Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Compliant with building standards" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heatproof concrete

The invention discloses heatproof concrete. The concrete is made from the following raw materials through uniform mixing according to a ratio, 95-115 kg / m<3> of water, 320-340 kg / m<3> of cement, 40-80 kg / m<3> of coal ash, 120-1040 kg / m<3> of mineral powder, 739-852 kg / m<3> of sand, 890-1040 kg / m<3> of fine stone and 3.80-4.00 kg / m<3> of an additive. The heatproof concrete is reasonable in design and wide in application range.

Owner:蔡建华

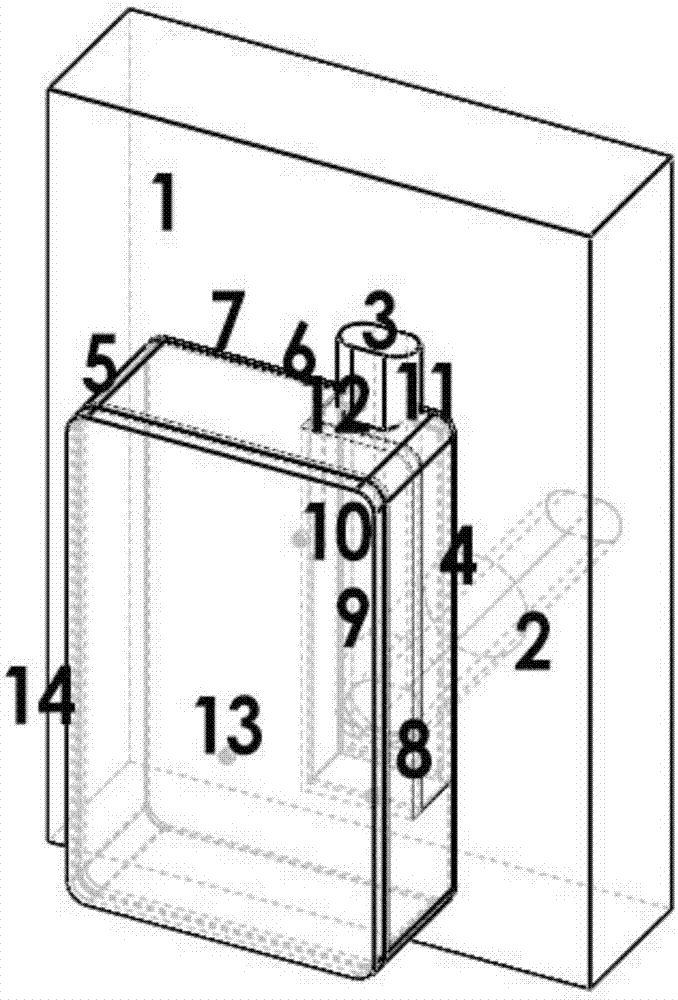

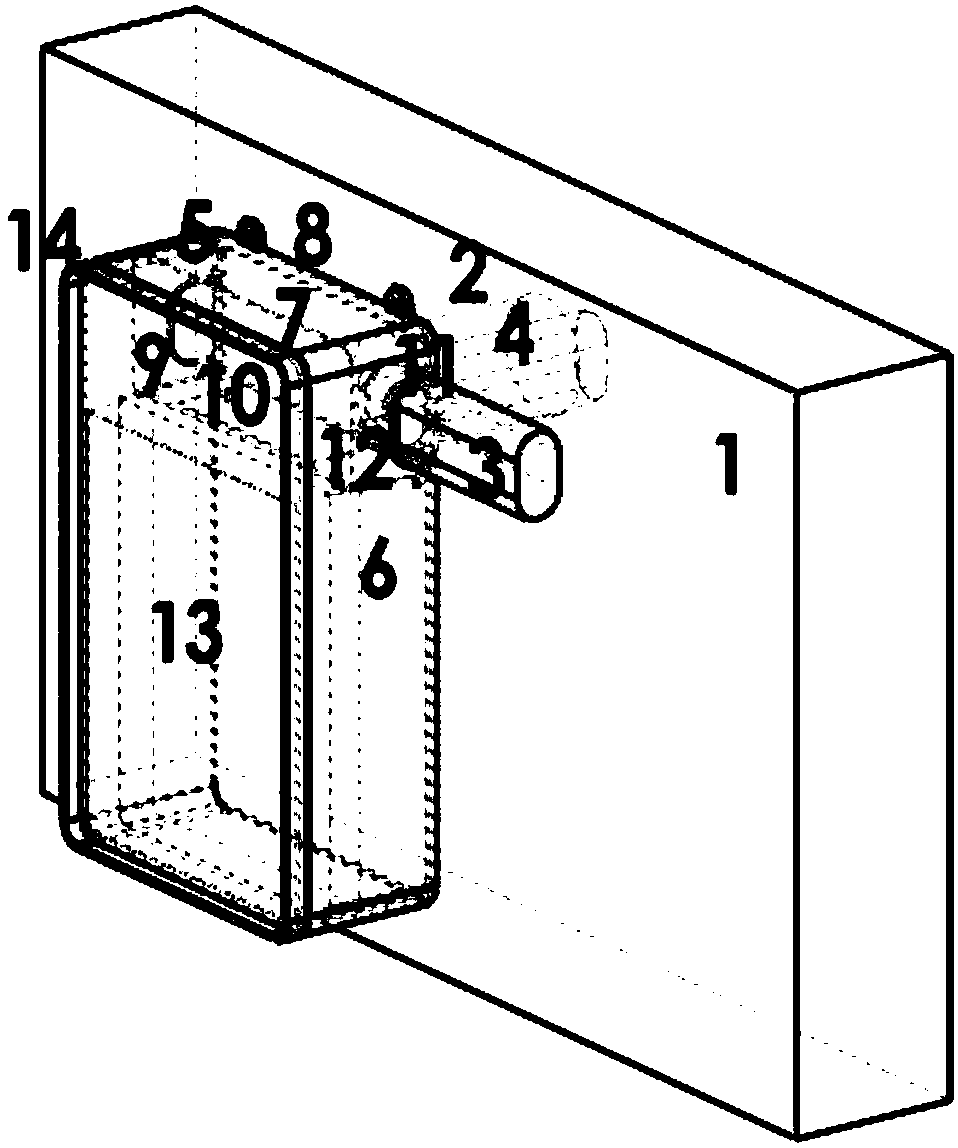

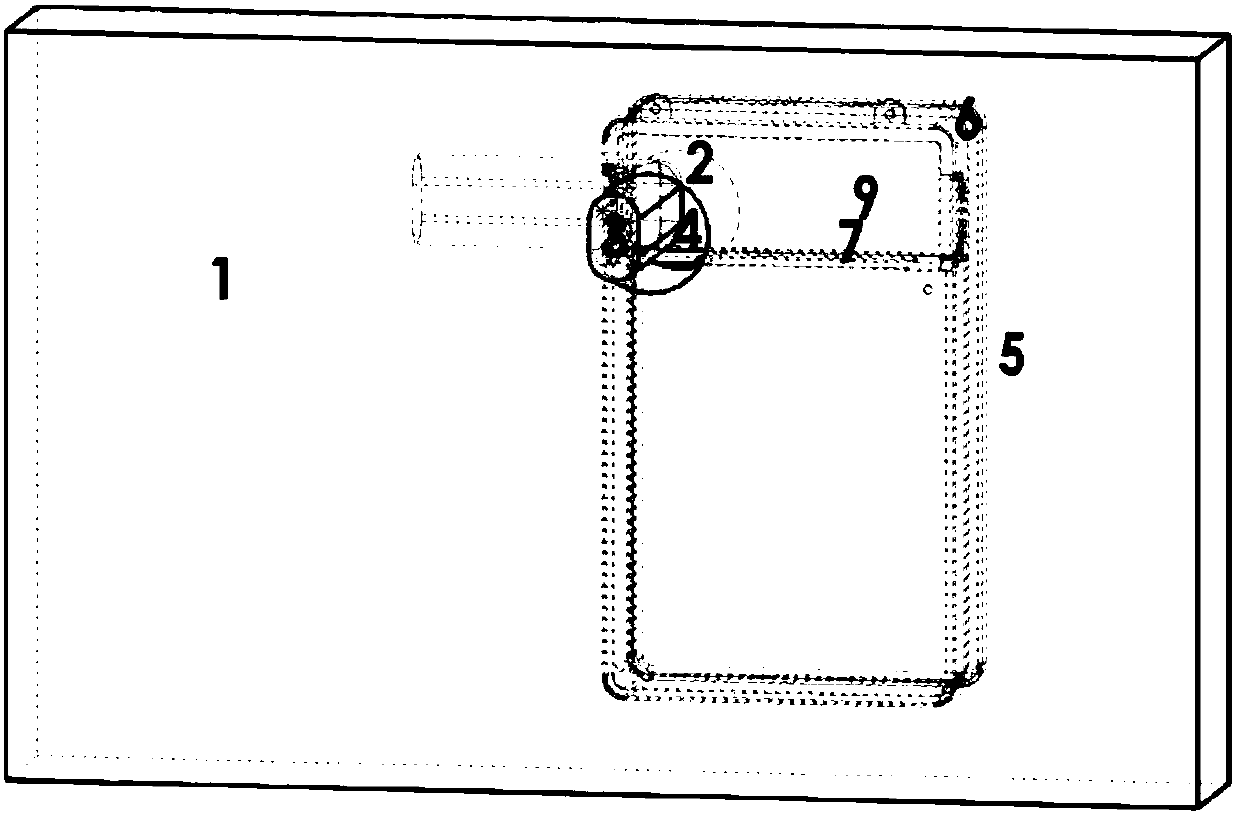

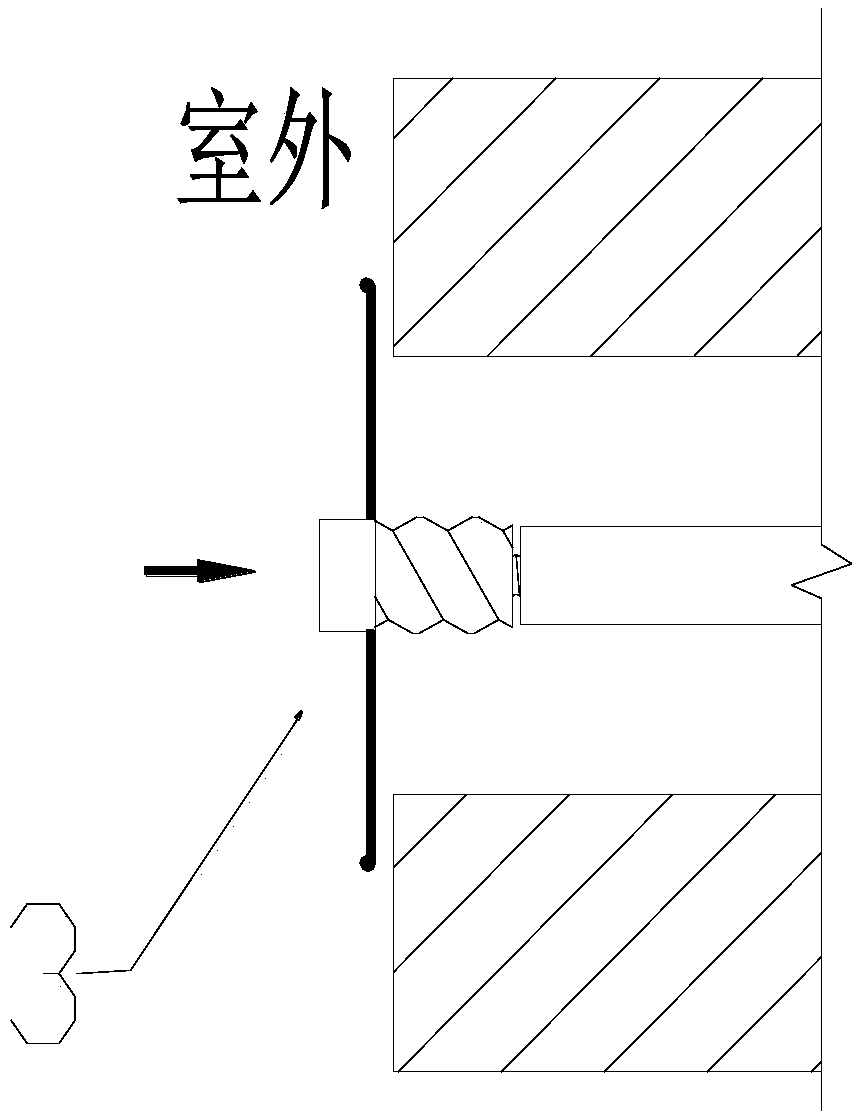

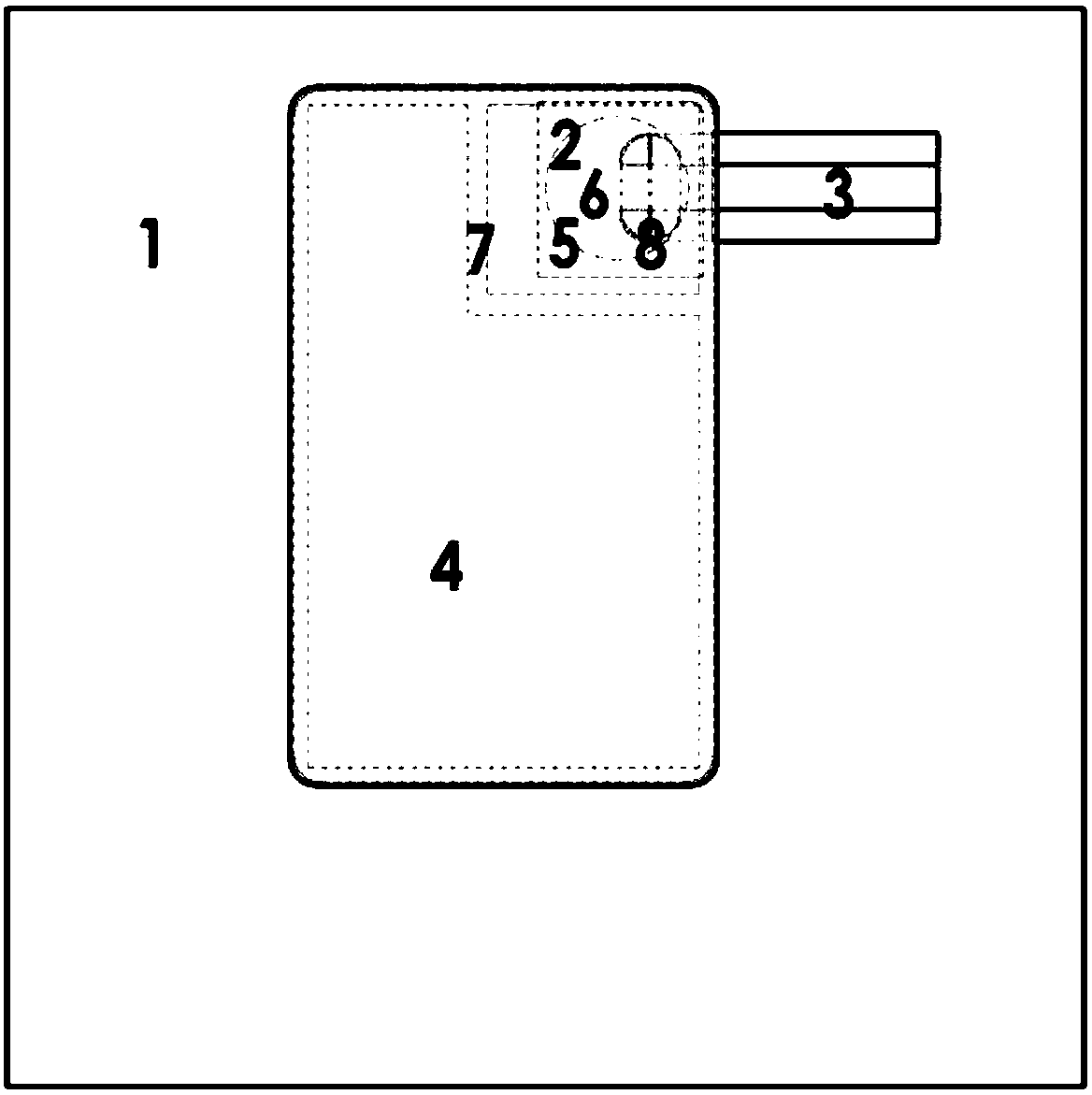

Installation method of wall-mounted purification fresh air blower for ventilation through directly shared air conditioner installation hole

