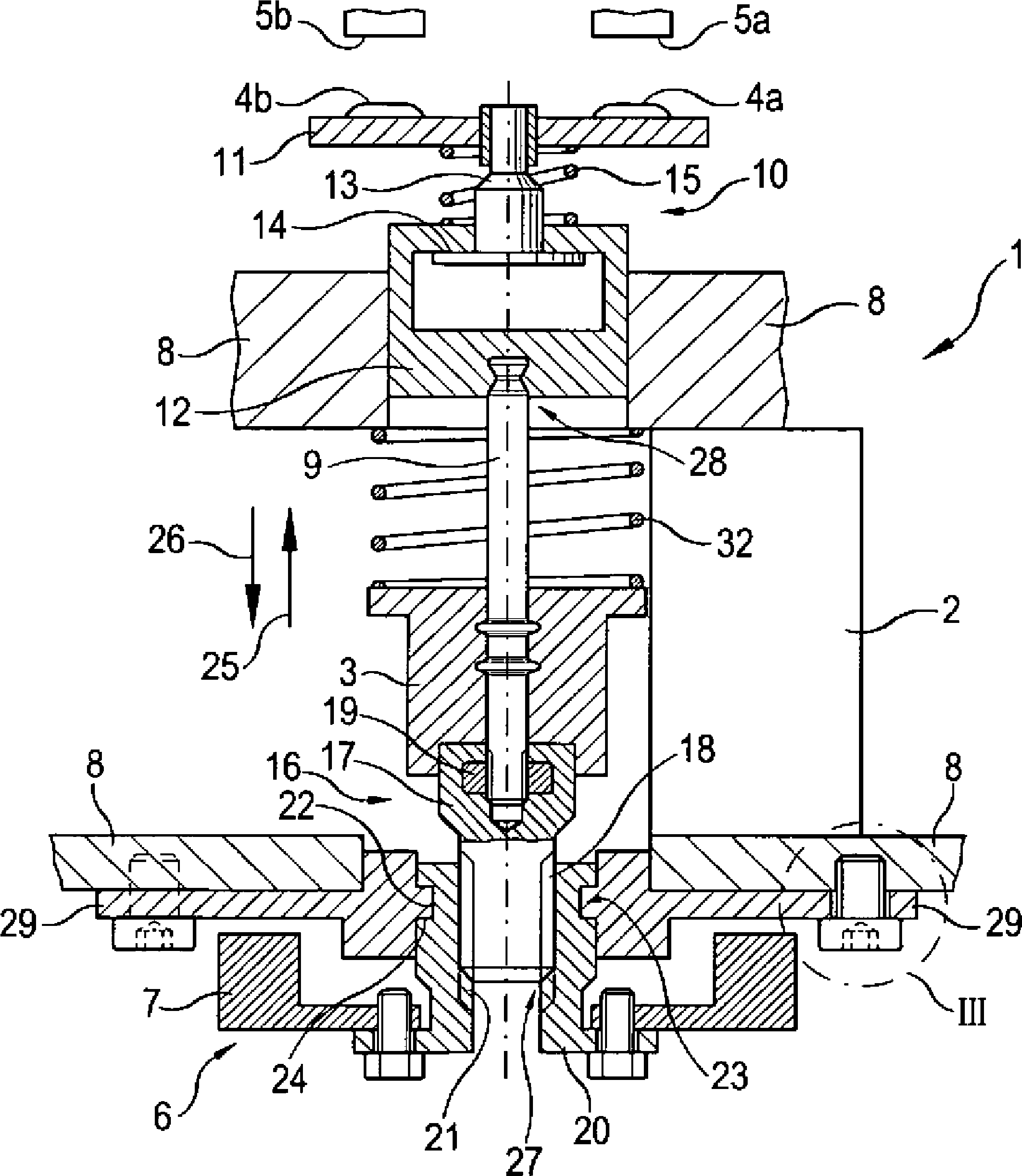

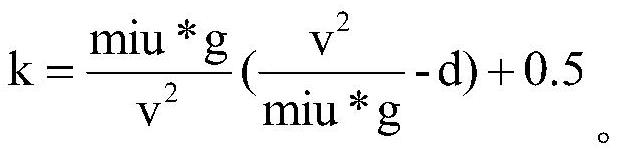

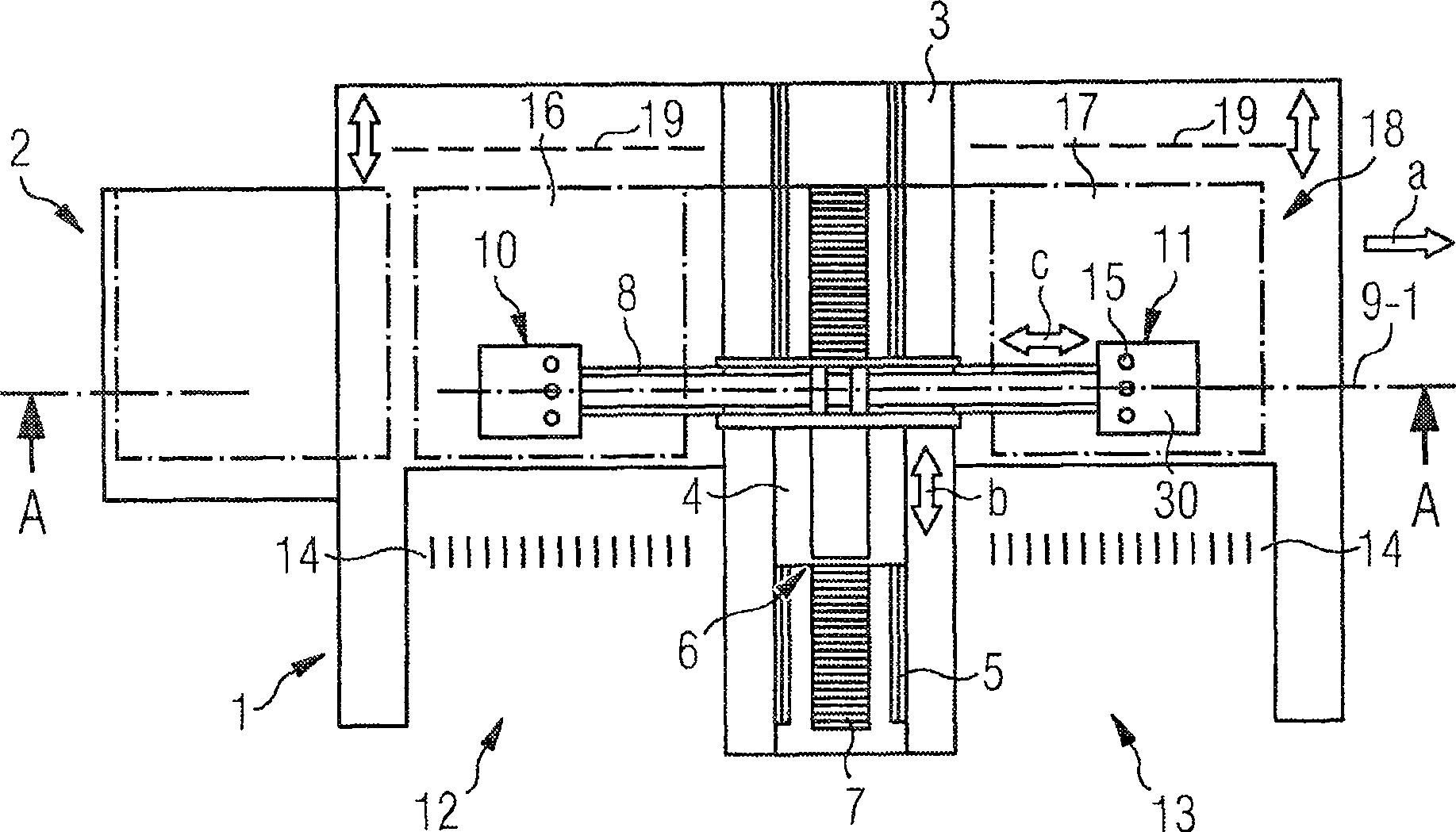

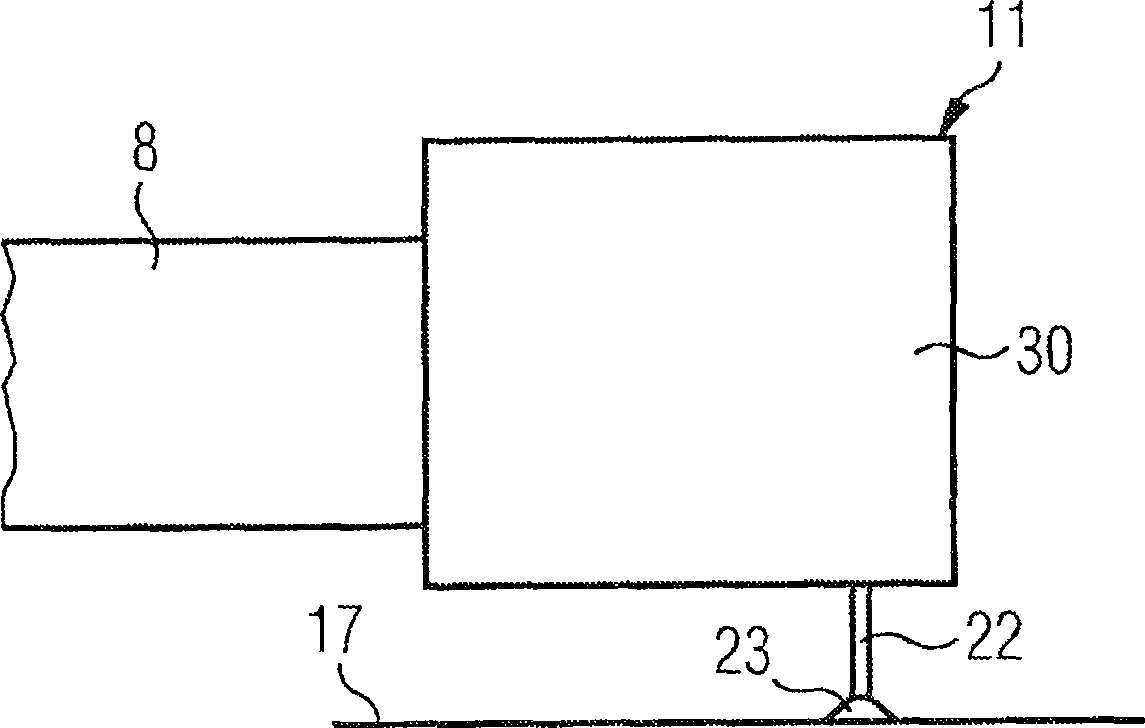

Loading system and method for loading substrates with electrical components

InactiveCN101019478ASupport structure is stableReduce the number of movesElectrical componentsEngineeringMechanical engineering

A loading system for loading substrates with electrical components comprises at least one transporting line (2), by means of which a first and a second substrate (16, 17) can be transported in a transporting direction, a basic carrier (3), a first carrier slide (4), which is mounted on the basic carrier (3) displaceably in a displacing direction, an elongated first carrier arm (8), the longitudinal axis (9-1) of which is oriented transversely in relation to the displacing direction and which is mounted on the first carrier slide (4) displaceably in the direction of its longitudinal axis (9-1), and a first loading head (10) and a second loading head (11), which are arranged at a fixed distance from each other on the first carrier arm (8) on opposite sides of the carrier slide in the direction of the longitudinal axis (9-1) of the first carrier arm (8).

Owner:ASM ASSEMBLY SYST GMBH & CO

Apparatus and method for controlling flow control valve for high pressure fuel pump

ActiveUS10316785B2Reduce vibration and noiseReduce collision speedElectrical controlEngine testingControl flowElectricity

An apparatus and a method for controlling a flow control valve for a high-pressure fuel pump include: a pressure sensor for fuel in a delivery pipe; a control unit for controlling an operation of a flow control valve by controlling a current applied to a coil; a power switching unit for supplying or blocking driving power supplied to the flow control valve based on a control signal of the control unit; and a current adjustment unit electrically connected / disconnected with the flow control valve by the power switching unit to reduce a current supplied to the flow control valve when the current adjustment unit is connected with the flow control valve. Therefore, a noise and a vibration by collision between the plunger and the core upon closing the flow control valve may be attenuated by adjusting a current amount applied to the coil.

