Woodworking full-automatic drilling and riveting system and working mode thereof

A working method and fully automatic technology, which is applied to wood processing equipment, manufacturing tools, fixed drilling machines, etc., to improve production efficiency, improve processing accuracy, and reduce environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Such as Figure 7 As shown: the first workpiece 501 includes, but is not limited to, some feature processing related to the mortise and tenon structure, such as connection holes and positioning grooves of some dining table boards or wooden office table boards. Use the automatic alignment workbench 1 to position the edge of the table or platen, and then use the drilling robot 3 to perform operations such as drilling connection holes and milling positioning slots according to the two-dimensional coordinates provided by the system, and then perform operations such as drilling connection holes and milling positioning slots on the relevant connections. The mounting nails are riveted on the holes, and finally the palletizing is completed.

Embodiment 2

[0058] Such as Figure 8 As shown: the second processing part 502 includes but is not limited to the fine carving process of industrial wood tooling boards. After the automatic alignment workbench 1 positions the second workpiece 502, it processes it according to the fine carving requirements of the tooling board. After setting the origin, you can compile the corresponding path for processing. The processing path can be two-dimensional or three-dimensional. After the fine carving process of the working board is completed, the positioning bushing or bolt bushing is riveted according to the demand, and the stacking is done after completion.

Embodiment 3

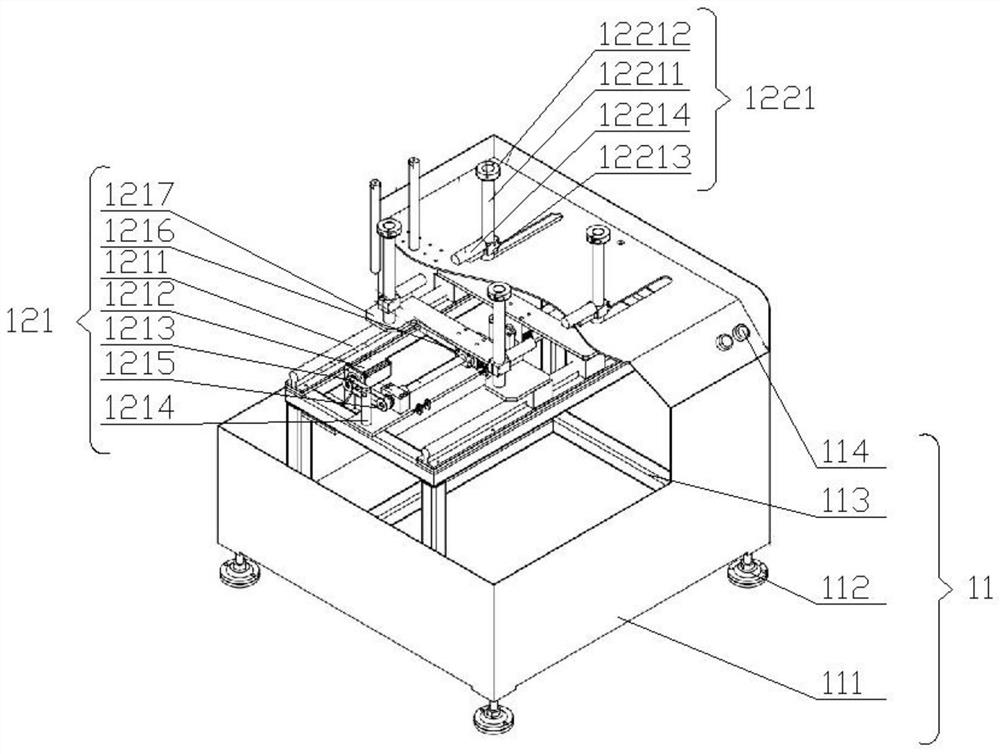

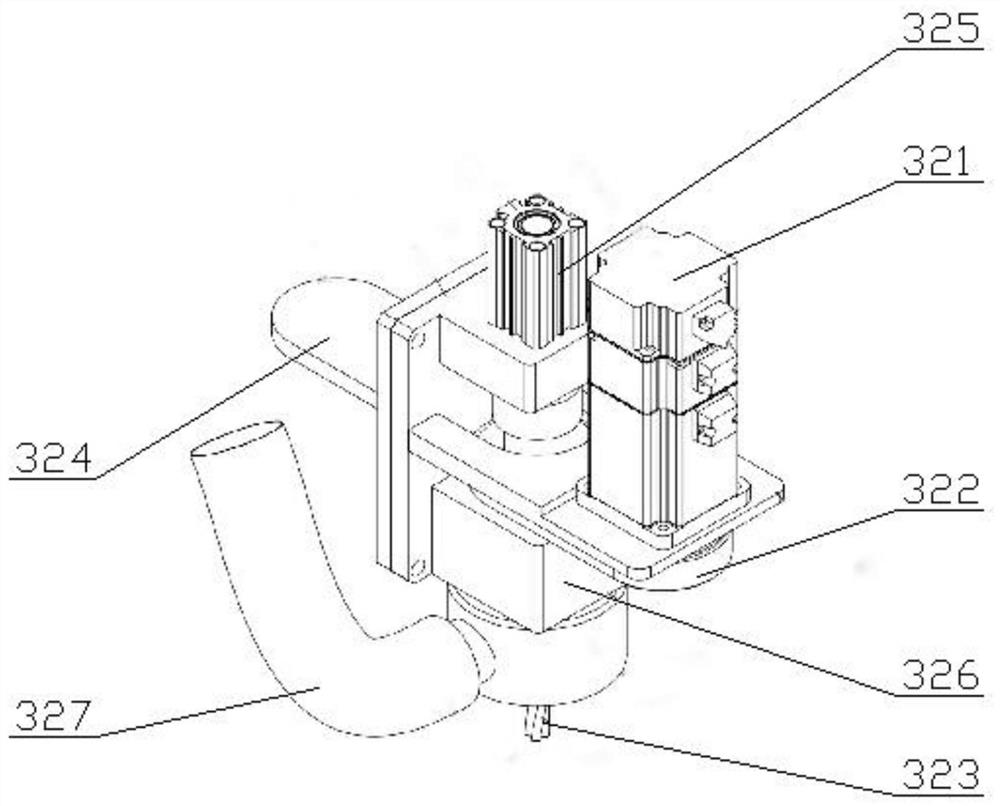

[0060] A fully automatic drilling and riveting system for woodworking, which consists of an automatic alignment workbench 1, a feeding robot 2, a drilling robot 3, a riveting robot 4, a dust collection system 5, an M6 bolt riveting machine 6, an M8 bolt riveting machine 7, The chair board feeding station 8 and the chair board unloading station 9 are composed;

[0061] Riveting robot 4 comprises riveting robot 41, riveting robot 42, and described M6 bolt riveting machine 6 comprises M6 bolt riveting machine 61, M6 bolt riveting machine 62, and described M8 bolt riveting machine) comprises M8 bolt riveting machine 71, M8 Bolt riveting machine 72, described manipulator control cabinet 10 comprises manipulator control cabinet 101, manipulator control cabinet (02, and described chair panel blanking station 9 comprises chair panel blanking station 91, chair panel blanking station 92, so The automatic alignment workbench 1 can automatically position and clamp the chair board through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com