PendingCN107883506AAvoid harmMeet fitness levelDucting arrangementsMechanical apparatusFresh airEngineering

The invention relates to an installation method of a wall-mounted purification fresh air blower for ventilation through a directly shared air conditioner installation hole. An air conditioner pipe setpenetrates through a machine box through a through hole formed in the rear side of a top plate of the machine box according to the direction of the air conditioner pipe set, the building reserved airconditioner installation hole in a wall is covered with an air inlet of the wall-mounted purification fresh air blower, a back plate of the wall-mounted purification fresh air blower is connected with the wall, and by means of remaining space, generated after an air conditioner is installed, of the building reserved air conditioner installation hole in the wall, ventilation between the wall-mounted purification fresh air blower and the outdoor is achieved through the remaining space of the air conditioner installation hole, so that the wall-mounted purification fresh air blower is installed without punching an installation hole, the wall-mounted purification fresh air blower is widely applied to bedrooms and studies in houses and office environments with the area of 20 square meters or below, influences of outdoor haze and pollen are effectively prevented, and the installation cost can be reduced by more than 100 yuan.

Owner:北京东方智明科技有限公司

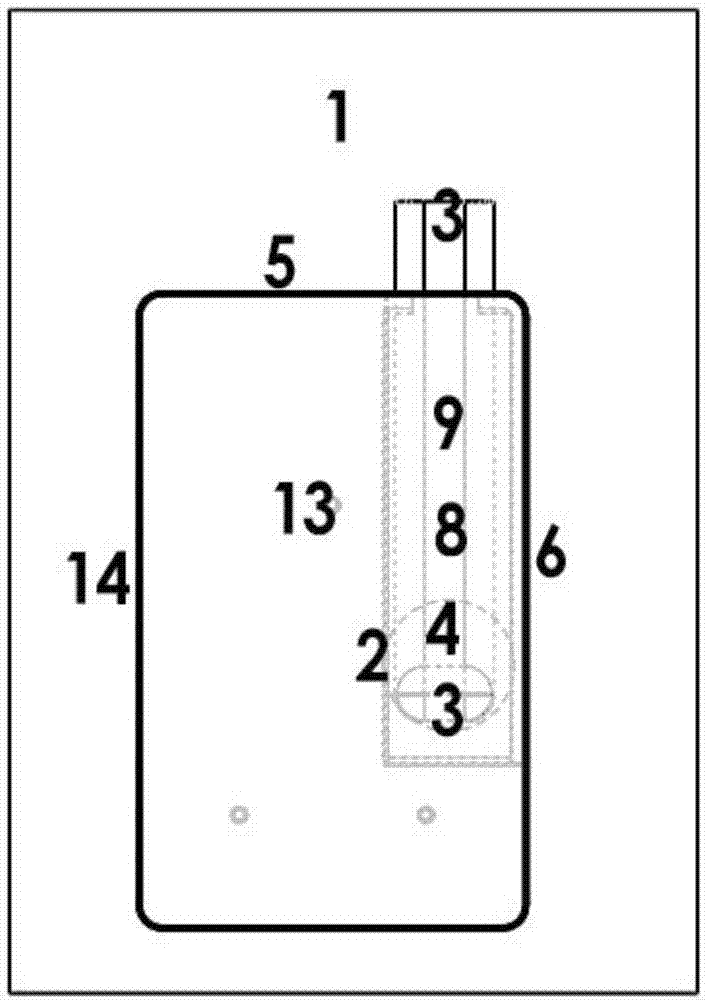

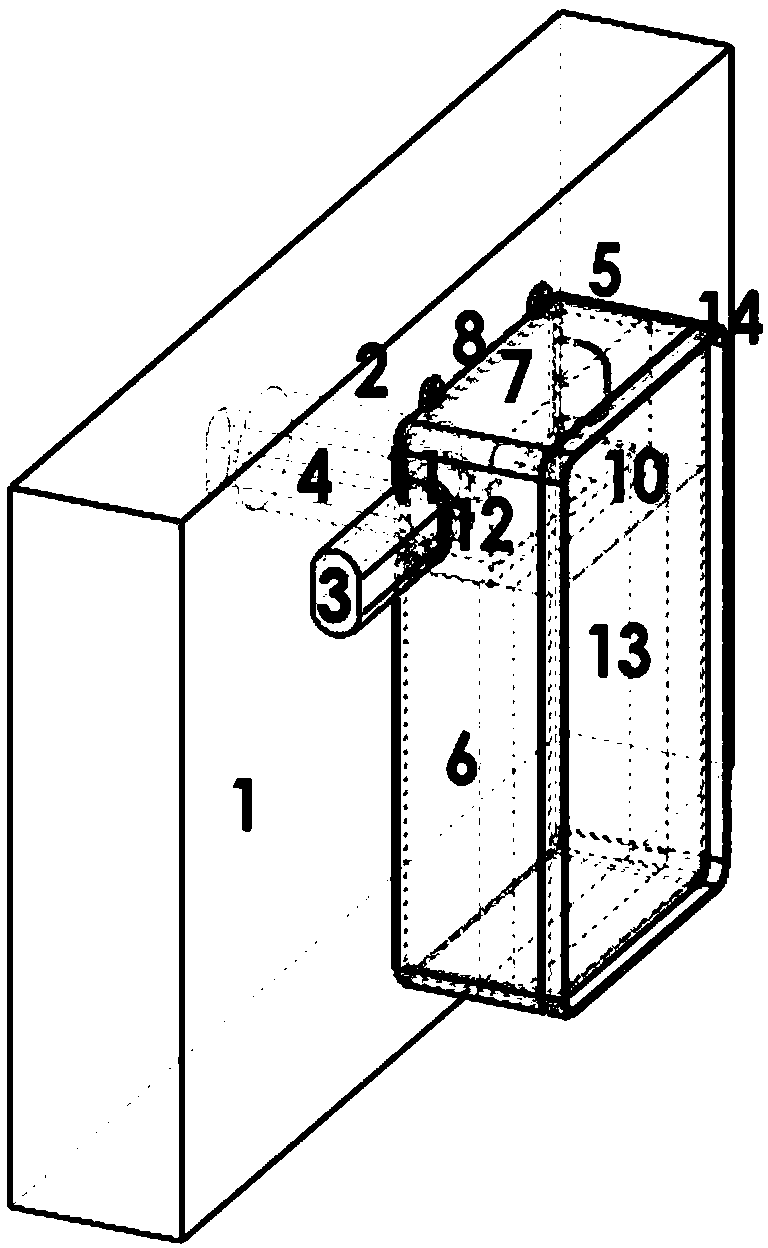

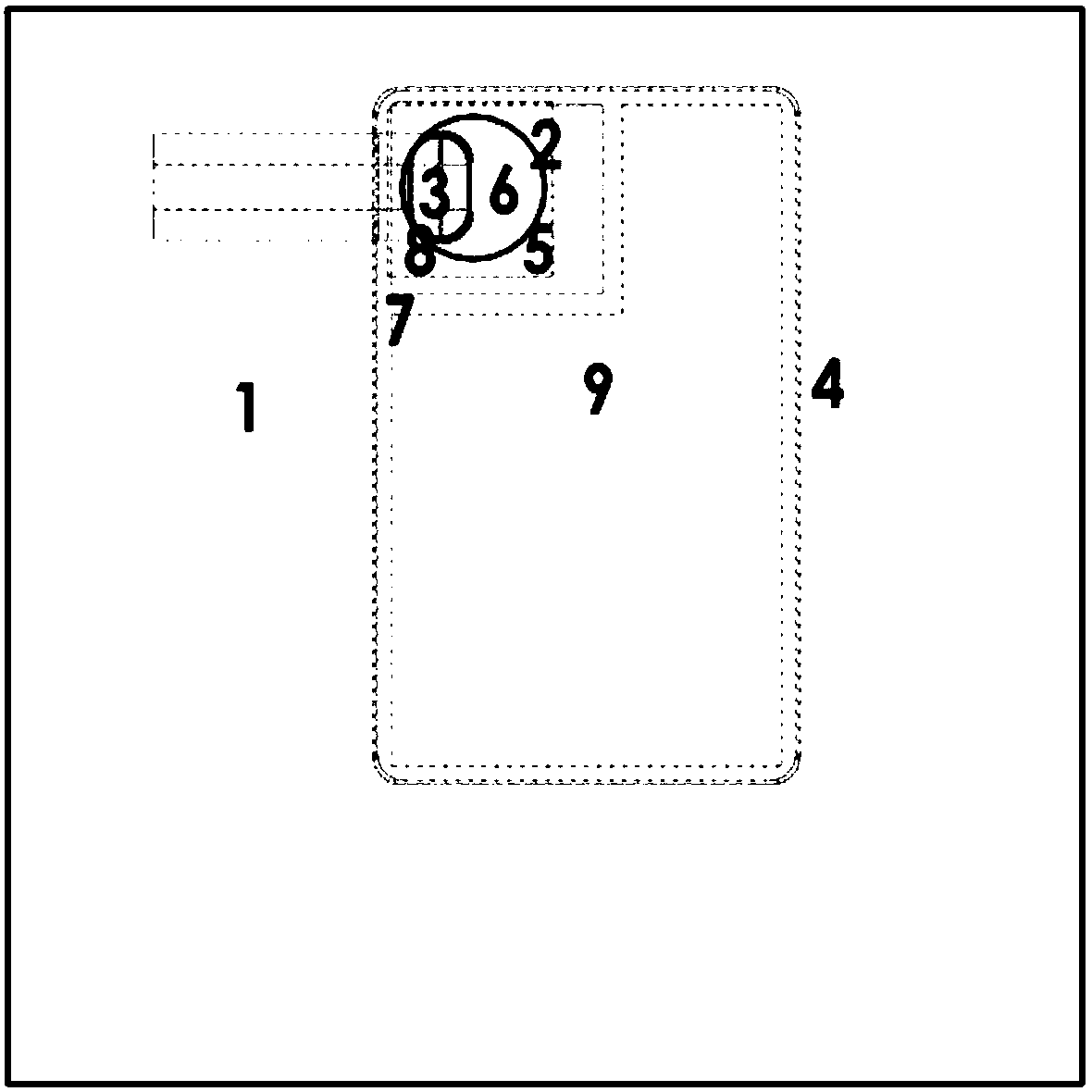

Two-way mounting method of wall-mounted purification fresh air ventilator sharing air conditioner mounting hole to ventilate

PendingCN107676957AAvoid harmMeet fitness levelDucting arrangementsLighting and heating apparatusDaily livingPipe fitting

The invention discloses a two-way mounting method of a wall-mounted purification fresh air ventilator sharing an air conditioner mounting hole to ventilate. An air conditioner pipe fitting set passingthrough hole is formed in the rear part of the corresponding side of a chassis according to the direction of an air conditioner pipe fitting set for enabling the air conditioner pipe fitting set to penetrate out of the chassis; a back plate intake port, formed in a back plate of the wall-mounted purification fresh air ventilator, is used for covering the air conditioner mounting hole reserved ina wall; and an air conditioner mounting hole residual space formed after the air conditioner pipe fitting set is installed in the air conditioner mounting hole with the size accordant with the construction standards in the wall, and the back plate intake port form a wall-mounted purification fresh air ventilator and outside ventilation channel, so that the wall-mounted purification fresh air ventilator achieves ventilation with the outside by directly using the air conditioner mounting hole residual space, the installation of the wall-mounted purification fresh air ventilator is completed, thewall-mounted purification fresh air ventilator facilitates people's daily life and working environments, the people health level is improved, the integrity of the wall is not destructed any more, andthe punching cost about 100 Yuan in installation of each fresh air ventilator can be saved.

