Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Protect the end" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

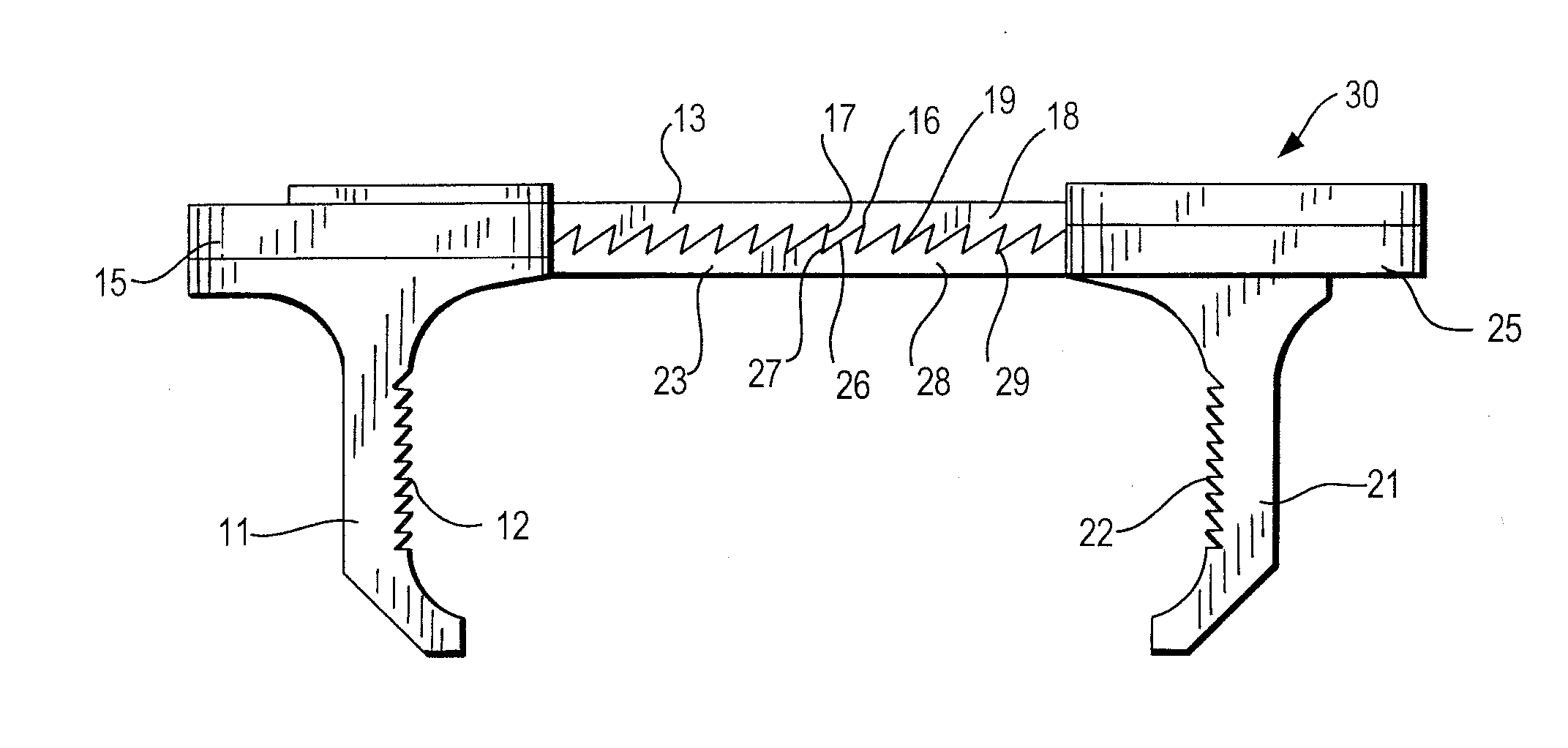

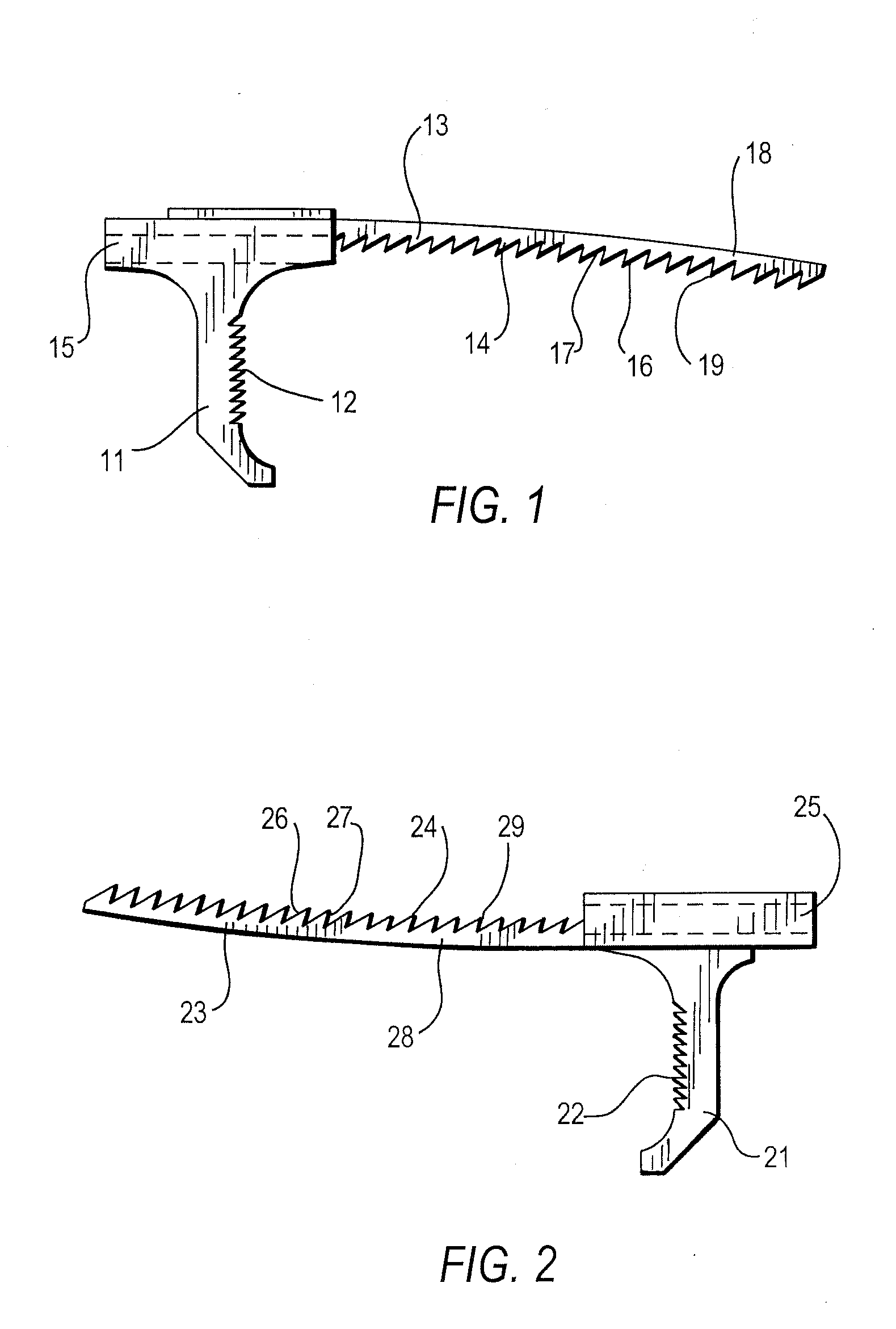

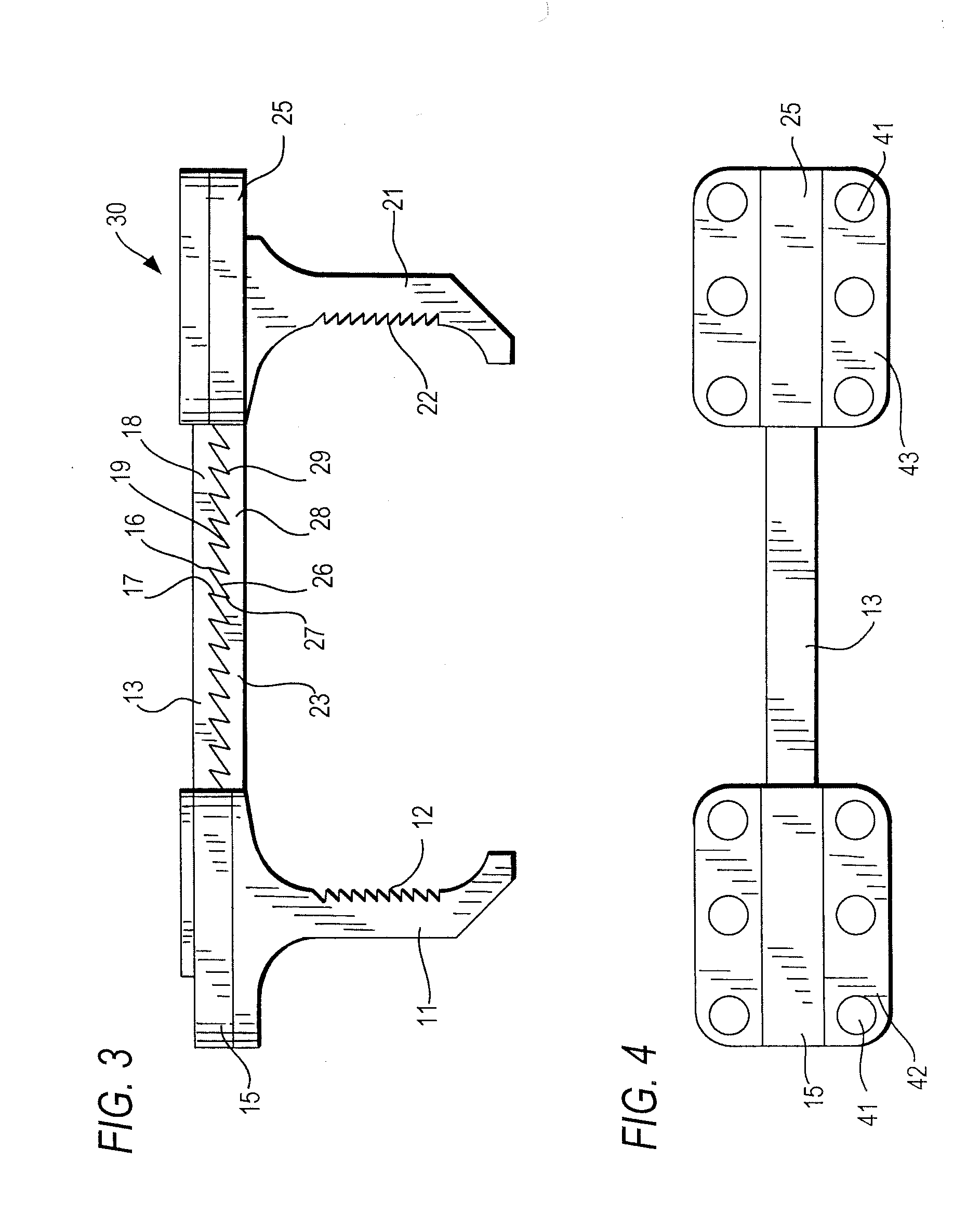

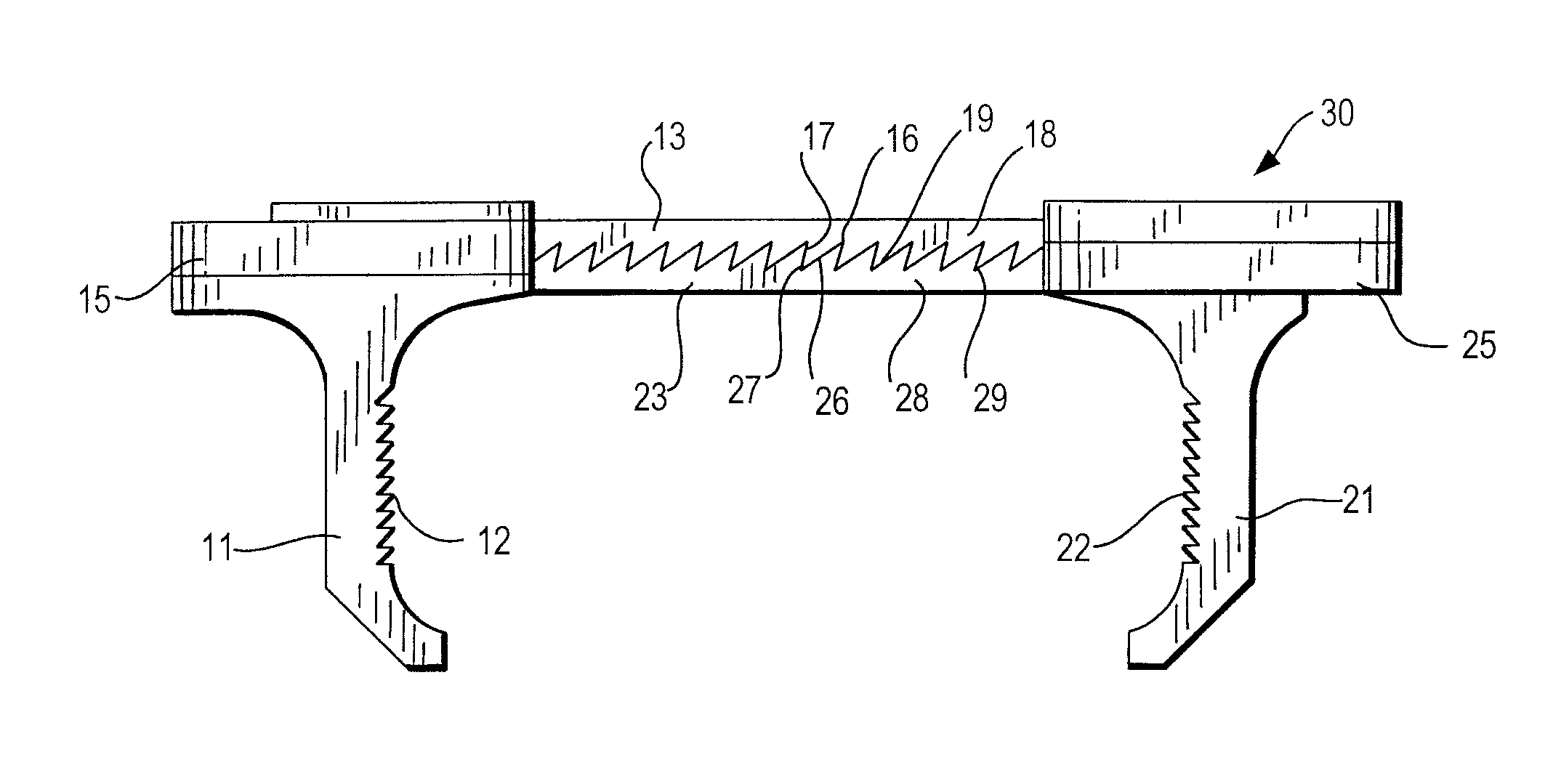

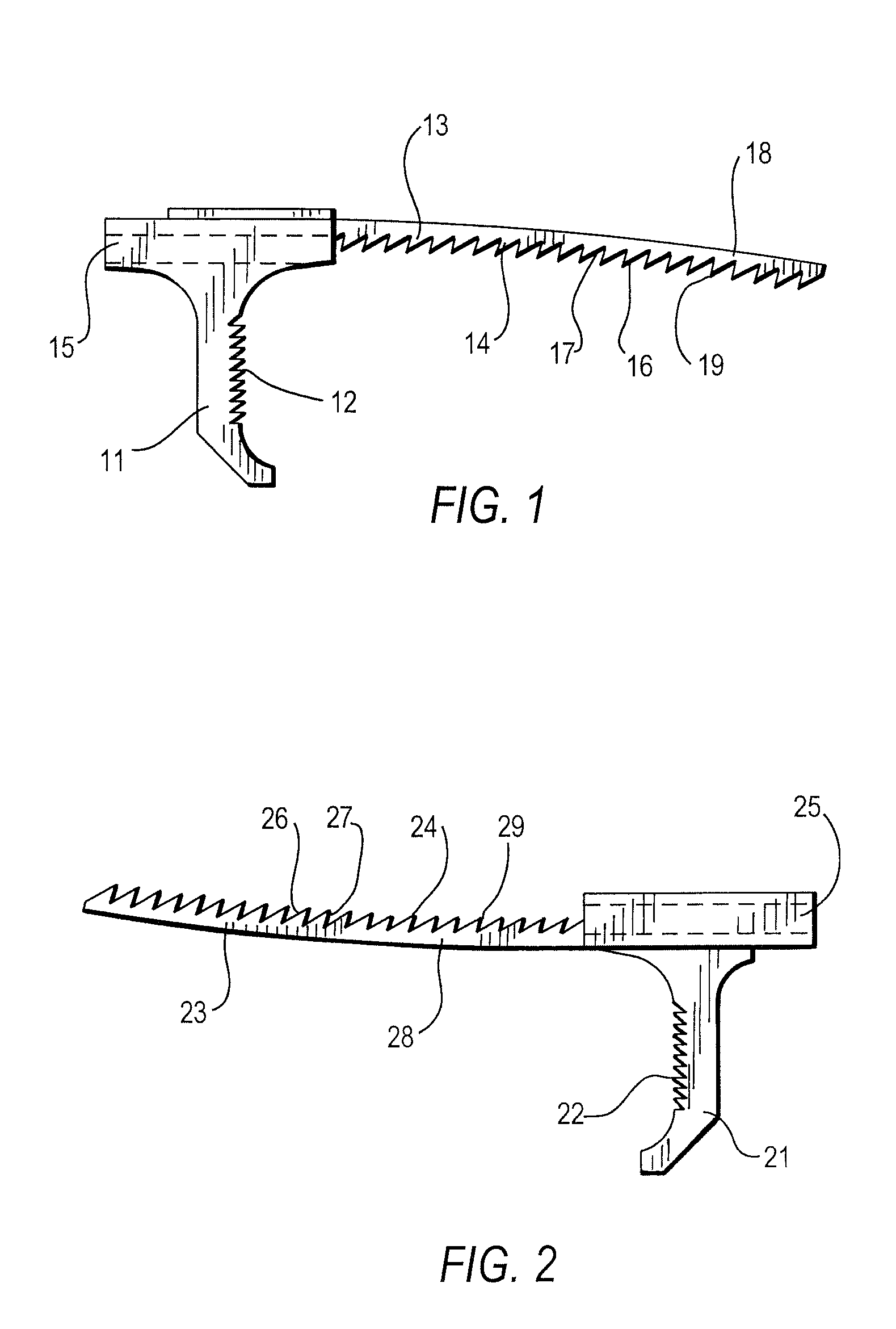

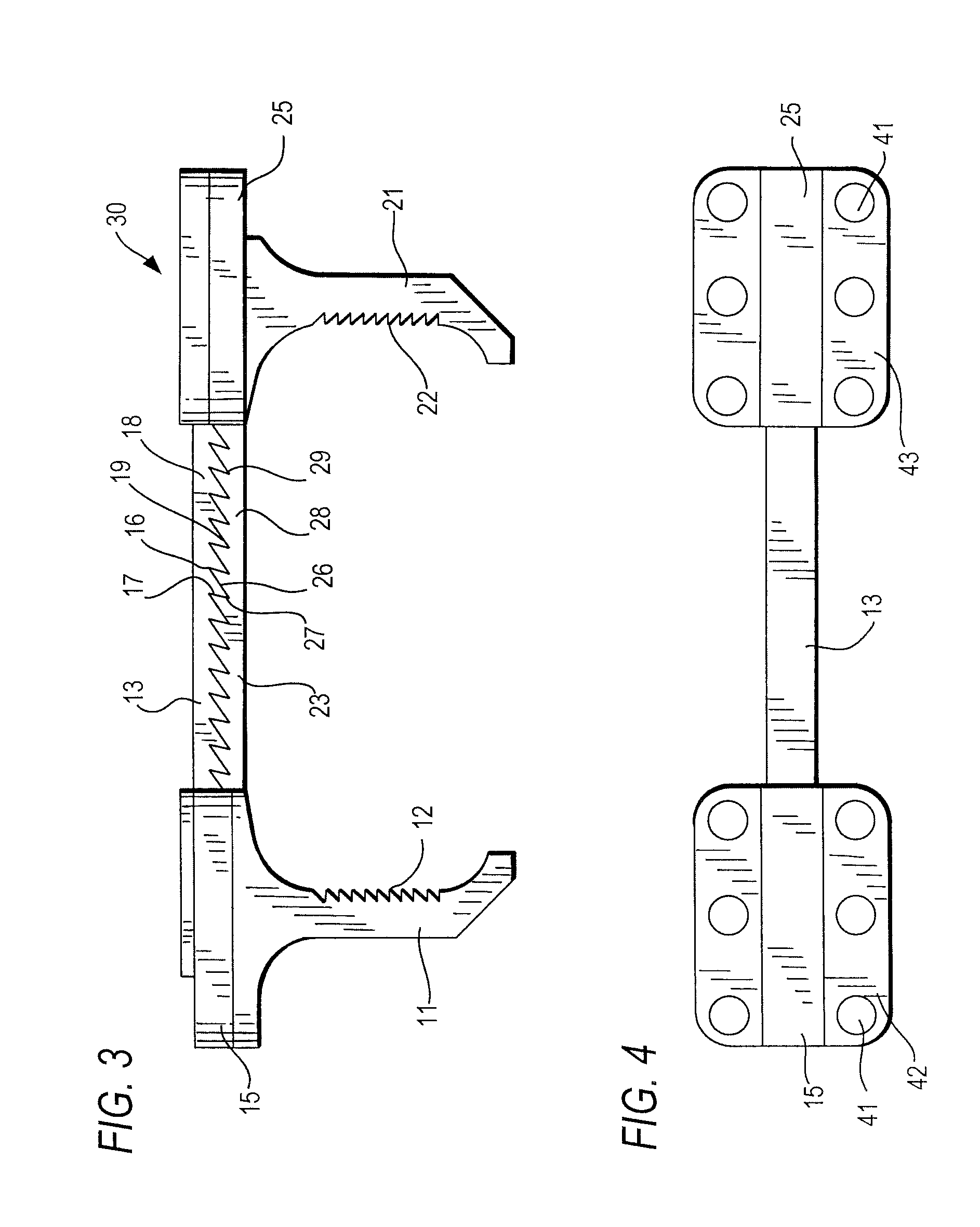

Method and apparatus for surgical clamping

InactiveUS20090125073A1Easy to lockIncrease resistanceSnap fastenersSuture equipmentsLeft halfSurgical Clamps

The invention concerns a clamp, especially a surgical clamp, with a left clamp half to receive a left half of a breastbone during a surgical procedure, a right clamp half to receive a right half of the breastbone, as well as a first toothed rod and a detent mechanism engaging in the first toothed rod to secure the left clamp half at a distance from the right clamp half, wherein the detent mechanism engaging in the first toothed rod has a detent region extending at least from the left clamp half to the right clamp half.

