Adjustable tool rest drill clamp of digital control lathes

A CNC lathe, adjustable technology, applied in tool holders, boring/drilling devices, drilling/drilling equipment, etc., can solve the problems of small number of CNC tool holders, no drill bits, low efficiency, etc., and achieve positioning accuracy High, high production efficiency, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

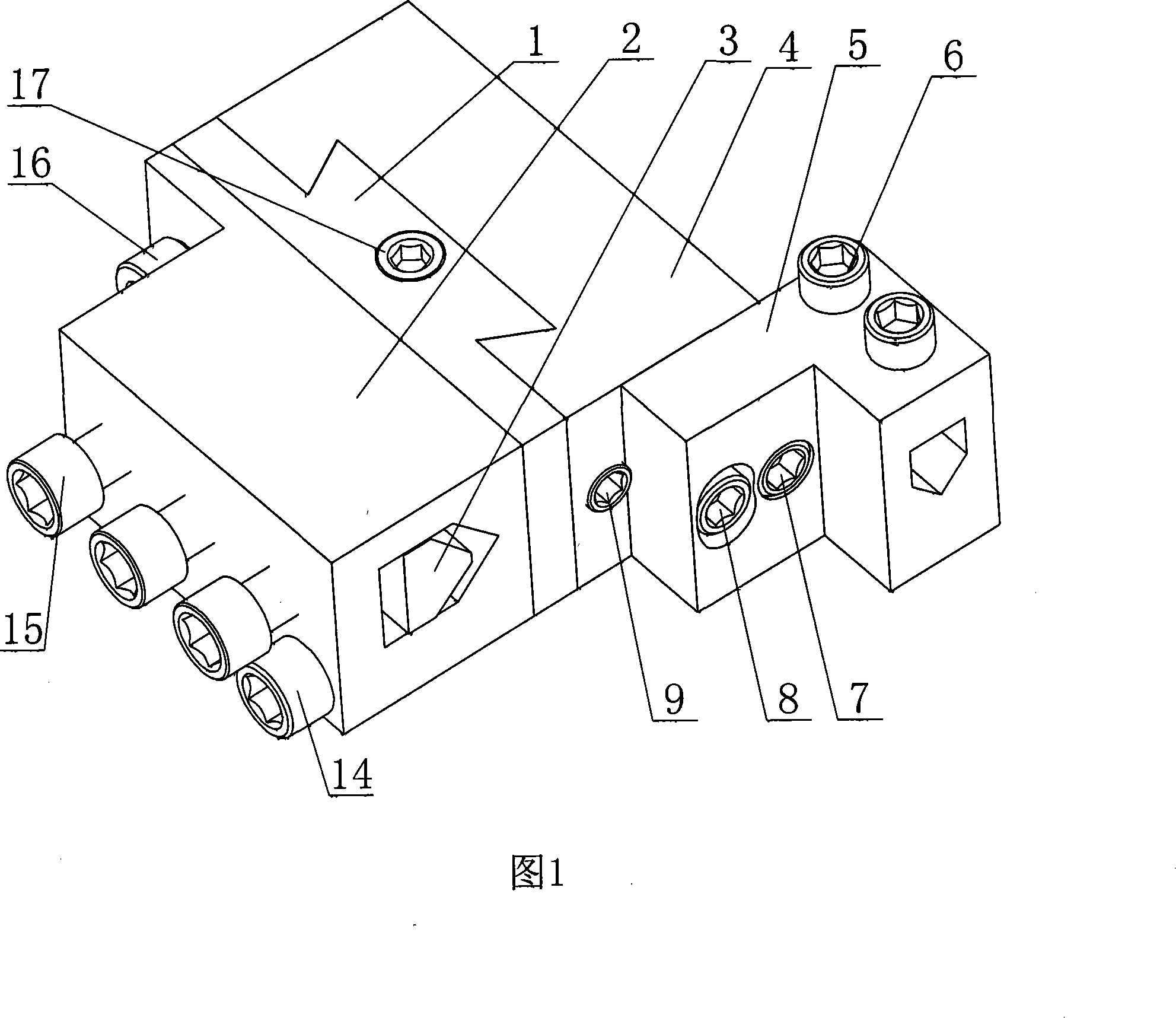

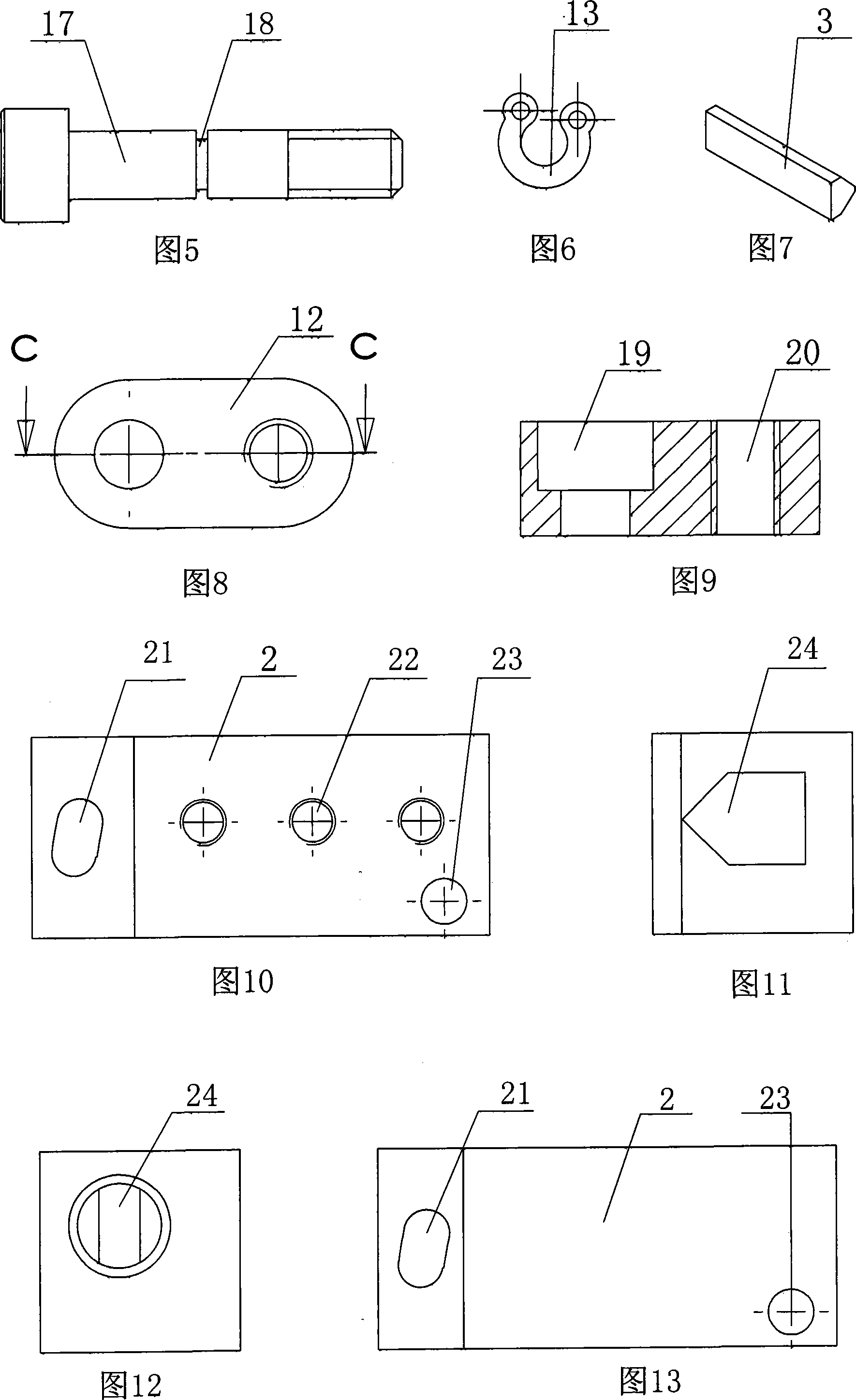

[0034] The best embodiment of the utility model is like this, with reference to Fig. 1 to shown in Fig. 19, a kind of adjustable CNC lathe tool rest drill clip, comprises by drill sleeve, slide block, fixed block, center drill sleeve, wherein, all The fixed block (4) is provided with a concave dovetail groove to cooperate with the convex dovetail groove of the slider (1), and the bottom surface of the concave and convex dovetail groove is provided with an insert groove (28) to install the insert (12), and the drill sleeve (2 ) and the slide block (1) are fixed with bolts (14,16), and the drill sleeve (2) is horizontally provided with a V-shaped groove (24) to match the drill bit and the V-shaped block (3), and the drill bit is fixed with the bolt (15); The center drill sleeve (5) is connected on the fixed block (4) with bolts (7, 8); the described slide block (1) has a hole (29) passing through the height adjustment screw (17), and the screw (17) The groove (18) snaps into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com