Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Reduce cold flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing process of polytetrafluoroethylene composite elastic body shim and product thereof

The invention relates to the production of politef multiple elastic cushion, which mainly solves the issues of poor elasticity and strength of the politef production, with smooth surface and good sealing performance. It uses glue smelting, pre compression forming, machining the politef cushion using lathe machine tools, overall surface activation, applying sticking glue, sticking the rubber cushion and the politef shell, sulfur forming, and trimming to get the final product. The cushion comprises rubber cushion coated with politef shell with several protruding waterlines.

Owner:浙江国泰萧星密封材料股份有限公司

Functionalized diene elastomer, and rubber composition containing same

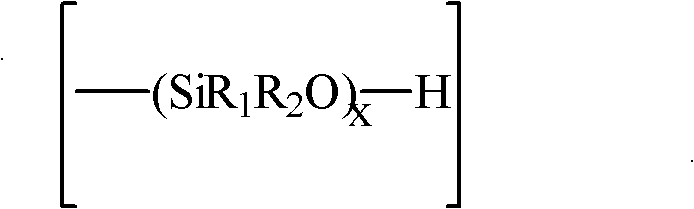

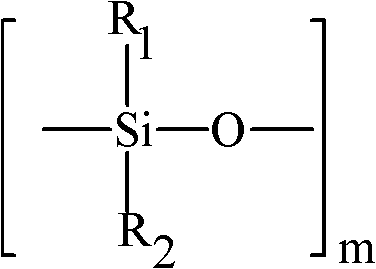

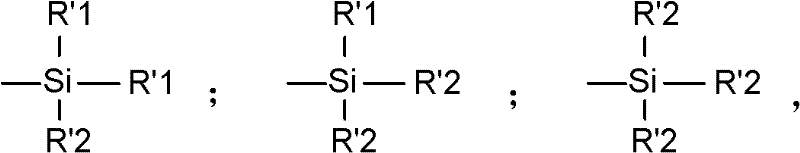

The present invention relates to a specific functionalized diene elastomer. Said functionalized elastomer has a reduced cold flow without weakening the properties of a reinforced rubber composition containing same, in particular the implementation properties and hysteretic properties. Said functionalized diene elastomer has, at a chain end, a silanol function or a polysiloxane block having a silanol end and is partially coupled or studded with tin.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Hygroscopic antibacterial hydrocolloid dressing and preparation method thereof

InactiveCN106729961AImprove mechanical propertiesGood flexibilityBandagesBiopolymerAntibacterial property

The invention belongs to the field of medical biopolymer materials and particularly relates to a hygroscopic antibacterial hydrocolloid dressing and a preparation method thereof. The preparation method comprises the steps of burdening, extruding, secondary extrusion, injection molding and ageing molding in sequence to prepare a hygroscopic antibacterial hydrocolloid dressing product. The preparation technology is simple and easy to process and massive production is easy to implement; the prepared hygroscopic antibacterial hydrocolloid dressing is capable of absorbing a lot of seepage and creating a humid microenvironment for wound healing; meanwhile, the contained sodium alginate and quaternized carboxymethyl chitosan are fully mixed and then form more hydrogen bonds, so that the gelatinization reaction is strengthened, the hydrocolloid dressing is capable of keeping relatively good integrity after absorbing a lot of wound seepage, is not sticky to a wound and has certain elasticity, antibacterial property and autohension; the comfort level of a patient is improved; and healing of the wound is accelerated.