Owner:MOTONIC

Electromagnetic valve device

InactiveCN100416143CReduce vibrationStop the spreadOperating means/releasing devices for valvesLift valveReciprocating motionEngineering

An electromagnetic valve device for reducing noise resulting from an internal collision of a movable core against a guide member has a fixed core, a cylindrical movable core, a valve member, for reciprocating in an axial direction of the movable core in a cooperative manner with the movable core to open and close fluid paths, coil sections for forming a magnetic field by electrical conduction thereof to attract the movable core to the fixed core so as to move the movable core in the axial direction, and a guide member having a guide wall for guiding the movable core in the axial direction from inside of the movable core in its radial direction. A space is formed inside the guide wall in its radial direction.

Owner:DENSO CORP

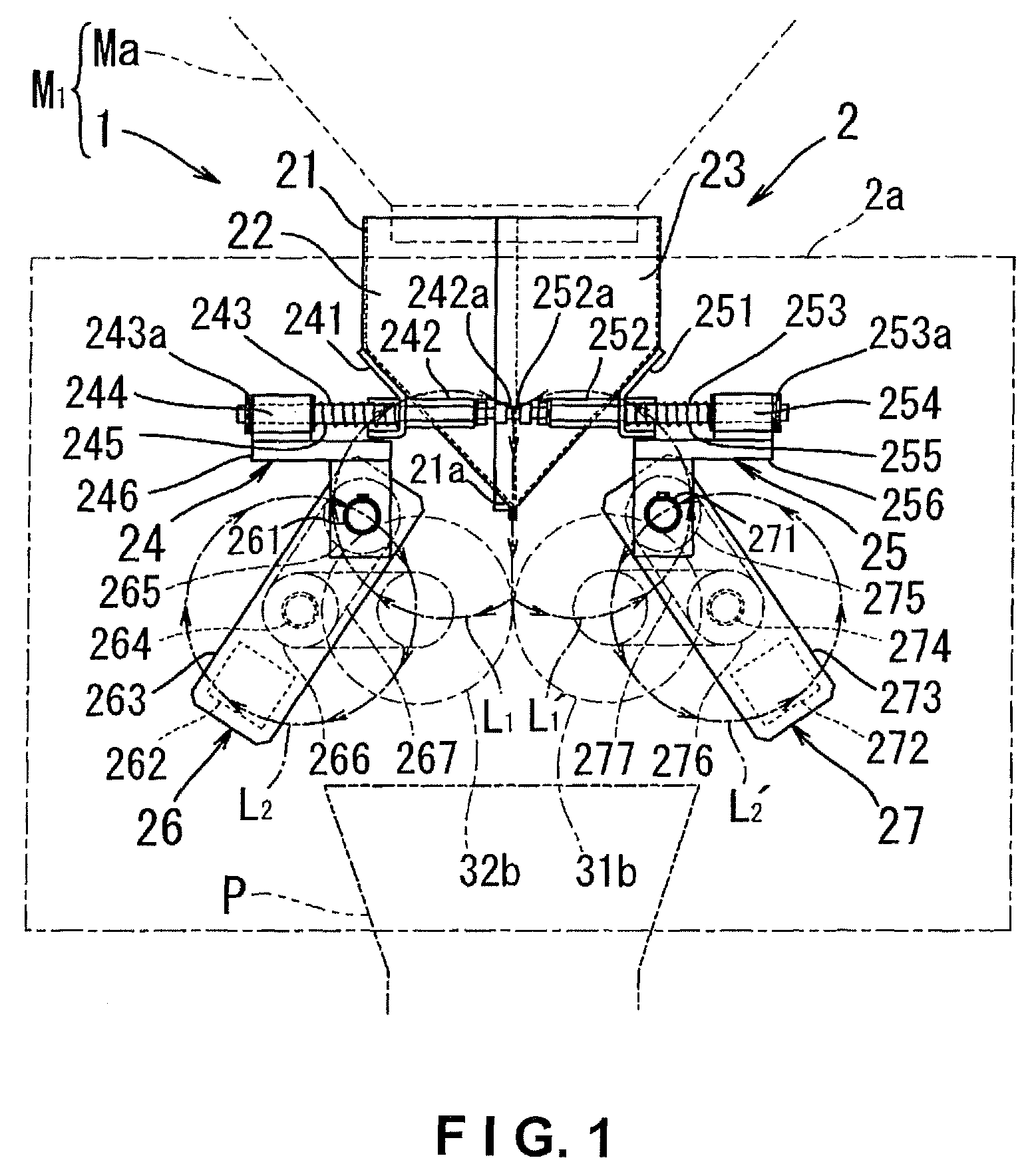

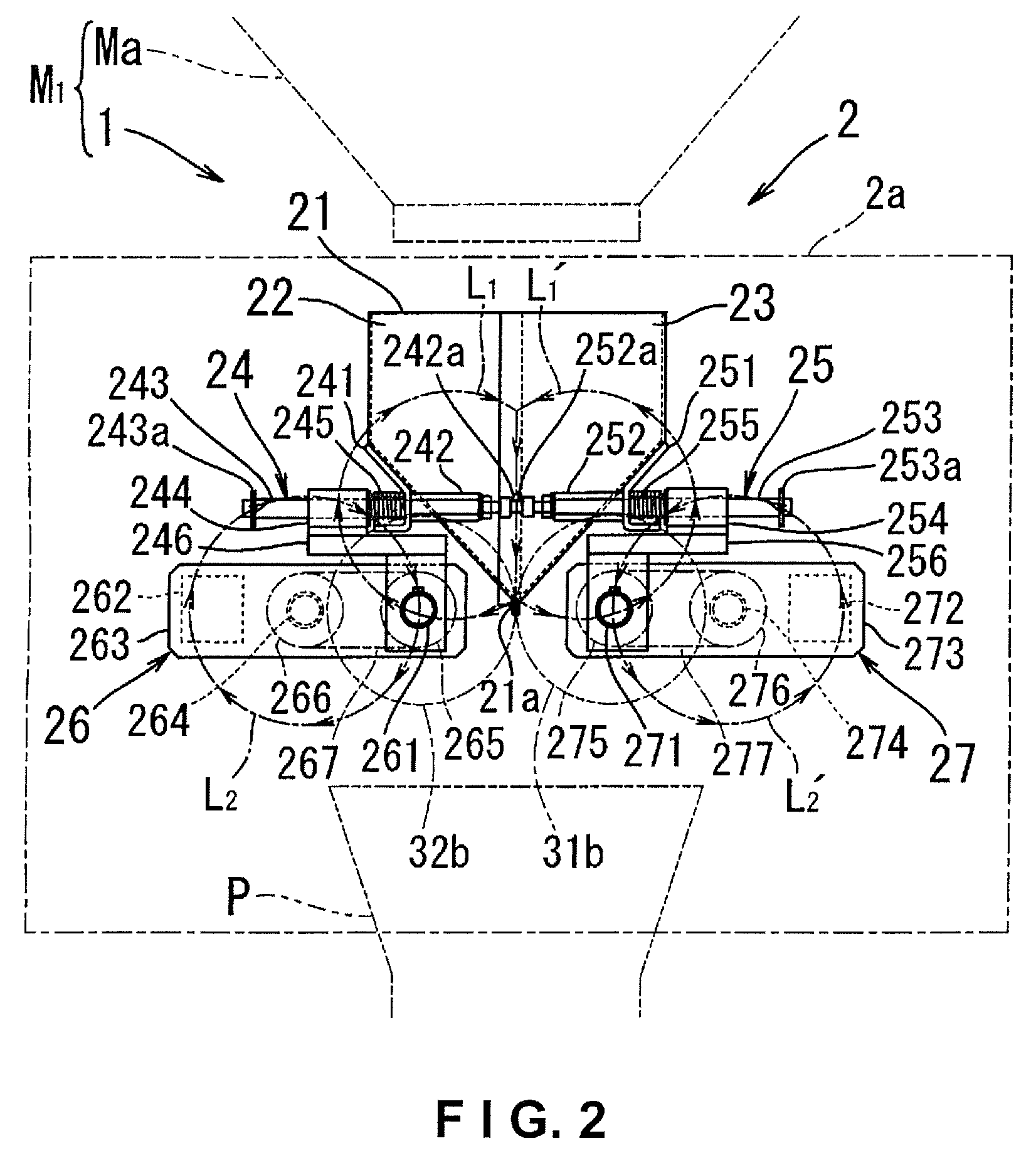

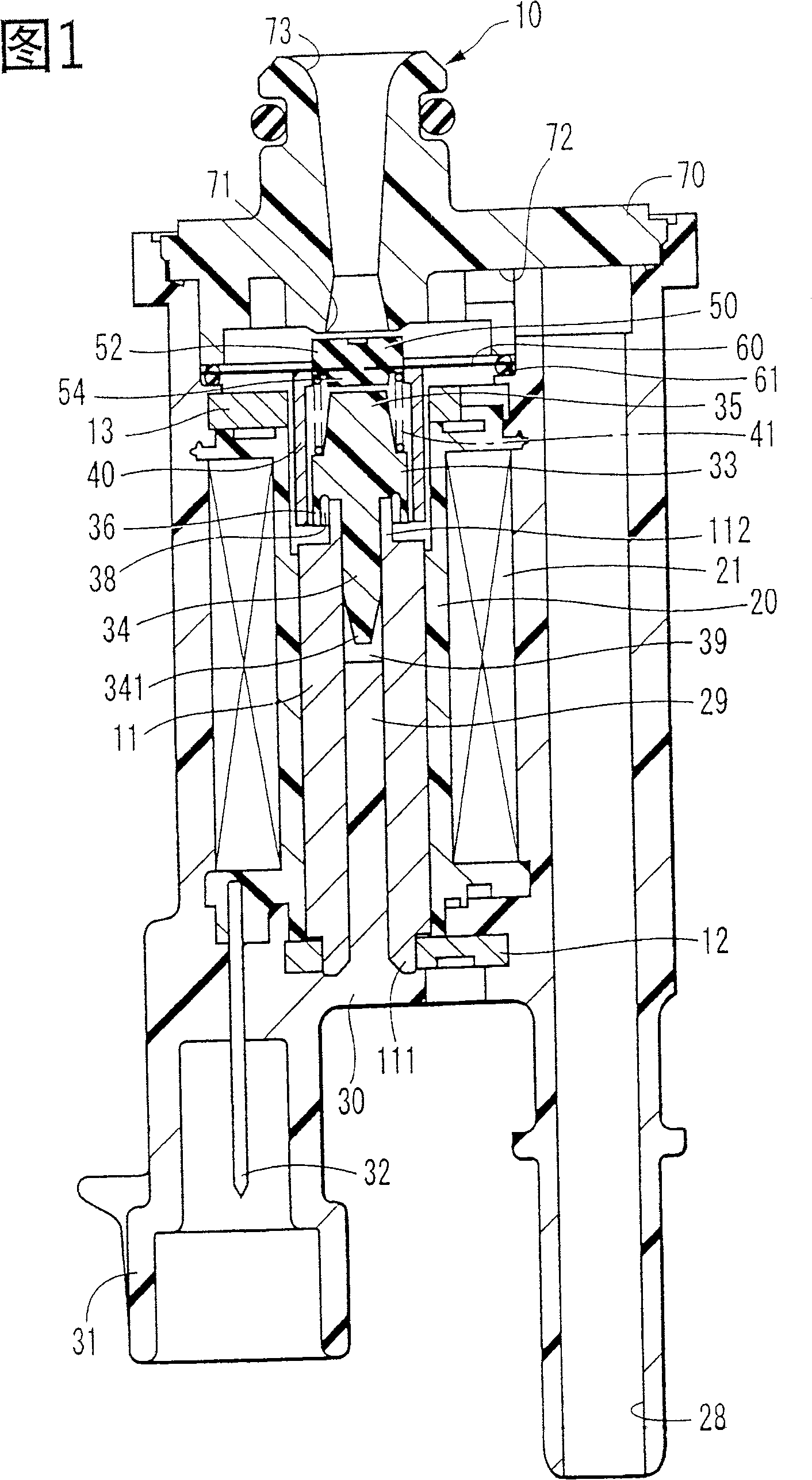

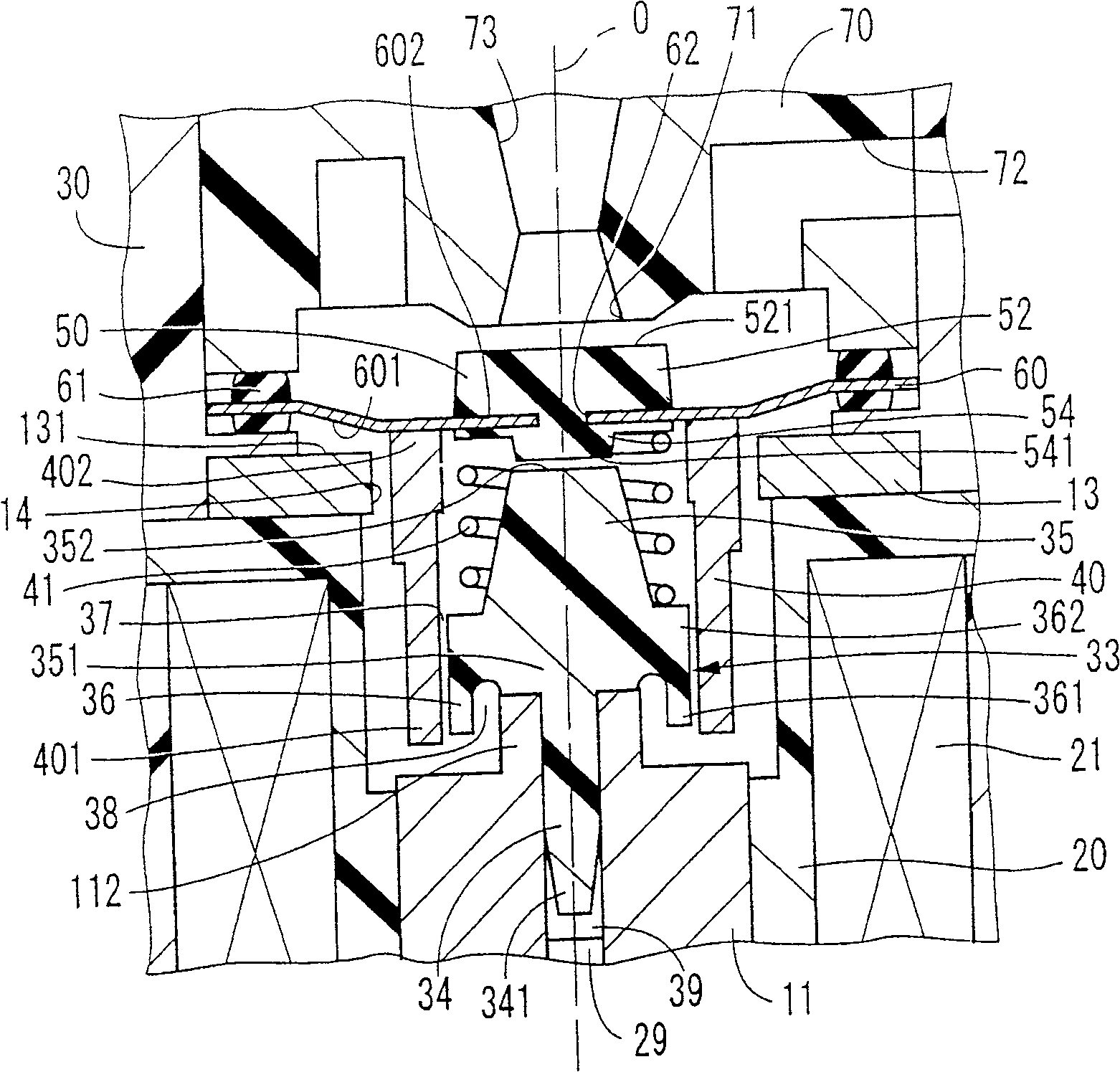

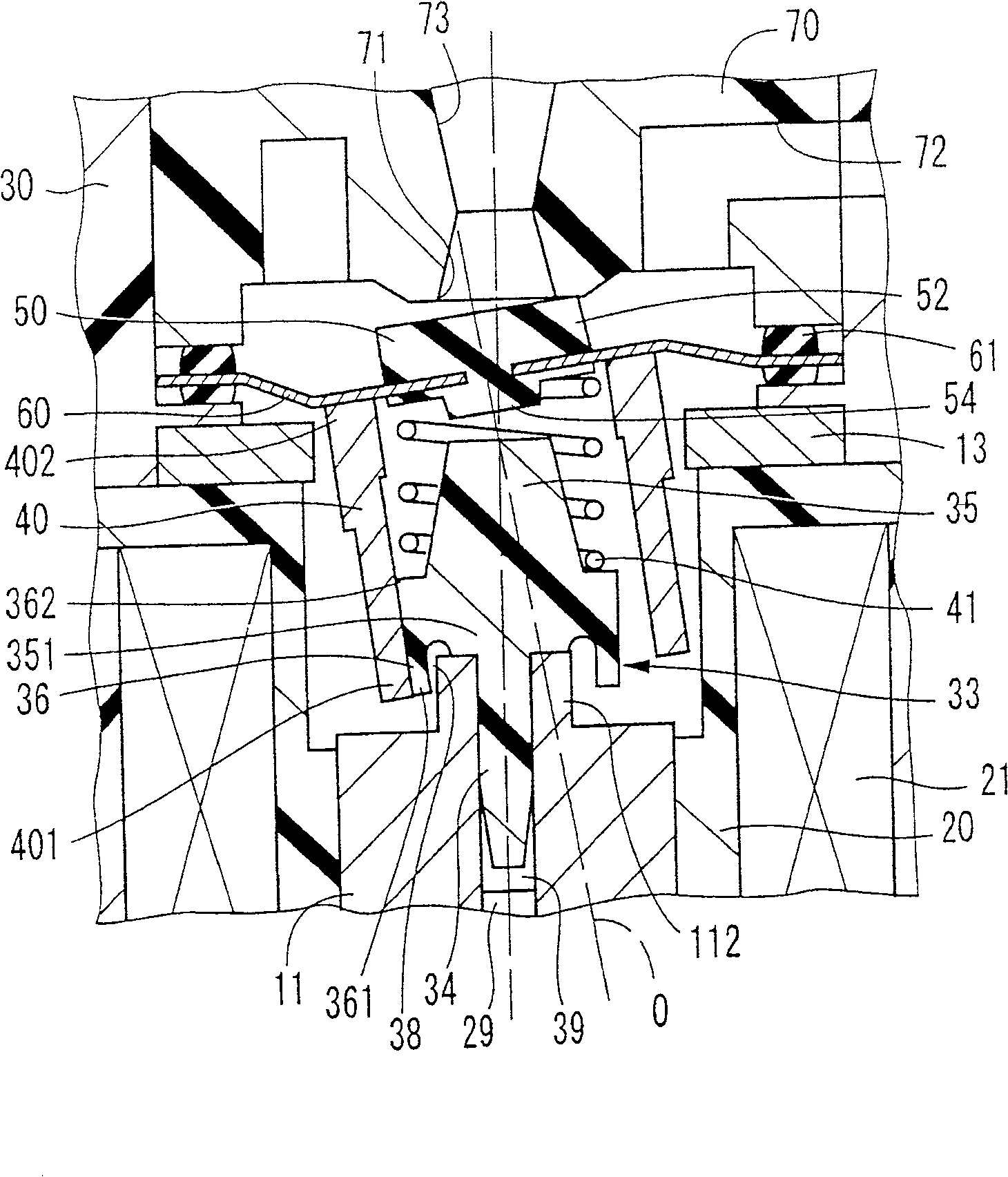

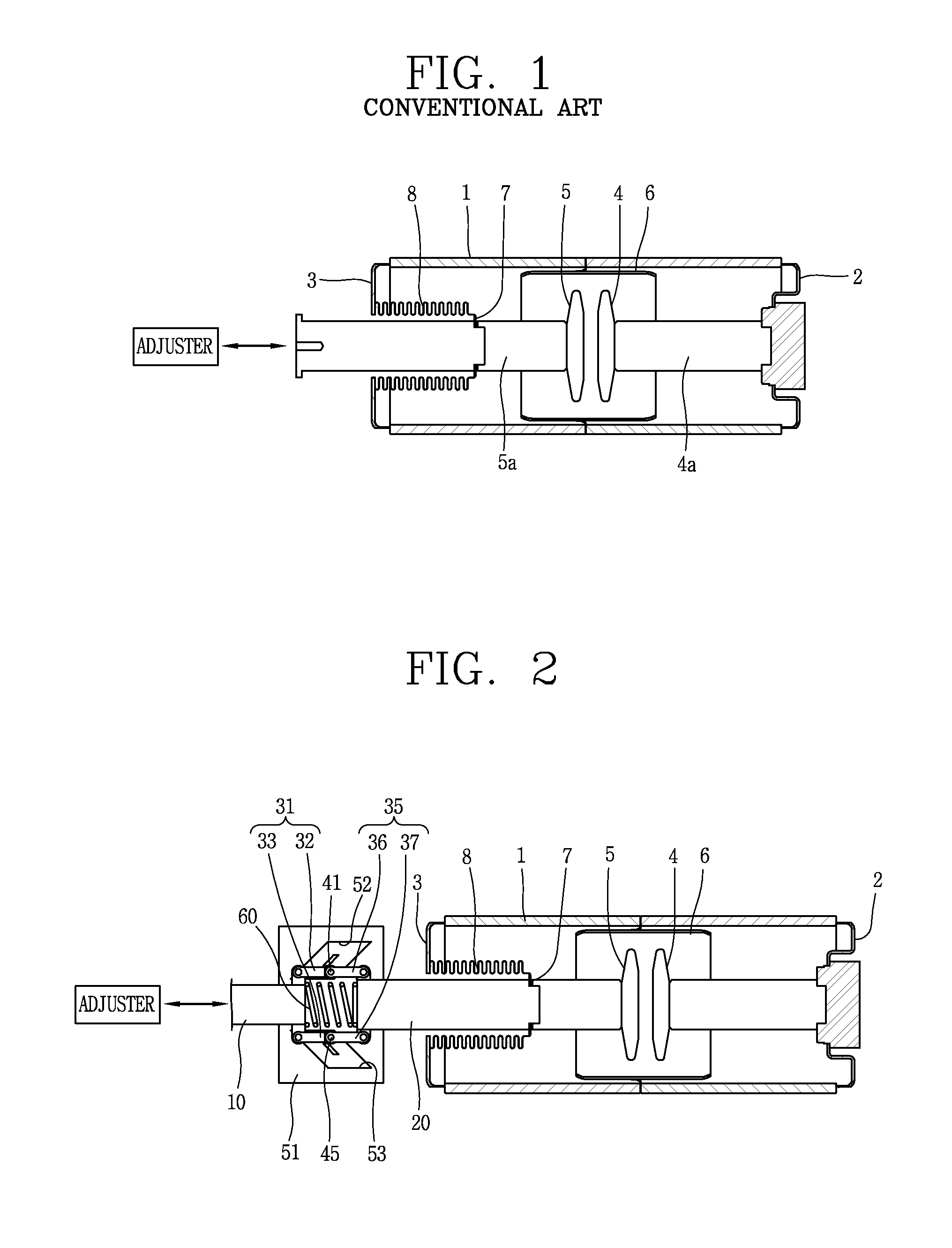

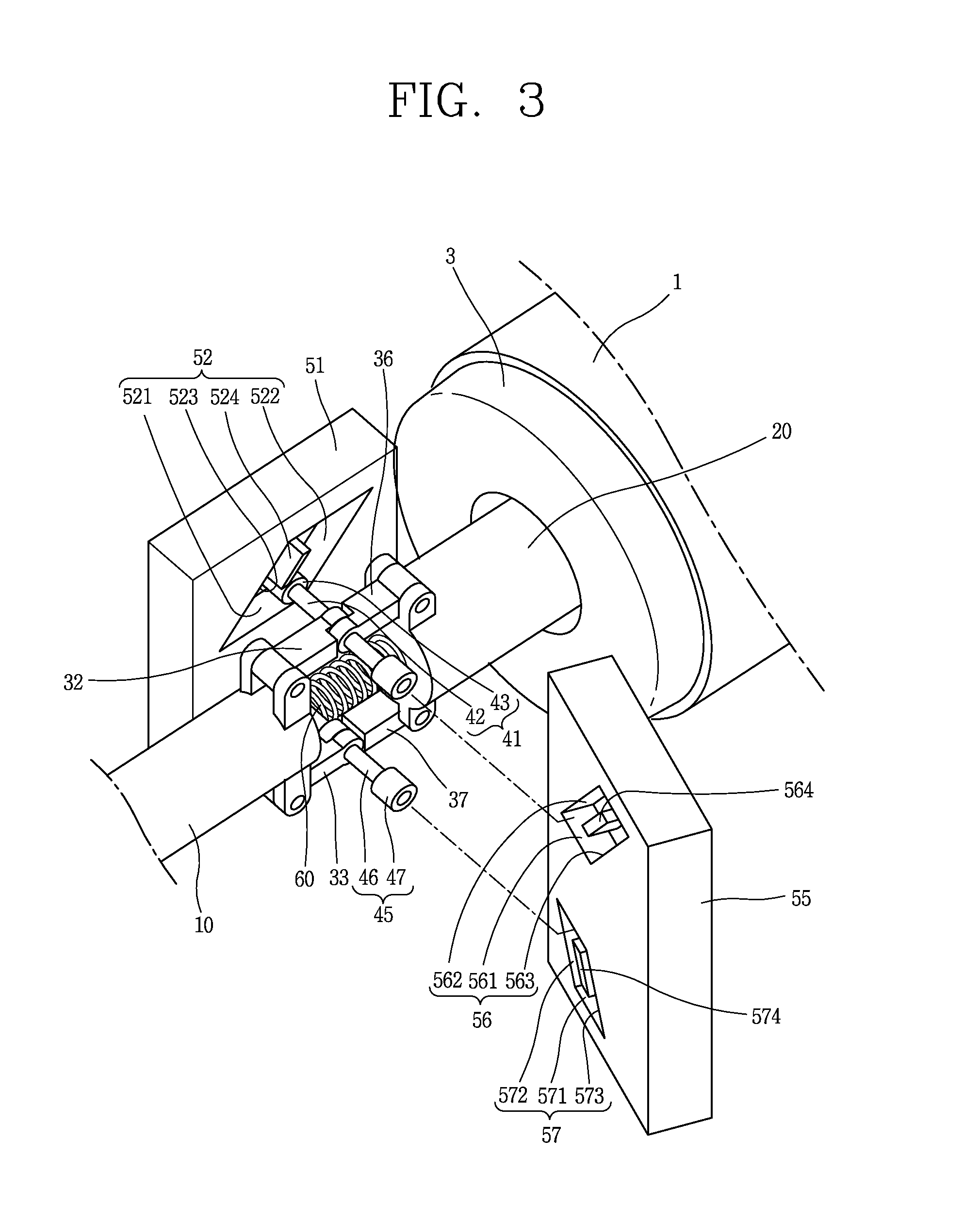