Owner:北京东方智明科技有限公司

Processing technology of baking-free bricks

The invention discloses a processing technology of baking-free bricks. The concrete is prepared by evenly mixing the raw materials by a mixture ratio: 70-80 of sand, 7-12 of cement, 5-15 of lime, 0.5-1 of straw and 0.5-1.5 of additives, wherein river sand or mountain sand is adopted as the sand for making the baking-free bricks, slag cement or fly ash cement is used as the cement which adopts ordinary Portland cement as a cementing material, calcium oxide is used as the lime, the used fly ash is wet ash or dry ash. The processing technology comprises the steps of firstly, evenly stirring the sand, the cement, the lime, the straw and water according to the ratio, adding the additives into the mixture, and stirring for 5-10min; putting the product into a mould, molding and cutting; removingthe mould when the product reaches mould removal strength, and carrying out natural curing. The freezing resistance disturbed compressive strength torsional loss of the baking-free bricks is not greater than 25%, the water resistance and water saturation strength of the baking-free bricks are 5.0-10.0MPa, and the water absorption rate is more than 20%.

Owner:蔡建华

Epoxy resin concrete

The invention discloses an epoxy resin concrete, which is uniformly mixed with raw materials in the following proportions: 2-6.5 kg of epoxy resin, 0.2-0.6 kg of butyl phthalate, and 0.15-0.5 kg of ethylenediamine kg, cement 4-8kg, sand 4-9kg, gravel 4-9kg, admixture 0.8-1.2kg, silicon powder 0.5-1.5kg, mineral powder 1.2-1.8kg. The mixing proportion of the concrete in the invention is reasonable, and the application range is wide, and can be applied to cast-in-place concrete such as foundations, beams, columns, frames, bridges, etc. of high-rise buildings, and integral pouring of T-shaped joints. It can ensure the quality of the overall building and meet the building standards.

Owner:彭龙喜

Hole filling tool and method

A hole filling tool includes: a cap having a screw; a canopy having ribs and fabric supported by the ribs, wherein the screw of the cap runs through the center of the canopy; a connection rod, whereinthe head of the connection rod has a screw thread, the tail of the connection rod has a shank, and the screw of the cap is fixedly connected with the head of the connection rod in threaded manner; aslide rod, wherein the head of the slide rod has a screw thread, and the shank of the connection rod is fixedly connected with the head of the slide rod in threaded manner.

Owner:SHANGHAI TRENDZONE CONSTRUCTION DECORATION GROUP CO LTD

Road concrete

The invention discloses road concrete, which is uniformly mixed with raw materials in the following mixing ratios: water 170-182kg / m³, cement 385-468kg / m³, fly ash 45-60kg / m³, sand 668-kg / m³ 753kg / m³, fine stone 1069‑1095kg / m³, silica fume 104‑128kg / m³, admixture 6.5‑8.8kg / m³, debris 325‑368kg / m³ and waste rock 650‑714kg / m³. The invention has the advantages of reasonable design and wide application range.

