Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Realize automatic drilling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

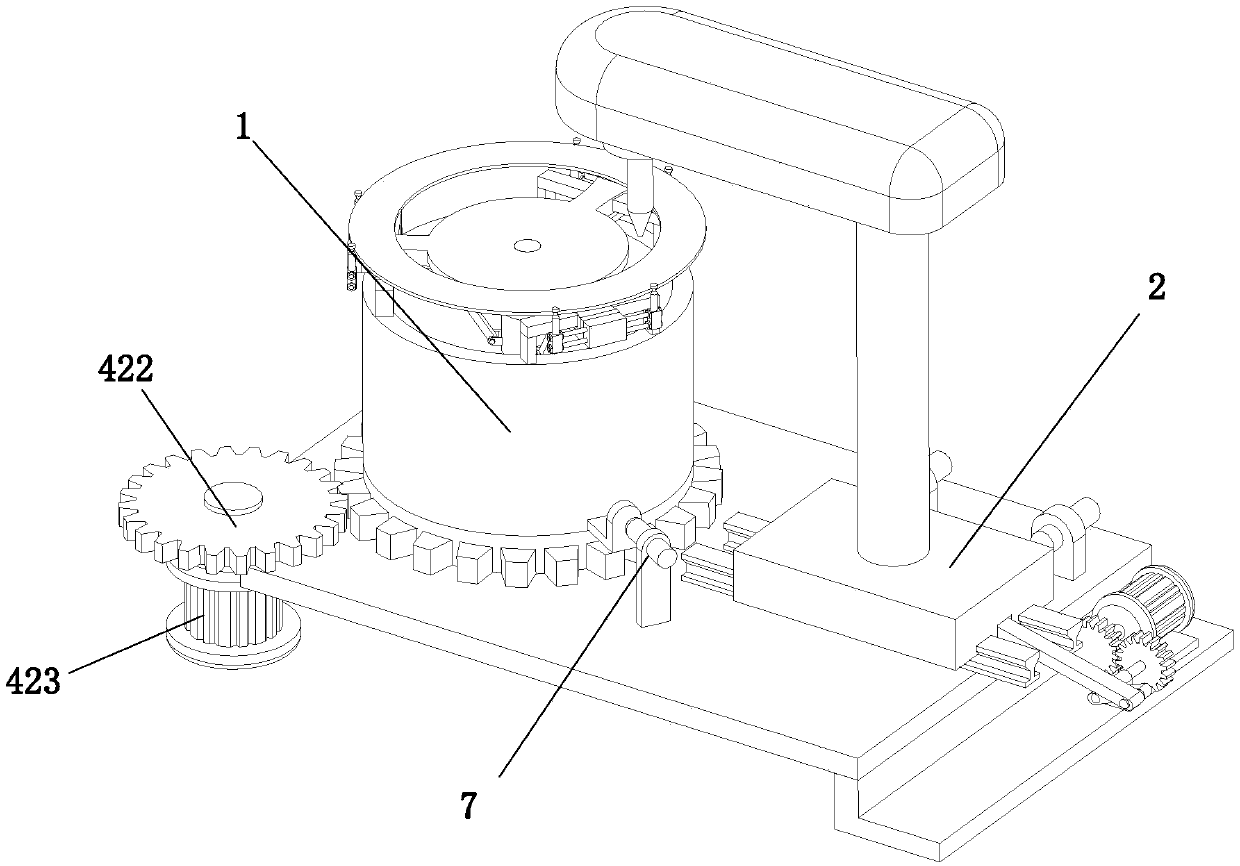

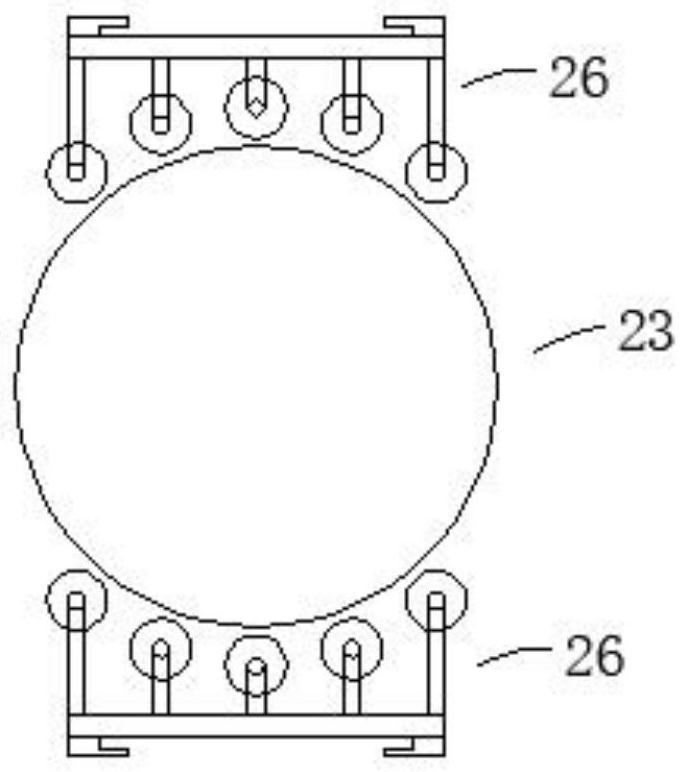

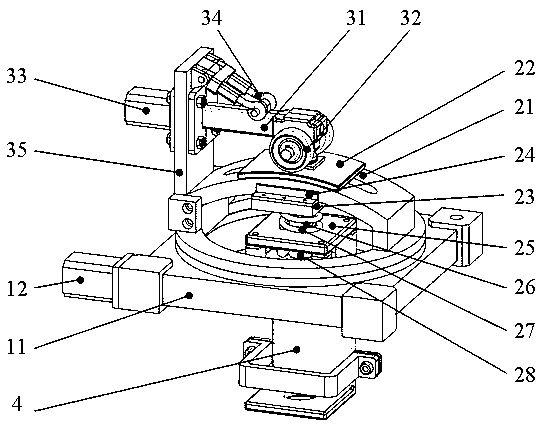

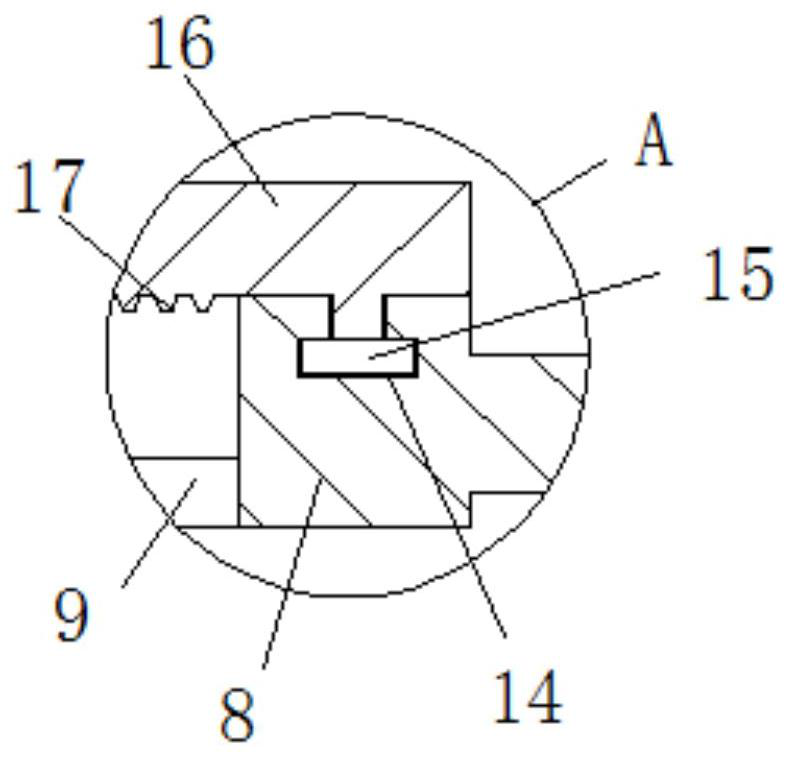

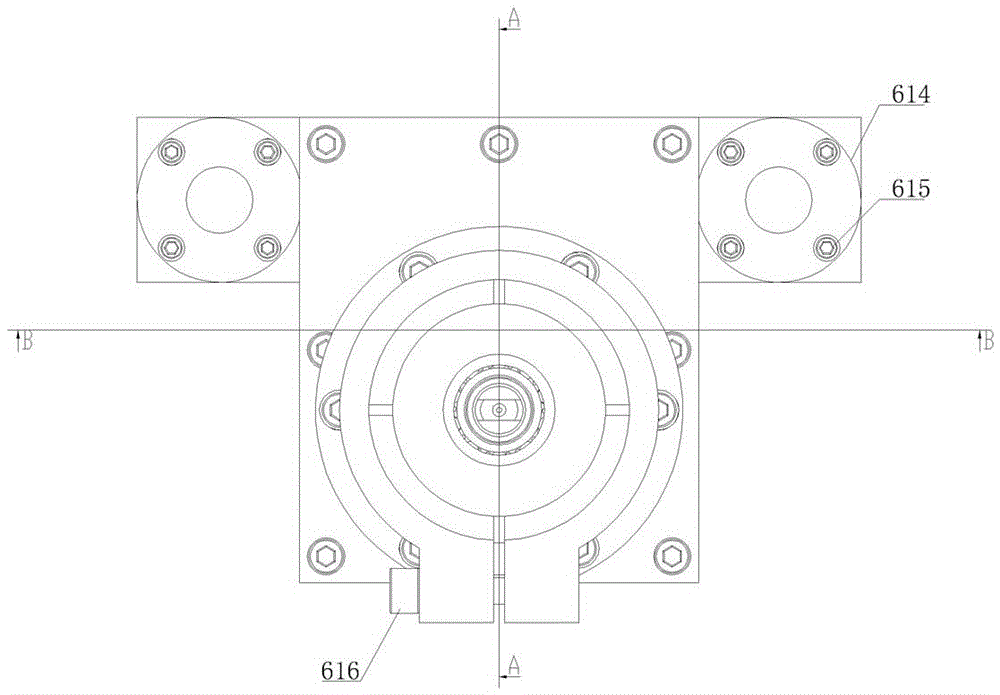

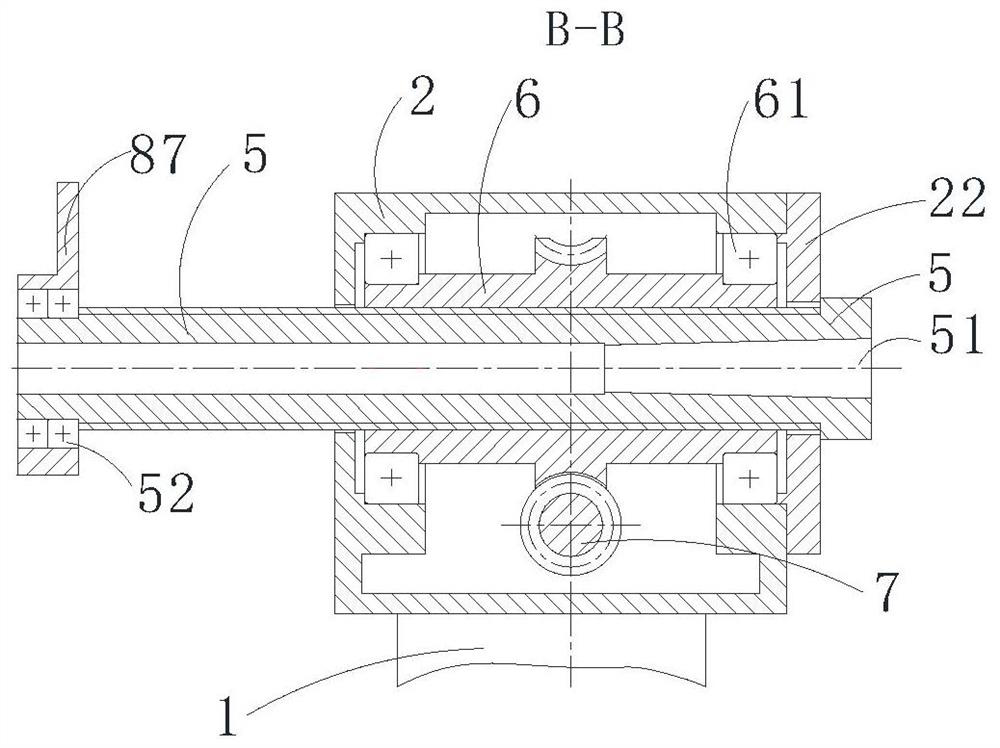

Processing device suitable for drilling disc flanges of plurality of specifications

InactiveCN109093150ARealize the clamping effectRealize automatic drillingFeeding apparatusPositioning apparatusCircular discEngineering

The invention relates to the field of machining, in particular to a processing device suitable for drilling disc flanges of a plurality of specifications, includes a positioning device, a drilling device and a control device, the positioning device comprises a clamping mechanism and a rotating mechanism, the drilling device comprises a vertical drilling machine and an adjusting mechanism, the control device comprises a controller and a sensor assembly. The clamping mechanism comprises a positioning fixture and a driving assembly, and the rotating mechanism comprises a rotating platform and a rotating assembly. The invention can realize automatic clamping and automatic drilling of the disc flange, thereby improving the processing efficiency of the disc flange and reducing the human cost.

Owner:浙江指南针智能科技有限公司

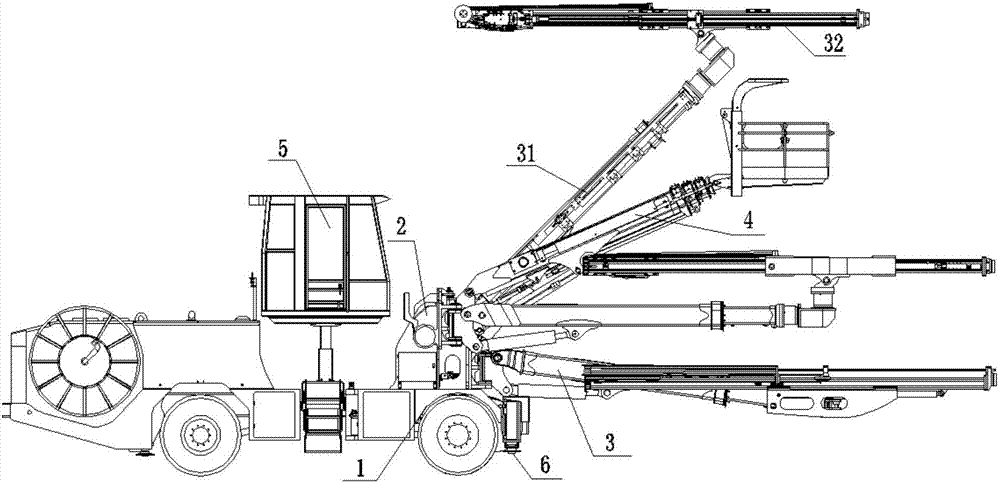

Intelligent drill jumbo

PendingCN107575161ARealize automatic drillingHigh precisionDerricks/mastsDrilling machines and methodsReducerDrill

The invention discloses an intelligent drill jumbo comprising a chassis, a support, at least one drill arm and a controller. Each drill arm comprises a base, a swing seat, an arm rest, an arm rest swing oil cylinder, an arm rest pitching oil cylinder, an arm rest telescopic oil cylinder, a propulsion beam, a propulsion beam sliding seat, a propulsion oil cylinder for controlling the propulsion beam to slide on the propulsion beam sliding seat, a rock drill, a drilling oil cylinder for controlling the rock drill to slide on the propulsion beam, a first rotating speed reducer for controlling thepropulsion beam sliding seat to swing, a second rotating speed reducer for controlling pitching of the first rotating speed reducer so as to drive pitching of the propulsion beam sliding seat, and aspeed reducer supporting seat for supporting the first rotating speed reducer and the second rotating speed reducer. By applying the intelligent drill jumbo provided by the invention, the angle and depth of drilling and the distribution positions of holes can be controlled accurately, and therefore the accuracy of end faces after blasting can be effectively improved, and construction quality and construction efficiency are further improved.

