Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Reasonable mix design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Formula of anti-corrosion concrete used for filling pile and preparation method of anti-corrosion concrete

InactiveCN104150837AChanging practice in estimating fly ash useReasonable mix designSolid waste managementStructural engineeringChloride ion penetration

The invention discloses a formula of anti-corrosion concrete used for a filling pile and a preparation method of the anti-corrosion concrete. Ordinary Portland cement and two-stage coal ash are adopted as cementing agents for concrete, and an appropriate amount of high molecular material polyacrylate and sodium nitrite are added to be used as modified materials for concrete, so that the concrete, with the function of preventing the erosion of sulfate and chloride ions, for the filling pile is prepared. The doping amount of the coal ash is given by adopting a computation method, so that the design of mix proportion is more reasonable; the concrete has better workability, and the working performance of the concrete for the filling pile is guaranteed; a chloride ion penetration experiment proves that the electric flux is quite low, and accordingly, the concrete has higher compactness; especially, after the concrete is put into a sodium sulfate solution of 10% and subjected to dry-wet cycling for 150 times, the compressive strength ratio is still 0.92, and the surface of a concrete briquette is complete without loss basically; the materials are easy to obtain, the preparation method is simple, the cost is low, and positive significance on the environmental protection is achieved.

Owner:HEBEI CONSTR & INVESTIGATION RES INST

Heatproof concrete

The invention discloses heatproof concrete. The concrete is made from the following raw materials through uniform mixing according to a ratio, 95-115 kg / m<3> of water, 320-340 kg / m<3> of cement, 40-80 kg / m<3> of coal ash, 120-1040 kg / m<3> of mineral powder, 739-852 kg / m<3> of sand, 890-1040 kg / m<3> of fine stone and 3.80-4.00 kg / m<3> of an additive. The heatproof concrete is reasonable in design and wide in application range.

Owner:蔡建华

Processing technology of baking-free bricks

The invention discloses a processing technology of baking-free bricks. The concrete is prepared by evenly mixing the raw materials by a mixture ratio: 70-80 of sand, 7-12 of cement, 5-15 of lime, 0.5-1 of straw and 0.5-1.5 of additives, wherein river sand or mountain sand is adopted as the sand for making the baking-free bricks, slag cement or fly ash cement is used as the cement which adopts ordinary Portland cement as a cementing material, calcium oxide is used as the lime, the used fly ash is wet ash or dry ash. The processing technology comprises the steps of firstly, evenly stirring the sand, the cement, the lime, the straw and water according to the ratio, adding the additives into the mixture, and stirring for 5-10min; putting the product into a mould, molding and cutting; removingthe mould when the product reaches mould removal strength, and carrying out natural curing. The freezing resistance disturbed compressive strength torsional loss of the baking-free bricks is not greater than 25%, the water resistance and water saturation strength of the baking-free bricks are 5.0-10.0MPa, and the water absorption rate is more than 20%.

Owner:蔡建华

Lime-based plaster formula

The invention discloses a lime-based plaster formula, wherein the components comprise, by weight, 74-82 g of building lime, 294-306 g of building gypsum, 611-629 g of heavy calcium powder, 1-4 g of wood fiber, 1-3 g of cellulose ether, 0.2-1 g of a retarder, 1-3 g of poly-acid styrene, 1-3 g of foamed polystyrene, 1-4 g of starch ether, and 1-3 g of a hydrophobic agent. The lime-based plaster of the present invention has advantages of reasonable ratio design, low cost, moisture prevention, weathering prevention and extremely strong heat insulation capability.