Owner:张秧林

Concrete used for tunnels

The invention discloses concrete used for tunnels. The concrete is formed by evenly stirring raw materials in the following mixing proportion and comprises 160-162kg / m<3> of water, 210-220kg / m<3> of cement, 50-55kg / m<3> of pulverized fuel ash, 70-75kg / m<3> of mineral powder, 796-805kg / m<3> of sand, 1050-1060kg / m<3> of fine stone, 180-210kg / m<3> of silica powder and 4.0-4.2kg / m<3> of an admixture. The concrete used for tunnels has the advantages of being reasonable in design and wide in application range.

Owner:蔡建华

Concrete for pipeline

The invention discloses a Concrete for A pipeline, and the concrete is prepared by evenly mixing the following raw materials in proportion: 166-167kg / m<3> of water, 365-406kg / m<3> of cement, 45-50kg / m<3> of fly ash, 662-710kg / m<3> of sand, 1064-1080kg / m<3> of fine stones, 80-120kg / m<3> of silicon powder, 6.20-7.00kg / m<3> of an additive, 320kg / m3 of detritus and 625-680kg / m<3> of waste stone. The invention has the advantages of reasonable design and wide application range.

Owner:张秧林

Heatproof concrete

InactiveCN106565146AReasonable mix designQuality assuranceSolid waste managementMaterials scienceSilica fume

Heatproof concrete is disclosed. The concrete is prepared by uniformly blending 166-168 kg / m<3> of water, 225-232 kg / m<3> of cement, 73-75 kg / m<3> of fly ash, 735-824 kg / m<3> of sand, 1008-1021 kg / m<3> of fine stone, 220-240 kg / m<3> of silica fume, 3.9-4.0 kg / m<3> of an admixture, 340-350 kg / m<3> chippings and 438-441 kg / m<3> of waste stone. The concrete has advantages of a reasonable design and a wide range of application.

Owner:张秧林

Heat preservation type concrete

InactiveCN106554183AReasonable mix ratioReasonable designSolid waste managementMaterials scienceRaw material

The invention discloses heat preservation type concrete. The concrete is formed by evenly stirring and combining raw materials according to the following mix proportion, wherein the raw materials include water with the density ranging from 166 kg / m<3> to 168 kg / m<3>, cement with the density ranging from 157 kg / m<3> to 163 kg / m<3>, fly ash with the density ranging from 80 kg / m<3> to 90 kg / m<3>, mineral powder with the density ranging from 35 kg / m<3> to 38 kg / m<3>, sand with the density ranging from 860 kg / m<3> to 870 kg / m<3>, fine stone with the density ranging from 1022 kg / m<3> to 1032 kg / m<3>, silicon powder with the density ranging from 180 kg / m<3> to 190 kg / m<3>, and an additive with the density ranging from 3.4 kg / m<3> to 3.6 kg / m<3>. The heat preservation type concrete has the beneficial effects of being reasonable in design and wide in application range.

Owner:蔡建华

Vibration reduction type concrete

The invention discloses a vibration reduction type concrete, which is formed by uniformly stirring the following raw materials: 150-160 kg / m<3> of water, 320-336 kg / m<3> of cement, 45 kg / m<3> of fly ash, 65-71 kg / m<3> of ore powder, 686-704 kg / m<3> of sand, 1070-1085 kg / m<3> of fine stone, and 6.9-7.5 kg / m<3> of an admixture. The vibration reduction type concrete of the present invention has advantages of reasonable design and wide application range.

Owner:张秧林

Concrete of paddy field ridge brick

The invention discloses a concrete for paddy field ridge bricks. The concrete is uniformly mixed with the following raw materials: ordinary silicon cement 20-30, fly ash 15-25, industrial waste slag 35-50, sand 5-15 , admixture 0.075~0.125, rice straw 1~5, water 15~20, the present invention has the advantages of reasonable design and wide application range.

Owner:蔡建华

Bottom roof plate concrete

The invention discloses a concrete for the bottom slab of a roof slab. The concrete is uniformly mixed with the following raw materials: water 192-215kg / m³, cement 315-345kg / m³, fly ash 98-140kg / m³, sand 762‑792 kg / m³, mineral powder 6.8‑9.2 kg / m³, pebble 1080‑1153 kg / m³, silicon powder 10.6‑18.9 kg / m³, admixture 4.9‑6.5 kg / m³, debris 310‑330 kg / m³ , Wood calcium 1.8‑3.1 kg / m³. The invention has the advantages of reasonable design and wide application range.

Owner:张秧林

Bridge concrete

The invention discloses a bridge concrete, which is uniformly mixed with the following raw materials: water 108-124kg / m³, cement 280-304kg / m³, fly ash 38-59kg / m³, mineral powder 54- 78kg / m³, sand 605‑679kg / m³, fine stone 1002‑1094 kg / m³ and admixture 2.8‑3.9kg / m³. The invention has the advantages of reasonable design and wide application range.

Owner:张秧林

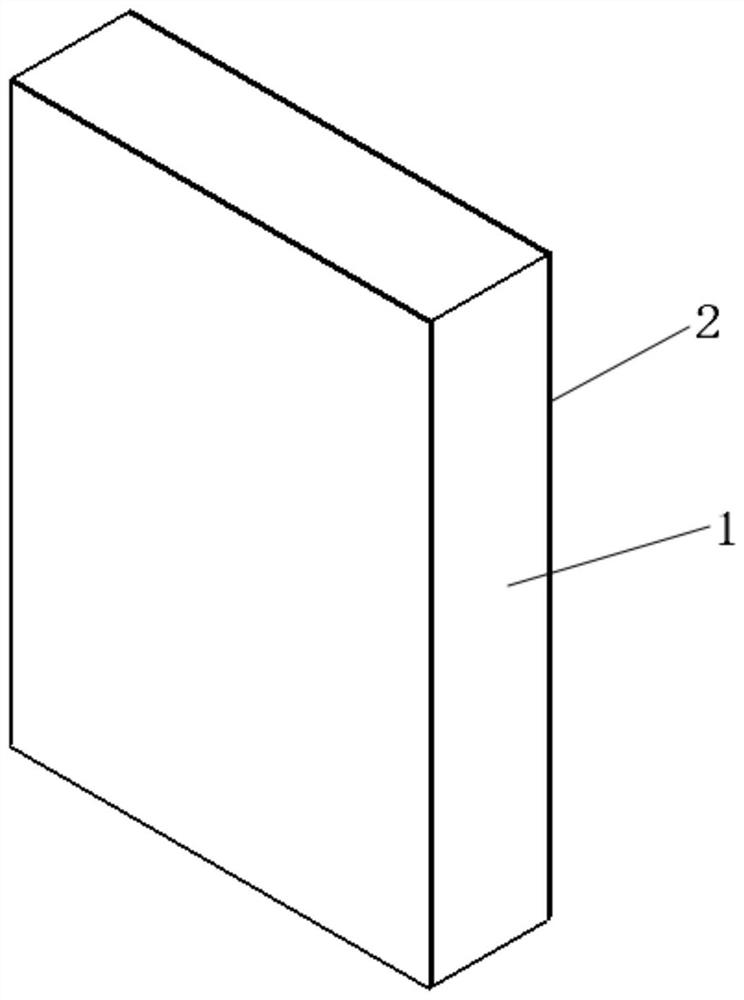

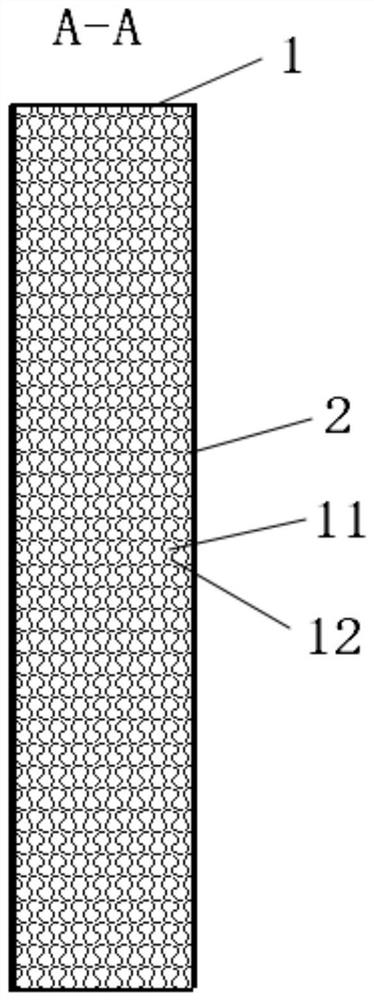

Portable outer formwork, wall body structure and production method of outer formwork