Owner:MAX HAUSER SUDDEUTE CHIRURGIEMECHANIK +1

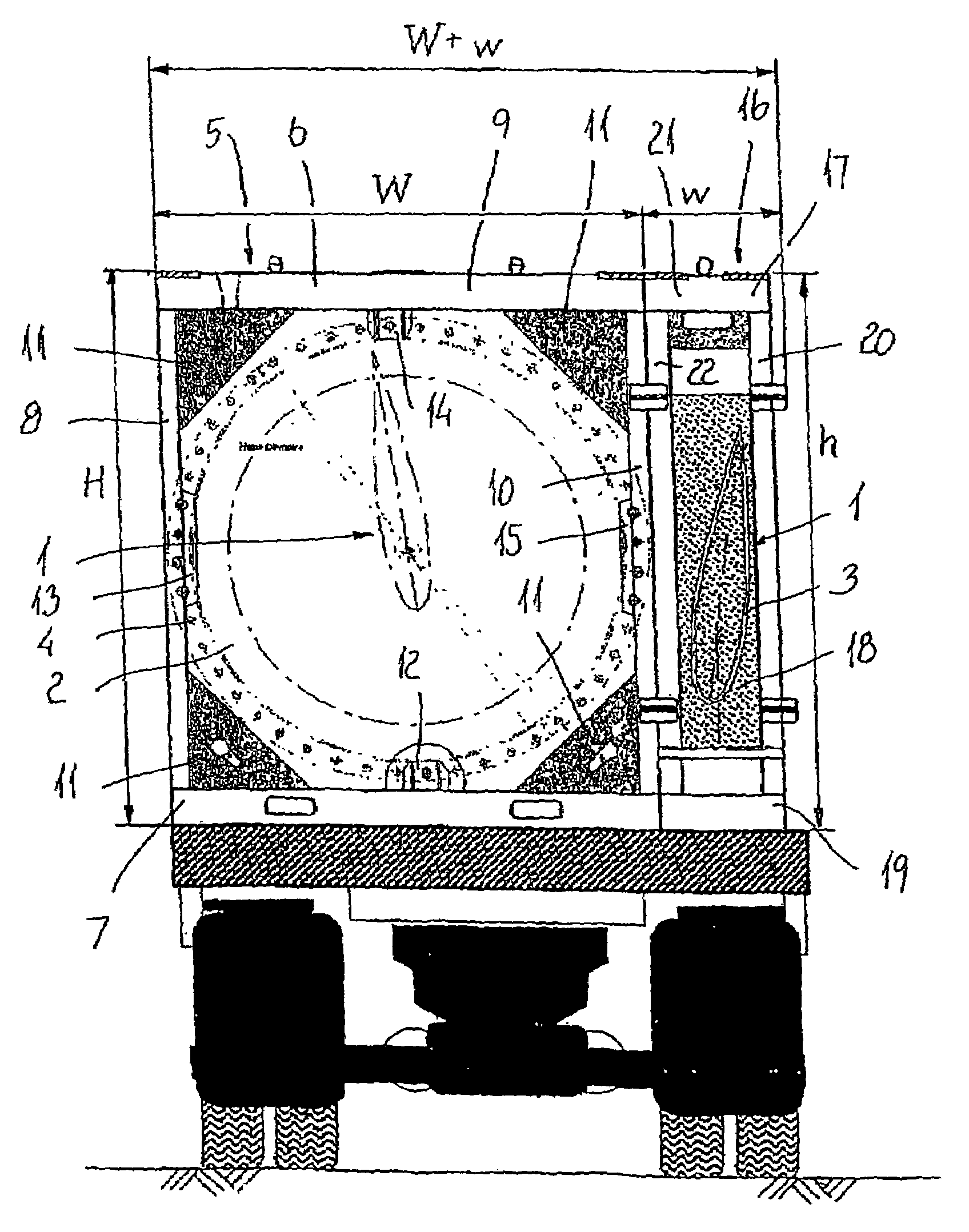

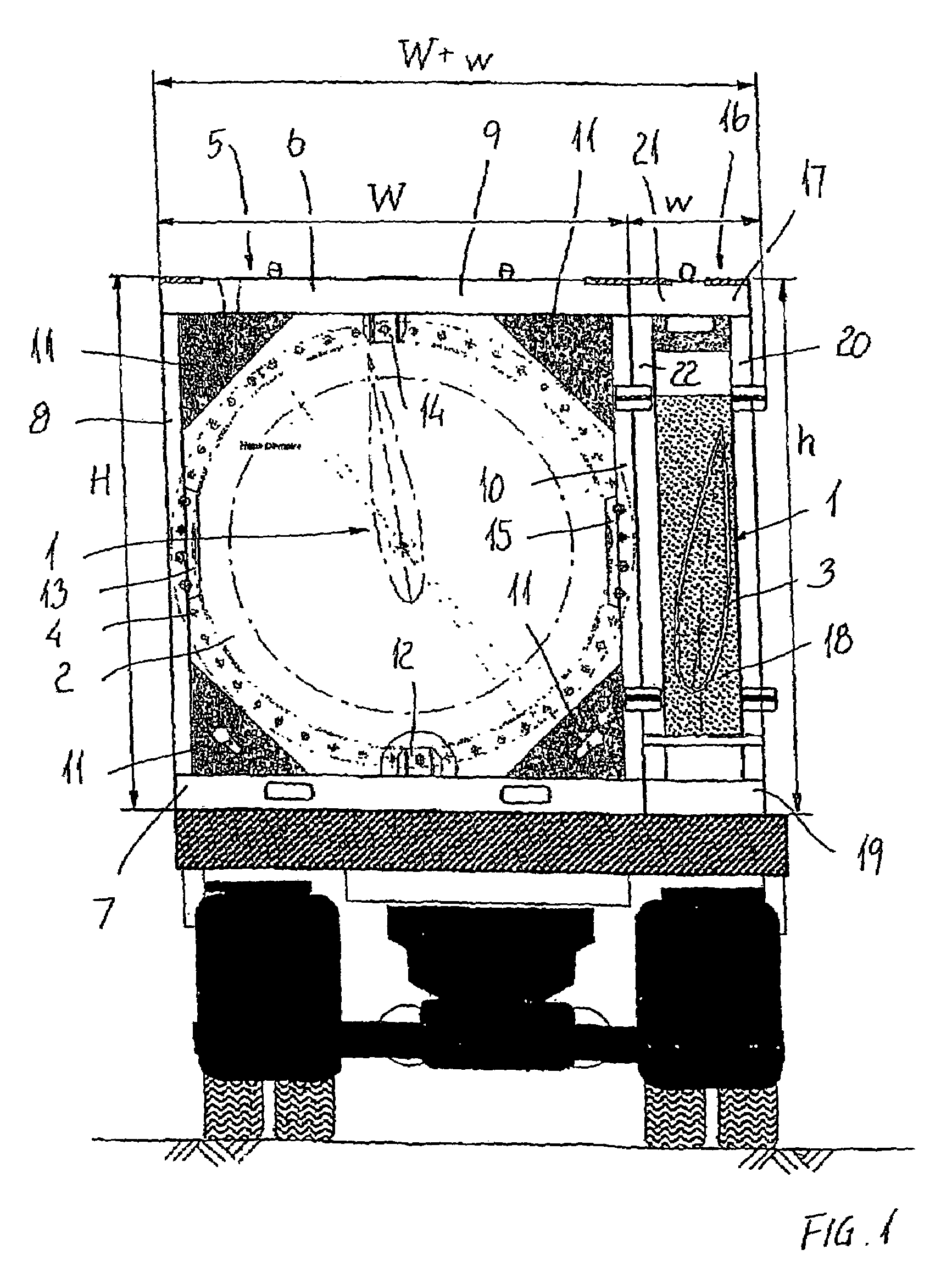

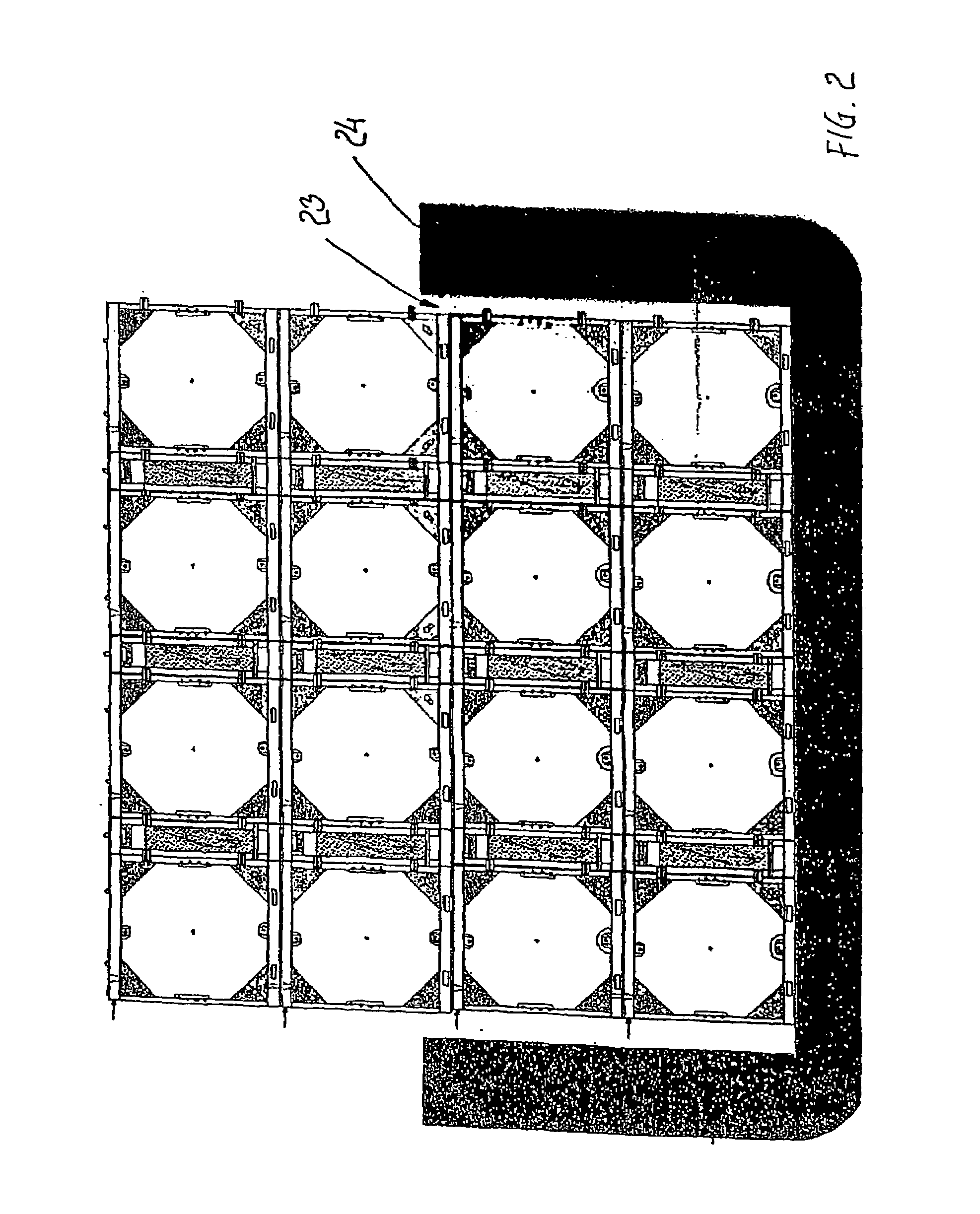

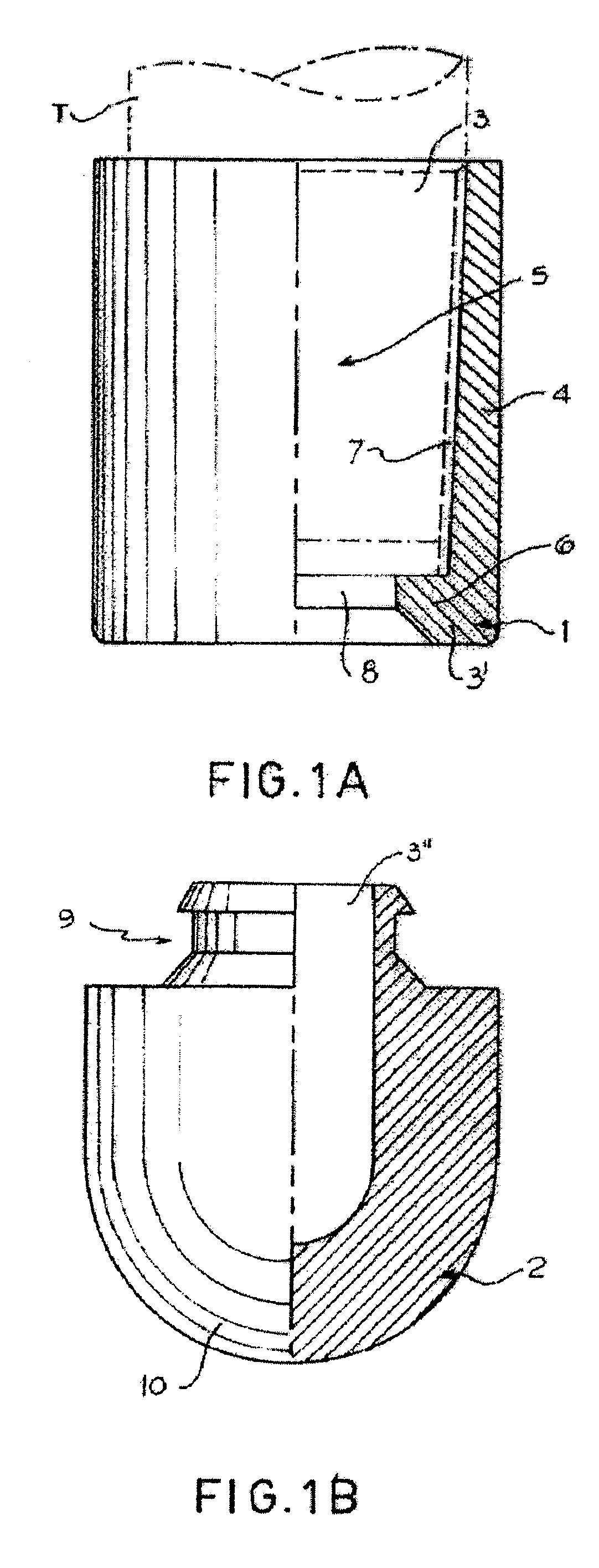

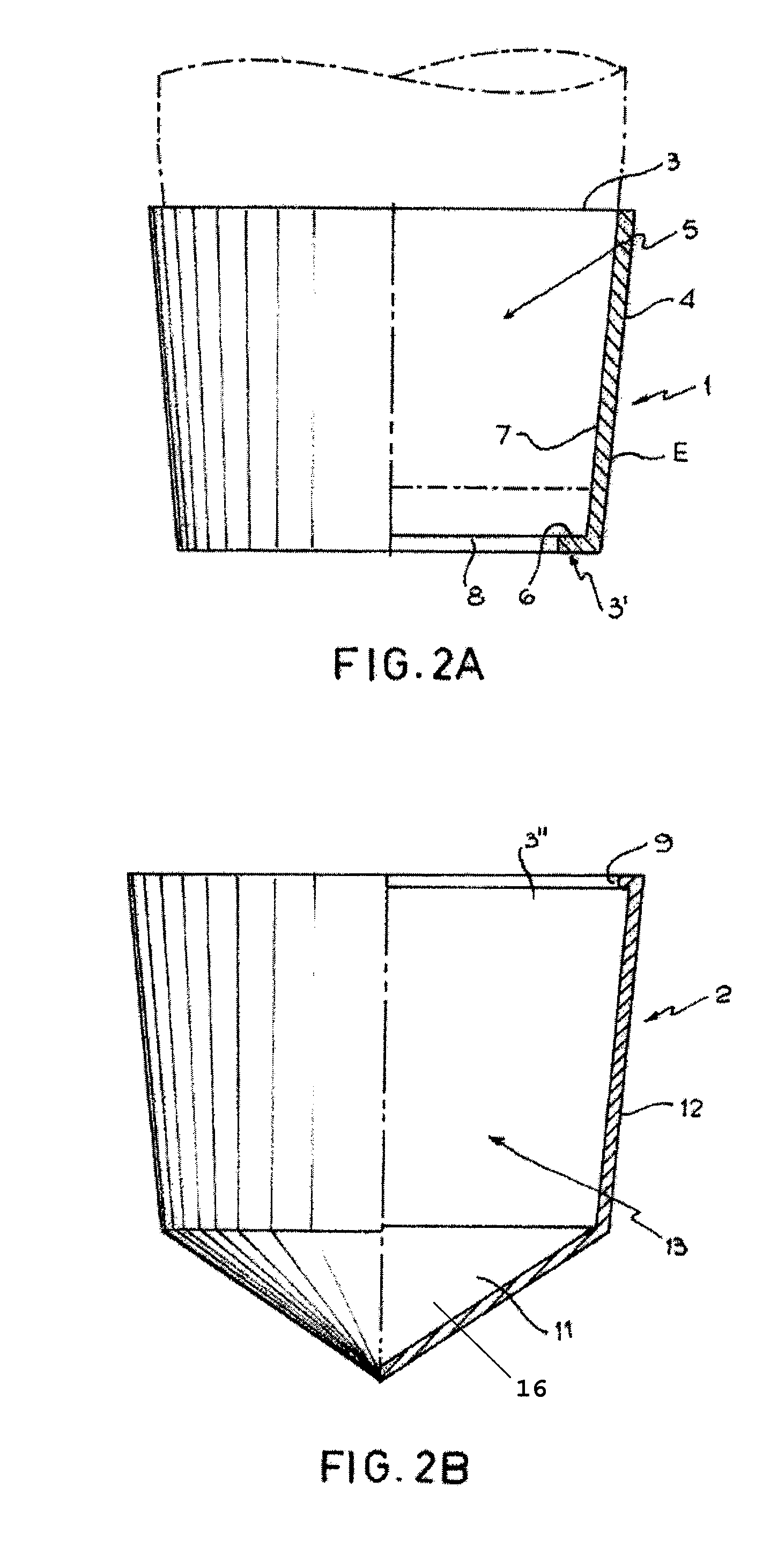

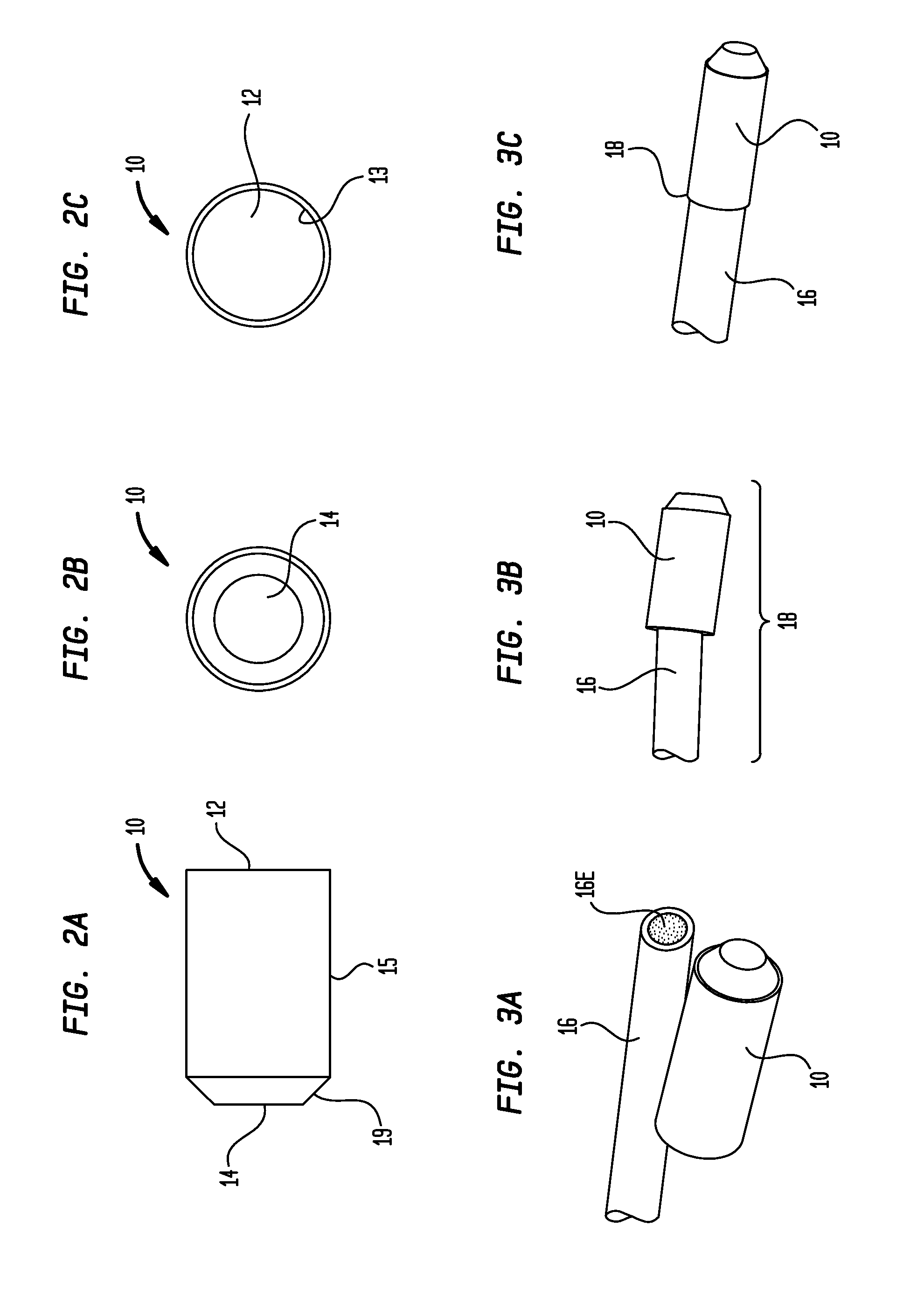

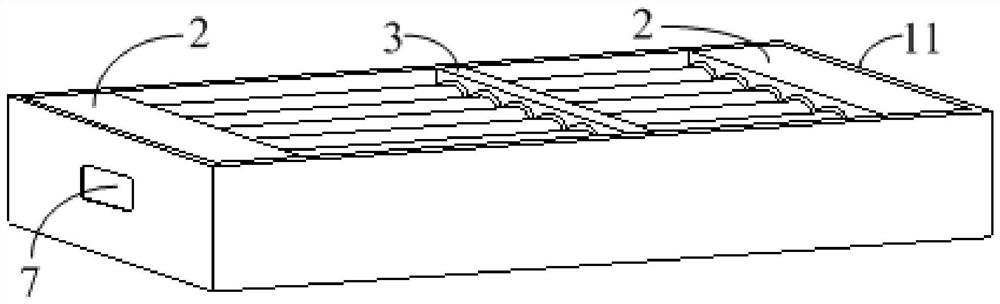

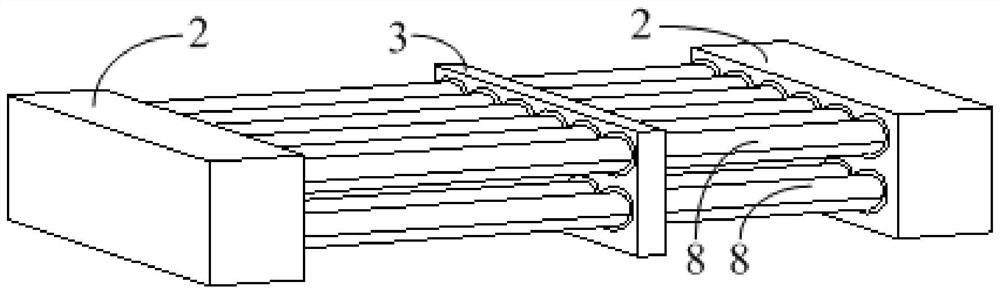

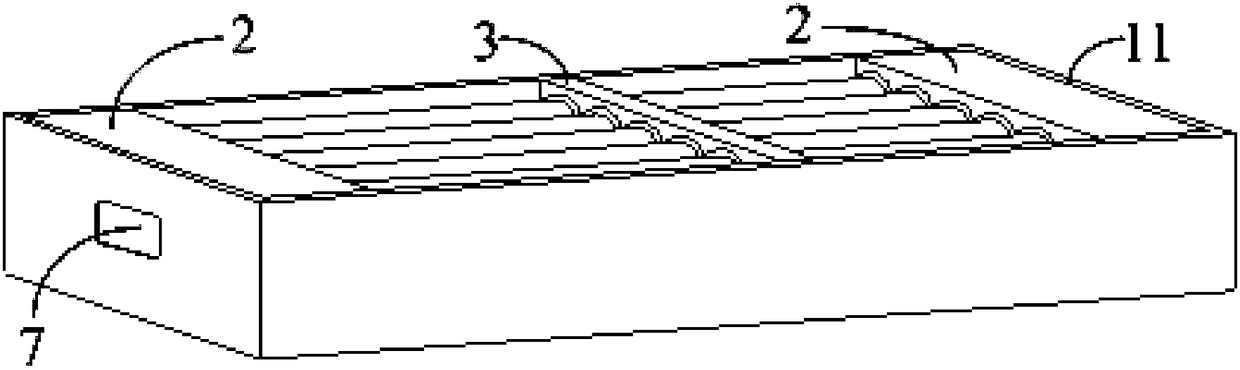

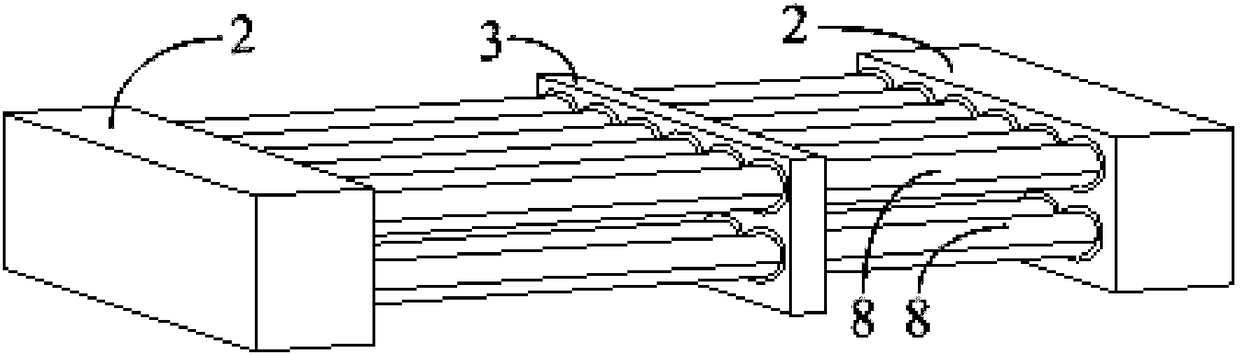

Method for transporting a set of large longitudinal items, a package system to be used by the method and use of such a package system

InactiveUS6983844B2Easy to useEasy to transportLarge containersMultiple wrapper applicationTurbine bladeLateral extension

The invention relates to a transportation method and a package system for transporting a set of large longitudinal items such as blades for a wind turbine (1) or a tower for a wind turbine. Taking wind turbine blades (1) as an example, the advantages of the invention reside in packaging a tip (3) of one blade and a base (2) of a second blade in the one and same package (5) such that two blades (1) may be transported in packages (5, 16) having an overall lateral extension, approximately the same as the base of only one blade (1) for the wind turbine. Thereby a very compact but also a very easy means of transportation of large longitudinal items such as wind turbine blades (1) is provided.

Owner:VESTAS WIND SYST AS

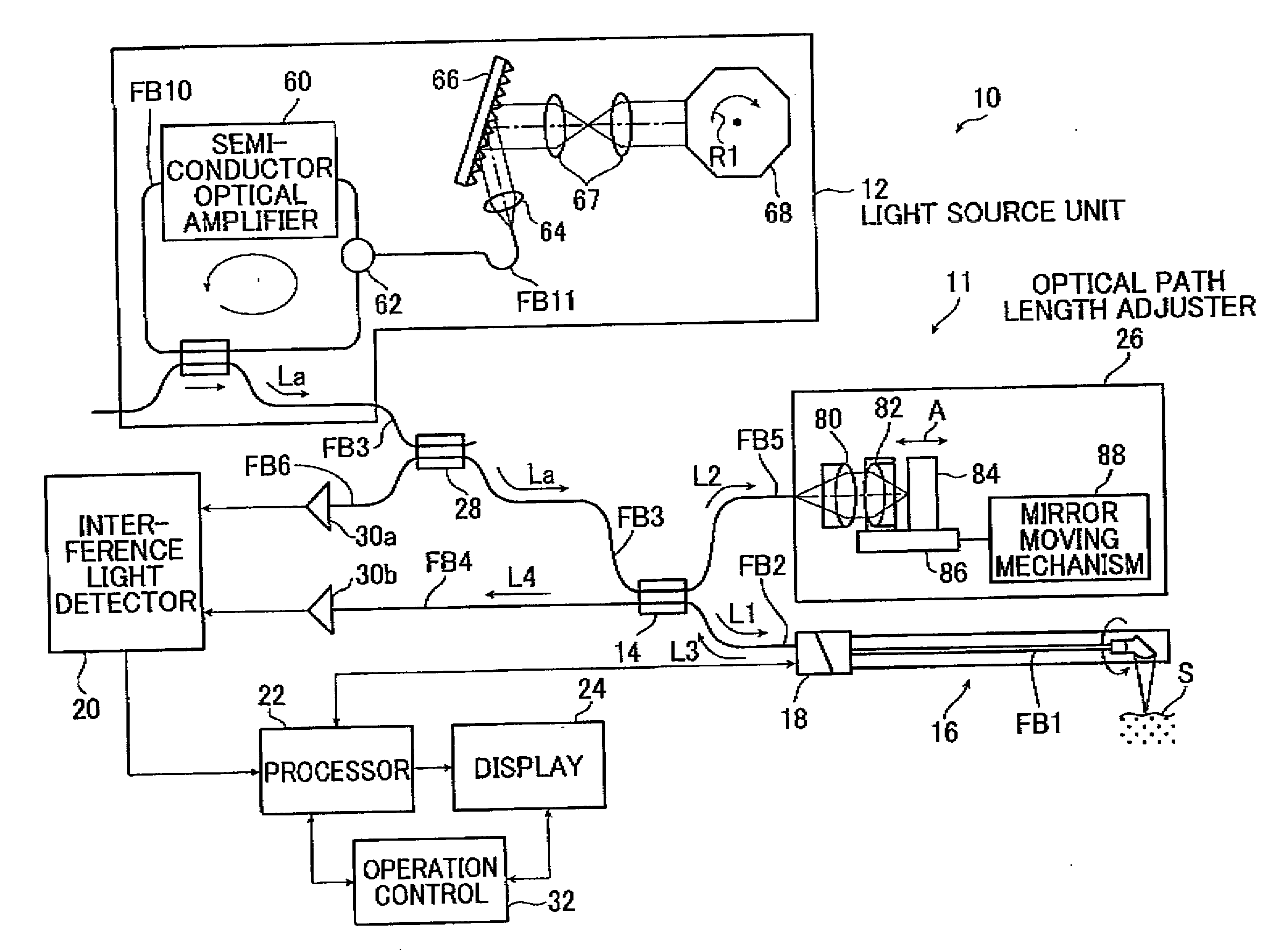

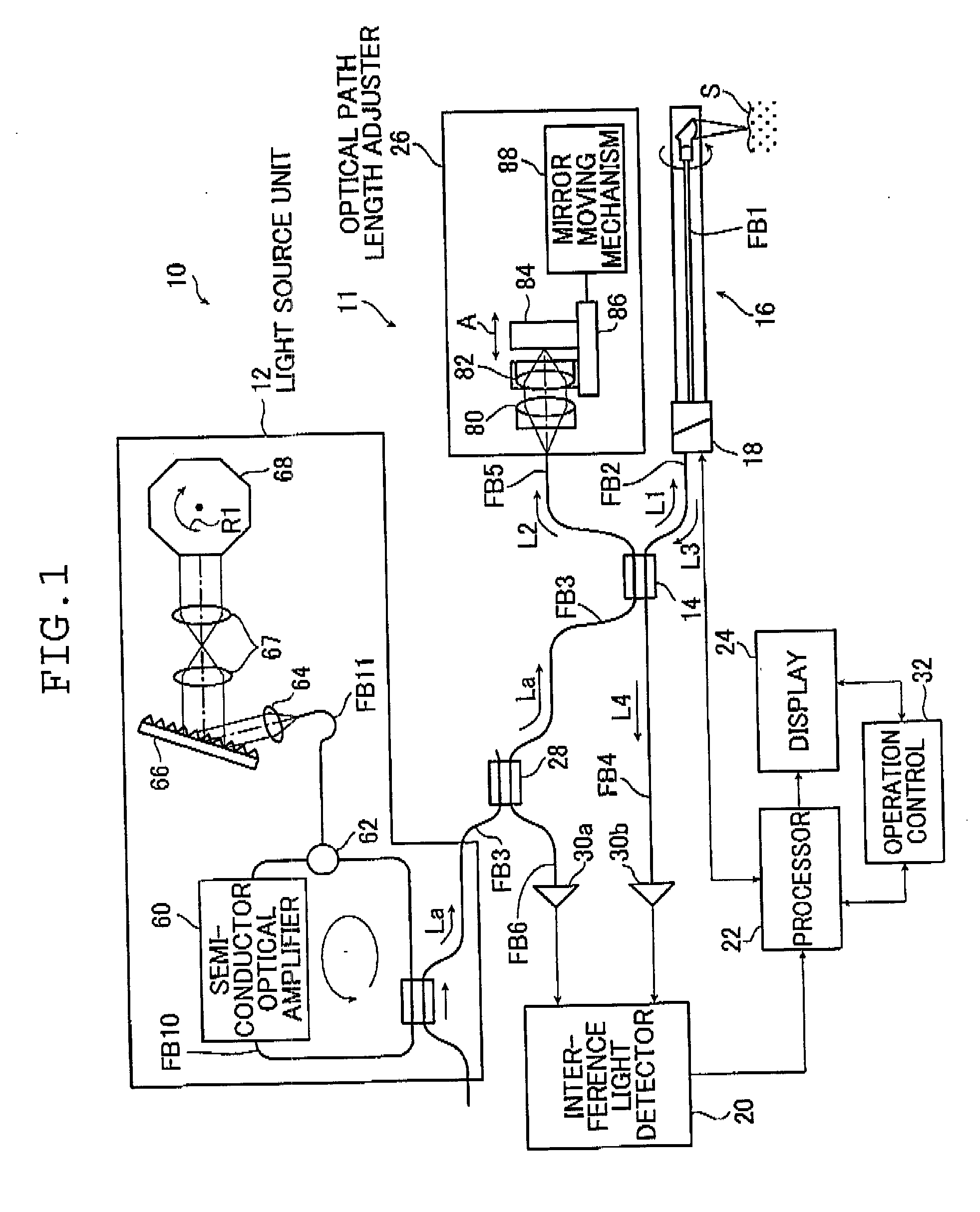

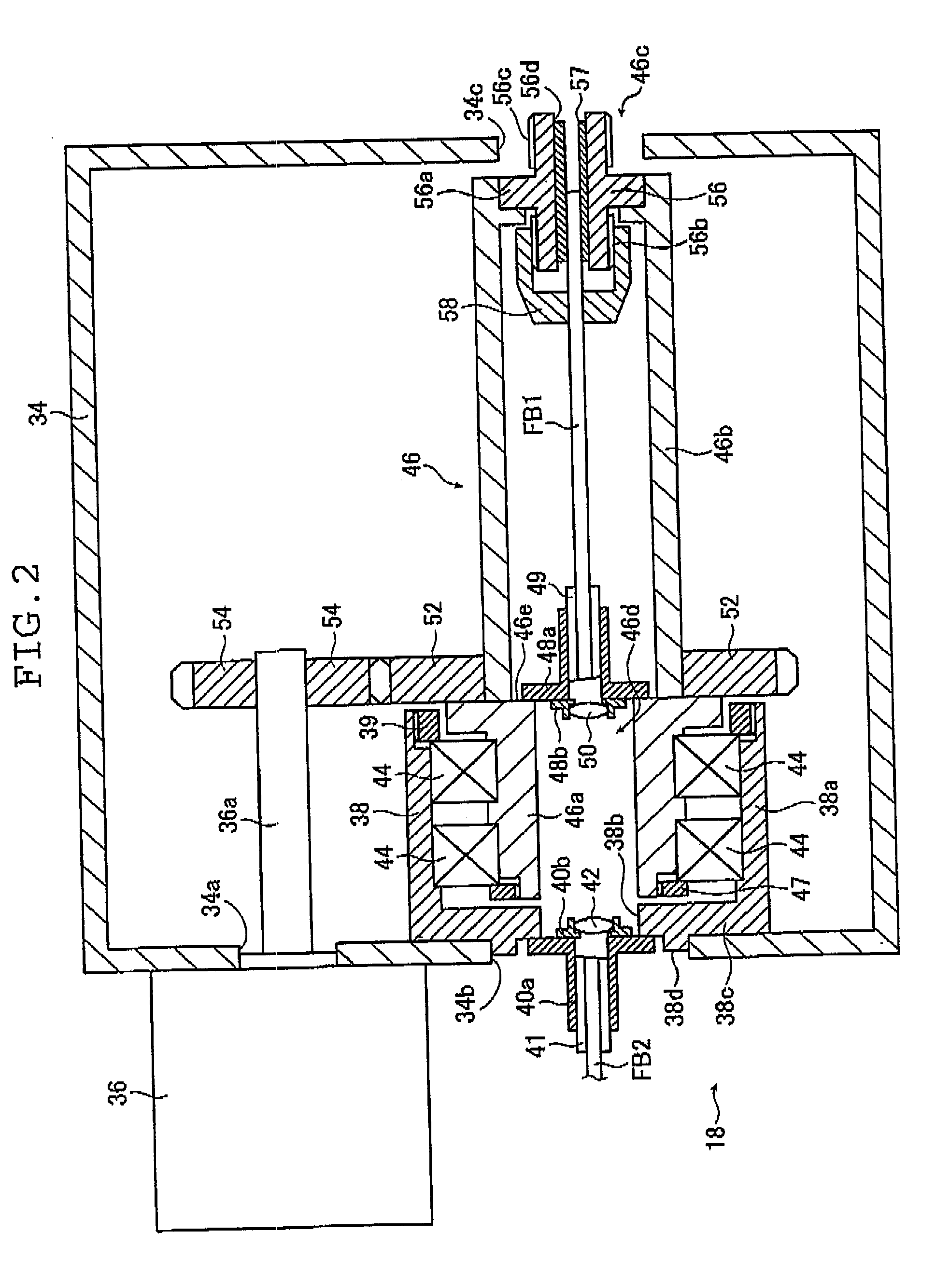

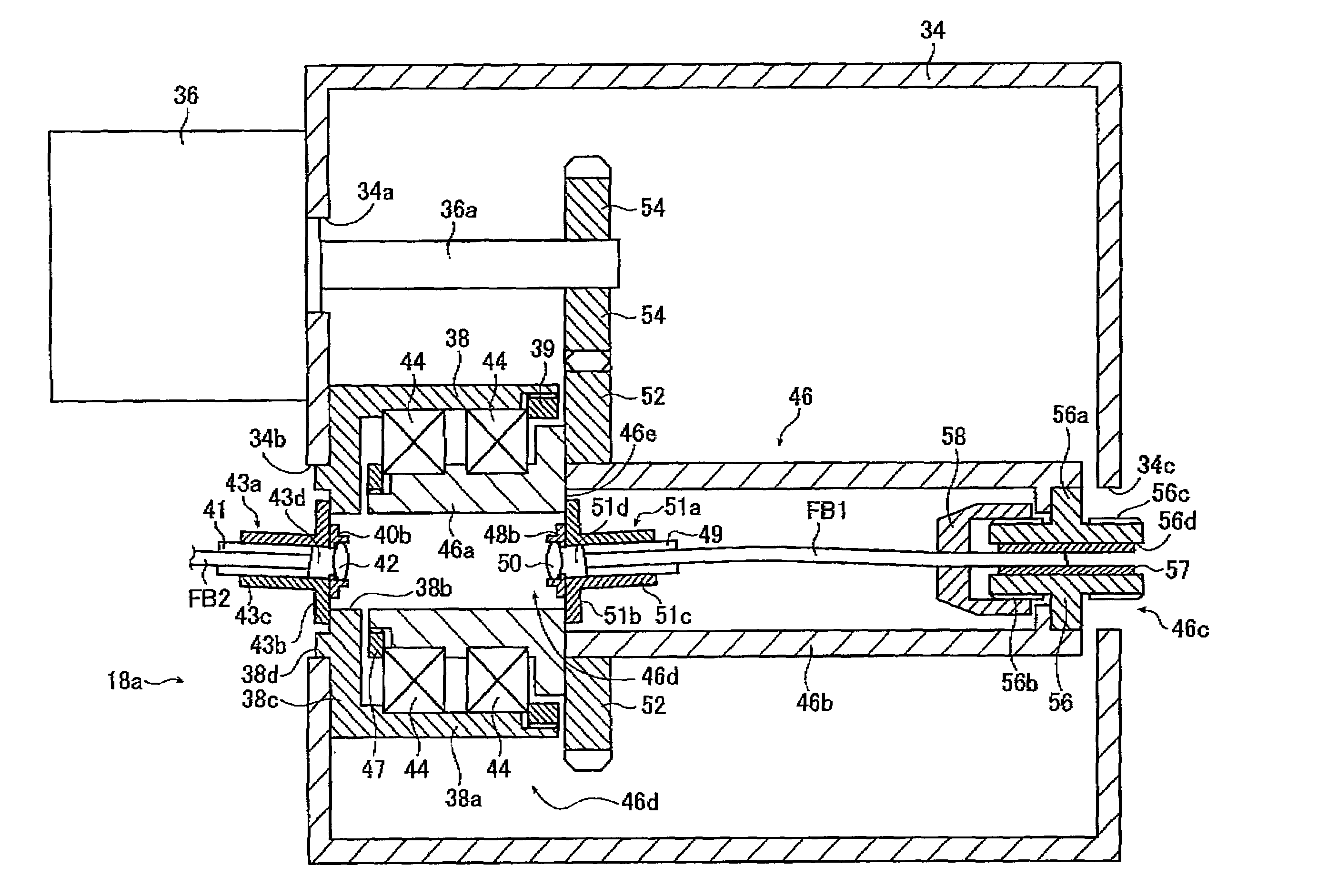

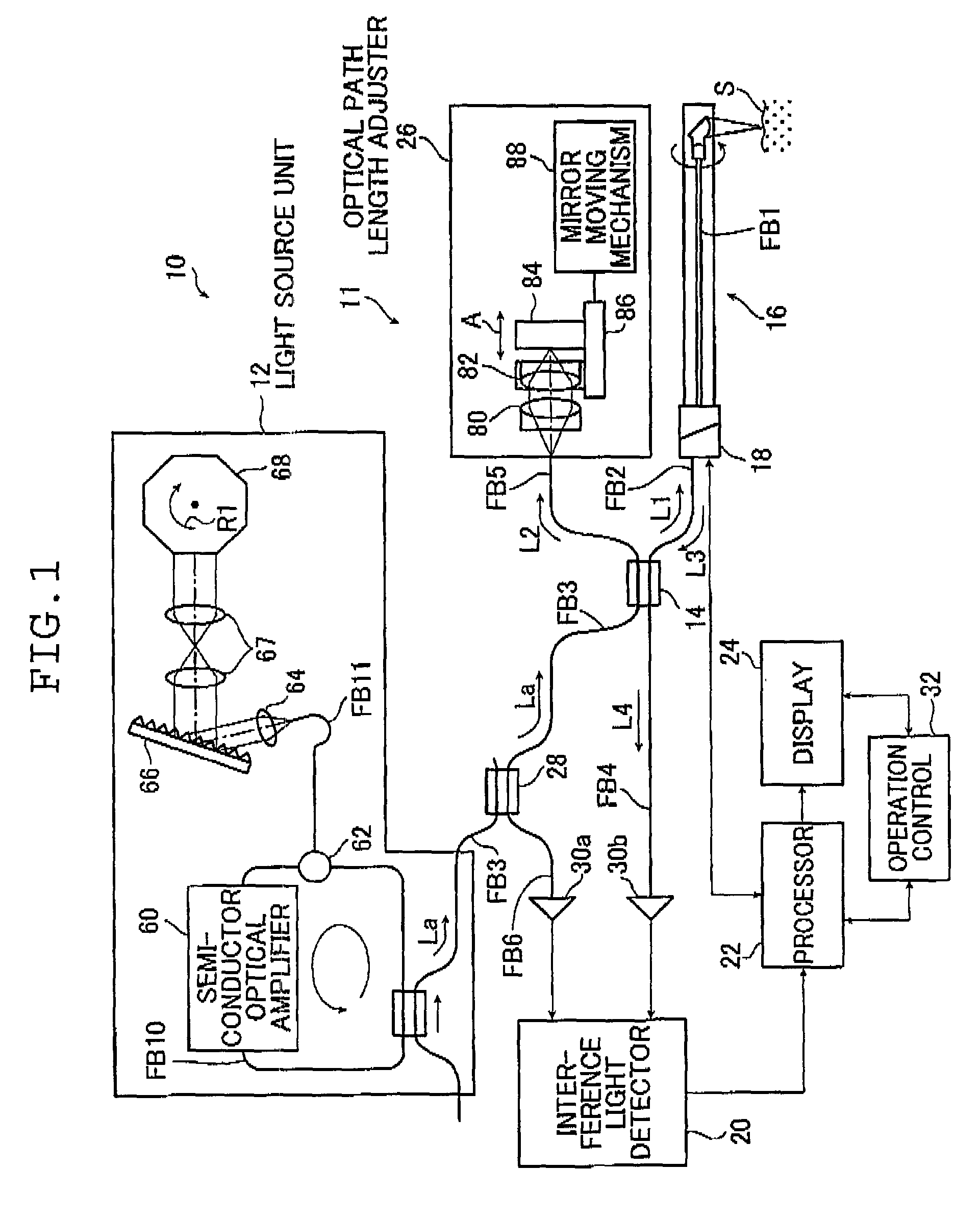

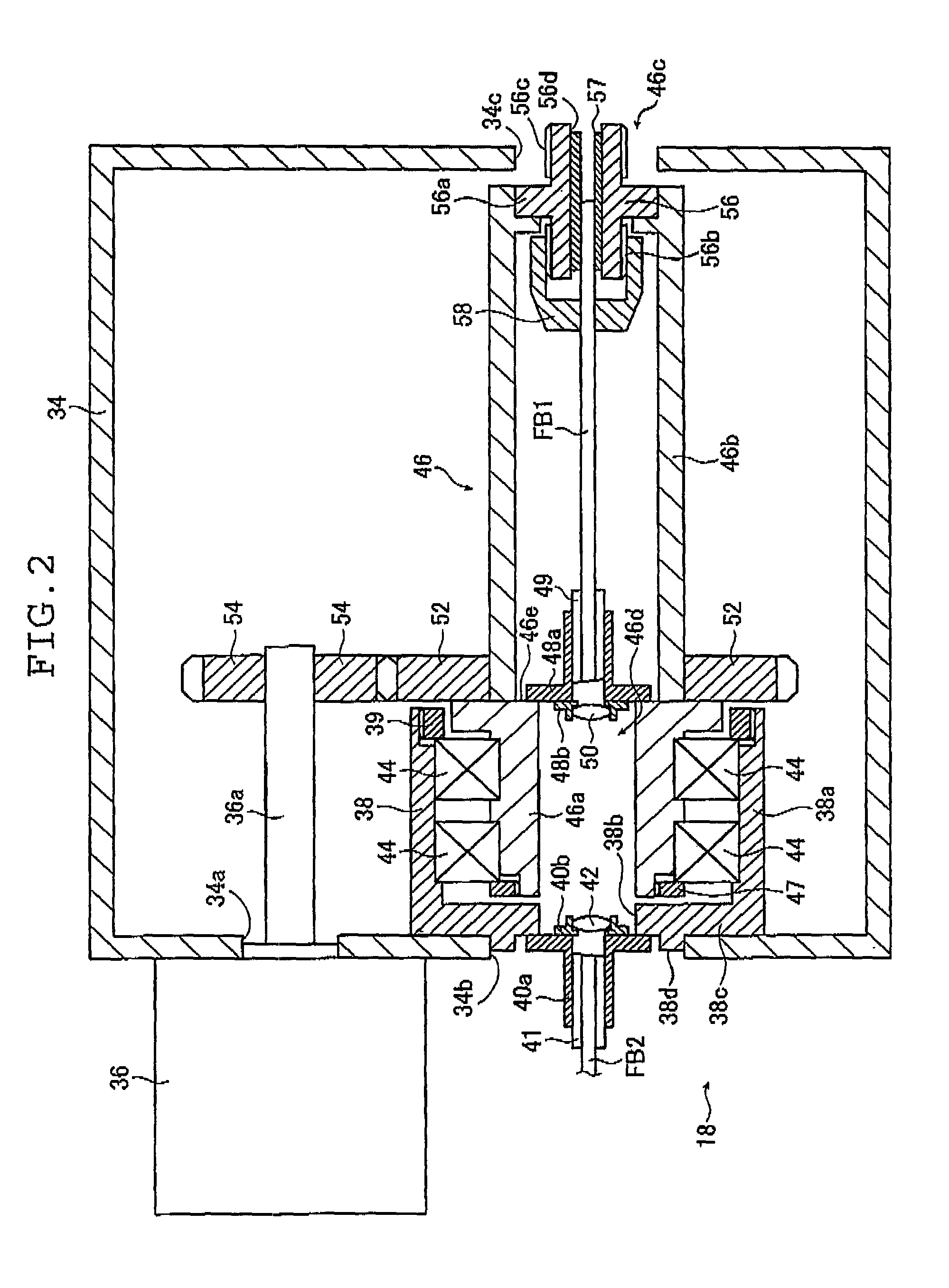

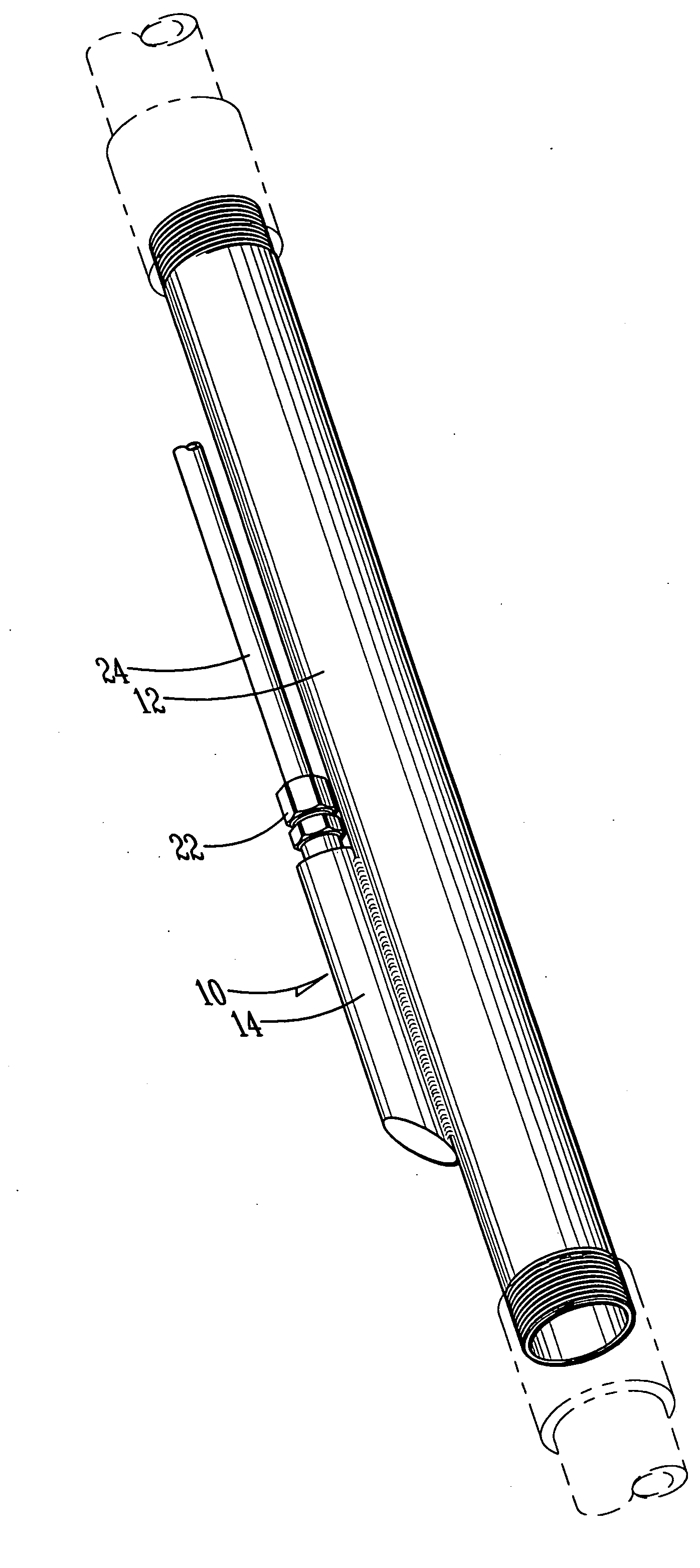

Optical rotary adapter and optical tomographic imaging system using the same

ActiveUS20090251704A1Decrease of signal-to-noise ratioReduce return lightInterferometersMaterial analysis by optical meansUltrasound attenuationEngineering

