A profile automatic punching machine

A punching machine, automatic technology, applied in the direction of automatic control device, driving device, boring/drilling, etc., can solve the problem of inability to guarantee the relative position accuracy of holes, low production efficiency, and failure to meet the basic requirements of qualified products, etc. problems, to achieve high production efficiency, ensure positional accuracy, flexible and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

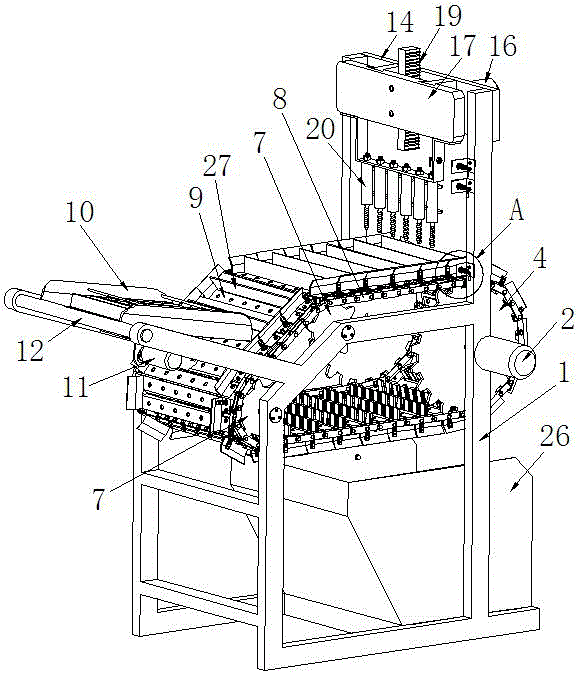

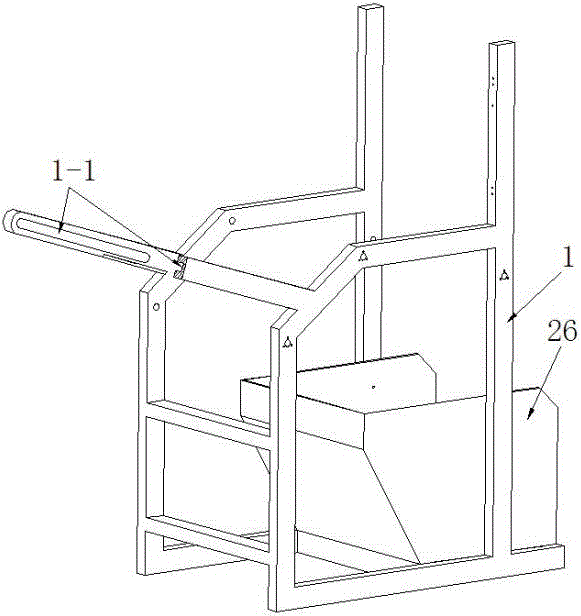

[0027] Example: see attached figure 1 ~ attached Figure 10 , an automatic punching machine for profiles, comprising a frame 1, a transmission mechanism, a feeding mechanism, and a punching mechanism located above the transmission mechanism.

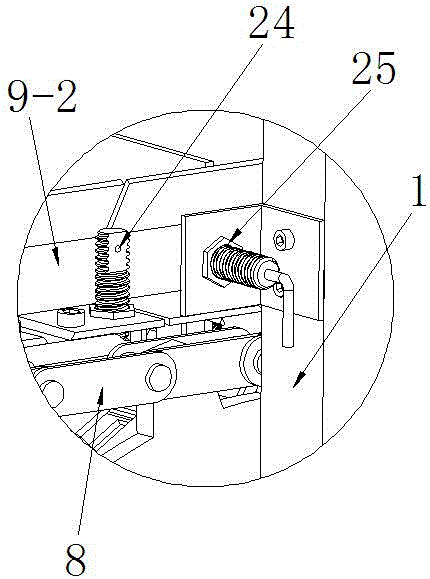

[0028] The transmission mechanism includes a transmission motor 2 fixed on the frame 1, a main shaft 3, two large sprockets 4 coaxial with the main shaft 3 and respectively fixed at both ends of the main shaft 3, an auxiliary shaft 1 parallel to the main shaft 3 and an auxiliary shaft 2 6, four small sprockets 7, two chains 8, 25 continuous long track shoes 9 side by side, one end of the main shaft 3 is fixedly connected to the output shaft of the transmission motor 2, and the other end of the main shaft 3 is movably connected to the machine through a bearing. Frame 1, the two ends of auxiliary shaft 1 5 and auxiliary shaft 2 6 are respectively movably connected to frame 1 through bearings, auxiliary shaft 1 5 is located at the upper po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com