Owner:彭龙喜

Epoxy resin concrete

The invention discloses an epoxy resin concrete, which is uniformly mixed with raw materials in the following proportions: 2-6.5 kg of epoxy resin, 0.2-0.6 kg of butyl phthalate, and 0.15-0.5 kg of ethylenediamine kg, cement 4-8kg, sand 4-9kg, gravel 4-9kg, admixture 0.8-1.2kg, silicon powder 0.5-1.5kg, mineral powder 1.2-1.8kg. The mixing proportion of the concrete in the invention is reasonable, and the application range is wide, and can be applied to cast-in-place concrete such as foundations, beams, columns, frames, bridges, etc. of high-rise buildings, and integral pouring of T-shaped joints. It can ensure the quality of the overall building and meet the building standards.

Owner:彭龙喜

Road concrete

The invention discloses road concrete, which is uniformly mixed with raw materials in the following mixing ratios: water 170-182kg / m³, cement 385-468kg / m³, fly ash 45-60kg / m³, sand 668-kg / m³ 753kg / m³, fine stone 1069‑1095kg / m³, silica fume 104‑128kg / m³, admixture 6.5‑8.8kg / m³, debris 325‑368kg / m³ and waste rock 650‑714kg / m³. The invention has the advantages of reasonable design and wide application range.

Owner:张秧林

General rubber pipe fabric layer frictioning rubber material

The invention discloses a rubber material for wiping the cloth layer of a general rubber hose, which is characterized in that: calculated according to parts by weight, it includes 60-70 parts of natural rubber, 10-30 parts of styrene-butadiene rubber, 30-45 parts of neoprene rubber, 30‑50 parts of reclaimed rubber, 13‑18 parts of sodium oxide, 8‑13 parts of chlorine oxide, 1.5‑3 parts of sulfur, 2‑7 parts of accelerator, 0.8‑1.2 parts of stearic acid, 7‑10 parts of coumarone resin , 11-17 parts of operating oil, 20-25 parts of carbon black, 1.5-3.5 parts of anti-aging agent, 71-84 parts of calcium carbonate, and 3-5 parts of tackifier. The invention has extremely reasonable design of mixing ratio, is suitable for the needs of existing production and life, has low cost, high labor productivity, low energy consumption in the process of processing and manufacturing, and can achieve high yield.

Owner:李舜林

Concrete used for tunnels

The invention discloses concrete used for tunnels. The concrete is formed by evenly stirring raw materials in the following mixing proportion and comprises 160-162kg / m<3> of water, 210-220kg / m<3> of cement, 50-55kg / m<3> of pulverized fuel ash, 70-75kg / m<3> of mineral powder, 796-805kg / m<3> of sand, 1050-1060kg / m<3> of fine stone, 180-210kg / m<3> of silica powder and 4.0-4.2kg / m<3> of an admixture. The concrete used for tunnels has the advantages of being reasonable in design and wide in application range.

Owner:蔡建华

Concrete for pipeline

The invention discloses a Concrete for A pipeline, and the concrete is prepared by evenly mixing the following raw materials in proportion: 166-167kg / m<3> of water, 365-406kg / m<3> of cement, 45-50kg / m<3> of fly ash, 662-710kg / m<3> of sand, 1064-1080kg / m<3> of fine stones, 80-120kg / m<3> of silicon powder, 6.20-7.00kg / m<3> of an additive, 320kg / m3 of detritus and 625-680kg / m<3> of waste stone. The invention has the advantages of reasonable design and wide application range.

Owner:张秧林

Heatproof concrete

InactiveCN106565146AReasonable mix designQuality assuranceSolid waste managementMaterials scienceSilica fume

Heatproof concrete is disclosed. The concrete is prepared by uniformly blending 166-168 kg / m<3> of water, 225-232 kg / m<3> of cement, 73-75 kg / m<3> of fly ash, 735-824 kg / m<3> of sand, 1008-1021 kg / m<3> of fine stone, 220-240 kg / m<3> of silica fume, 3.9-4.0 kg / m<3> of an admixture, 340-350 kg / m<3> chippings and 438-441 kg / m<3> of waste stone. The concrete has advantages of a reasonable design and a wide range of application.