Owner:HUNAN WUXIN TUNNEL INTELLIGENT EQUIP CO LTD

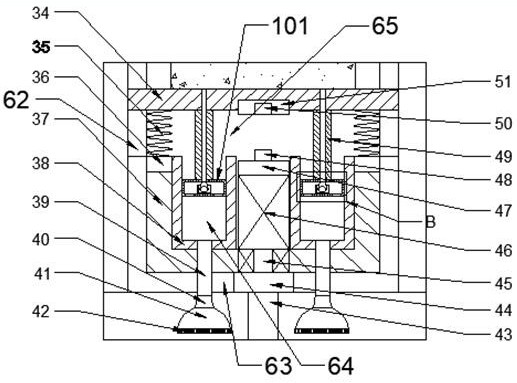

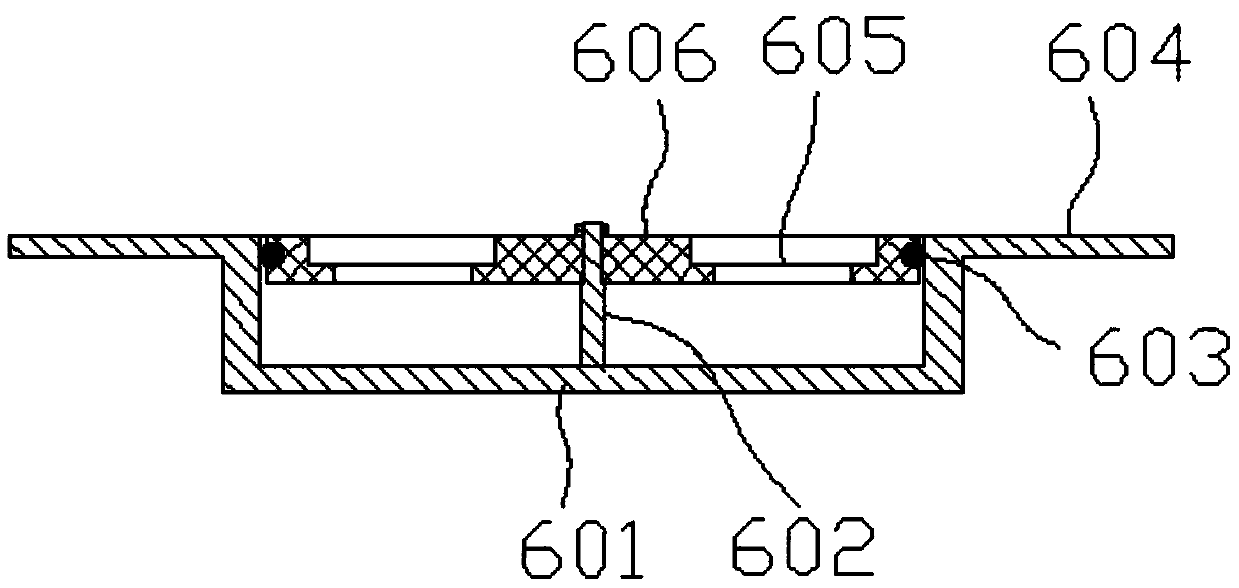

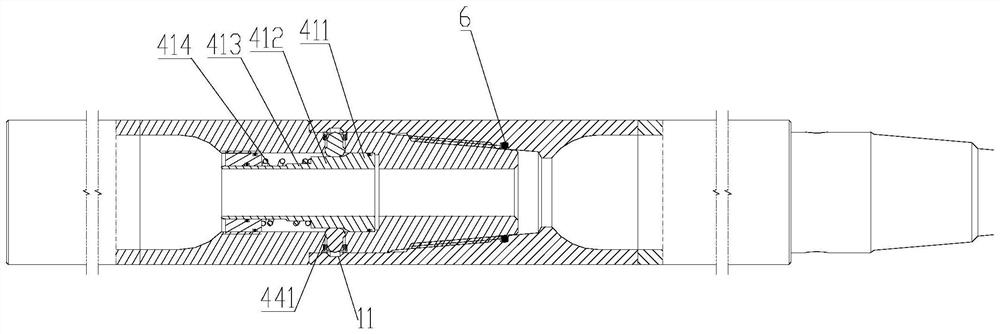

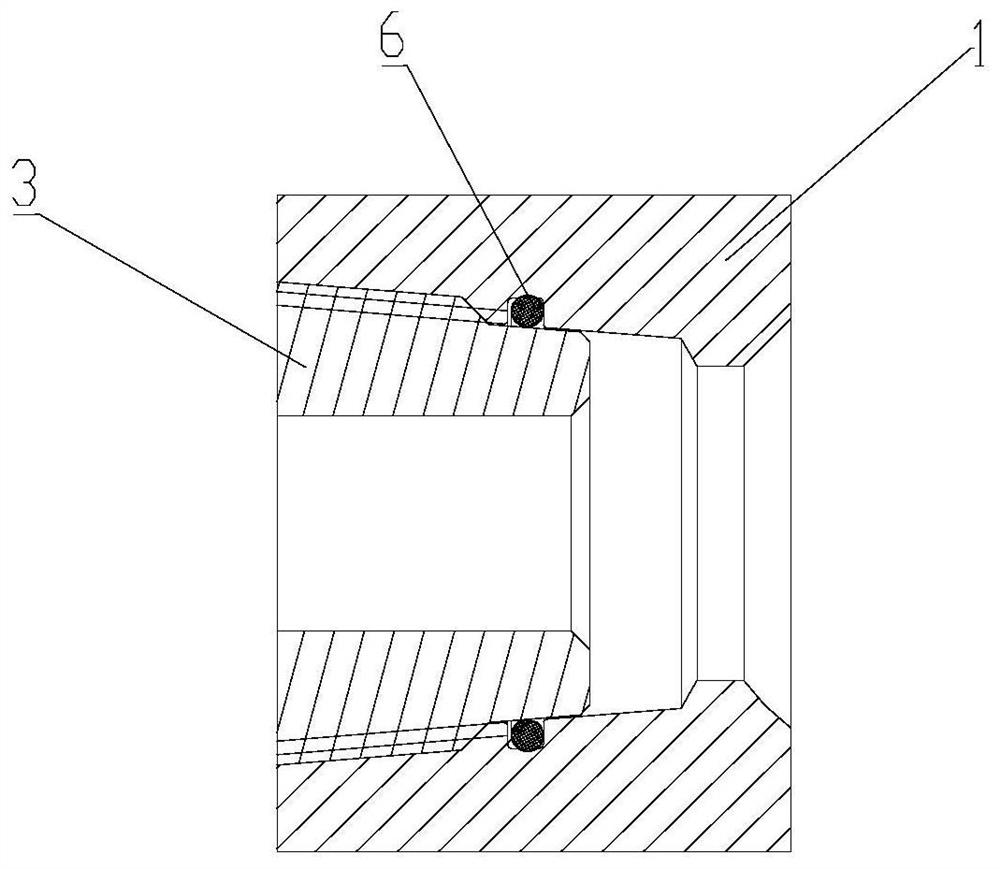

Liquid-gas type vibration absorber

InactiveCN101429852AImprove applicabilityImprove flexibilityDrilling rodsDrilling casingsFall protectionEngineering

The invention relates to a liquid gas type shock absorber, which consists of an upper connector, a spline external cylinder, a cylinder sleeve, a mandrel, a piston, a falling protection connector and a lower connector. The shock absorber is basically characterized in that the upper connector is connected with the spline external cylinder through a spline; the external cylinder of the shock absorber consists of the spline external cylinder and the cylinder sleeve; the mandrel and the piston are arranged inside the cylinder sleeve and are connected with the upper connector through thread; and the falling protection connector is connected with the cylinder sleeve and the lower connector through thread. According to the characteristic that the volume of gas changes along with the change of the temperature and pressure, the shock absorber adopts gas as an elastic element and has better shock absorbing performance. Simultaneously, liquid is taken as a pressure transfer element, thereby not only improving the stability of the shock absorbing system, but also carrying out the liquid sealing of the gas and consequently improving the tightness of the cylinder. The shock absorber has the advantages of wide application range, good flexibility, low impact, good stability, and the like.

Owner:中石化石油工程技术服务有限公司 +1

Drilling machine for road construction

InactiveCN107740675ARealize automatic drillingAvoid pollutionDrilling rodsConstructionsEngineeringRoad construction

The invention discloses a drilling machine for road construction, which comprises a device main body, a cylinder is arranged on the inner top plate of the device main body, a rotating motor is connected to the side of the cylinder away from the upper top plate of the device main body, two A group of guide shafts, the first sliders are arranged on the two groups of guide shafts, a connecting plate is welded between the two groups of first sliders, the rotating motor is arranged on the connecting plate, the end of the drill bit holder away from the connecting plate is connected with a drill bit, and The drill bit is connected with the output shaft of the rotating motor through the drill bit clamp. The two groups of guide shafts are respectively provided with second sliders. A connecting spring is connected between the first slider and the second slider. One of the two groups of second sliders opposite Connecting rods are welded on the two sides respectively, and a dust-proof box is connected between the two groups of connecting rods. In the present invention, the dust-proof box and spraying water from the nozzle can effectively prevent dust pollution during the drilling process, and the invention has a simple structure and is easy to manufacture. Low cost, easy to promote in small businesses and individual users.

Owner:CHENG DU XIN AO GUAN MEDICAL EQUIP

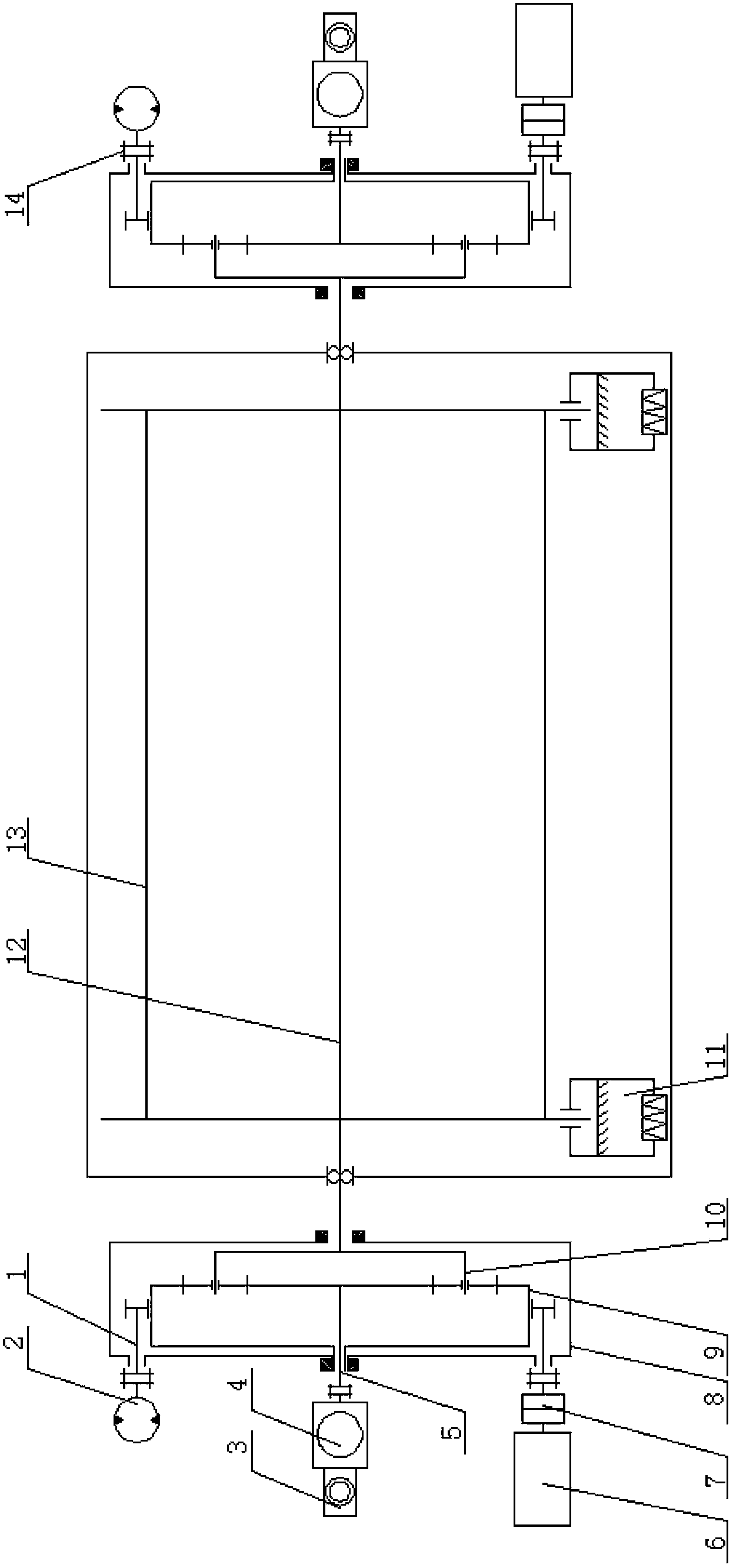

Rotary drilling processing control system of cylinder cover of diesel engine

ActiveCN105397145ARealize automatic drillingApplicable to the needs of large-scale productionAutomatic control devicesFeeding apparatusDiesel engineControl system

The invention provides a rotary drilling processing control system of a cylinder cover of a diesel engine. The system comprises a cylinder cover fixing device, a first drilling device, a second drilling device, a first driving devices, second driving devices, third driving devices, a first ranging sensor, a second ranging sensor and a control device, wherein the cylinder cover fixing device is used for fixing the cylinder cover; the first driving devices are used for driving the cylinder cover fixing device to rotate; the first drilling device is used for processing first position holes in a first surface and a second surface of the cylinder cover; the second driving devices are connected to the first drilling device and used for driving the first drilling device to vertically move up and down on the corresponding first position hole; the second drilling device is used for processing second position holes in the first surface and the second surface of the cylinder cover; the third driving devices are used for driving the second drilling device to vertically move up and down below the corresponding second position hole. The system is simple in structure and can automatically drill the cylinder cover of the diesel engine.

Owner:全椒县新华机械有限责任公司

Adjustable tool rest drill clamp of digital control lathes

InactiveCN101219484ARealize automatic drillingRealize functionTool holdersAttachable boring/drilling devicesNumerical controlEngineering

The invention relates to a drill point of a tool carrier of an adjustable numerical control lathe, which comprises a drill sleeve, a sliding block, a fastening block, central drill sleeve, which is characterized in that: the fastening block is provided with concave dovetail slot matching with convex dovetail slot of the sliding block; the bottoms of the concave and convex dovetails are provided with panel board groove for installing panel board; the drill sleeve and sliding block are fastened by bolts; central line of the drill sleeve is horizontally provided with a V-shaped groove matching with a drill head and V-shaped block; the drill head is fastened by bolts; the central drill sleeve is connected to a fastening block using bolts. The invention has the advantages of simple structure, two knife position being provided with a clamping apparatuses, drill head and central drill or cutter knife being capable of arranging at the same time, having height and level adjustment function, high precision, convenient use, realizing numerical control and automatically drilling and reaming function and high production efficiency.