PendingCN112922196AReduce thicknessQuick installationWallsCeramic shaping apparatusCompression moldingHeat conservation

The invention provides a portable outer formwork, a wall body structure and a production method of the outer formwork. The portable outer formwork comprises a heat preservation plate main body, gridding cloth is arranged on the two sides of the heat preservation plate main body, the gridding cloth is directly compounded on the heat preservation plate main body in a pressure applying mode, the gridding cloth and the heat preservation plate main body are integrally formed, the heat preservation plate main body is an inorganic material coated organic particle plate, the two sides of the inorganic material coated organic particle plate are directly compounded with gridding cloth for compression molding, so that the compactness is greatly improved, the air permeability and the water permeability are reduced, the heat preservation effect and the waterproof effect are greatly improved, the mechanical strength is greatly improved, and the effects that the heat preservation plate main body is thinner and lighter, and the safety performance is better are achieved. In addition, the invention further provides a wall body structure which comprises the outer formwork and further comprises a base layer wall body, the outer formwork is laid on the outer side of the base layer wall body, and the construction and construction cost is saved to a great extent.

Owner:山东国创节能科技股份有限公司

Industrial concrete

The invention discloses an industrial concrete, which is uniformly mixed with the following raw materials: water 124-138kg / m³, cement 266-295kg / m³, fly ash 41-54kg / m³, mineral powder 49 ‑68kg / m³, sand 715‑789kg / m³, fine stone 998‑1068kg / m³, calcium lignosulfonate 1.2‑2.9 kg / m³ and admixture 3.4‑5.2kg / m³. The invention has the advantages of reasonable design and wide application range.

Owner:张秧林

Floor slab concrete for high-rise building

The invention discloses floor slab concrete for a high-rise building. The concrete is prepared by uniformly mixing the following raw materials in proportion: 164 to 166 kg / m<3> of water, 282 to 319 kg / m<3> of cement, 50 kg / m<3> of fly ash, 762 to 792 kg / m<3> of sand, 1050 to 1053 kg / m<3> of fine stone, 160 to 200 kg / m<3> of silica fume, 4.5 to 5.3 kg / m<3> of an additive, 325 to 330 kg / m<3> of debris and 520 to 568 kg / m<3> of a material. The floor slab concrete provided by the invention has the advantages of reasonable design and wide application range.

Owner:张秧林

Baking-free concrete brick

The invention discloses a non-fired concrete brick, which is uniformly mixed with the following raw materials: ordinary silicon cement 20-30, fly ash 15-25, industrial waste slag 35-50, sand 5-15, Admixture 0.075~0.125, straw 1~5, water 15~20, the present invention can be applied to cast-in-situ concrete such as foundation, beam, column, frame, bridge of high-rise building, and the integral pouring of T-shaped joint. It can guarantee the quality of the overall building and meet the building standards.

Owner:蔡建华

Extremely-high-strength concrete

The invention discloses a concrete with excellent strength. The concrete is uniformly mixed with the following raw materials: water 145-158kg / m³, cement 197-221kg / m³, fly ash 97-108kg / m³, sand 735‑824 kg / m³, pebbles 1320‑1521 kg / m³, wood calcium 1.4‑2.93 kg / m³, bentonite 543‑621.9 kg / m³, admixture 3.9‑4.0 kg / m³, debris 386‑394 kg / m³ and waste Stone 488‑495 kg / m³. The invention has the advantages of reasonable design and wide application range.

Owner:张秧林

Concrete baking-free bricks

The invention discloses concrete baking-free bricks. The concrete baking-free bricks are prepared by evenly mixing the following raw materials by a ratio: 35-50 coal ash, 28-40 zeolite powder, 30-40 coke powder, 1-3 natural gypsum and 5-10 magnesium chloride water. The concrete baking-free bricks have the advantages of being reasonable in design and wide in application scope.

