Manufacturing process of polytetrafluoroethylene composite elastic body shim and product thereof

A polytetrafluoroethylene and production method technology, applied in other household appliances, household components, applications, etc., can solve the problems of poor elasticity and strength, insufficient overall use effect, poor sealing performance, etc., and achieve high sealing specific pressure. , Reduce the blowout resistance, reduce the effect of gasket cold flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: the step of the production method of polytetrafluoroethylene composite elastomer gasket of the present invention is:

[0027] a. Preparation of mixed rubber. The composition and mass percentage of mixed rubber are: 70% of fluorine rubber, 1.7% of vulcanizing agent, 13.7% of acid absorbing agent, 13.7% of reinforcing agent, and the rest are operating aids;

[0028] b. Pre-press molding under the conditions of temperature 80-90℃ and pressure 15-30Mpa;

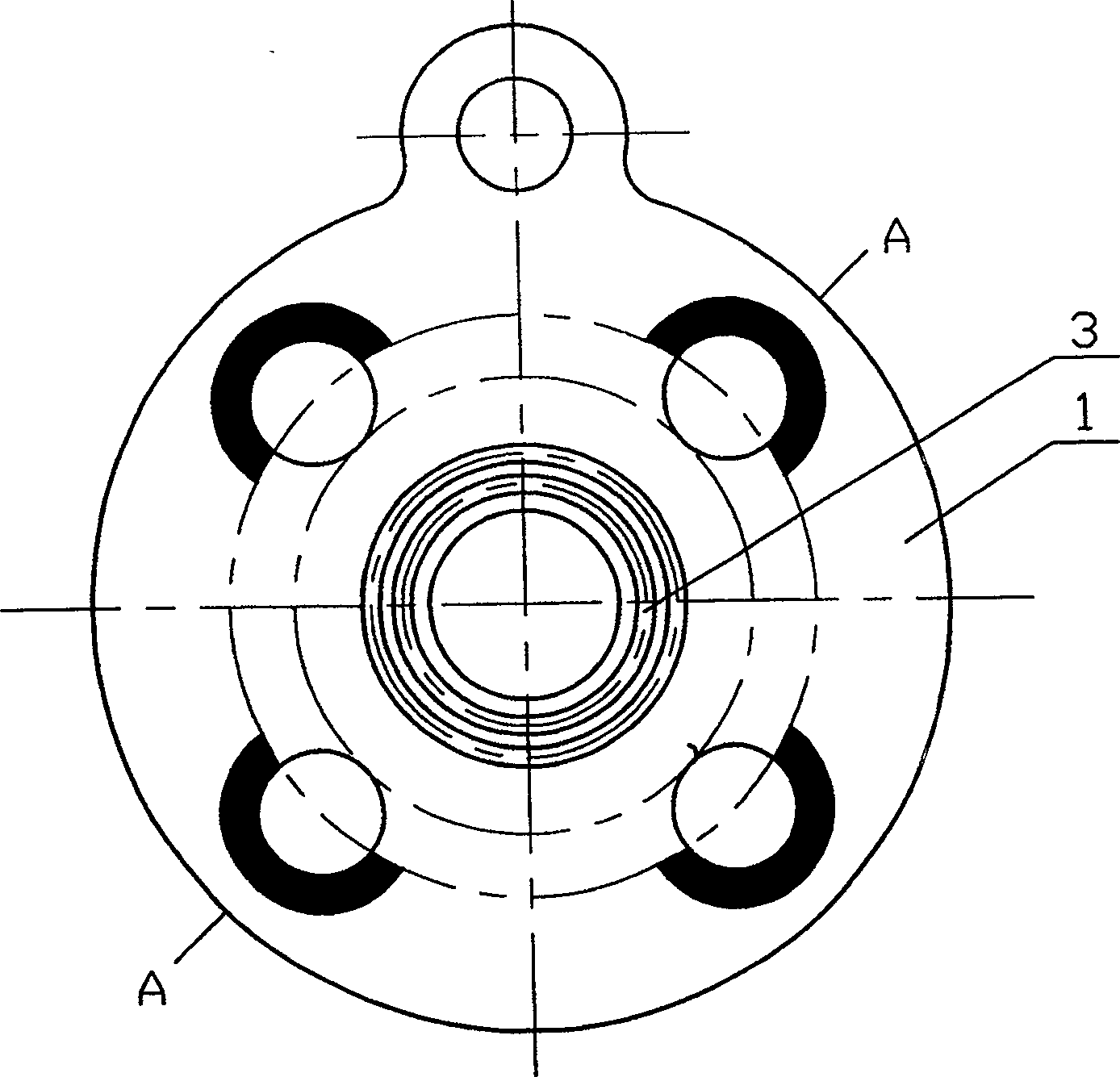

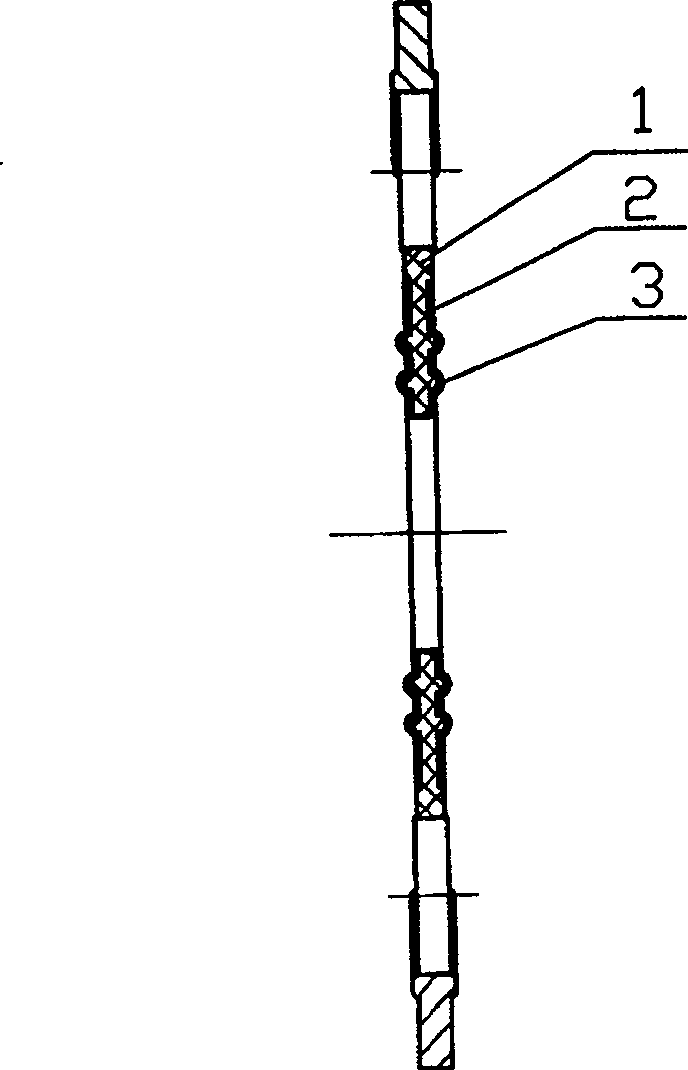

[0029] c. Process the PTFE gasket through machine tool cutting, and process the water line 3;

[0030] d, polytetrafluoroethylene and rubber bonding parts are surface-activated with naphthalene sodium treatment agent, naphthalene sodium treatment agent is: naphthalene and sodium are dissolved in a sufficient amount of tetrahydrofuran solution, and the molar ratio of naphthalene to sodium is 1:1;

[0031] e. Apply adhesive to bond the rubber gasket 1 to the PTFE shell 2;

[0032] f. Vulcanization molding und...

Embodiment 2

[0037] Embodiment 2: the step of the production method of polytetrafluoroethylene composite elastomer gasket of the present invention is:

[0038] a. Preparation of mixed rubber. The composition and mass percentage of mixed rubber are: 60% of fluorine rubber, 3% of vulcanizing agent, 15% of acid absorbing agent, 15% of reinforcing agent, and the rest are operating aids;