Owner:广西达业科技有限公司

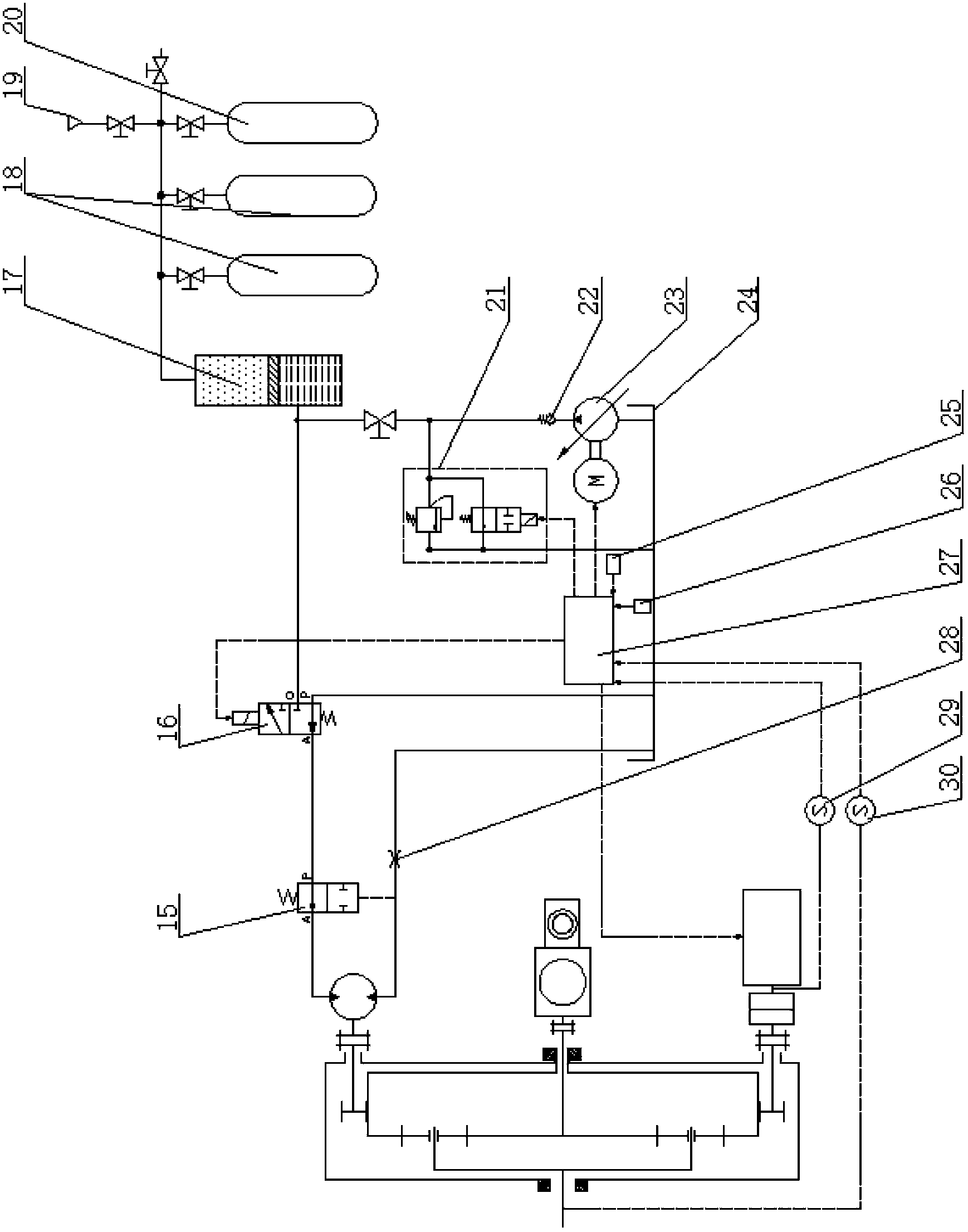

Winch heave compensation device of marine floating drilling platform

InactiveCN102691484BLower center of gravityReduce loadDrilling rodsWinding mechanismsHydraulic motorProgrammable logic controller

The invention discloses a novel winch heave compensation device of a marine floating drilling platform. A differential planet gear train is adopted as a transmission mechanism for heave compensation of a winch; power from an active compensation motor and a passive compensation hydraulic motor is input from an outer gear ring; the power from a drilling motor is input by a sun gear; a planet carrier outputs power to drive a winch roller to move; a PLC (programmable logic controller) control unit controls the active compensation motor to drive the outer gear ring of a differential gear reducer to rotate based on the detected platform heave signal; the heave movement of the platform is compensated by driving the roller to rotate forwardly and reversely, and the drilling motor is controlled to drive the sun gear to rotate based on the detected drill pressure change signal so as to achieve automatic drilling movement. A pneumatic hydraulic convertor bears a part of static load of a drilling column through the passive compensation hydraulic motor; and the active compensation motor overcomes the other loads in the movement compensation process so as to reduce the energy consumption of the system and improve the compensation precision.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

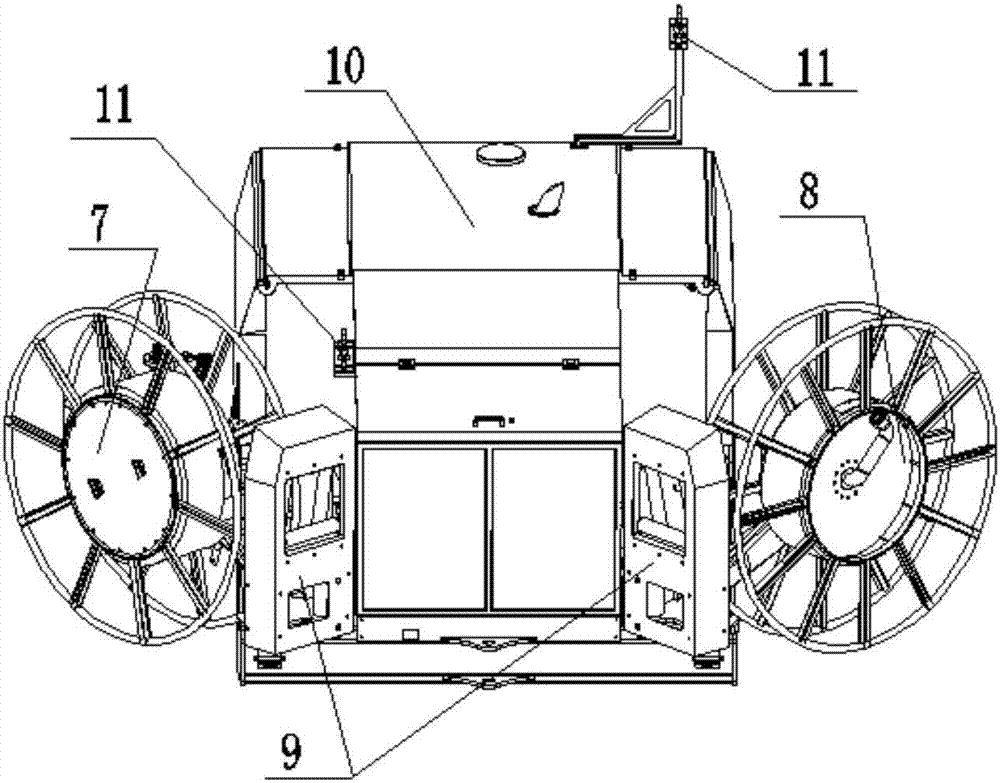

Armour crab seabed exploration and drilling robot

InactiveCN109025824AUnmanned operationSimple structureConstructionsDerricks/mastsResource developmentOcean sea

The invention provides an armour crab seabed exploration and a drilling robot and belongs to the field of prospection devices. A walking device 2 is installed on the lower end of a vehicle body 1. Fixed devices 3 are installed on four corners of the vehicle body 1. A drilling device 4 is installed in the center position of the vehicle body 1. Inspection devices 8 are installed all around the bodyof the vehicle body 1. A hydraulic device 6 is installed in the vehicle body 1. The hydraulic device 6 is connected with the walking device 2, the fixed device and the drilling device 4. The robot issuitable for the sea area with the depth of water of 100m; automatic exploration of hard rock on the seabed can be achieved; drilling and sampling are performed on the seabed; the sampling length is 20m; the exploration cost is reduced; and sea resource development is accelerated.

Owner:招远市铱璐光电科技有限公司

Woodworking full-automatic drilling and riveting system and working mode thereof

PendingCN112405766ARealize automatic feeding processImprove machining accuracyStationary drilling machinesBark-zones/chip/dust/waste removalEngineeringIndustrial engineering

The invention discloses a woodworking full-automatic drilling and riveting system and a working mode thereof. The woodworking full-automatic drilling and riveting system is composed of two chair platefeeding stations, a feeding robot, an automatic alignment workbench, a drilling robot, two riveting robots, two M6 bolt riveting machines, two M8 bolt riveting machines, a set of dust collecting system, two chair plate discharging stations, a set of protective nets and two sets of mechanical hand control cabinets. The swivel chair production automation degree can be effectively improved, the labor efficiency is improved, thus, industrial transformation and upgrading are promoted, and the woodworking full-automatic drilling and riveting system and the working mode thereof can be applied to thefield of furniture machining.

Owner:SHENZHEN SONGJIAN ROBOT CO LTD

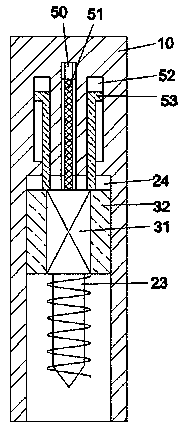

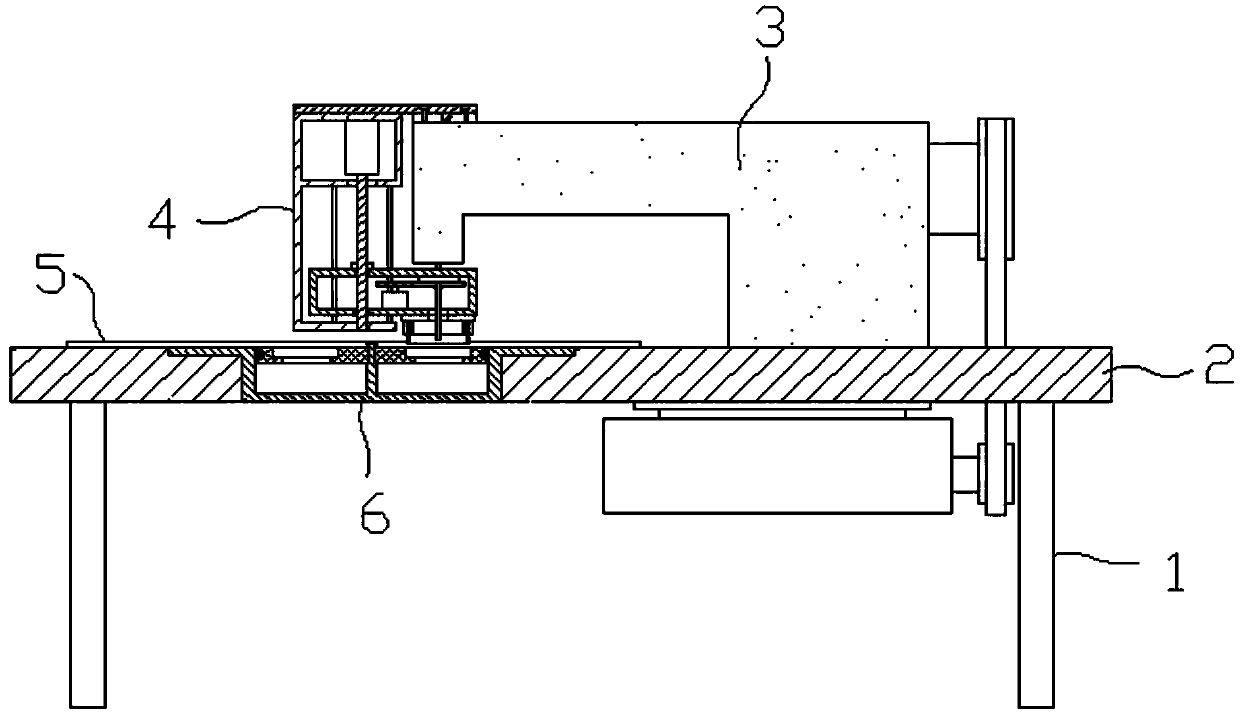

Accounting document hole drilling machine

ActiveCN110370373APrevent problems such as deformationAvoid accidental injuryMetal working apparatusDrilling machinesPetroleum engineering

The invention relates to the technical field of official business handling equipment and discloses an accounting document hole drilling machine. During drilling by the accounting document hole drilling machine, firstly a compressing sleeve is used for compressing a hole drilling portion, then hole drilling is performed, the problem that tearing and the like occur to an accounting document at the position of the hole drilling portion can be effectively solved, and the problem of deformation and the like at the hole drilling position is solved. Meanwhile, the accounting document hole drilling machine is further provided with an outer protecting barrel, and on one hand, a drilling cutter can be protected, and it is prevented that mistaken injuries are caused to operators; and on the other hand, during drilling, a lifting driving barrel moves up and down while driving the drilling cutter to rotate, and automatic hole drilling is achieved; besides, when the accounting document hole drillingmachine performs drilling, paper scraps are sucked out due to negative pressure, and the situation that a drill bit is stuck by the paper scraps and consequently the accounting document is damaged bythe drill bit is prevented; and the drilling cutter is of a cylindrical thin-wall structure, the paper scraps are directly sucked out from the center according to the cut-out shape, and operation iseasy and convenient.

