Electrostatic dust collector used for preform rod extending technology

An electrostatic precipitator and preformed rod technology, applied in the field of electrostatic precipitators, can solve problems such as unstable quality, and achieve the effects of reducing production costs, increasing cleanliness and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

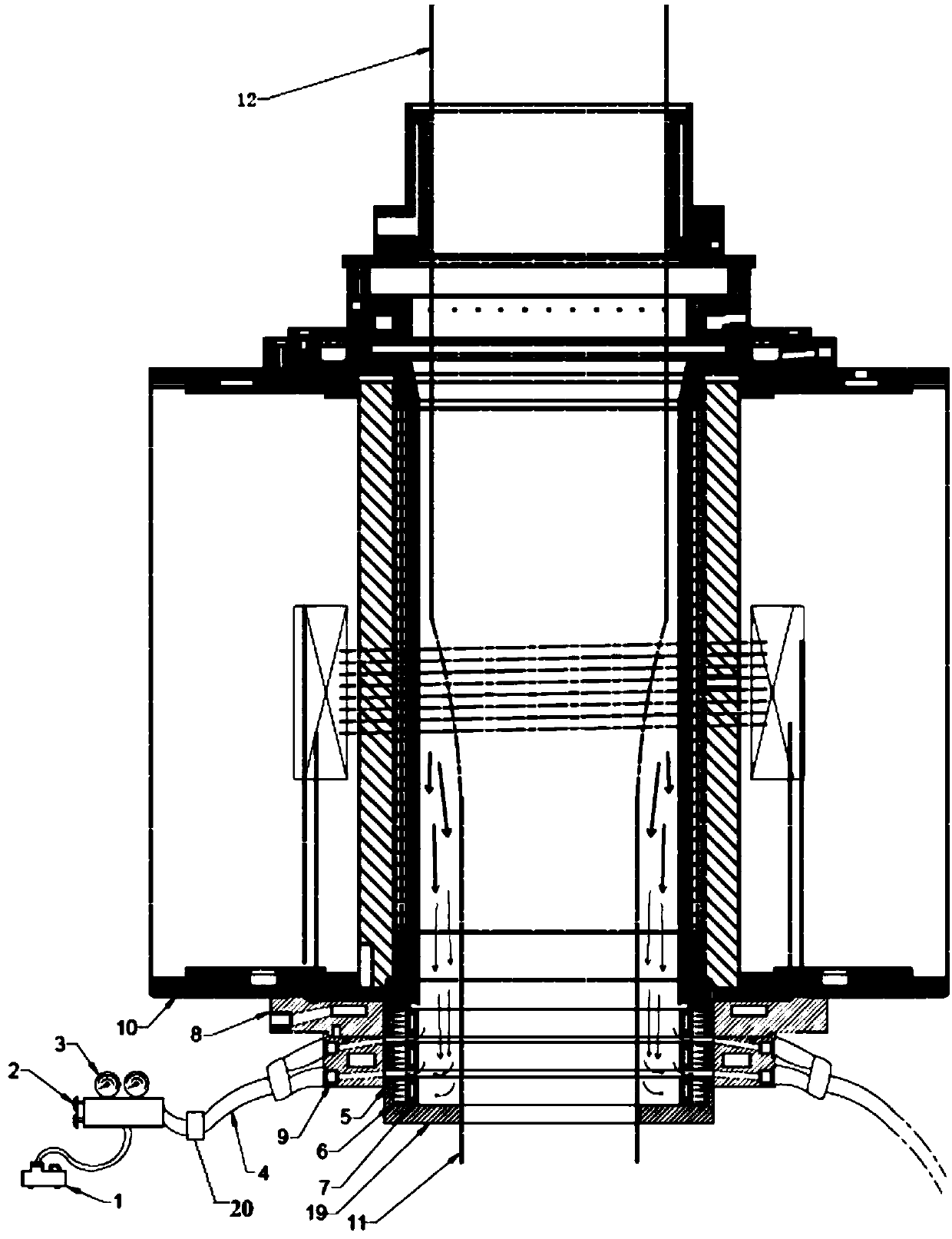

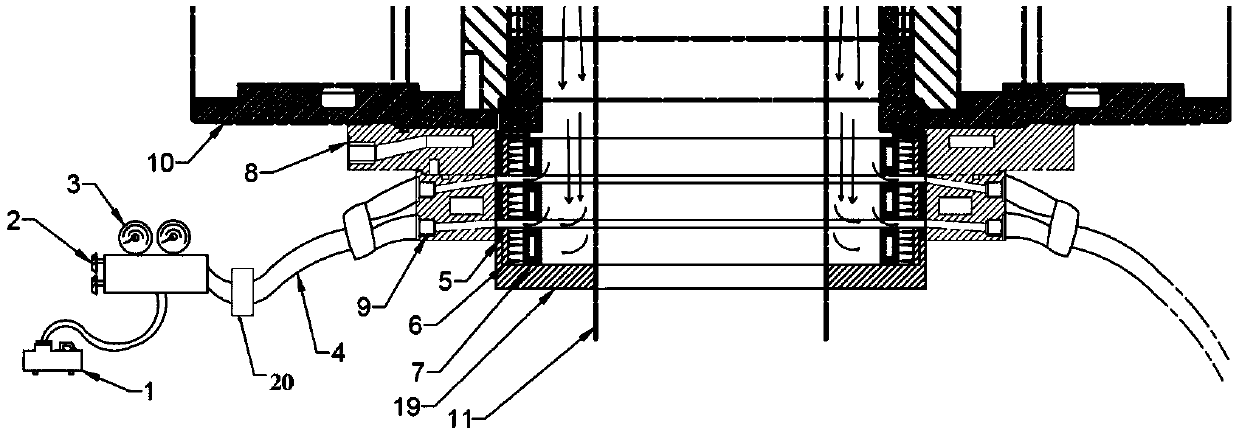

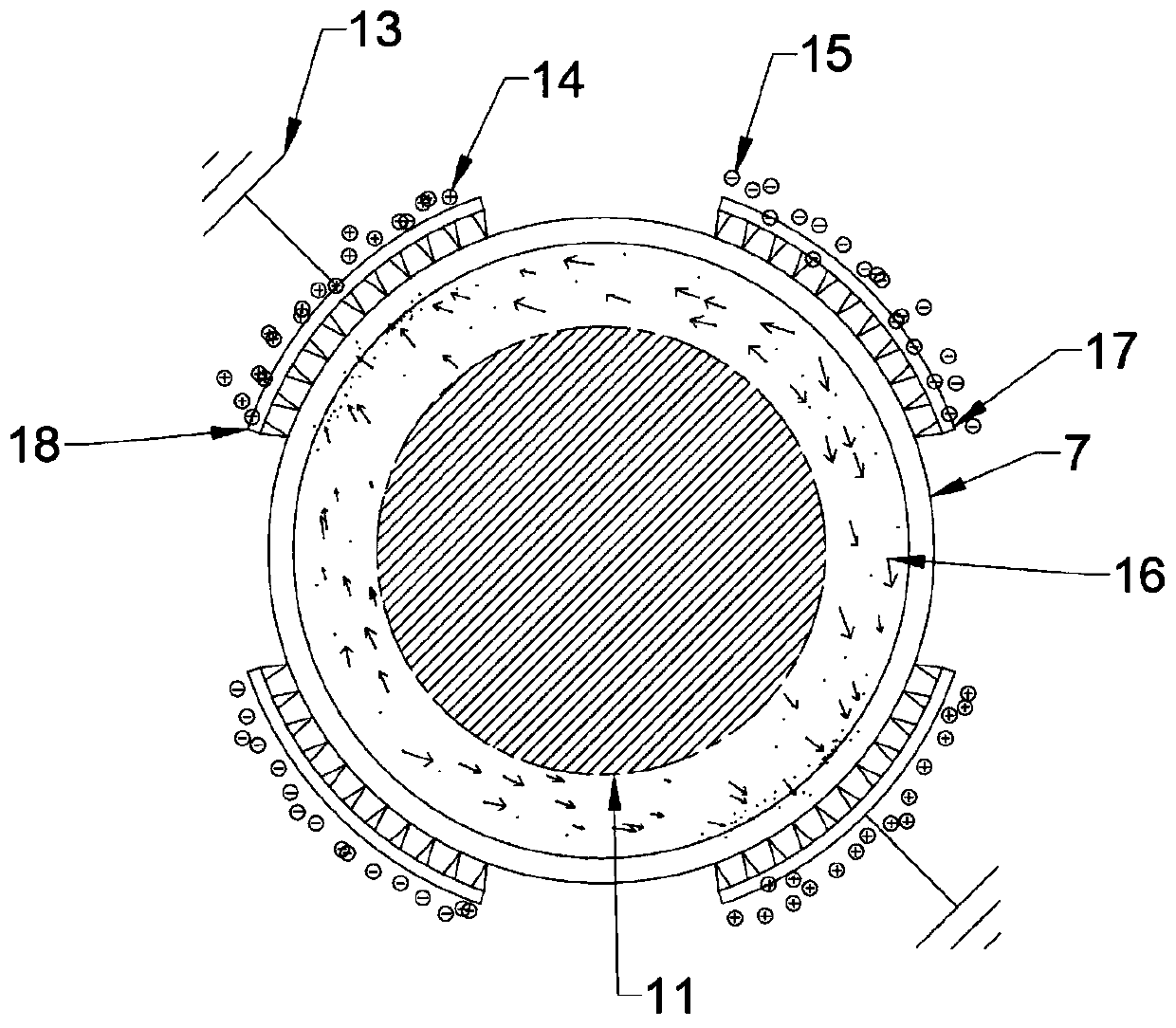

[0030] Such as figure 1 , figure 2 As shown, an electrostatic precipitator in the preform extension process, wherein the electrostatic precipitator is located at the outlet below the extension furnace 10, and the electrostatic precipitator has a first water-cooled plate 8 and a second water-cooled plate 9 outside; the electrostatic precipitator includes an electrostatic precipitator Field generating device and exhaust device, the electrostatic field generating device includes an electrode water cooling plate 7, an electrostatic field electrode plate 6, and an insulating component 5 arranged in sequence from the inside to the outside; Externally, the insulating part 5 is located between the electrostatic field plate 6 and the first water-cooled plate 8 and the second water-cooled plate 9; the exhaust device includes an exhaust pump 1, a control valve 2, a pressure gauge 3, an exhaust pipe 4 connected in sequence, and exhaust The air outlet of the gas pipeline 4 communicates w...

Embodiment 2

[0041] Such as figure 1 , figure 2 As shown, an electrostatic precipitator in the preform extension process, wherein the electrostatic precipitator is located at the outlet below the extension furnace 10, and the electrostatic precipitator has a first water-cooled plate 8 and a second water-cooled plate 9 outside; the electrostatic precipitator includes an electrostatic precipitator Field generating device and exhaust device, the electrostatic field generating device includes an electrode water cooling plate 7, an electrostatic field electrode plate 6, and an insulating component 5 arranged in sequence from the inside to the outside; Externally, the insulating part 5 is located between the electrostatic field plate 6, the first water cooling plate 8, and the second water cooling plate 9; The air outlet of the gas pipeline 4 communicates with the exhaust pump 1 , and the air inlet of the exhaust pipeline 4 communicates with the air hole on the electrode water cooling plate 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com