The optical rotary adapter is used with an optical tomographic imaging system for acquiring an optical tomographic image of an object under measurement. The adapter includes a fixed sleeve, a stationary optical fiber supported by the fixed sleeve and having an inclined end face, a stationary collimating lens spaced a given distance from the inclined end face, a mounting cylinder carried rotatably with respect to the fixed sleeve, a rotary optical fiber mounted to the mounting cylinder and having an inclined end face, a rotary collimating lens mounted to the mounting cylinder and disposed with a given distance from the inclined end face, and a rotation actuating device for rotating said mounting cylinder. The central axes of the stationary and rotary optical fibers are offset from or inclined with respect to a central axis of rotation of the mounting cylinder to reduce attenuation of returning light from the object.

Owner:TERUMO KK

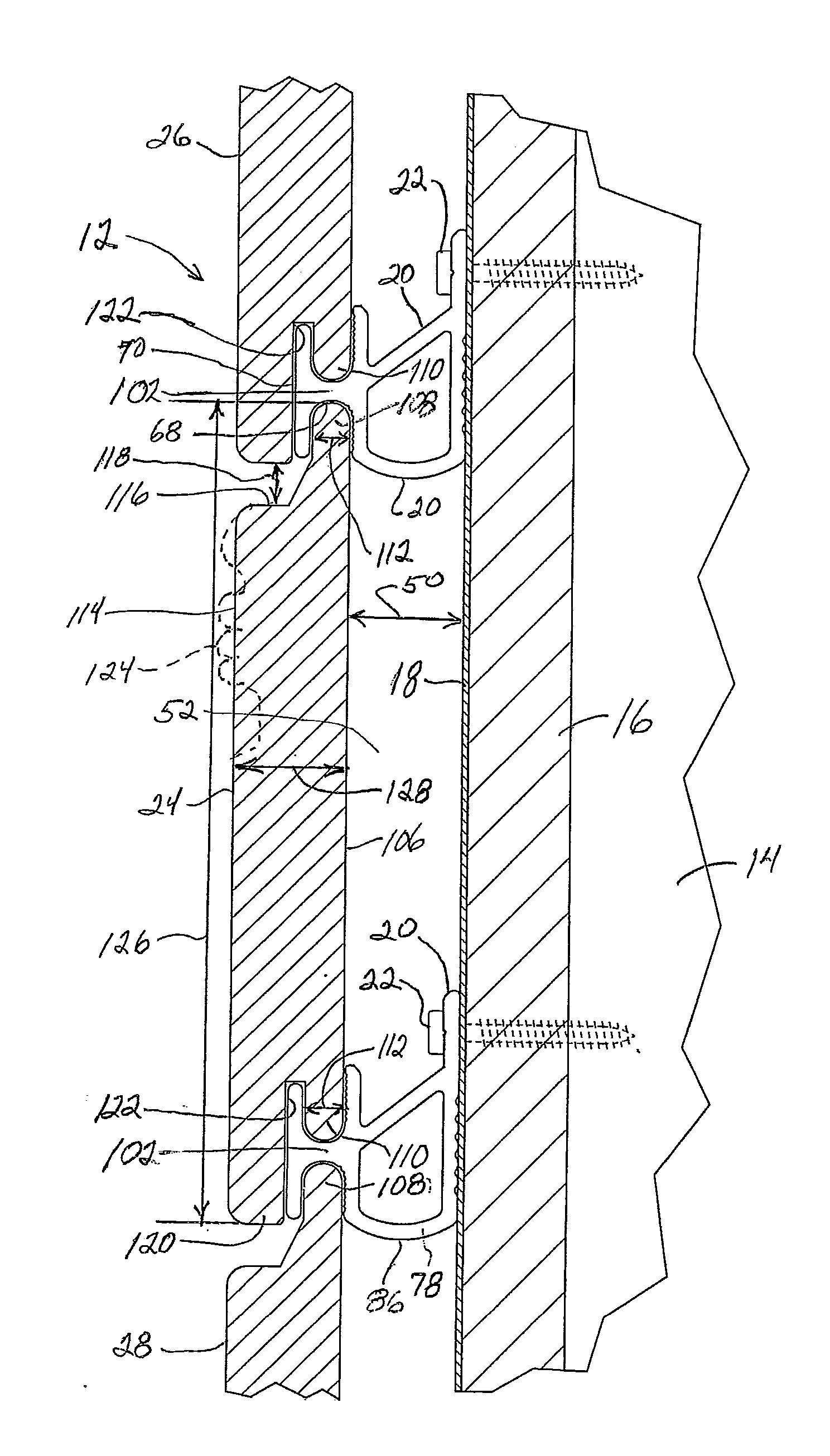

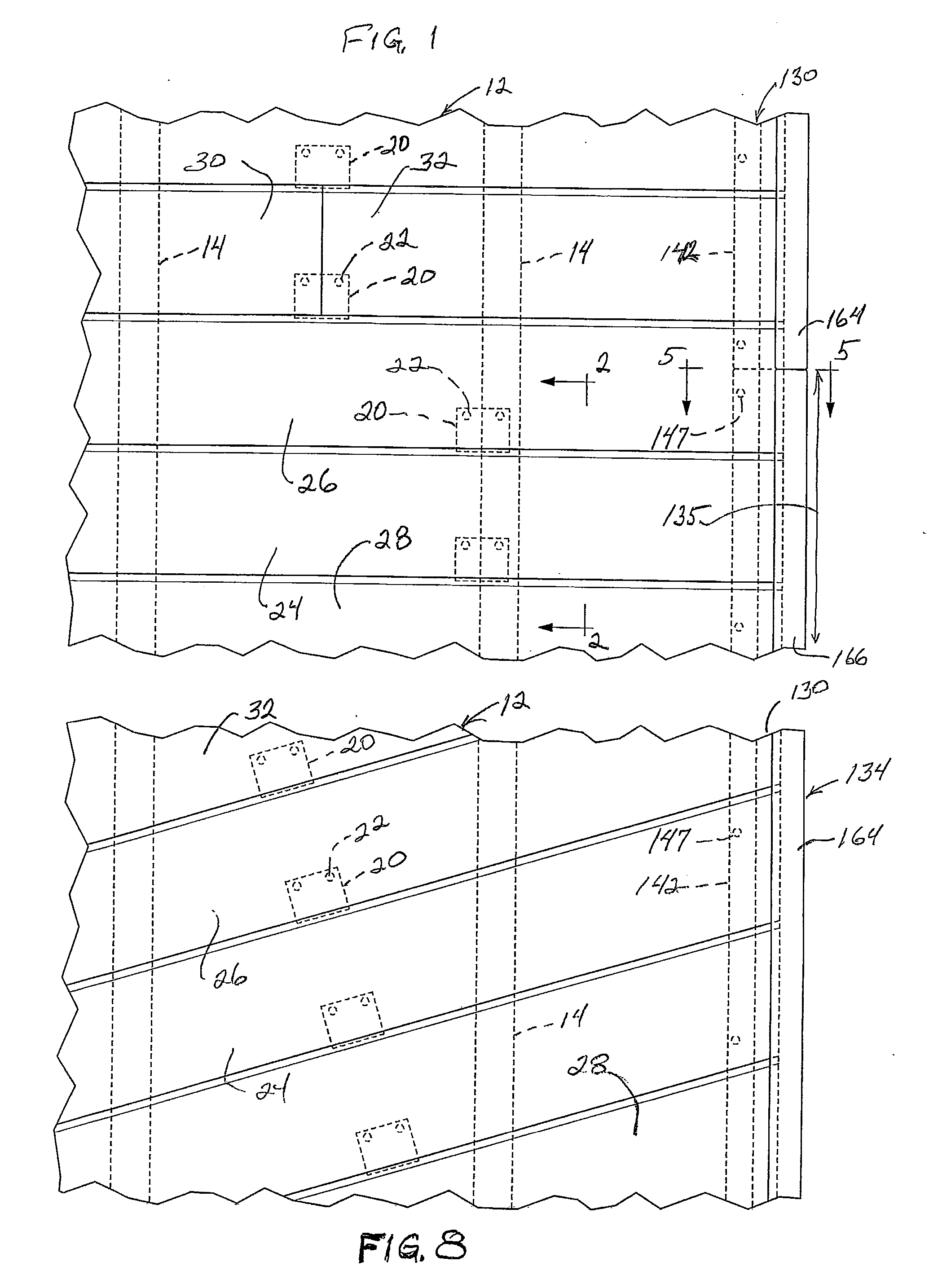

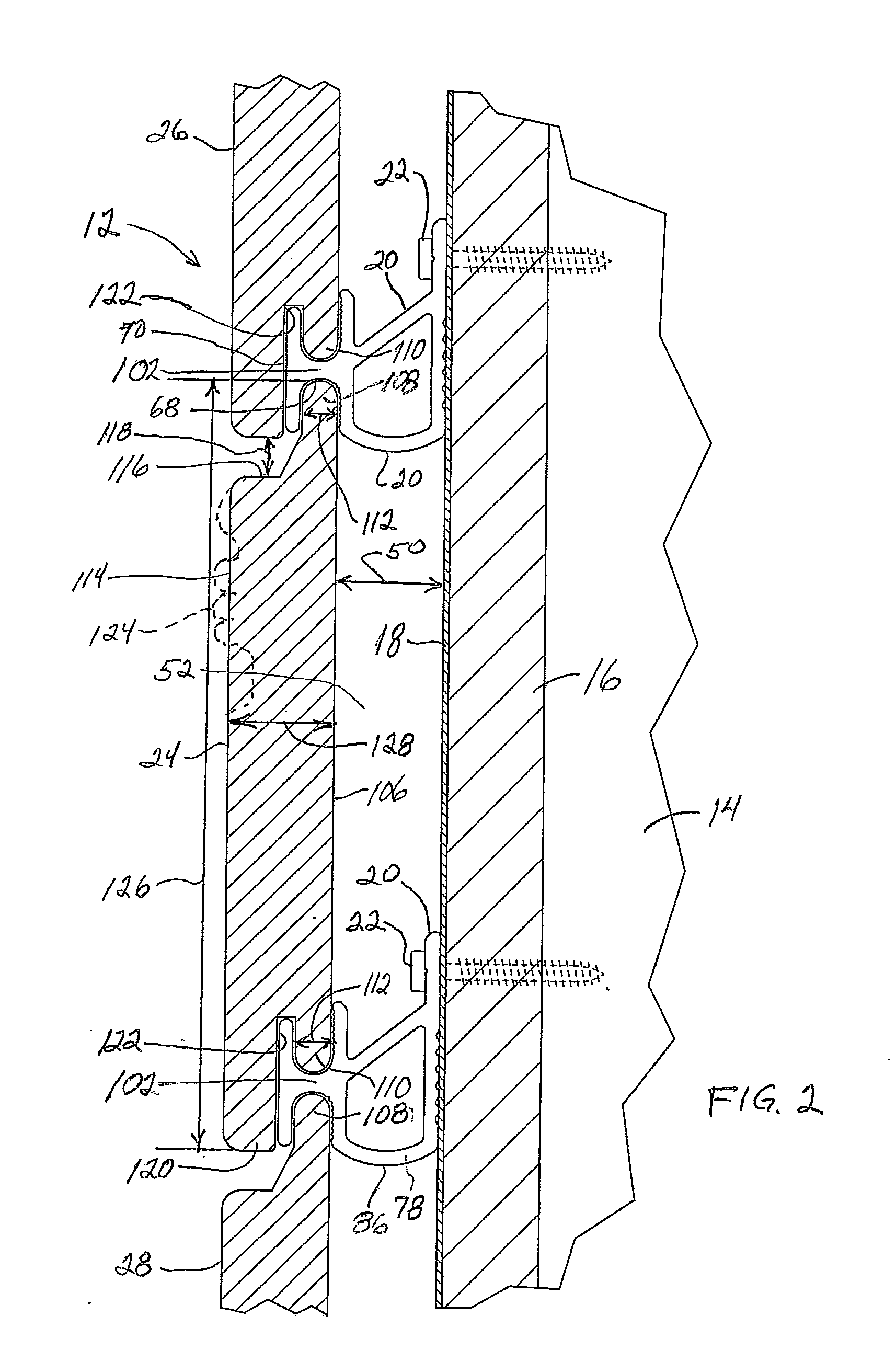

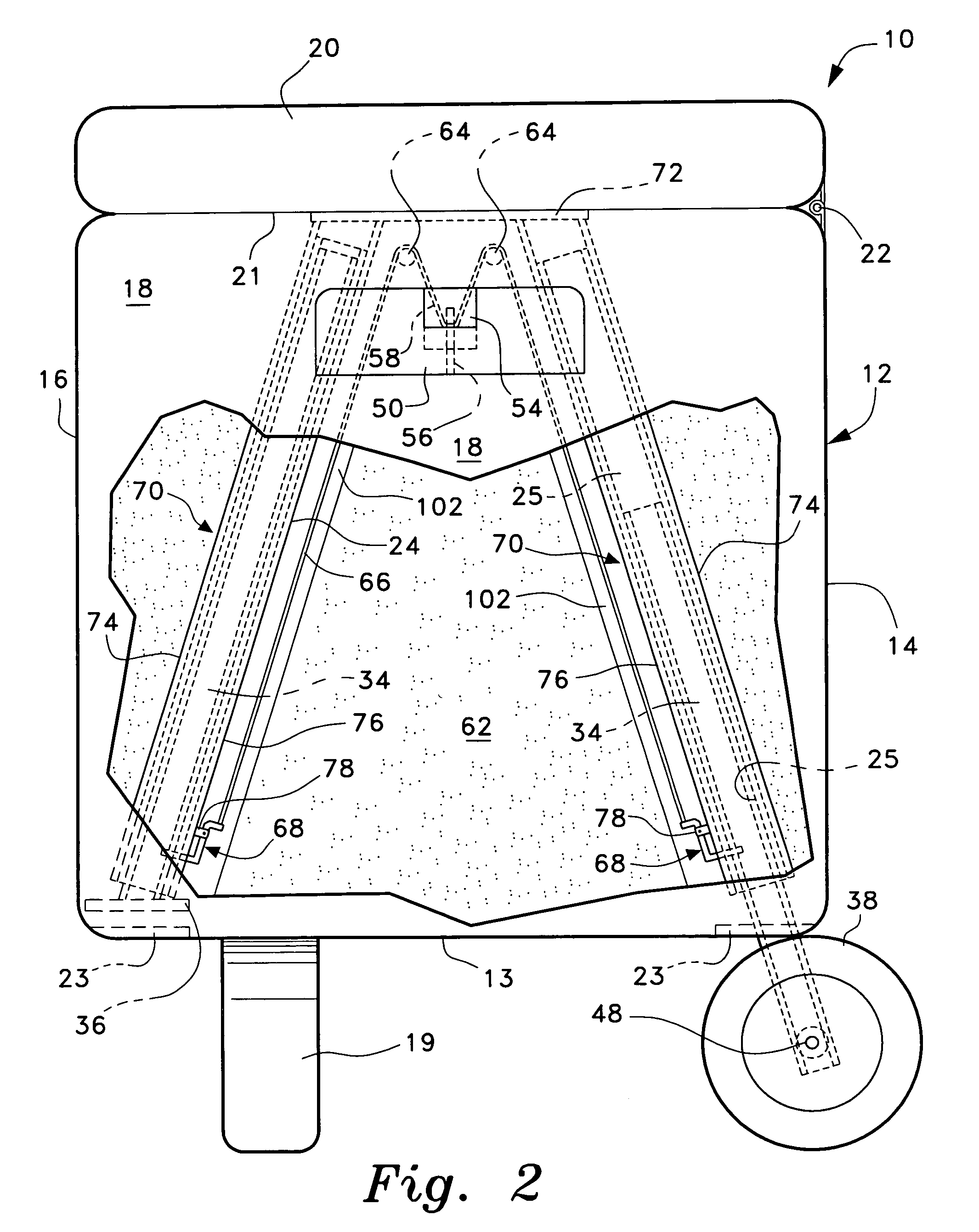

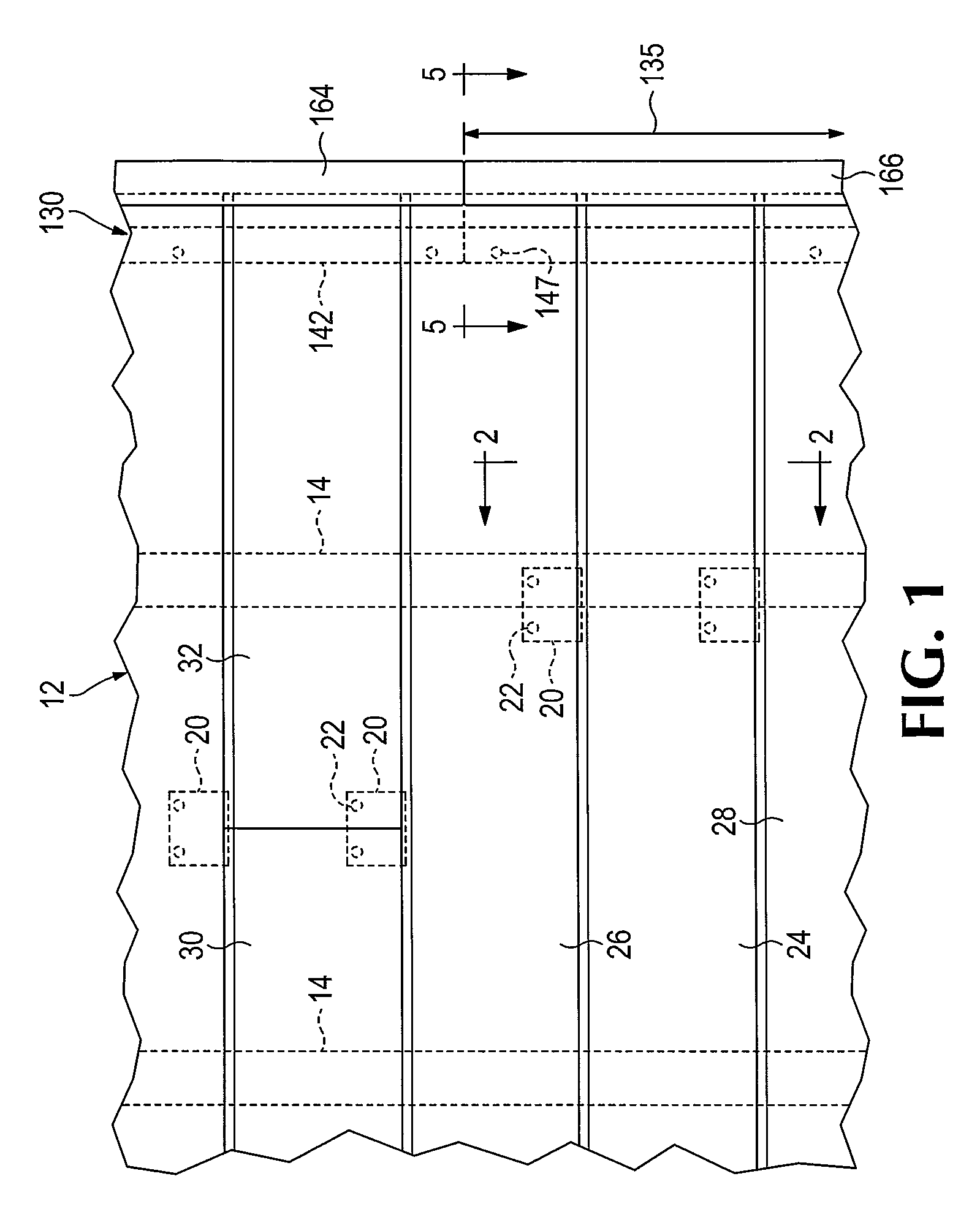

Rain screen siding system

A rain-screen siding system for buildings, including clips to support siding boards parallel with a flat surface of a building wall structure but spaced apart from the building wall to allow air to circulate between the building wall structure and the siding boards. The clips include paired, opposed channels and the siding boards have tongues that fit into the channels. Drainage grooves are defined in the clips. Bottom support members may extend horizontally to support the siding boards at the bottom of the rain screen siding. Corner closing members are provided to protect end faces of siding boards at an exterior corner of a building wall.

Owner:WOOD SIDING SYST

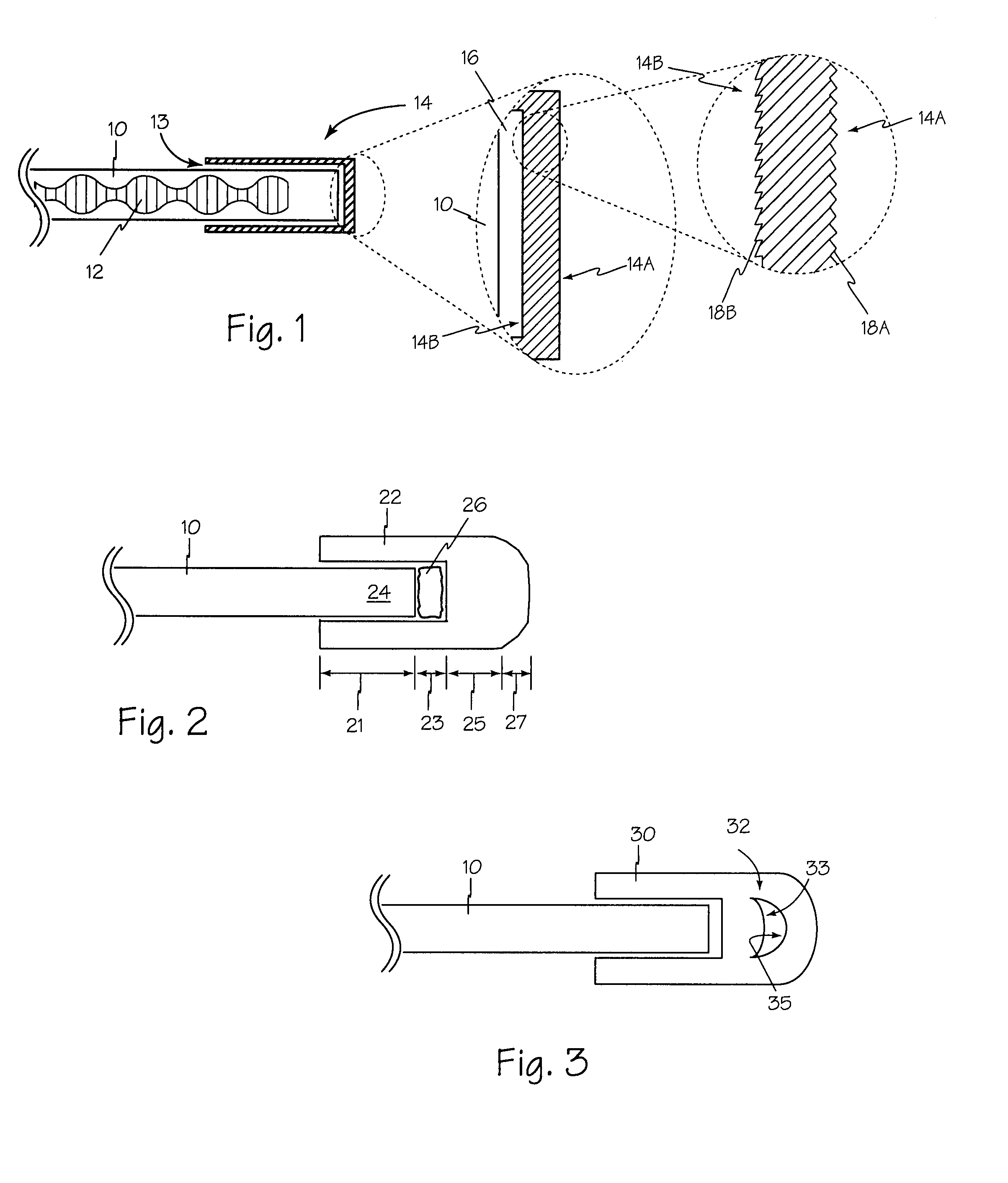

Micro-optic adapters and tips for surgical illumination fibers

ActiveUS7474820B2Low modification costProtect the endEndoscopesFibre light guidesFiberMicro structure

A microstructure optical adapter or tip according to the present disclosure may incorporate precision micro structure optical components engaging the input or output end of light energy delivery devices for customized light delivery of the light energy. The incorporation of precision micro structure optical components in injection molded plastic or glass parts will allow for inexpensive modification of the output light while also serving to protect the end of the illumination device. The micro structure optical components may also be incorporated in an adapter to tailor the light energy to the subsequent device.