Owner:GUANGDONG BAIYUN UNIV

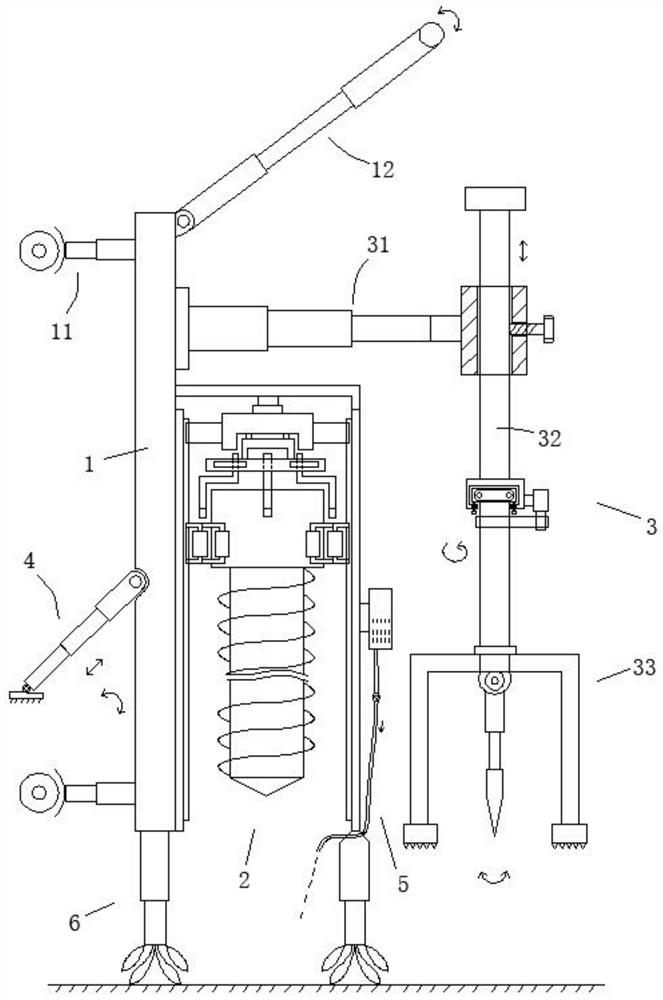

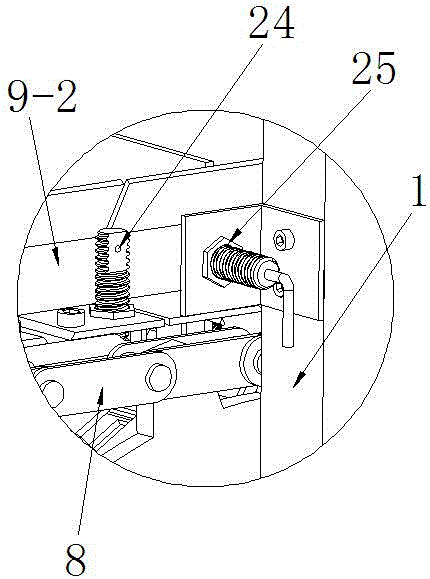

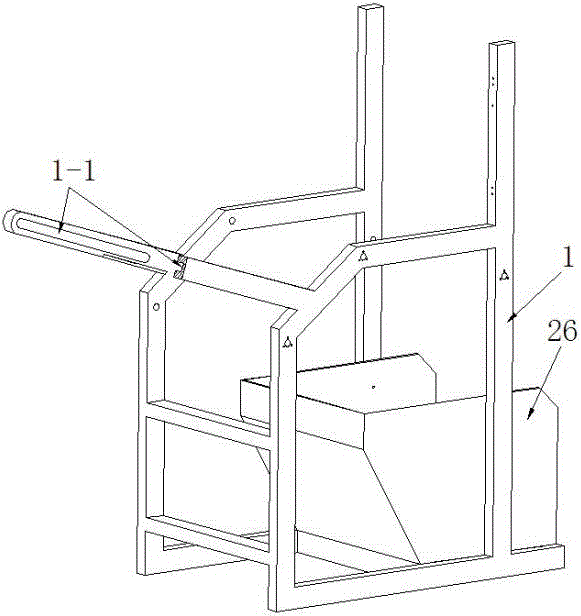

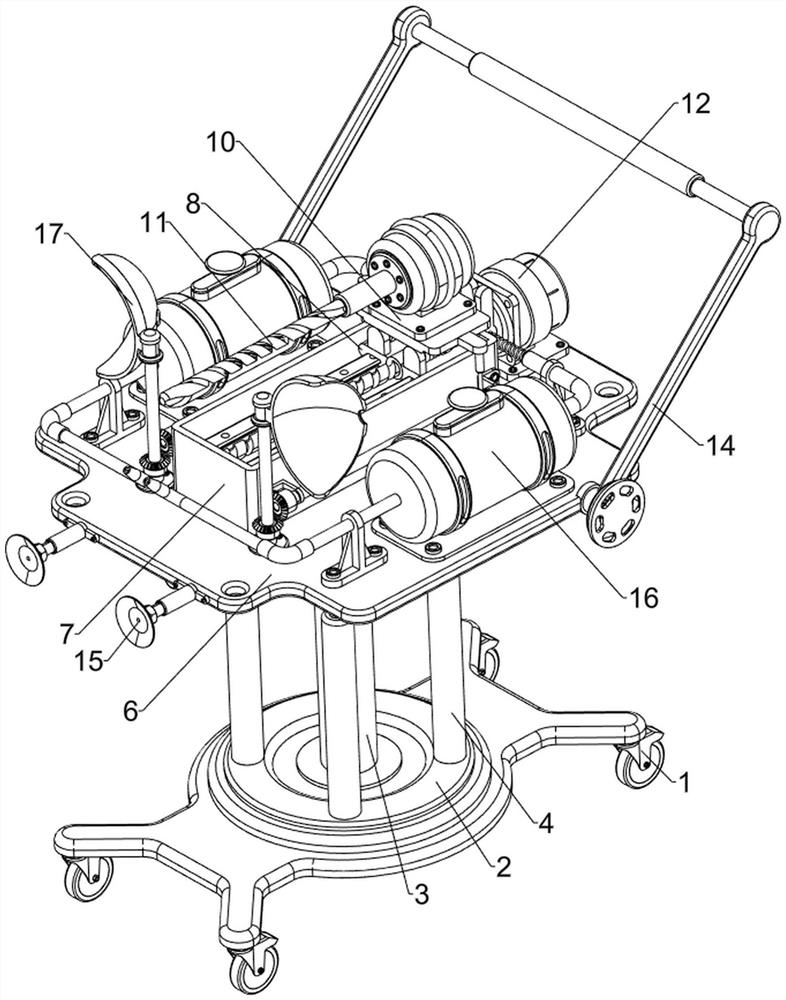

Automatic upgrading device for mining drilling machine and working method

PendingCN112031652ARealize automatic drillingImprove general performanceDrilling rodsDerricks/mastsControl systemEngineering

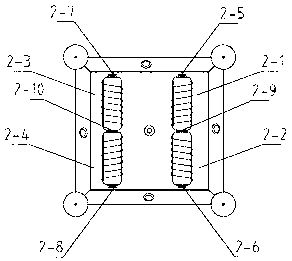

The invention discloses an automatic upgrading device for a mining drilling machine and a working method, and belongs to the field of mechanical equipment. The device comprises a main supporting frame(1), a movable truss structure (2), a drill rod gripper (3), a drill rod clamp (4), a water braid (5), an electromagnetic switch valve (6), a drill rod library (7), a control system (8) and an operating rod actuator (9), wherein the main supporting frame (1) is fixedly mounted on a supporting frame of a drilling machine propeller; the movable truss structure (2) is arranged at the upper part of the main supporting frame (1) and has two degrees of freedom; the drill rod gripper (3) is arranged on the movable truss structure (2); the drill rod clamp (4) is fixedly connected with a drilling machine spindle; the water braid (5) is arranged at the tail end of the drilling machine spindle; the electromagnetic switch valve (6) is arranged between the water braid (5) and a water pipe; the drill rod library (7) is arranged on the main supporting frame (1) and used for storing a drill rod; and the operating rod actuator (9) is used for driving an operating rod to act. The device realizes automatic drilling of the drilling machine, and automatic and intelligent transformation of the existing manual drilling machine can be realized by additionally mounting the automatic upgrading device for the drilling machine on the existing manual drilling machine.

Owner:JINING SHANYUN YUNEI ELECTROMECHANICAL TECH CO LTD

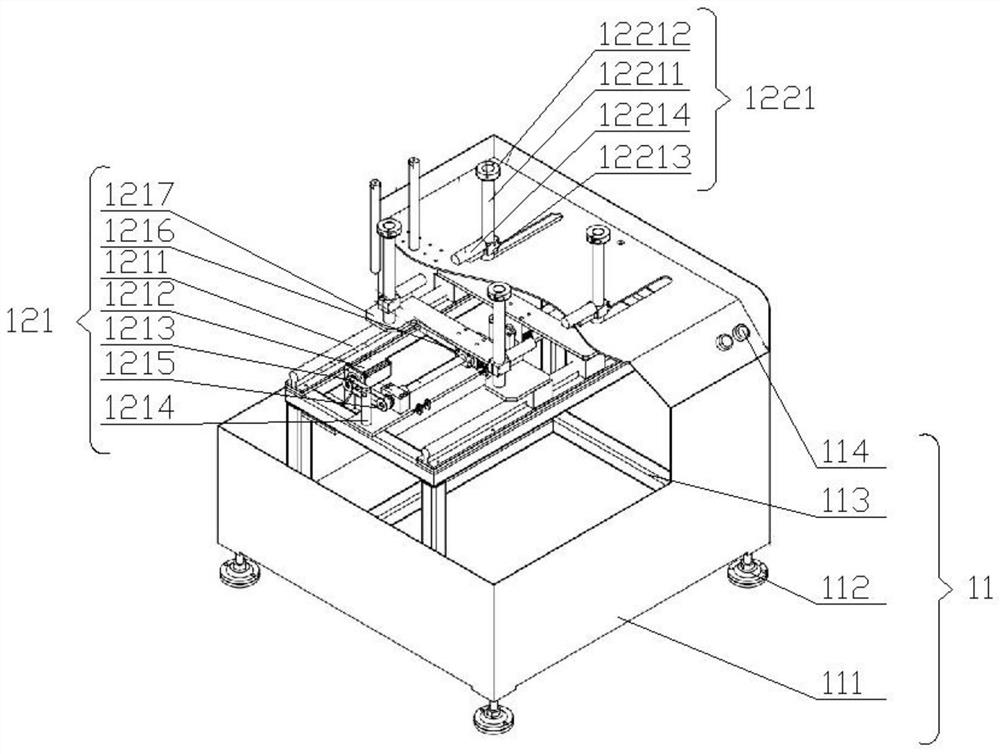

Plate feeding and discharging machine for plate drilling and drilling method thereof

ActiveCN114346483AAchieve positioningAchieve crawlingLaser beam welding apparatusConveyor partsStructural engineeringMachine

The invention is suitable for the technical field of plate processing and manufacturing, and provides a plate drilling, loading and unloading machine which comprises a rack, a drilling machine, a plate turning mechanism, a pallet fork mechanism, a positive positioning platform, a negative positioning platform, a grabbing mechanism and a multi-layer temporary storage mechanism. The drilling machine is used for drilling a plate; the plate turning mechanism is arranged beside the drilling machine and used for turning over the plates. The pallet fork mechanism is arranged on one side of the drilling machine and used for grabbing plates. The reverse positioning platform is arranged beside the plate turnover mechanism and is used for positioning the plates; the positive positioning platform is arranged on the side, away from the plate turnover mechanism, of the drilling machine and used for positioning the plate. The grabbing mechanism is used for grabbing plates; the multi-layer temporary storage is used for storing NG plates and detection sample plates; the automatic drilling equipment is complete in function, capable of automatically achieving positioning, drilling, turning over and re-drilling of plates, high in intelligent degree, capable of achieving automatic drilling of the front faces and the back faces of the plates and accurate classified storage of the plates after drilling, and high in practicability.

Owner:深圳市创新特科技有限公司

High-voltage transmission line ground wire operation device

ActiveCN112542798AGood grounding effectRealize automatic drillingDerricks/mastsDirectional drillingEngineeringMechanical engineering

The invention provides a high-voltage transmission line ground wire operation device and belongs to the technical field of power construction tools. The device comprises a vehicle body, a drilling mechanism, a reaming mechanism and a pushing mechanism; the vehicle body can overturn towards one side; the drilling mechanism is transversely arranged at the upper end of the vehicle body in a sliding manner; the drilling mechanism is used for drilling a hole in the ground after the vehicle body overturns; after a hole is formed, an earth screen or an earthing body connected with the earthing end ofa high-voltage line is placed in the drilled hole; the reaming mechanism is arranged at the upper end of the vehicle body and arranged side by side with the drilling mechanism; and after the drillingmechanism drills, the reaming mechanism is used for drilling again in the drilled hole and expanding the inner diameter of the drilled hole; one end of the pushing mechanism is hinged to the bottom end of the vehicle body, and the other end of the pushing mechanism is used for abutting against the ground and pushing the vehicle body to turn towards the drilling side of the drilling mechanism. According to the high-voltage transmission line ground wire operation device provided by the invention, automatic drilling of high-voltage line grounding operation can be realized, manual operation is not needed, reaming can also be performed, the labor intensity is low, the grounding area is large, and the grounding effect of the high-voltage transmission line is good.