Power transmission device for vacuum interrupter and vacuum breaker having the same

ActiveUS20130026020A1Reduce collision speedReduce pre arc timeContact driving mechanismsSnap-action arrangementsCamPower transmission

Disclosed are a power transmission device for a vacuum interrupter, and a vacuum breaker having the same. The device includes: a driving link coupled to an adjuster; a driven link coupled to a movable electrode of a vacuum interrupter; connection links configured to connect the driving link and the driven link with each other, and coupled to the driving link and the driven link such that an interval between the driving link and the driven link is varied; cams coupled to the connection links in a perpendicular direction; and cam guides having guide recesses for slidably coupling the cams, and configured to guide the interval between the driving link and the driven link to be changed.

Owner:LSIS CO LTD

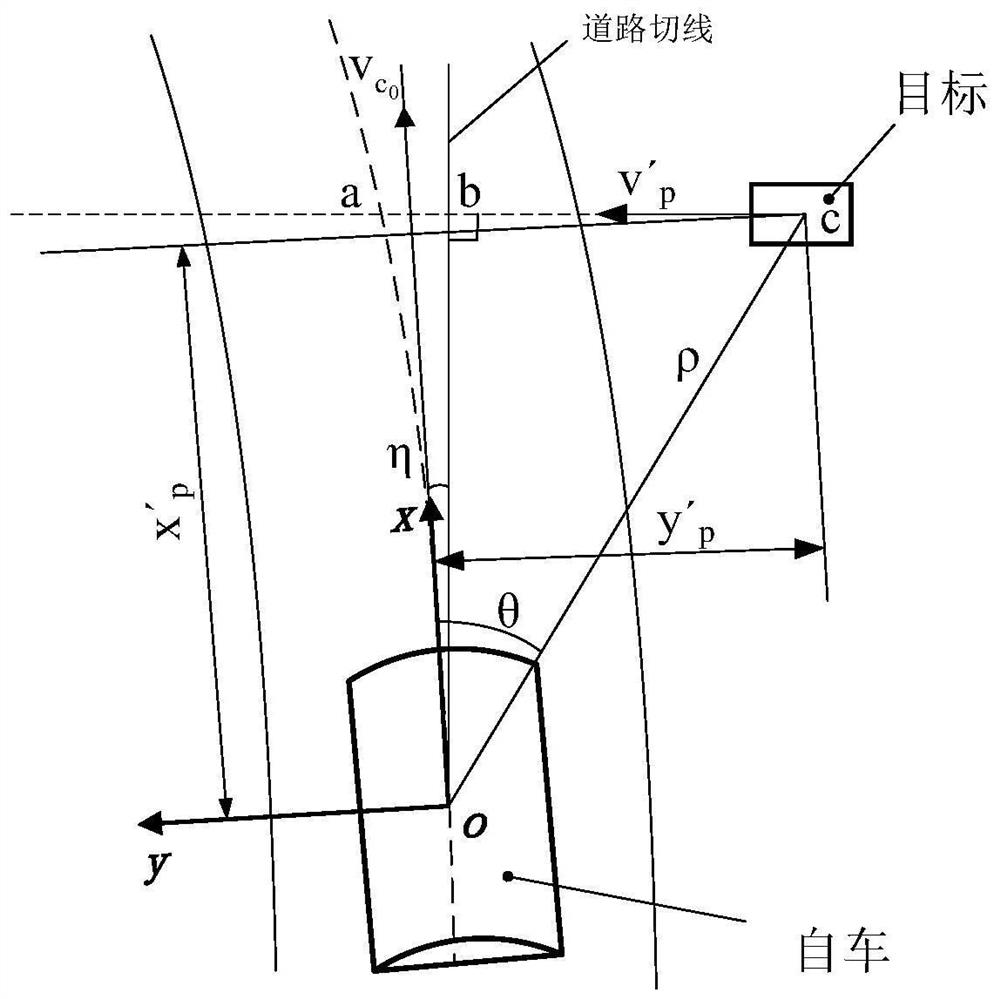

Automobile collision avoidance system for vulnerable road users and control method thereof

PendingCN113232648AAvoid collisionReduce collision speedAnti-collision systemsExternal condition input parametersRoad userControl signal

The invention discloses an automobile collision avoidance system for vulnerable road users and a control method thereof, and relates to the field of vehicle driving safety. A decision module receives information collected by a sensing module and makes a corresponding scheme, and an execution module is used for executing the scheme of the decision module; the decision module receives the automobile motion information, the motion information of surrounding targets and the road condition information acquired by the sensing module, judges whether a dangerous target exists or not, determines a collision avoidance scheme after evaluating the feasibility of active braking and active steering, and calculates the expected braking pressure, the expected throttle opening and the expected steering wheel turning angle; the execution module is based on a control signal of the decision module, when the automobile is actively braked, a brake and a throttle valve controller work cooperatively, and braking deceleration is output; and when the automobile actively steers, the steering system enables the automobile to steer along the planned path. Active braking or active steering operation is adopted, collision between the automobile and a dangerous target is avoided to the maximum extent, and therefore the road safety is remarkably improved.