Owner:GUANGDONG TAIBAO MEDICAL DEVICE TECH RES INST CO LTD

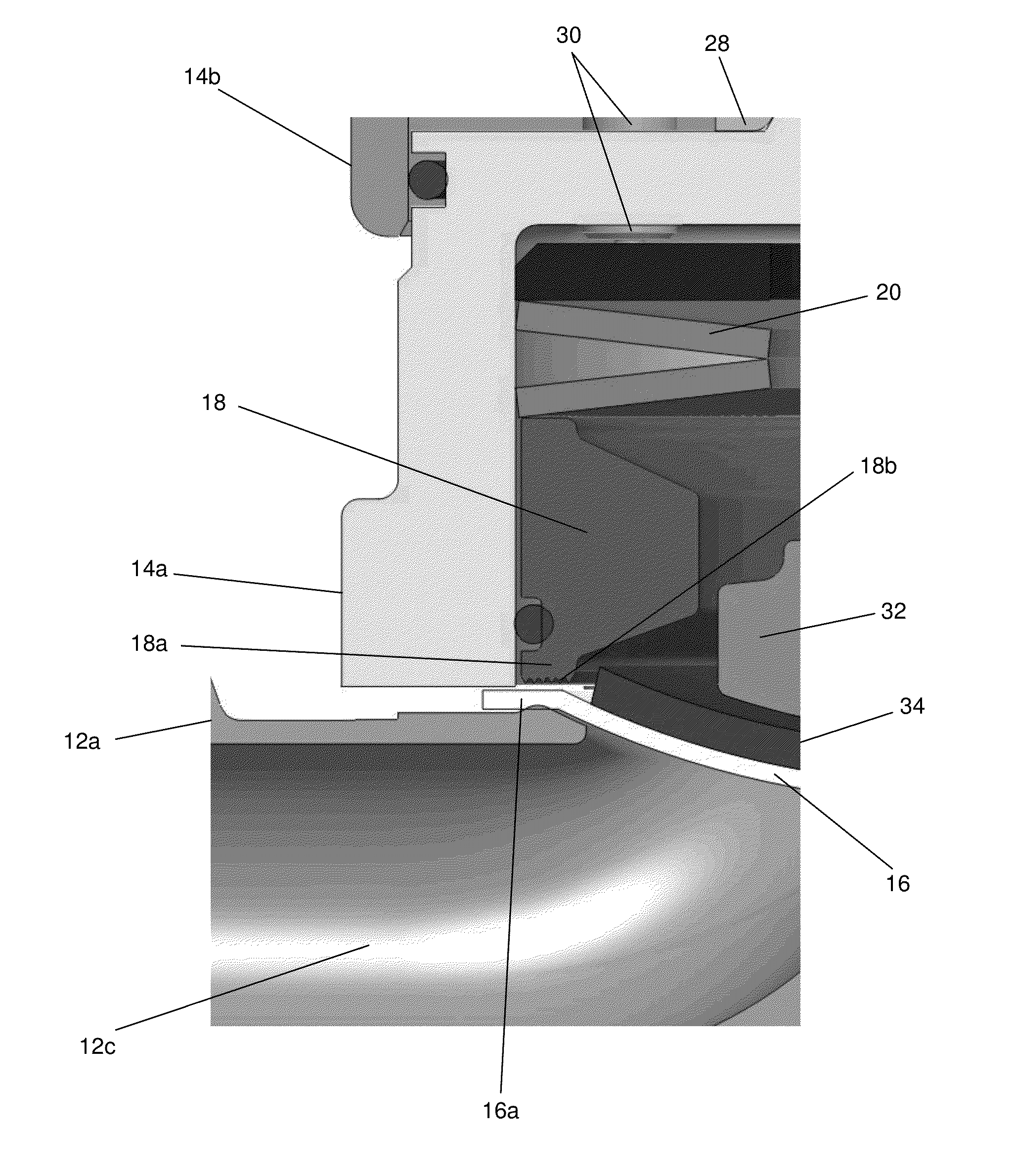

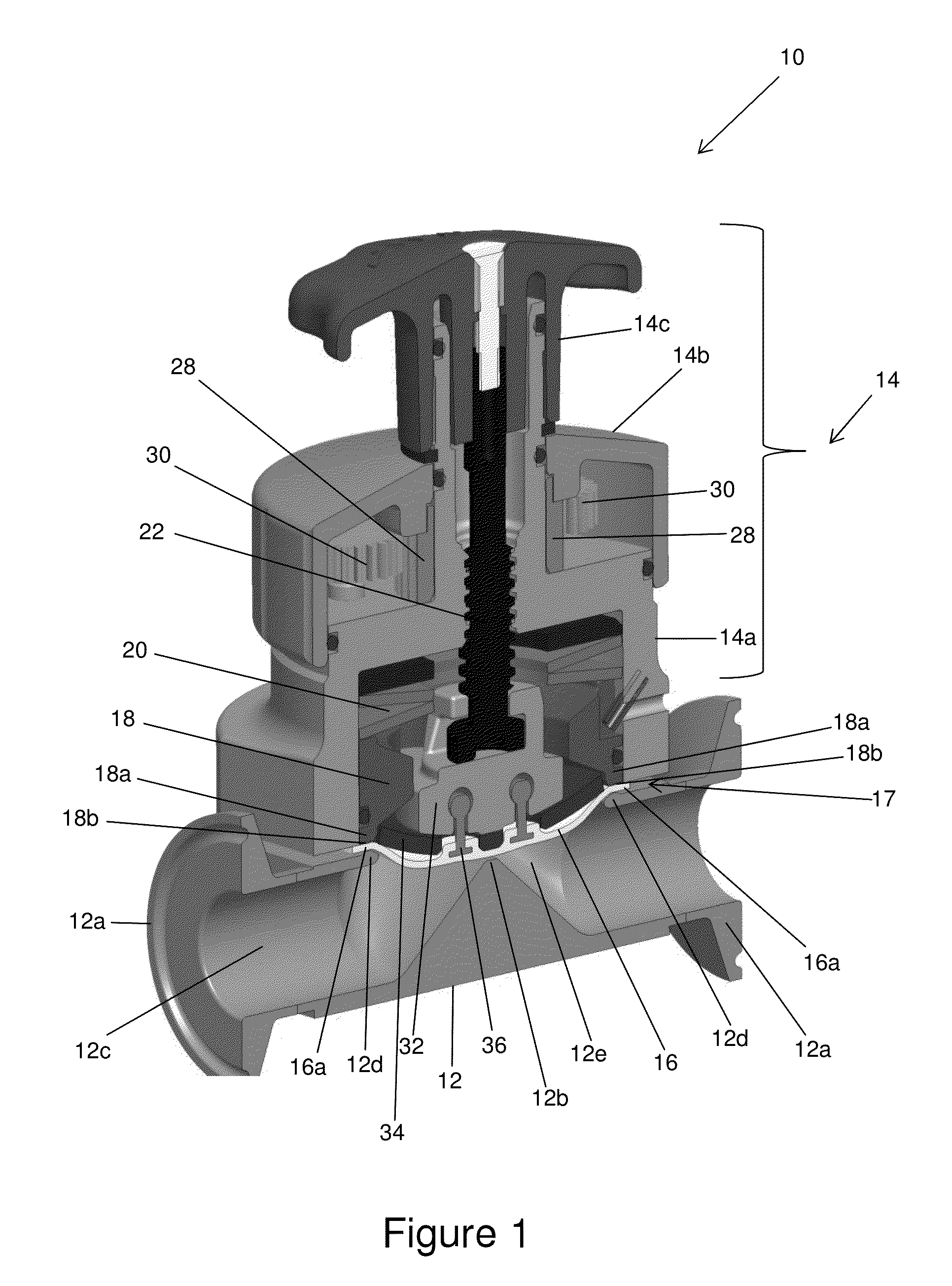

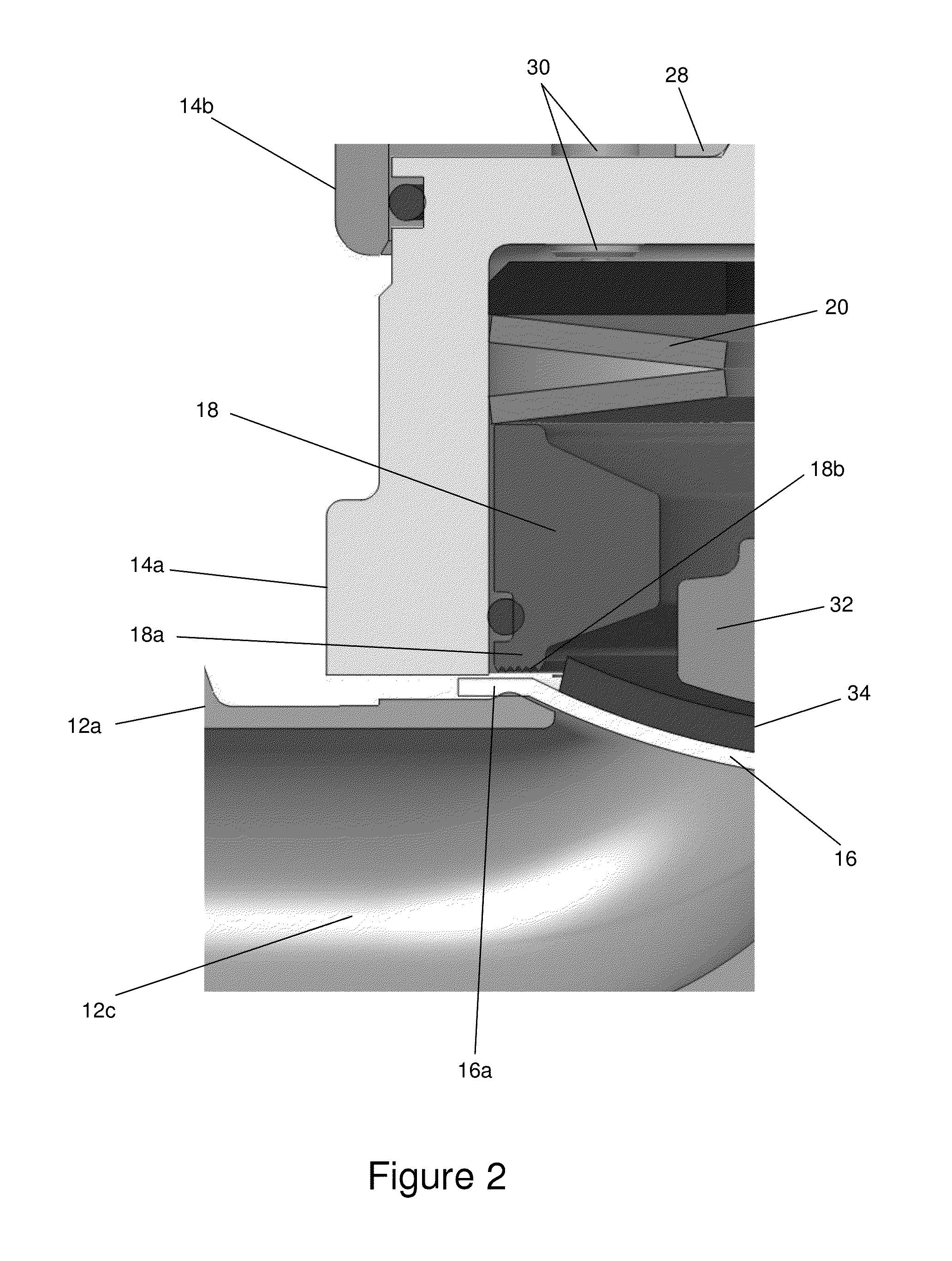

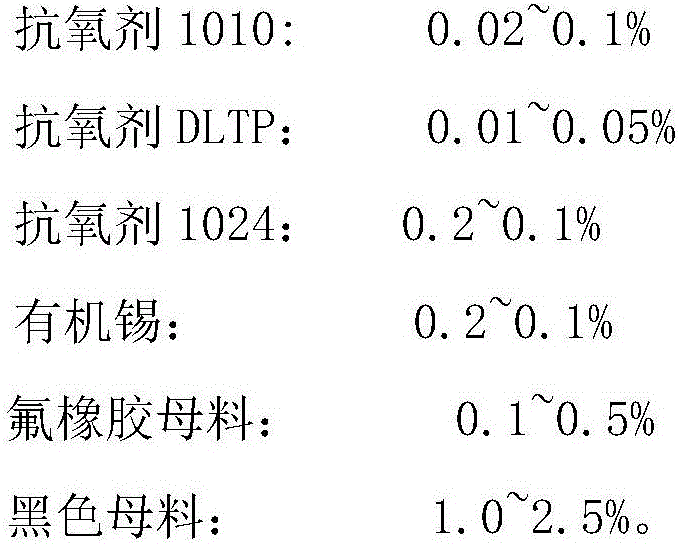

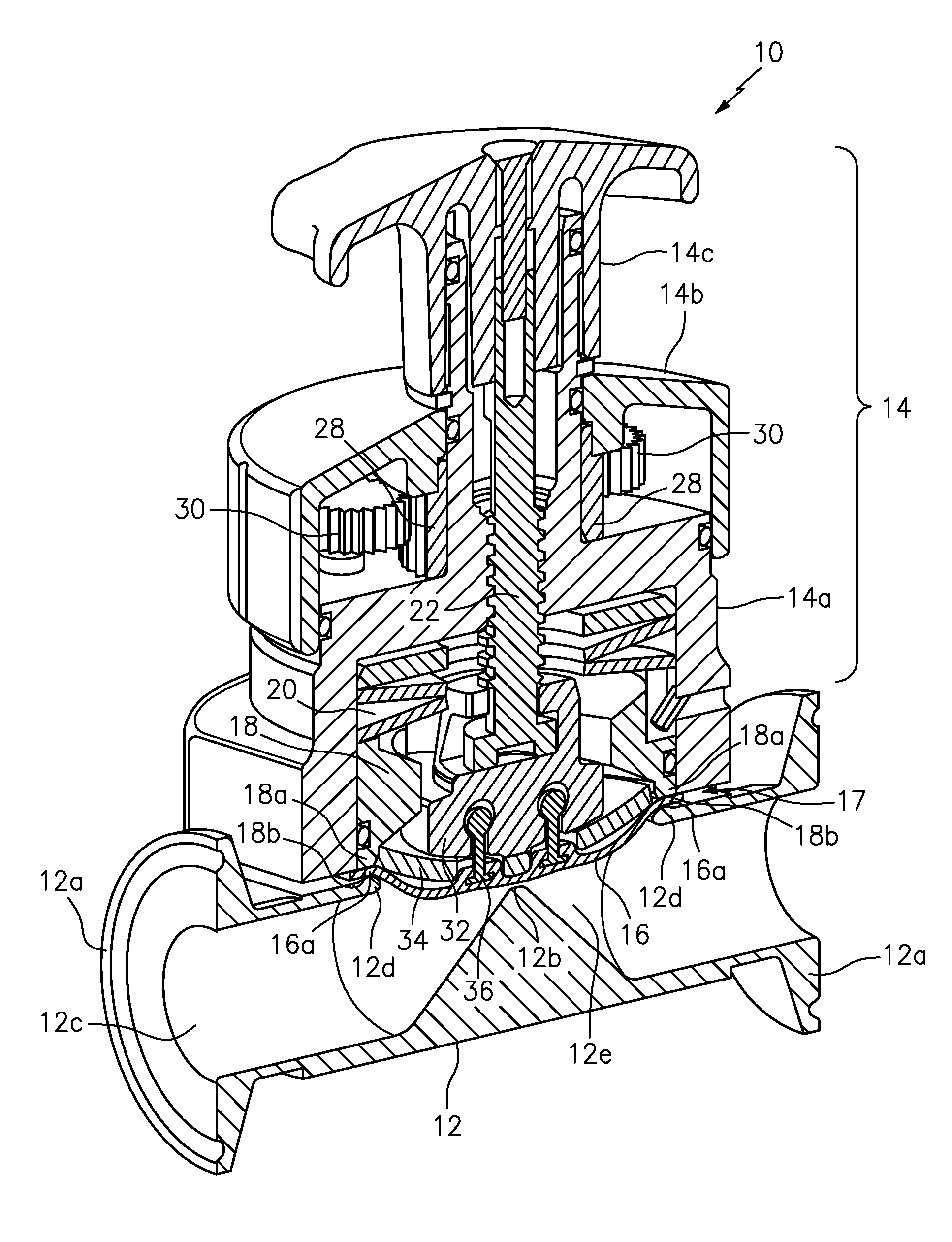

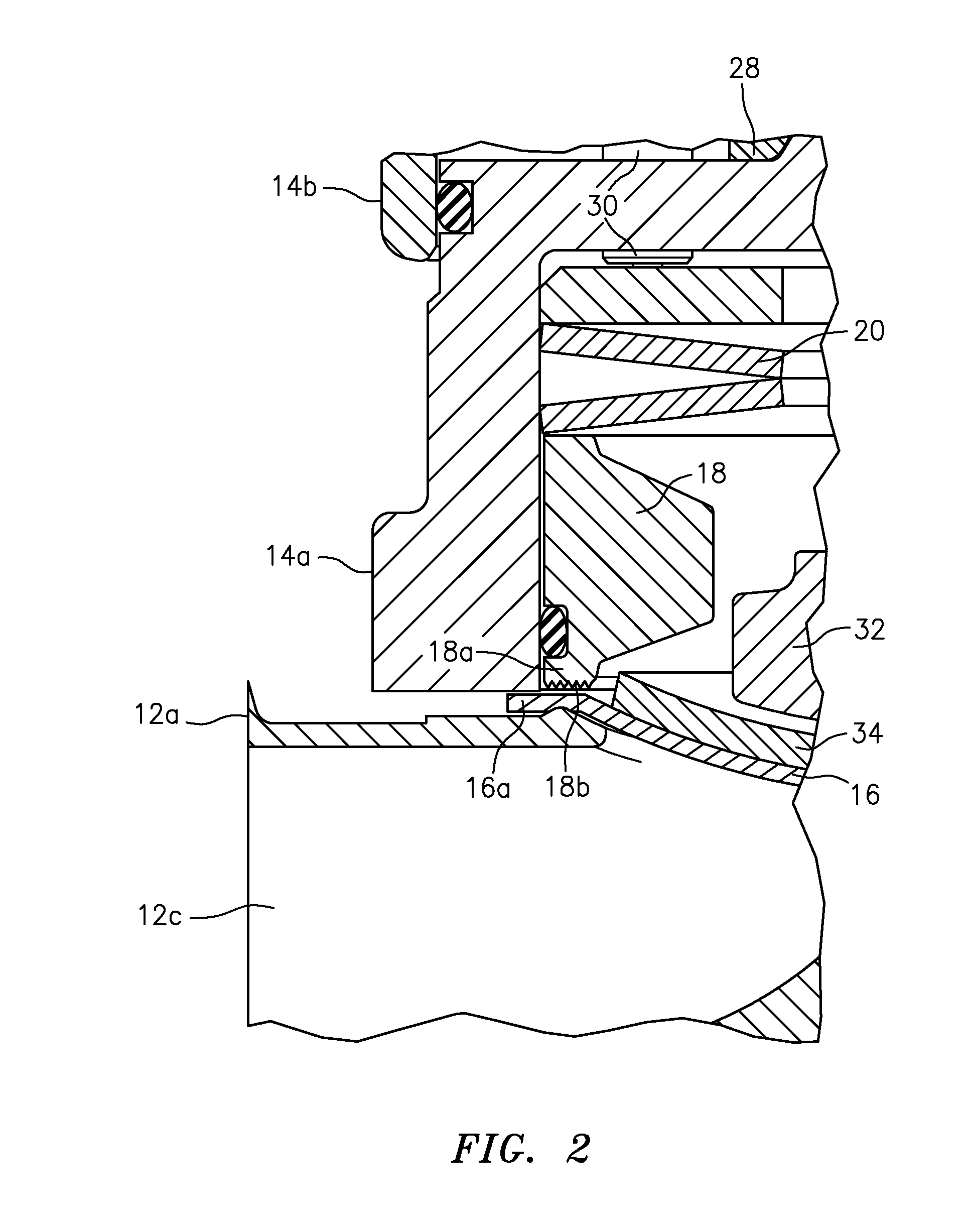

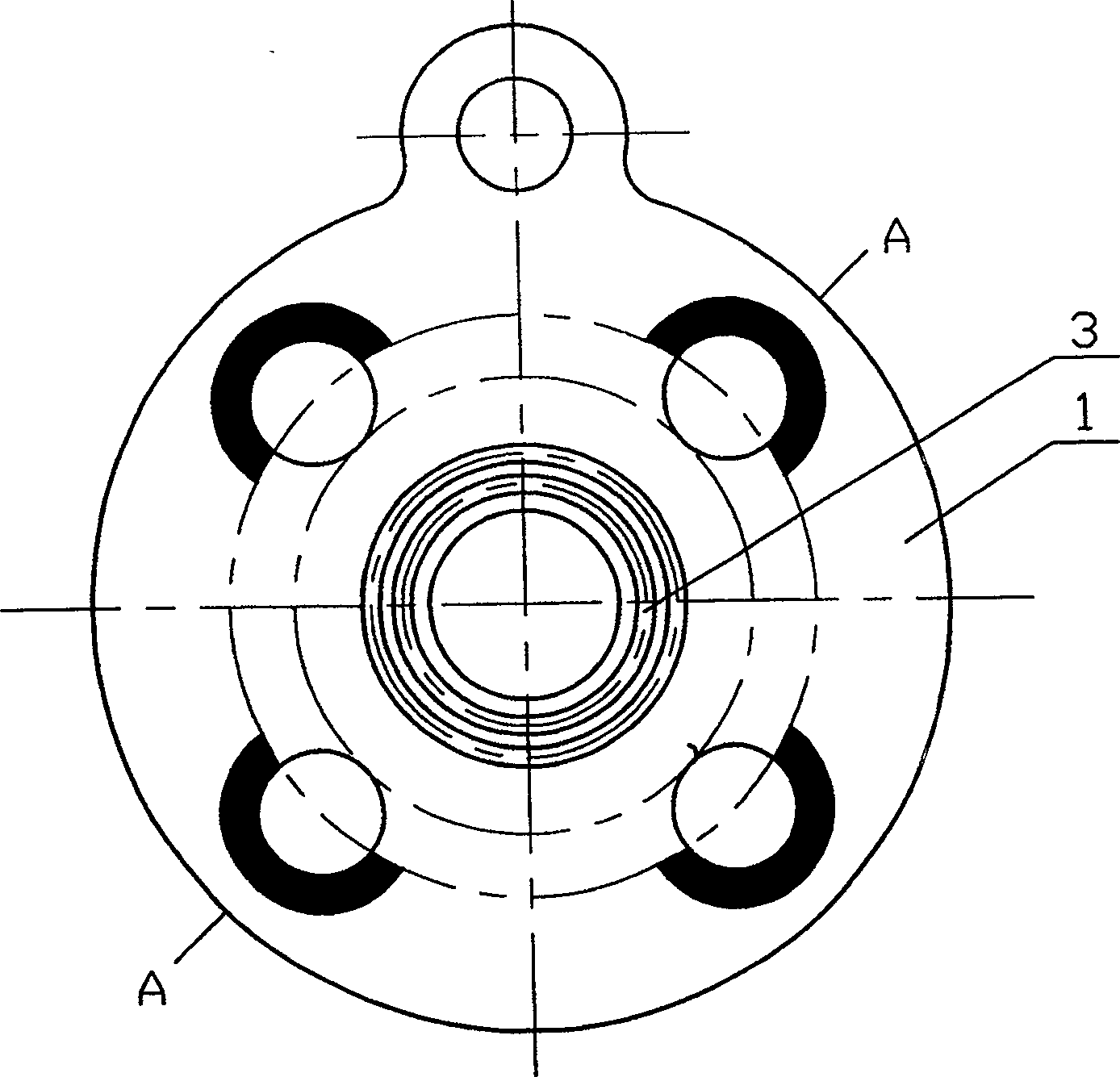

Temperature compensating flanged joint for a teflon diaphragm valve

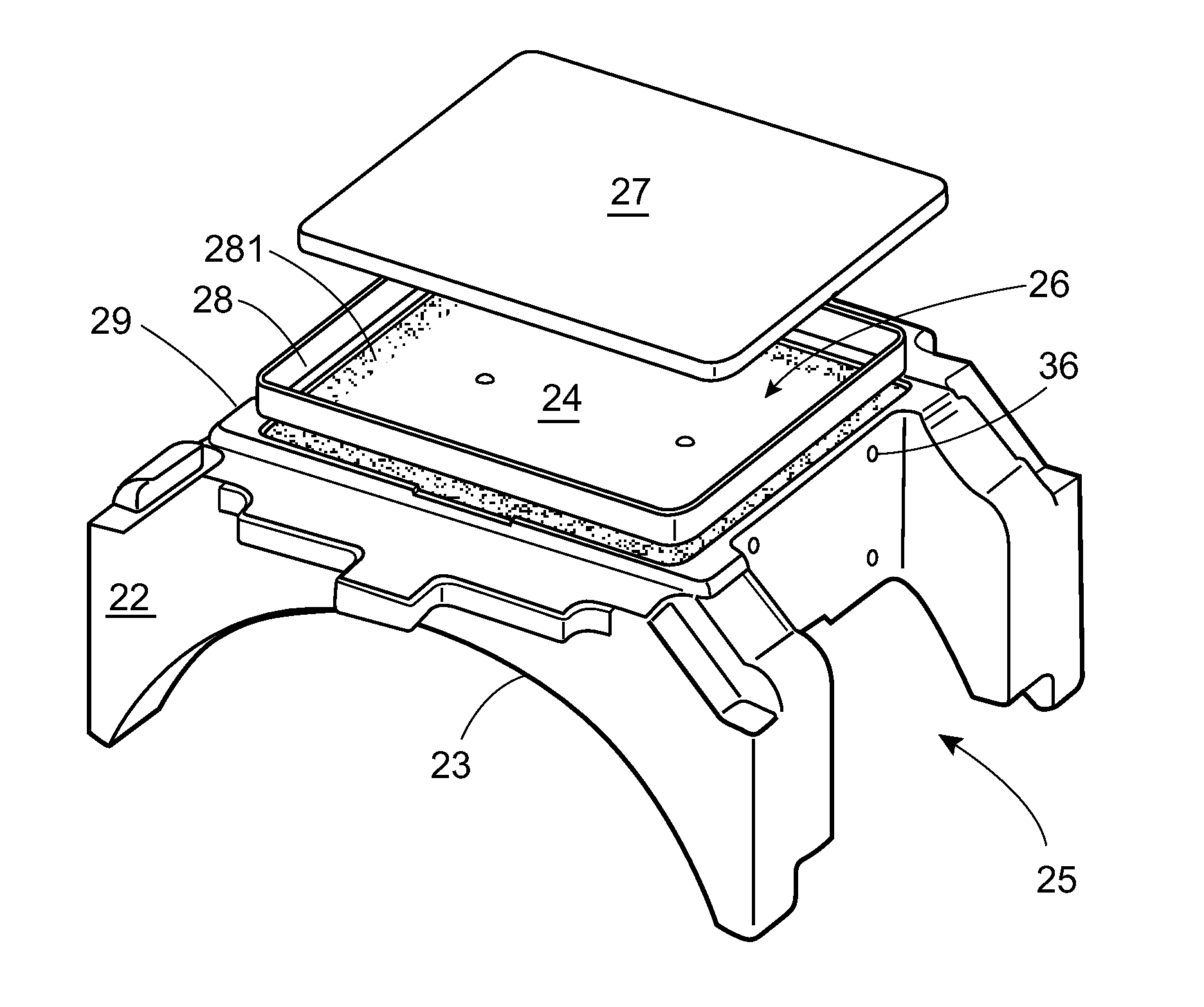

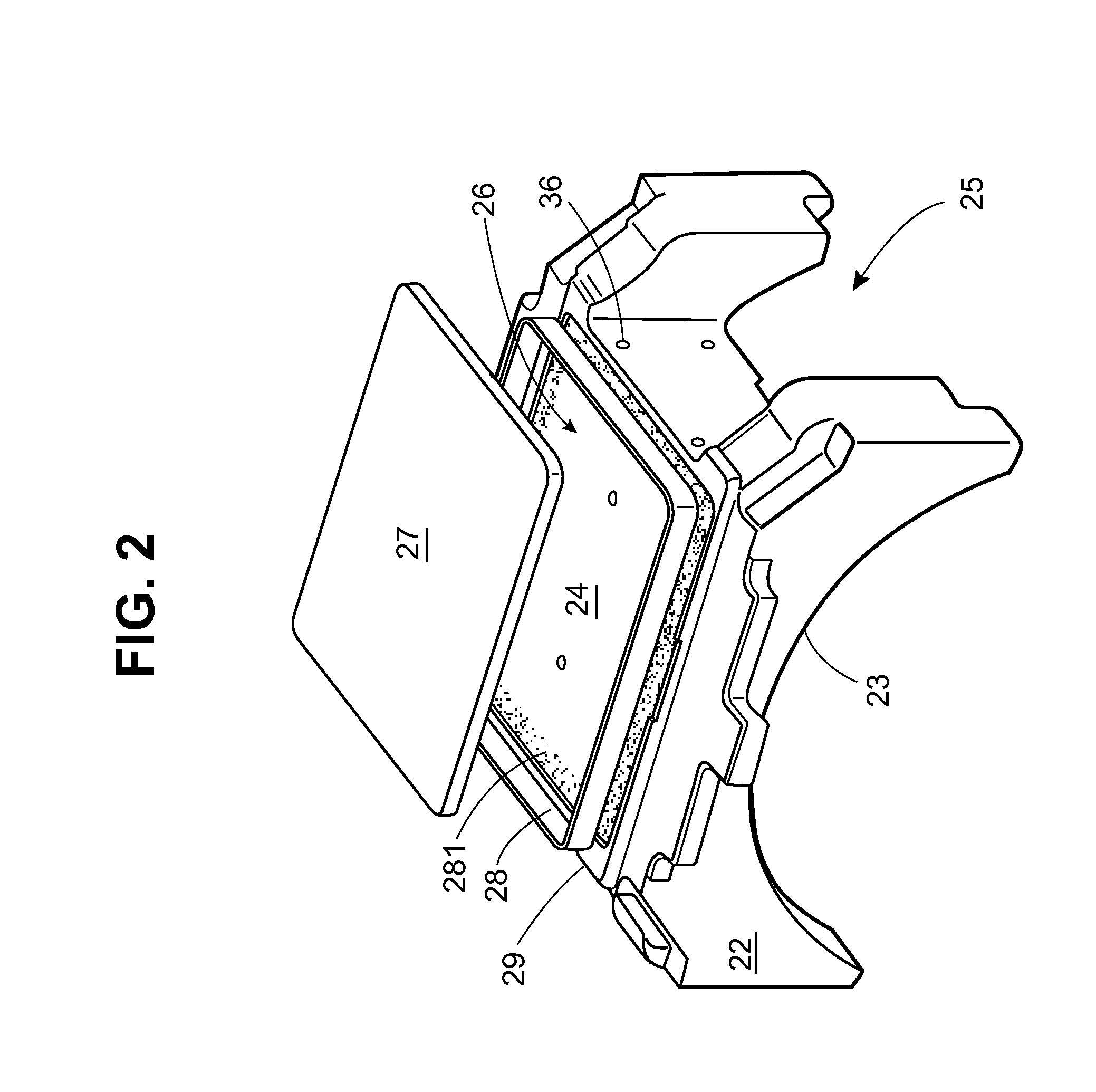

ActiveUS20140021391A1Constant sealing forcePrevent radial movementPlug valvesDiaphragm valvesEngineeringDiaphragm valve

Apparatus, including a diaphragm valve, is provided featuring a valve body, a diaphragm, a pressure ring, and at least one elastomeric member. The valve body may include a circumferential flange. The diaphragm may include a circumferential gasket portion configured to be seated on the circumferential flange so as to form a joint between the valve body and the diaphragm. The pressure ring may include concentric fluctuations, and may be configured to apply a sealing force against the joint so that the concentric fluctuations prevent radial movement of the circumferential gasket portion and the circumferential flange. The elastomeric member may be configured to respond to a compressive force and provide a substantially constant sealing force, transmitted through the pressure ring, regardless of small variations in the thickness or material dimensions of the circumferential gasket portion caused by temperature fluctuation or material flow and age.