Owner:蔡建华

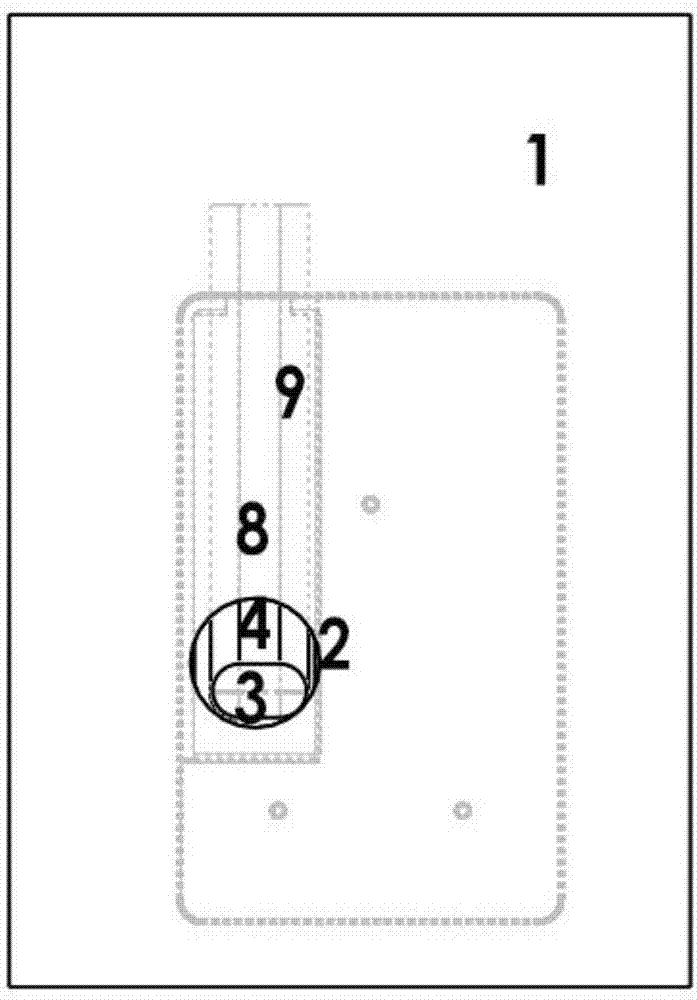

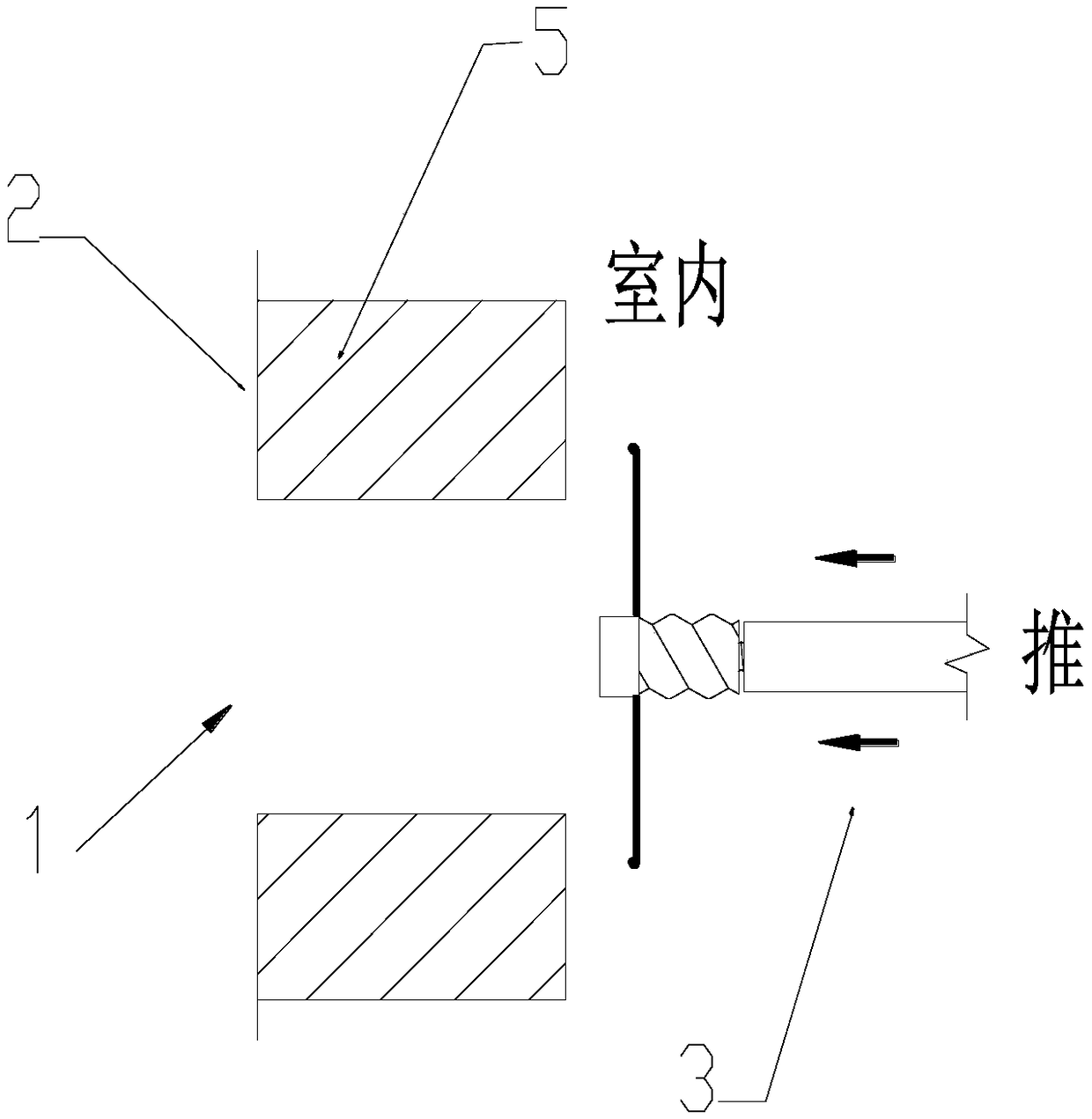

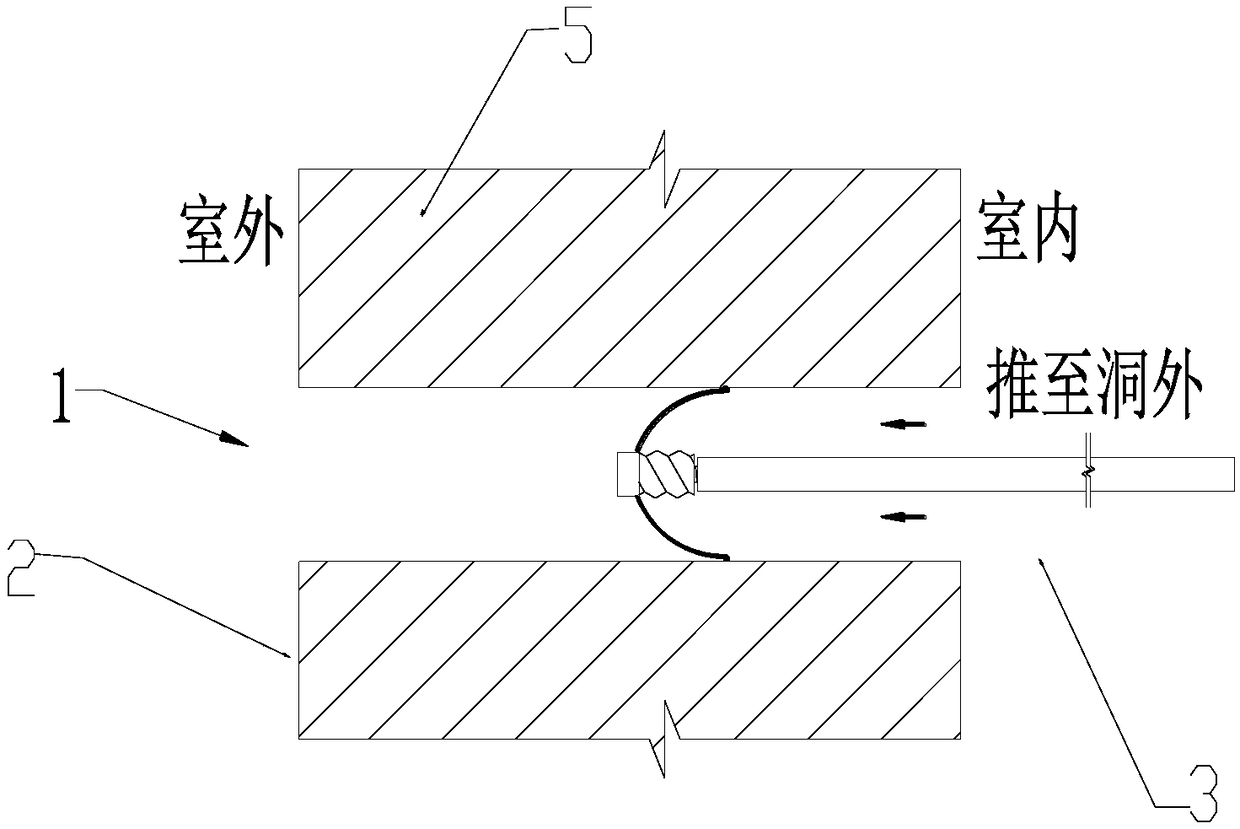

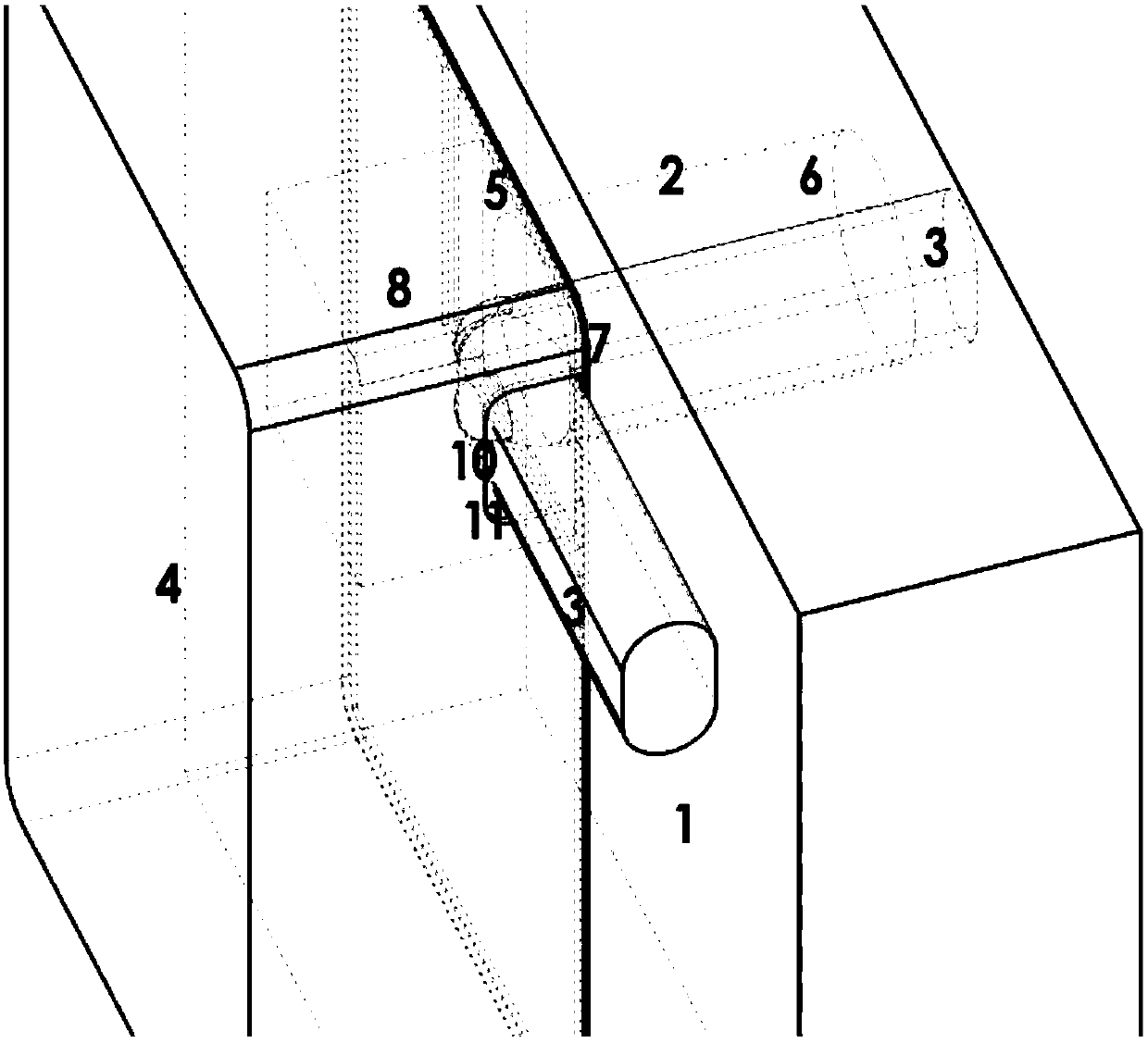

Installation method of wall-mounted purification fresh air ventilator directly sharing air conditioning mounting hole ventilation

PendingCN107781942AAvoid harmMeet fitness levelDucting arrangementsLighting and heating apparatusPipe fittingWorking environment

The invention provides an installation method of a wall-mounted purification fresh air ventilator directly sharing air conditioning mounting hole ventilation. The installation method overcomes the main restraining factor that a special installing hole is drilled when the wall-mounted purification fresh air ventilator is installed, and remaining air conditioning mounting hole space is generated after an air conditioner pipe unit is mounted in an air conditioning mounting hole reserved by a building and serves as a 'ventilation hole' of the wall-mounted purification fresh air ventilator. By theaid of the wall-mounted purification fresh air ventilator, daily life and working environments of people are facilitated, the health level of people is improved, wall integrity is no longer broken, and hole drilling cost can be saved by about 100 Yuan when each fresh air ventilator is installed.

Owner:北京东方智明科技有限公司

Low-shrinkage concrete

The invention discloses low-shrinkage concrete. The low-shrinkage concrete is formed by evenly stirring raw materials of the following mixing proportion and comprises 160-165kg / m<3> of water, 152-187kg / m<3> of cement, 70-80kg / m<3> of pulverized fuel ash, 33-43kg / m<3> of mineral powder, 860-909kg / m<3> of sand, 985-1011kg / m<3> of fine stone, 253-255kg / m<3> of silica powder and 3.3-3.6kg / m<3> of an additive. The low-shrinkage concrete has the advantages of being reasonable in design and wide in application range.

Owner:蔡建华

Concrete for high-rise floor slabs

The invention discloses concrete for high-rise floor slabs. The concrete is formed by evenly mixing the following raw materials of, by weight, 170-180 kg / m<3> of water, 230-250 kg / m<3> of cement, 50-60 kg / m<3> of coal ash, 52-62 kg / m<3> of mineral powder, 785-795 kg / m<3> of sand, 1050-1060 kg / m<3> of fine stone, 110-220 kg / m<3> of silicon powder and 4.2-5.2 kg / m<3> of additives. The concrete for high-rise floor slabs has the advantages of being reasonable in structure and wide in application range.

Owner:蔡建华

Thermal-insulation concrete

The invention discloses a thermal-insulation concrete. Per cubic meter of the thermal-insulation concrete is prepared by uniformly blending the following raw materials: 172 to 176 kg of water, 450 to 476 kg of cement, 56 kg of fly ash, 39 to 41 kg of mineral powder, 605 to 631 kg of sand, 1074 to 1076 kg of fine stone and 8.8 to 9.8 kg of an additive. The thermal-insulation concrete has the advantages of reasonable design and a wide application scope.