Owner:张秧林

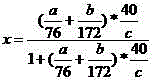

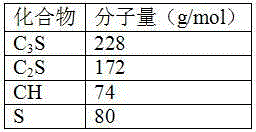

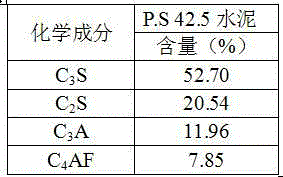

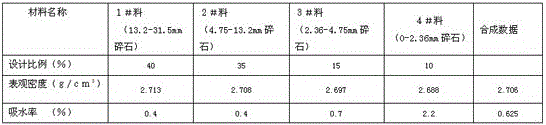

Theoretical calculation method for water content of mixed material of cement stabilized macadam road pavement

InactiveCN106447541AOptimal water contentBest moisture contentData processing applicationsMixed materialsRoad surface

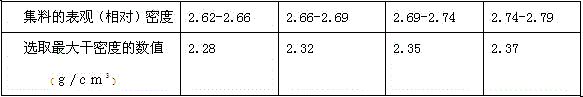

The invention discloses a theoretical calculation method for the water content of a mixed material of a cement stabilized macadam road pavement, and aims to determine an optimal water content of the mixed material of the cement stabilized macadam road pavement, and the optimal water content of the mixed material can be relatively precisely and reasonably determined with comparison with an indoor testing result. The theoretical calculation method comprises the following steps: performing theoretical calculation on the standard water rate of cement in a test part used in an indoor test, the water absorption rate of an aggregate and the water rate of a middle gap of the mixed material, converting calculated results into the water amount of the cement in the test part, the water absorption amount of the aggregate and the water amount of the middle gap of the mixed material so as to determine an actual optimal water amount of the mixed material, and further converting the optimal water amount of the mixed material into the optimal water content of the mixed material. By adopting the theoretical calculation method, the situation that the optimal water content of the mixed material can be only determined by using an indoor testing method can be changed, the proportioning rate of the water content of the mixed material of the cement stabilized macadam road pavement can be relatively and reasonably designed, the construction quality can be improved, rework can be avoided, and the production cost can be lowered.

Owner:中石化石油工程技术服务有限公司 +1

Heat preservation type concrete

InactiveCN106554183AReasonable mix ratioReasonable designSolid waste managementMaterials scienceRaw material

The invention discloses heat preservation type concrete. The concrete is formed by evenly stirring and combining raw materials according to the following mix proportion, wherein the raw materials include water with the density ranging from 166 kg / m<3> to 168 kg / m<3>, cement with the density ranging from 157 kg / m<3> to 163 kg / m<3>, fly ash with the density ranging from 80 kg / m<3> to 90 kg / m<3>, mineral powder with the density ranging from 35 kg / m<3> to 38 kg / m<3>, sand with the density ranging from 860 kg / m<3> to 870 kg / m<3>, fine stone with the density ranging from 1022 kg / m<3> to 1032 kg / m<3>, silicon powder with the density ranging from 180 kg / m<3> to 190 kg / m<3>, and an additive with the density ranging from 3.4 kg / m<3> to 3.6 kg / m<3>. The heat preservation type concrete has the beneficial effects of being reasonable in design and wide in application range.

Owner:蔡建华

Flame retardant conveying belt covering rubber formula

The invention discloses a formula for covering rubber of a flame-retardant conveyor belt, which comprises 65-84 parts of polyvinyl chloride, 25-34 parts of nitrile rubber, 0.5-2 parts of sulfur, and dicumyl peroxide in terms of parts by weight 3‑7 parts, accelerator 1‑4 parts, nitrite 4‑9 parts, stearic acid 3‑5 parts, antiaging agent 1‑3 parts, tricresyl phosphate 40‑55 parts, butyl phthalate 10 parts ‑25 parts, 15‑25 parts of chlorinated paraffin, 15‑35 parts of zinc borate, 25‑40 parts of carbon black, 10‑14 parts of diyttrium trioxide, 2‑6 parts of antistatic agent, 2‑6 parts of zinc oxide, 25-40 parts of aluminum hydroxide, the design of the mixing ratio of the present invention is extremely reasonable, suitable for the needs of existing production and life, low cost, high labor productivity, low energy consumption in the process of processing and manufacturing, and can achieve high-yield flame retardant Formulation of conveyor belt covering rubber.