Owner:ITT MFG ENTERPRISES LLC

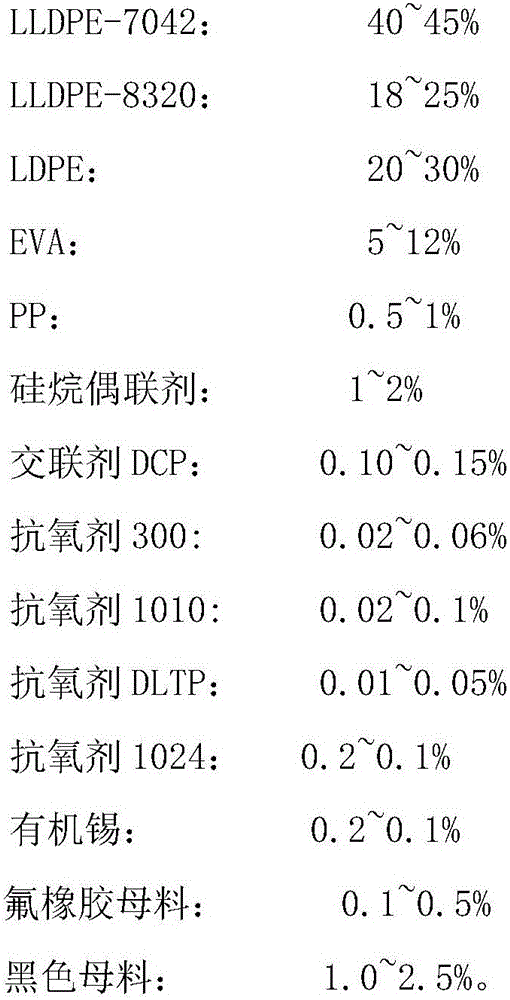

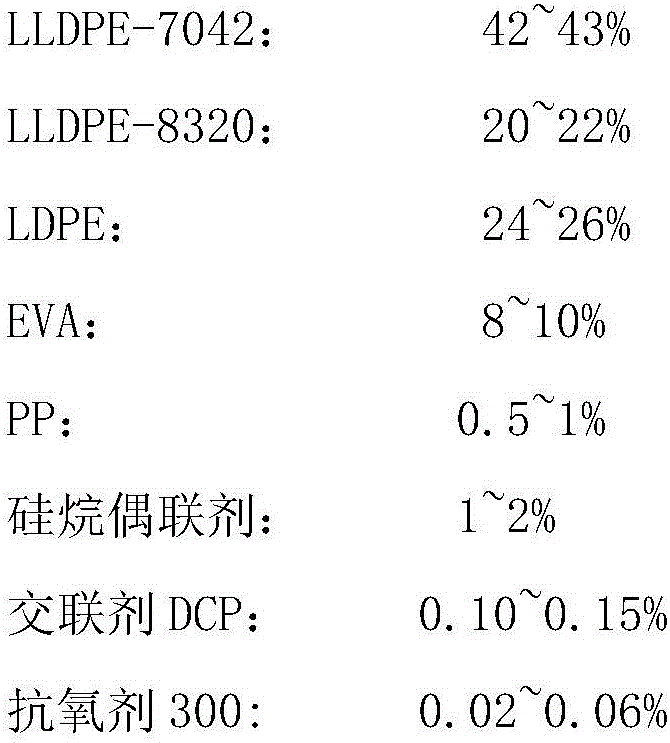

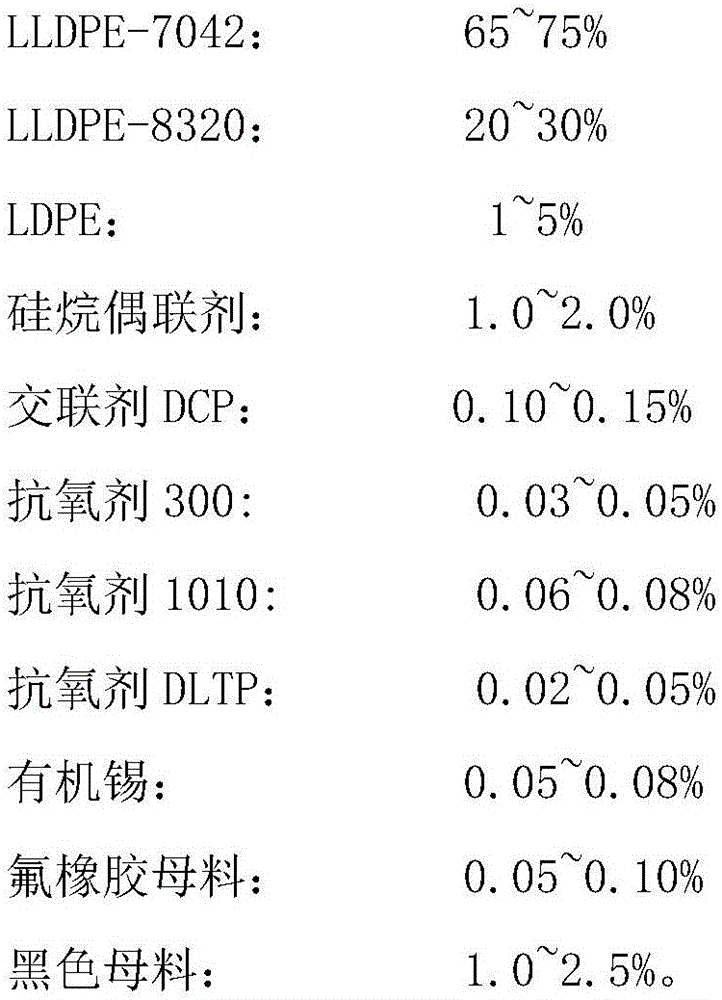

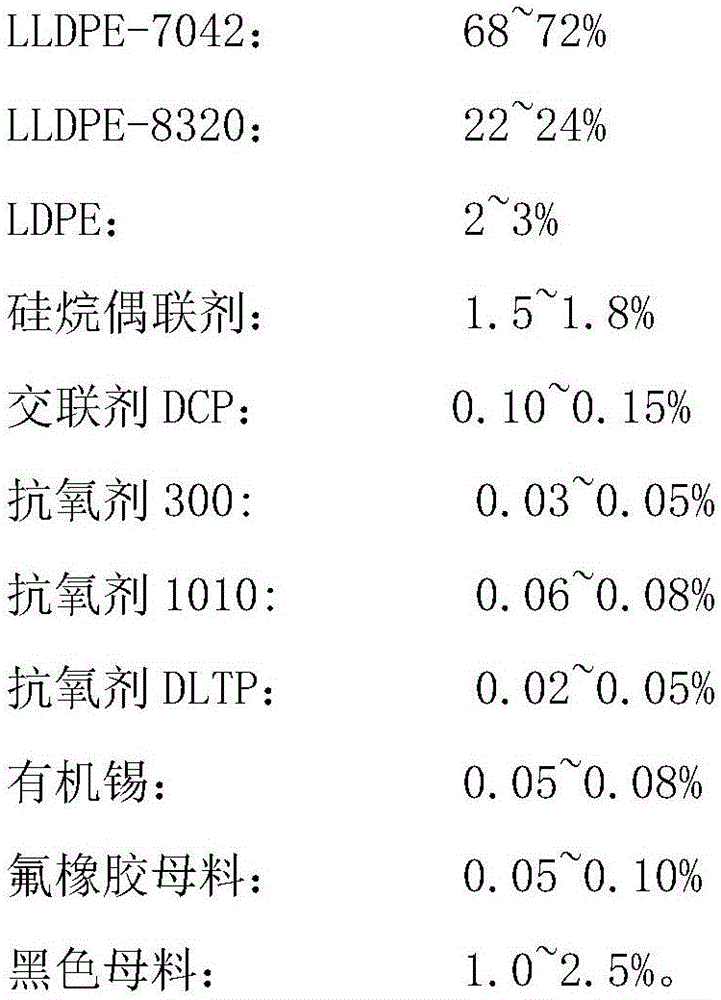

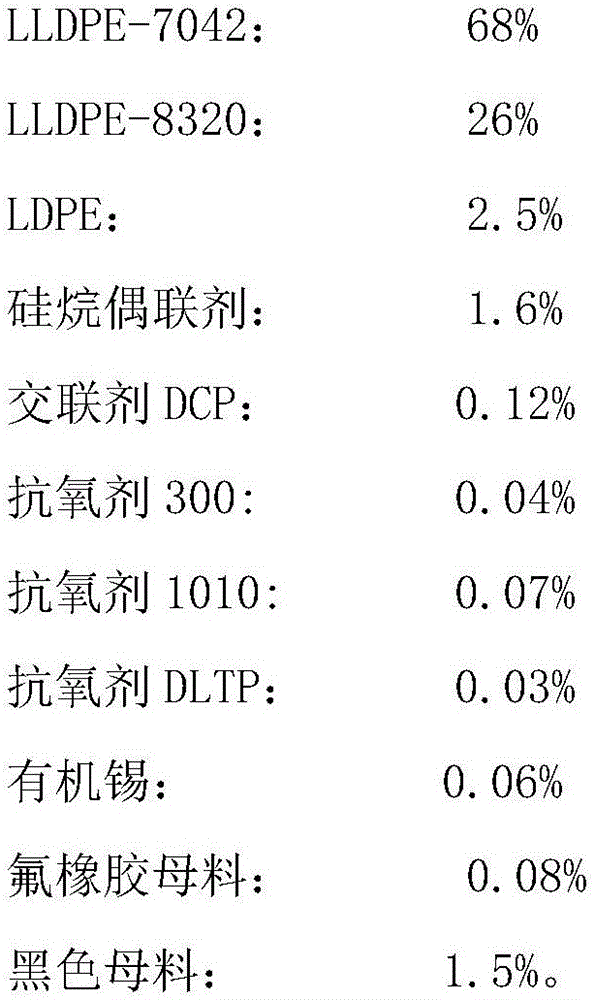

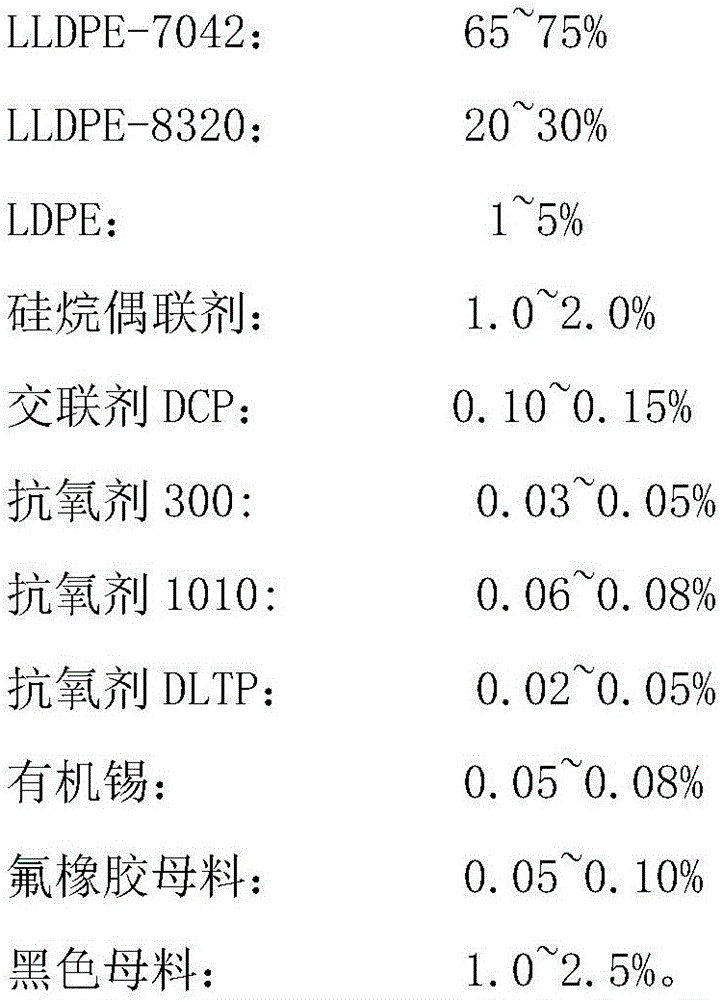

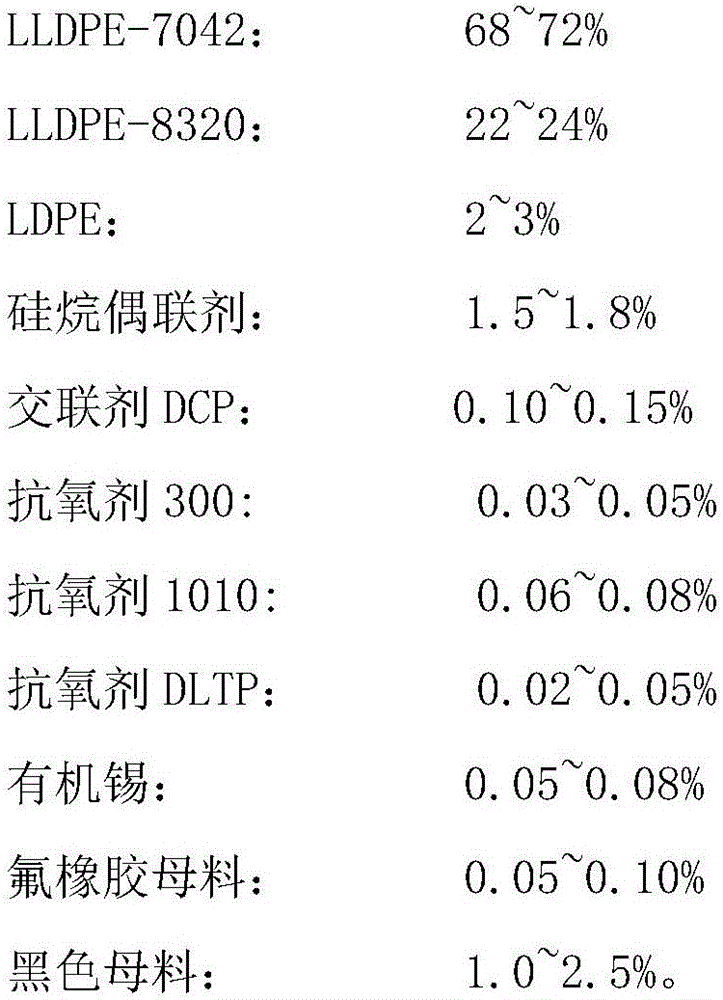

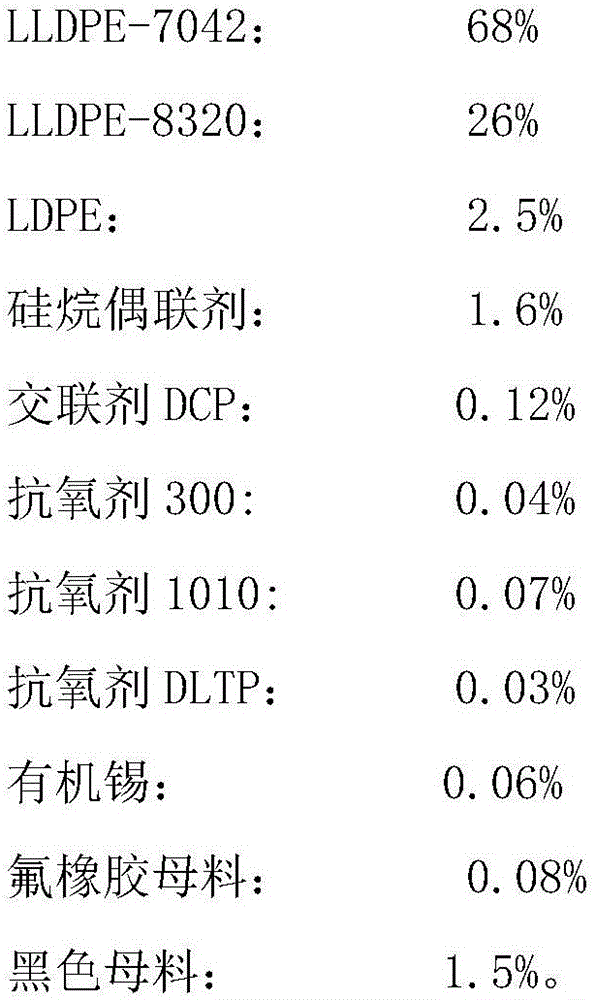

Method for preparing silane crosslinking polyethylene insulating material for 10 kV or below black wires and cables through one step

InactiveCN106009224AImprove insulation performanceStable speedPlastic/resin/waxes insulatorsCross-linkSilanes

