Locking coupling

A technology of couplings and components, applied in the direction of couplings, mechanical equipment, etc., can solve problems such as loosening of fixed parts, and achieve the effect of avoiding leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

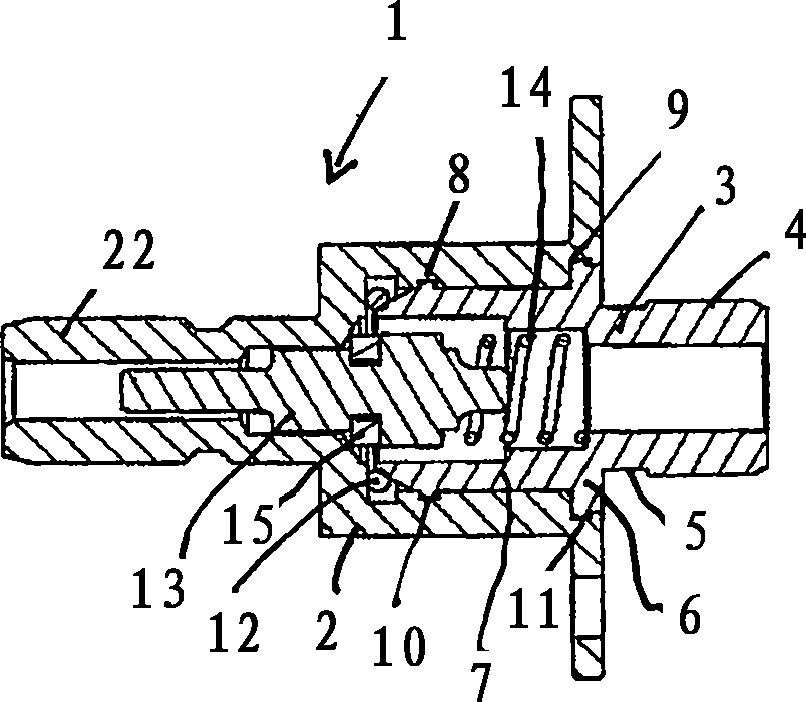

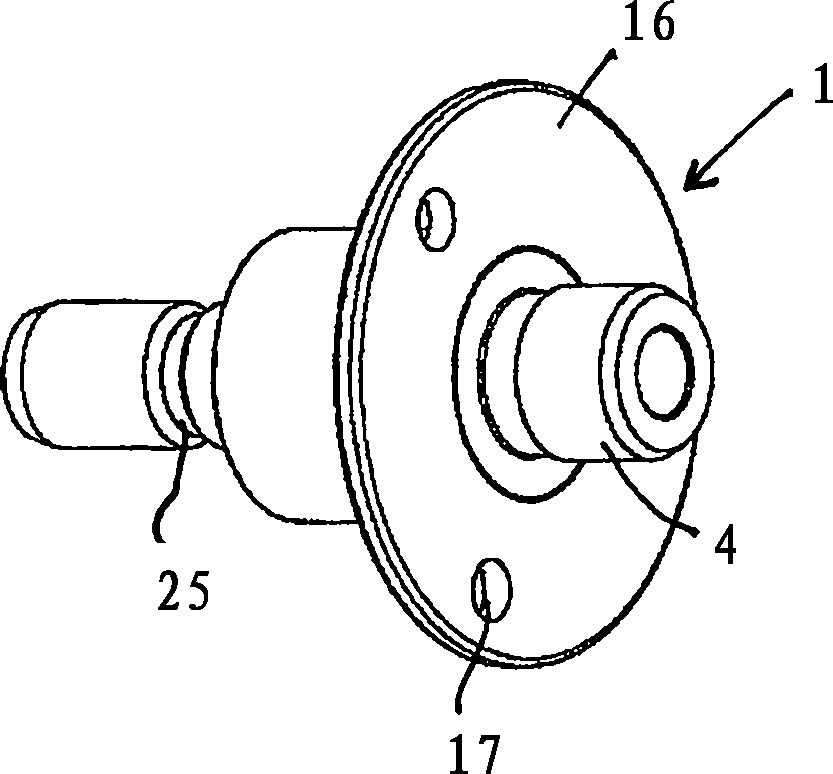

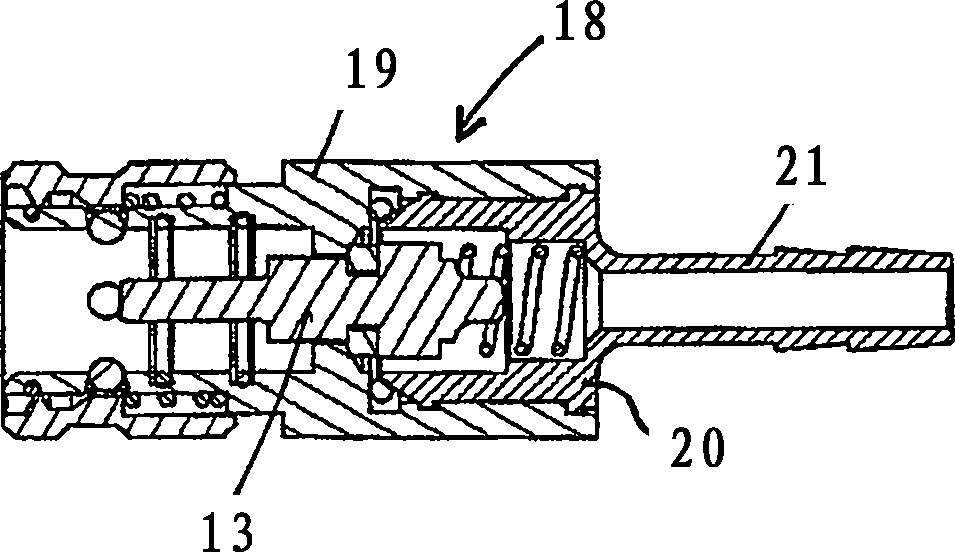

[0027] exist Figure 1a and 1b The nipple parts shown in are generally designated with the reference number 1 . It is composed of a nipple element 2 and a closure 3 which is inserted into the nipple element 2 . On its free end section, the closure element 3 comprises a threaded section 4 or else a smooth cylinder which merges behind the constriction 5 into the flange-like projection 6 . This is followed by a segment with a smooth cylindrical peripheral surface, which has an outer annular bead 8 near its free end. Flange 6 likewise includes an annular projection 9 on its outer circumference.

[0028] Figure 1a and 1b The locked state of the locking element 3 into the nipple element 2 is shown. For this purpose, annular grooves 10 and 11 are formed at corresponding positions on the inner surface of the inner connection element 2 , into which annular projections 8 and 9 snap into place elastically. It is to be understood here that the locking element 3 and the connector ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com