Liquid-gas type vibration absorber

A liquid-gas shock absorber and shock absorber technology, applied in drilling equipment, earthwork drilling, drill pipe and other directions, can solve the problems of general shock absorption effect, small change range and small compressibility, and achieve shock absorption. Good effect, prevent secondary impact, increase the effect of applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

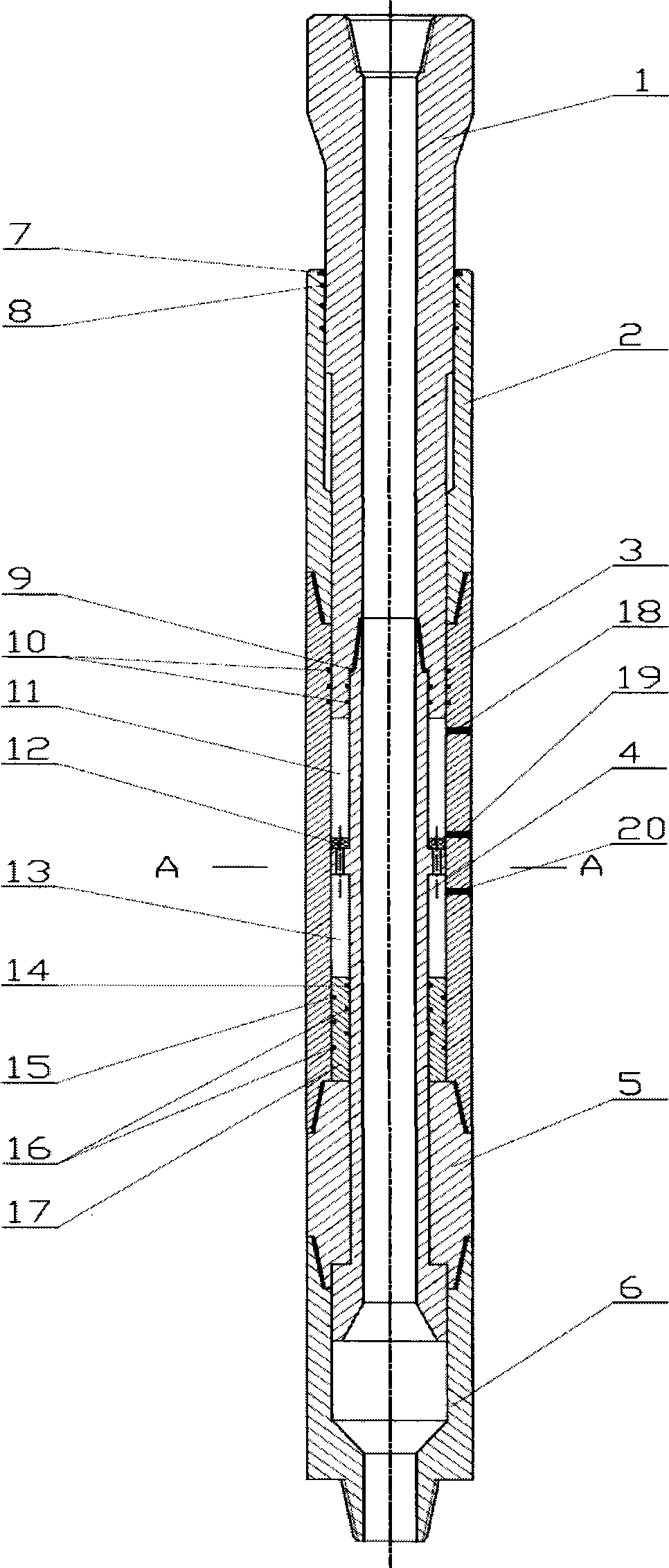

[0025] Combine now figure 1 , figure 2 Describe its invention further. According to the characteristic that the volume of gas changes with the change of temperature and pressure, the shock absorber uses gas as the elastic element, which has good shock absorption performance, and uses liquid as the pressure transmission element, which can not only increase the stability of the shock absorption system, Moreover, the gas is liquid-sealed, which increases the airtightness of the cylinder 11 .

[0026] The shock absorber presses figure 1 After assembly, according to the damping requirements, inject high-pressure gas into the cylinder through the gas nozzle 19, and inject low-pressure liquid into the liquid cylinder through the oil nozzle 20. And install it in the lower drilling tool assembly according to the need, and drill down to the bottom.

[0027] When impact and vibration loads occur on the drill bit, the lower joint 6 transmits the vibration load to the anti-drop joint ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com