Non-halogen flame-retardant polyethylene sheath insulating material and preparation method thereof

A flame retardant polyethylene and insulating material technology, applied in insulators, insulated conductors, insulated cables, etc., can solve problems such as large gaps, achieve high insulation resistance, improve thermal deformation resistance, and reduce quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

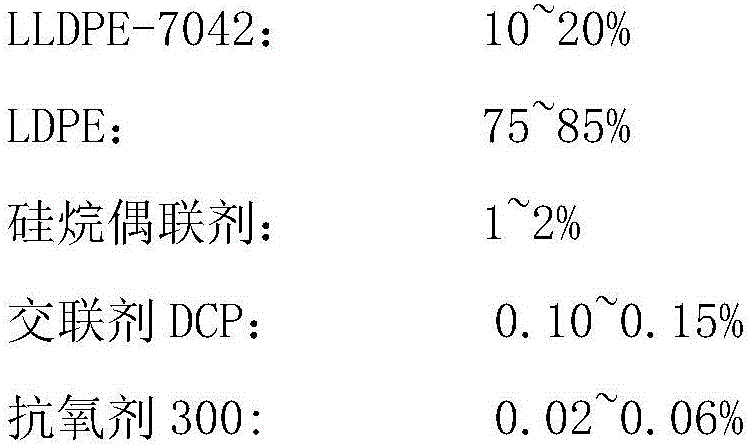

[0044] A halogen-free flame-retardant polyethylene sheath insulating material, which is prepared from the following components by weight percentage:

[0045]

[0046] and catalyst masterbatch;

[0047] Described catalyst masterbatch is made of following component:

[0048]

[0049] The two-step method for preparing the above-mentioned halogen-free flame-retardant polyethylene sheath insulating material mainly consists of two parts, one is the preparation of the catalyst masterbatch, and the other is the preparation of the finished product.

[0050] 1. Catalyst masterbatch preparation:

[0051] Stir the above materials in the mixer, first stir at low speed for 1 minute and then at high speed for 3 minutes, then release and pour into the hopper of the extruder (extruder temperature: 140-180°C), extrude through the twin-screw, and then pass through the cooling water tank for cooling , and then blown dry by a fan before cutting into pellets. The pellets are dried in a dryi...

Embodiment 2

[0061] A halogen-free flame-retardant polyethylene sheath insulating material, which is prepared from the following components by weight percentage:

[0062]

[0063] and catalyst masterbatch;

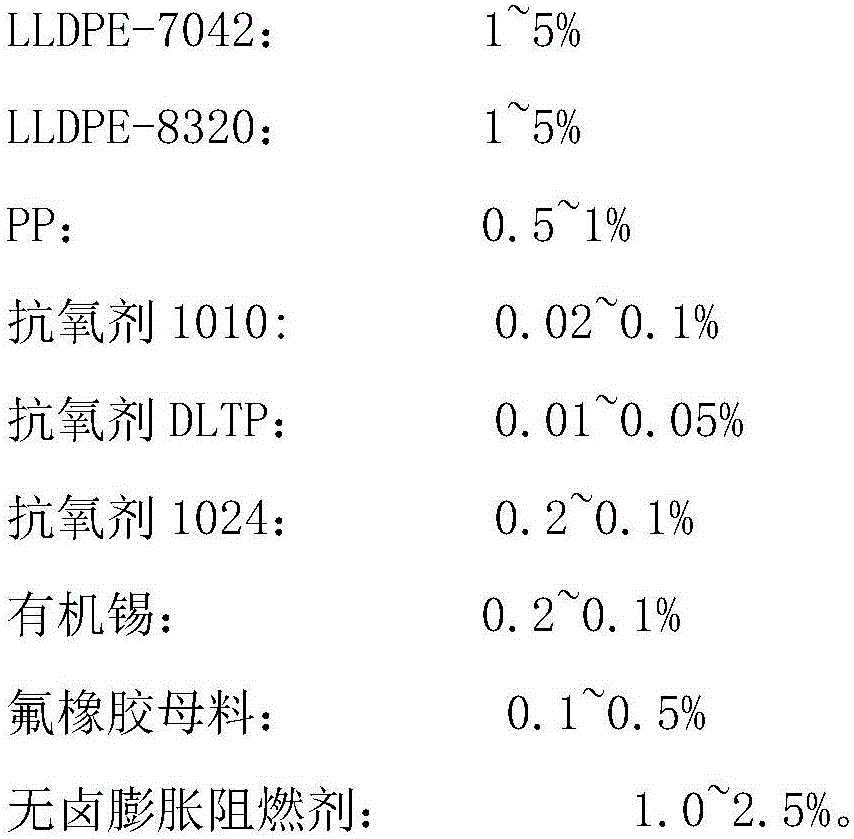

[0064] Described catalyst masterbatch is made of following component:

[0065]

[0066]

[0067] The insulating material mentioned above was prepared by the two-step method of Example 1.

Embodiment 3

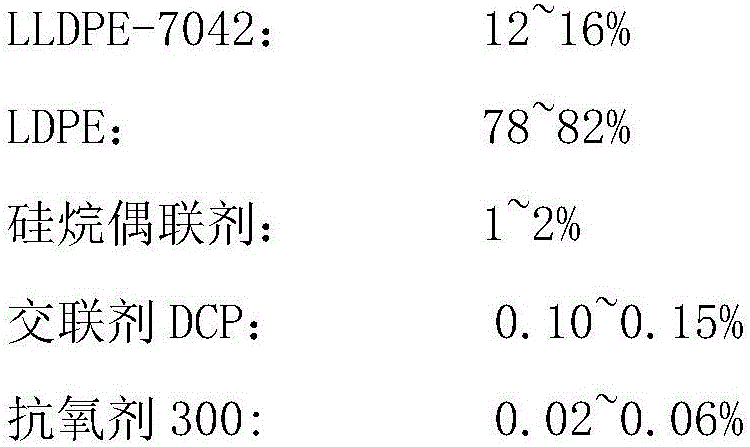

[0069] A halogen-free flame-retardant polyethylene sheath insulating material, which is prepared from the following components by weight percentage:

[0070]

[0071] and catalyst masterbatch;

[0072] Described catalyst masterbatch is made of following component:

[0073]

[0074] The one-step method for preparing the above-mentioned halogen-free flame-retardant polyethylene sheath insulating material mainly consists of two parts, one is the preparation of the catalyst masterbatch, and the other is the preparation of the finished product.

[0075] 1) Catalyst masterbatch preparation: Stir the above catalyst masterbatch materials in a mixer, first stir at low speed for 1 minute, then stir at high speed for 3 minutes, then release and pour into the hopper of the extruder. After the screw is extruded, it is cooled by the cooling water tank, and then dried by the fan before being pelletized. The pellets are dried in the drying tower at 80°C for more than 2 hours, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com