Owner:XINGTAI POWER SUPPLY +2

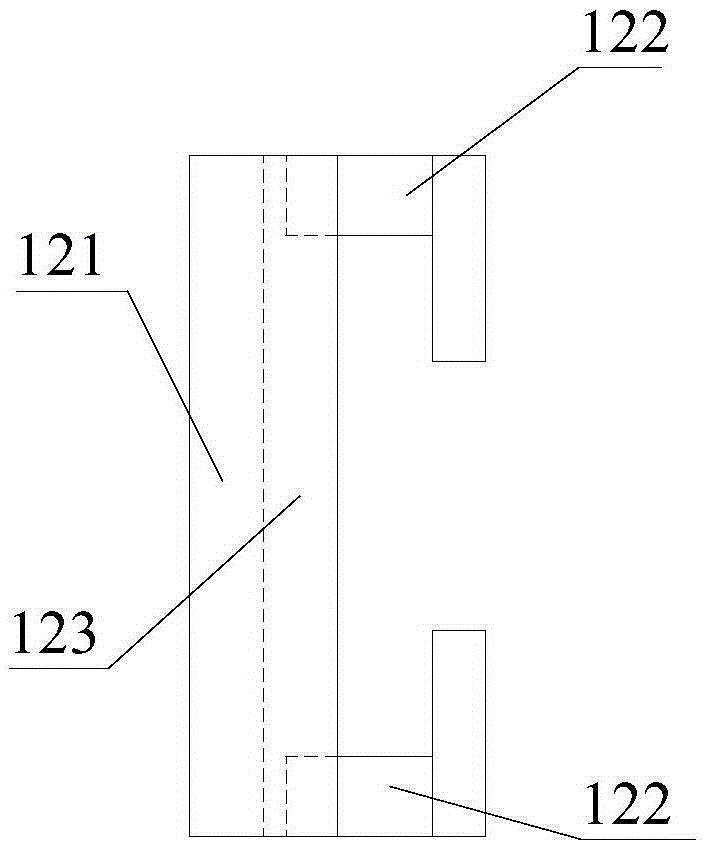

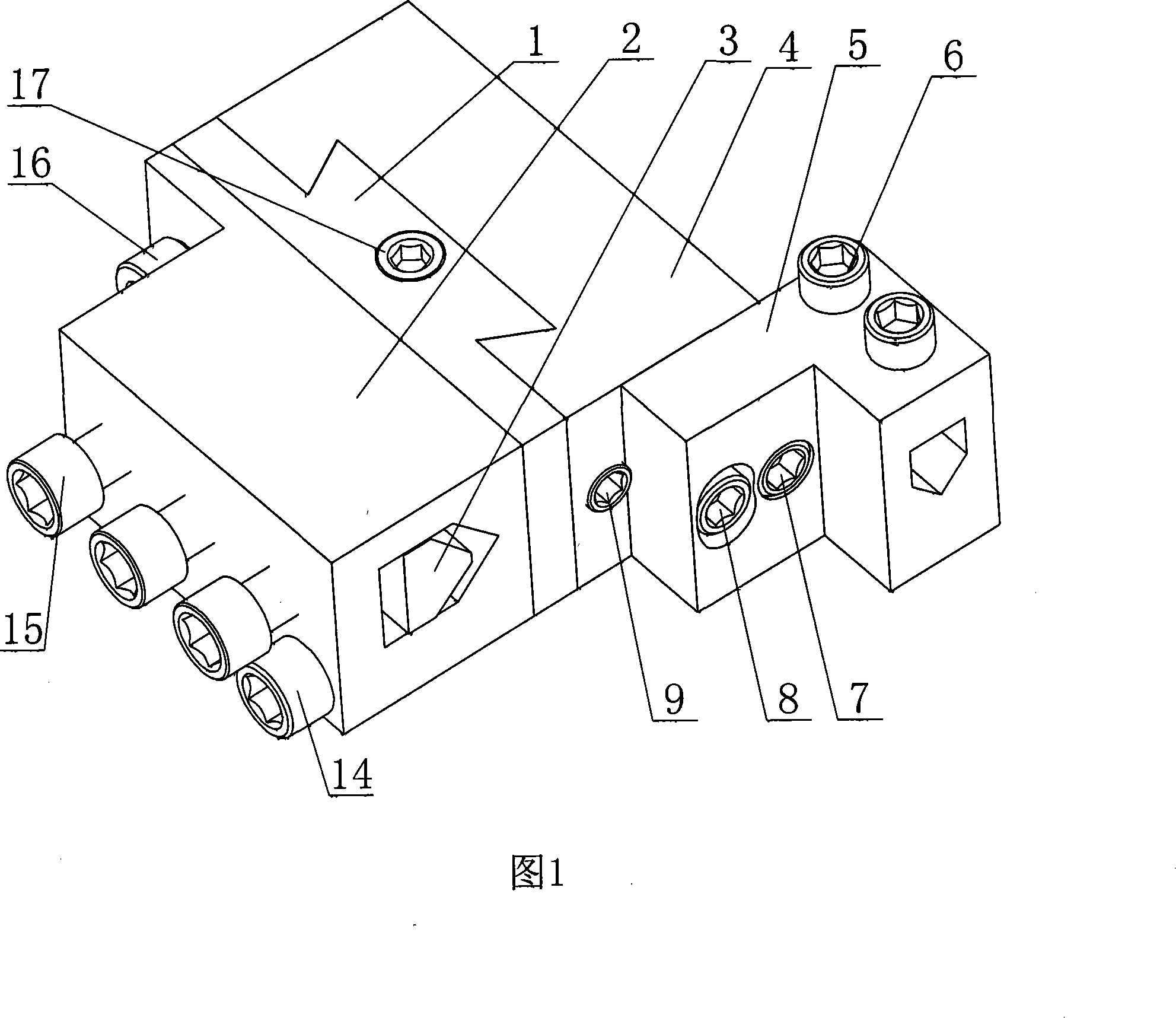

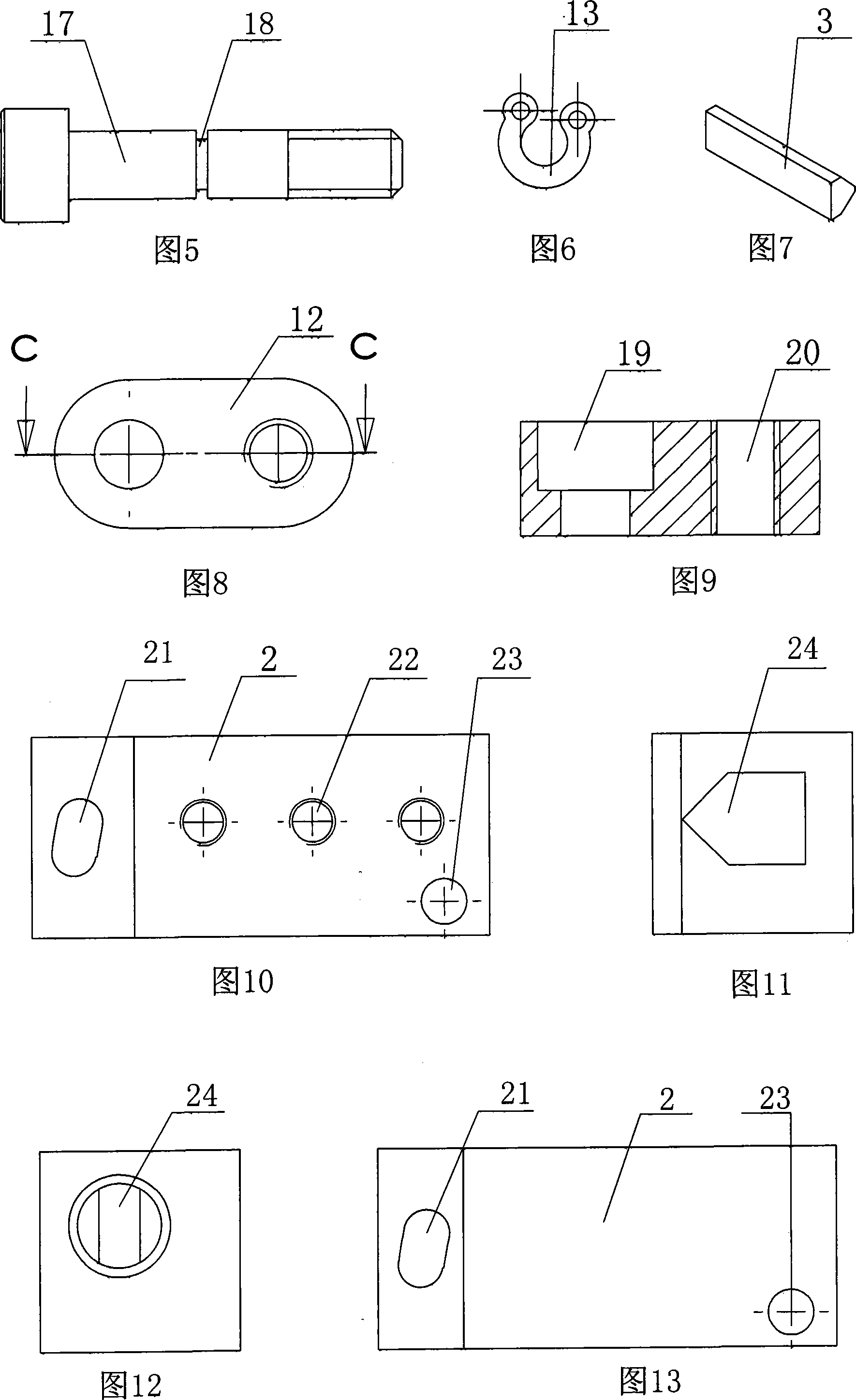

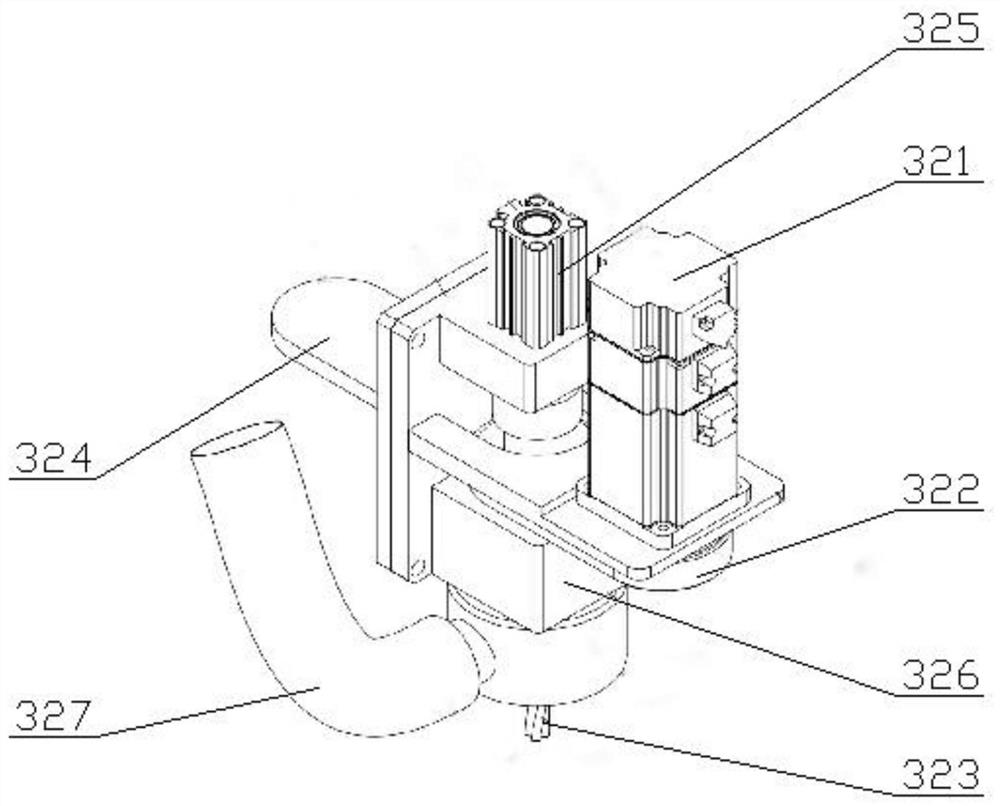

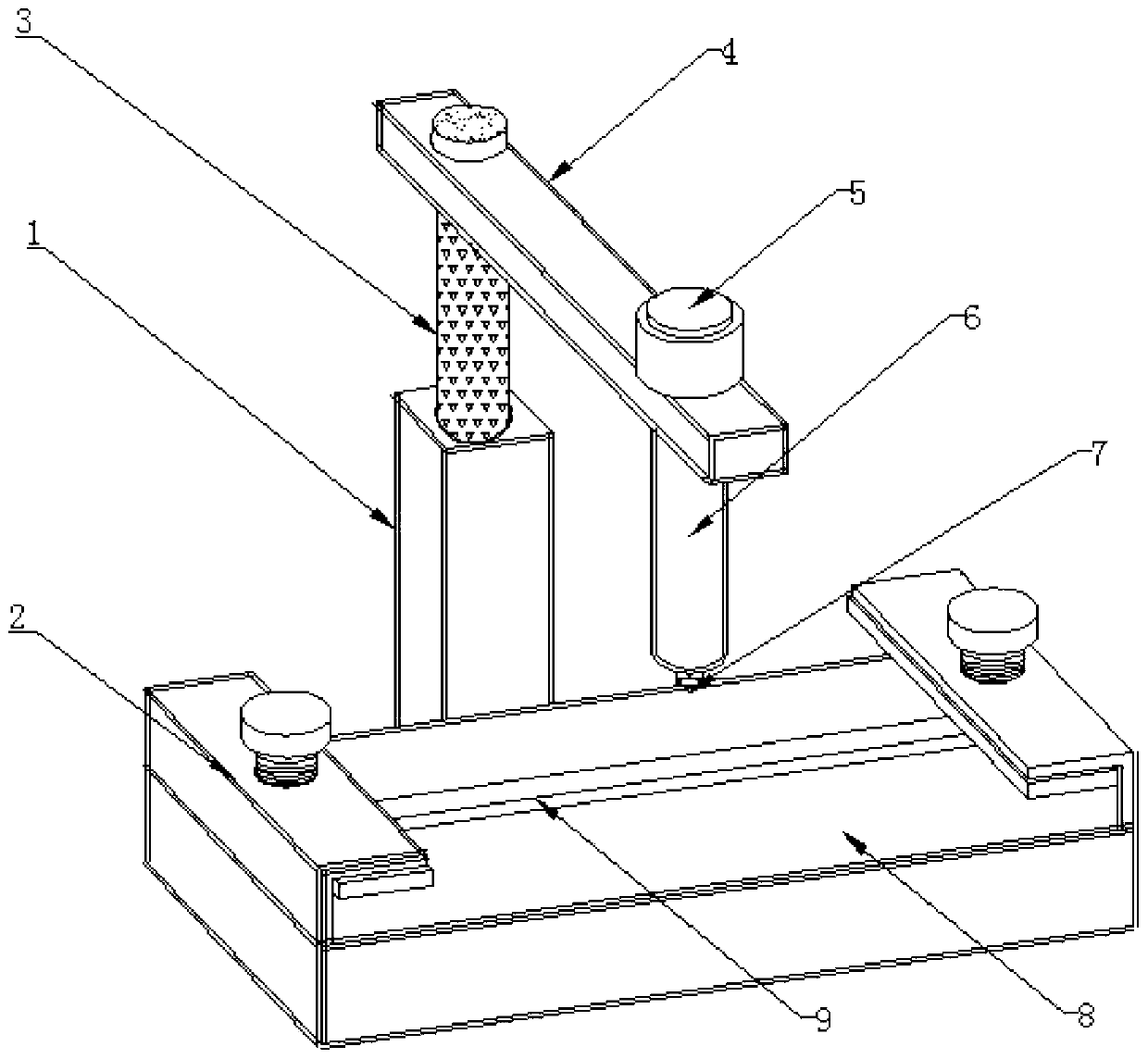

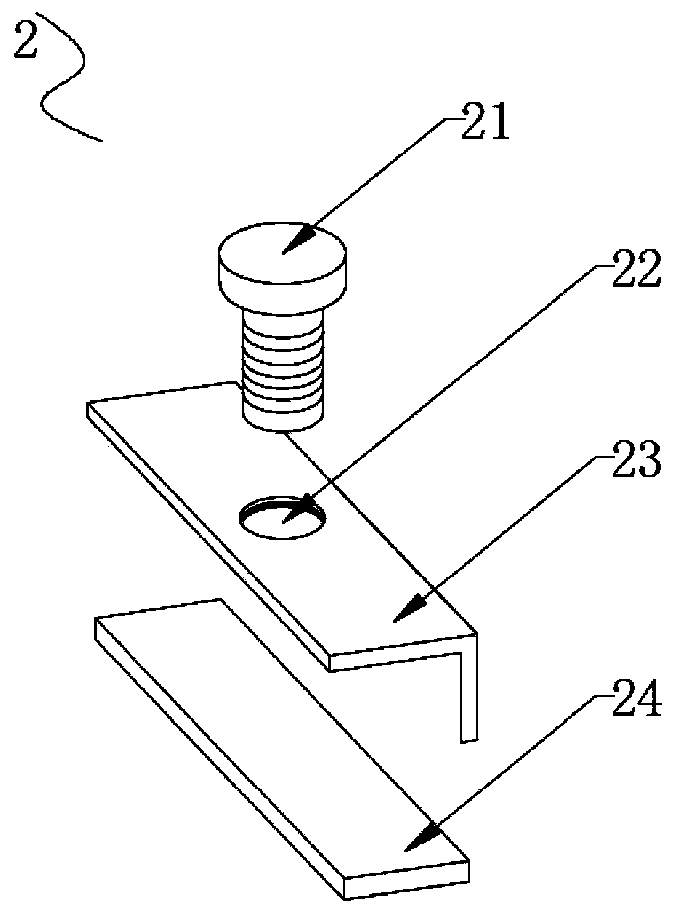

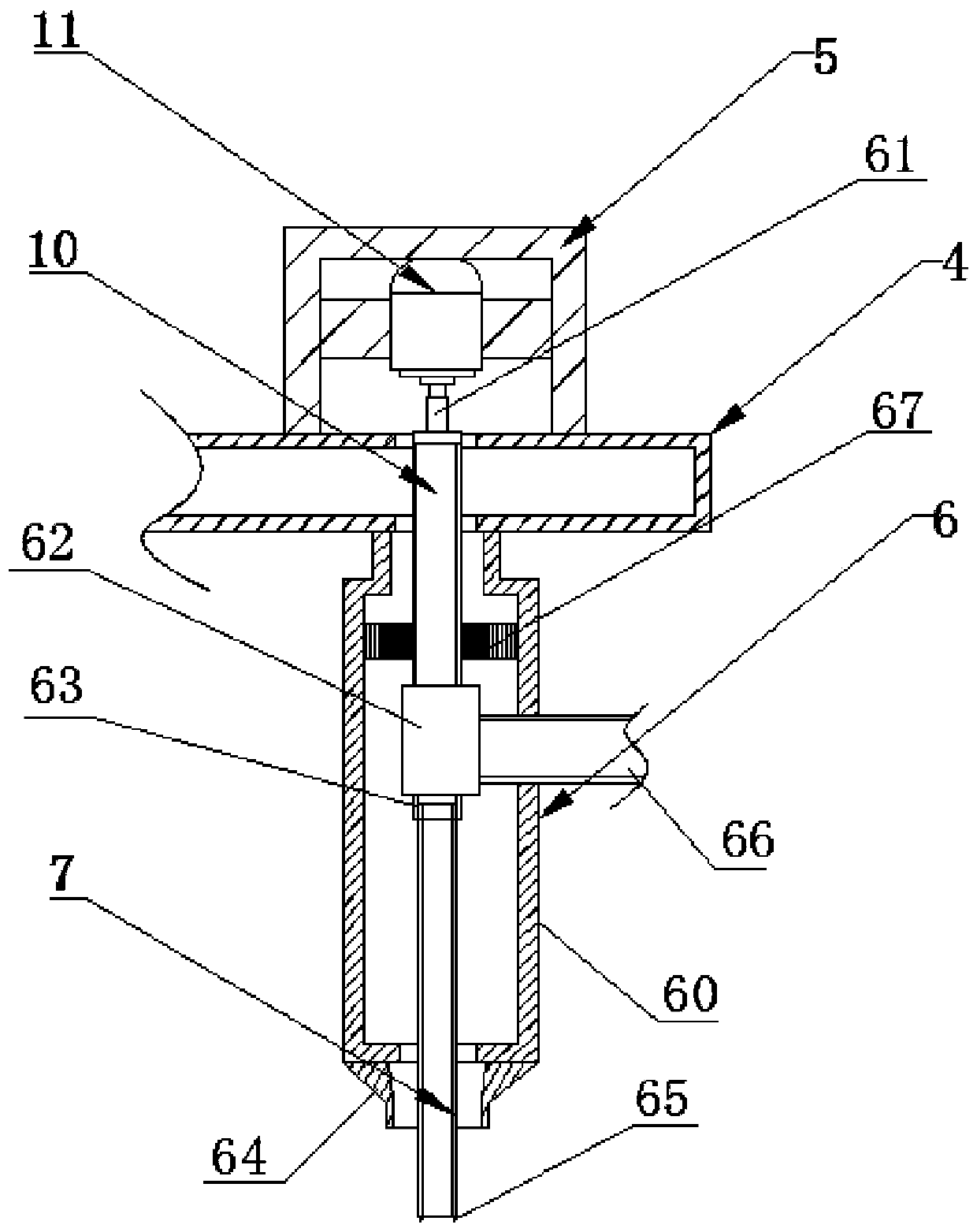

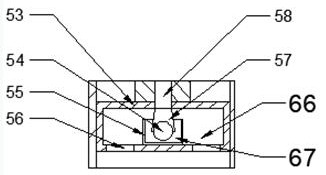

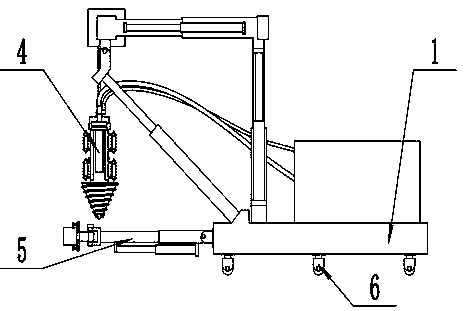

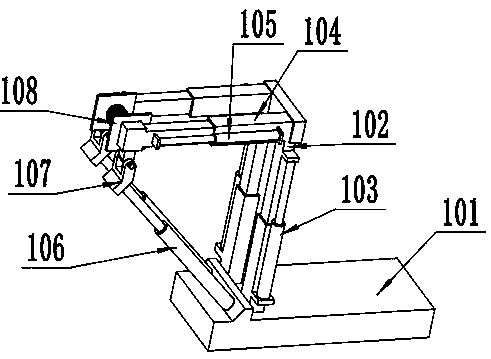

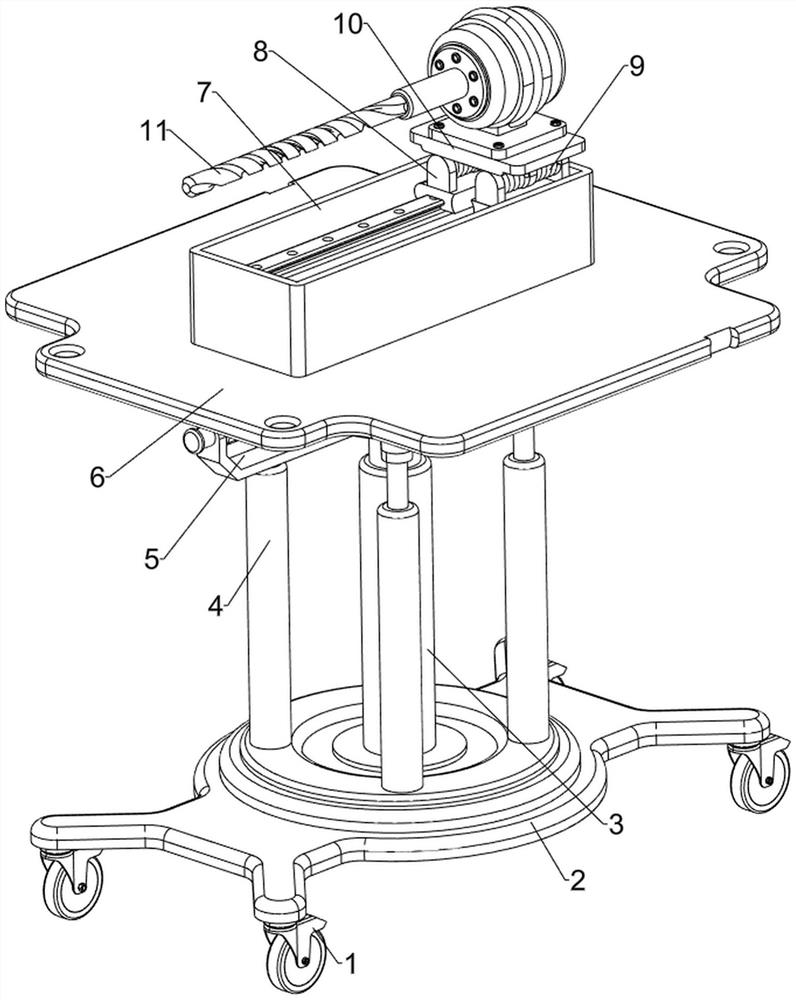

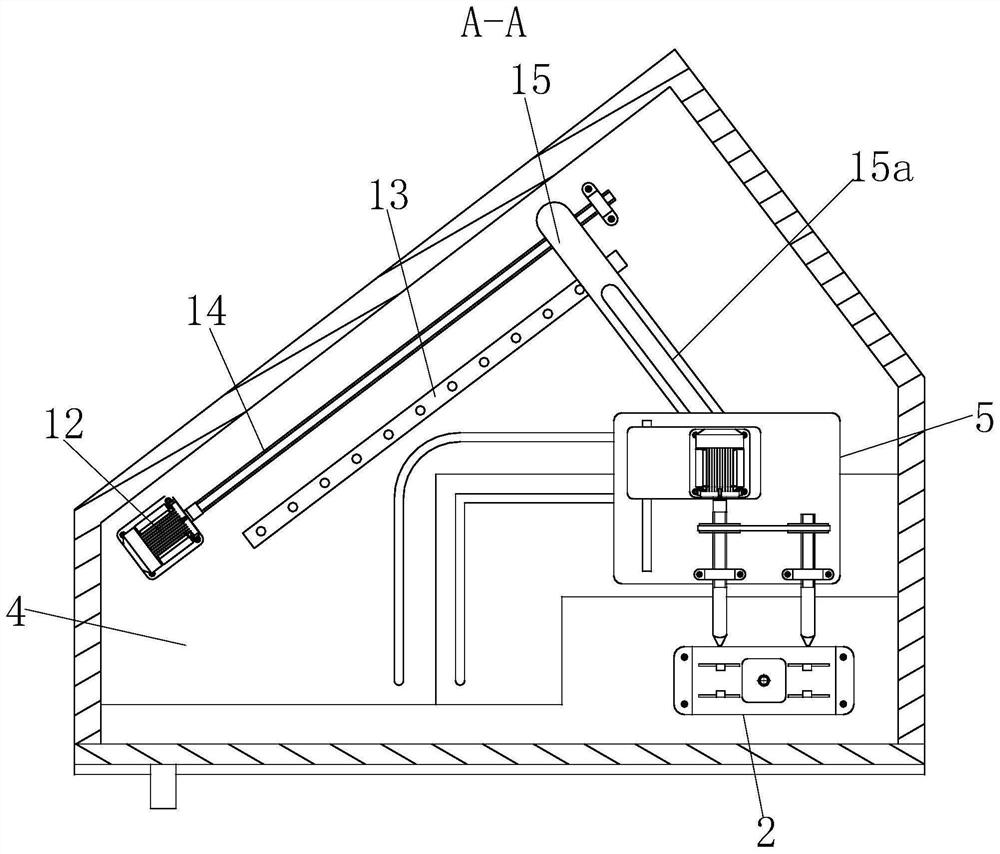

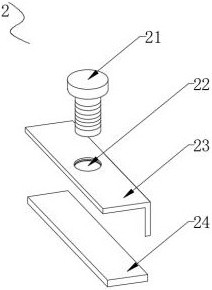

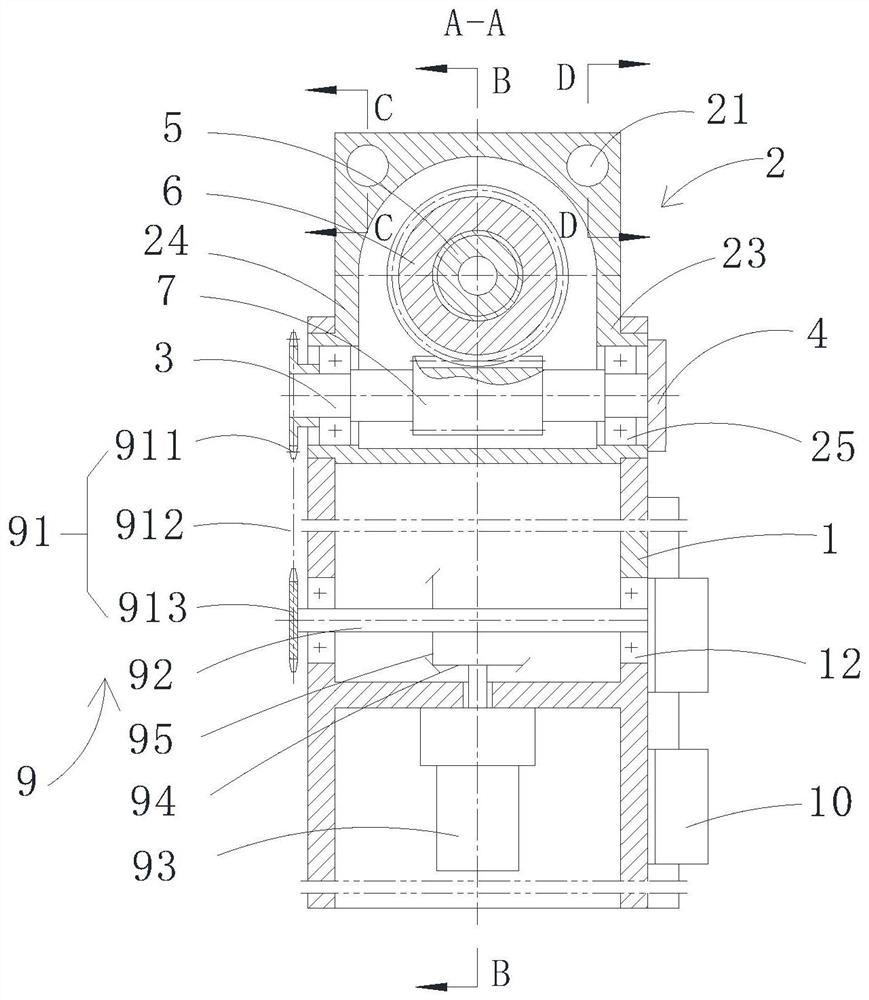

Camera fine-adjusting bracket for guiding composite drilling robot

PendingCN108302298AImprove drilling qualityRealize automatic drillingStands/trestlesEngineeringCamera angle

By applying a machine vision technology in the process that a composite is drilled through a robot, the robot can be guided to automatically drill and conduct drilling quality detection and feedback,and the production efficiency and the drilling quality are improved. Therefore, the invention discloses a camera fine-adjusting bracket for guiding the composite drilling robot in order to achieve camera angle and inclination adjusting. The bracket mainly comprises an angle fine-adjusting unit 1, an inclination fine-adjusting unit 2, a compression and transmission unit 3 and a camera base 4.

Owner:HARBIN UNIV OF SCI & TECH

Pressing type drilling technology based on negative feedback temperature adjustment

InactiveCN112647876ASimple equipment structureEasy to operateEarth drilling toolsConstructionsProcess engineeringDrill bit

The invention discloses a pressing type drilling technology based on negative feedback temperature adjustment. A machine body and two supporting columns symmetrically and fixedly connected to the left end and the right end of the bottom end of the machine body are included; and a first cavity is formed in the machine body. According to the pressing type drilling technology based on negative feedback temperature adjustment, the equipment structure is simple, operation is convenient, automatic ground drilling is achieved, all procedures are matched with one another and do not affect one another, the temperature is detected in real time through a negative feedback adjusting system, then a drill bit can be continuously cooled in the drilling process, drilled dust can be removed, the practical performance and efficiency of a device are improved, waste of manpower and material resources is effectively avoided, and therefore cost is greatly reduced.

Owner:靳国保

A profile automatic punching machine

ActiveCN104353858BRealize automatic drillingIncrease productivityAutomatic control devicesDriving apparatusPunchingSprocket

Owner:中略装备无锡有限公司

Fertilization equipment capable of drilling and backfilling

InactiveCN111436253AImprove efficiencyRealize automatic drillingPlantingTransportation and packagingFertilizerDrill hole