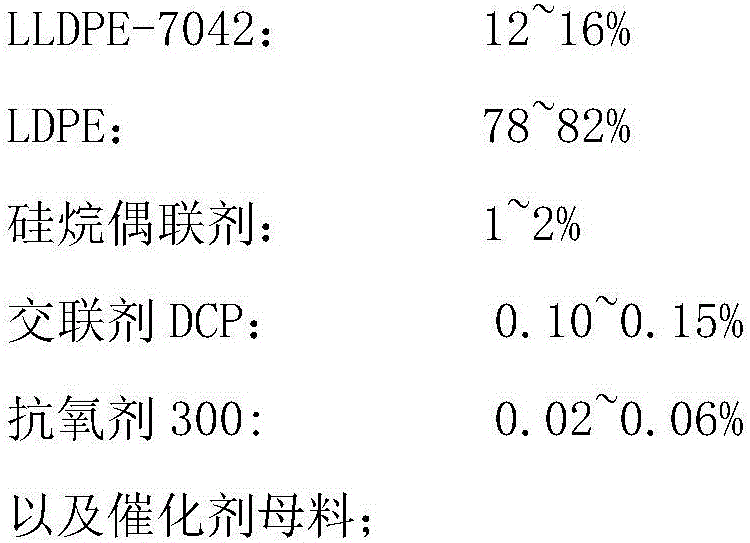

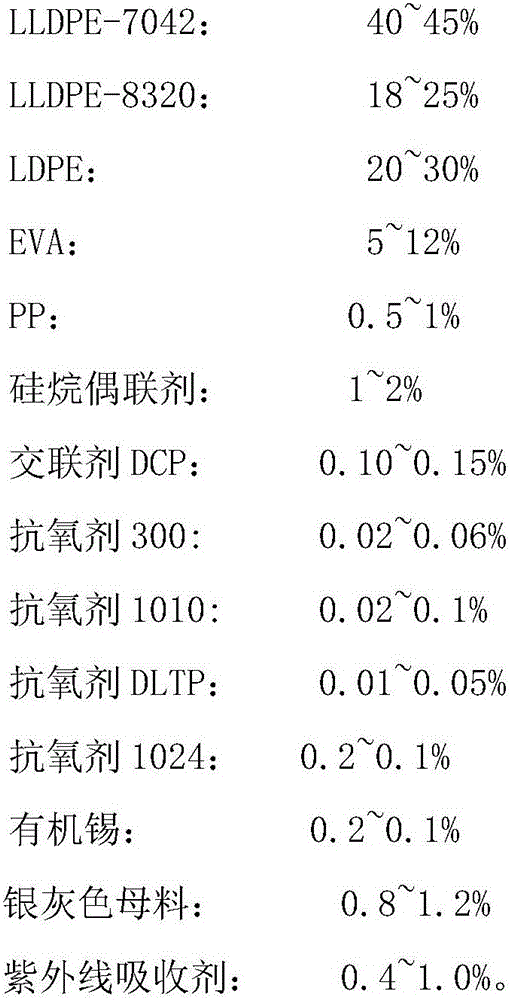

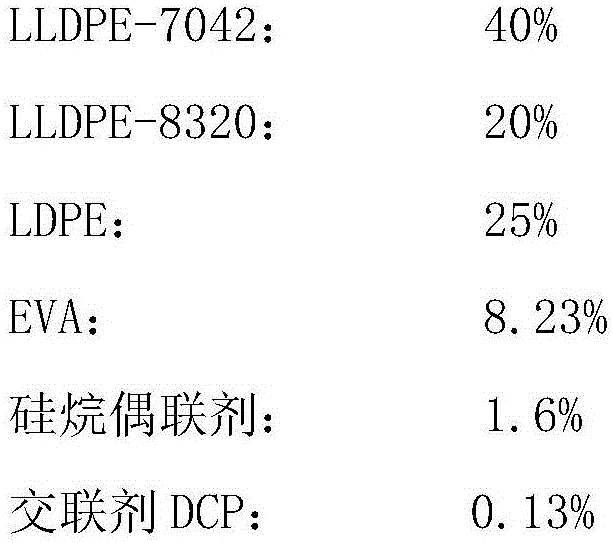

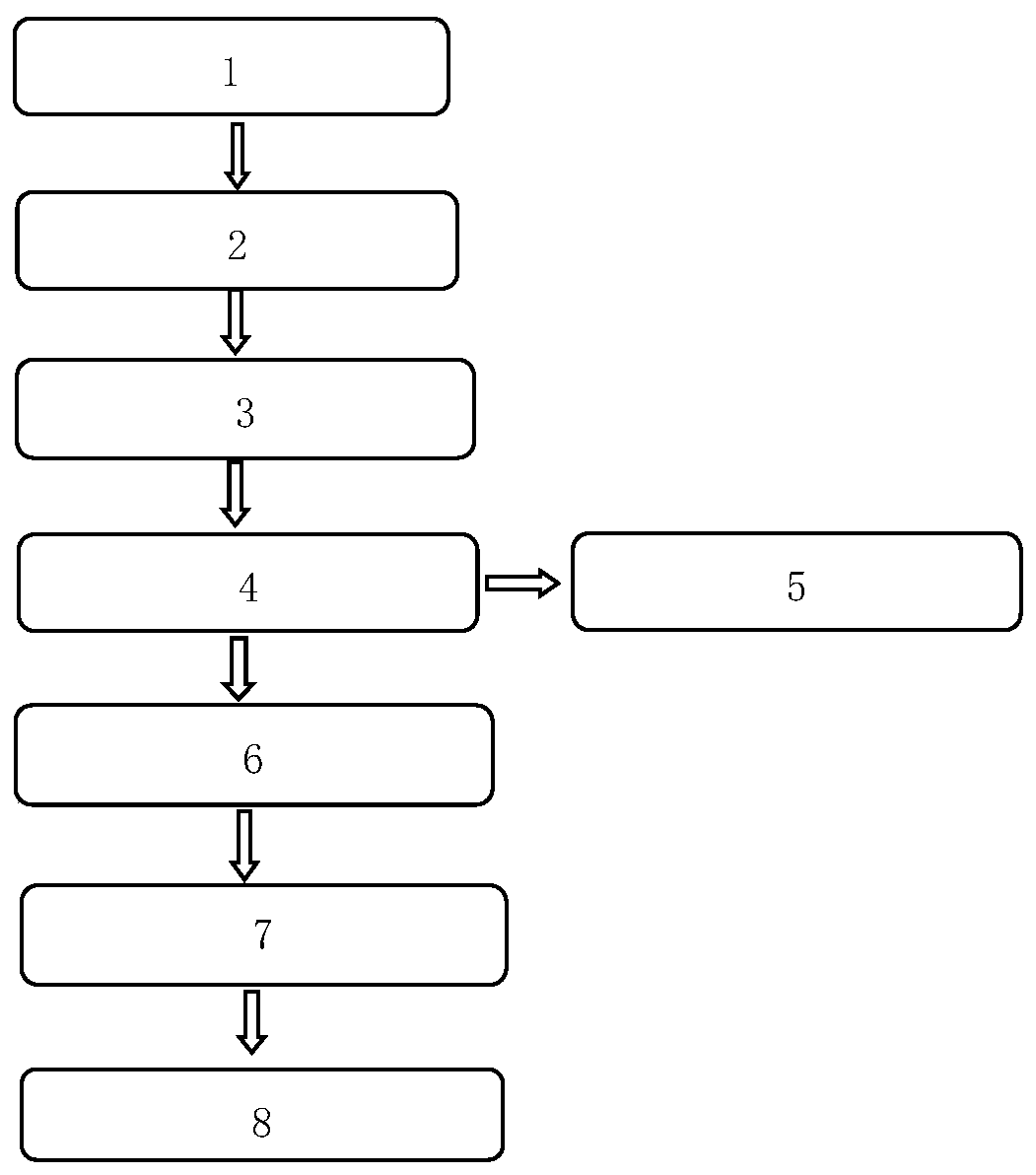

The invention relates to the field of insulating materials, in particular to a silane crosslinking polyethylene insulating material for 10 kV or below black wires and cables. A method for preparing the insulating material for the 10 kV or below black wires and cables through one step mainly comprises the two steps of catalyst master batch preparation and finished product preparation. The insulating material is prepared from, by weight, LLDPE-7042, LLDPE-8320, LDPE, EVA, PP, a silane coupling agent, a cross-linking agent DCP, an antioxidant 300, an antioxidant 1010, an antioxidant DLTP, an antioxidant 1024, organotin, fluororubber master batches and black master batches. The insulating material is mainly used for insulating layers of the cables and mainly replaces a current PVC material, the insulating property is superior to that of PVC, PVC can emit toxic and harmful gases when the wires fire due to aging and the like, but the silane insulating material is poisonless and harmless.

Owner:浙江太湖远大新材料股份有限公司

Temperature compensating flanged joint for a teflon diaphragm valve

ActiveUS9322482B2Reduce cold flowPrevent radial movementPlug valvesDiaphragm valvesEngineeringDiaphragm valve

Apparatus, including a diaphragm valve, is provided featuring a valve body, a diaphragm, a pressure ring, and at least one elastomeric member. The valve body may include a circumferential flange. The diaphragm may include a circumferential gasket portion configured to be seated on the circumferential flange so as to form a joint between the valve body and the diaphragm. The pressure ring may include concentric fluctuations, and may be configured to apply a sealing force against the joint so that the concentric fluctuations prevent radial movement of the circumferential gasket portion and the circumferential flange. The elastomeric member may be configured to respond to a compressive force and provide a substantially constant sealing force, transmitted through the pressure ring, regardless of small variations in the thickness or material dimensions of the circumferential gasket portion caused by temperature fluctuation or material flow and age.

Owner:ITT MFG ENTERPRISES LLC

Preparation method of insulating material for electrical equipment

InactiveCN108084534AExcellent dielectric propertiesWith high voltageRubber insulatorsPlastic/resin/waxes insulatorsMolten stateEpoxy

The invention provides a preparation method of an insulating material for electrical equipment. The method comprises the following steps: a, leading waste rubber, epoxy resin and silicone rubber intoan internal mixer, performing banburying on the material till the mixture is molten, then sequentially adding a fire retardant, nanosilicon dioxide and carbon black, and reducing the temperature for banburying, so as to obtain a mixture I; mixing and putting a processing auxiliary material, polyimide, sodium alginate, lignin and an antioxidant into a mixer, heating, and performing ultrasonic oscillation, so as to obtain a mixture II; c, adding silicone oil and a coupling agent into the mixture II, putting the mixture II into a stirrer to perform stirring, then putting the mixture II in a vacuum environment, and performing defoaming treatment, so as to obtain a mixture III; and d. uniformly mixing the mixture I, the mixture III, organic tin and a curing agent, leading the mixture into a single screw to perform extrusion, adding the mixture into a dehydrator to perform dehydration, and putting the mixture into a closed container, leaving the mixture to stand, curing, and forming. The method is simple, short in preparation flow, mainly adopts a waste rubber material, and has certain environmental protection significance.

Owner:马鞍山佳夫尼电气科技有限公司

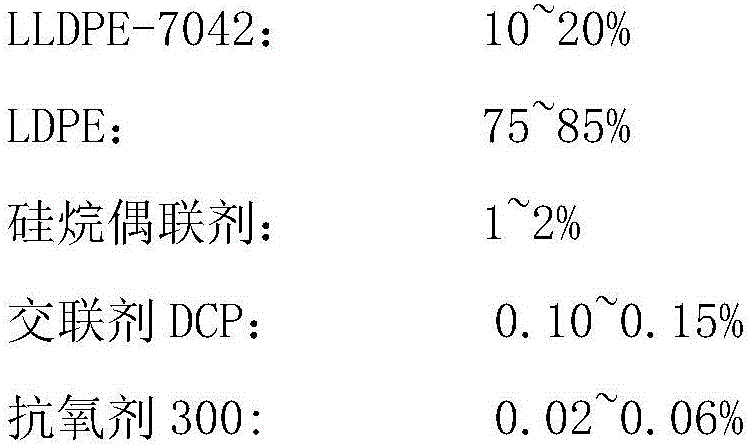

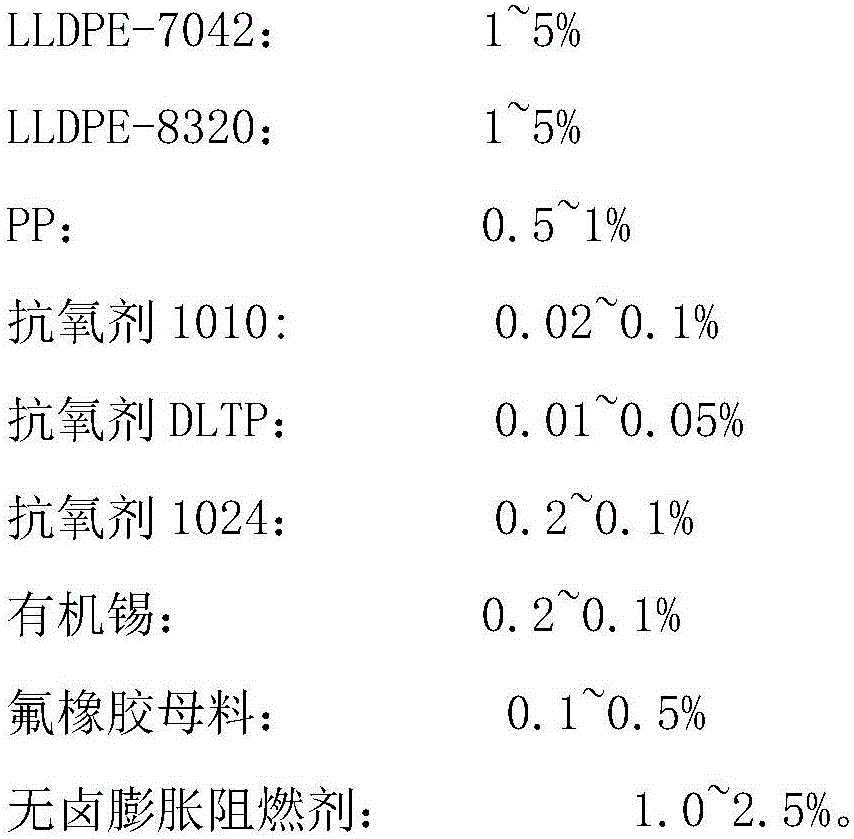

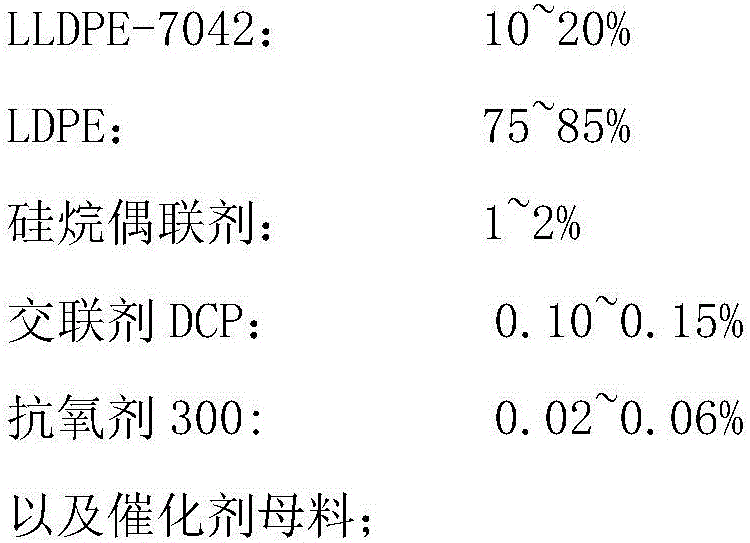

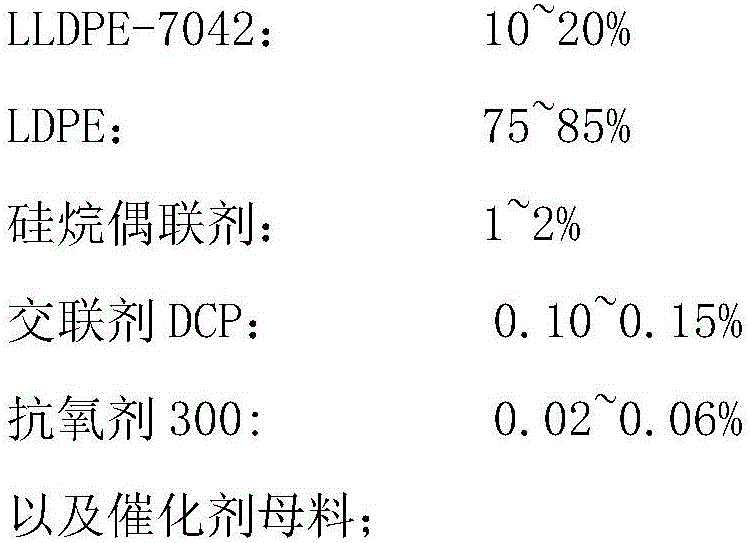

Non-halogen flame-retardant polyethylene sheath insulating material and preparation method thereof

InactiveCN106084409AImprove insulation performanceStable speedPlastic/resin/waxes insulatorsInsulated cablesLinear low-density polyethylenePolymer science

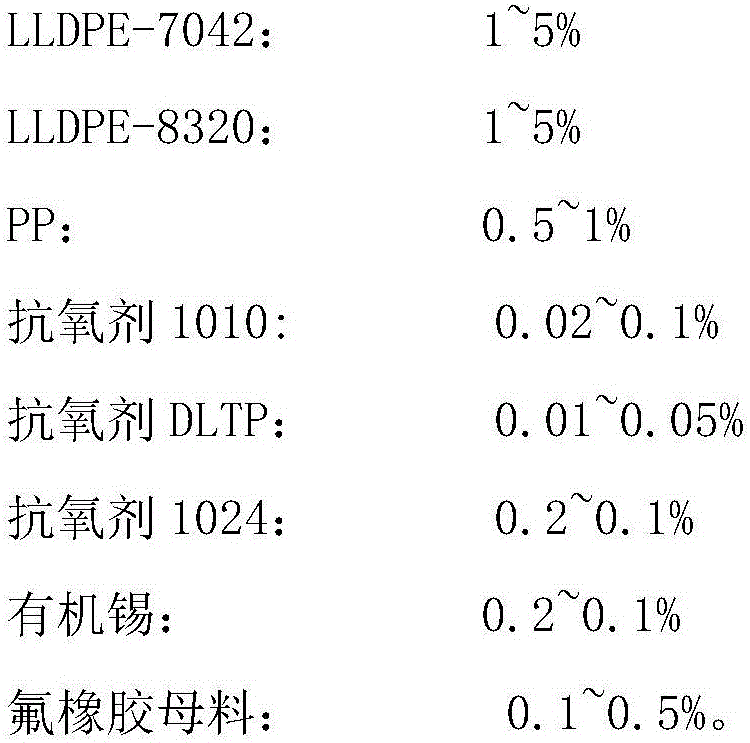

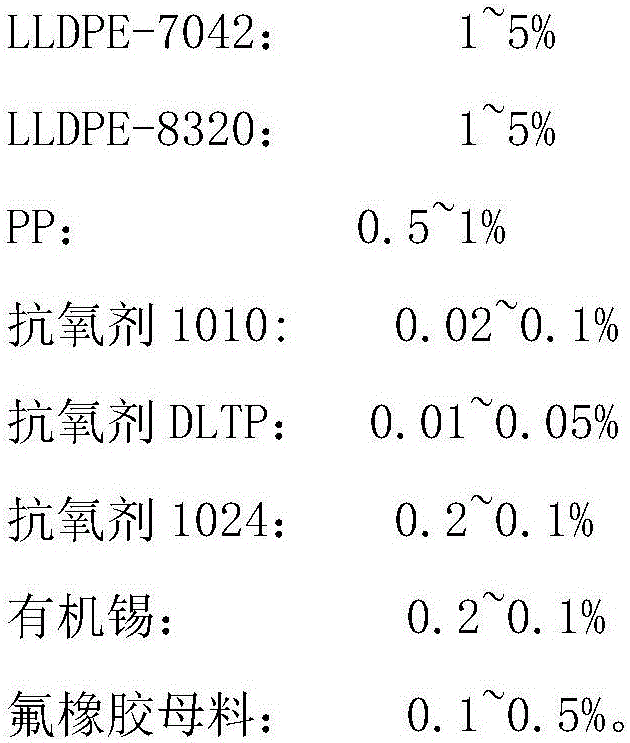

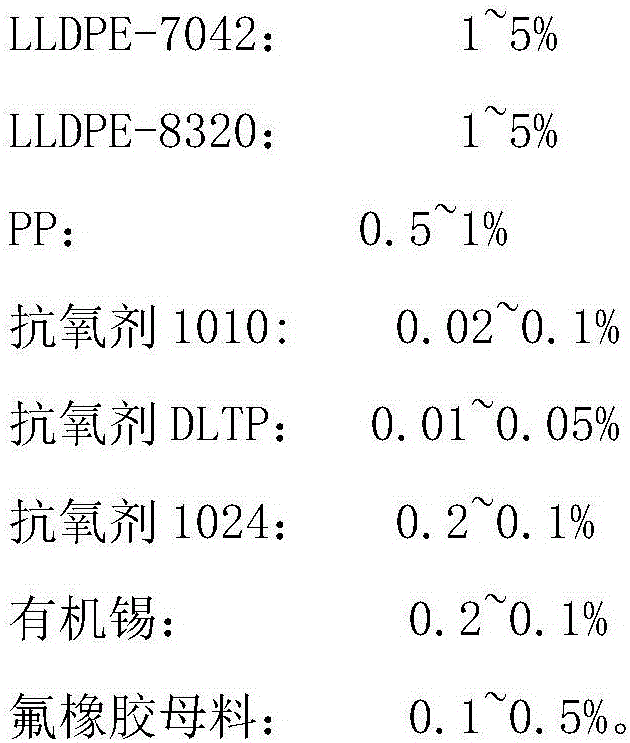

The invention relates to the field of insulating materials, in particular to a non-halogen flame-retardant polyethylene sheath insulating material and a preparation method thereof. The non-halogen flame-retardant polyethylene sheath insulating material is prepared from components as follows: LLDPE-7042 (linear low density polyethylene-7042), LDPE (low-density polyethylene), a silane coupling agent, a cross-linking agent DCP, an antioxidant 300 and a catalyst masterbatch, wherein the catalyst masterbatch comprises components as follows: LLDPE-7042, LLDPE-8320, PP (polypropylene), an antioxidant 1010, an antioxidant DLTP, an antioxidant 1024, organic tin, a fluororubber masterbatch and a non-halogen intumescent flame retardant. The material is mainly applied to an insulating layer of a cable and is mainly used for replacing a current PVC (polyvinyl chloride) material, the insulating property of the material is superior to that of PVC, and the silane insulating material is non-toxic and harmless while PVC can release toxic and harmful gas when a wire is on fire caused by aging and the like.