Owner:李舜林

Hard polyvinyl chloride low-foaming building pipe material formula

The invention discloses a rigid polyvinyl chloride low-foaming building pipe formula, which comprises 56-65g of polyvinyl chloride resin, 4-10g of MBS impact modifier, 2-7g of lead salt stabilizer, AC Foaming agent 0.3-1g, stearic acid 0.1-1g, calcium carbonate 0.5-6g. The rigid polyvinyl chloride low-foaming construction pipe material of the present invention has reasonable design of mixing ratio, low cost, high strength, strong moisture-proof, weather-proof and heat-insulating capabilities.

Owner:彭龙喜

Formula of millable polyurethane rubber

The invention discloses a formula of mixing type polyurethane rubber, which comprises 87-104 parts of raw material mixing type polyurethane rubber, 12-29 parts of coumarone resin, 6-9 parts of accelerator, and anti-aging agent, calculated according to parts by weight 1‑3 parts, 2‑5 parts of sulfur, 4‑6 parts of high wear-resistant carbon black, 2.5‑4 parts of stearic acid, 6‑9 parts of sodium stearate, 11‑19 parts of sulfur, 2‑6 parts of pine tar , the present invention has an extremely reasonable mix design, is suitable for the needs of existing production and life, has low cost, high labor productivity, low energy consumption in the manufacturing process, and can achieve high-yield rubber formula.

Owner:李舜林

Formula of lead salt stabilizing agent

The invention discloses a lead salt stabilizer formula, which comprises 92-103 parts of polyvinyl chloride resin powder, 18-27 parts of nitrate trisalt, 9-15 parts of chlorinated disalt, and stearic acid in parts by weight. 1.5-2.5 parts of calcium, 1.5-2.5 parts of barium stearate, 1-2 parts of lead stearate, 0.5-1.5 parts of stearic acid, 6-9 parts of acrylic anti-impact agent, 6-13 parts of bentonite, stearin 2‑5 parts of citric acid, 2‑8 parts of active light calcium, 5‑11 parts of titanium dioxide, 0.5‑2 parts of oxidized polyethylene wax, and 0.5‑1 part of paraffin wax. The design of the mixing ratio of the present invention is extremely reasonable, and when it is attached to the surface of PVC during PVC resin processing, the adhesive force is excellent and no peeling will occur.

Owner:王玉楼

Formula of barium and calcium composite stabilizer

The invention discloses a formula of a barium-calcium composite stabilizer, calculated in parts by weight, comprising 25-30 parts of zinc stearate, 20-25 parts of calcium stearate, 15-20 parts of hydrotalcite and 15-20 parts of zeolite , 3-5 parts of polyethylene wax, 3-5 parts of paraffin wax, 15-20 parts of calcium carbonate, 1-5 parts of dibenzoylmethane, 4-11 parts of diquateritol, 2-7 parts of antioxidant, hydrogen chloride 1-4 parts of ammonium. The mixing ratio design of the invention is extremely reasonable, and when it is attached to the PVC surface during the processing of the PVC resin, the adhesion is excellent and no peeling occurs.

Owner:王玉楼

Vibration reduction type concrete

The invention discloses a vibration reduction type concrete, which is formed by uniformly stirring the following raw materials: 150-160 kg / m<3> of water, 320-336 kg / m<3> of cement, 45 kg / m<3> of fly ash, 65-71 kg / m<3> of ore powder, 686-704 kg / m<3> of sand, 1070-1085 kg / m<3> of fine stone, and 6.9-7.5 kg / m<3> of an admixture. The vibration reduction type concrete of the present invention has advantages of reasonable design and wide application range.