Owner:JIANGSU UNIV

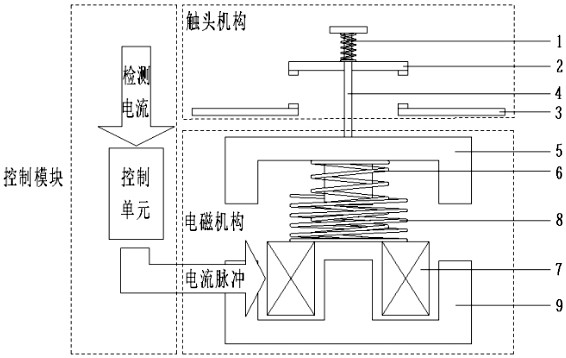

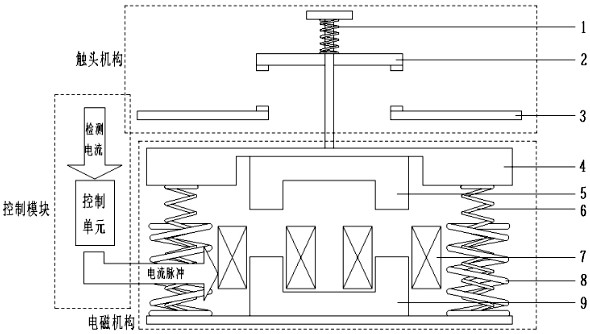

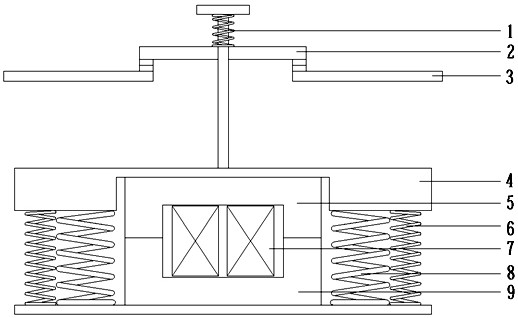

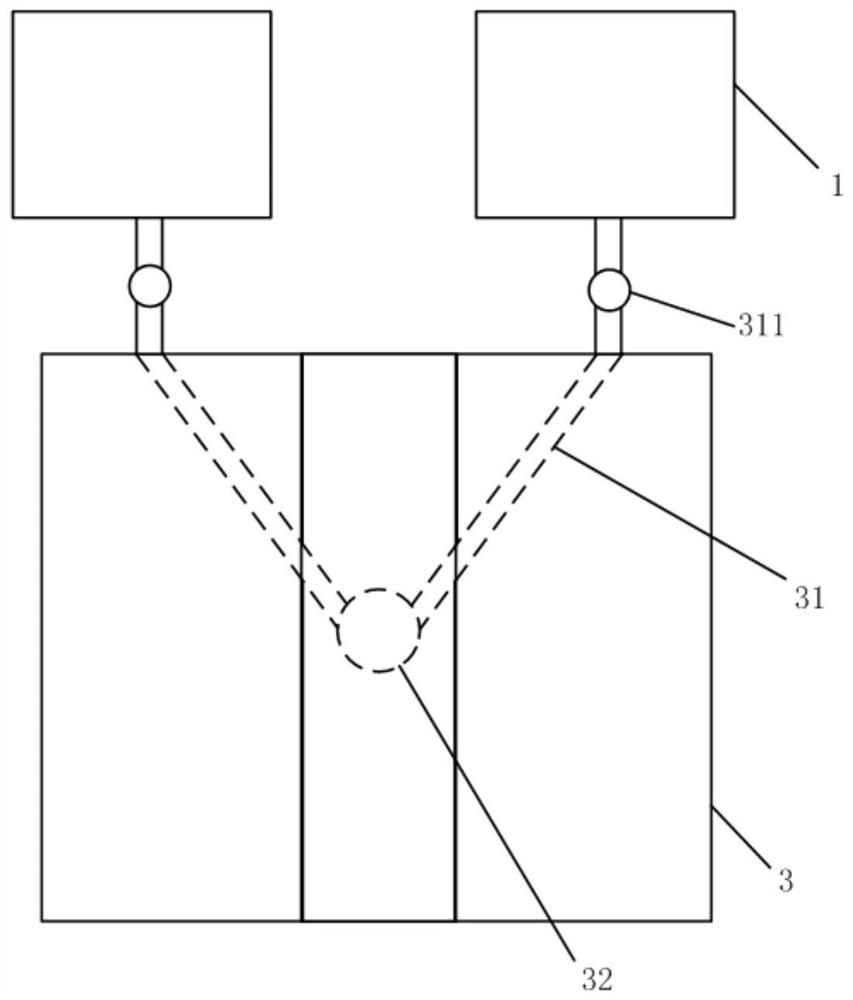

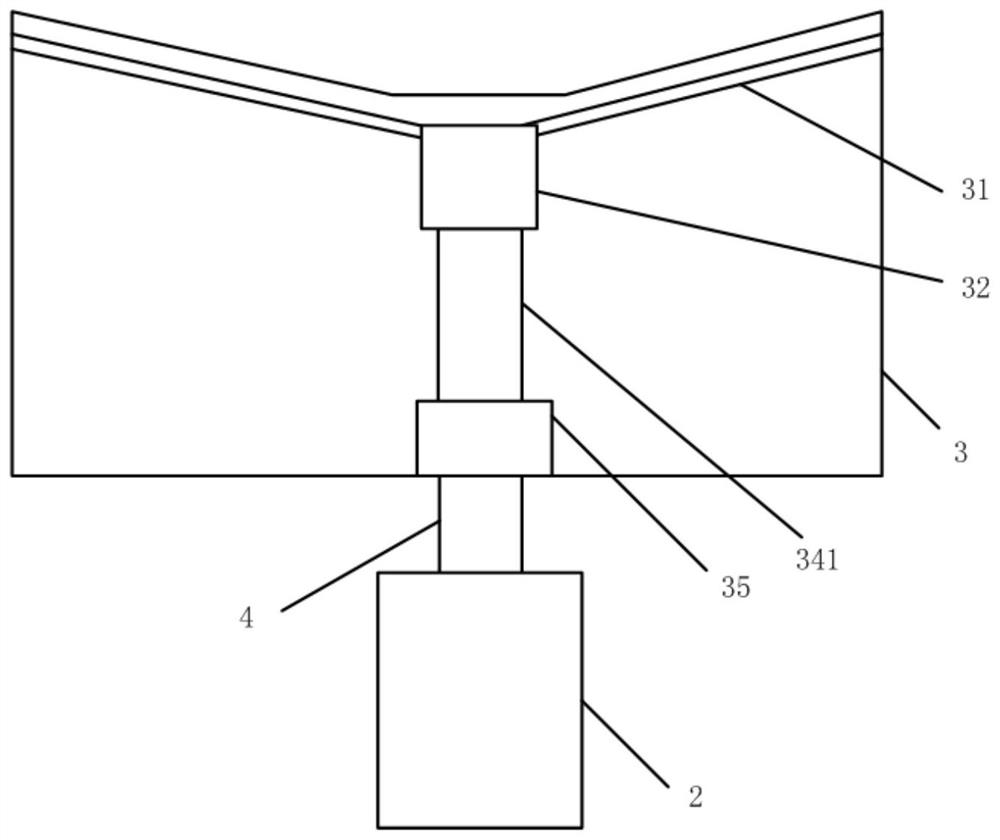

Double-counterforce opening-distance-adjustable intelligent switching device and working method thereof

PendingCN114242480ASmall initial reaction forceReduce collision speedContact vibration/shock dampingSwitch power arrangementsPhysicsSmart control

The invention provides a double-counterforce opening-distance-adjustable intelligent switching device and a working method thereof. The double-counterforce opening-distance-adjustable intelligent switching device comprises an electromagnetic mechanism, a contact mechanism, a control module, a connecting mechanism and a base. The electromagnetic mechanism comprises a movable iron core, a static iron core, a coil, a first counter-force spring and a second counter-force spring; the length of the first reaction spring is larger than that of the second reaction spring, and the stiffness coefficient of the first reaction spring is smaller than that of the second reaction spring. The contact mechanism is composed of a moving contact, a static contact and a contact spring. And a gap is formed between the moving contact and the static contact. Through compression of the first reaction spring and the second reaction spring, the attraction impact force of the iron core is reduced; during breaking, large counter-force is generated through release of the first counter-force spring and the second counter-force spring, and the breaking speed of the contact is increased. The size and the breaking type of the breaking current are detected through the control module, the opening distance of the contact is adjusted according to requirements, intelligent control over the breaking process is achieved, and the purpose of prolonging the service life of a switching device is achieved.

Owner:FUZHOU UNIVERSITY

Cold spraying preparation method of corrosion-resistant aluminum-based or zinc-aluminum-based metal coating on magnesium alloy surface

ActiveCN105256307BDeposition will notImprove corrosion resistanceMolten spray coatingPressure inorganic powder coatingSurface engineeringBase metal

The invention discloses a cold spraying manufacturing method for an anticorrosive aluminum base or a zinc-aluminum base metal coating on a magnesium alloy surface and belongs to the field of the material surface engineering technology and mechanical manufacturing. The method includes the following steps that firstly, aluminum base or zinc-aluminum base metal powder is mixed with hard metal powder so as to manufacture mixed powder for cold spraying; and secondly, a cold spraying process is adopted, the mixed powder is sprayed to a pretreated magnesium alloy matrix, and the anticorrosive aluminum base or zinc-aluminum base metal coating is manufactured on the surface of the magnesium alloy matrix. By the adoption of the method, the grain speed and the deposition temperature do not need to be remarkably improved, operation is easy, a sedimentary body manufactured through the method is more excellent in electric conductivity and thermal conductivity and higher in corrosion resistance, abrasion resistance and mechanical performance, and therefore the method can be widely applied for manufacturing coatings with high electric conductivity, thermal conductivity, corrosion resistance and abrasion resistance or workpieces with the high mechanical performance.

Owner:XUZHEN NEW ENERGY TECH (SHANGHAI) CO LTD

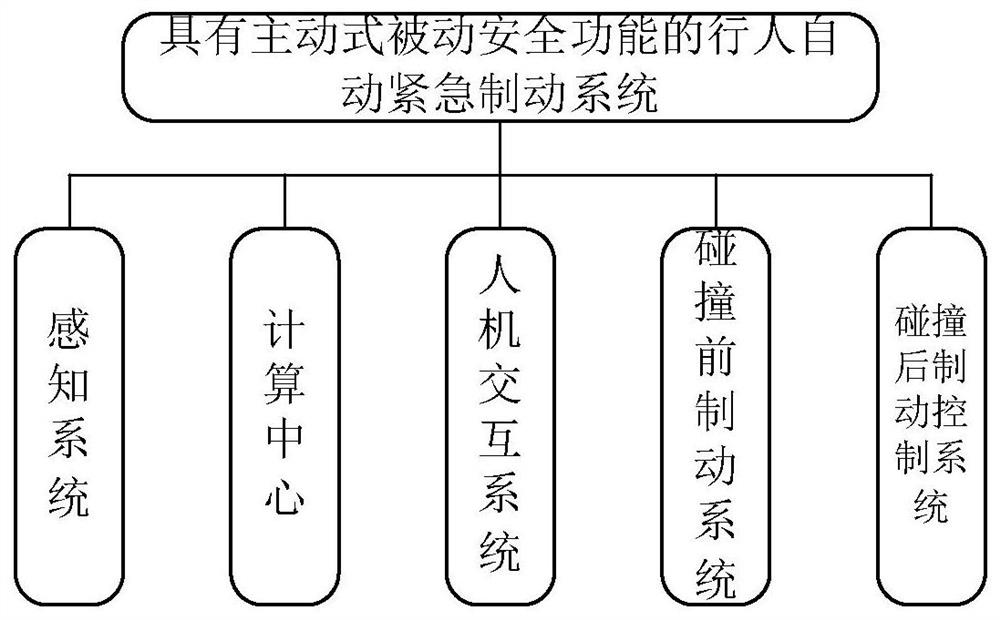

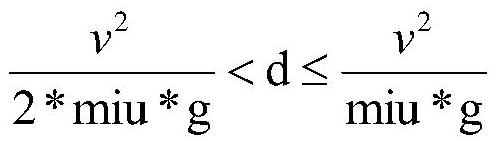

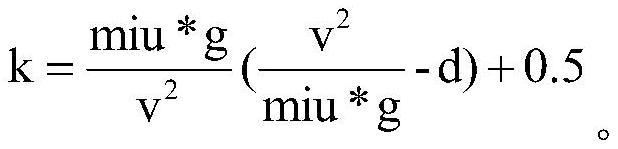

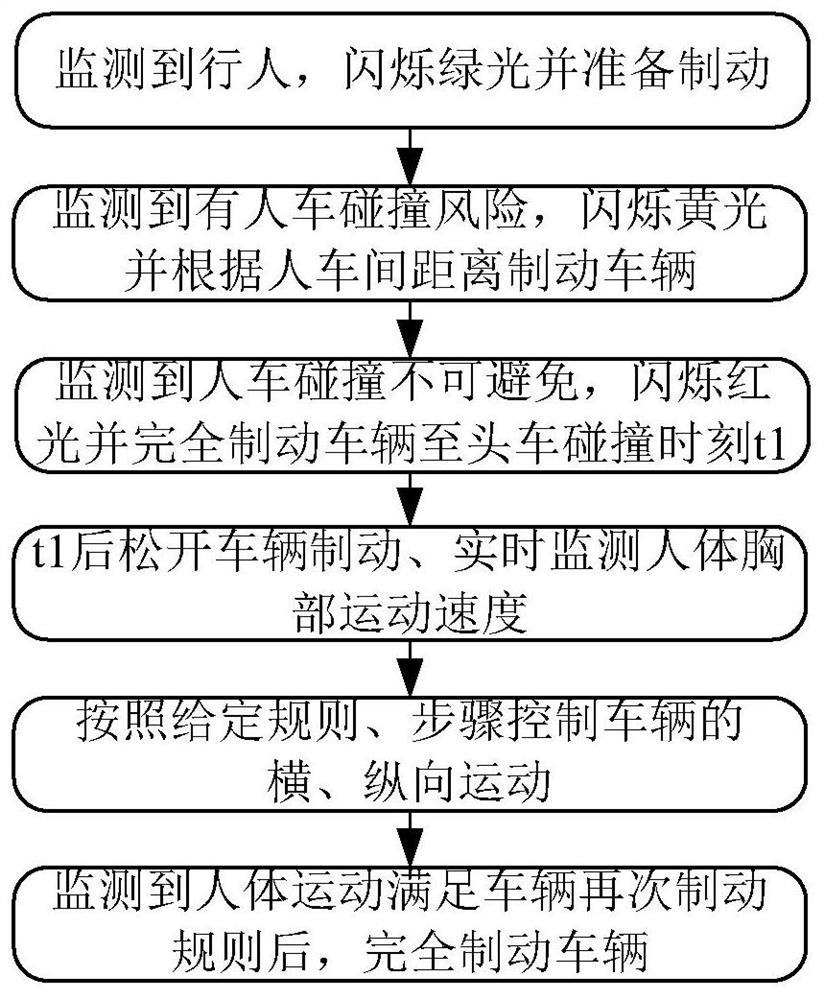

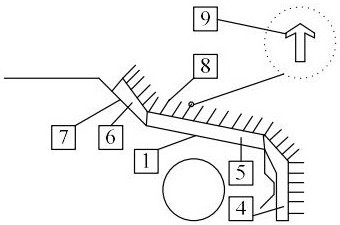

Pedestrian automatic emergency braking system with active passive safety function

ActiveCN112918469AReduce collision damageImprove the accident avoidance rateComputing centerControl system

Aiming at the problem that man-machine interaction and ground collision damage protection are not considered in existing achievement, the invention provides a pedestrian automatic emergency braking system with an active passive safety function. The system comprises a sensing system, a computing center, a man-machine interaction system, a pre-collision braking system and a post-collision braking control system; and the sensing system is responsible for sensing the environment outside a vehicle and monitoring human motion response in an accident in real time, the computing center is responsible for making a decision according to sensing information to guide other systems to work, the man-machine interaction system is composed of acousto-optic warning lamps installed on a roof and is responsible for warning pedestrians, the pre-collision braking system brakes the vehicle according to instructions of the computing center, and the post-collision braking control system controls the vehicle to brake according to instructions of the computing center. Compared with the prior art, the pedestrian automatic emergency braking system has the beneficial effects that the vehicle is braked before collision, pedestrians are warned to improve the accident avoidance rate, vehicle braking is controlled after collision to reduce human-ground collision damage, and accordingly the pedestrians are protected to the maximum extent.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

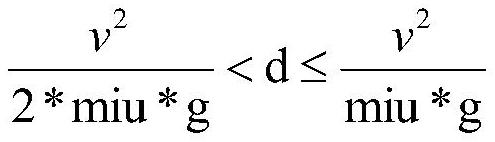

Intelligent automatic emergency braking method for protecting pedestrians

ActiveCN112918470AReduce collision damageImprove the accident avoidance rateAccident avoidanceEmergency brake

Aiming at the problem that man-machine interaction and ground collision damage protection are not considered in existing achievement, the invention provides an intelligent automatic emergency braking method for protecting pedestrians. According to the method, interaction with pedestrians is achieved through acousto-optic warning before collision occurs, and a vehicle is controlled to move after collision so as to prevent the pedestrians from being damaged by collision. Compared with the prior art, the method has the beneficial effects that the vehicle is braked before collision, pedestrians are warned to improve the accident avoidance rate, the vehicle is controlled to move after collision to reduce human-ground collision damage, and accordingly the pedestrians are protected to the maximum extent.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Loading system and method for loading substrates with electrical components

An assembly system for equipping substrates with electrical components, which has: at least one transfer line (2) that can transfer a first and a second substrate (16, 17) in a transfer direction; a main bracket (3 ); a first support slide (4) fixed on the main bracket (3) and movable in a moving direction; a longitudinally extending, with its longitudinal axis (9-1) perpendicular to the moving direction A first arm (8), which is fixed on the first support slide (4) and can move in the direction of its longitudinal axis (9-1); a first assembly head (10) and a second assembly head (11), the first and second assembly heads are fixed on the first arm (8), on the longitudinal axis (9) of the first arm (8) -1) are located on two opposite sides of the support slide, with a fixed distance between them.