Owner:浙江太湖远大新材料股份有限公司

Functional diene elastomer with a low pi and improved cold flow, and rubber composition containing same

The invention relates to a functionalized diene elastomer composed:a) of a diene elastomer functionalized, at the chain end or in the middle of the chain, by a tin functional group, exhibiting a monomodal distribution of molecular weights before functionalization and a polydispersity index before functionalization of less than or equal to 1.3,b) of a diene elastomer star-branched with a tin compound, exhibiting a monomodal distribution of molecular weights before star-branching and a polydispersity index before star-branching of less than or equal to 1.3, andc) of a content of less than 15% by weight, with respect to the total weight of the functionalized diene elastomer, of a non-tin-functional diene elastomer,the said diene elastomers a), b) and c) being, before optional functionalization or optional star-branching, the same in nature.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN +1

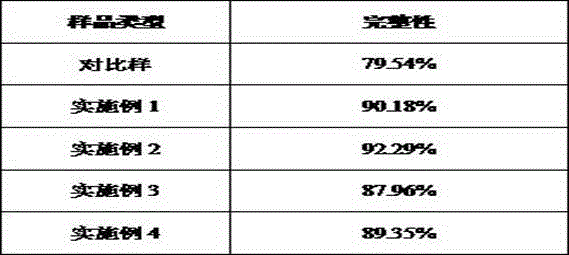

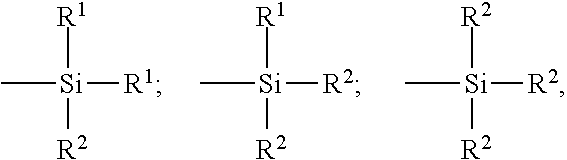

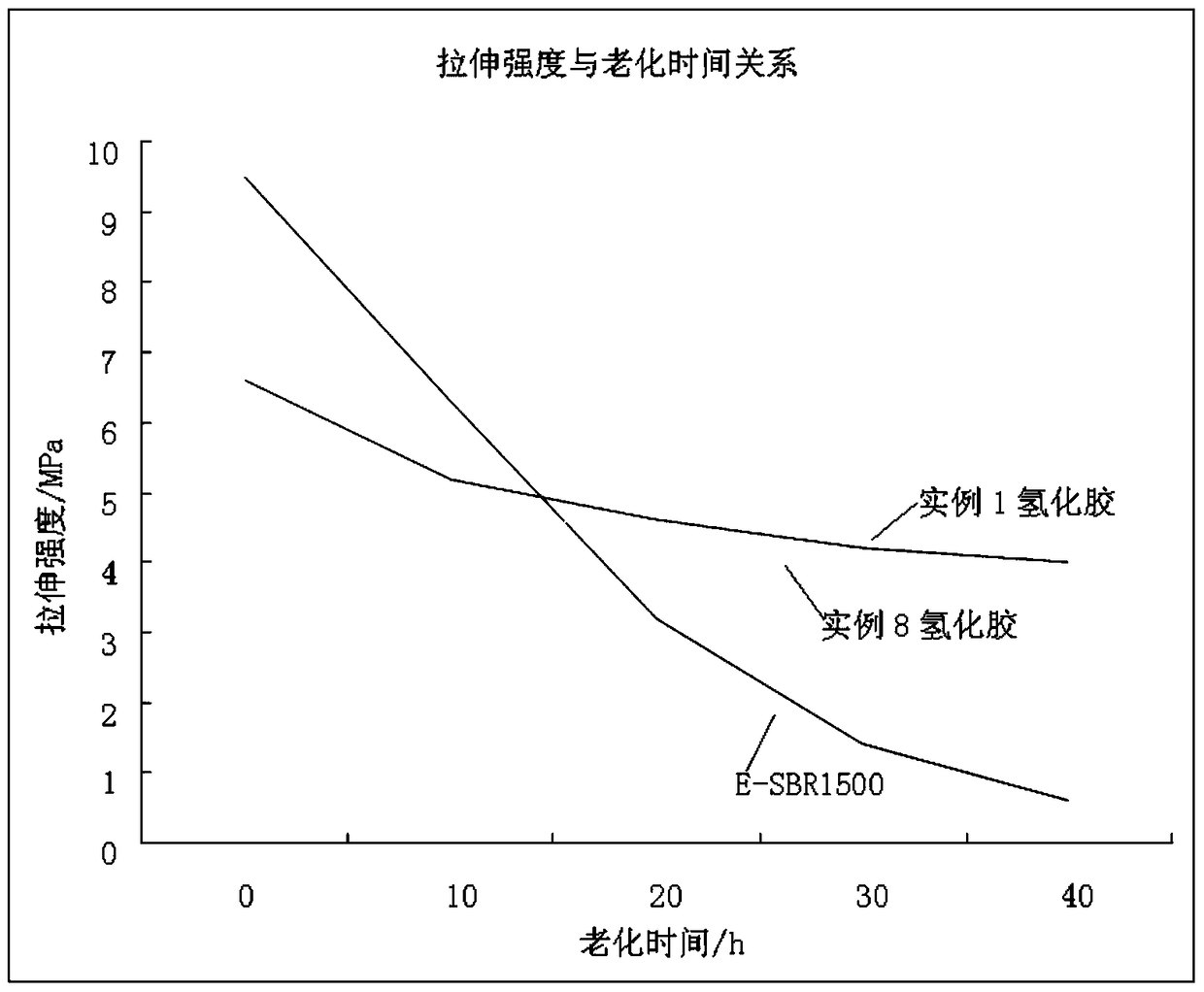

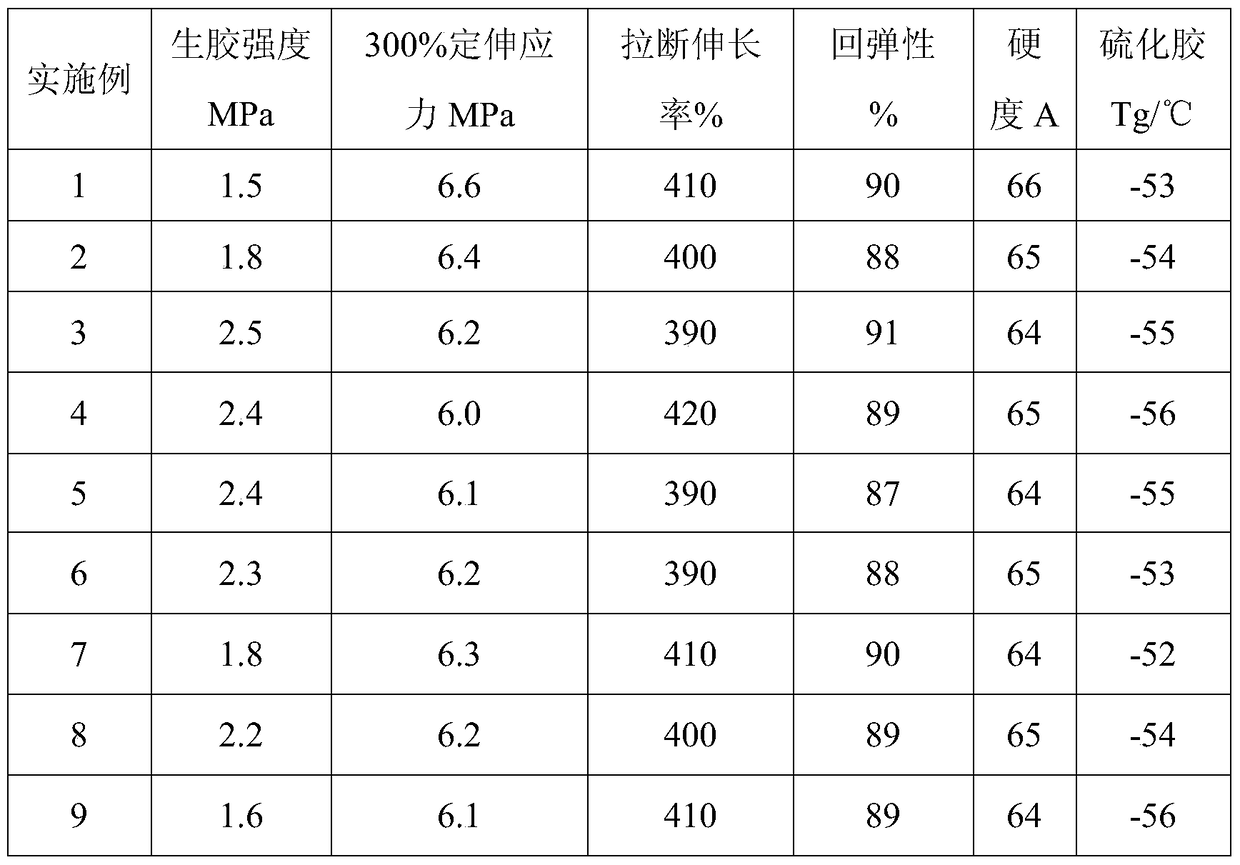

A kind of hydrogenated polystyrene-b-styrene/butadiene/isoprene random copolymer and its preparation method and application

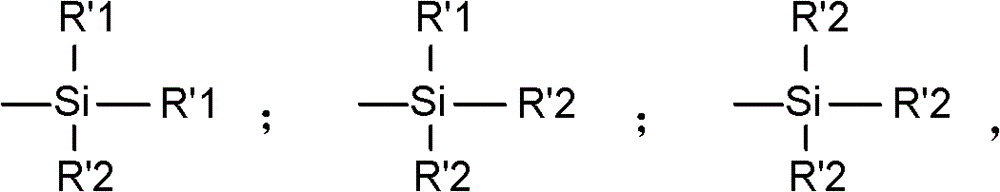

The invention discloses a hydrogenated polystyrene-b-styrene / butadiene / isoprene random copolymer as well as a preparation method and application thereof. The hydrogenated polystyrene-b-styrene / butadiene / isoprene random copolymer is obtained by hydrogenating a mixed polymer consisting of Sn-b-BSmIR, (Sn-b-BSmI)2Si(CH3)2, (Sn-b-BSmI)3SiCH3 and (Sn-b-BSmI)4Si. The preparation method comprises the following steps: preparing a polystyrene block at first, then grafting a styrene / butadiene / isoprene random copolymer block to the polystyrene block, further coupling by using a compound coupling agent, and finally performing partial hydrogenation to obtain the hydrogenated polystyrene-b-styrene / butadiene / isoprene random copolymer. The preparation method is simple and low in cost, and the prepared hydrogenated polystyrene-b-styrene / butadiene / isoprene random copolymer is good in mechanical property and ageing resistance and has vulcanizable double bonds; and after the random copolymer is vulcanized, the prepared vulcanized rubber has very good elasticity, keeps relatively good rigidity and strength, is good in ageing resistance, and is suitable for outdoor sealing materials.

Owner:CHINA PETROLEUM & CHEM CORP

Preparation method of liquid polybutadiene with wide molecular weight distribution

ActiveCN114395062AGuaranteed mechanical propertiesReduce cold flowRolling resistance optimizationPolymer scienceButadiene Dioxide

The invention relates to a preparation method of liquid polybutadiene with wide molecular weight distribution, which comprises the following steps: adopting organic lithium as an initiator, adding a polarity regulator and a solvent, adding butadiene and organic lithium in batches to carry out anionic polymerization reaction, after the organic lithium is completely added, continuously adding the residual butadiene into a reaction kettle to carry out reaction, and after the polymerization is finished, cooling to room temperature to obtain the liquid polybutadiene with wide molecular weight distribution. Adding a terminator to terminate the reaction; the butadiene and the organic lithium are fed in batches, the single-time feeding amount of the butadiene is 2-10% of the total mass of the butadiene, the single-time feeding amount of the organic lithium is 5-15% of the total mass of the organic lithium, the adding frequency of the organic lithium is 8-20, and the next-time feeding of the butadiene and the organic lithium is carried out after the butadiene added in the previous time completely reacts. The reaction conditions are mild, the molecular weight distribution of polybutadiene can be regulated and controlled by changing the feeding times and the single feeding amount of the initiator to obtain uniform single-peak width distribution, and the prepared product has good mechanical properties and processability.

Owner:LIMING RES INST OF CHEM IND

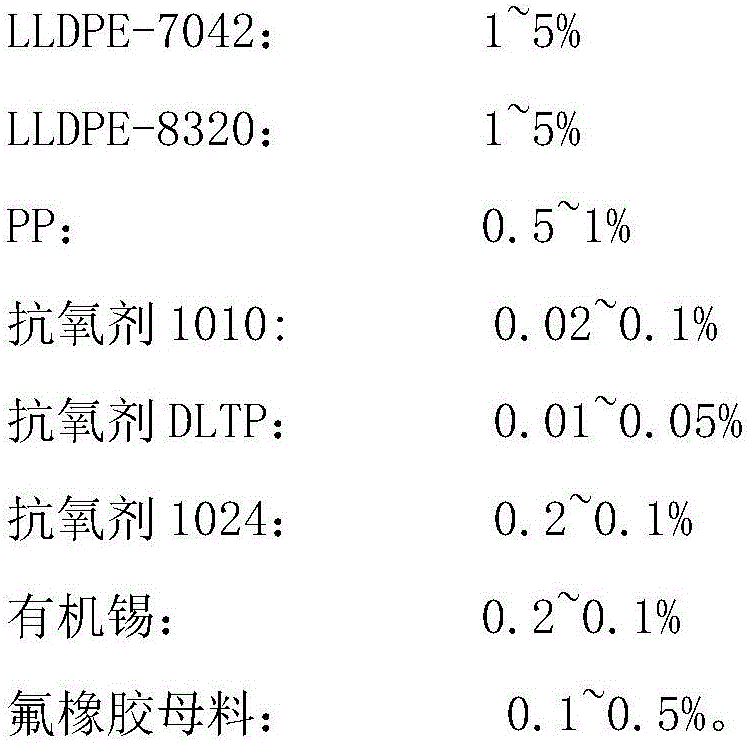

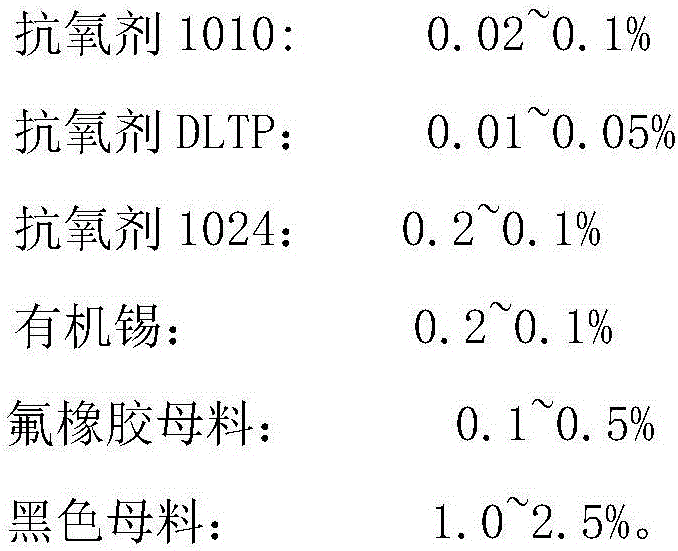

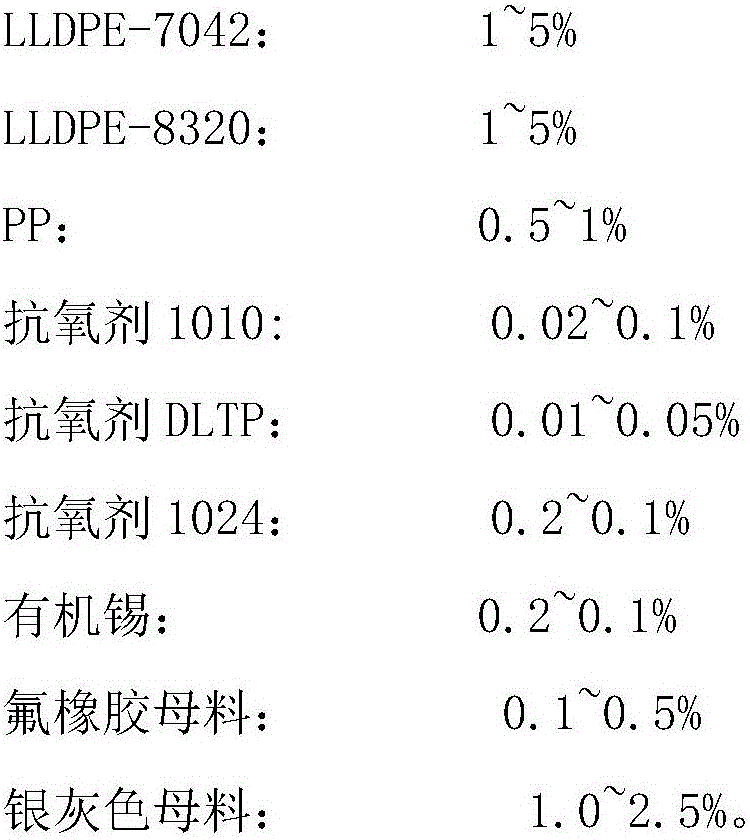

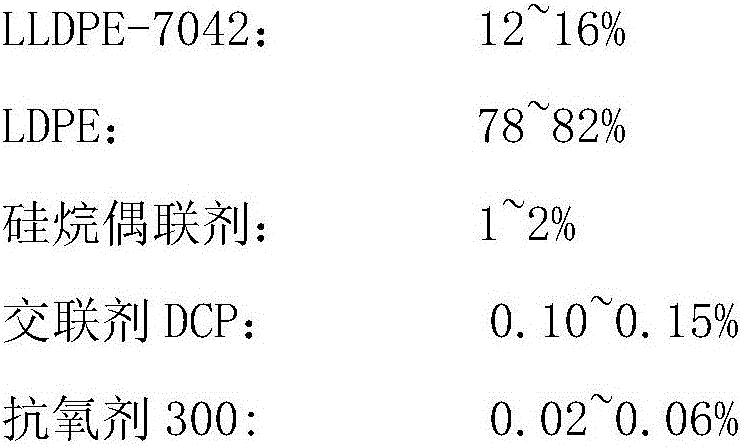

Method for preparing silane crosslinked polyethylene insulation material for electric wires and cables by two-step way

InactiveCN106188742AImprove insulation performanceStable speedPlastic/resin/waxes insulatorsClimate change adaptationLow-density polyethyleneLinear low-density polyethylene

The invention relates to the field of insulation materials, in particular to a silane crosslinked polyethylene insulation material for electric wires and cables. A method for preparing the silane crosslinked polyethylene insulation material for electric wires and cables by a two-step way mainly comprises two steps of 1, preparation of a catalyst master batch; 2, preparation of a finished product. The insulation material is prepared from the following components of LLDPE (linear low density polyethylene)-7042, LDPE (low density polyethylene), a silane coupling agent, a crosslinking agent DCP, an antioxidant 300 and the catalyst master batch; the catalyst master batch comprises the following components of LLDPE-7042, LLDPE-8320, PP (polypropylene), an antioxidant DLTP, an antioxidant 1024, organic tin and a fluororubber master batch. The insulation material has the advantages that the insulation material is mainly used for insulation layers of cables, and is mainly used for replacing the existing PVC (polyvinyl chloride) material; the insulation property is better than the insulation property of PVC, and the poisonous and harmful gas will be released by the PVC when the electric wire is aged and catches a fire, but the silane insulation material has no poison and harm.