The invention discloses fertilization equipment capable of drilling and backfilling. The fertilization equipment comprises a working box, wherein bilaterally symmetric wheels are rotationally arrangedon the front end surface and the rear end surface of the working box; a storage cavity with an inner bottom wall being a slope is formed in the working box; a working transmission cavity is formed inan inner wall of the right side of the storage cavity; a working cavity with a downward opening is formed in the inner wall of the right side of the working transmission cavity; and a falling mechanism is arranged on the inner wall of the right side of the working cavity. According to the fertilization equipment, automatic drilling of land is realized; power during drilling is utilized, the dug soil is collected into a stirring cavity to be stirred and mixed with a fertilizer, and the stirred and mixed fertilizer is backfilled into a soil pit again when a drill bit is reset; and after the drill bit is reset, the function of patting off the soil remaining on the drill bit is completed by using energy accumulated when the drill bit is reset, and backfilling of the soil pit is completed, sothat the efficiency of fertilization work is improved.

Owner:三门罗荣机械科技有限公司

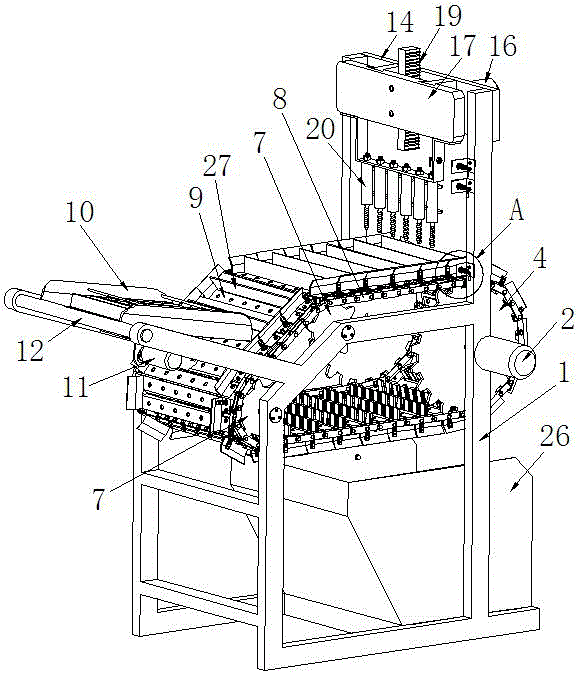

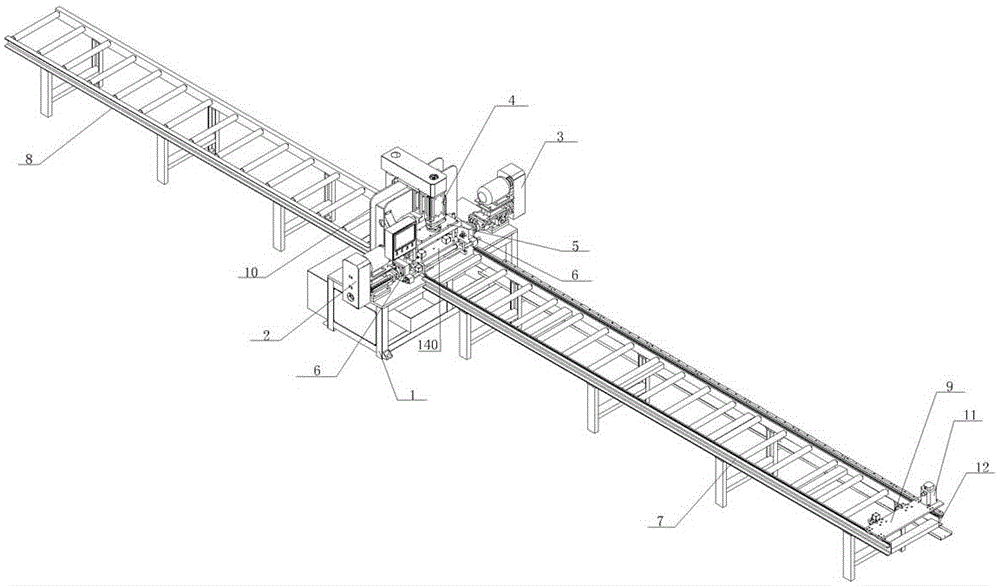

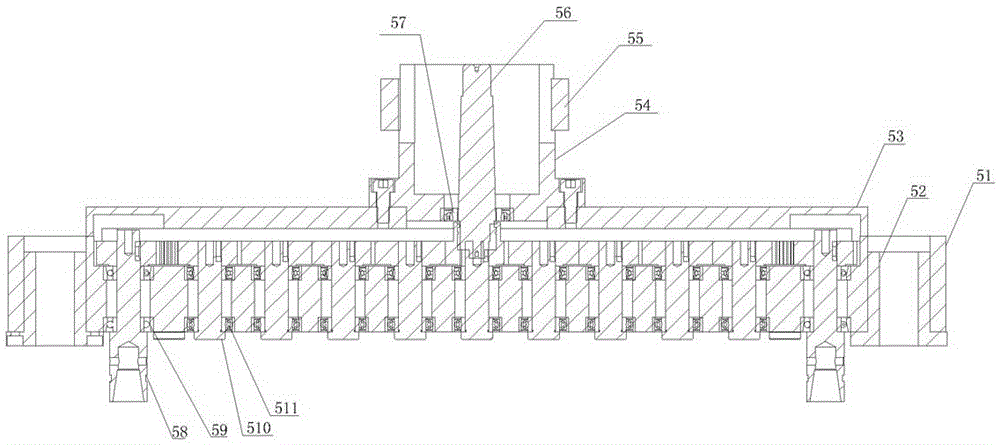

Drilling machine used for ladder string of composite material cable bridge stand and capable of machining out six holes simultaneously

ActiveCN105033308AShorten the timeAvoid the shortcomings of inconsistent drilling positions and inconvenient installationBoring/drilling componentsBoring/drilling machinesChinese charactersEngineering

The invention relates to a drilling machine used for a ladder string of a composite material cable bridge stand and capable of machining out six holes simultaneously. The drilling machine is characterized in that an upper drilling power head is installed on a bracket shaped like a Chinese character 'hui', a left side drilling power head and a right side drilling power head are arranged at the two sides of the upper drilling power head respectively, an upper drilling power head multiaxial device is arranged below the upper drilling power head, side direction drilling power head multiaxial devices are arranged at the inner side of the left side drilling power head and the inner side of the right side drilling power head respectively, a feeding bed is arranged in front of a base, a blanking bed is arranged behind the base, and a servo cart is arranged at the top end of the feeding bed. The drilling machine has the advantages that the six holes can be drilled continuously and simultaneously, time and labor are saved, defects that drilling holes are inconsistent in position, and the installation is inconvenient are avoided, no measurement is required, time of workers is saved, the working efficiency is raised, and the automated drilling is achieved through the PLC control.