Owner:张秧林

Aqueous two-component polyurethane coating material formula

InactiveCN108300030AWon't fall offReasonable mix designPolyurea/polyurethane coatingsAntioxidantStearic acid

The invention discloses an aqueous two-component polyurethane coating material formula, wherein the components comprise, by weight, 25-30 parts of zinc stearate, 20-25 parts of calcium stearate, 15-20parts of hydrotalcite, 15-20 parts of zeolite, 3-5 parts of polyethylene wax, 3-5 parts of paraffin, 15-20 parts of calcium carbonate, 1-5 parts of dibenzoylmethane, 4-11 parts of dipentaerythritol,2-7 parts of an antioxidant, and 1-4 parts of ammonium hydrogen chloride. According to the present invention, the ratio design is extremely reasonable, the construction process is simple, and the paint film cannot shed.

Owner:王玉楼

Concrete of paddy field ridge brick

The invention discloses a concrete for paddy field ridge bricks. The concrete is uniformly mixed with the following raw materials: ordinary silicon cement 20-30, fly ash 15-25, industrial waste slag 35-50, sand 5-15 , admixture 0.075~0.125, rice straw 1~5, water 15~20, the present invention has the advantages of reasonable design and wide application range.

Owner:蔡建华

Formula of rubber for automobile inner tube

InactiveCN107778602AReasonable mix designLow costSpecial tyresBuilding insulationsRubber materialButyl rubber

The invention discloses a formula of rubber for an automobile inner tube. The formula comprises the following components in parts by weight: 81-109 parts of raw material rubber, 25-41 parts of rosin soft butylbenzene, 92-115 parts of butyl rubber, 2-7 parts of zinc oxide, 2-5 parts of calcium stearate, 15-30 parts of semi-reinforcing carbon black, 10-23 parts of high wear-proof carbon black, 2-7 parts of pine tar, 8-14 parts of mixed gas carbon black, 2-4 parts of an anti-aging agent, 1-3 parts of paraffin, 4-6 parts of asphalt and 0.5-1.5 parts of an accelerant. The formula of rubber is veryreasonable in mixture ratio design, suitable for existing production and living requirements, low in cost, high in labor productivity, low in energy consumption in processing and manufacturing procedures, and capable of achieving high yield.

Owner:李舜林

Natural rubber formula

The invention discloses a formula of natural rubber, which comprises 92-106 parts of raw rubber, 7-12 parts of ferrous sulfate, 2-5 parts of polyamic acid, 51-57 parts of coloring agent, plasticizing 9-14 parts of agent, 6-13 parts of stabilizer, 4-7 parts of lubricant, 2-6 parts of accelerator, 1-4 parts of anti-aging agent, 2.5-6.5 parts of sulfur. The invention has extremely reasonable design of mixing ratio, is suitable for the needs of existing production and life, has low cost, high labor productivity, low energy consumption in the processing and manufacturing process, and can achieve high-yield rubber formula.

Owner:李舜林

Bottom roof plate concrete

The invention discloses a concrete for the bottom slab of a roof slab. The concrete is uniformly mixed with the following raw materials: water 192-215kg / m³, cement 315-345kg / m³, fly ash 98-140kg / m³, sand 762‑792 kg / m³, mineral powder 6.8‑9.2 kg / m³, pebble 1080‑1153 kg / m³, silicon powder 10.6‑18.9 kg / m³, admixture 4.9‑6.5 kg / m³, debris 310‑330 kg / m³ , Wood calcium 1.8‑3.1 kg / m³. The invention has the advantages of reasonable design and wide application range.