Owner:张秧林

Lightweight concrete

The invention discloses a lightweight concrete, which is prepared by uniformly stirring the following raw materials: 150-160 kg / m<3> of water, 283-300 kg / m<3> of cement, 48-50 kg / m<3> of fly ash, 53-65 kg / m<3> of mineral powder, 750-766 kg / m<3> of sand, 1039-1065 kg / m<3> of fine stone, and 6.2-6.6 kg / m<3> of an admixture. The lightweight concrete of the present invention has advantages of reasonable design and wide application range.

Owner:张秧林

Concrete used for bottom bearing walls

The invention discloses a concrete used for bottom bearing walls. The concrete is produced by uniformly blending the following raw materials with the following ratio: 95-135 kg / m<3> of water, 290-340 kg / m<3> of cement, 30-70 kg / m<3> of fly ash, 890-1020 kg / m<3> of ore powder, 788-875 kg / m<3> of sands, 120-1040 kg / <3> of fine stone, and 3.5 kg / <3> of an additive. The concrete has the advantages of reasonable design and wide application scope.

Owner:蔡建华

Mixed injection concrete

The invention discloses a mixed injection concrete, which is formed by uniform mixing of raw materials in the following proportions: the concrete is formed by uniform mixing of raw materials in the following proportions: cement: 30-50, magnesium oxide: 5-15 , Magnesium chloride: 5‑10, foaming agent: 3‑5, straw: 0.5‑1, the present invention has the advantages of reasonable design and wide application range, it can be heated and mixed and injected into a mold for molding, and is used for non-load-bearing wall construction.

Owner:蔡建华

Pressure-resistant concrete

The invention discloses a pressure-resistant concrete, the concrete is prepared by uniformly mixing the following raw materials according to the following mixing proportion: 160-170 kg / m<3> of water, 220-265 kg / m<3> of concrete, 45-55 kg / m<3> of fly ash, 51-80 kg / m<3> of mineral powder, 780-793 kg / m<3> of sand, 1035-1047 kg / m<3> of fine stone and 4.4-4.6 kg / m<3> of admixture. The concrete has the advantages of being reasonable in design and wide in application range.

Owner:张秧林

Baking-free brick concrete

The invention discloses a non-burning brick concrete. The concrete is uniformly mixed with raw materials in the following mixing ratios: fly ash binder 12-14; fly ash 32-34; slag 45-47; admixture 8-9; Water 8-9, the present invention can be applied to cast-in-place concrete such as foundations, beams, columns, frames, bridges, etc. of high-rise buildings, as well as integral pouring of T-joints. It can ensure the quality of the overall building, meet the building standards, improve the quality of concrete, reduce energy consumption and increase output.

Owner:蔡建华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com