Owner:HEBEI YANWU EXPLODEPROOF ELECTRICAL EQUIP

Special drilling machine for brake disc multi-hole machining

InactiveCN112570750AExpand the scope of processingImprove practicalityFeeding apparatusDriving apparatusBrakeElectric machinery

The invention discloses a special drilling machine for brake disc multi-hole machining. The special drilling machine comprises a base, screw rods, a mounting plate, a sliding block and a rotary disc;a workbench is arranged on the upper surface of the base, and supporting legs are installed at the lower end of the base; a support is installed at the upper end of the base, and mounting bases are arranged on the inner side of the support; the screw rods are installed between the mounting bases, and servo motors are installed at the upper ends of the screw rods; lug plates are connected to the middles of the screw rods in a penetrating mode, and the mounting plate is arranged between the lug plates; a sliding groove is formed in the middle of the mounting plate, and a sliding block is installed in the middle of the sliding groove; gear boxes are installed at the lower end of the sliding block; and a motor is installed on the outer side of each gear box. The special drilling machine for brake disc multi-hole machining is provided with the rotary disc and the sliding block, the rotary disc is driven by a main motor to rotate, the position of the sliding block is adjusted through cooperation of threads and the sliding block, thus the position of a drill bit can be adjusted according to the size of a brake disc and the position of the hole diameter, the machining range is widened, andthe practicability of the device is improved.

Owner:WUHU YUTAI AUTOBRAKING

An underground drilling machine

ActiveCN108756737BImprove drilling efficiencyRealize automatic drillingDrill bitsDrilling rodsHydraulic cylinderTerrain

The invention relates to an underground drilling machine. The underground drilling machine comprises a base, a drilling part, six walking parts, a fixed part, a waste liquid treatment part and a waterstorage device. The underground drilling machine is characterized in that the six walking parts enable the machine to walk to a place which needs to be drilled; two first hydraulic cylinders, two second hydraulic cylinders and two third hydraulic cylinders of the base work cooperatively to determine a precise position; the drilling part is lowered to the ground position by rotating a wire rope electric hoist; the two side surfaces of a bit fixing frame of the drilling part are clamped through the fixing part; a first stepping motor drives a bit to rotate downwards to drill a hole; water is drawn from a water receiver by a water inlet pump and then flows into the underground through a water pipe; eight propulsive crawlers are outward and tightly attached to the wall of a well and rotates simultaneously to generate propulsive force for downward drilling; and waste water is drawn into the waste liquid treatment part through a water suction pump, then downward drilling is carried out continuously, so that the underground drilling machine has higher drilling efficiency and can adapt to different terrains, automatic drilling is achieved, and the drilling efficiency and quality are improved.

Owner:南通永泰建设工程有限公司

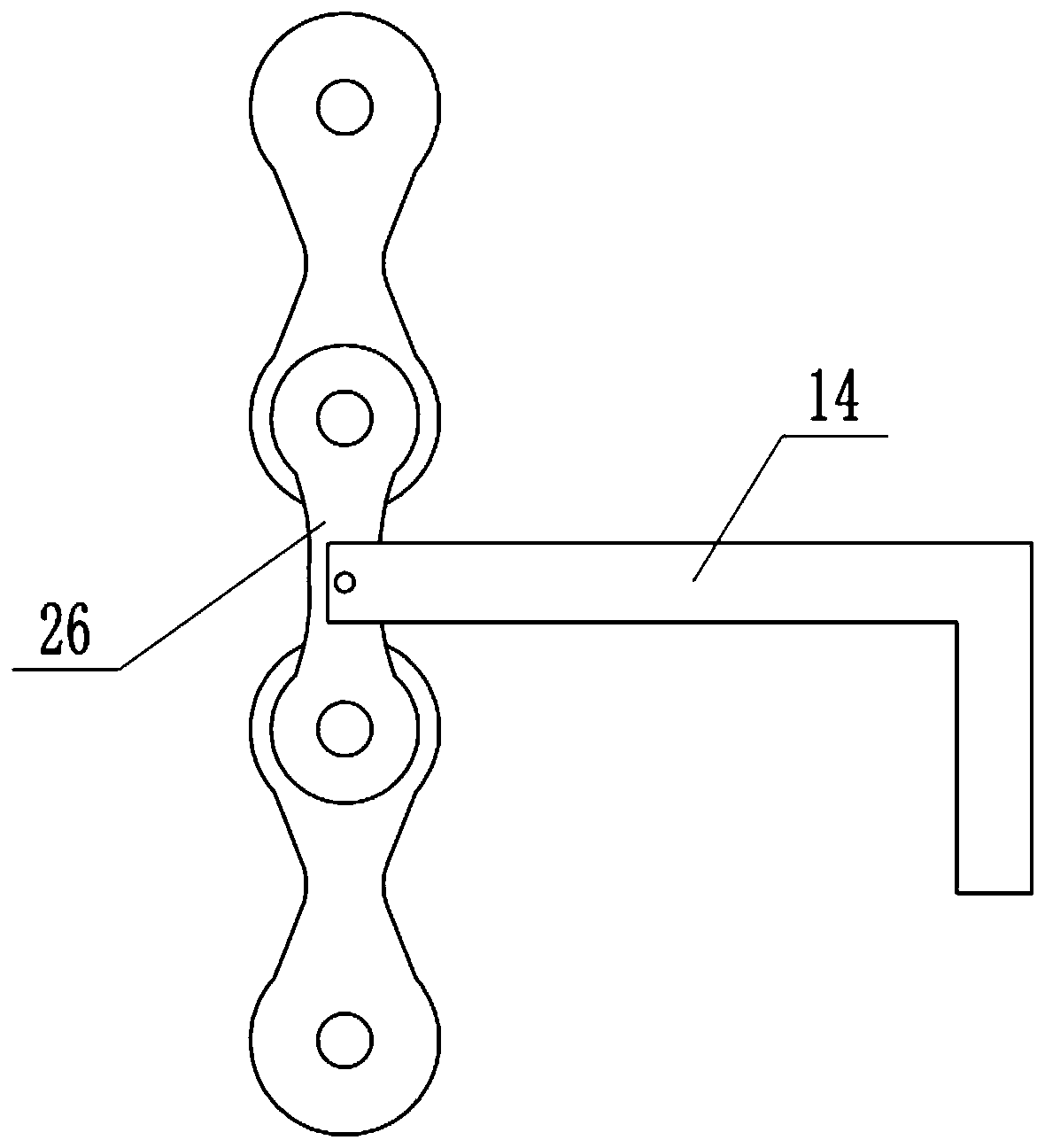

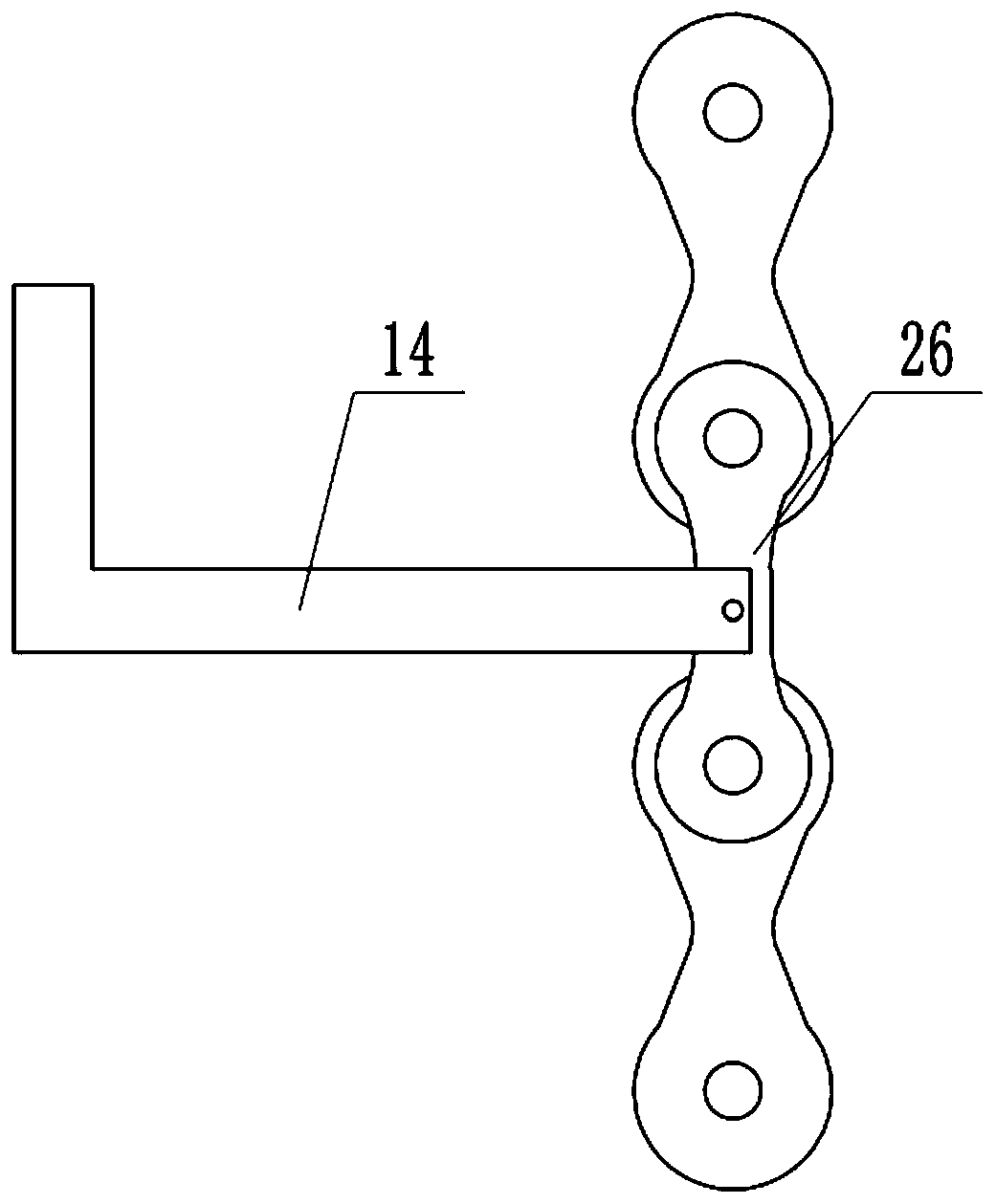

A battery pack bracket punching device for a motorcycle

ActiveCN109465477BRealize automatic adjustmentNo need for automatic adjustmentLarge fixed membersBoring/drilling componentsPunchingEngineering

The invention relates to the field of machining, in particular to a motorcycle battery pack bracket punching device which comprises a workbench and a motor, and further comprises a first chain wheel,a second chain wheel, a third chain wheel, a fourth chain wheel and a sliding plate, wherein a drill bit is connected onto the motor; a closed chain is connected among the first chain wheel, the second chain wheel, the third chain wheel and the fourth chain wheel; an L-shaped pressing plate is rotationally connected with a chain link of the chain; a torsional spring is arranged on the part, rotationally connected with the chain link, of the pressing plate; both the top and the side of a motor shell are capable of being propped against the pressing plate; the sliding plate is capable of transversely sliding; the motor is vertically and slidably connected onto the sliding plate; a first spring is connected onto the motor; a first telescopic cylinder is arranged on the outer side of the firstspring in a sleeving manner; a second spring is connected onto the sliding plate; a second telescopic cylinder is arranged on the outer side of the second spring in a sleeving manner; and a placementslot used for the placement of a bracket is arranged on the workbench. Through the scheme of the motorcycle battery pack bracket punching device, the automatic movement of the bracket in the drillingprocess can be achieved.