Owner:INVUITY

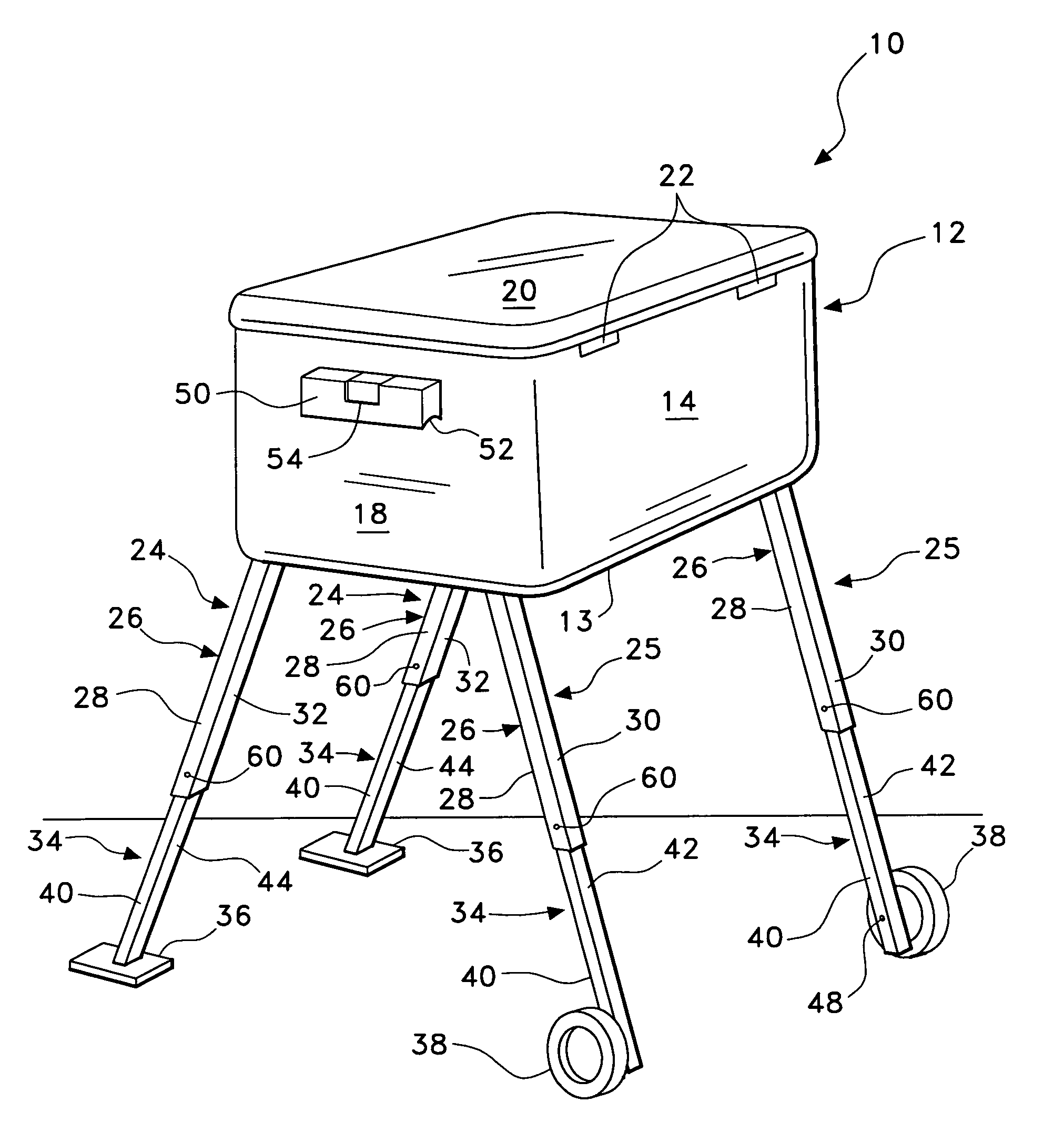

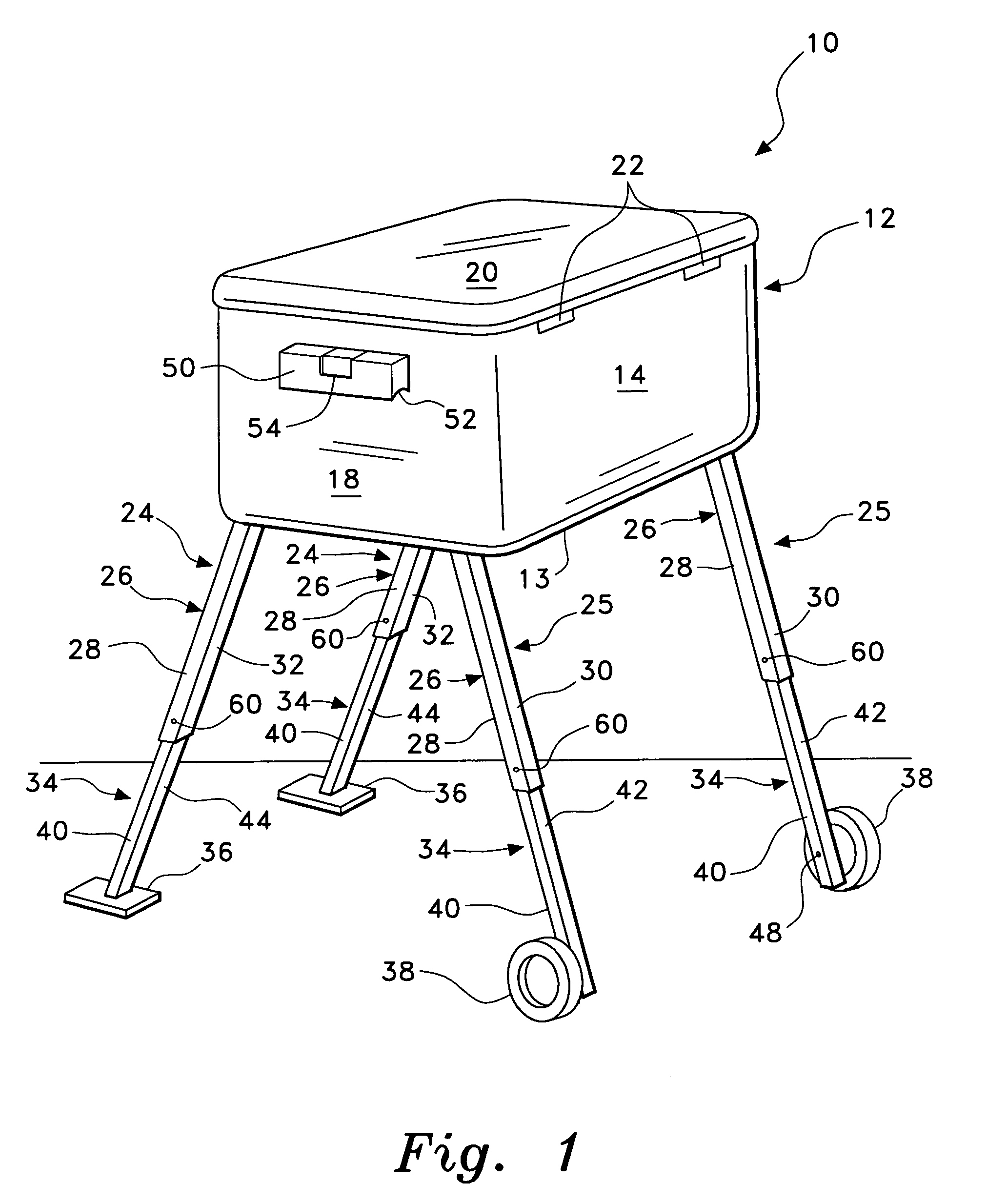

Ice chest and cooler having retractable legs

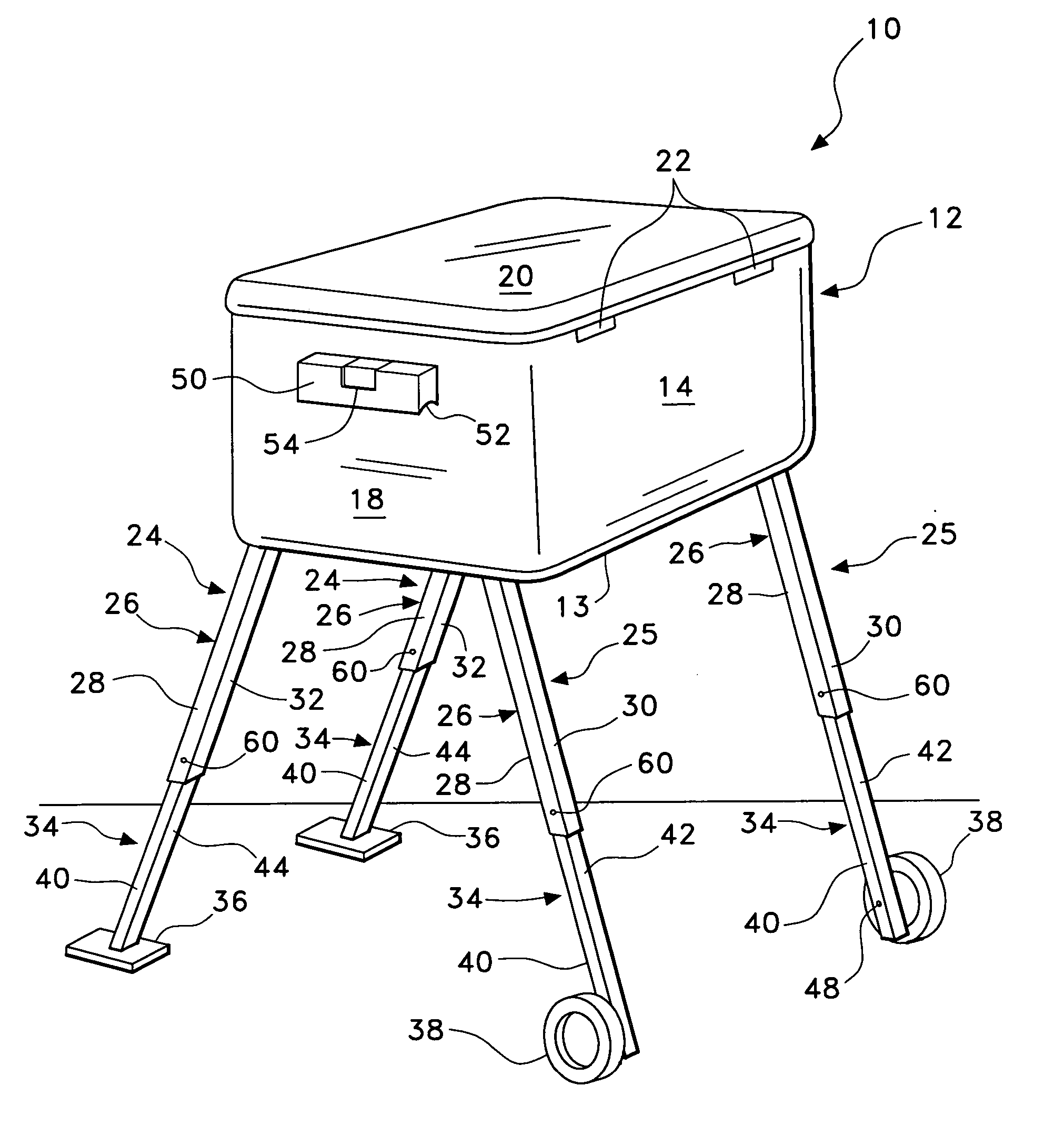

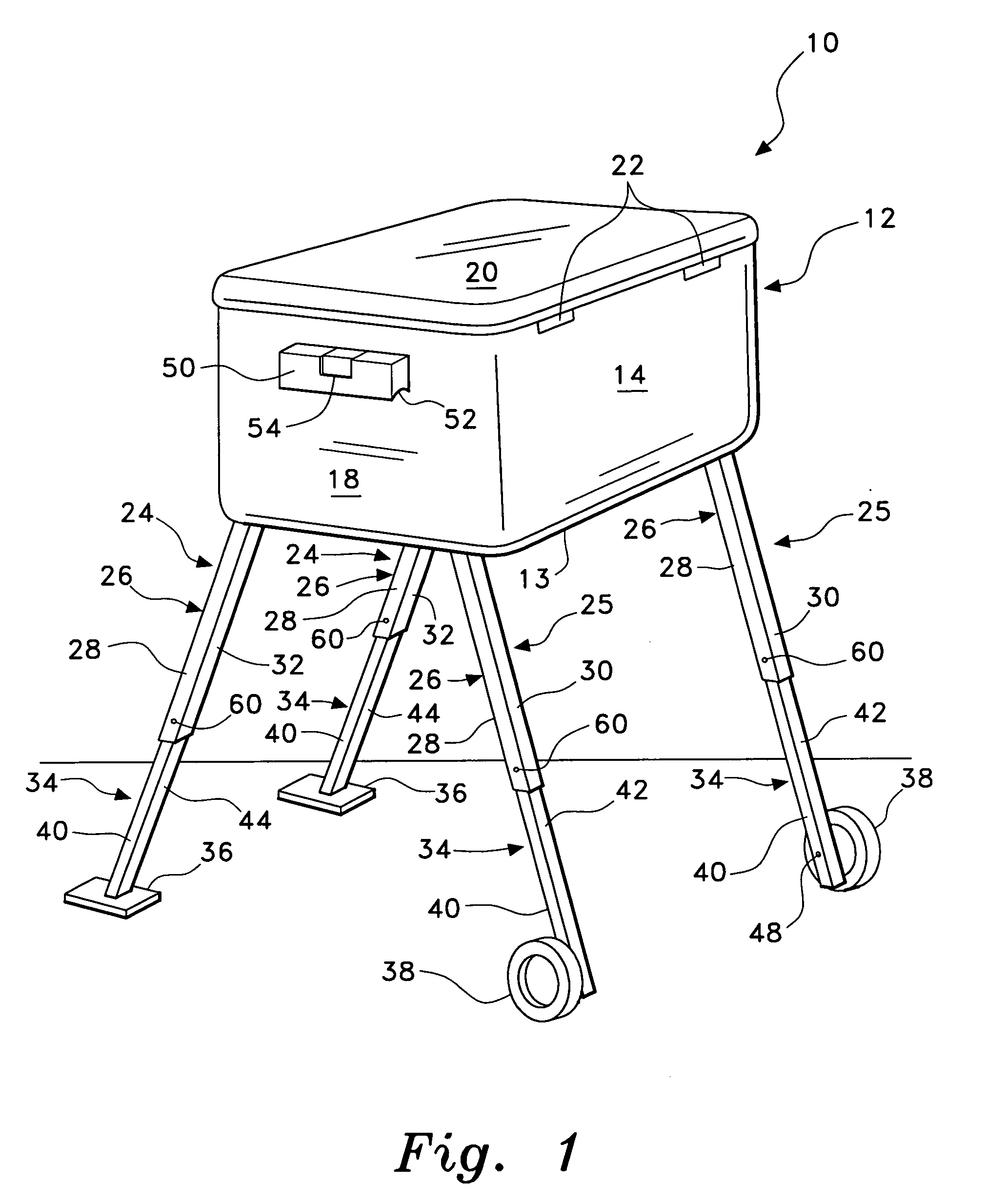

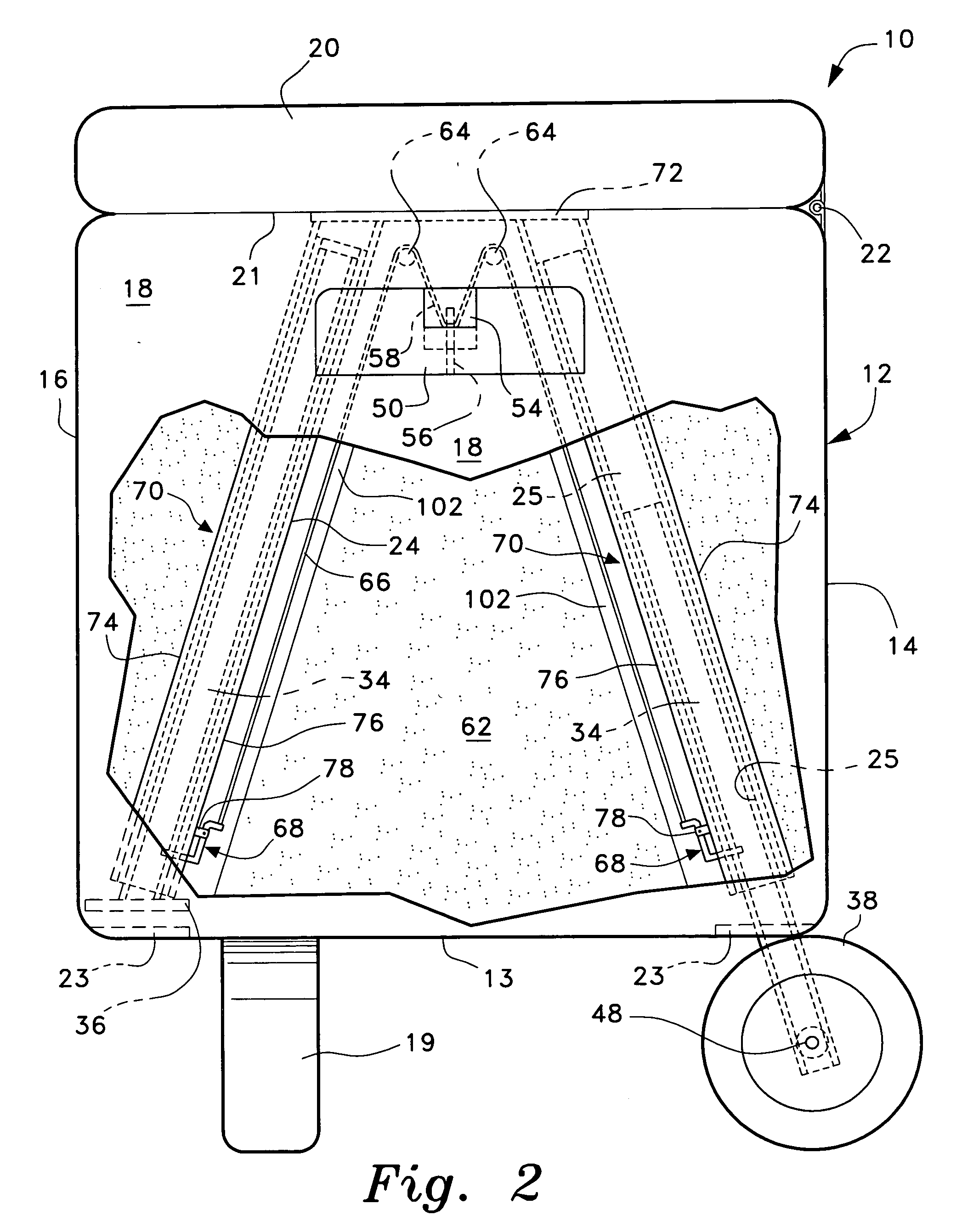

InactiveUS7341164B2Protect the endImprove distributionLighting and heating apparatusLarge containersLinkage conceptPush-button

An ice chest has retractable, telescoping legs extending at respective forward and rearward angles from each respective endwall of the ice chest. The ice chest has handles at the upper central portion of the ice chest endwall having push buttons therein which release the telescoping legs from a locked position and which fall to the open position under their own weight and lock in a secure position. The push buttons actuate the locks by a linkage system. The front legs have pads at their lower ends, protecting the ends of the legs, and providing weight to pull the legs into the open, locked position. The rear legs have wheels which also providing weight to pull the legs into the open, locked position. A similar water cooler has retractable legs which have pads on their lower ends pulling the legs downward upon pushing buttons on handles on the sidewalls.

Owner:BARQUIST AARON W +1

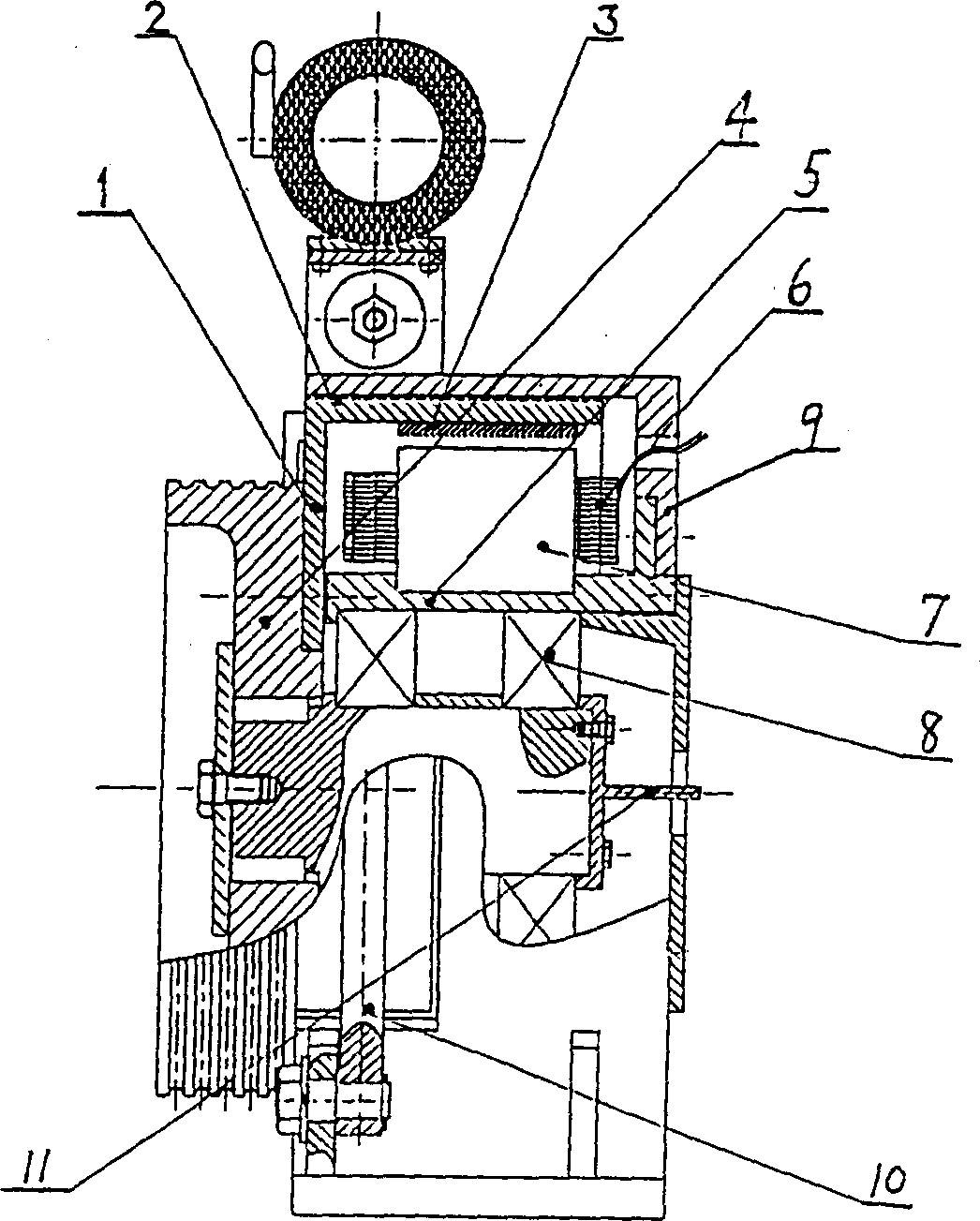

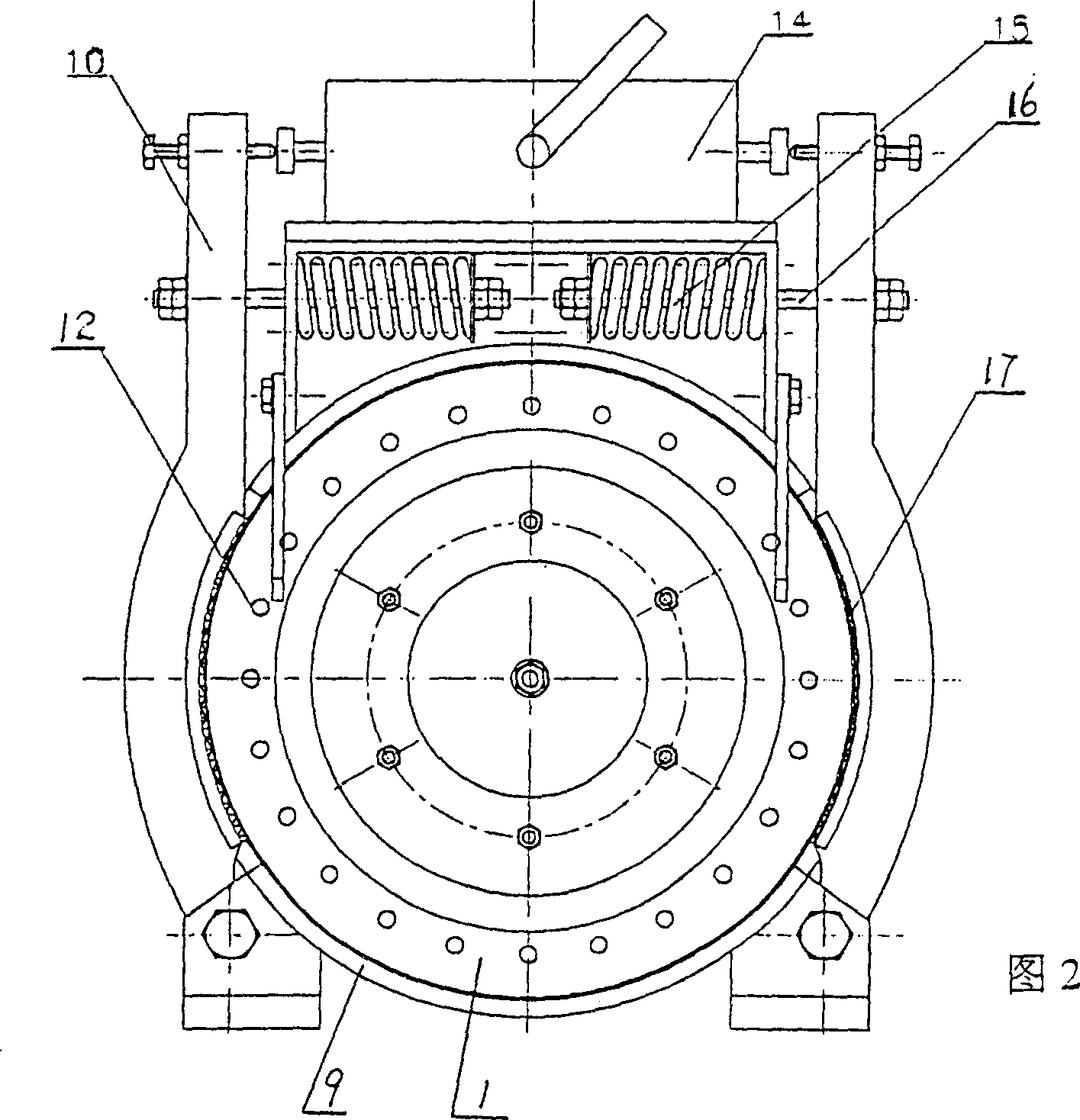

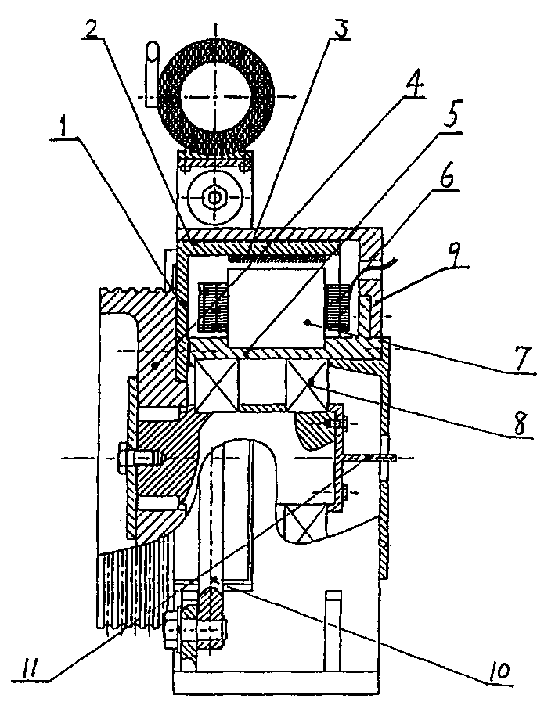

Directly driven synchronous dragger with Nd-Fe-B permanent magnetic rotor

InactiveCN1141775CProtect the endSmooth runningMechanical energy handlingStructural associationSpecial designRing type

In this invention multipole outer rotor structure is used, said out rotor is also used as brake wheel, drag wheel is fit on outer rotor. The special design makes the structure be very compact and can realize direct driving without gear wheel. The special two-layer ring-type stator structure can not only increase working reliability but also improve mfg. process, remarkably. The invention has advantages of lifting steady and flat-layer exact, and two set of brake component is used so as to realize braking and stopping with high reliability.

Owner:SHANGHAI JIAO TONG UNIV +1

Ice chest and cooler having retractable legs

InactiveUS20050279750A1Prevent sinkingProtect the endLighting and heating apparatusLarge containersLinkage conceptPush-button

An ice chest has retractable, telescoping legs extending at respective forward and rearward angles from each respective endwall of the ice chest. The ice chest has handles at the upper central portion of the ice chest endwall having push buttons therein which release the telescoping legs from a locked position and which fall to the open position under their own weight and lock in a secure position. The push buttons actuate the locks by a linkage system. The front legs have pads at their lower ends, protecting the ends of the legs, and providing weight to pull the legs into the open, locked position. The rear legs have wheels which also providing weight to pull the legs into the open, locked position. A similar water cooler has retractable legs which have pads on their lower ends pulling the legs downward upon pushing buttons on handles on the sidewalls.

Owner:BARQUIST AARON W +1

Optical rotary adapter and optical tomographic imaging system using the same

ActiveUS8055107B2Guaranteed normal transmissionProtect the endInterferometersMaterial analysis by optical meansUltrasound attenuationEngineering

The optical rotary adapter is used with an optical tomographic imaging system for acquiring an optical tomographic image of an object under measurement. The adapter includes a fixed sleeve, a stationary optical fiber supported by the fixed sleeve and having an inclined end face, a stationary collimating lens spaced a given distance from the inclined end face, a mounting cylinder carried rotatably with respect to the fixed sleeve, a rotary optical fiber mounted to the mounting cylinder and having an inclined end face, a rotary collimating lens mounted to the mounting cylinder and disposed with a given distance from the inclined end face, and a rotation actuating device for rotating said mounting cylinder. The central axes of the stationary and rotary optical fibers are offset from or inclined with respect to a central axis of rotation of the mounting cylinder to reduce attenuation of returning light from the object.