Owner:浙江太湖远大新材料股份有限公司

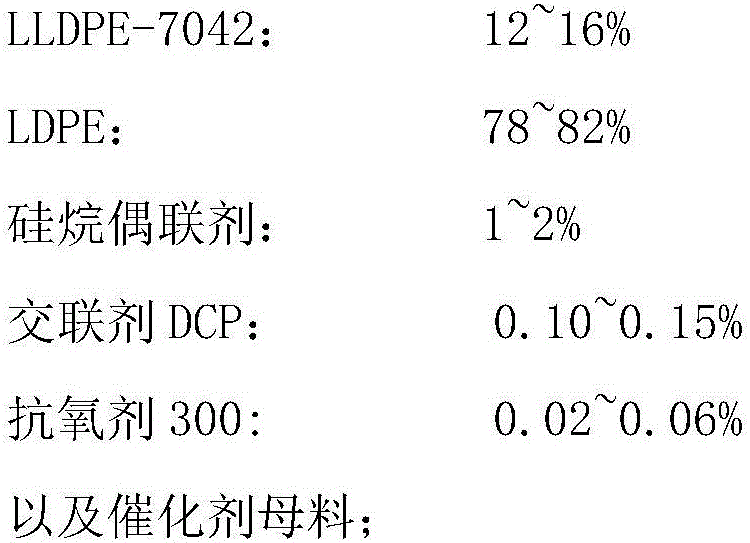

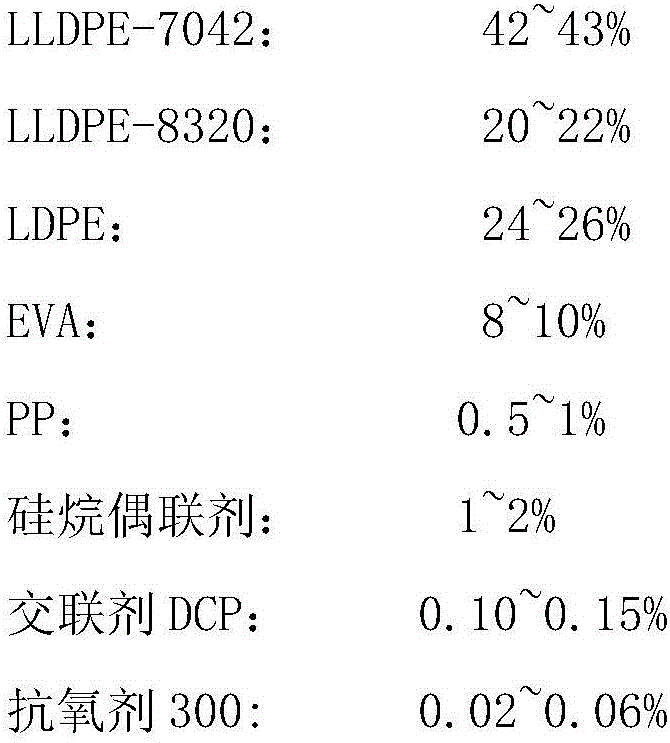

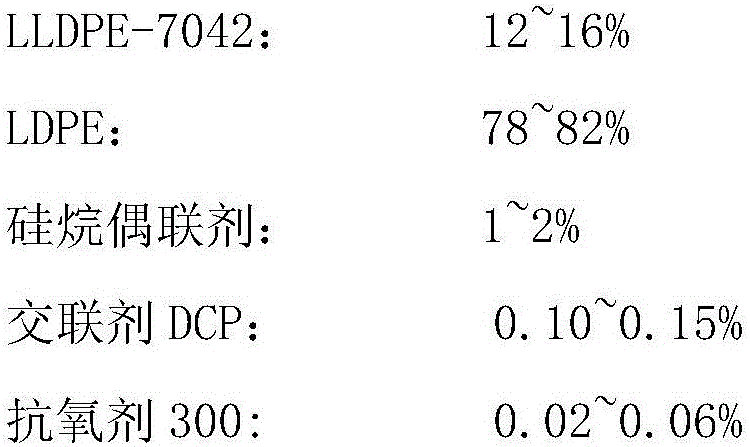

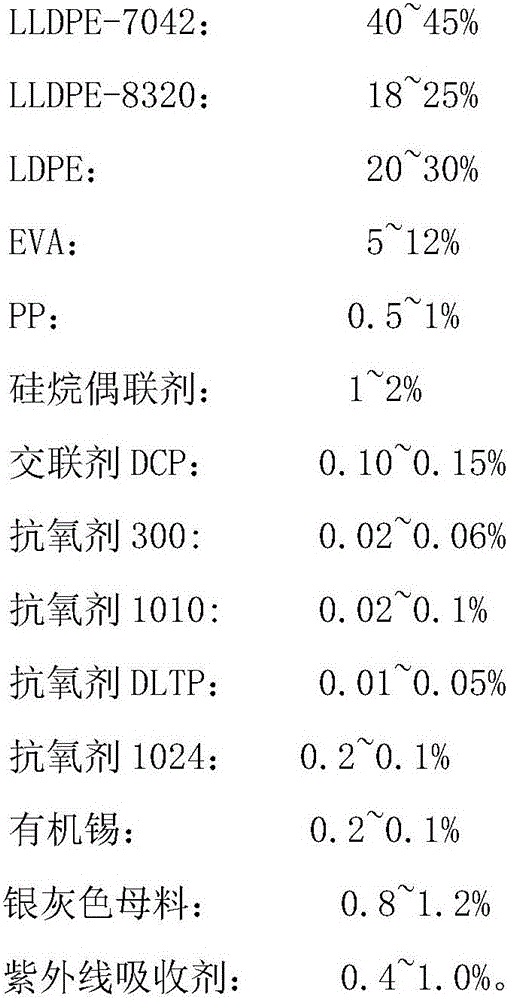

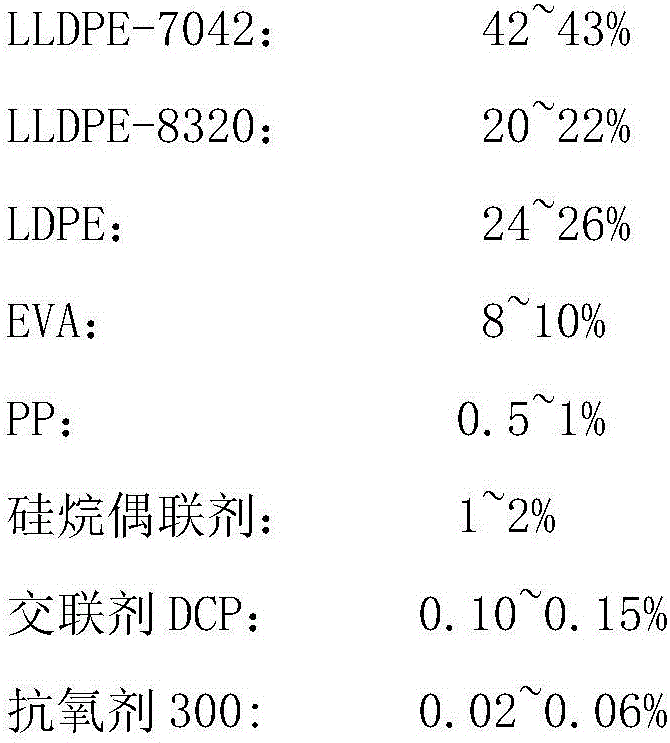

Method for preparing silane crosslinking polyethylene insulating material for 10 kV or below wires and cables through one step

InactiveCN106009234AImprove insulation performanceReduce quality problemsPlastic/resin/waxes insulatorsCross-linkMasterbatch

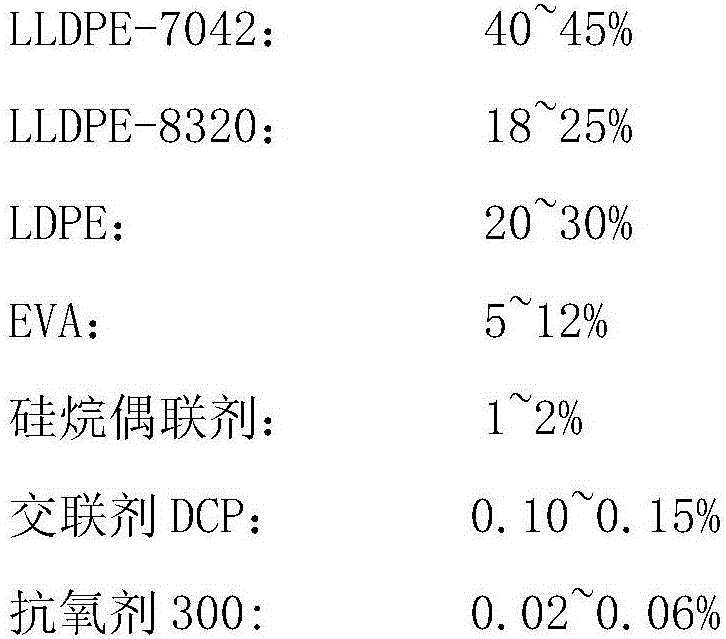

The invention relates to the field of insulating materials, in particular to a silane crosslinking polyethylene insulating material for 10 kV or below wires and cables. A method for preparing the insulating material for the 10 kV or below wires and cables through one step mainly comprises the two steps of catalyst master batch preparation and finished product preparation. The insulating material is prepared from, by weight, LLDPE-7042, LLDPE-8320, LDPE, EVA, PP, a silane coupling agent, a cross-linking agent DCP, an antioxidant 300, an antioxidant 1010, an antioxidant DLTP, an antioxidant 1024, organotin and fluororubber master batch. The insulating material is mainly used for insulating layers of the cables and mainly replaces a current PVC material, the insulating property is superior to that of PVC, PVC can emit toxic and harmful gases when the wires fire due to aging and the like, but the silane insulating material is poisonless and harmless.

Owner:浙江太湖远大新材料股份有限公司

Tetrafluoroethylene composite teeth sealing gasket and method for making same

InactiveCN1594923AReduce surface requirements for high conditionsReduce cold flowEngine sealsTetrafluoroethyleneHigh pressure

This invention discloses a tetrafluoro complex sealed shim and its facture. In the shim is embedded with the mental tooth-shaped shim, the colophony around is suppressed and sintered under the high temperature from 370 deg. C to 430 deg. C. it makes use of the high pressure of the tooth-shaped shim, the causticity of tetrafluoro and the easily sealing of the surface to reduce the cold flow of tetrafluoro and the high requirements of the surface of the shim. This invention is suitable for high pressure and strong causticity; it seals well in the cycling temperature and pressure fluctuation. It is used in the temperature from minus 210 deg. C to 250 deg. C, the pressure from 4.0 MPa to 42.0 MPa, in the fields of medical chemistry, FI chemistry, deep cooling, and oil chemistry.

Owner:ZHEJIANG UNIV

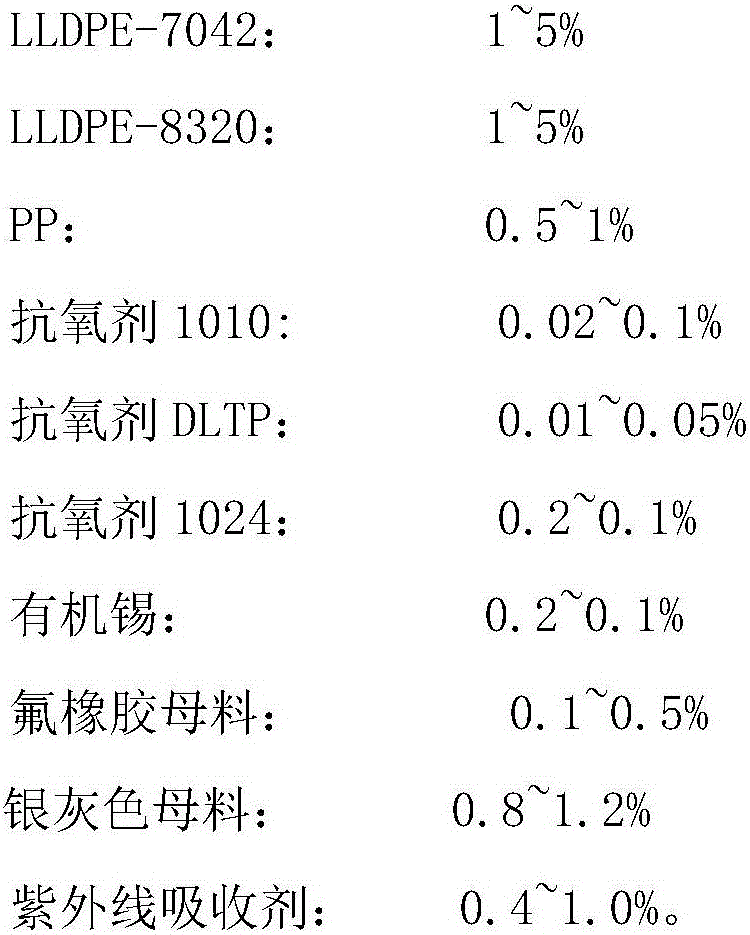

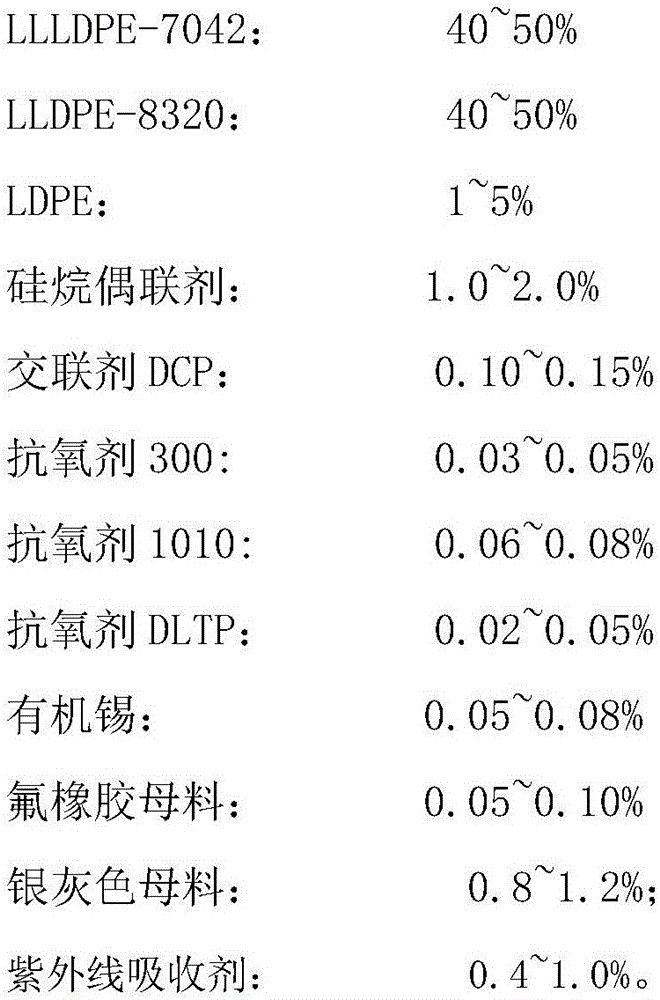

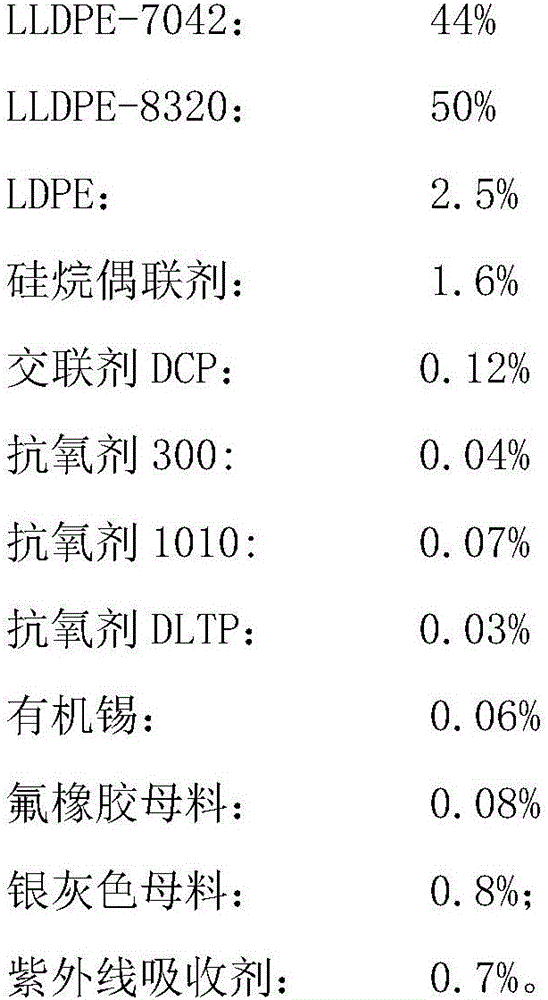

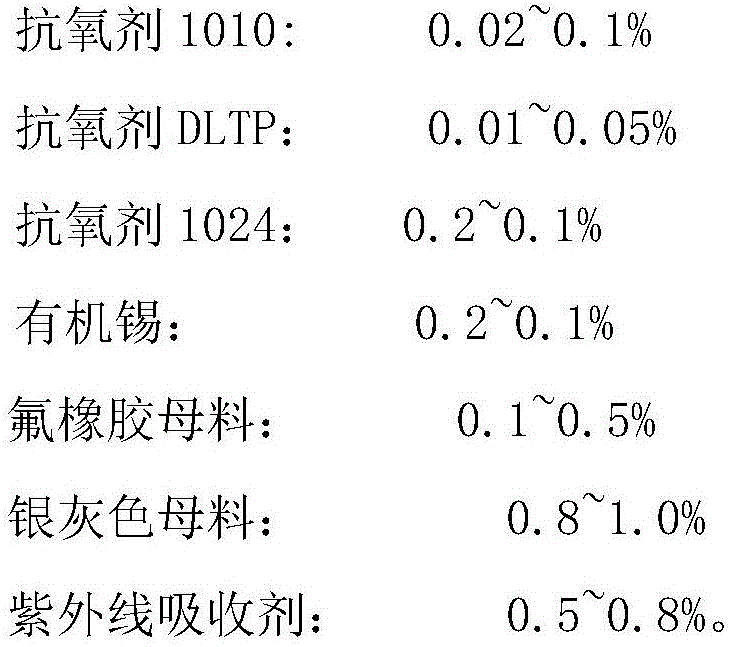

Silane cross-linked polyethylene insulation material for 10 kV and below silver-gray wires and cables, and preparation method thereof