[0039] b. Pre-press molding under the conditions of temperature 80-90℃ and pressure 15-30Mpa;

[0040] c. Process the PTFE gasket through machine tool cutting, and process the water line 3;

[0041] d, polytetrafluoroethylene and rubber bonding parts are surface-activated with naphthalene sodium treatment agent, naphthalene sodium treatment agent is: naphthalene and sodium are dissolved in a sufficient amount of tetrahydrofuran solution, and the molar ratio of naphthalene to sodium is 1:1;

[0042] e. Apply adhesive to bond the rubber gasket 1 to the PTFE shell 2;

[0043] f. Vulcanization molding under the...

Embodiment 3

[0048] Embodiment 3: the step of the production method of polytetrafluoroethylene composite elastomer gasket of the present invention is:

[0049]a. Preparation of mixed rubber. The composition and mass percentage of mixed rubber are: 50% of fluorine rubber, 1.5% of vulcanizing agent, 10% of acid absorbing agent, 10% of reinforcing agent, and the rest are operating aids;

[0050] b. Pre-press molding under the conditions of temperature 80-90℃ and pressure 15-30Mpa;

[0051] c. Process the PTFE gasket through machine tool cutting, and process the water line 3;

[0052] d, polytetrafluoroethylene and rubber bonded parts carry out surface activation treatment with naphthalene sodium treatment agent, naphthalene sodium treatment agent is: naphthalene and sodium are dissolved in a sufficient amount of tetrahydrofuran solution, and the molar ratio of naphthalene to sodium is 1:1;

[0053] e. Apply adhesive to bond the rubber gasket 1 to the PTFE shell 2;

[0054] f. Vulcanization ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| compression ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com