Owner:ASM ASSEMBLY SYST GMBH & CO

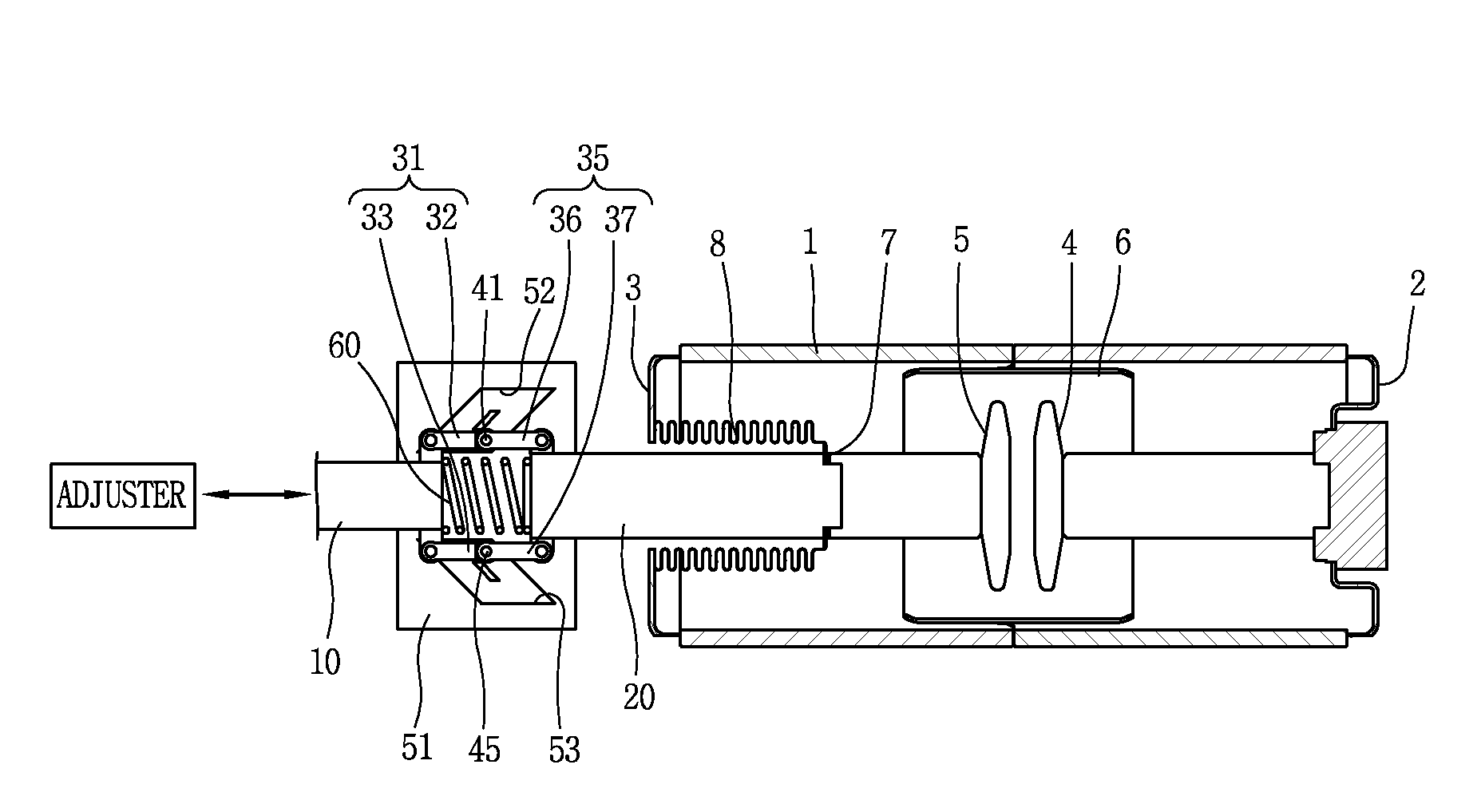

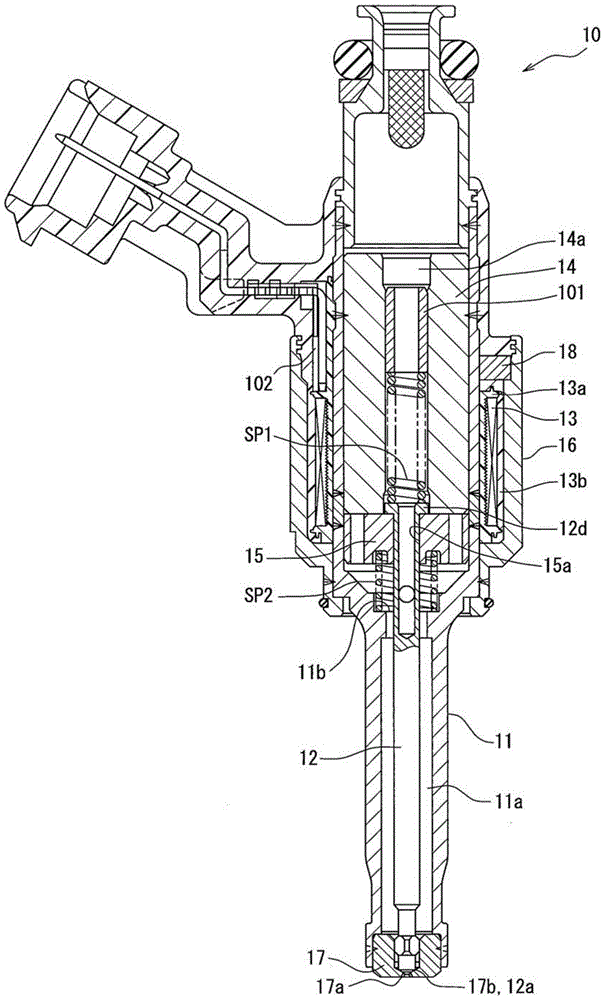

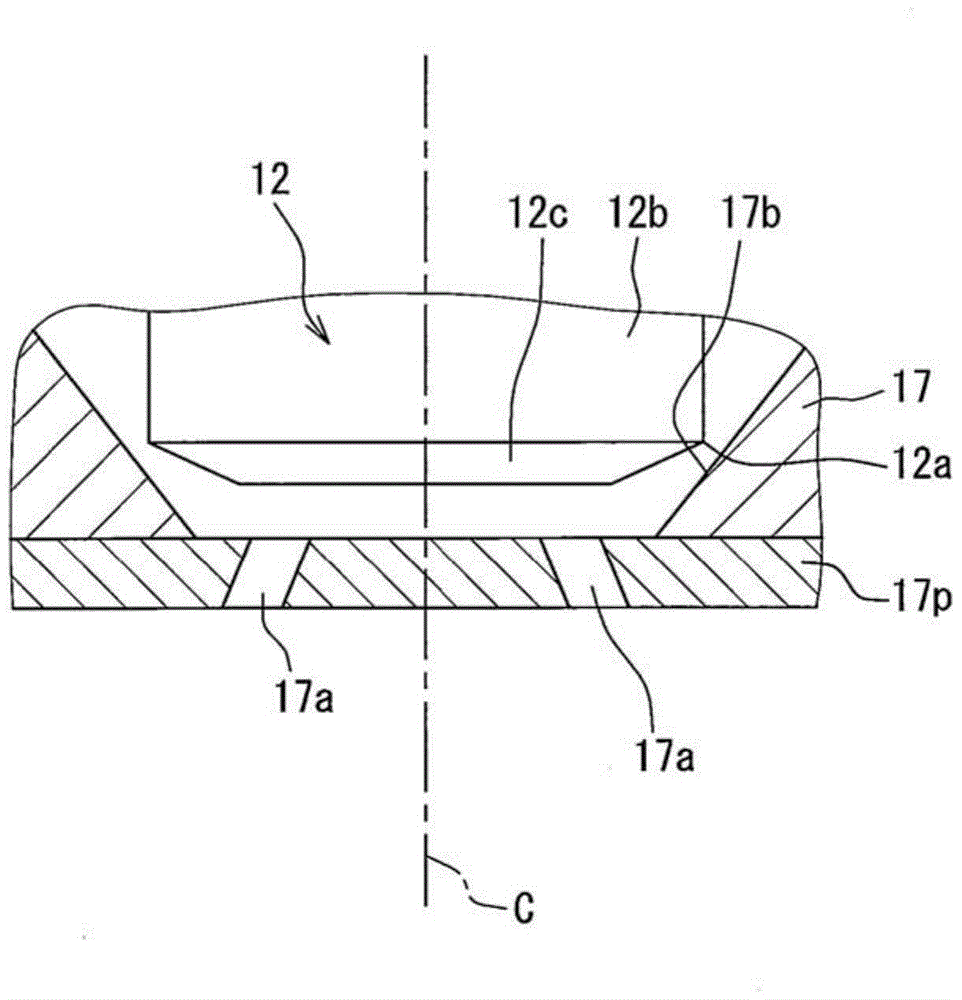

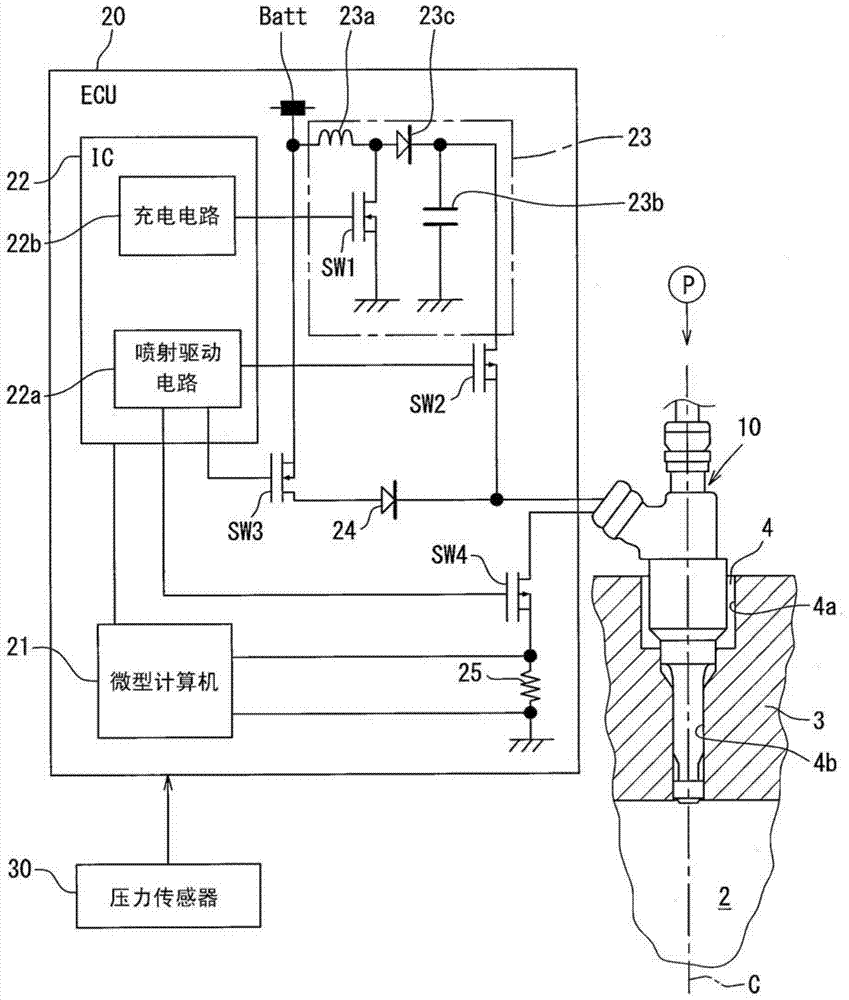

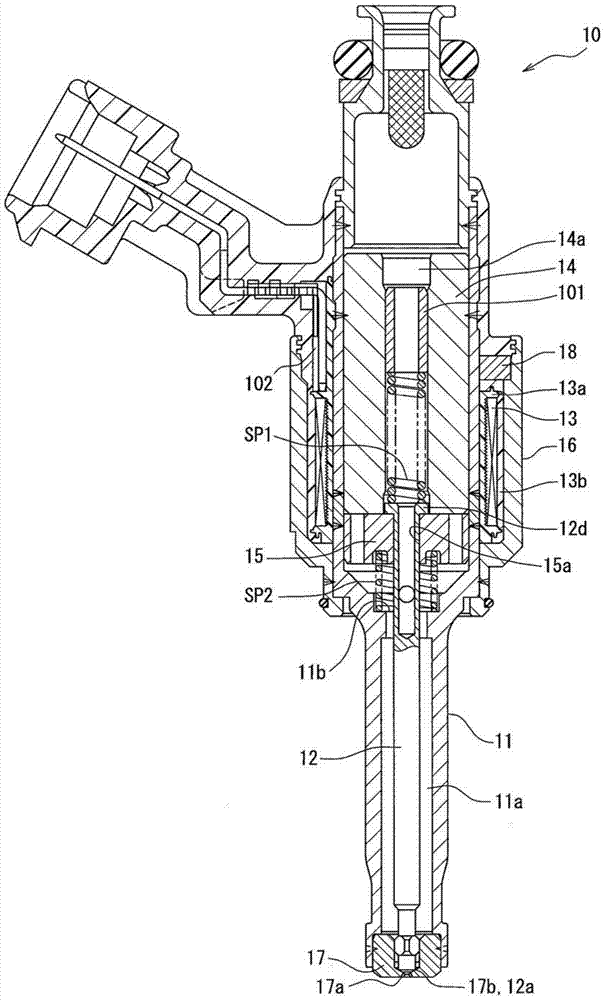

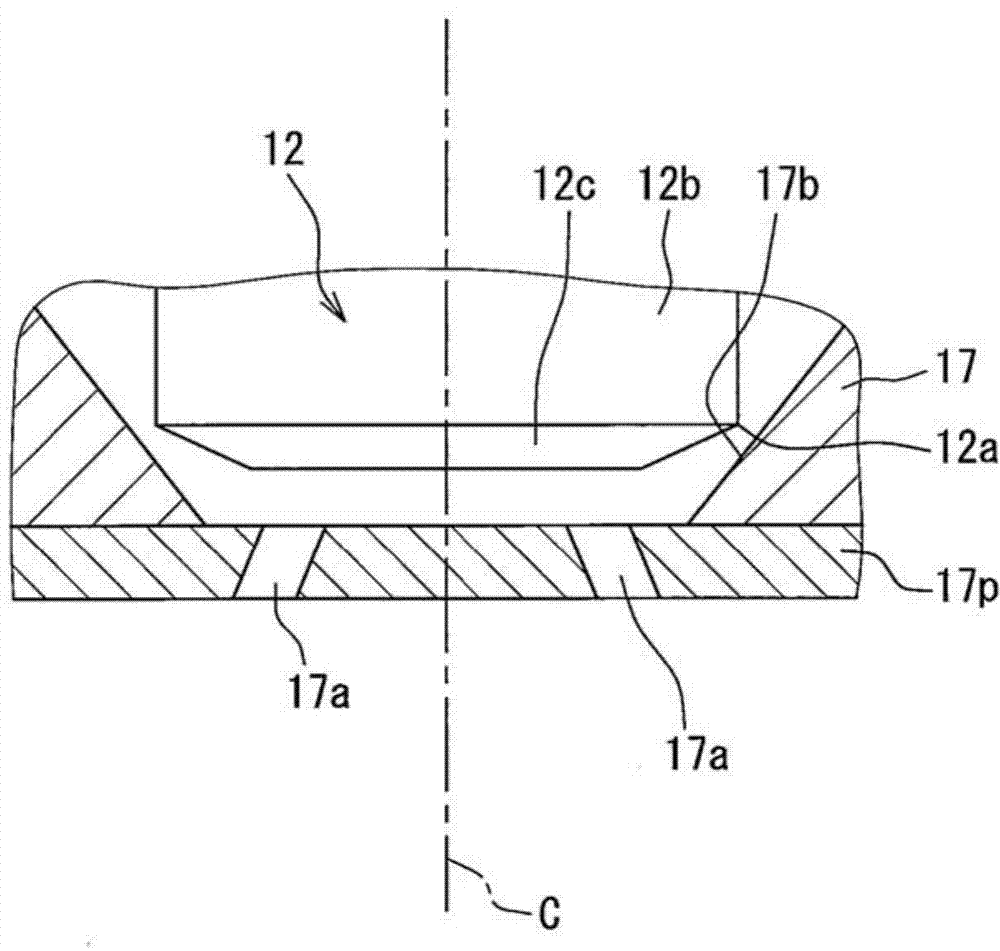

Fuel injector and fuel injection device using same

ActiveCN103925134BReduce collision speedFuel injection apparatusMachines/enginesVALVE PORTFuel injection

A fuel injector includes a valve body moved together with a movable core and opening an injection port, and an elastic-force applying portion being elastically deformable according to a movement of the valve body to apply an elastic force to the valve body in a valve-closing direction. An elastic coefficient of the elastic-force applying portion is set to meet a condition that Ffc−Ffo≰L×K. In this case, a fuel-pressure valve-closing force of when the valve body is closed is referred to as Ffc, and the fuel-pressure valve-closing force of when the valve body is completely opened is referred to as Ffo. A movement distance of the valve body from a time point that the valve body is closed to a time point that the valve body is completely opened is referred to as L. The elastic coefficient is referred to as K.

Owner:DENSO CORP

Fuel Injector And Fuel Injection Device Using The Same

ActiveCN103925134ALimited reboundControl damageFuel injection apparatusMachines/enginesInjection portEngineering

A fuel injector includes a valve body moved together with a movable core and opening an injection port, and an elastic-force applying portion being elastically deformable according to a movement of the valve body to apply an elastic force to the valve body in a valve-closing direction. An elastic coefficient of the elastic-force applying portion is set to meet a condition that Ffc-Ffo<=LK. In this case, a fuel-pressure valve-closing force of when the valve body is closed is referred to as Ffc, and the fuel-pressure valve-closing force of when the valve body is completely opened is referred to as Ffo. A movement distance of the valve body from a time point that the valve body is closed to a time point that the valve body is completely opened is referred to as L. The elastic coefficient is referred to as K.

Owner:DENSO CORP

A working method of a hood for a smart car to protect pedestrians

ActiveCN109760621BReduce direct collision forceReduce collision speedPedestrian/occupant safety arrangementSuperstructure subunitsMobile vehicleAirbag