InactiveCN106084440AImprove insulation performanceStable speedPlastic/resin/waxes insulatorsInsulation layerPolymer science

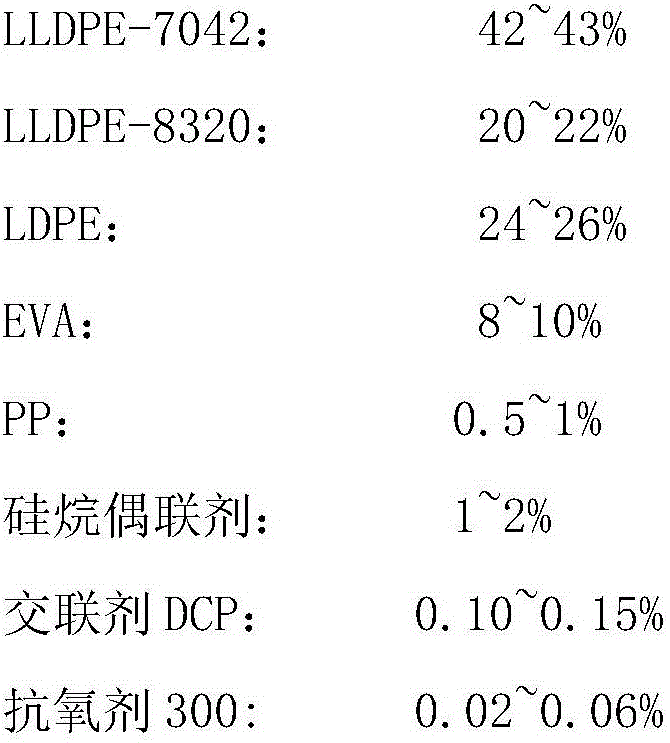

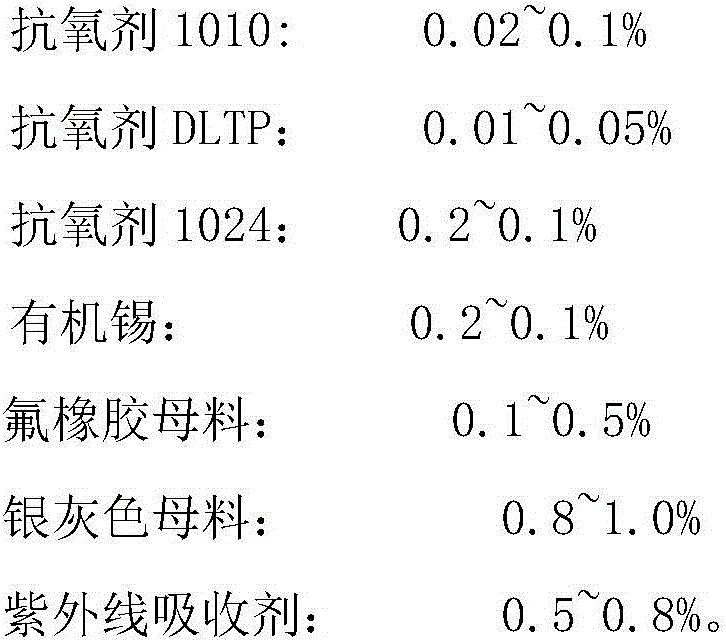

The invention relates to the field of insulation materials, in particular to a silane cross-linked polyethylene insulation material for 10 kV and below silver-gray wires and cables, and a preparation method thereof. The insulation material is prepared by the following components: LLDPE-7042, LLDPE-8320, LDPE, EVA, PP, a silane coupling agent, a crosslinking agent DCP, an antioxidant 300, an antioxidant 1010, an antioxidant DLTP, an antioxidant 1024, organic tin, a fluorine rubber master batch, a UV absorber and a silver-gray master batch. The material is mainly used in an insulation layer of the cable to replace the current main PVC materials, and is better than PVC in insulation property, PVC emits toxic and harmful gases when the wires fire due to aging, while the silane insulation material is non-toxic and harmless.

Owner:浙江太湖远大新材料股份有限公司

Organosilane crosslinked polyethylene wires and cables of 10 kV or below and preparation method thereof

InactiveCN106009226AImprove insulation performanceStable speedPlastic/resin/waxes insulatorsMasterbatchPolymer science

The invention relates to the field of insulating materials, in particular to silane crosslinked polyethylene wires and cables of 10kV and below and a preparation method thereof. The insulating material of the wire and cable is prepared from the following components by weight percentage: LLDPE-7042, LLDPE-8320, LDPE, EVA, PP, silane coupling agent, crosslinking agent DCP, antioxidant 300, antioxidant 1010, antioxidant DLTP, antioxidant 1024, organic tin, fluorine rubber masterbatch. The present invention mainly replaces the current PVC material, and its insulation performance is better than that of PVC. However, PVC will release toxic and harmful gases when the wires are aging and catch fire, while the silane insulating material is non-toxic and harmless.

Owner:浙江太湖远大新材料股份有限公司

Low-radioactivity background waterproof sealing adhesive tape and preparation method thereof

InactiveCN110804403ALow radioactive backgroundImprove compatibilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceButyl rubber

The embodiment of the invention discloses a low-radioactivity background waterproof sealing adhesive tape. The waterproof sealing adhesive tape comprises the following components in parts by weight: 9-11 parts of butyl rubber, 4.5-5.5 parts of diene rubber, 30-40 parts of medium molecular weight polyisobutene, 12-18 parts of low molecular weight polyisobutene, 18-22 parts of a hydrophobic reinforcing agent, 7-8 parts of a hydrophobic filler and 7-8 parts of hydrogenated tackifying resin. The embodiment of the invention also provides a preparation method of a low-radioactivity background waterproof sealant.

Owner:SHENYANG RUBBER RES & DESIGN INST CO LTD

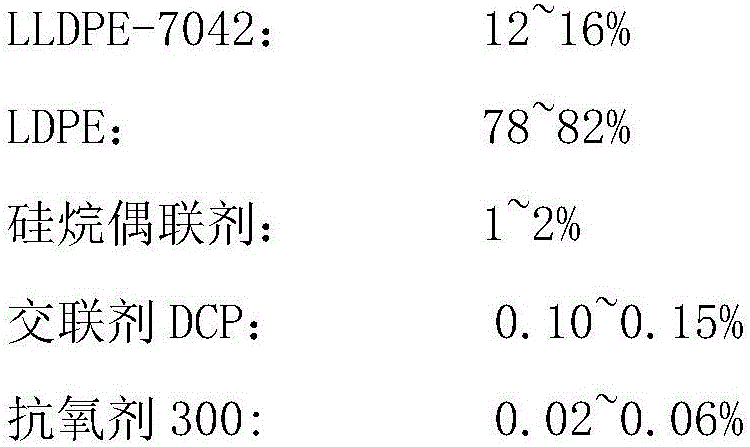

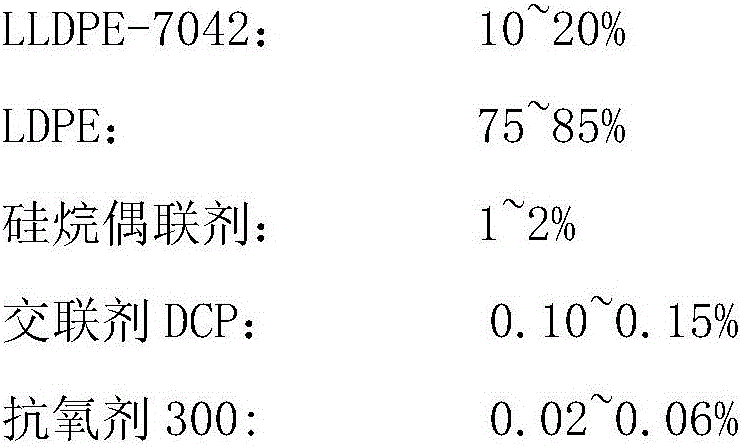

Flame-retardant silane crosslinked polyethylene insulating material and preparation method thereof

PendingCN113563657AGood heat denaturation resistanceStrong overload resistancePlastic/resin/waxes insulatorsPolymer sciencePtru catalyst

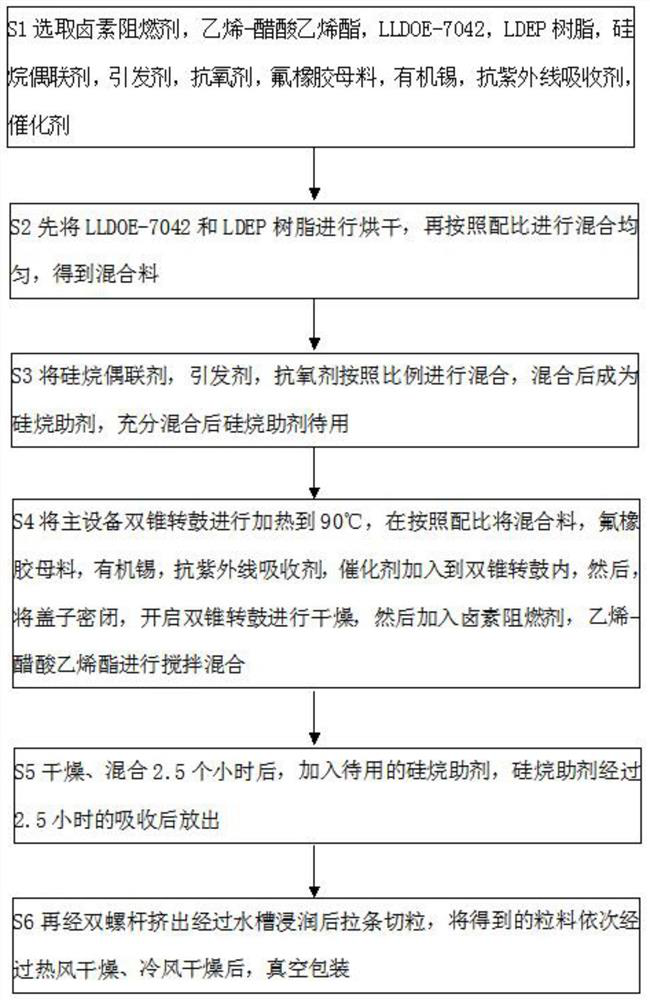

The invention discloses a flame-retardant silane crosslinked polyethylene insulating material and a preparation method thereof. The flame-retardant silane crosslinked polyethylene insulating material is prepared from the following components in percentage by weight: 4%-6% of a halogen flame retardant, 4%-7% of ethylene-vinyl acetate, 8%-15% of LLDOE-7042, 75%-85% of LDEP resin, 1%-2% of a silane coupling agent, 0.1-0.3% of an initiator, 0.2-0.4% of an antioxidant, 0.1-0.5% of fluororubber master batch, 0.2-0.5% of organic tin, 0.4-1% of an anti-ultraviolet light absorber and 2-3% of a catalyst. The material provided by the invention has the advantages of good thermal denaturation resistance, strong overload resistance, improved mechanical properties at high temperature, enhanced chemical stability and solvent resistance, reduced cold flow property, and high insulation resistance.

Owner:浙江太湖远大新材料股份有限公司

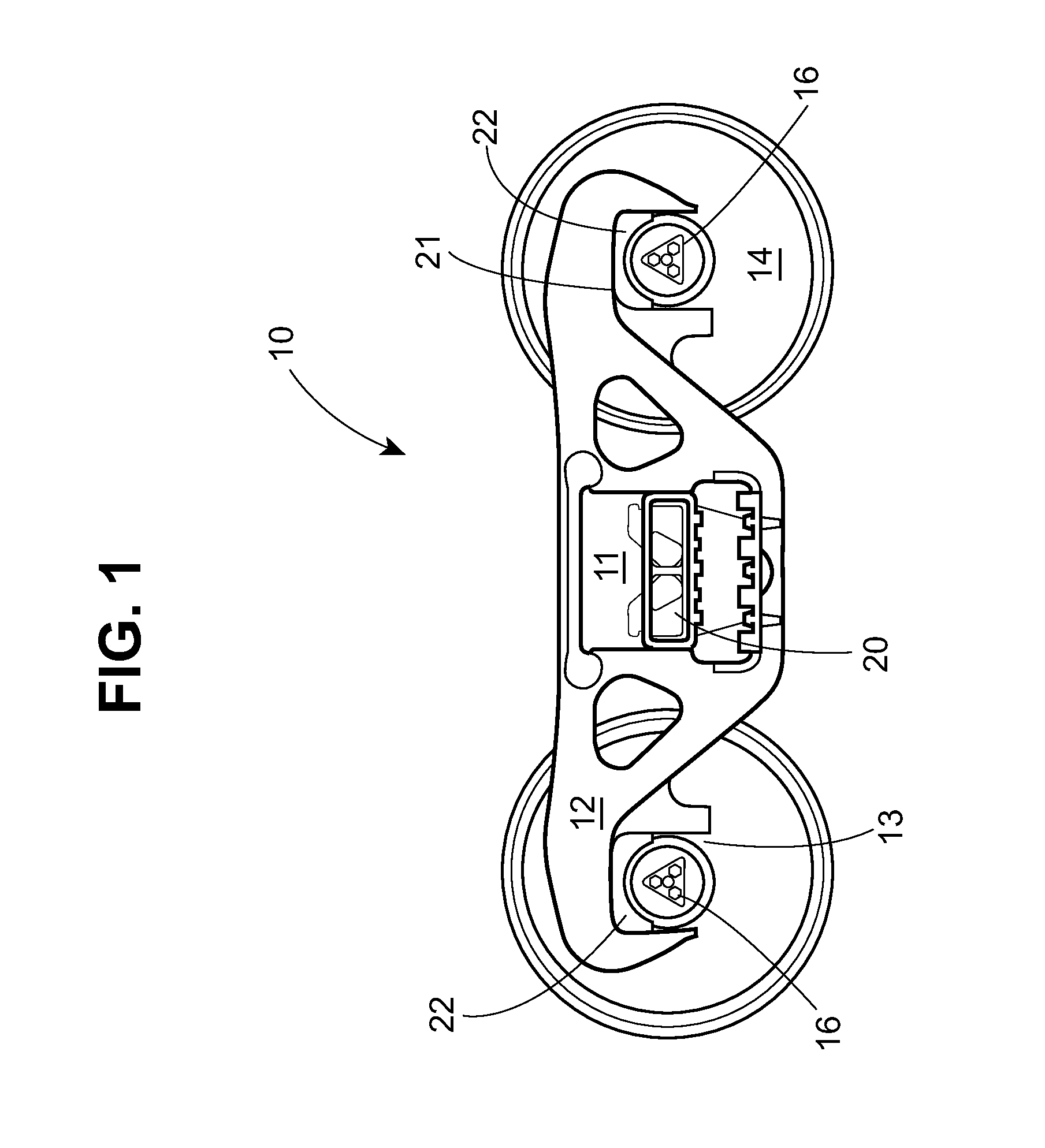

Bearing adapter side frame interface for a railway car truck

InactiveUS20160176418A1Reduce cold flowReduce coefficient of frictionAxle-boxesBogiesInterconnectionTruck

The invention relates to a railway car truck incorporating an interconnection between a side frame and a bearing adapter. The bearing adapter may receive a reduced coefficient of friction surface member in a recess on a top surface of the bearing adapter, facilitating a reduced lateral spring rate of the wheelset. Alternatively, or in combination, an adapter plate is received in the pedestal jaw on the bearing adapter to retain the reduced coefficient of friction surface member above or below the adapter plate. The adapter plate may be provided with surfaces about perpendicular to the longitudinal and lateral axes of the side frame to support elastomeric members, which may provide different longitudinal and lateral spring rates in response to a load applied to the truck.