Owner:重庆鑫劲宏景机械有限公司

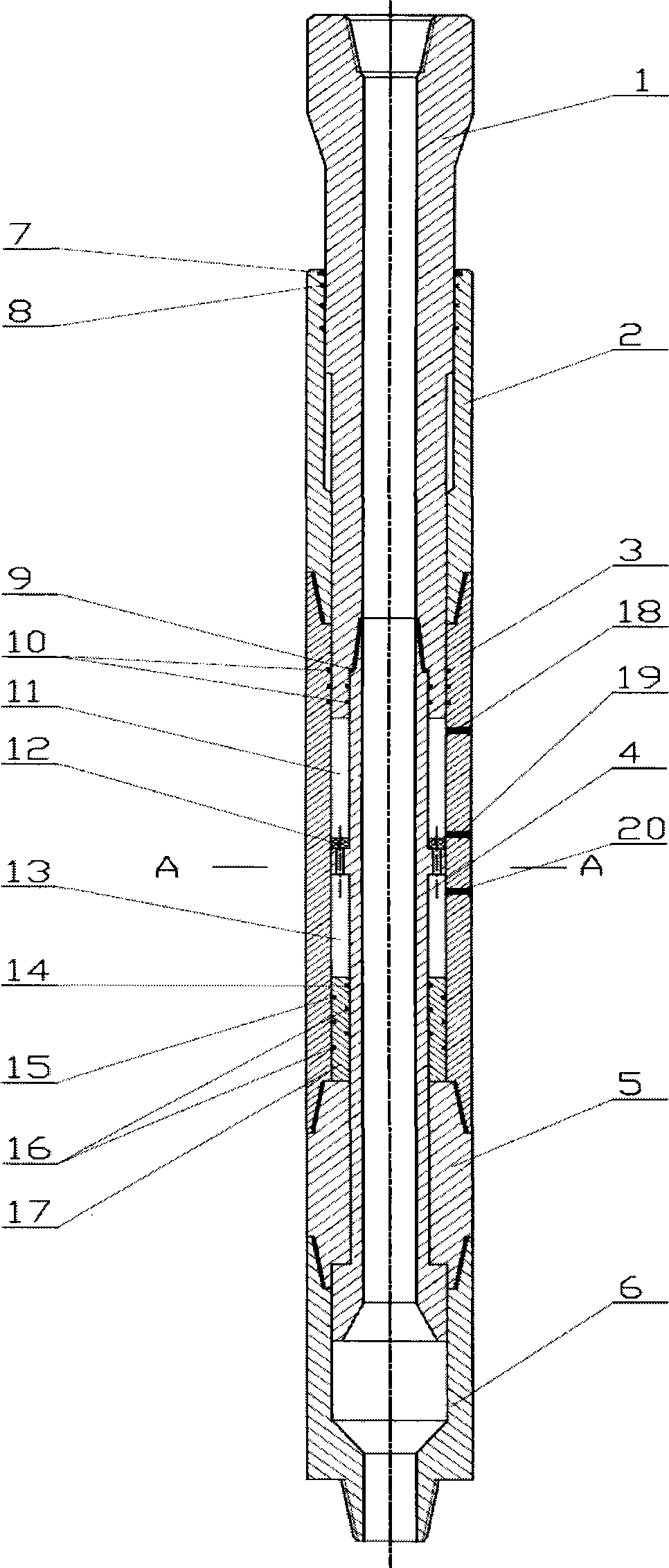

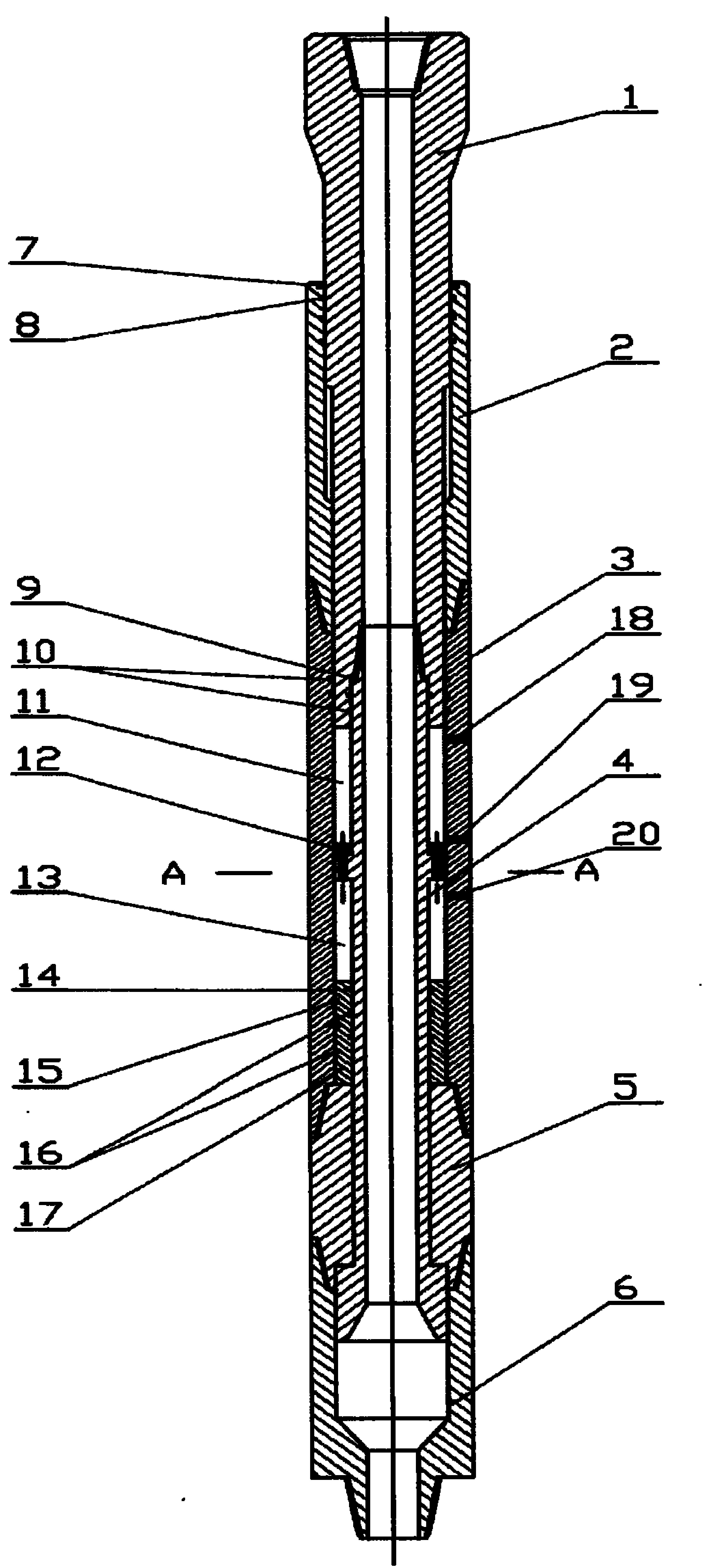

Liquid-gas type vibration absorber

InactiveCN101429852BImprove applicabilityImprove flexibilityDrilling rodsDrilling casingsPressure transmissionFall protection

The invention relates to a liquid gas type shock absorber, which consists of an upper connector, a spline external cylinder, a cylinder sleeve, a mandrel, a piston, a falling protection connector and a lower connector. The shock absorber is basically characterized in that the upper connector is connected with the spline external cylinder through a spline; the external cylinder of the shock absorber consists of the spline external cylinder and the cylinder sleeve; the mandrel and the piston are arranged inside the cylinder sleeve and are connected with the upper connector through thread; and the falling protection connector is connected with the cylinder sleeve and the lower connector through thread. According to the characteristic that the volume of gas changes along with the change of the temperature and pressure, the shock absorber adopts gas as an elastic element and has better shock absorbing performance. Simultaneously, liquid is taken as a pressure transfer element, thereby not only improving the stability of the shock absorbing system, but also carrying out the liquid sealing of the gas and consequently improving the tightness of the cylinder. The shock absorber has the advantages of wide application range, good flexibility, low impact, good stability, and the like.

Owner:中石化石油工程技术服务有限公司 +1

Drilling machine for simultaneous processing of six holes for the ladder side of composite cable tray

ActiveCN105033308BShorten the timeImprove work efficiencyBoring/drilling componentsBoring/drilling machinesChinese charactersCable tray

The invention relates to a drilling machine used for a ladder string of a composite material cable bridge stand and capable of machining out six holes simultaneously. The drilling machine is characterized in that an upper drilling power head is installed on a bracket shaped like a Chinese character 'hui', a left side drilling power head and a right side drilling power head are arranged at the two sides of the upper drilling power head respectively, an upper drilling power head multiaxial device is arranged below the upper drilling power head, side direction drilling power head multiaxial devices are arranged at the inner side of the left side drilling power head and the inner side of the right side drilling power head respectively, a feeding bed is arranged in front of a base, a blanking bed is arranged behind the base, and a servo cart is arranged at the top end of the feeding bed. The drilling machine has the advantages that the six holes can be drilled continuously and simultaneously, time and labor are saved, defects that drilling holes are inconsistent in position, and the installation is inconvenient are avoided, no measurement is required, time of workers is saved, the working efficiency is raised, and the automated drilling is achieved through the PLC control.

Owner:HEBEI YANWU EXPLODEPROOF ELECTRICAL EQUIP

Drilling equipment for tunnel excavation

PendingCN114856601AReduce manpower consumptionPrecise drillingDust removalFire preventionHydraulic cylinderArchitectural engineering

The invention relates to drilling equipment, in particular to drilling equipment for tunnel excavation. According to the drilling equipment for tunnel excavation, manual drilling is not needed, and the state after adjustment can be kept for automatic drilling. Drilling equipment for tunnel excavation comprises a base, and universal wheels convenient to move are symmetrically arranged on the left side and the right side of the bottom of the base front and back; the hydraulic cylinder for driving height adjustment is arranged at the top of the base; the four first guide seats are arranged at the top of the base, a connecting frame is slidably connected between the tops of the first guide seats, and a mounting plate is hinged to the top of the connecting frame. A worker can push the handheld rod to drive the mounting plate and the parts above to move freely and easily, the electric drill does not need to be carried by hands to work, and manpower consumption is reduced.

Owner:CCCC SECOND HIGHWAY ENG CO LTD

An Intelligent Sewing Machine for Continuously Sewing Decorative Objects

ActiveCN107805891BRealize automatic sewingIncrease productivityWorkpiece carriersMetal working apparatusCounterboreIndustrial engineering

The invention discloses an intelligent sewing machine sewing ornamental stuff continuously. The intelligent sewing machine comprises a support, a work panel and a sewing machine body, a drilling module is installed on the sewing machine body, and a rotatable ornamental stuff placing platform is arranged at the lower end of the drilling module; the rotatable ornamental stuff placing platform comprises a cylinder of which the upper end is open, a support column, balls and a platform body, wherein the support column is fixed to the middle of the cylinder, the platform body is arranged on the support column, and the balls are arranged between the side face of the platform body and the inner wall of the cylinder; multiple through counterbores matched with the ornamental stuff are formed in theplatform body and distributed in a circular array around the center axis of the support column; fixed lugs are arranged on the cylinder and fixed to the work panel; the through counterbores are correspondingly formed under a needle of the sewing machine body and under the drilling module. The intelligent sewing machine sewing the ornamental stuff continuously has the function of automatic drilling, accordingly achieves automated sewing of the ornamental stuff, and improves the efficiency of producing clothes with the ornamental stuff.

Owner:会同县峰铧轩服装有限责任公司

An automobile steering knuckle drilling machine

ActiveCN111673113BHigh degree of automationRealize automatic drillingBoring/drilling componentsBoring/drilling machinesControl engineeringMachine

The invention relates to an automobile steering knuckle drilling machine, which comprises a chassis, and a clamping seat is installed on the right front part of the chassis; a double-layer frame is fixedly installed inside the casing, and a movable plate is mounted on the upper part of the double-layer frame. A drilling assembly is installed on the movable plate; a transfer control assembly is connected to the movable plate. A slidable box door is also installed at the front end of the box. The center of the clamping seat is provided with a sinking groove, and the center of the lower end of the sinking groove is provided with a threaded bottom groove; the left and right sides of the upper end of the clamping seat are provided with a pair of movable grooves, and each movable groove is slidably installed with an L-shaped limit block. The invention has a high degree of automation. On the basis of the function of limiting and clamping the steering knuckle, it can also realize automatic drilling of the steering knuckle, and realize the control of the drill bit from the front drilling station to the side drilling station. Automatic conversion between machines, thus realizing automatic drilling while saving manpower.

Owner:WUHU KAIDE MACHINERY MFG

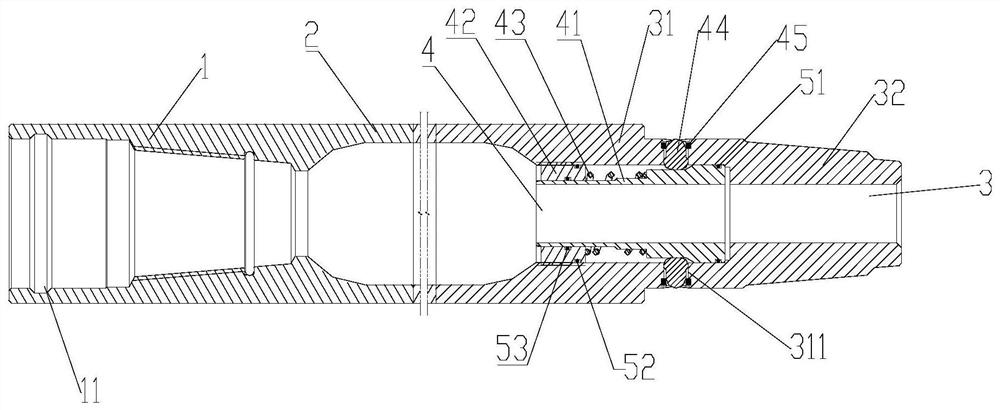

Forward and reverse automatic detachable drill pipe for mining

ActiveCN110374521BRealize automatic drillingReduce manual assisted disassembly and assemblyDrilling rodsDrilling casingsMining engineeringStructural engineering

The invention discloses a mining forward and reverse rotation automatic dismounting and mounting type drill pipe. The drill pipe comprises more than one drill pipe units which can be sequentially connected. Each drill pipe unit comprises a female joint, a tube body and a male joint which are connected in sequence. The two adjacent drill pipe units are detachably connected through the cooperation of the male joints and the female joints. Each male joint comprises a control section and a lead-in section which are hollow to form a stepped hole, wherein the inner diameter of the control section islarger than the inner diameter of the lead-in section; and a jacking and clamping mechanism is arranged in a hole of the control section and is used for maintaining the connection between or disconnecting the male joints and the female joints in a controlled mode. Simple mechanisms are additionally arranged in an existing common one-way threaded drill pipe joint, drill pipes are locked and unlocked through the change of cuttings hydraulic force during drilling of the drill pipe, forward and reverse rotation of the drill pipe meets the requirements for rock debris cutting and jam release, thelink of using manpower to assist in disassembly and assembly is omitted, and at the time, the threaded connection structure can realize automatic dismounting of a drilling machine.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

A drilling machine for accounting documents

ActiveCN110370373BPrevent problems such as deformationAvoid accidental injuryMetal working apparatusMining engineeringPaper dust

The invention relates to the technical field of official business handling equipment and discloses an accounting document hole drilling machine. During drilling by the accounting document hole drilling machine, firstly a compressing sleeve is used for compressing a hole drilling portion, then hole drilling is performed, the problem that tearing and the like occur to an accounting document at the position of the hole drilling portion can be effectively solved, and the problem of deformation and the like at the hole drilling position is solved. Meanwhile, the accounting document hole drilling machine is further provided with an outer protecting barrel, and on one hand, a drilling cutter can be protected, and it is prevented that mistaken injuries are caused to operators; and on the other hand, during drilling, a lifting driving barrel moves up and down while driving the drilling cutter to rotate, and automatic hole drilling is achieved; besides, when the accounting document hole drillingmachine performs drilling, paper scraps are sucked out due to negative pressure, and the situation that a drill bit is stuck by the paper scraps and consequently the accounting document is damaged bythe drill bit is prevented; and the drilling cutter is of a cylindrical thin-wall structure, the paper scraps are directly sucked out from the center according to the cut-out shape, and operation iseasy and convenient.

Owner:GUANGDONG BAIYUN UNIV

Bi-directional drilling head

ActiveCN109500421BRealize automatic drillingAutomatic drillingFeeding apparatusLarge fixed membersRotational axisEngineering

The invention provides a double-direction drilling power head and belongs to the technical field of drilling equipment. The double-direction drilling power head comprises a stand column, a main shaftbox, a swinging rotating mechanism, a main shaft used for installing a drill bit, a worm gear, a worm, a main shaft linear feeding mechanism used for driving the main shaft to move linearly in the axis direction of the main shaft, and a main shaft rotating driving mechanism used for driving the main shaft to rotate; the main shaft box is arranged above the stand column and is rotationally connected with the stand column through a rotating shaft; the swinging rotating mechanism is used for driving the main shaft box to perform 90-degree swinging rotating around the rotating shaft and to be locked; the worm gear is used for driving the main shaft to rotate and perform drilling; the worm gear is arranged on the outer side of the main shaft in a sleeving manner and is engaged with the worm fixedly arranged on the rotating shaft; and the worm and the rotating shaft are coaxial, and in the axis direction of the main shaft, the main shaft and the worm gear are in sliding fit. The double-direction drilling power head is suitable for meeting the requirements for drilling positioning pin holes in the two directions of the horizontal direction and the vertical direction in the narrow and small space in armed chariots, operation is easy, the labor intensity of an operator is relieved, and the machining efficiency and the machining precision are improved.

Owner:YANSHAN UNIV

High voltage transmission line ground wire work device

ActiveCN112542798BGood grounding effectRealize automatic drillingDerricks/mastsDirectional drillingGrounding gridEngineering

Owner:XINGTAI POWER SUPPLY +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com