Owner:张秧林

Bridge concrete

The invention discloses a bridge concrete, which is uniformly mixed with the following raw materials: water 108-124kg / m³, cement 280-304kg / m³, fly ash 38-59kg / m³, mineral powder 54- 78kg / m³, sand 605‑679kg / m³, fine stone 1002‑1094 kg / m³ and admixture 2.8‑3.9kg / m³. The invention has the advantages of reasonable design and wide application range.

Owner:张秧林

Industrial concrete

The invention discloses an industrial concrete, which is uniformly mixed with the following raw materials: water 124-138kg / m³, cement 266-295kg / m³, fly ash 41-54kg / m³, mineral powder 49 ‑68kg / m³, sand 715‑789kg / m³, fine stone 998‑1068kg / m³, calcium lignosulfonate 1.2‑2.9 kg / m³ and admixture 3.4‑5.2kg / m³. The invention has the advantages of reasonable design and wide application range.

Owner:张秧林

Floor slab concrete for high-rise building

The invention discloses floor slab concrete for a high-rise building. The concrete is prepared by uniformly mixing the following raw materials in proportion: 164 to 166 kg / m<3> of water, 282 to 319 kg / m<3> of cement, 50 kg / m<3> of fly ash, 762 to 792 kg / m<3> of sand, 1050 to 1053 kg / m<3> of fine stone, 160 to 200 kg / m<3> of silica fume, 4.5 to 5.3 kg / m<3> of an additive, 325 to 330 kg / m<3> of debris and 520 to 568 kg / m<3> of a material. The floor slab concrete provided by the invention has the advantages of reasonable design and wide application range.

Owner:张秧林

Baking-free concrete brick

The invention discloses a non-fired concrete brick, which is uniformly mixed with the following raw materials: ordinary silicon cement 20-30, fly ash 15-25, industrial waste slag 35-50, sand 5-15, Admixture 0.075~0.125, straw 1~5, water 15~20, the present invention can be applied to cast-in-situ concrete such as foundation, beam, column, frame, bridge of high-rise building, and the integral pouring of T-shaped joint. It can guarantee the quality of the overall building and meet the building standards.

Owner:蔡建华

Extremely-high-strength concrete

The invention discloses a concrete with excellent strength. The concrete is uniformly mixed with the following raw materials: water 145-158kg / m³, cement 197-221kg / m³, fly ash 97-108kg / m³, sand 735‑824 kg / m³, pebbles 1320‑1521 kg / m³, wood calcium 1.4‑2.93 kg / m³, bentonite 543‑621.9 kg / m³, admixture 3.9‑4.0 kg / m³, debris 386‑394 kg / m³ and waste Stone 488‑495 kg / m³. The invention has the advantages of reasonable design and wide application range.

Owner:张秧林

Concrete baking-free bricks

The invention discloses concrete baking-free bricks. The concrete baking-free bricks are prepared by evenly mixing the following raw materials by a ratio: 35-50 coal ash, 28-40 zeolite powder, 30-40 coke powder, 1-3 natural gypsum and 5-10 magnesium chloride water. The concrete baking-free bricks have the advantages of being reasonable in design and wide in application scope.

Owner:蔡建华

Chloroprene rubber formula

The invention discloses a formula of chloroprene rubber, which comprises 104-132 parts of raw material chloroprene rubber, 24-31 parts of magnesium oxide, 6-9 parts of stearic acid and 3-3 parts of semi-reinforced furnace black, calculated according to parts by weight 8 parts, 4-7 parts of zinc oxide, 1-2.5 parts of sodium sulfate, 8-11 parts of copper stearate, 8-18 parts of sulfur, 3-7 parts of anti-aging agent, 2.5-4.5 parts of accelerator, the mixing ratio design of the present invention It is extremely reasonable, suitable for the needs of existing production and life, low in cost, high in labor productivity, low in energy consumption during processing and manufacturing, and can achieve high-yield rubber formula.

Owner:李舜林

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com