Owner:STRATO AG

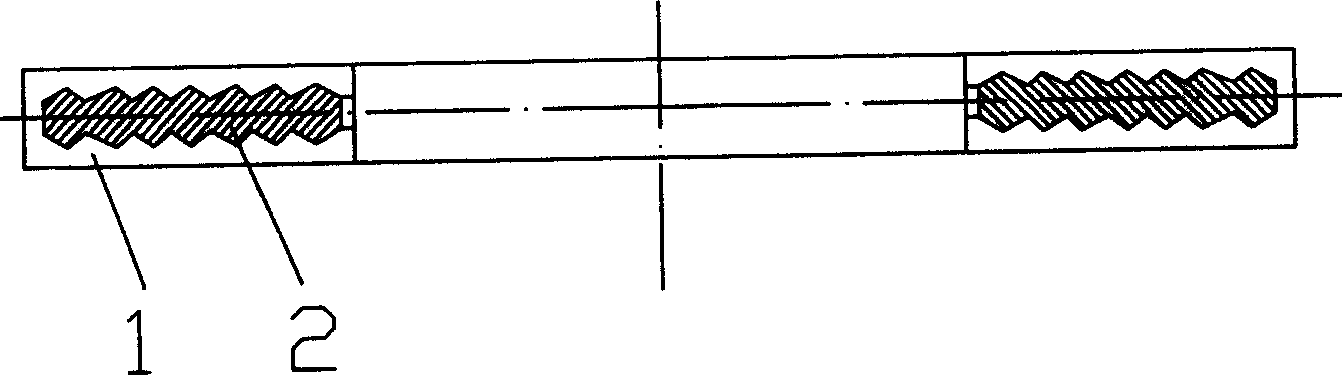

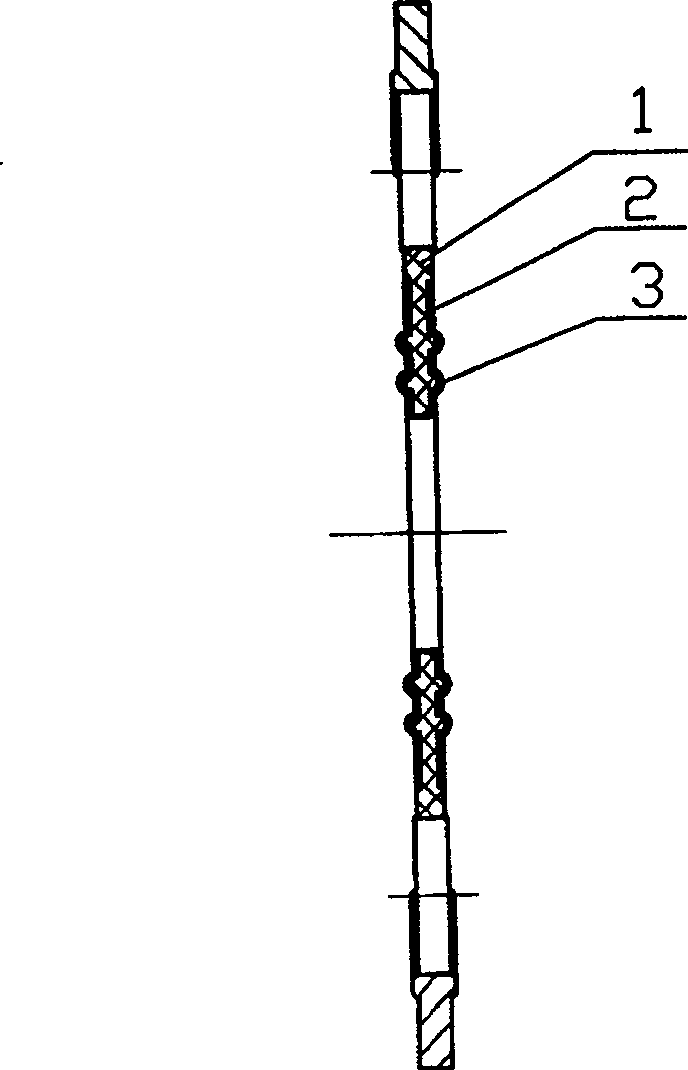

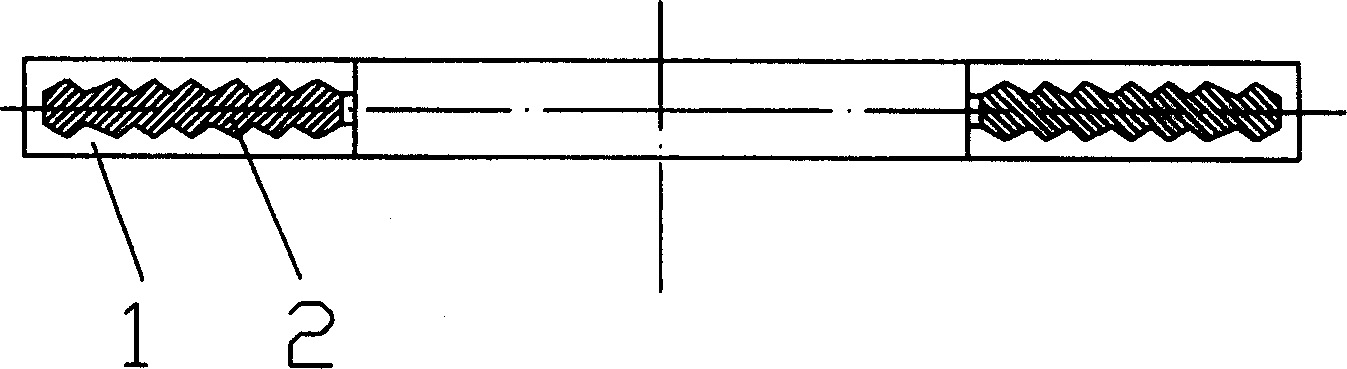

Silane crosslinking polyethylene insulating material electric wire cable and preparation method thereof

InactiveCN106046501AReduce quality problemsGood heat denaturation resistancePlastic/resin/waxes insulatorsCross-linkMasterbatch

The invention relates to the field of insulating material electric wire cables, in particular to a silane crosslinking polyethylene insulating material electric wire cable and a preparation method thereof. The electric wire cable comprises an insulating material and a wire; the insulating material is prepared from LLDPE-7042, LDPE, a silane coupling agent, a cross-linking agent DCP, an antioxidant 300 and catalyst masterbatch; the catalyst masterbatch is prepared from LLDPE-7042, LLDPE-8320, PP, an antioxidant 1010, an antioxidant DLTP, an antioxidant 1024, organic tin and fluororubber masterbatch. According to the silane crosslinking polyethylene insulating material electric wire cable and the preparation method thereof, the insulating material mainly replaces an existing PVC material, the insulating property is superior to that of the PVC, the PVC can release poisonous and harmful gas when a fire breaks out due to the fact that an electric wire is aged, but the silane insulating material is nontoxic and harmless.

Owner:浙江太湖远大新材料股份有限公司

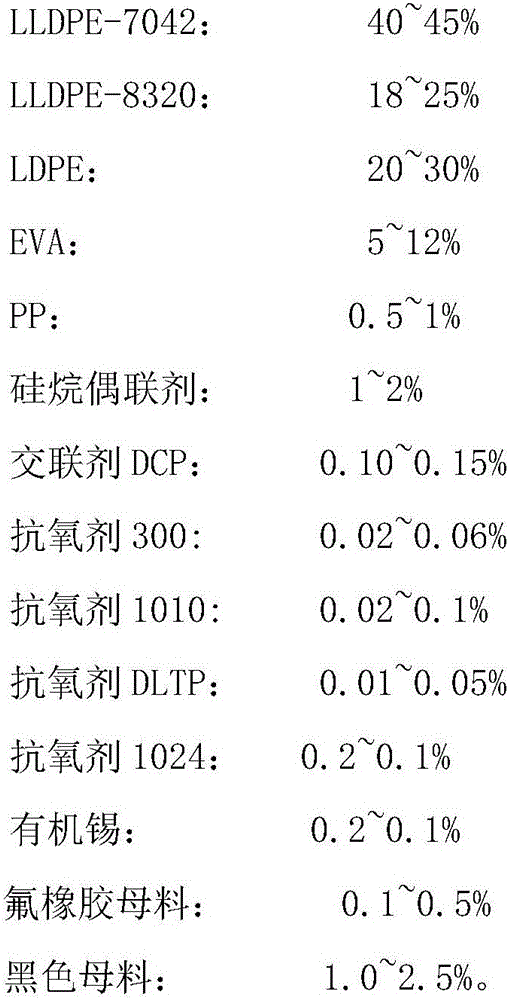

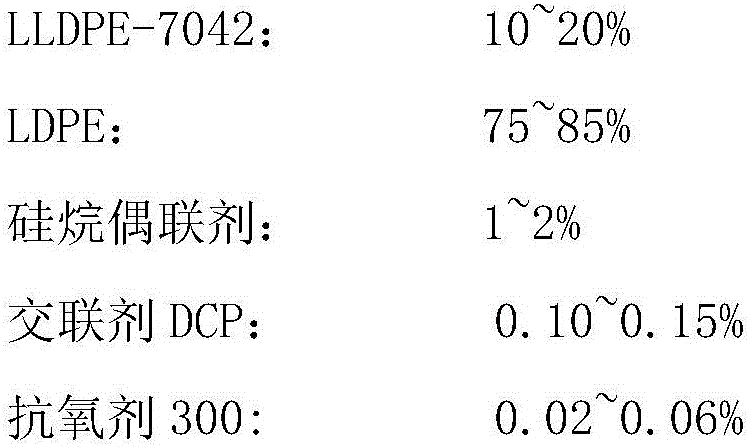

Silane cross-linked polyethylene insulation material for 10 kV and below black wires and cables, and preparation method thereof

InactiveCN106084439AImprove insulation performanceStable speedPlastic/resin/waxes insulatorsMasterbatchPolymer science

The invention relates to the field of insulation materials, in particular to a silane cross-linked polyethylene insulation material for 10 kV and below black wires and cables, and a preparation method thereof. The insulation material is prepared by the following components in percentage by weight: LLDPE-7042, LLDPE-8320, LDPE, EVA, PP, a silane coupling agent, a crosslinking agent DCP, an antioxidant 300, an antioxidant 1010, an antioxidant DLTP, an antioxidant 1024, organic tin, a fluorine rubber masterbatch and a black masterbatch. The material is mainly used in an insulation layer of the cable to replace the current main PVC materials, and is better than PVC in insulation property, PVC emits toxic and harmful gases when the wires fire due to aging, and the silane insulation material is non-toxic and harmless.

Owner:浙江太湖远大新材料股份有限公司

Method for preparing silver gray silane crosslinked polyethylene insulating material for wires and cables by one-step process

InactiveCN106084411AImprove insulation performanceStable speedPlastic/resin/waxes insulatorsLow-density polyethyleneLinear low-density polyethylene

The invention relates to the field of insulating materials, particularly a silver gray silane crosslinked polyethylene insulating material for wires and cables. The method for preparing a silver gray silane crosslinked polyethylene insulating material for wires and cables by a one-step process mainly comprises the following two steps: 1. preparing a catalyst master batch; and 2. preparing the finished product. The insulating material is prepared from LLDPE-7042 (linear low-density polyethylene 7042), LDPE (low-density polyethylene), a silane coupling agent, a crosslinking agent DCP, an antioxidant 300 and the catalyst master batch. The catalyst master batch is composed of LLDPE-7042, LLDPE-8320, PP (polypropylene), an antioxidant 1010, an antioxidant DLTP (dilauryl thiodipropionate), an antioxidant 1024, organic tin, a fluororubber master batch, a silver gray master batch and an ultraviolet absorbent. The material is mainly used as an insulation layer of the cable to mainly substitute the existing PVC (polyvinyl chloride) material, and has better insulating properties than PVC. The PVC can emit toxic harmful gas when the wire is aged or catches fire, but the silane insulating material does not have toxicity or harm.

Owner:浙江太湖远大新材料股份有限公司

Manufacturing process of polytetrafluoroethylene composite elastic body shim and product thereof

ActiveCN100482458CReduce cold flowHigh strengthEngine sealsDomestic articlesElastomerTetrafluoroethylene

The invention relates to the production of politef multiple elastic cushion, which mainly solves the issues of poor elasticity and strength of the politef production, with smooth surface and good sealing performance. It uses glue smelting, pre compression forming, machining the politef cushion using lathe machine tools, overall surface activation, applying sticking glue, sticking the rubber cushion and the politef shell, sulfur forming, and trimming to get the final product. The cushion comprises rubber cushion coated with politef shell with several protruding waterlines.

Owner:浙江国泰萧星密封材料股份有限公司

Tetrafluoroethylene composite teeth sealing gasket and method for making same

InactiveCN1303346CReduce surface requirements for high conditionsReduce cold flowEngine sealsTetrafluoroethyleneHigh pressure

This invention discloses a tetrafluoro complex sealed shim and its facture. In the shim is embedded with the mental tooth-shaped shim, the colophony around is suppressed and sintered under the high temperature from 370 deg. C to 430 deg. C. it makes use of the high pressure of the tooth-shaped shim, the causticity of tetrafluoro and the easily sealing of the surface to reduce the cold flow of tetrafluoro and the high requirements of the surface of the shim. This invention is suitable for high pressure and strong causticity; it seals well in the cycling temperature and pressure fluctuation. It is used in the temperature from minus 210 deg. C to 250 deg. C, the pressure from 4.0 MPa to 42.0 MPa, in the fields of medical chemistry, FI chemistry, deep cooling, and oil chemistry.

Owner:ZHEJIANG UNIV

Insulating material for black overhead insulated cable and preparation method of insulating material

InactiveCN106188803AImprove insulation performanceStable speedPlastic/resin/waxes insulatorsMasterbatchElectricity

The invention relates to the field of insulating materials, in particular to an insulating material for a black overhead insulated cable and a preparation method of the insulating material. The insulating material for the black overhead insulated cable is prepared from the following components in percentage by weight: LLDPE-7020, LLDPE-8320, LDPE, a silane coupling agent, a cross-linking agent DCP, an antioxidant 300, an antioxidant 1010, an antioxidant DLTP, organic tin, fluorine rubber masterbatches and black masterbatches. The insulating material provided by the invention is used for an overhead electric wire for transmitting electricity, and has the insulating property better than that of PVC, while the PVC releases toxic and harmful gases when the electric wire causes a fire by aging and the like, and the silane insulating material is nontoxic and harmless.

Owner:浙江太湖远大新材料股份有限公司

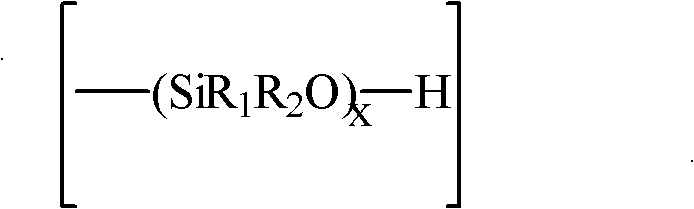

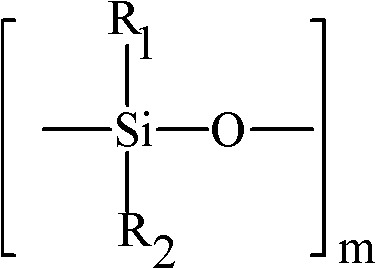

Functionalized diene elastomer, and rubber composition containing same

The present invention relates to a specific functionalized diene elastomer. This functionalized elastomer exhibits a reduced cold flow without, however, damaging the properties of a reinforced rubber composition in which it is present, in particular the processing properties and the hysteresis properties. This functionalized diene elastomer carries, at the chain end, a silanol functional group or a polysiloxane block having a silanol end and is partially coupled by or star-branched by tin.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Two-step preparation method of insulation material for silver-gray aerial insulated cables

InactiveCN106188801AImprove insulation performanceStable speedPlastic/resin/waxes insulatorsSilanesUv absorber

The invention relates to the field of insulation materials, and especially relates to an insulation material for silver-gray aerial insulated cables. A two-step preparation method of the insulation material mainly comprises two steps: step one, preparing catalyst master batch, and step two, preparing finished products. The insulation material is prepared from the following components in percentage by weight: LLDPE-7042, LLDPE-8320, LDPE, a silane coupling agent, a crosslinking agent DCP, an antioxidant 300, an antioxidant 1010, an antioxidant DLTP, organic tin, fluorine rubber master batch, silver-grey master batch, and a UV absorbent. The provided insulation material is used to produce aerial insulated cables for power transmission, the insulation performance of the insulation material is better than that of PVC; when a wire is burned due to aging, PVC will give off toxic and harmful gas, while the silane insulation material is nontoxic and harmless.

Owner:浙江太湖远大新材料股份有限公司

Silane cross-linked polyethylene insulation silver gray electric wire and cable and preparation method thereof

InactiveCN106188744AImprove insulation performanceStable speedPlastic/resin/waxes insulatorsClimate change adaptationCross-linkMasterbatch

The invention relates to the field of insulation wires and cables, in particular to a silane cross-linked polyethylene insulation silver gray electric wire and cable and a preparation method thereof. The silver gray electric wire and cable comprises an insulation material and a wire, wherein the insulation material is prepared from the following components: LLDPE-7042, LDPE, a silane coupling agent, a cross-linking agent DCP, an antioxidant 300 and a catalyst masterbatch, and the catalyst masterbatch is prepared from the following components: LLDPE-7042, LLDPE-8320, PP, an antioxidant 1010, an antioxidant DLTP, an antioxidant 1024, organic tin, a fluorine rubber masterbatch, a UV absorber and a silver gray masterbatch. The insulation material provide by the invention is mainly used for replacing the existing PVC material, and the insulation property is better than that of PVC; the PVC emits toxic and harmful gases when the electric wire is on fire due to aging and the like, while the silane insulation material is non-toxic and harmless.

Owner:浙江太湖远大新材料股份有限公司

Method for preparing silane crosslinking polyethylene insulating material for 10 kV or below silver gray wires and cables through two-step method

InactiveCN106188802AImprove insulation performanceStable speedPlastic/resin/waxes insulatorsMasterbatchCross-link

The invention relates to the field of insulating materials, in particular to a silane crosslinking polyethylene insulating material for 10 kV or below silver gray wires and cables. A method for preparing the silane crosslinking polyethylene insulating material for the 10 kV or below silver gray wires and cables through a two-step method mainly comprises the two steps of catalyst master batch preparation and finished product preparation. The insulating material is prepared from, by weight, LLDPE-7042, LLDPE-8320, LDPE, EVA, PP, a silane coupling agent, a cross-linking agent DCP, an antioxidant 300, an antioxidant 1010, an antioxidant DLTP, an antioxidant 1024, organotin, fluororubber master batches, an ultraviolet light absorber and silver gray master batches. The insulating material is mainly used for insulating layers of the cables and mainly replaces a current PVC material, the insulating property is superior to that of PVC, PVC can emit toxic and harmful gases when the wires fire due to aging and the like, but the silane insulating material is poisonless and harmless.

Owner:浙江太湖远大新材料股份有限公司

Method for preparing insulating material for black aerial insulated cables through one step

The invention relates to the field of insulating materials, in particular to an insulating material for black aerial insulated cables. A method for preparing the insulating material for the black aerial insulated cables through one step mainly comprises the two steps of catalyst master batch preparation and finished product preparation. The insulating material is prepared from, by weight, LLDPE-7042, LLDPE-8320, LDPE, a silane coupling agent, a cross-linking agent DCP, an antioxidant 300, an antioxidant 1010, an antioxidant DLTP, organotin, fluororubber master batches and black master batches. The insulating material is used for erecting overhead wires to transmit electricity, the insulating property is superior to that of PVC, PVC can emit toxic and harmful gases when the wires fire due to aging and the like, but the silane insulating material is poisonless and harmless.

Owner:浙江太湖远大新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com