Aiming at the reality that most of the existing research results only protect people and vehicles from collision damage, the present invention designs a working method for the hood of an intelligent car to protect pedestrians. By detonating the airbag layer of the hood, the front of the car is covered with a hedgehog-shaped airbag to reduce the direct collision force between people and vehicles. At the same time, the barb-shaped air column on the outside of the airbag slows down the speed at which pedestrians are thrown out, achieving direct protection for people and vehicles. At the same time, it consumes the kinetic energy obtained by the human body from the car body; and then moves the vehicle so that the front of the car catches the human body, and the air column on the outside of the airbag delays the falling speed of the human body to further consume the potential energy and kinetic energy of the human body, thereby reducing the collision speed between the human body and the ground. Car and human-ground collision protection at the same time.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Electrical contactor with flywheel drive and method for switching on and/or disconnecting the electrical contactor

InactiveCN103890889BReduced rebound tendencyExtended service lifeContact driving mechanismsSwitch power arrangementsFlywheelKinetic energy

Disclosed is an electric contactor, in particular to be used in roadways, with the stator and an armature, the armature being connected with a contact region and being movable, during a switching-on operation and / or a switching-off operation of the contactor, from a first to a second position, the contact region being connected in at least one of these positions with a counter-contact region for closing an electric circuit, wherein a pushing device is connected with the armature which is rotational relative to the armature, wherein the pushing device at least temporarily pushes the armature supportively in the movement from the first to the second position of the switching-on and / or switching-off operation.

Owner:SCHALTBAU GMBH

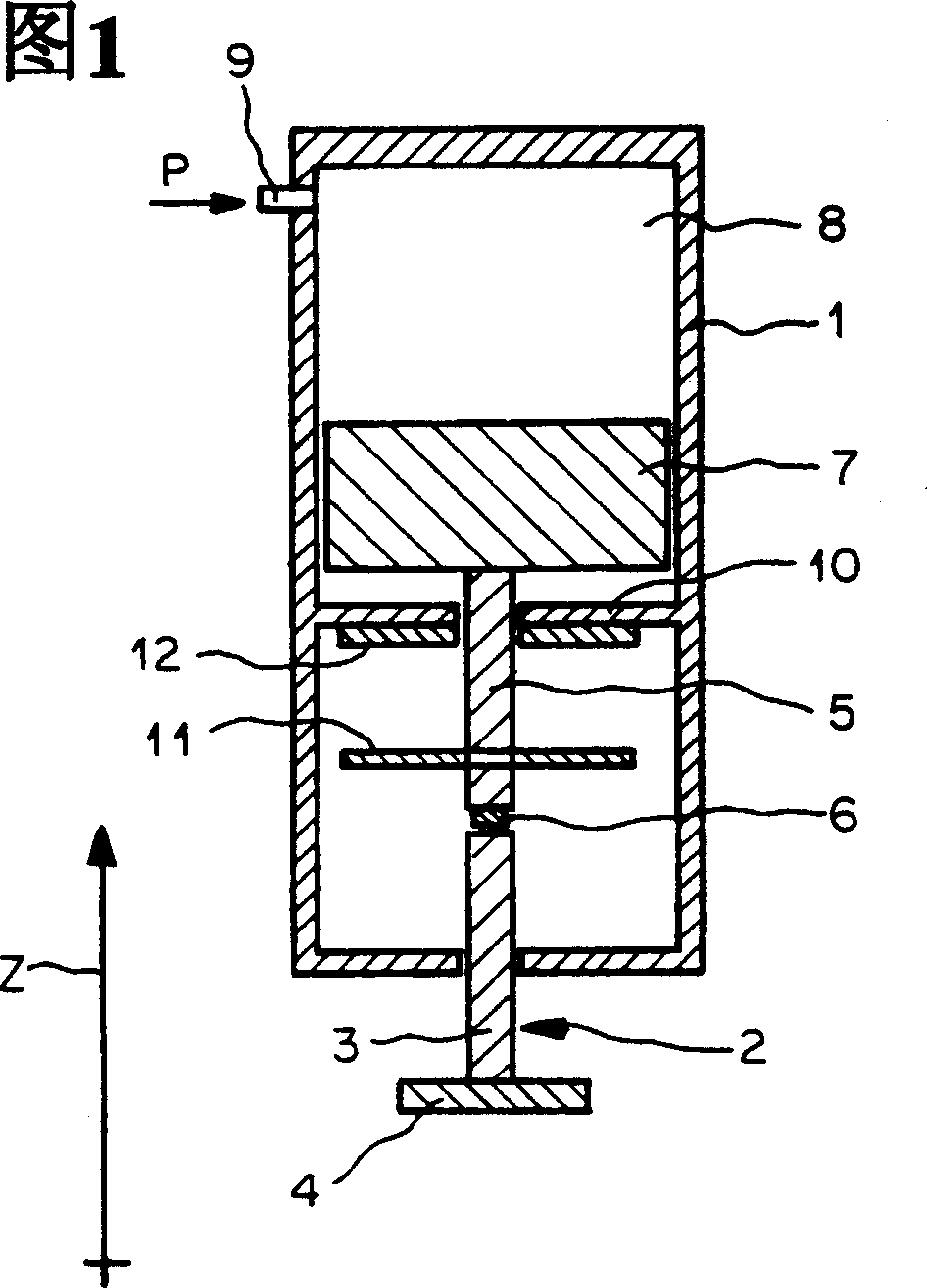

Method and equipment for preparing micronized medicines by using microreactor

ActiveCN113181852AReduce refluxReduce collision speedChemical/physical/physico-chemical microreactorsGranulation by liquid drop formationMicroreactorPharmaceutical drug

