Drilling machine for simultaneous processing of six holes for the ladder side of composite cable tray

A technology of cable tray and composite materials, which is applied in the direction of boring/drilling, metal processing equipment, drilling/drilling equipment, etc., which can solve the problems of low work efficiency, unsuccessful installation, time-consuming, etc., and improve work efficiency. Efficiency, saving time, avoiding the effect of non-uniform drilling positions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

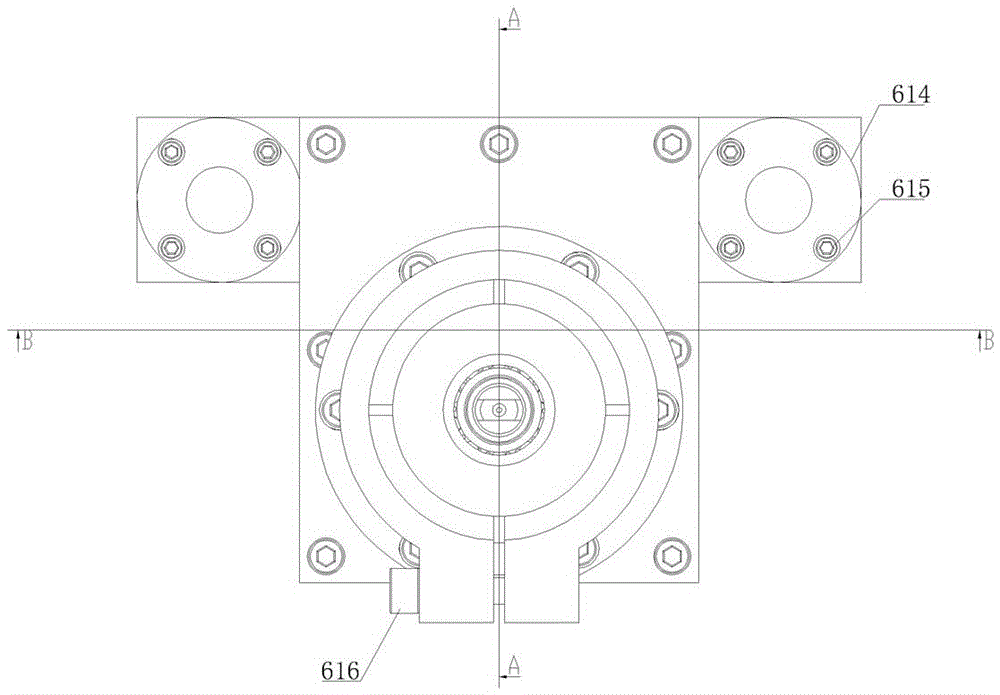

[0013] The present invention will be described in detail below with reference to the accompanying drawings. As shown in the drawings, the structure of the present invention includes a base 1, a left drilling power head 2, a right drilling power head 3, an upper drilling power head 4, a feeding bed 7, a feeding bed 8, and a servo trolley 9. Return frame 10, servo trolley power unit 11, servo chain groove 12, chain 13, limit device consisting of main cylinder 141, pressure plate 142, pressure rod 143, secondary cylinder 144, side cylinder 145, and side pressure rod 146 140, consisting of the upper multi-axis device box 51, the upper linear bearing 52, the upper multi-axis device upper cover 53, the upper connecting sleeve 54, the upper tightening ring 55, the upper driving shaft 56, the upper deep groove ball bearing A57, and the upper output shaft 58. The upper drilling power head multi-axis device 5 composed of the upper contact bearing 59, the upper intermediate shaft 510, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com