Owner:TERUMO KK

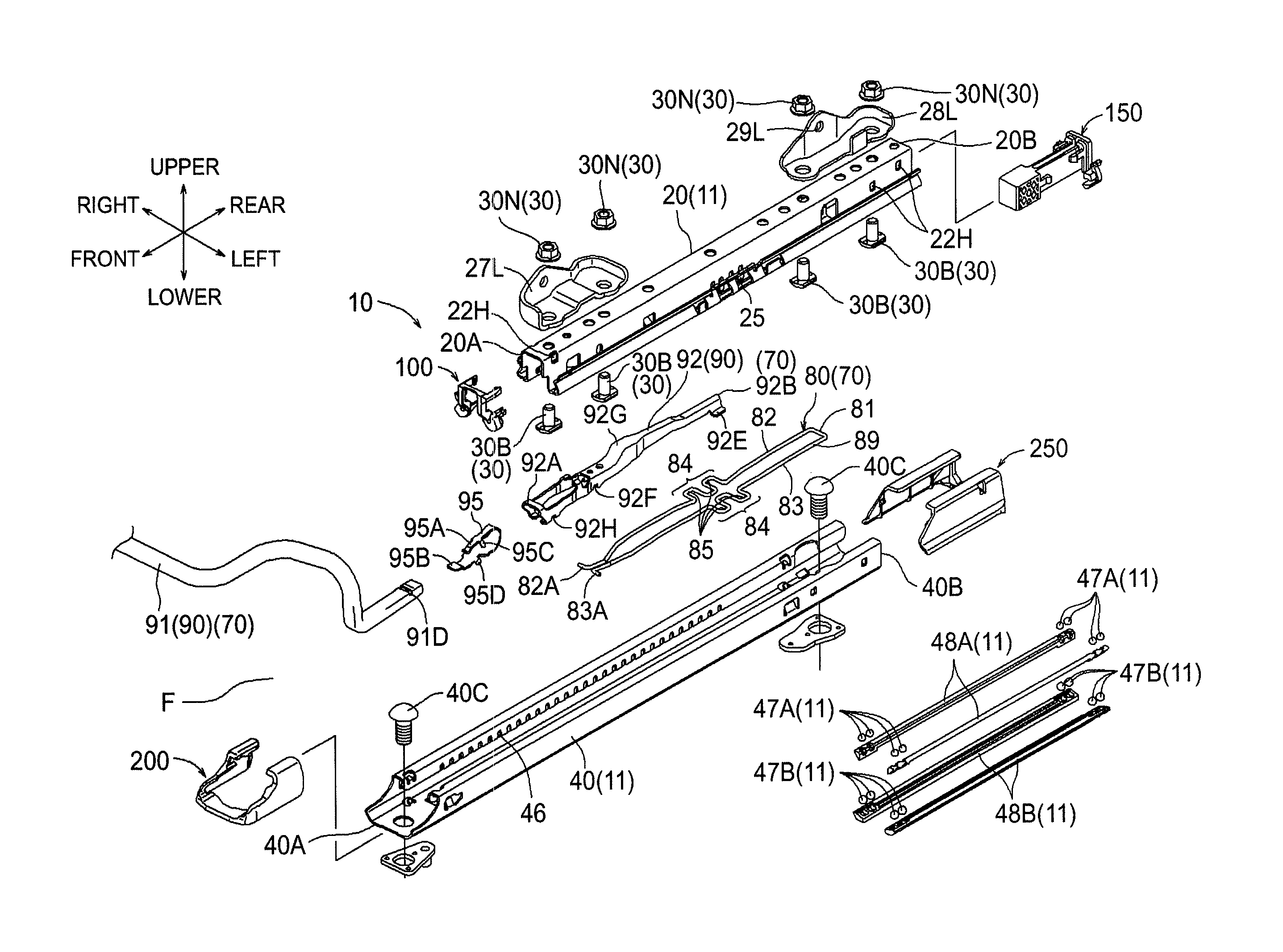

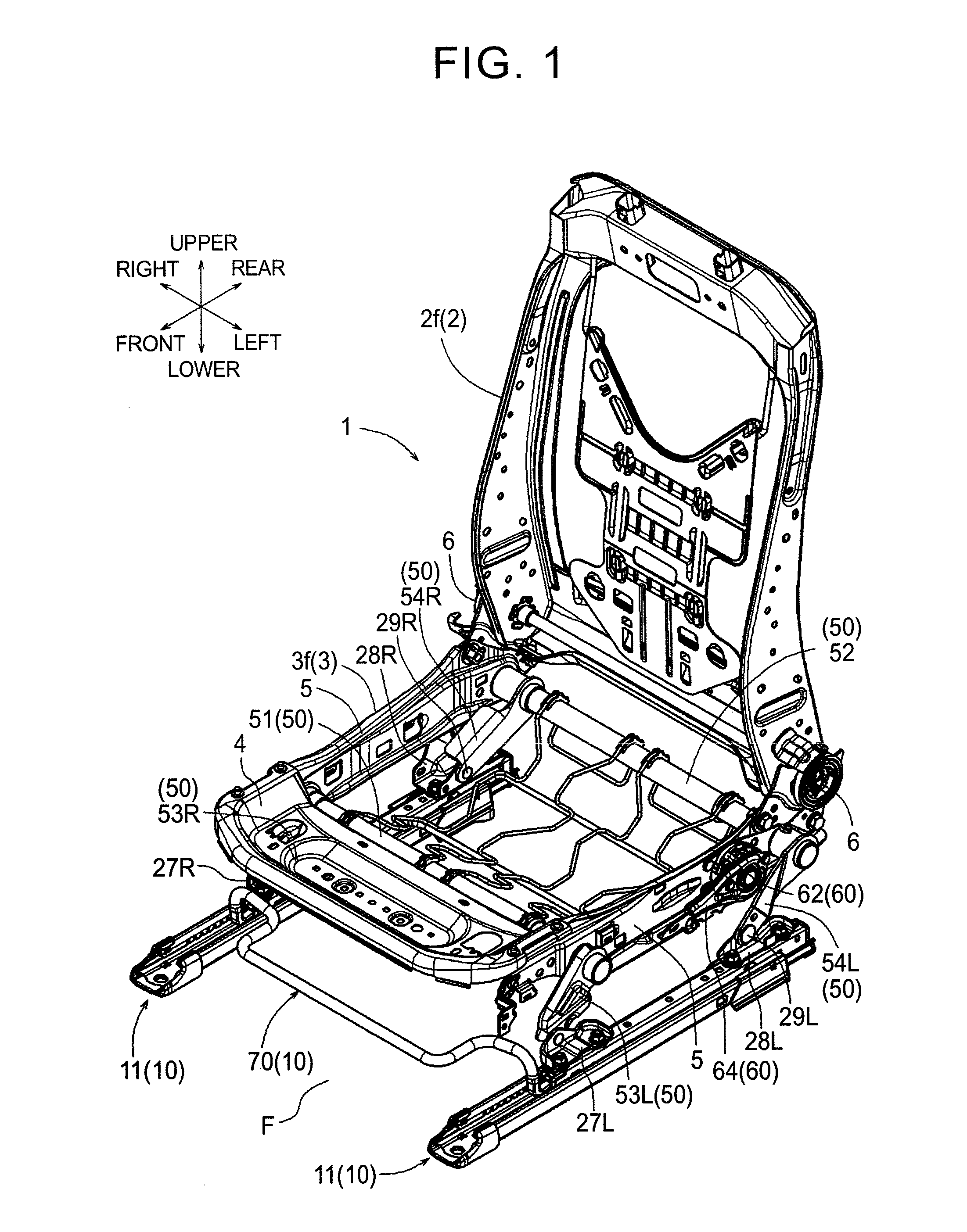

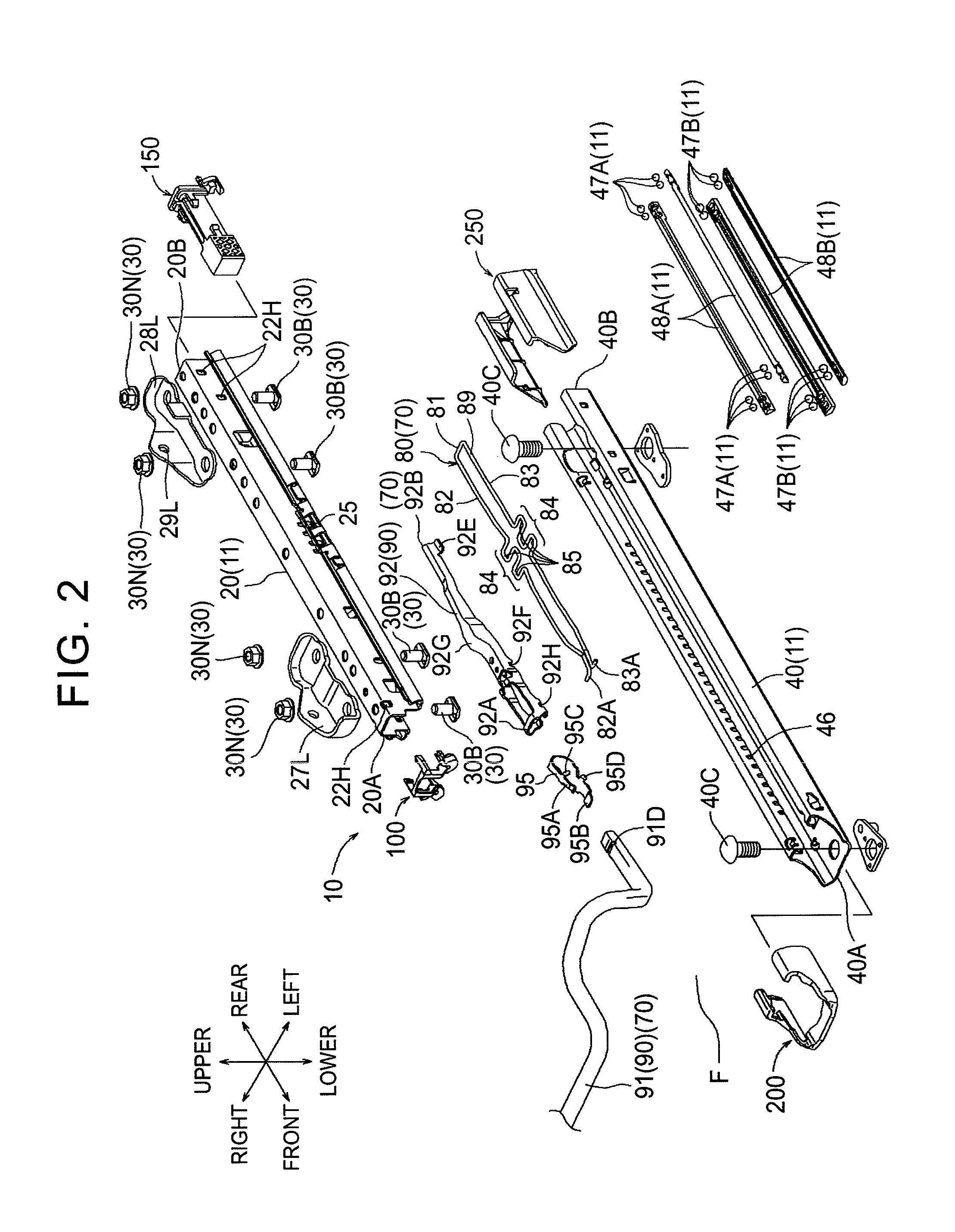

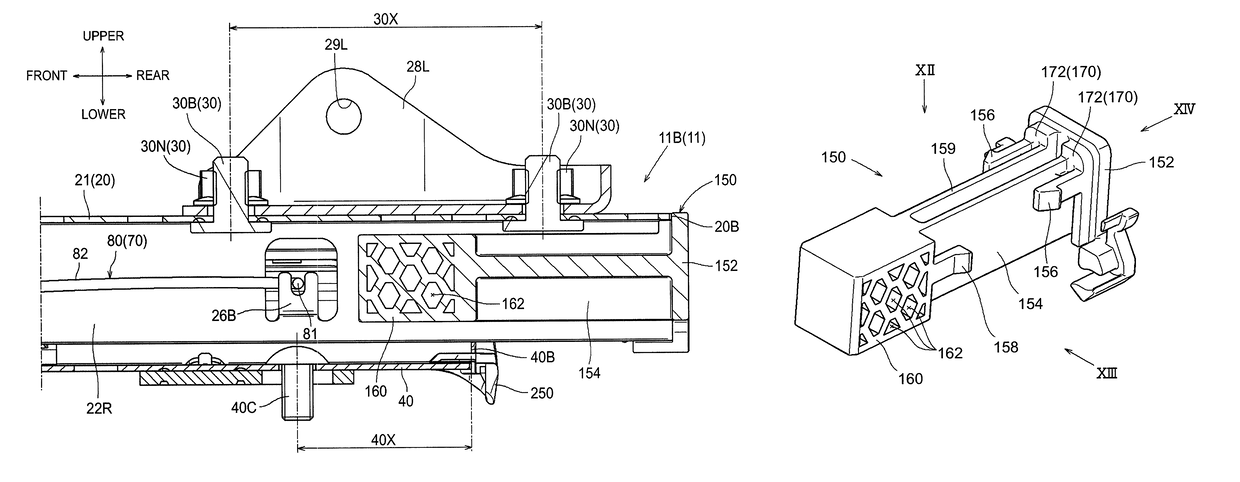

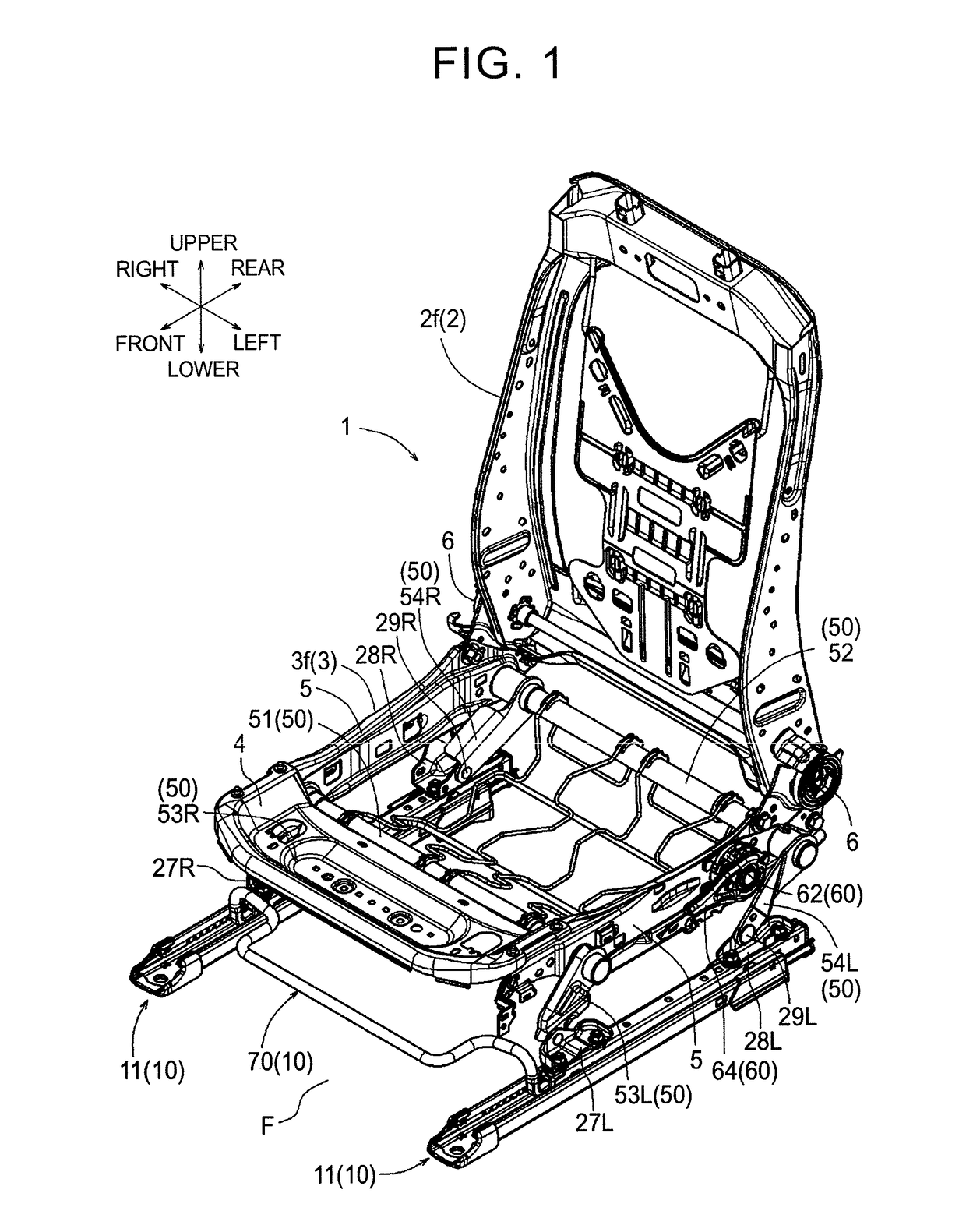

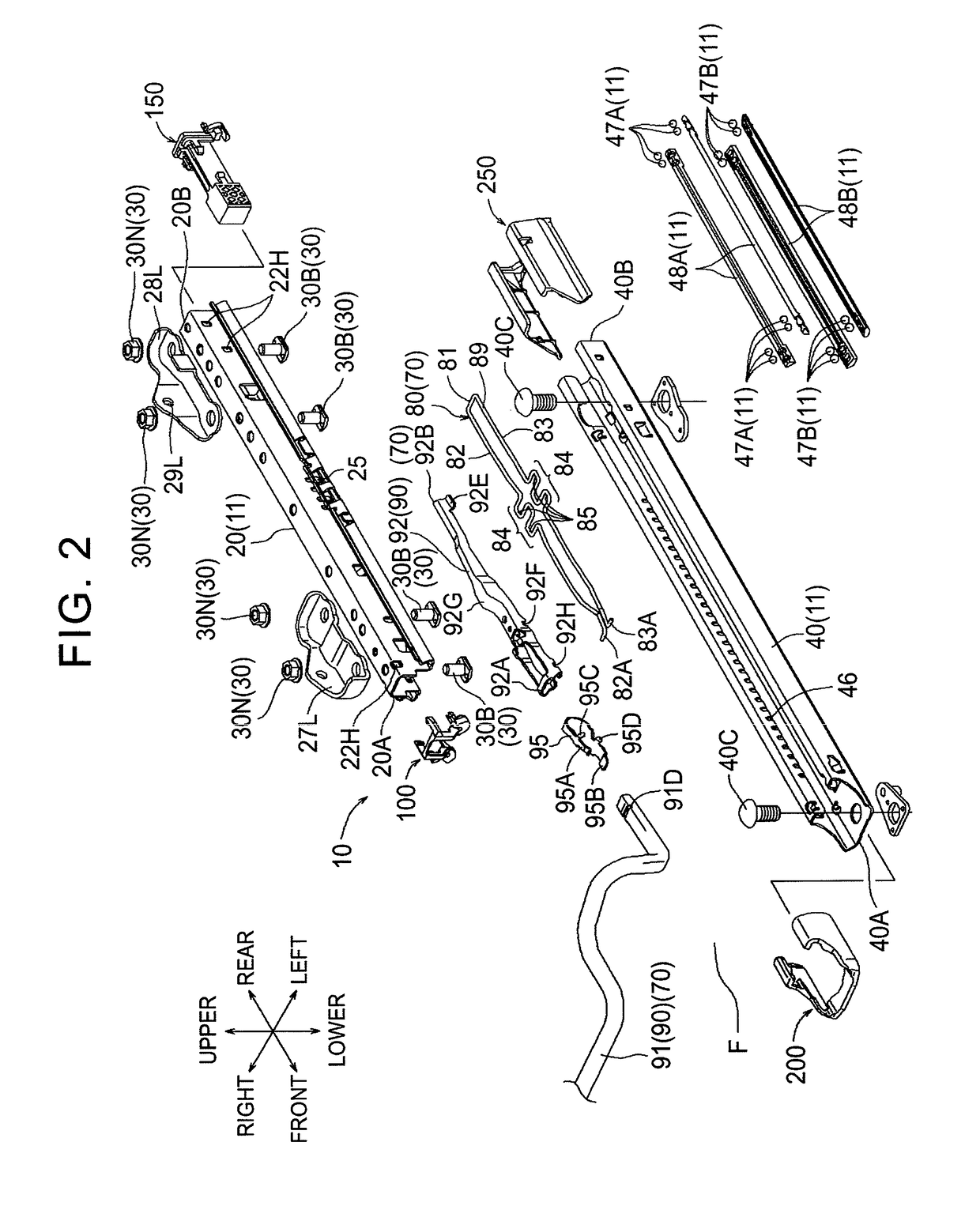

Vehicle seat

ActiveUS20150090853A1Avoid deformationProtect the endStands/trestlesKitchen equipmentEngineeringMechanical engineering

Owner:TOYOTA BOSHOKU KK +2

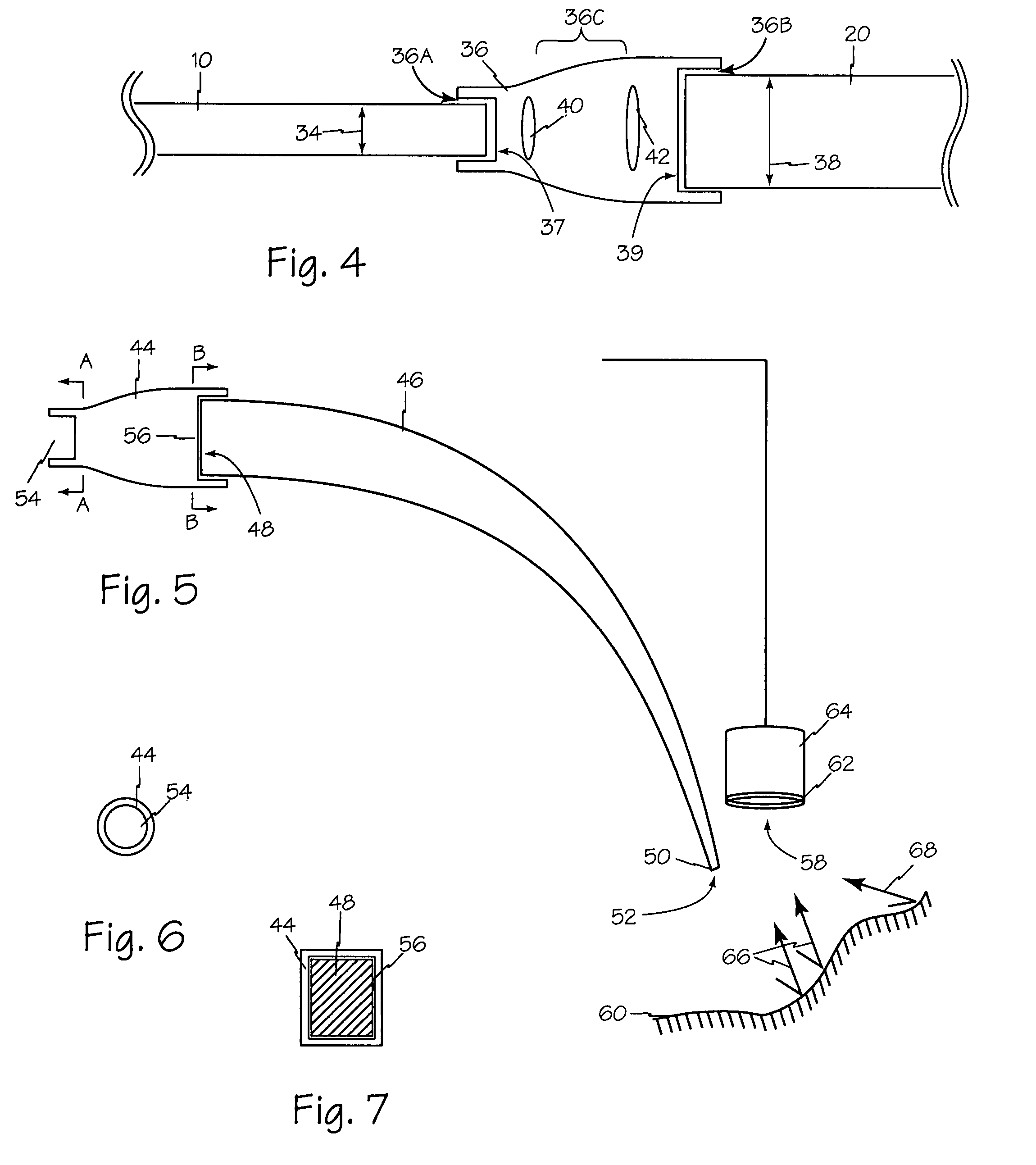

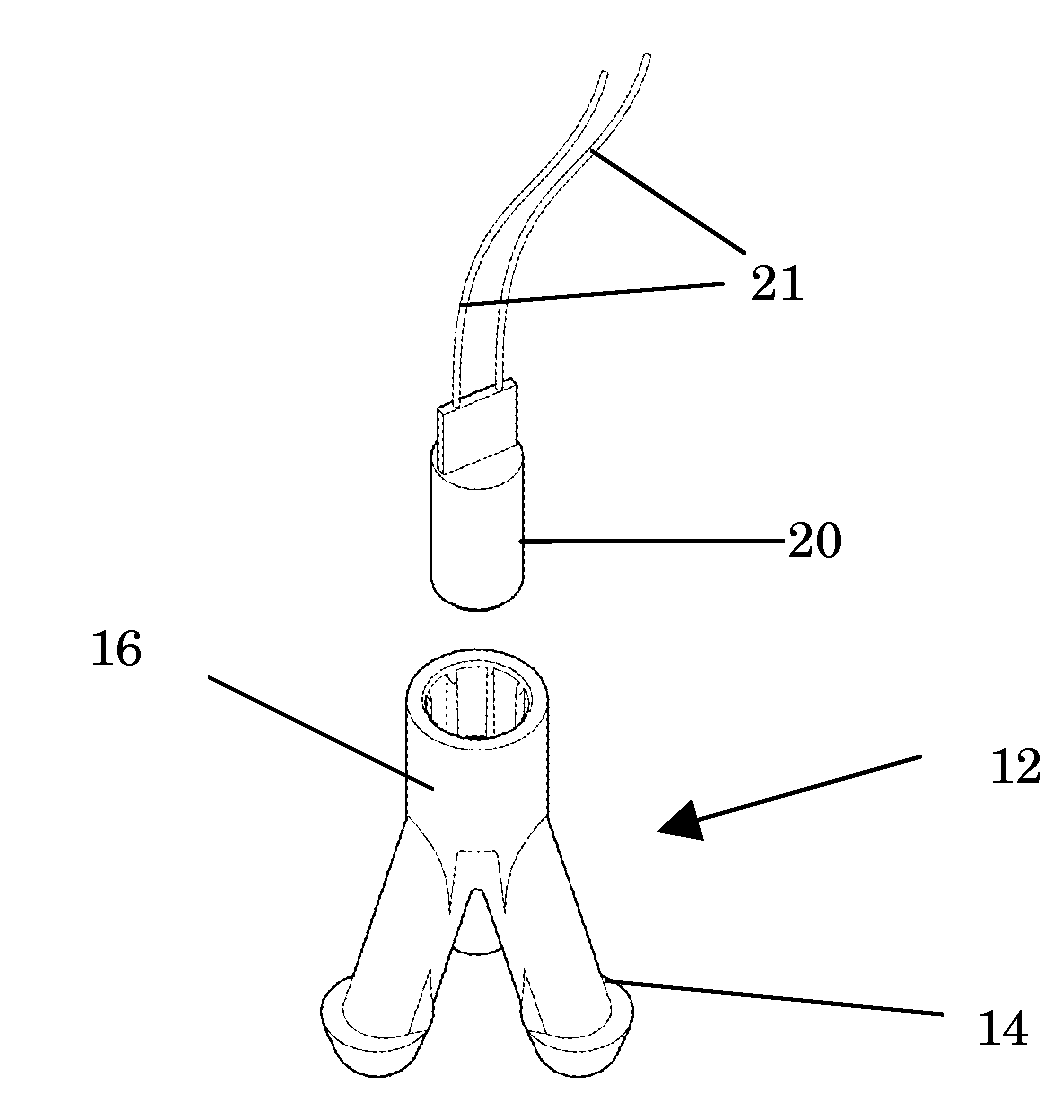

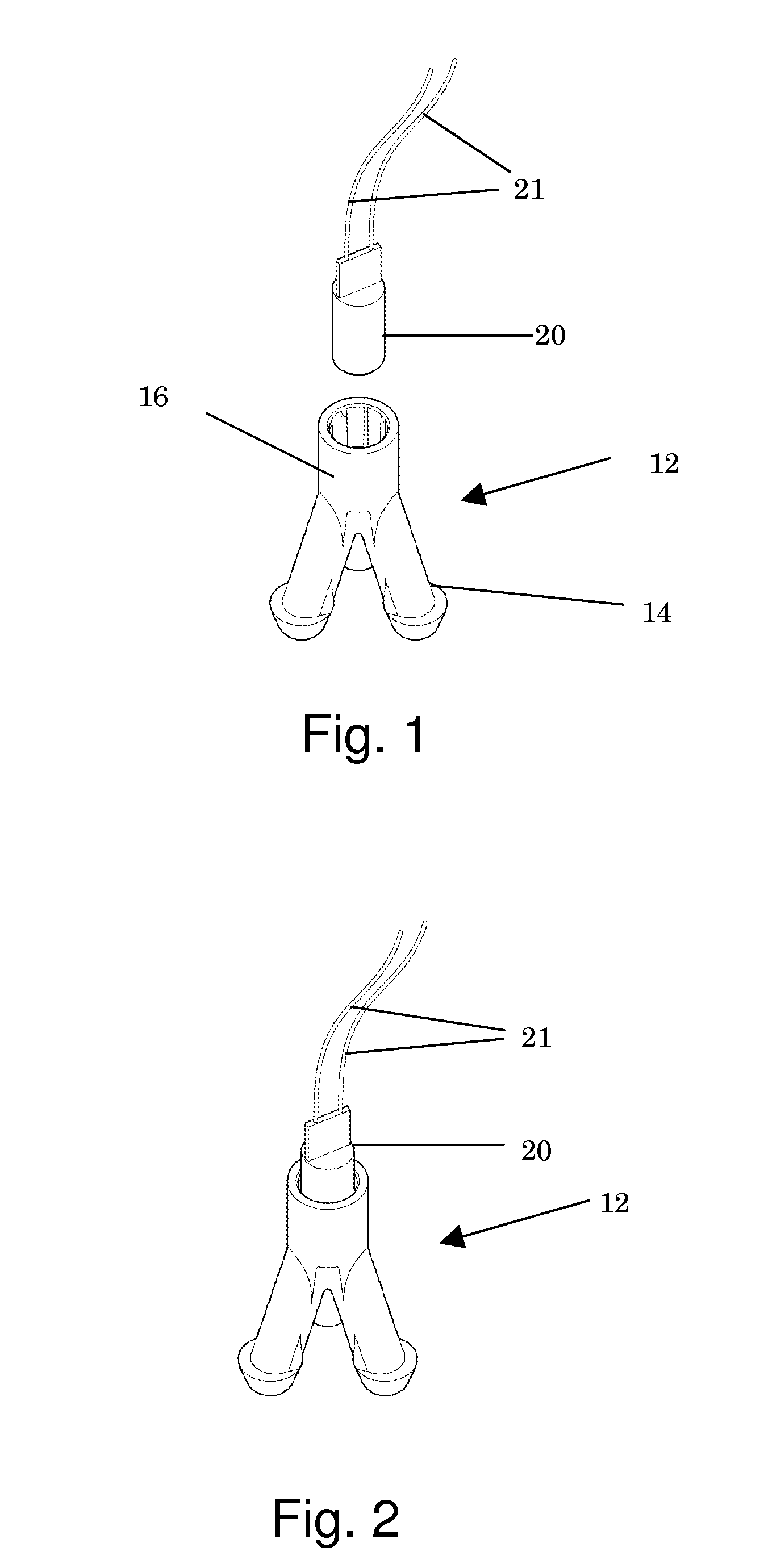

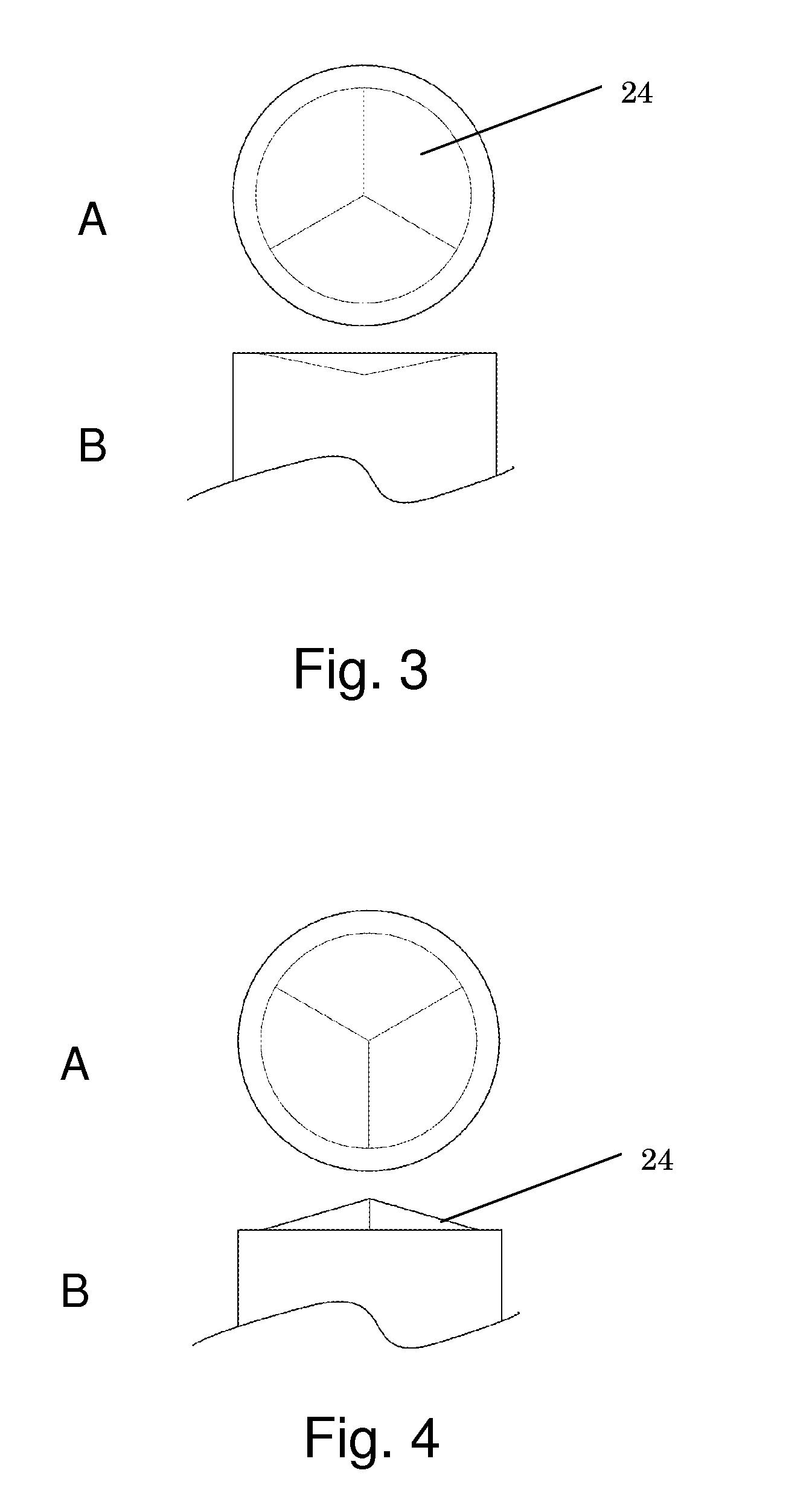

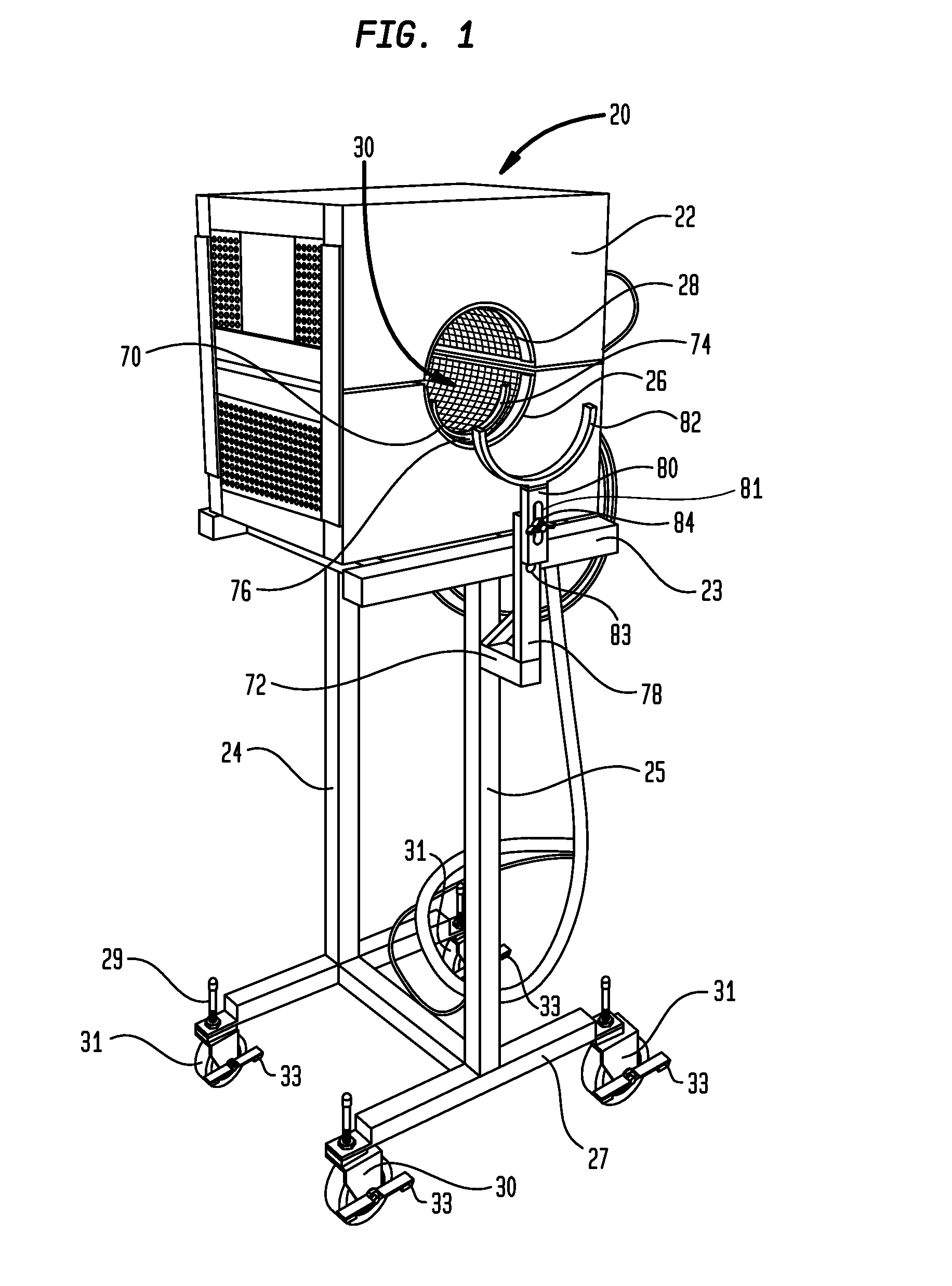

Laser hair and scalp treatment device

InactiveUS20090024116A1Promotes hair growthStable designSurgical instrument detailsLight therapyLight pipeDirect coupling

A handled laser treatment device provides a plurality of branched light pipes or light distribution tips distributed so as to evenly deliver laser radiation to the surface of the scalp. To make efficient use of each laser diode, each laser can coupled to a branched light pipe with the branches arranged to distribute light directly to the surface of the scalp. Each laser source is connected to a three branch light pipe. Alternatively, each laser diode can be directly coupled to a light distribution tip arranged in a triad. Each light pipe or light distribution tip acts as a tine or tooth in a comb to bring laser radiation to the scalp free of obstruction by hair, etc., with a tripod configuration that allows each light pipe assembly to evenly contact the rounded surface of the scalp. The branched light pipes or the light distribution tips are preferentially coupled to a flexible membrane so as to be capable of independent orientation allowing improved contact of the distal ends of the tripods or triads to the scalp.

