Cold spraying preparation method of corrosion-resistant aluminum-based or zinc-aluminum-based metal coating on magnesium alloy surface

A technology of magnesium alloy and base metal, which is applied in the field of cold spraying preparation of corrosion-resistant aluminum-based or zinc-aluminum-based metal coating on the surface of magnesium alloy, can solve the problems of high cost, clogging of spray gun, poor controllability of spraying process, etc. The effect of bond strength, excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

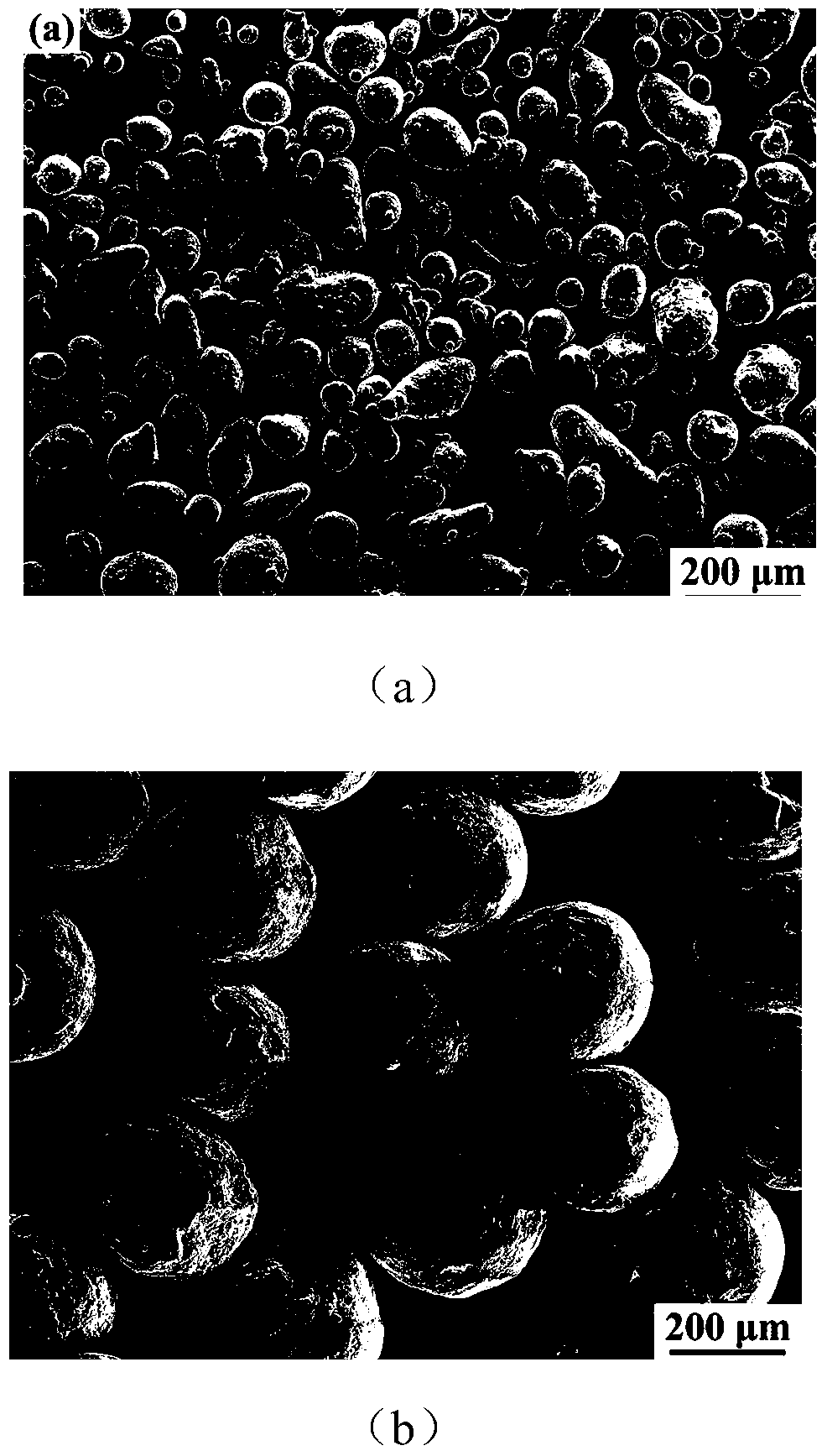

[0040] 1100Al powder with a particle size of 10-50 μm is used as the spraying material, and 316 stainless steel particles with a particle size of 200-300 μm are used as hard particles. The hardness of 1100Al and 316 stainless steel is about 25HV and 274HV respectively. Such as figure 1As shown, (a) is aluminum powder; (b) is 316 stainless steel hard particles; 1100Al powder is spherical and ellipsoidal in shape, and 316 stainless steel hard particles are spherical in shape. 40vol.% of hard particles were mechanically mixed with 1100Al powder as spray powder. AZ31 magnesium alloy is used as the base material, and the base is subjected to acetone ultrasonic cleaning and sandblasting surface roughening before spraying. Nitrogen was used as the working gas, and the gas pressure and gas temperature were set to 2.0 MPa and 200°C, respectively. The control sample is a coating prepared with pure 1100Al powder under the same spraying parameters.

