A processing method for a diesel engine valve seat

A processing method and technology of valve seats, which are applied in the manufacturing process of diesel engine valve seats, can solve problems such as high production costs, affecting equipment operation, and low bonding strength, so as to reduce production and manufacturing costs, improve product qualification rate, increase The effect of binding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

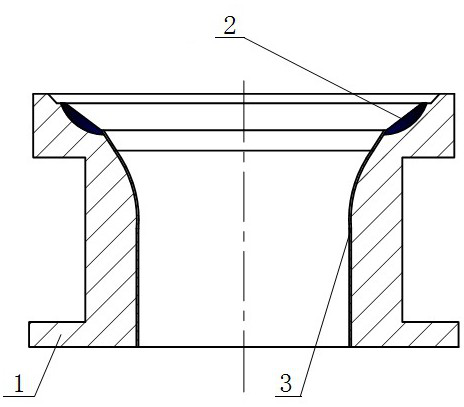

Image

Examples

Embodiment 1

[0032] Embodiment 1, a method for processing a diesel engine valve seat, which includes the following steps.

[0033] 1) Surfacing welding on the cone surface, the cone surface of the inner hole of the diesel engine valve seat is subjected to surfacing welding, and the surfacing layer is obtained on the cone surface of the inner hole, and then the flaw detection is carried out.

[0034] 2) Spraying, flame-spray the inner hole of the valve seat of the diesel engine with nickel-based alloy powder, first clean the valve seat with acetone or alcohol to remove rust or burrs on the base of the valve seat, and then use 0.3Mpa compressed air and 200μm quartz sand For the inner hole of the jet valve seat, the surface roughness Ra of the inner hole to be sprayed is 3.3 μm, and then the air valve seat is cleaned with clean 0.2 MPa compressed air, and finally sprayed. The specific process parameters are: first, the diesel engine gas The valve seat is preheated to 105°C, then fixed on the ...

Embodiment 2

[0042] Embodiment 2, a method for processing a diesel engine valve seat, which includes the following steps.

[0043] 1) Surfacing welding on the cone surface, the cone surface of the inner hole of the diesel engine valve seat is subjected to surfacing welding, and the surfacing layer is obtained on the cone surface of the inner hole, and then the flaw detection is carried out.

[0044] 2) Spraying, flame-spray the inner hole of the valve seat of the diesel engine with nickel-based alloy powder, first clean the valve seat with acetone or alcohol to remove rust or burrs on the base of the valve seat, and then use 0.35Mpa compressed air and 160μm quartz sand For the inner hole of the jet valve seat, the surface roughness Ra of the inner hole to be sprayed is 3.2μm, and then the air valve seat is cleaned with clean 0.14MPa compressed air, and finally the spraying treatment is carried out. The specific process parameters are: first, the diesel engine gas The valve seat is preheate...

Embodiment 3

[0052] Embodiment 3, a method for processing a diesel engine valve seat, which includes the following steps.

[0053] 1) Surfacing welding on the cone surface, the cone surface of the inner hole of the diesel engine valve seat is subjected to surfacing welding, and the surfacing layer is obtained on the cone surface of the inner hole, and then the flaw detection is carried out.

[0054] 2) Spraying, flame-spray the inner hole of the valve seat of the diesel engine with nickel-based alloy powder, first clean the valve seat with acetone or alcohol to remove rust or burrs on the base of the valve seat, and then use 0.34Mpa compressed air and 190μm quartz sand For the inner hole of the jet valve seat, make the surface roughness Ra of the inner hole to be sprayed be 3.3 μm, then use clean 0.14MPa compressed air to clean the air valve seat, and finally carry out spraying treatment. The specific process parameters are: first, the diesel engine gas The valve seat is preheated to 80°C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com