Owner:CHURCH & DWIGHT CO INC

Rain screen siding system

Owner:WOOD SIDING SYST

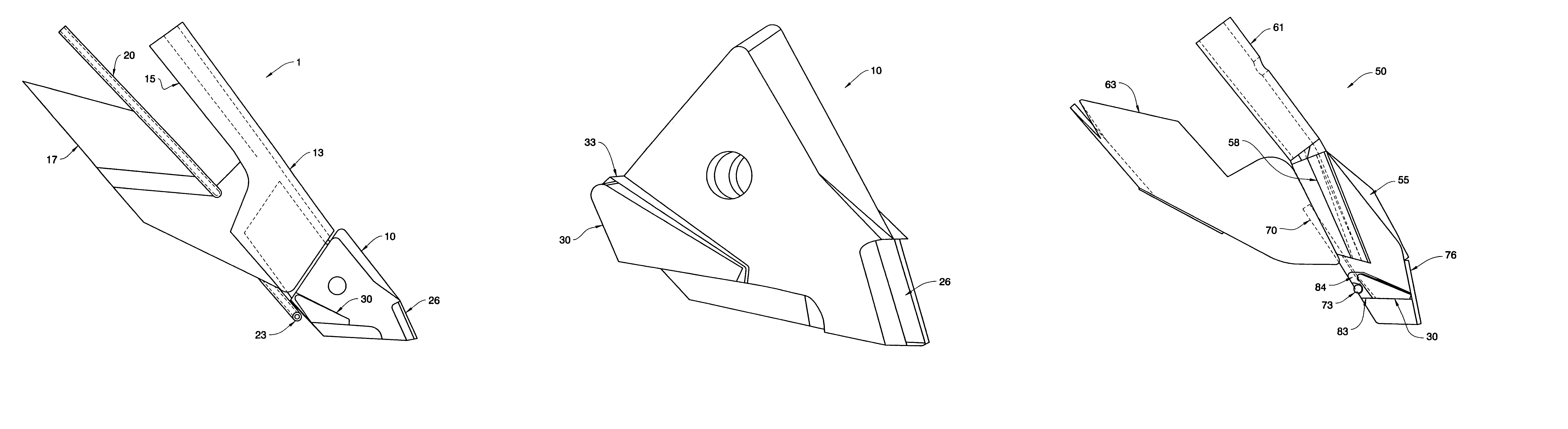

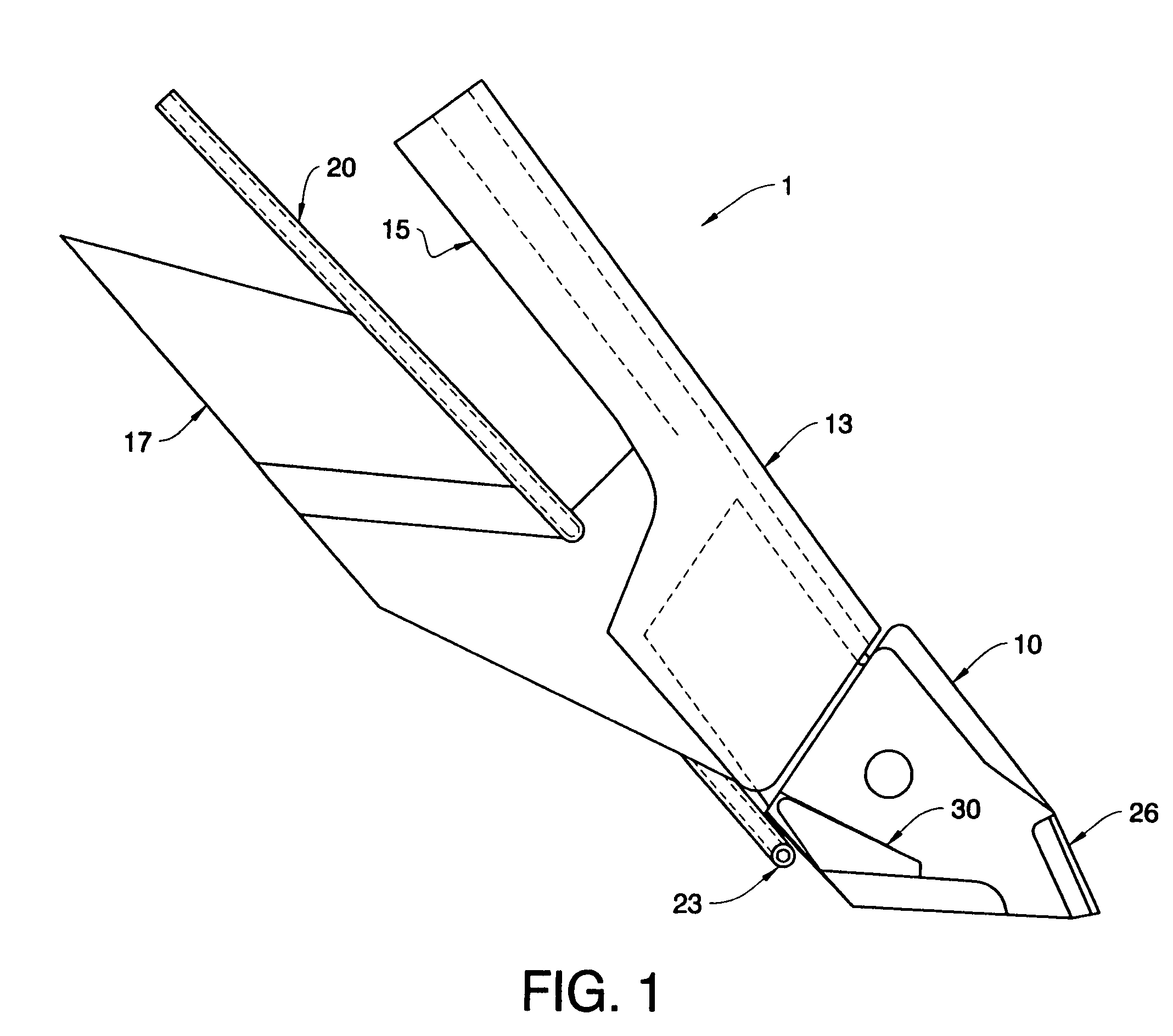

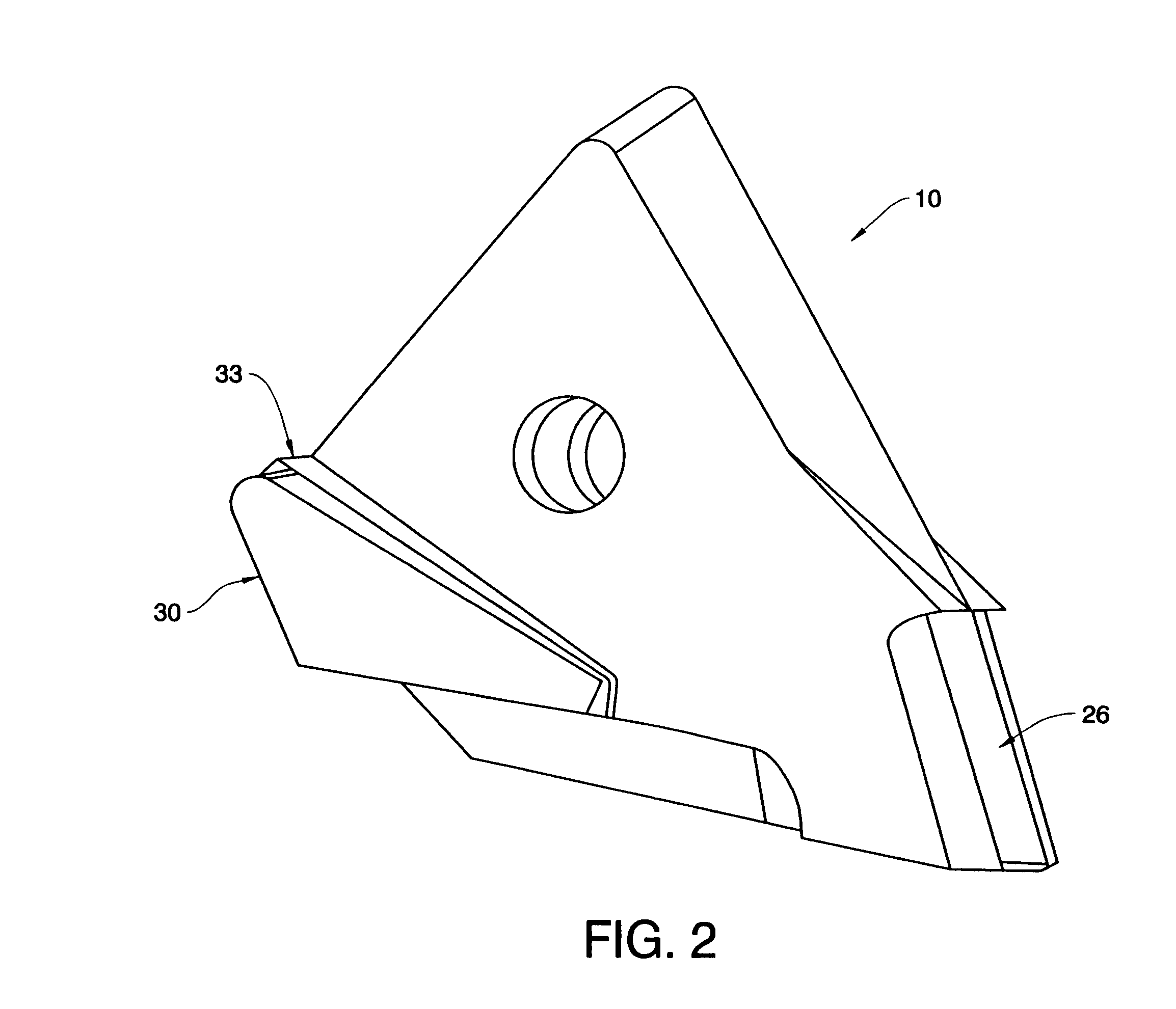

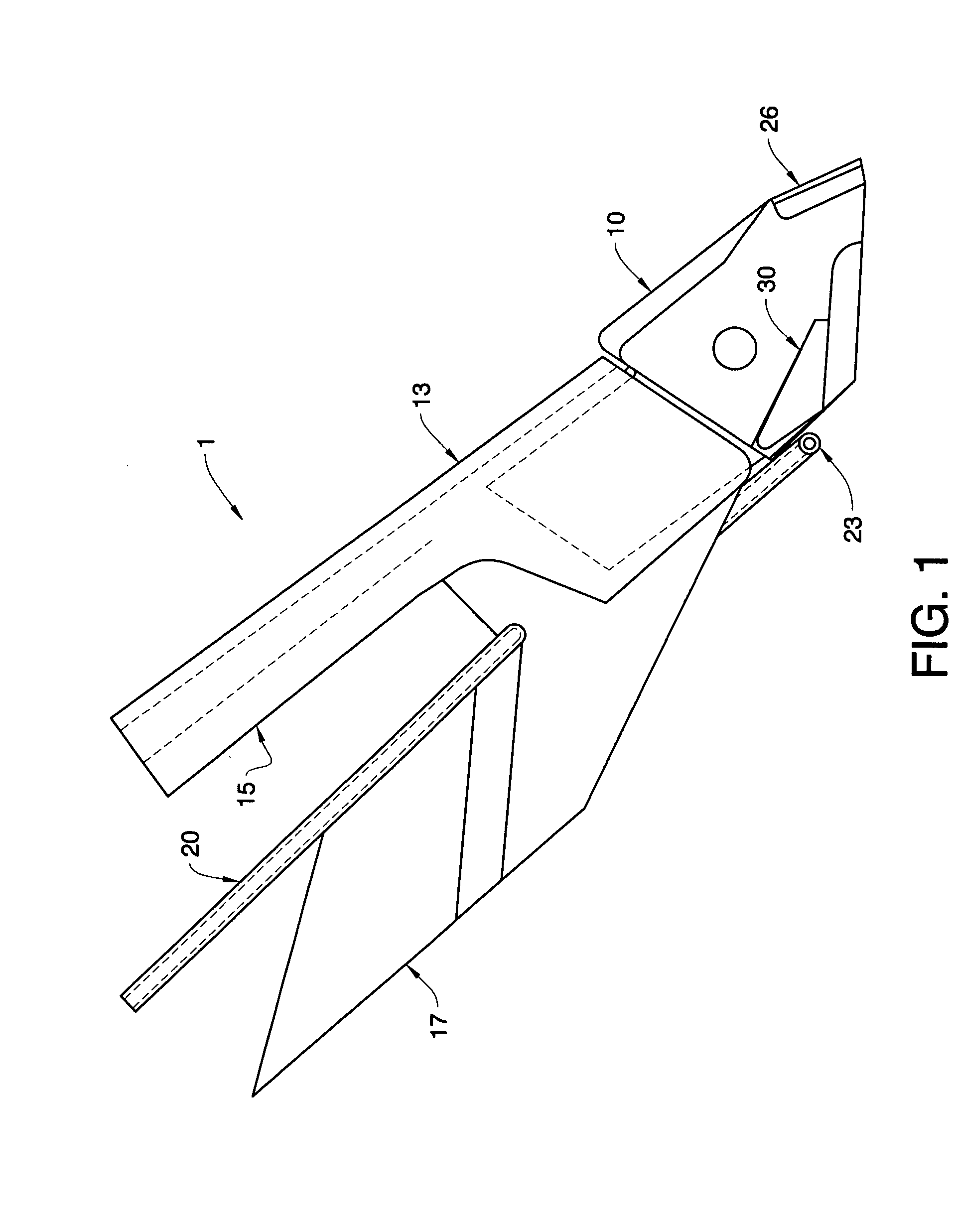

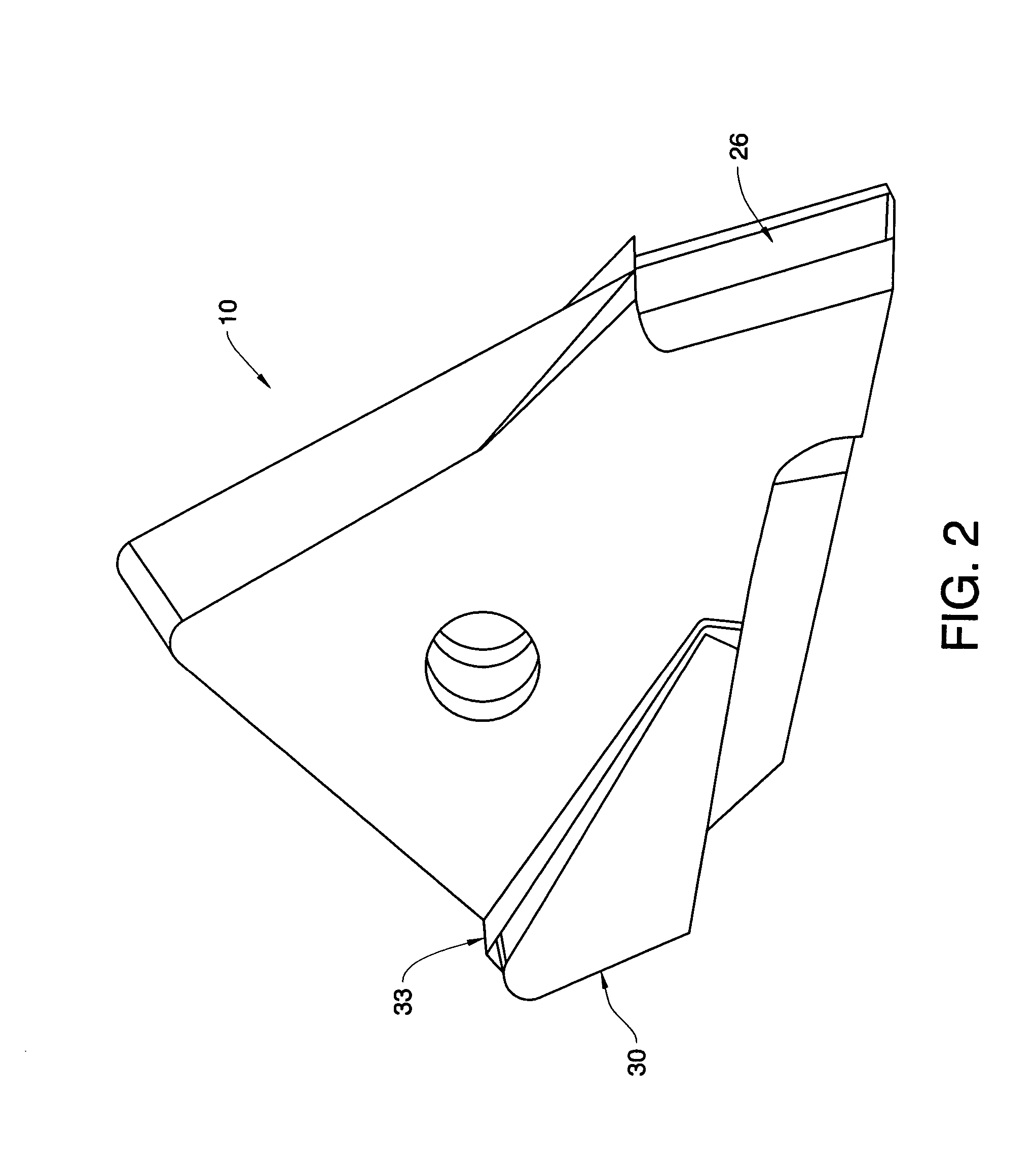

Seeding tool

InactiveUS6966270B2Protect the endSpace often becomes criticalSoil-working equipmentsLiquid fertiliser distributionAgricultural engineeringMechanical engineering

A seeding tool for depositing seeds and fertilizer within a furrow including a knife opener having a liquid wing projecting from the side thereof for providing and maintaining spacing between the seeds and fertilizer. Preferably, the liquid wing is a tungsten carbide insert secured to the side of the knife opener, and has a wing shaped structure which is shaped and sized to space the fertilizer apart from the seeds, to protect the end of the tube from which fertilizer is dispensed, and to present a small leading surface which displaces the soil easily and presents minimal resistance. Preferably, the largest, side surface of the liquid wing insert is inclined toward the side of the knife opener from a widest lower, rear member adjacent the end of the fertilizer tube to a narrower top, front member near a leading end of the knife opener.

Owner:KENNAMETAL INC +1

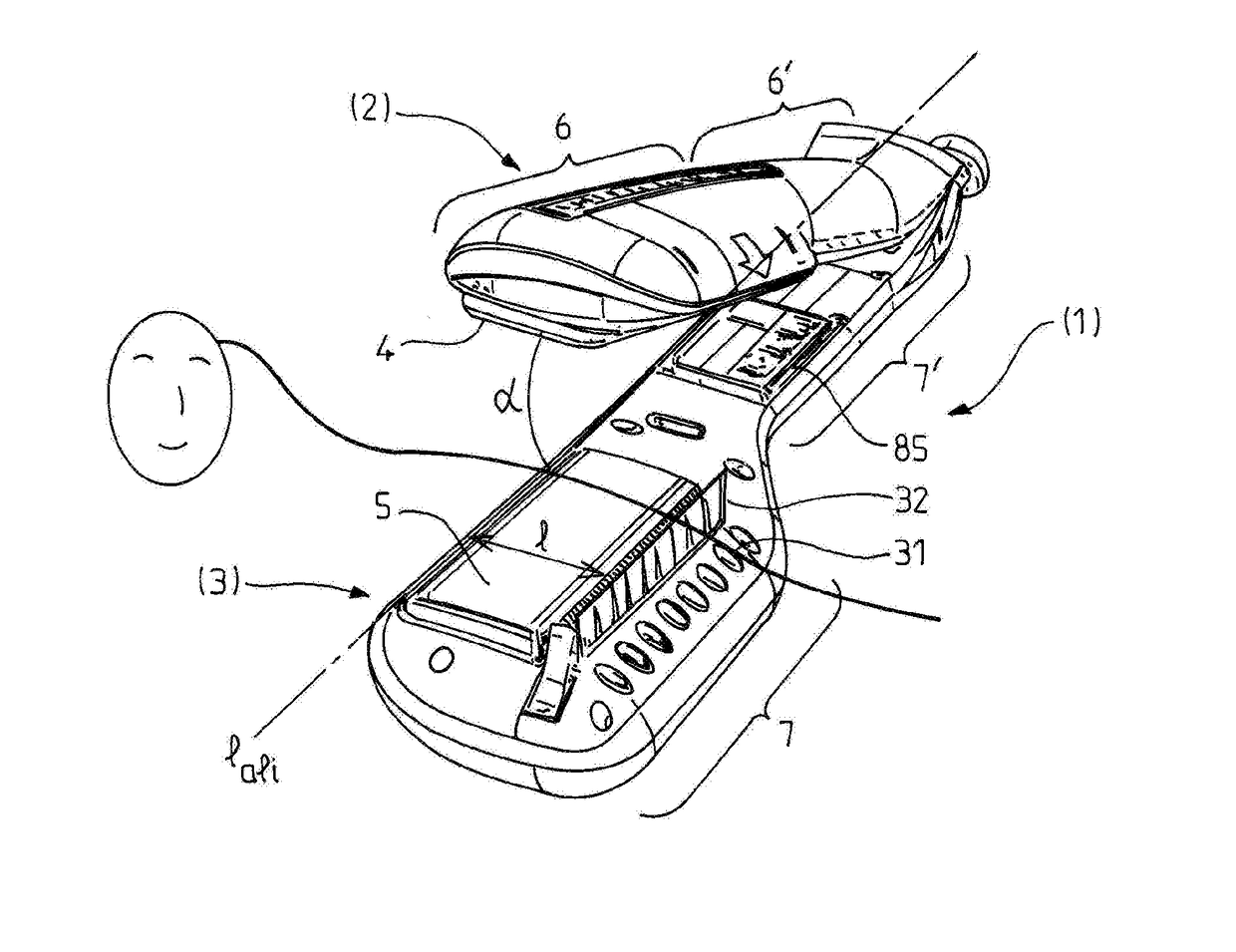

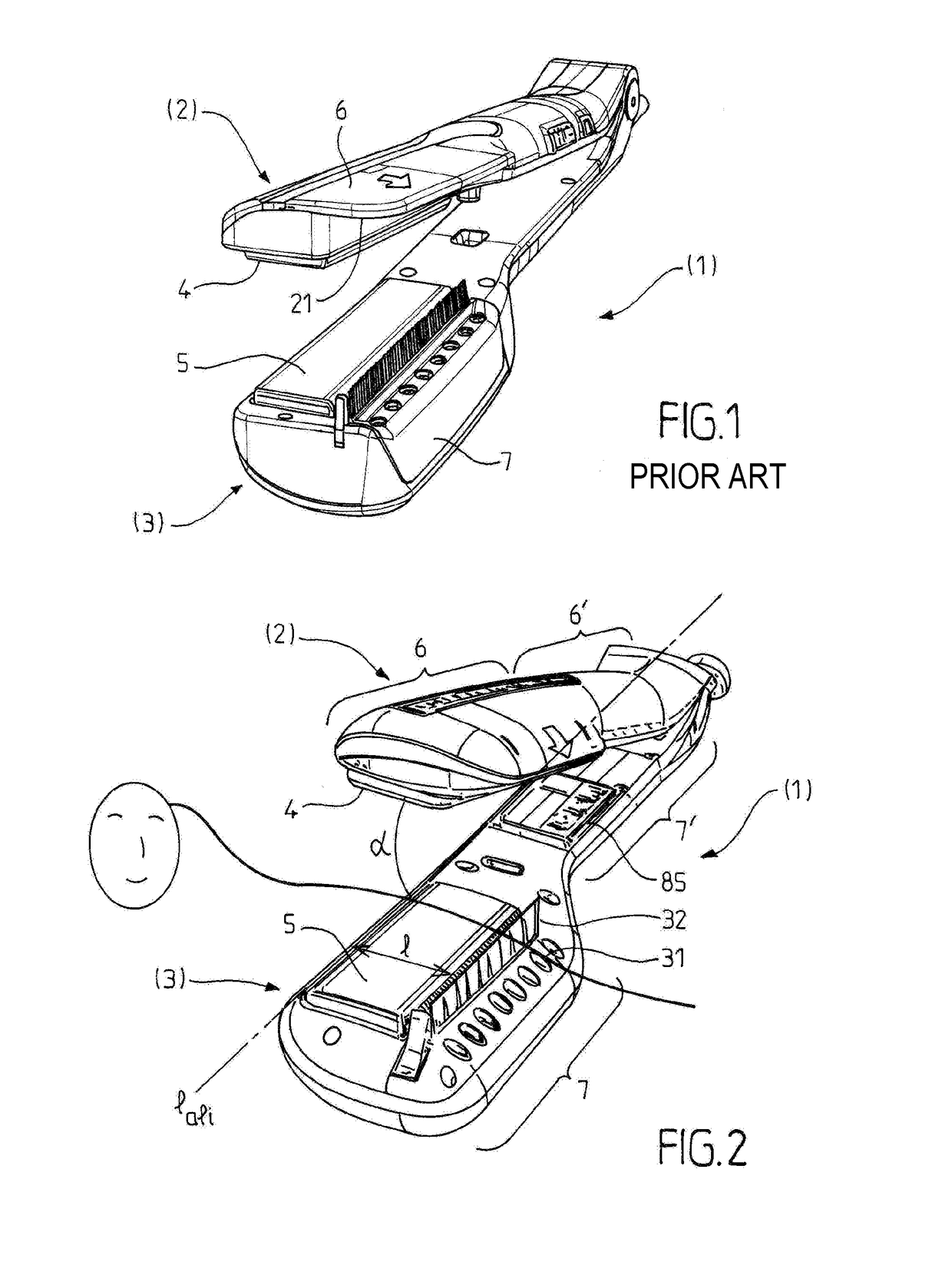

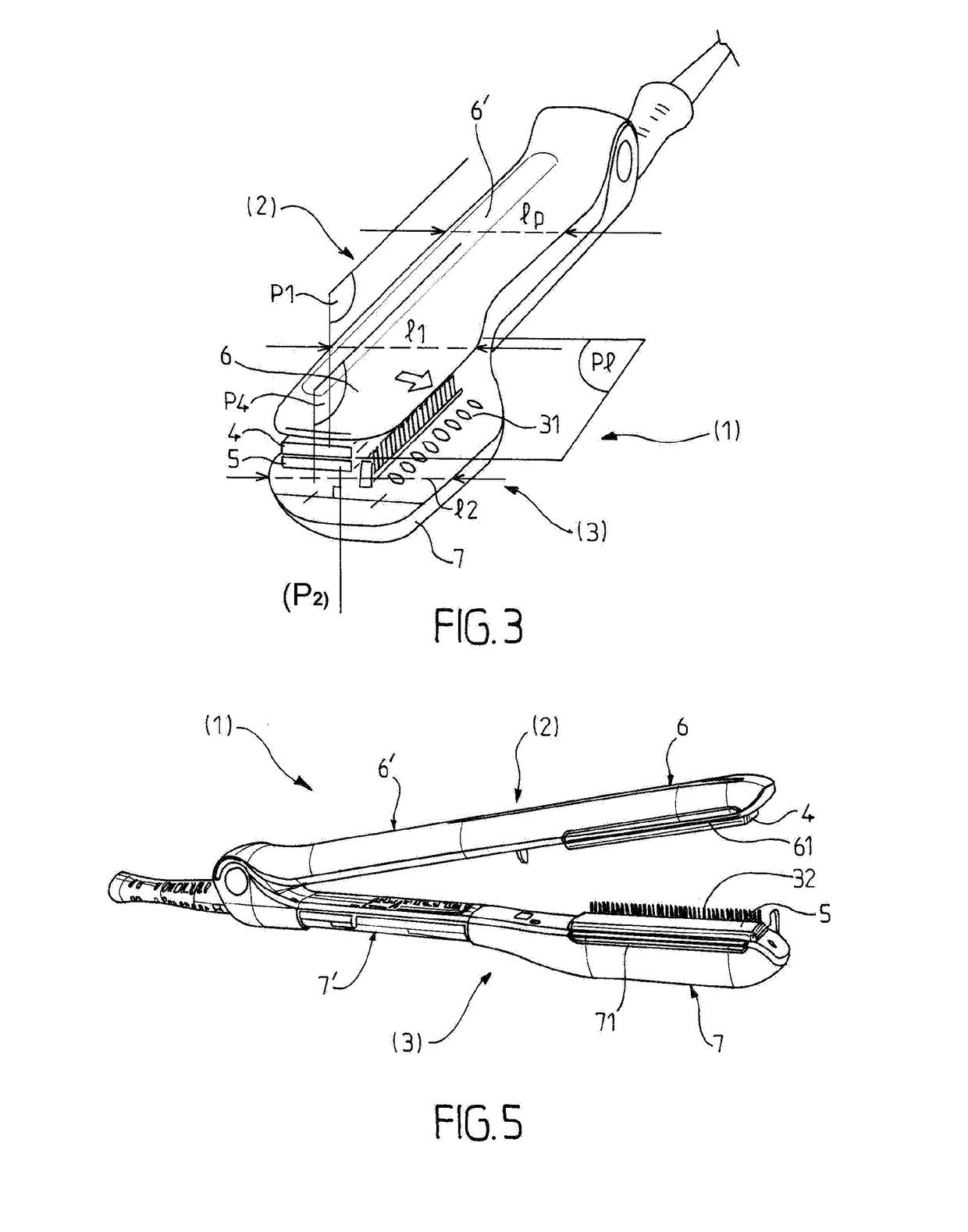

Hairstyling Apparatus for Forming Curls of Different Sizes

InactiveUS20170135457A1Guaranteed uptimeBulk is limitedCurling-ironsCurling-tongsBiomedical engineeringHeating element

Provided is a hairstyling apparatus (1) for curling and smoothing hair, which includes: first and second elongate jaws (2, 3) which are pivotably movable relative to one another, the first jaw (2) having a first casing (6) supporting a first inner planar treatment surface (4), and the second jaw (3) having a second casing (7) supporting a second inner planar treatment surface (5), the inner surfaces (4, 5) being intended for pinching a lock of hair; and at least one heating element (41, 510) intended for heating at least one inner treatment surface (4, 5). The largest width (l1) of the first casing (6) is no greater than 90% of the largest width (l2) of the second casing (7). The first casing (6) and / or the second casing (7) is asymmetrical relative to the median plane in a longitudinal crosssection of said first casing (6) or said second casing (7), respectively.

Owner:SEB SA

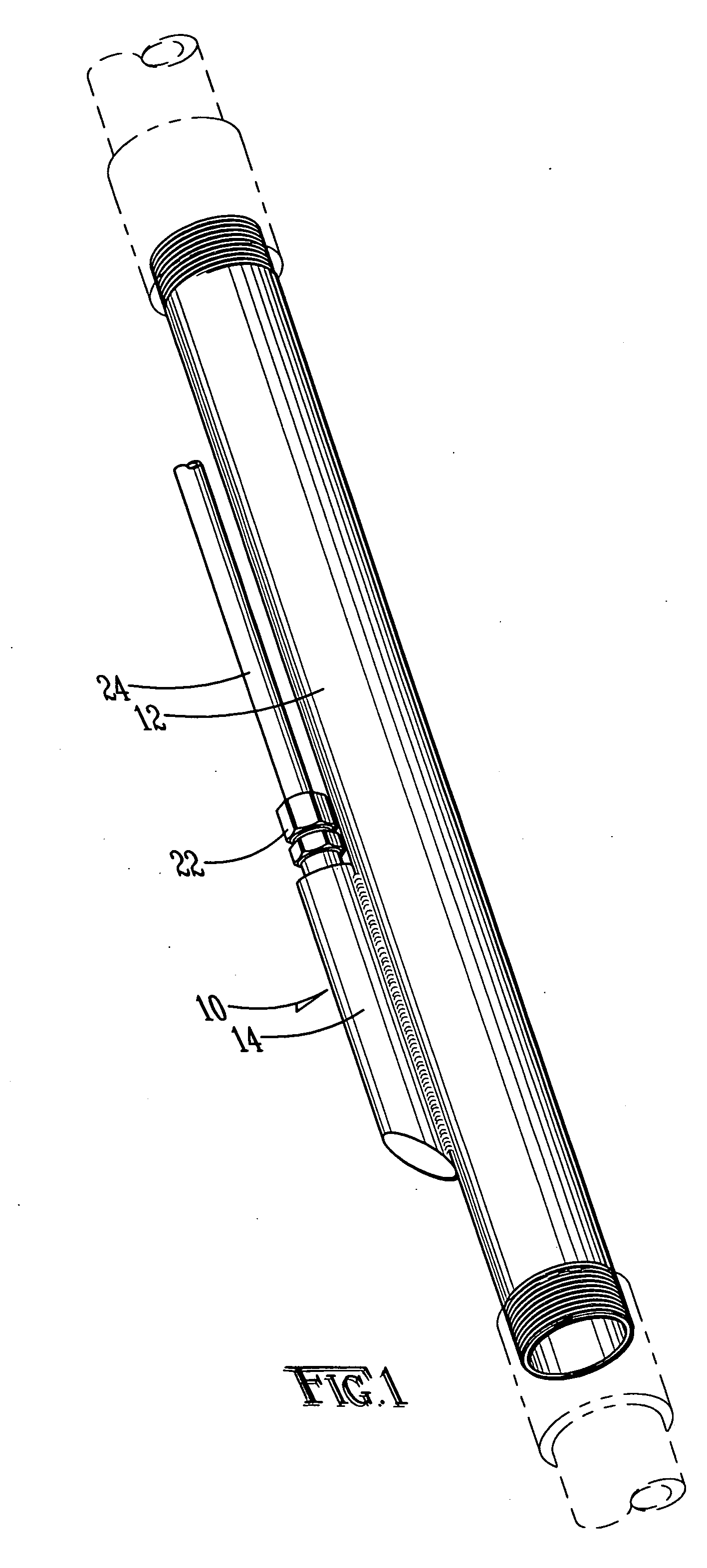

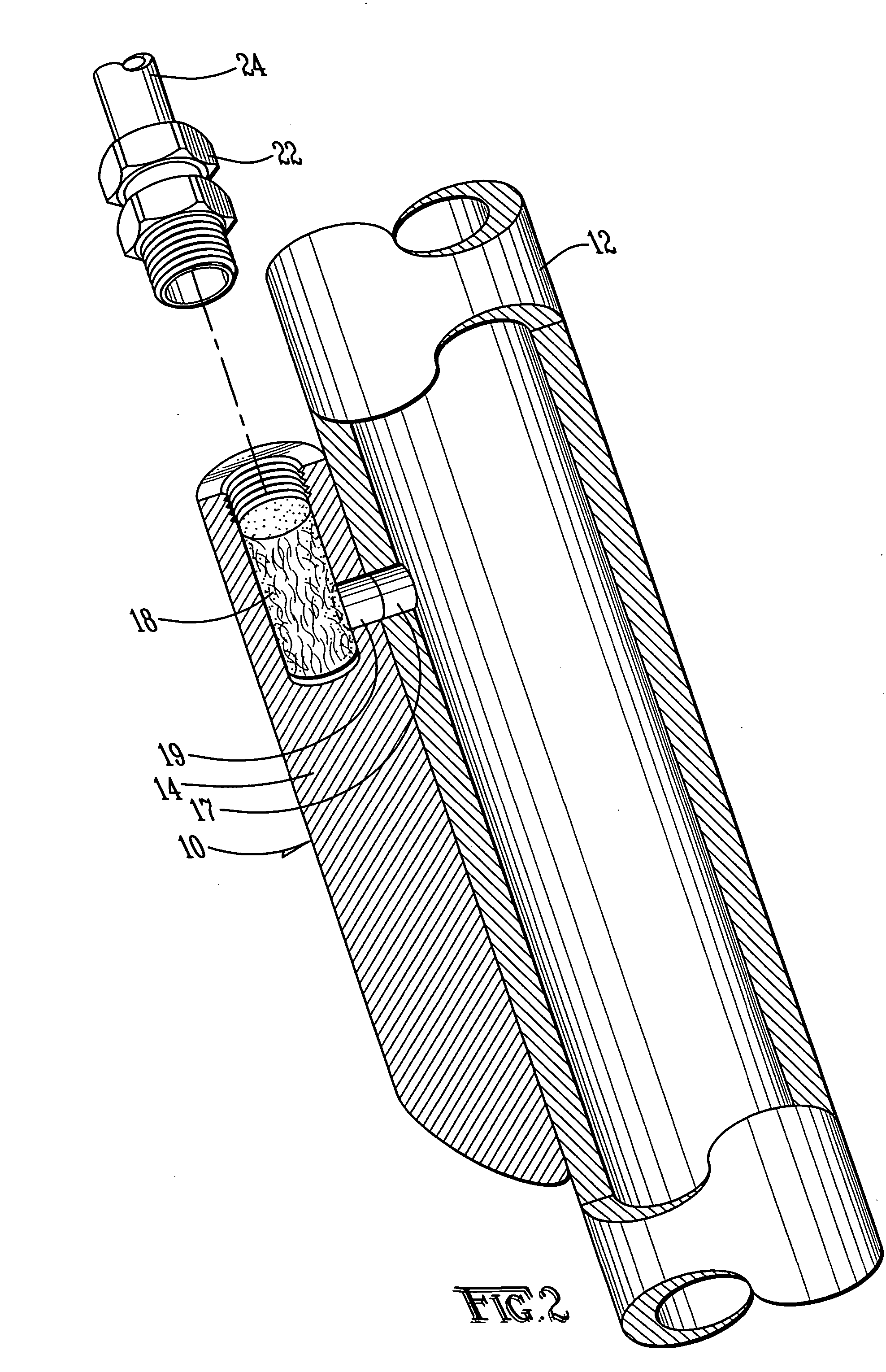

Apparatus for monitoring pressure using capillary tubing

InactiveUS20060185840A1Easy maintenanceProtect the endSurveyFluid removalCapillary TubingEngineering

An apparatus for monitoring the pressure in a gas well at a downhole location is disclosed. The apparatus uses a capillary tube connecting a downhole monitoring assembly with a pressure gauge or gauges at the wellhead. The downhole monitoring assembly and capillary tube are located externally to the production tube so as not to block the production tube for cleaning or other uses. A passage from the interior of the production tube passes gas to the capillary tube in order to measure the pressure at the downhole end of the production tube.

Owner:CONRAD GREG ALLEN

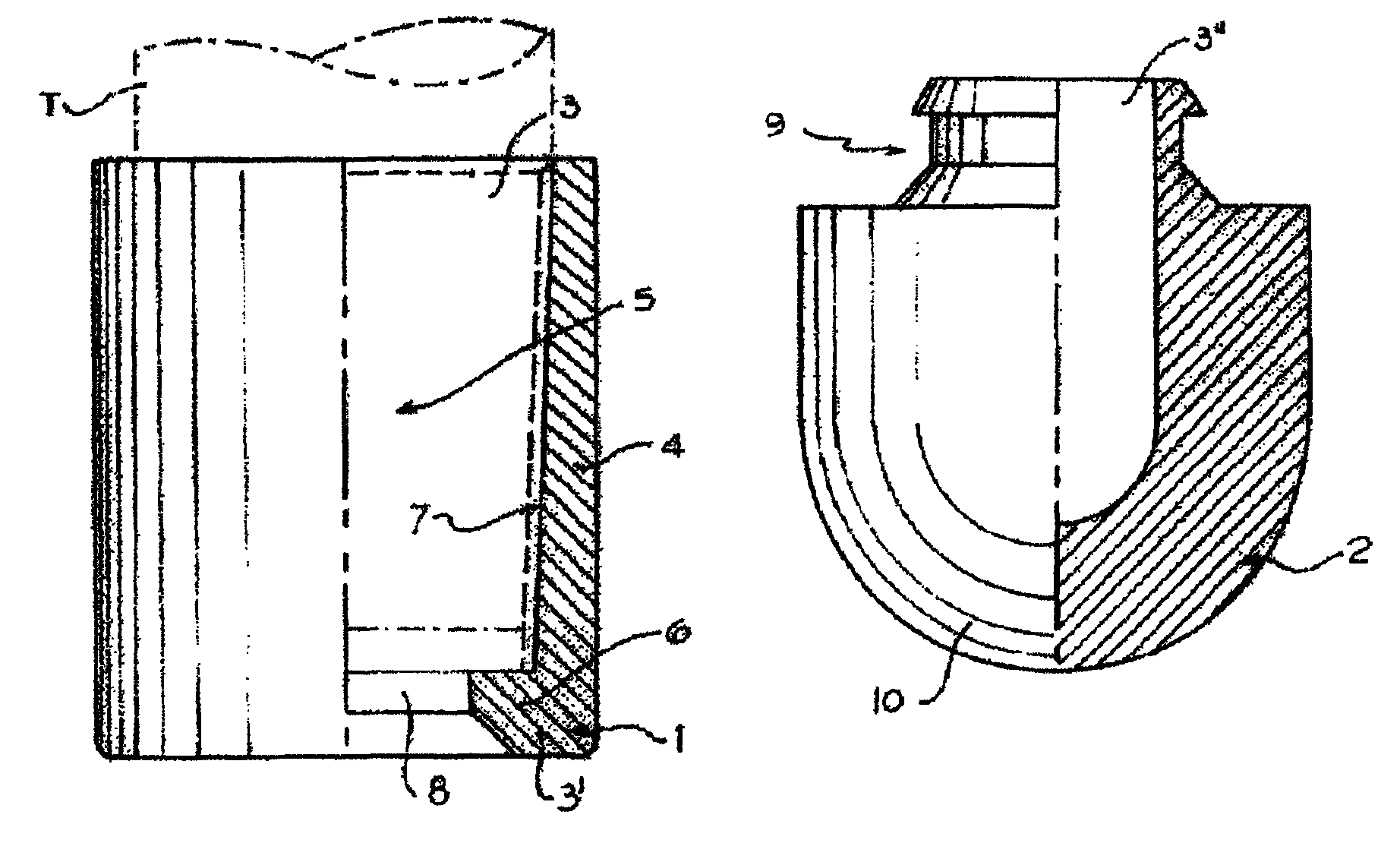

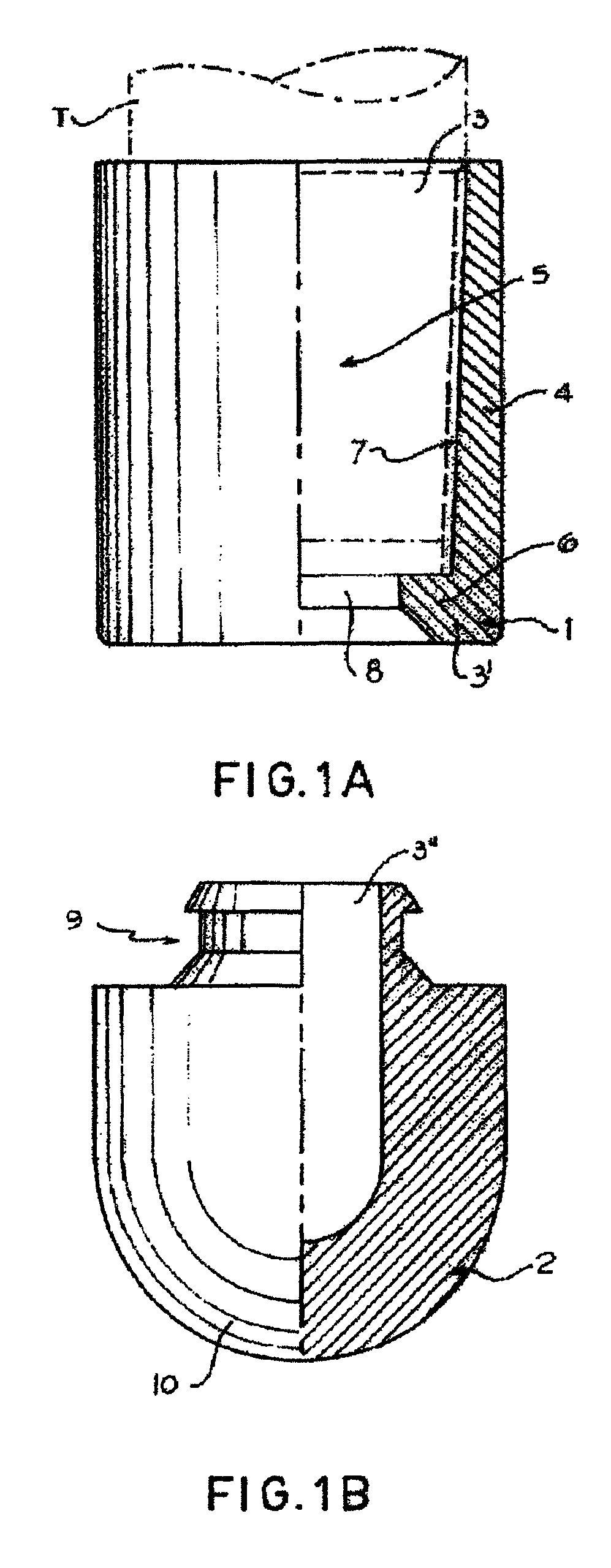

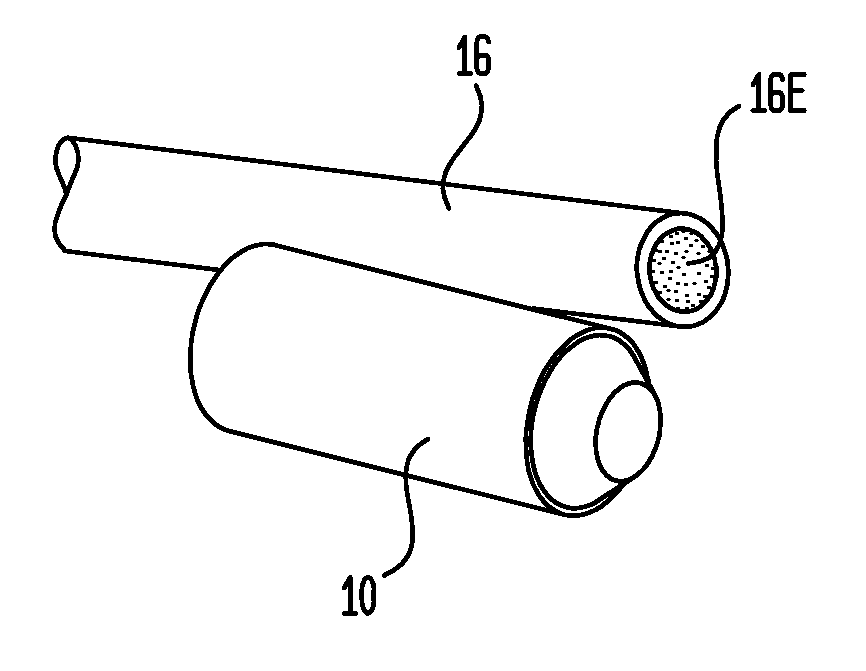

End protector device for tubular structures

InactiveUS8011391B2Improve the immunityProtect the endDrilling rodsClosure using stoppersEngineeringCylindrical geometry

A protector device for the ends of the tubular goods, such as tubes for the oil industry, OCTG, line pipes and the like is provided. The protector device may include two pieces, a generally elongate protector body and a bumper reinforcement that may be reversibly connected to the protector body. The protector body may be configured in a cylindrical geometry having a first end and a second end interconnected by lateral walls and defining a socket. The second end of the body further comprises a shoulder and an opening defining a socket in which a tubular good may be inserted. The bumper reinforcement includes an external curved or conical surface, capable of deforming in reaction to an external force in order to protect an enclosed tubular good.