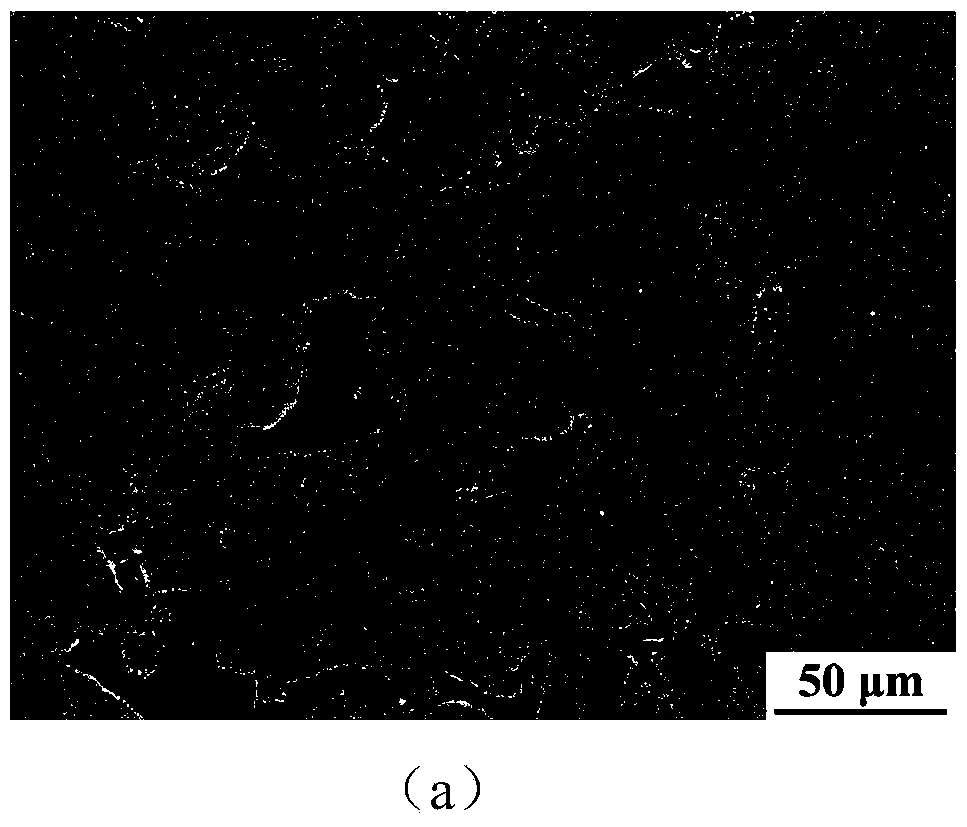

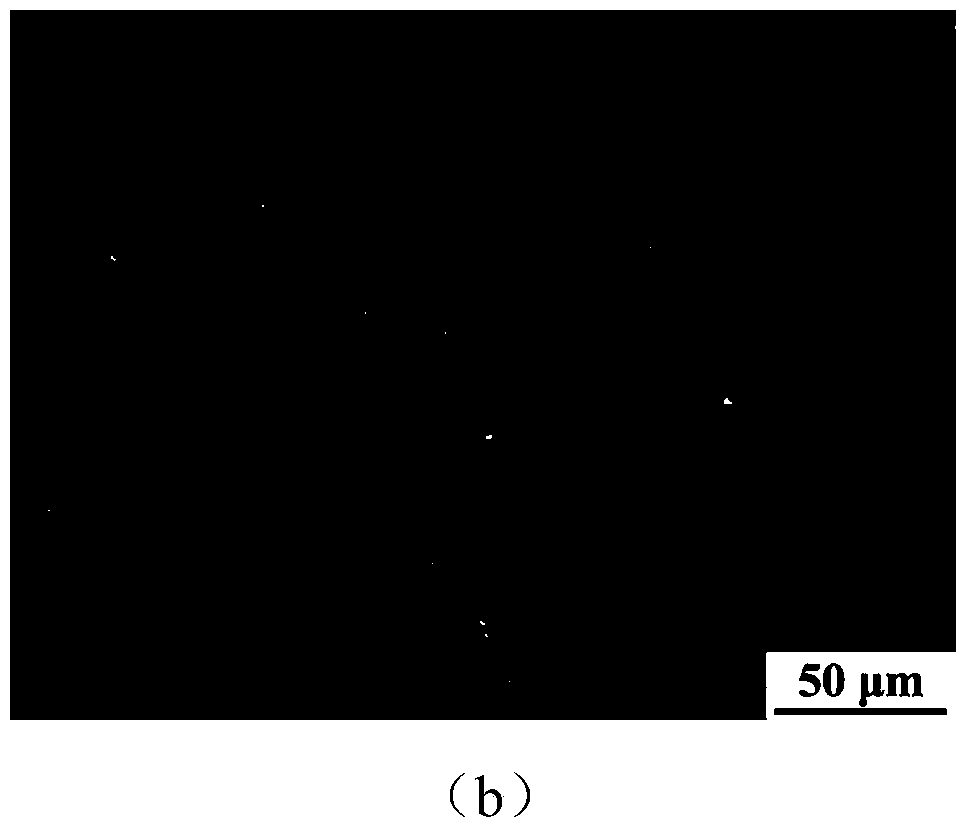

[0041] The cross-sectional structu...

Embodiment 2

[0044] Zn5%Al powder with a particle size of 15-50 μm is used as the spraying material, and 430 stainless steel particles with a particle size of 150-300 μm are used as hard particles. 50vol.% of hard particles were mechanically mixed with pure Al powder as spraying powder. AZ31 magnesium alloy is used as the base material, and the base is subjected to acetone ultrasonic cleaning and sandblasting surface roughening before spraying. Nitrogen was used as the working gas, and the gas pressure and gas temperature were set at 1.8 MPa and 250°C, respectively. The test results show that there are a lot of pores in the coating prepared by using a single Zn5%Al powder, and the image analysis results show that the porosity of the coating is as high as 10.7%. No obvious pores were found inside the Zn5%Al coating deposited by mixed powder, and the image analysis results showed that the porosity of the coating was only 0.4%. Electrochemical test results show that the self-corrosion poten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com