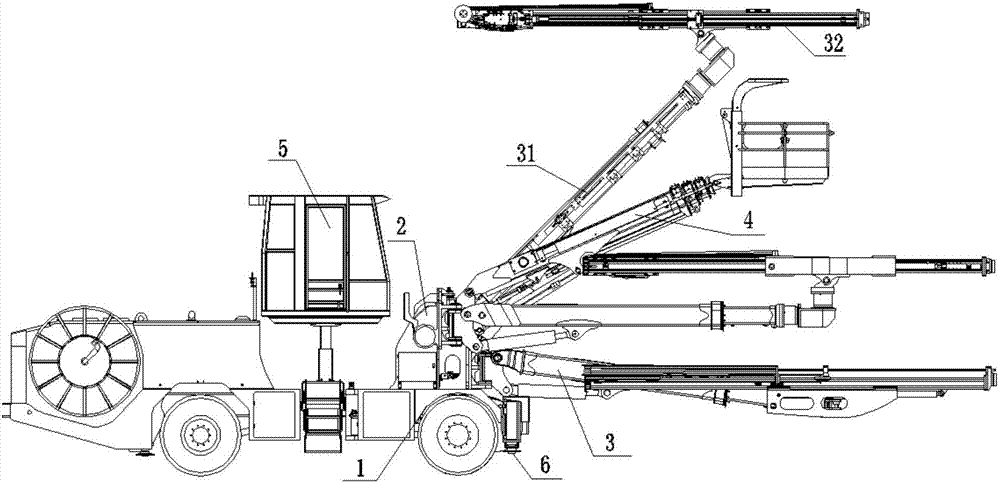

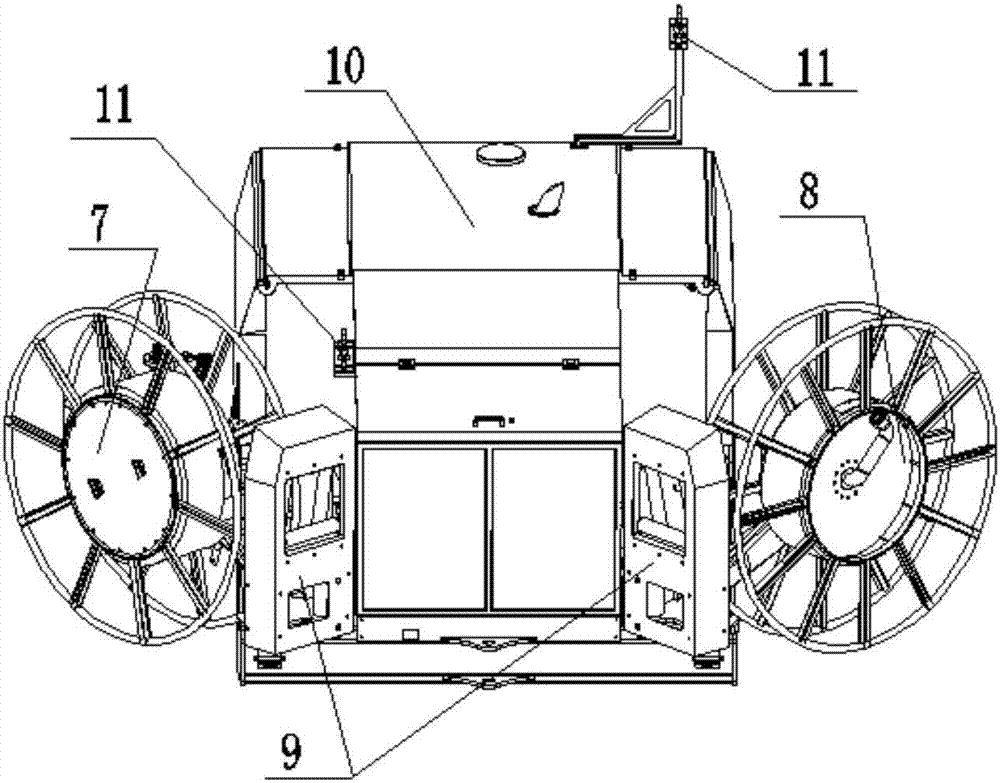

Intelligent drill jumbo

A technology of intelligent rock drilling jumbo and rock drilling machine, which is applied to drilling equipment, drilling equipment and methods, earthwork drilling and mining, etc. It can solve the problems of low drilling precision and low construction efficiency, and achieve the purpose of improving construction quality and construction efficiency, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] As mentioned in the background art section, the current drilling rigs have low drilling accuracy and low work efficiency.

[0029] Based on the above research, the embodiment of the present invention provides an intelligent rock drilling jumbo. The controller controls the drill arm to perform corresponding actions according to the internally stored hole layout diagram, so as to realize the purpose of automatic drilling. The position of each hole in the figure, the drilling angle and the number of holes, the drilling sequence, the posture control of the drill arm and the moving path can be automatically controlled by the pre-programmed program in the controller. By precisely controlling the drilling angle and The depth and the distribution position of the holes can effectively improve the accuracy of the end face after blasting, thereby improving the construction quality and construction efficiency.

[0030] In order to make the above objects, features and advantages of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com