Owner:SIDERCA I C

End protector device for tubular structures

InactiveUS20090050230A1Improve the immunityProtect the endDrilling rodsClosure using stoppersEngineeringConical surface

A protector device for the ends of the tubular goods, such as tubes for the oil industry, OCTG, line pipes and the like is provided. The protector device may include two pieces, a generally elongate protector body and a bumper reinforcement that may be reversibly connected to the protector body. The protector body may be configured in a cylindrical geometry having a first end and a second end interconnected by lateral walls and defining a socket. The second end of the body further comprises a shoulder and an opening defining a socket in which a tubular good may be inserted. The bumper reinforcement includes an external curved or conical surface, capable of deforming in reaction to an external force in order to protect an enclosed tubular good.

Owner:SIDERCA I C

Vehicle seat

Owner:TOYOTA BOSHOKU KK +2

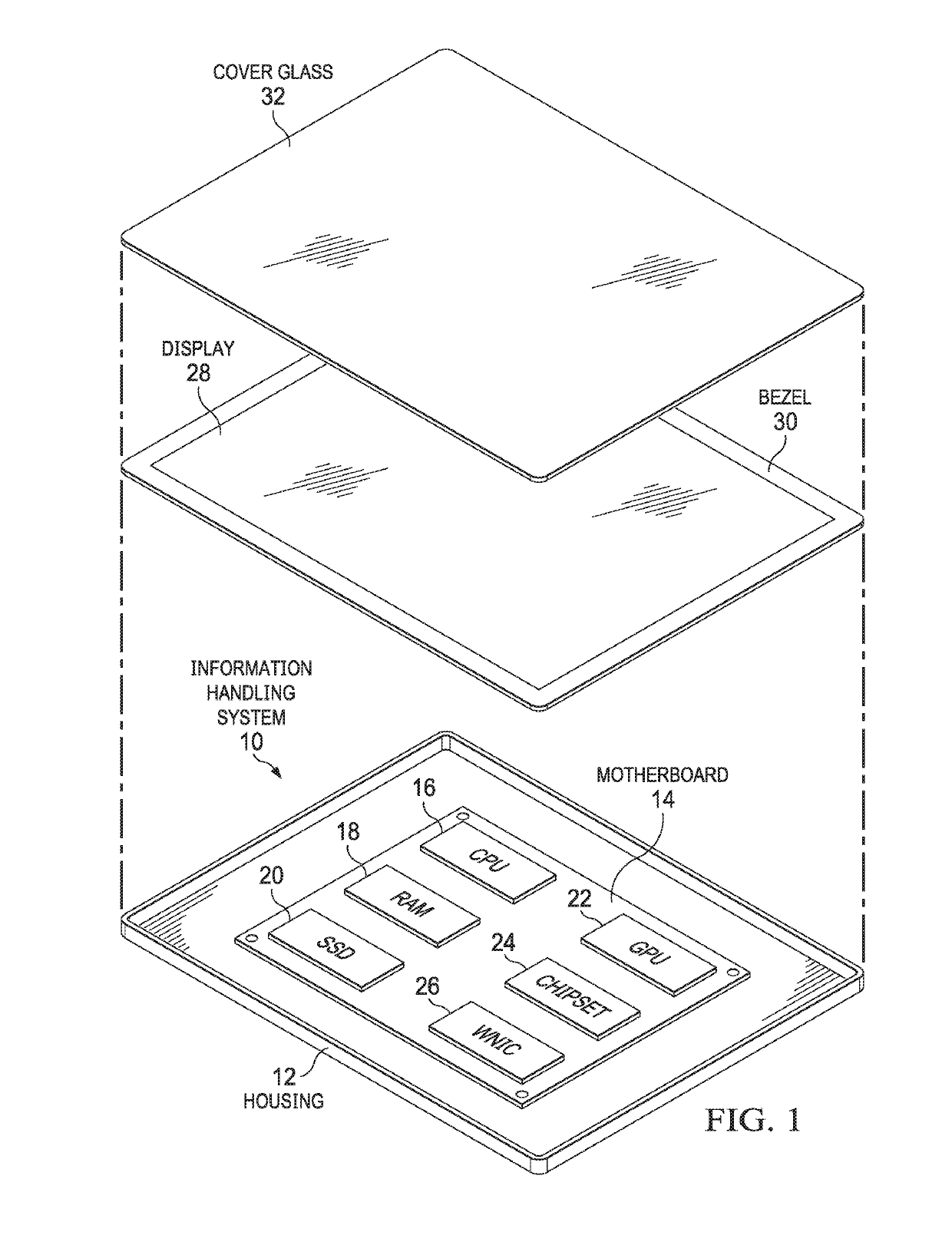

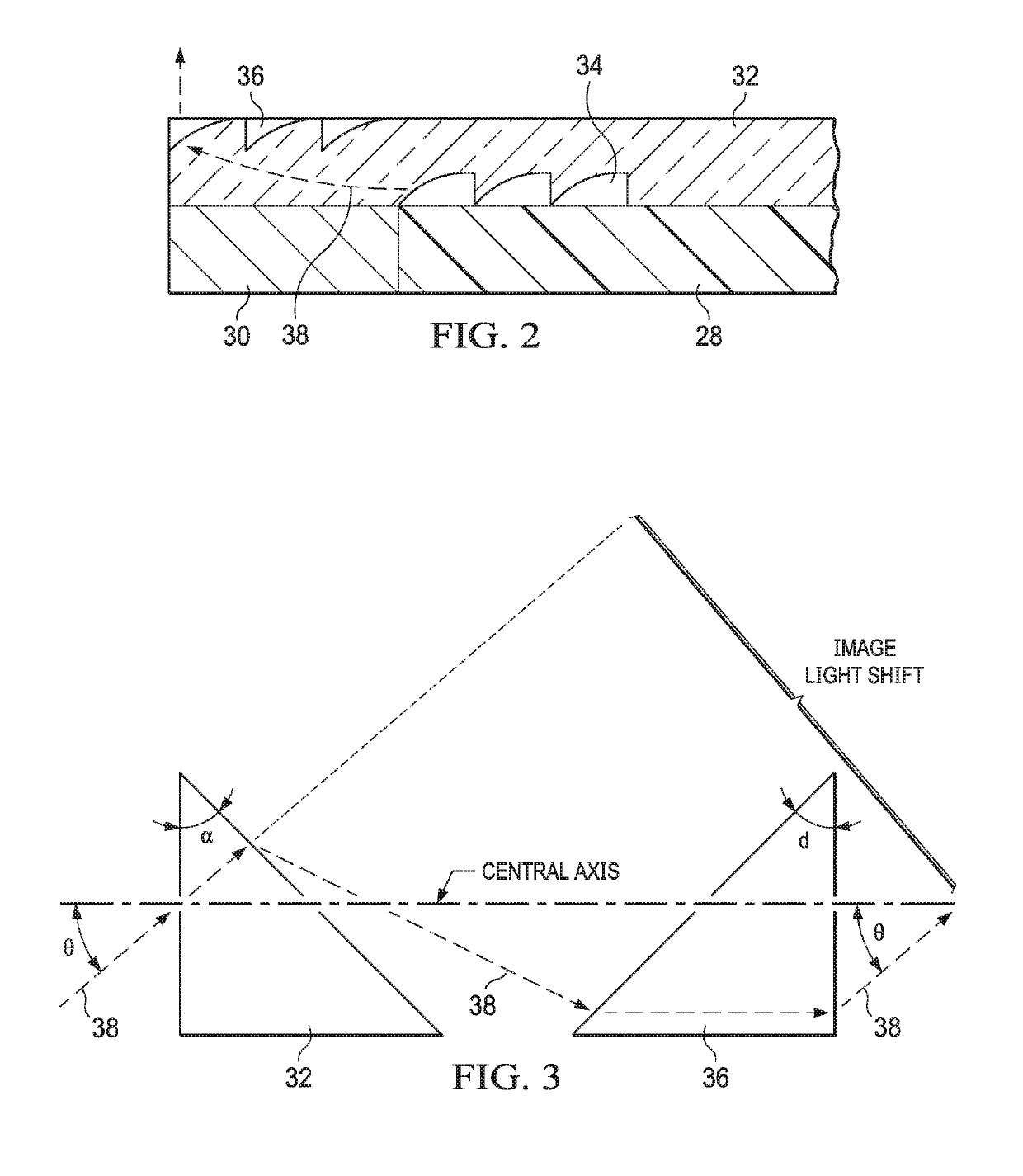

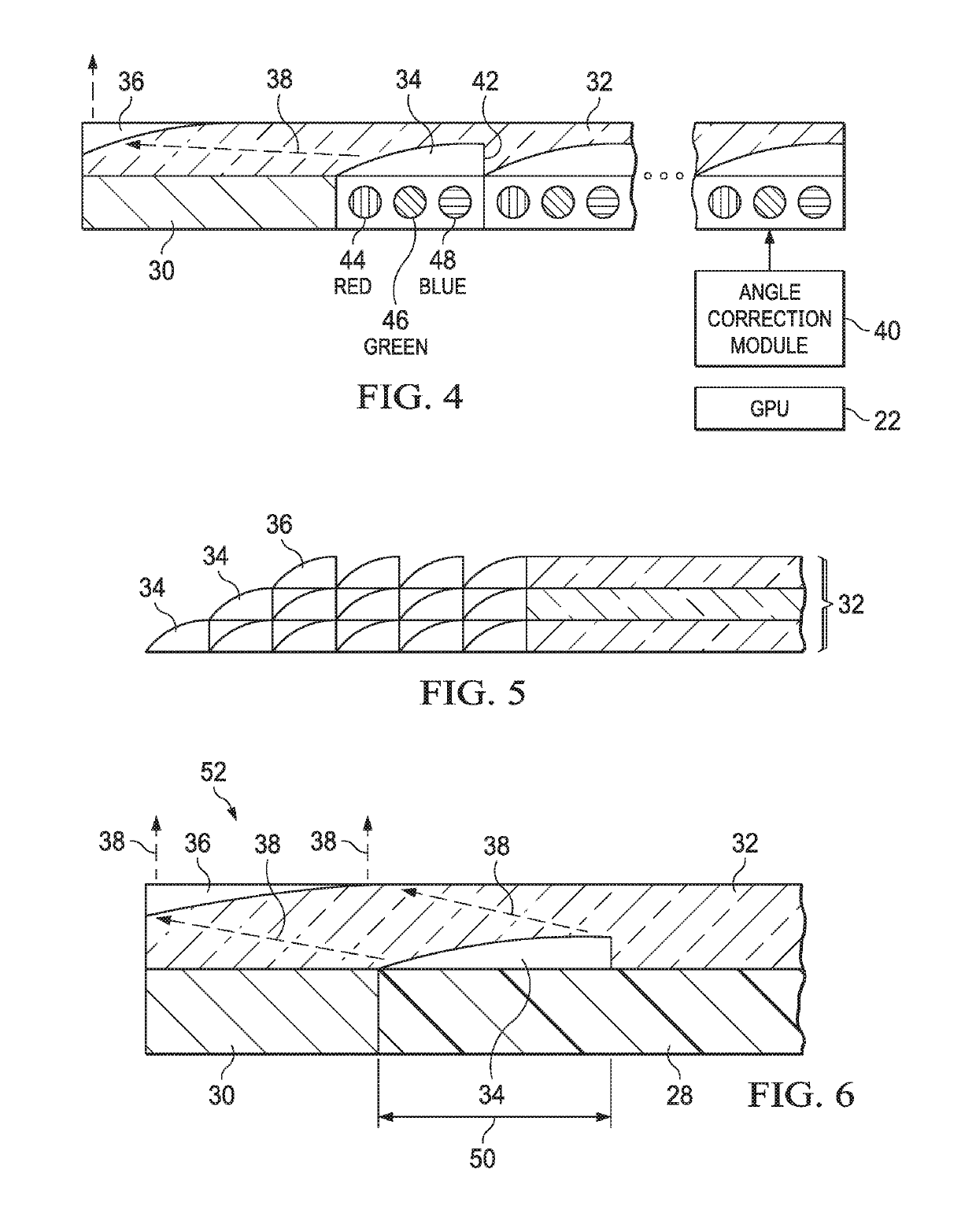

Information Handling System Optical Narrow Bezel

InactiveUS20190108816A1Reduce disadvantagesReduce problemsDigital data processing detailsCathode-ray tube indicatorsDisplay deviceEngineering

An information handling system display presents visual images that extend over a bezel disposed about the display perimeter. A first lens structure integrated in a cover placed over the display redirects light from proceeding out of the cover over the display to instead proceed towards the bezel. A second lens structure integrated in the cover placed over the bezel redirects light proceeding from the first lens structure to proceed out of the cover over the bezel.

Owner:DELL PROD LP

Seeding tool

ActiveUS20050072583A1Protect the endSpace often becomes criticalLiquid fertiliser distributionSoil-working equipmentsMechanical engineeringTungsten carbide

A seeding tool for depositing seeds and fertilizer within a furrow including a knife opener having a liquid wing projecting from the side thereof for providing and maintaining spacing between the seeds and fertilizer. Preferably, the liquid wing is a tungsten carbide insert secured to the side of the knife opener, and has a wing shaped structure which is shaped and sized to space the fertilizer apart from the seeds, to protect the end of the tube from which fertilizer is dispensed, and to present a small leading surface which displaces the soil easily and presents minimal resistance. Preferably, the largest, side surface of the liquid wing insert is inclined toward the side of the knife opener from a widest lower, rear member adjacent the end of the fertilizer tube to a narrower top, front member near a leading end of the knife opener.

Owner:KENNAMETAL INC +1

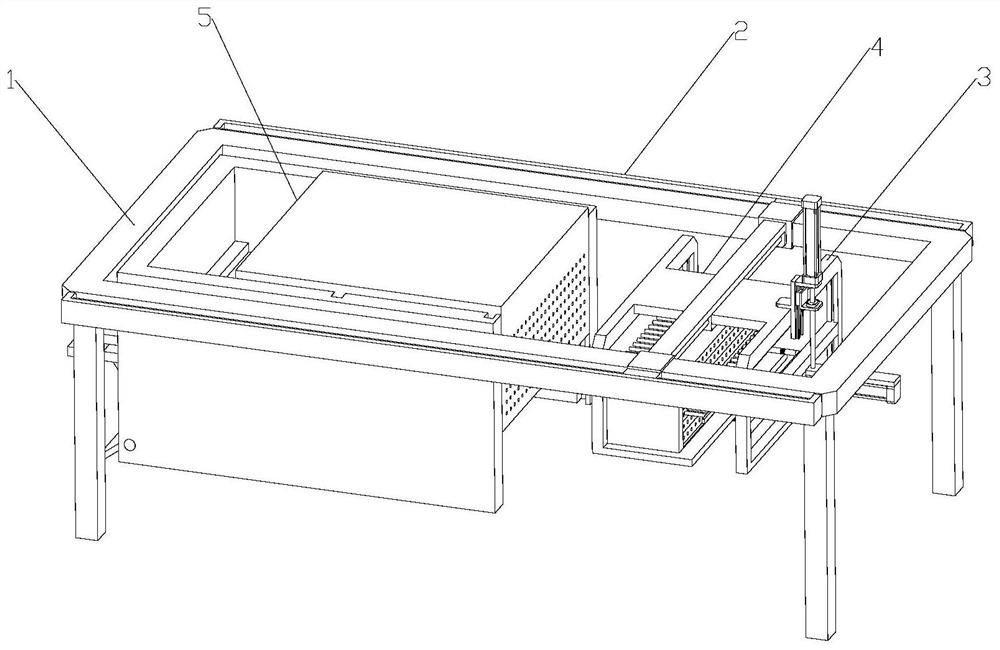

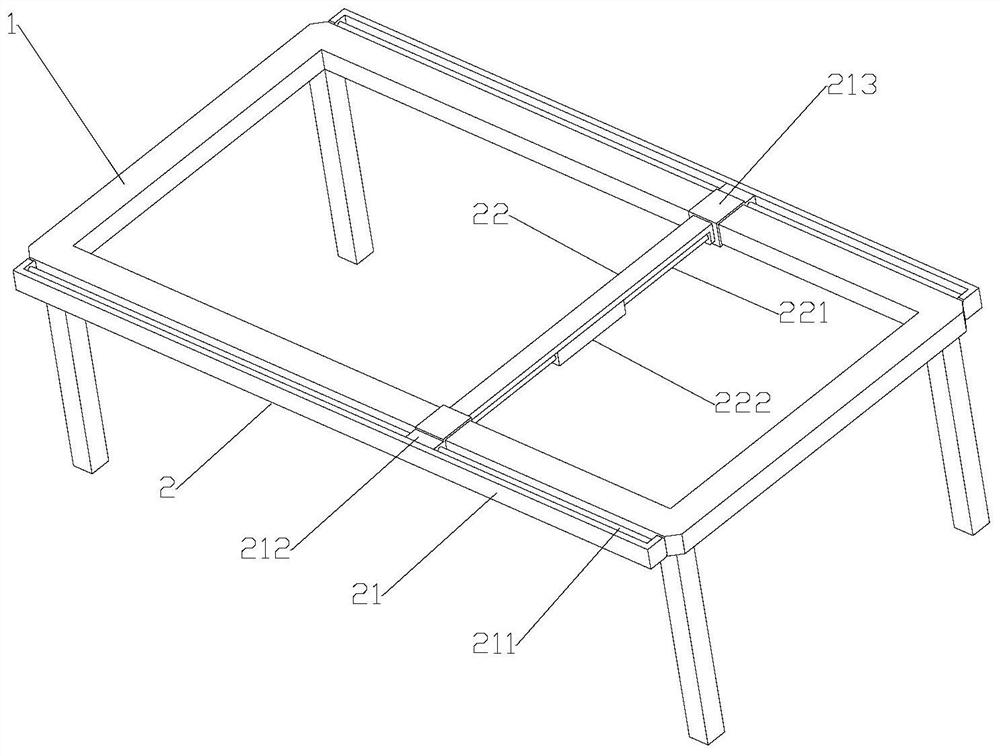

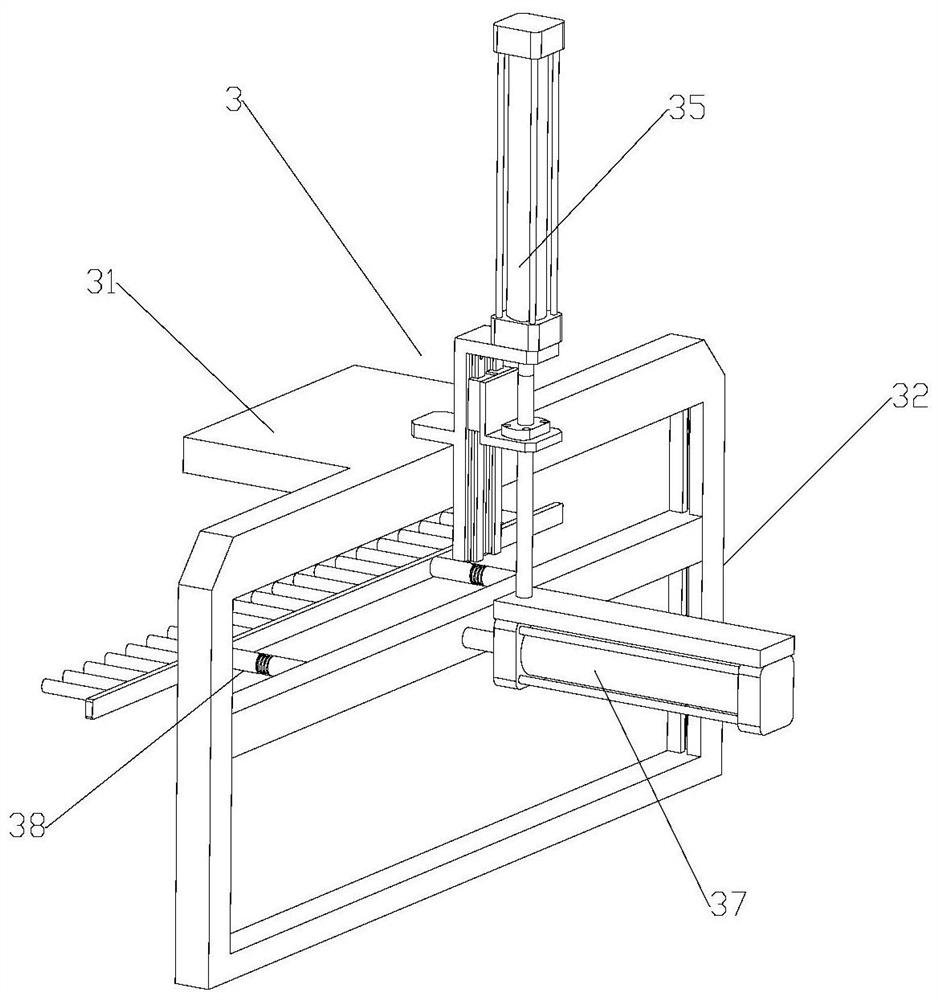

Diode packaging feeding device

ActiveCN112061759AEasy to adjust up and down positionEasy alignmentConveyor partsElectric machineryMaterials science

The invention discloses a diode packaging feeding device, and relates to the field of diode feeding. A feeding driving piece comprises a first pneumatic cylinder and a second pneumatic cylinder, the vertical and horizontal positions of a feeding driving rod can be adjusted conveniently, the feeding driving rod can be conveniently aligned with the ends of diodes, and the ends of the diodes can be effectively protected through the arrangement of a buffer component and are prevented from being damaged by pressure. A plurality of layers of diodes are arranged in a feeding fixing piece, when the height of the diodes is inconsistent with that of the feeding driving rod, the height of the diodes is adjusted through driving of a motor and meshing of a gear and a rack, the diodes and the feeding driving rod are made to be horizontal, and one layer of diodes can be pushed at a time. During use, a whole feeding die frame rotates around a first rotating rod, the bottom of one end of the feeding die frame presses a second rotating rod downwards, at the moment, a first rotating plate is lifted upwards, a movable plate penetrates through a penetrating groove, the movable plate is attached to thefeeding die frame, it can be guaranteed that the feeding die frame is in a horizontal state, and feeding precision is guaranteed.

Owner:广东铖电微电子有限公司

Systems and Methods for Protecting a Cut End of an Electrical Conductor

InactiveUS20160013604A1Protect the endConnection end capsConnection formation by deformationSufficient timeBiomedical engineering

Systems and methods for protecting a cut end of an electrical conductor via the use of an end cap and an end cap attachment apparatus. The end cap attachment apparatus easily and quickly heat shrinks the end cap onto the electrical conductor, thereby sealing the end. The system comprises a heat-shrinkable end cap and an end cap installation apparatus. The end cap is placed over the cut end of electrical conductor. The apparatus comprises an inner heating chamber controlled through a control panel. The end cap installation apparatus applies heat evenly and rapidly to shrink and seal the end cap onto the cut end. The method comprises placing the cut end of the electrical conductor surrounded by an unshrunken end cap into the heating inner chamber for a sufficient time to shrink the end cap onto the end of the electrical conductor and then removing.

Owner:SUPER SEAL

Method and apparatus for surgical clamping

InactiveUS8348984B2Considerable stabilityEasy to handleSnap fastenersSuture equipmentsLeft halfSurgical Clamps

The invention concerns a clamp, especially a surgical clamp, with a left clamp half to receive a left half of a breastbone during a surgical procedure, a right clamp half to receive a right half of the breastbone, as well as a first toothed rod and a detent mechanism engaging in the first toothed rod to secure the left clamp half at a distance from the right clamp half, wherein the detent mechanism engaging in the first toothed rod has a detent region extending at least from the left clamp half to the right clamp half.

Owner:MAX HAUSER SUDDEUTE CHIRURGIEMECHANIK +1

Manufacturing method of galvanized water pipe internally coated with stainless steel

InactiveCN109764192AAchieve high-strength compositeEasy to operateNon-macromolecular adhesive additivesMacromolecular adhesive additivesMetallurgyAdhesive

The invention discloses a manufacturing method of a galvanized water pipe internally coated with stainless steel. The method comprises the following steps that A, the surface of the galvanized water pipe is polished, the burrs are removed, then the galvanized water pipe is flushed with the clean water repeatedly, and then the galvanized water pipe is dried at the ventilation place; B, the surfaceof a stainless steel pipe is polished and immersed into a decontaminant to remove the surface oil stain, and then the stainless steel pipe is flushed with the clean water repeatedly and dried; C, a player of high-strength adhesive is sprayed on the inner wall of the galvanized water pipe and the outer wall of the stainless steel pipe; D, the stainless steel pipe is sleeved with the galvanized water pipe; E, the stainless steel pipe is sleeved with a hole expansion mold for pipe expansion of the stainless steel pipe, so that the outer wall of the stainless steel pipe is completely stuck to theinner wall of the galvanized water pipe through the adhesive; and F, finally, the end of stainless steel pipe exposed out of the two ends of the galvanized water pipe are bent by using a bending process, and then the end of the galvanized water pipe is fixed. The manufacturing method is simple in operation, the high-strength composite of the galvanized water pipe and the stainless steel pipe can be achieved, and the service life of the galvanized water pipe is prolonged.