The invention belongs to the technical field of medicine production, and particularly relates to a method and equipment for preparing micronized medicines by using a microreactor. The method is carried out by using a microreactor, and the microreactor comprises: a plurality of raw material boxes; a reactor main body which comprises a protective shell, a sample injection pipe, a flow guide table, a reaction cavity, drainage pipes and a dryer, wherein the flow guide table is installed in the protective shell and is a double-layer sleeve, a plurality of vertical flow guide grooves are formed in the outer side wall of an inner-layer pipe of the sleeve, the reaction cavity is reserved between the bottom wall of an outer-layer pipe and the bottom wall of the inner-layer pipe of the flow guide table, the bottom of the reaction cavity is communicated with the multiple drainage pipes, and the dryer is arranged at the bottoms of the drainage pipes; and a collecting box which is communicated with the drying cavity through a powder collecting pipeline. The flow guide table, the reaction cavity and the drainage pipes capable of buffering liquid molecule collision are arranged between the sample injection pipe and the reaction cavity, so that the molecule collision speed is reduced, and the problem that liquid flows back into the sample injection pipeline or flows into a sample discharge pipeline early is solved.

Owner:HUBEI POLYTECHNIC UNIV

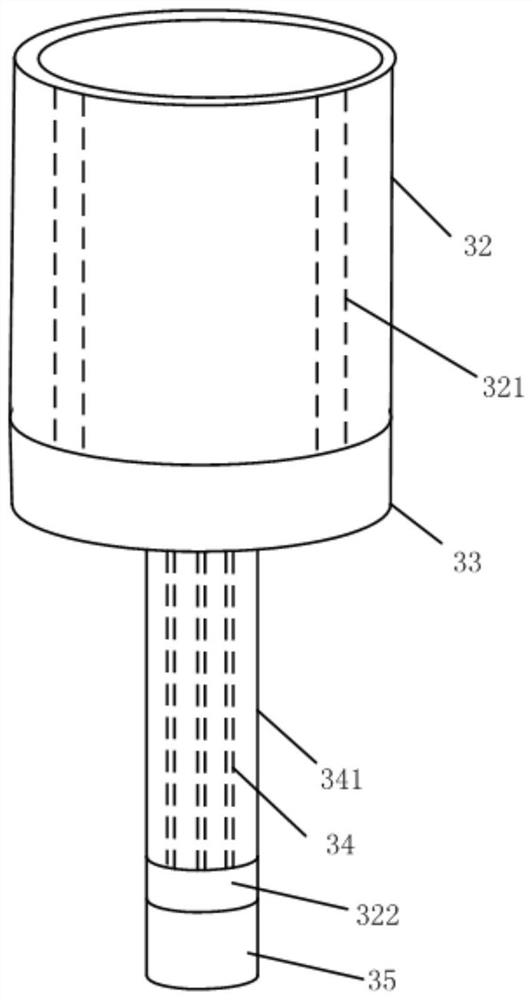

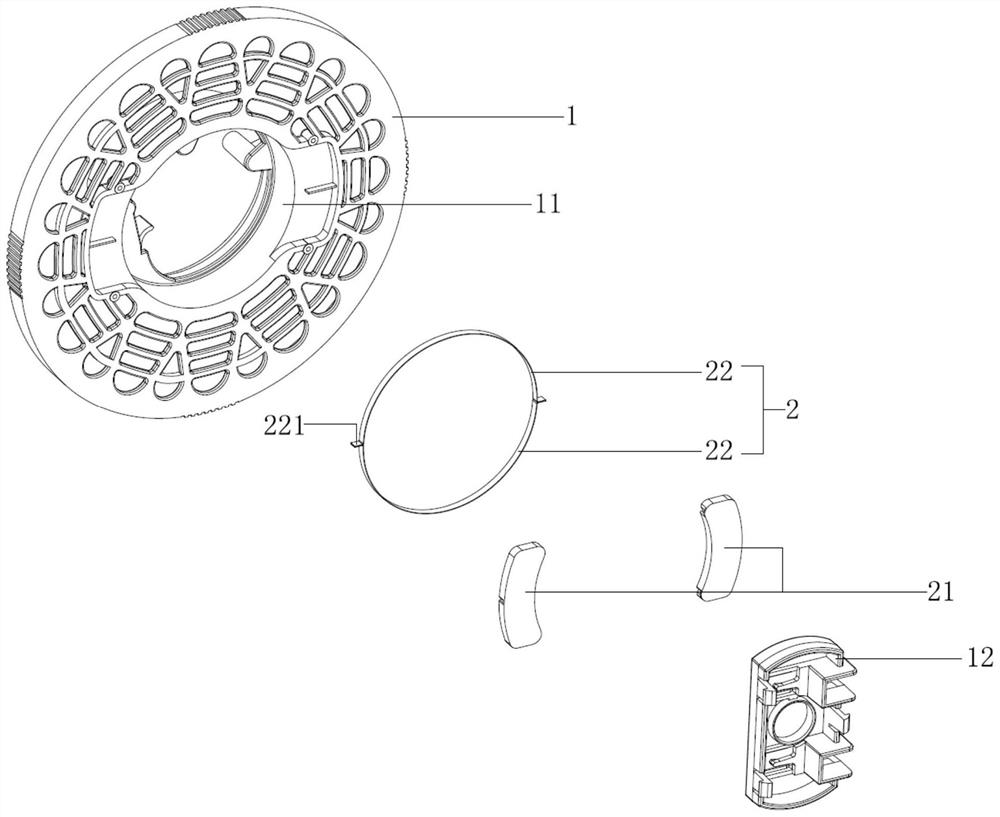

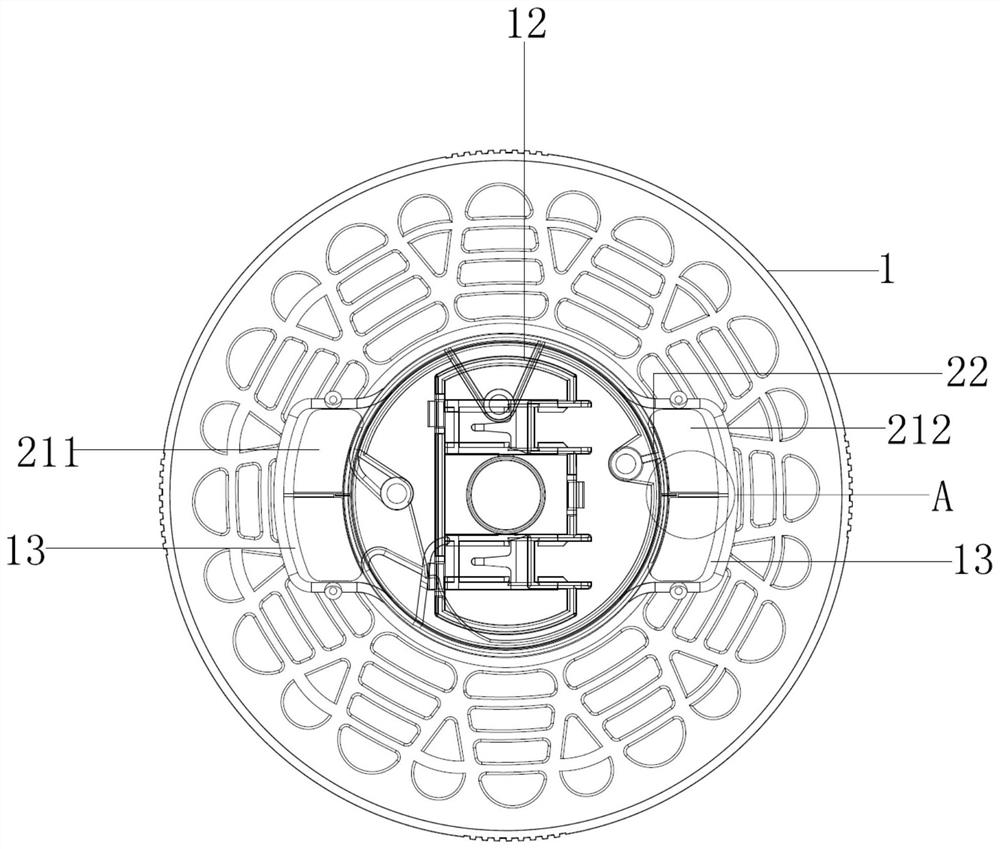

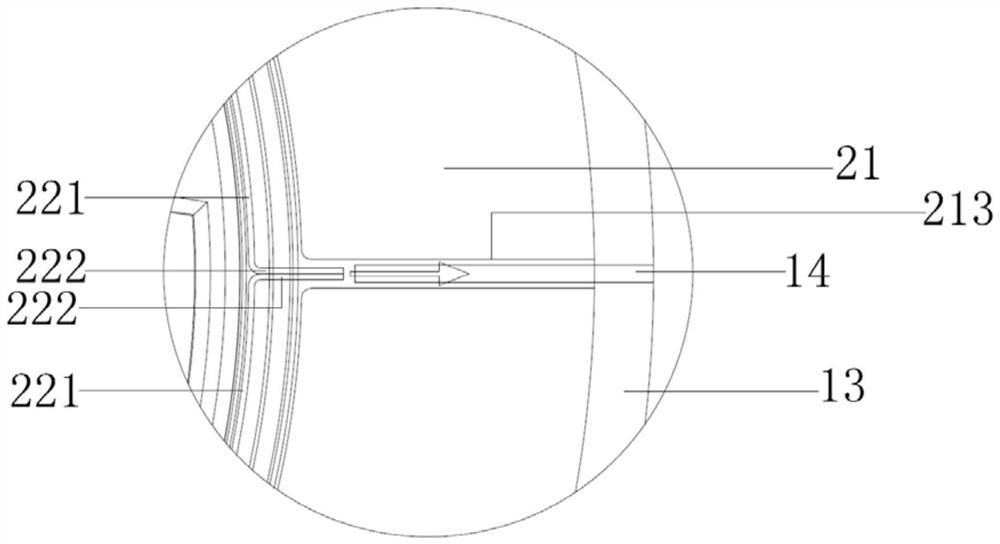

Winder with winding speed slowing mechanism

The invention provides a winder with a winding speed slowing mechanism. The winder comprises a winding reel and a deformable annular piece, wherein the winding reel is rotatably mounted on a winding support, and the winding support is provided with a support insert embedded in a central circular hole of the winding reel; and the deformable annular piece is installed in the central circular hole, at least one brake component is fixedly connected to the outer edge of the annular piece, the brake component is slidably connected to the surface of the winding reel at the same time, and the brake component slides back and forth in a radial direction of the winding reel and drives the annular piece to deform. Compared with the prior art, the safety and stability of the winder in use can be improved, and the service life of the whole winder is effectively prolonged.

Owner:SUZHOU CHUNJU ELECTRIC CO LTD

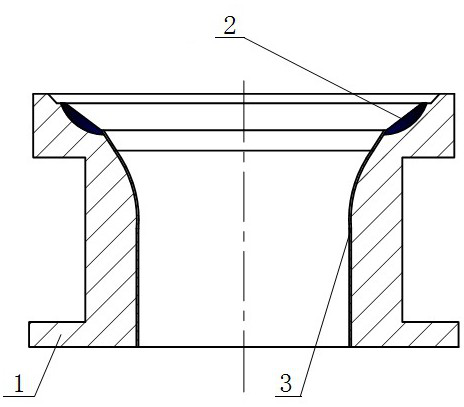

A processing method for a diesel engine valve seat

Owner:CHONGQING YUEJIN MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com