Owner:江苏振栋精密材料科技有限公司

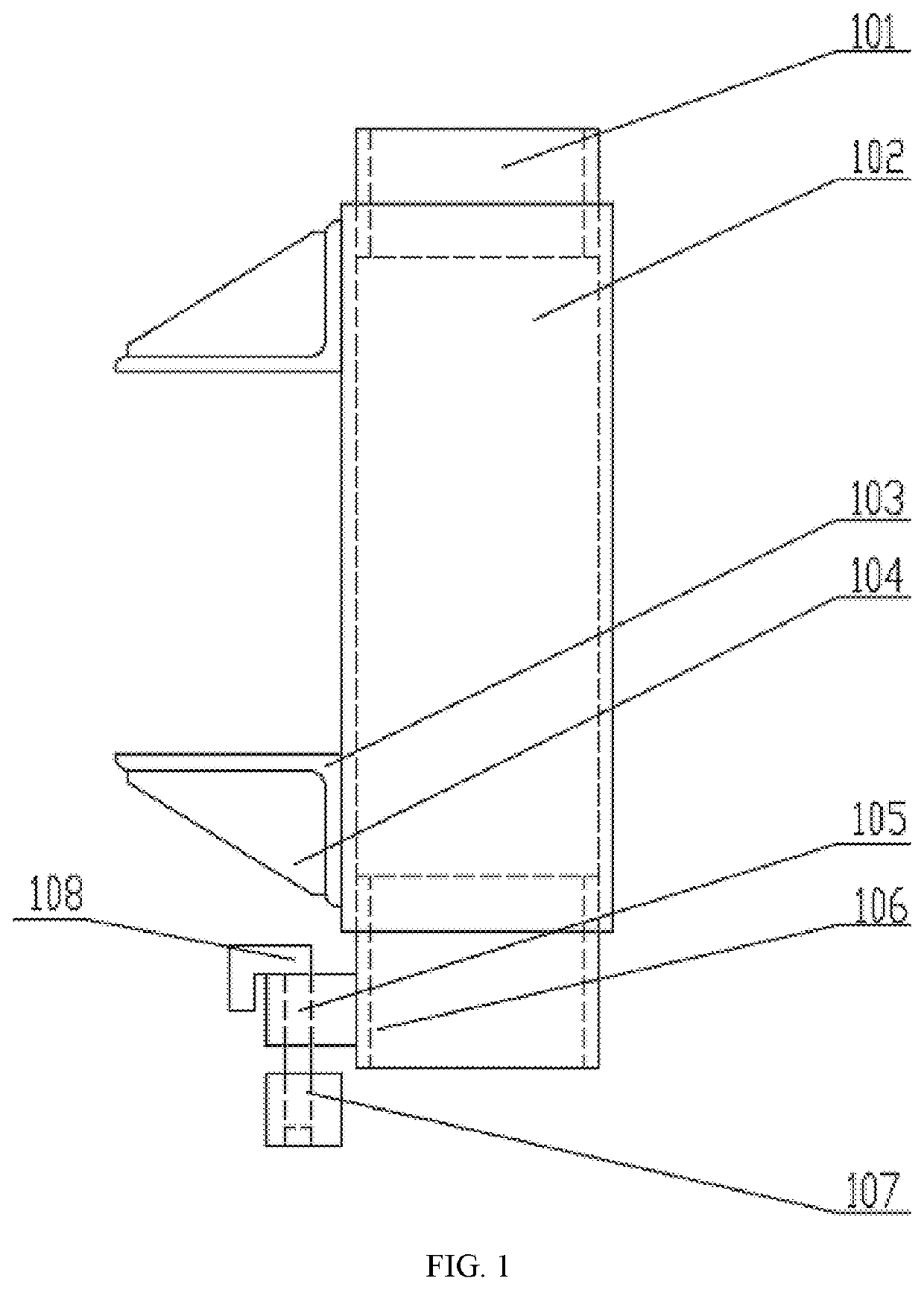

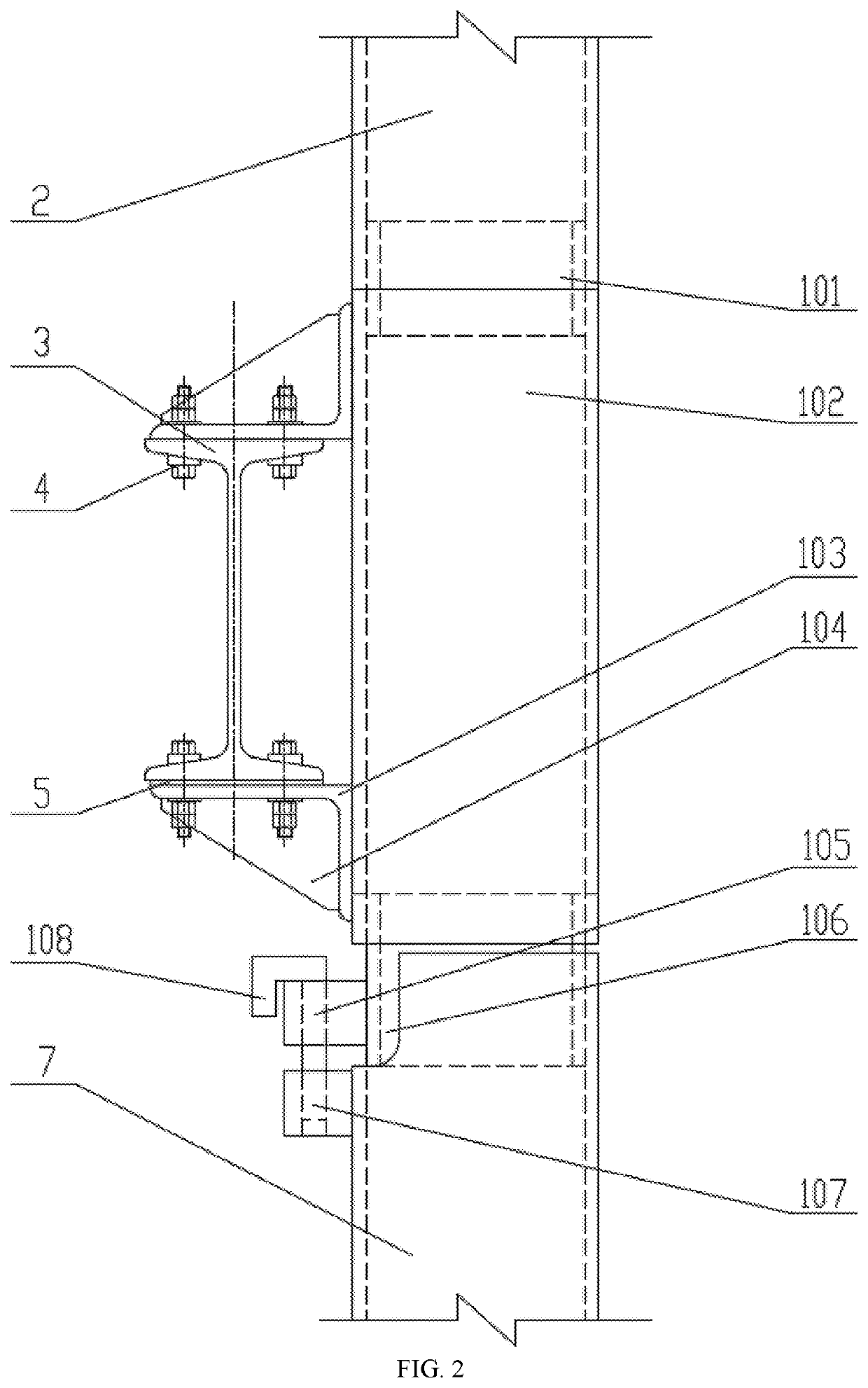

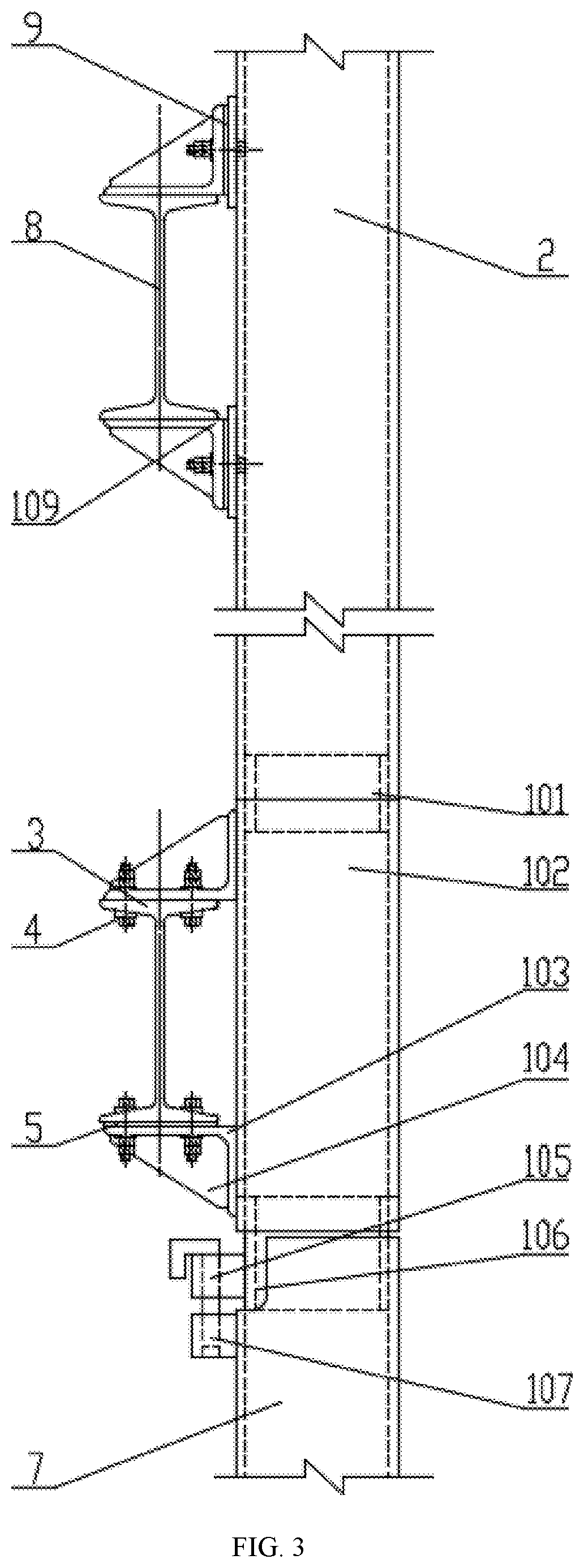

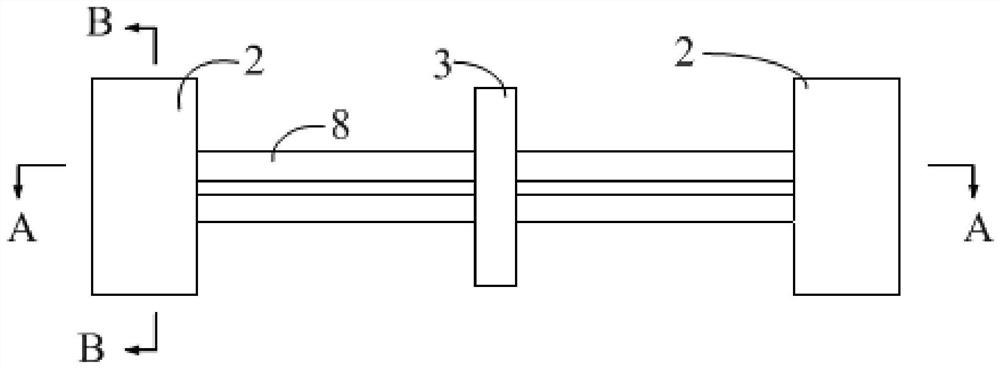

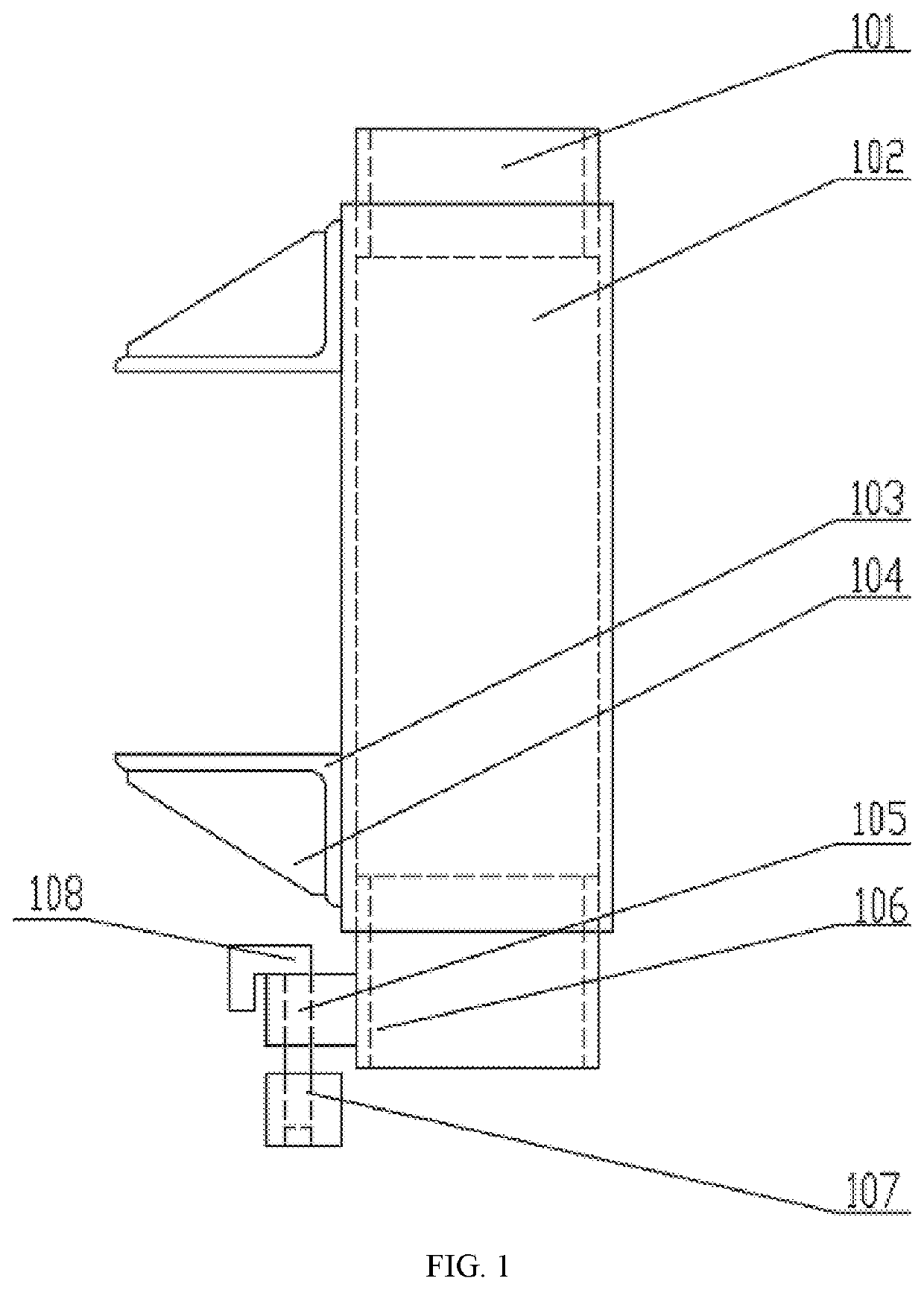

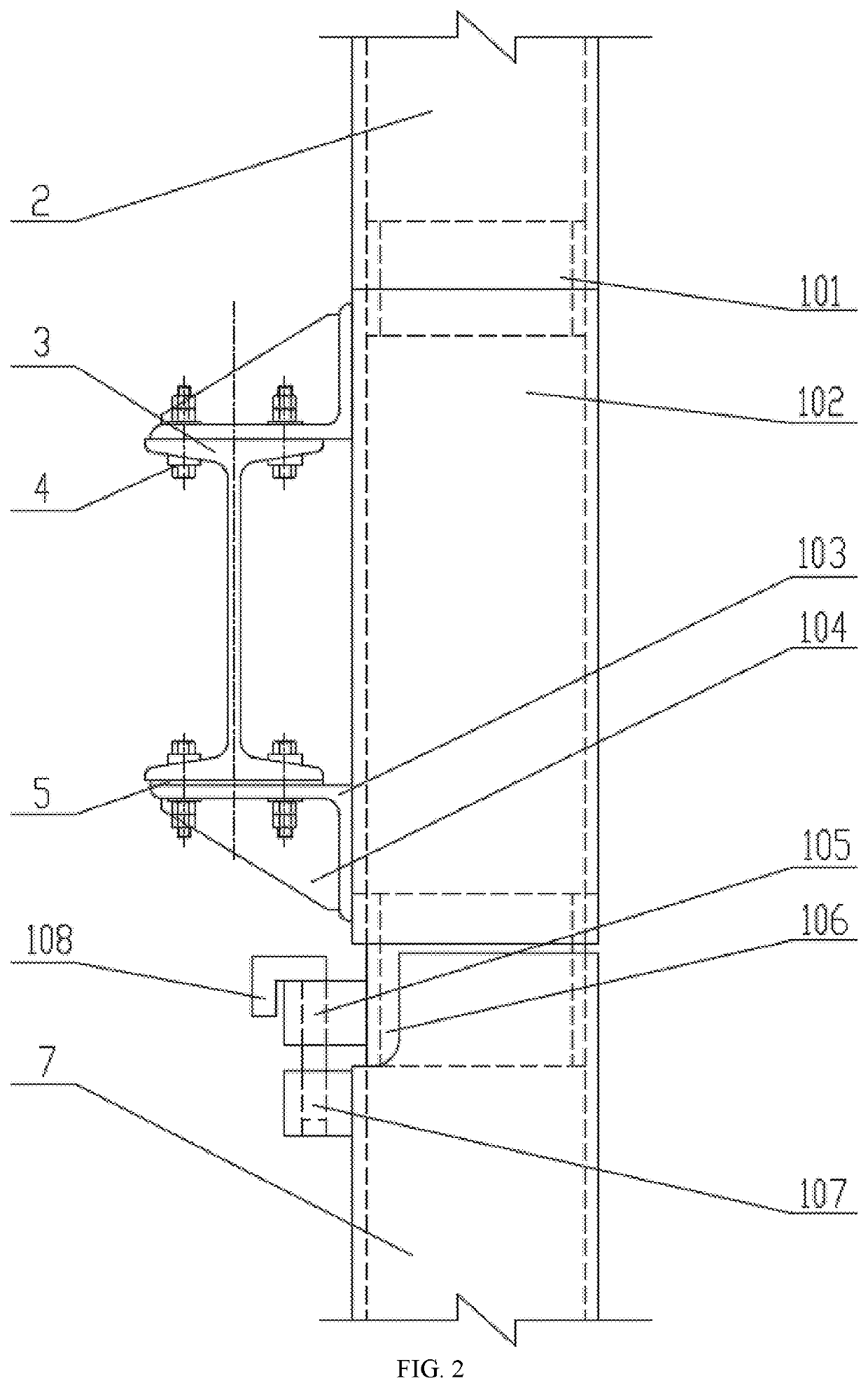

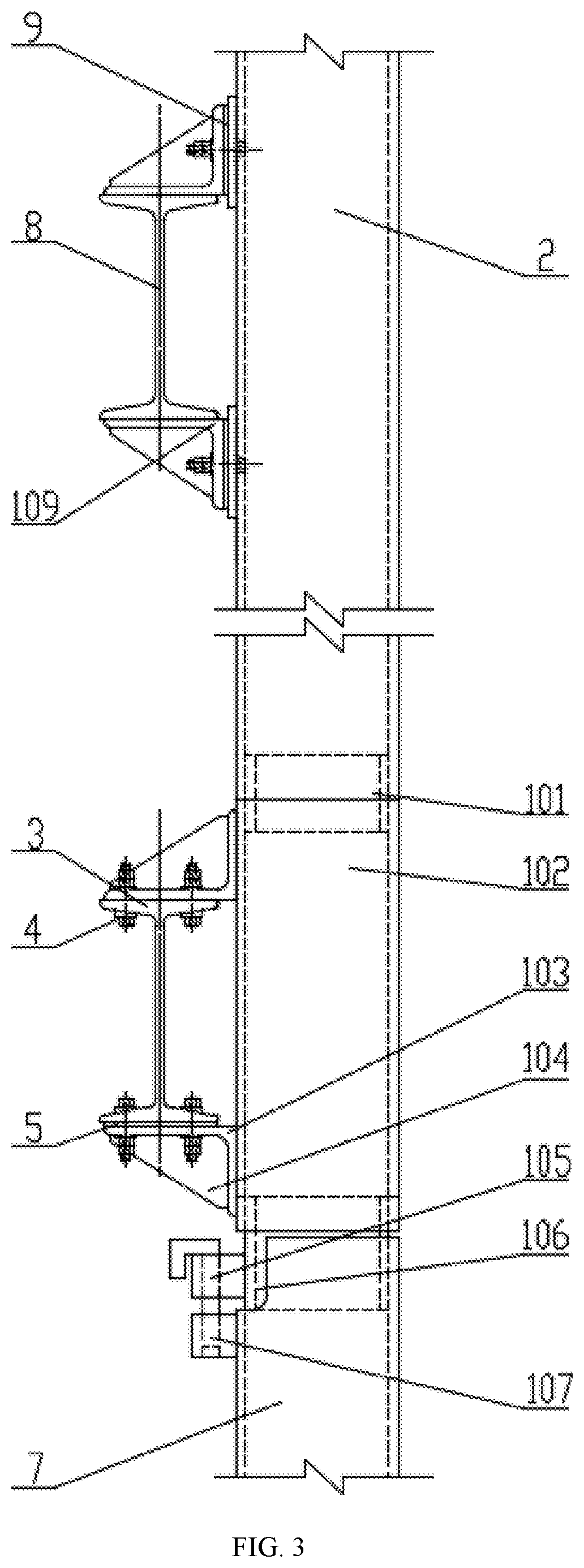

Cageway connecting device and connecting method thereof

ActiveUS20200232321A1Improve device stabilityImproves stability and firmnessElevatorsMine liftsEngineeringMechanical engineering

Owner:HEFEI DESIGN & RES INST OF COAL IND CO LTD +2

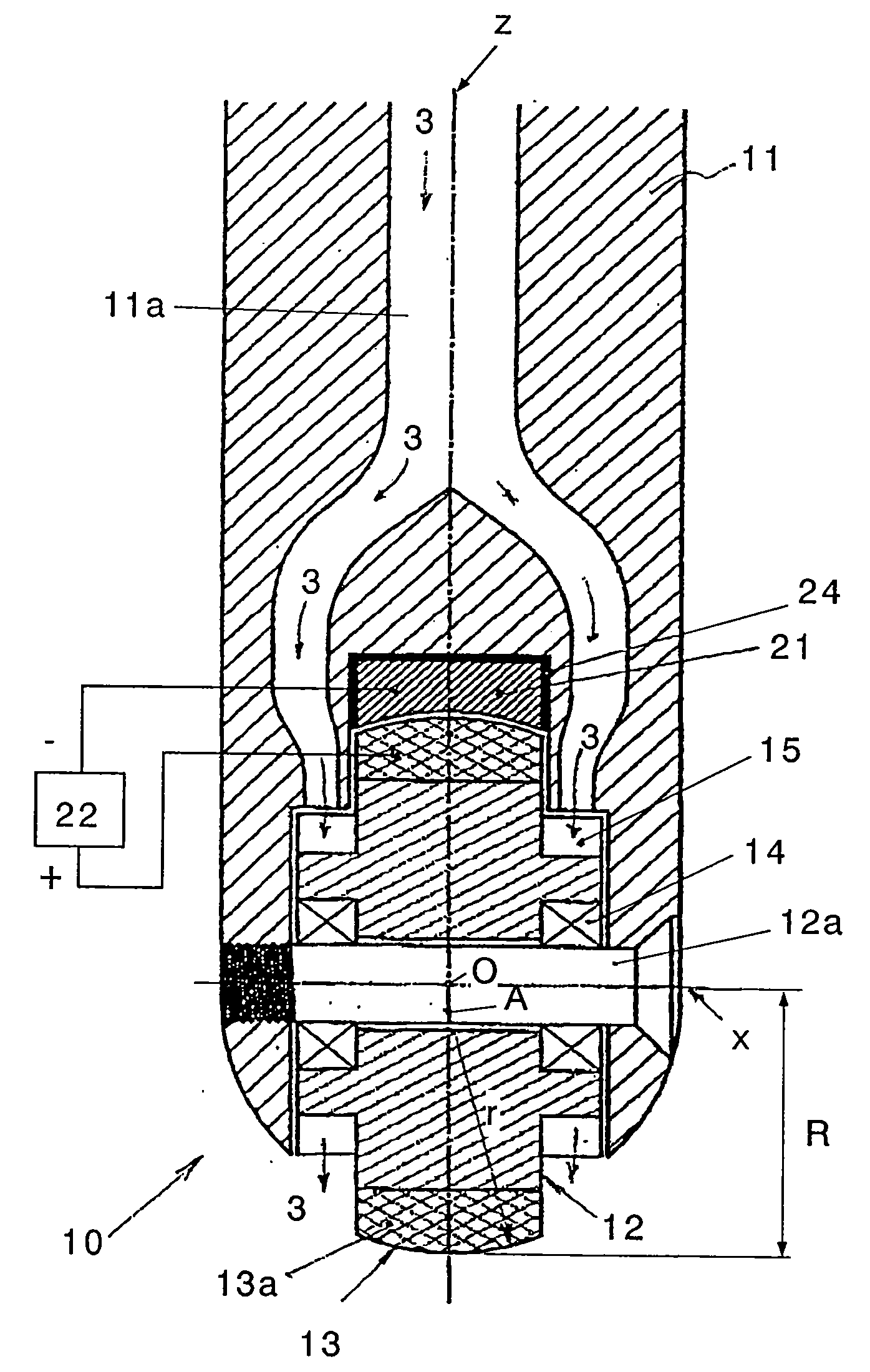

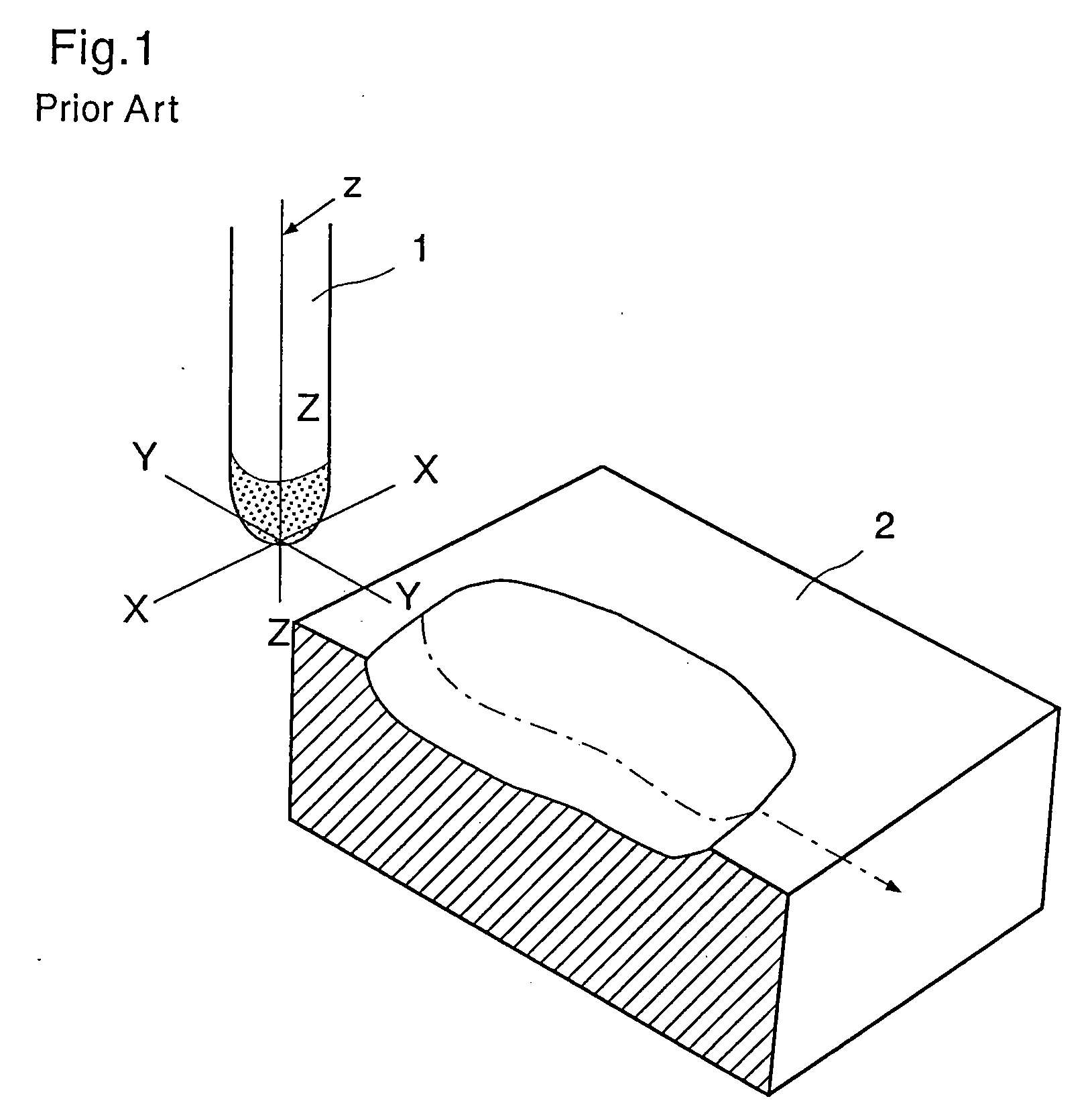

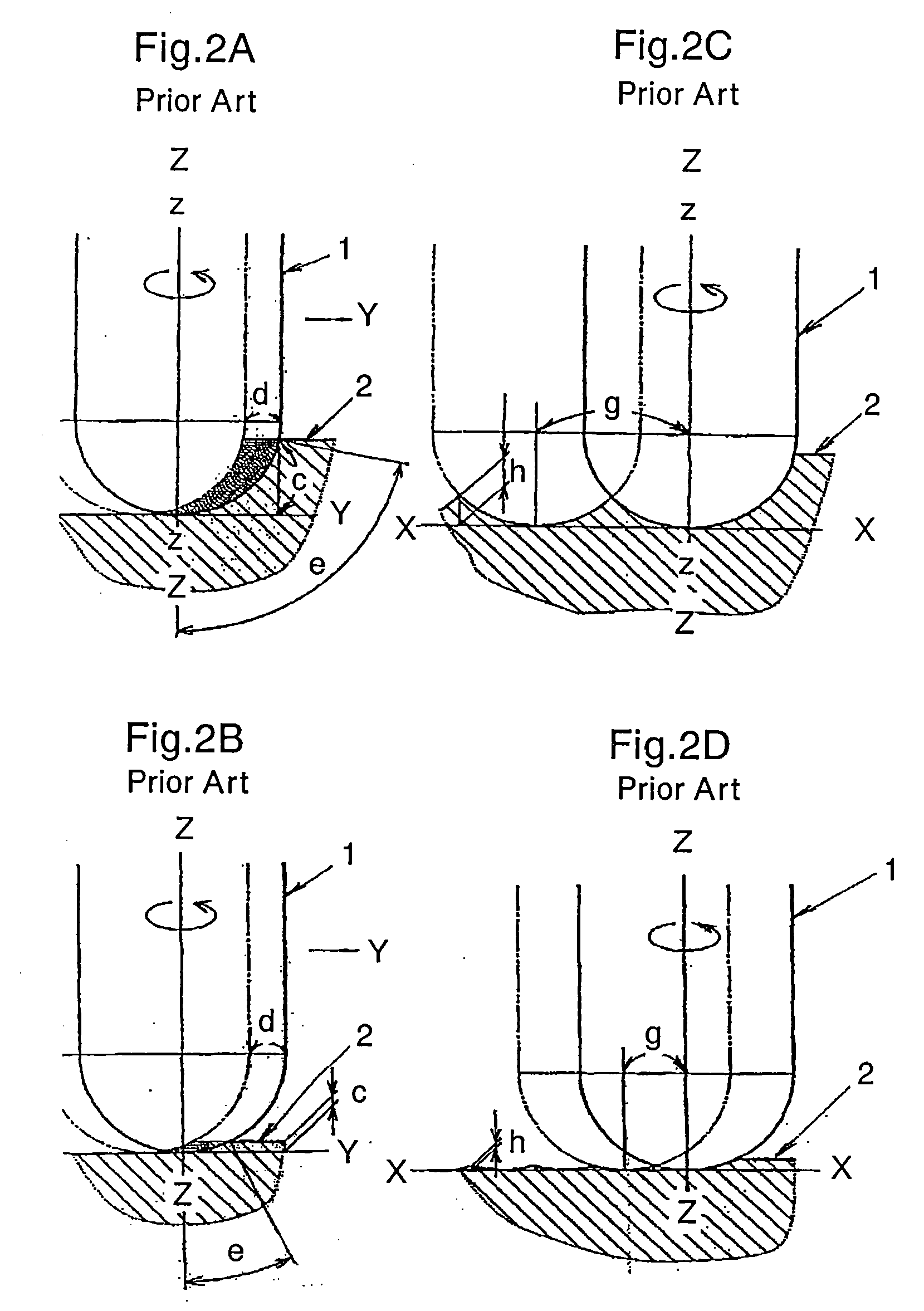

Free curved surface precision machining tool

InactiveUS20070004318A1Efficient precision machiningMaintain clarityMilling cuttersGrinding feed controlMachined surfaceConvex side

A free curved surface precision machining tool for precision-machining a surface to be machined with the lower end in contact therewith by rotation around an axis x. It includes a drum-shaped tool having a rotation axis x orthogonal to the axis z and rotationally driven around the rotation axis x. This drum-shaped tool has a convex machining surface in the form of an arcuate rotary body obtained by rotating an arc of a radius r with the center at the intersection O between the axis z and the rotation axis x around the rotation axis x. The convex machining surface contacts the surface to be machined to precision-machine the latter, while the convex machining surface is rotated around the orthogonal axis x so as to disperse the machining position of the convex machining surface.

Owner:RIKEN +2

Shock-absorbing and cushioning packaging device

ActiveCN108328055BImprove shock absorption and cushioning effectGuaranteed shock absorptionRigid containersDamagable goods packagingEngineeringMechanical engineering

Owner:SHENZHEN S F TAISEN HLDG (GRP) CO LTD

Cageway connecting device and connecting method thereof

ActiveUS11199091B2Firmly connectedProtect the endElevatorsMine liftsMechanical engineeringGeneral surgery

Owner:HEFEI DESIGN & RES INST OF COAL IND CO LTD +2

Shock absorbing and buffering packaging device

ActiveCN108328055AImprove shock absorption and cushioning effectGuaranteed shock absorptionRigid containersDamagable goods packagingEngineering

Owner:SHENZHEN S F TAISEN HLDG (GRP) CO LTD

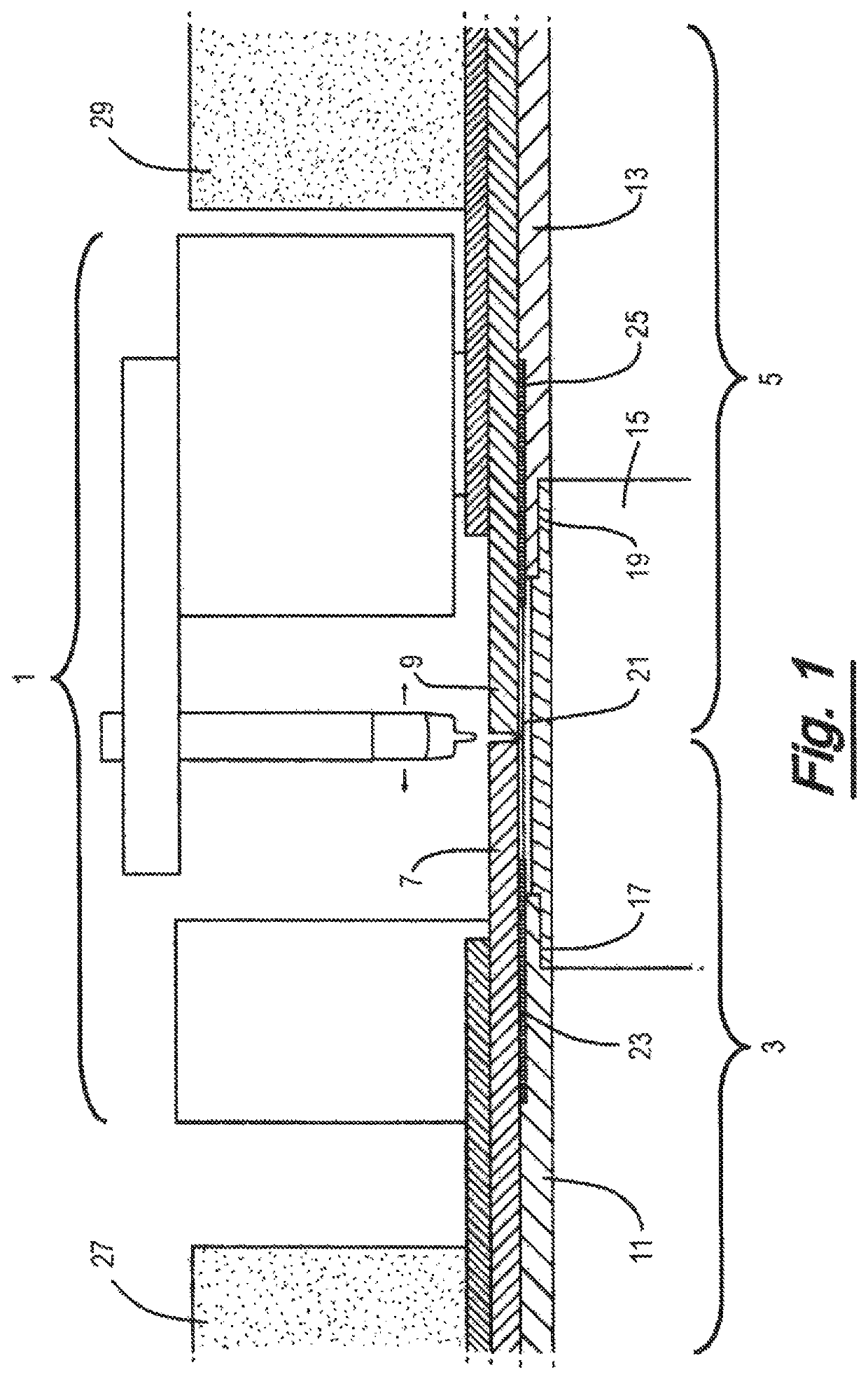

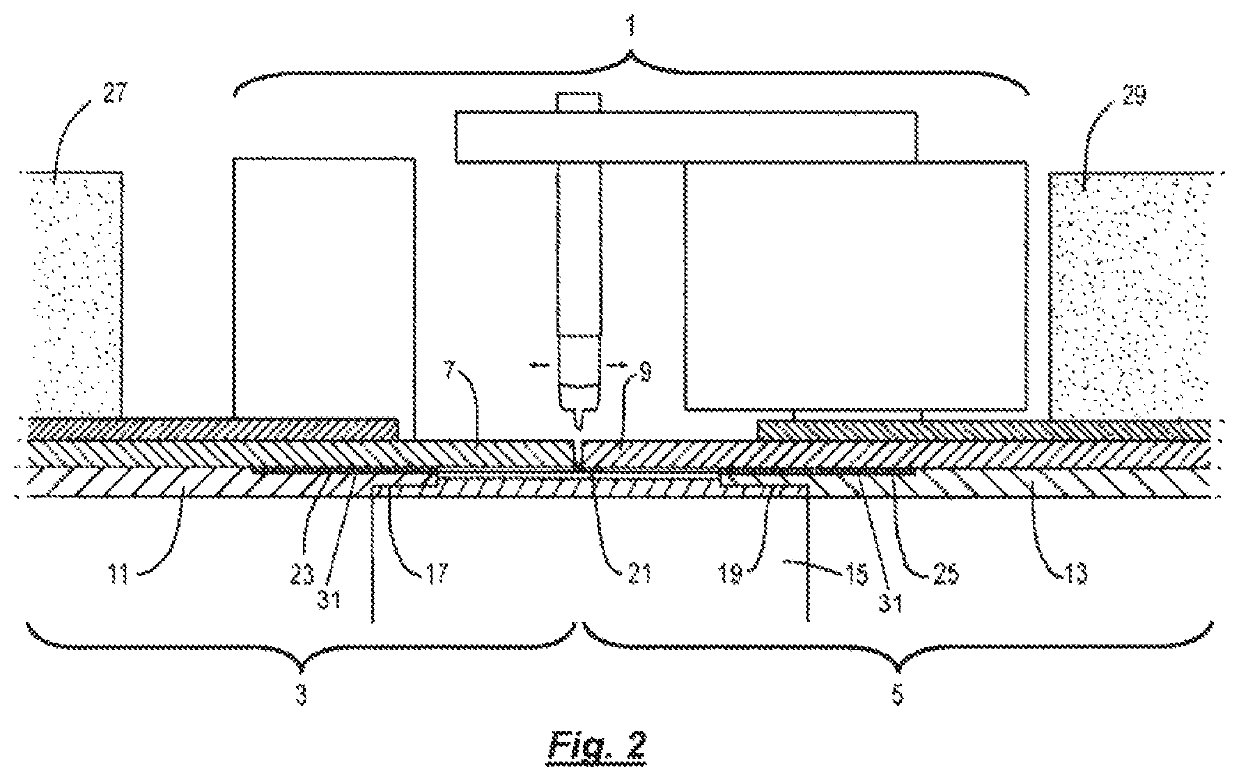

Joining lined pipe sections

ActiveUS11047513B2Reduce the overall diameterProtect the endPipe laying and repairThermal insulationEngineeringPipe

In order to reduce or remove the potential risk of heat damage in the absence of cooling jackets when joining lined pipe sections, each lined pipe section is provided with an insulatory sleeve which is disposed between the host pipe and the respective liner. The sleeves provide discrete thermal protection to the ends of the liners and, where applicable, electrofusion welds between an electrofusion fitting and the liners. The sleeves are first located in the ends of the host pipes which are then lined by drawing the liners through the host pipes via a reduction die to reduce their external diameter. The liners are then reverted towards their original dimensions resulting in a tight fitting against the internal surface of the host pipes and of the insulatory sleeves thereby compressing the insulation material.

Owner:PIONEER LINING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com