Manufacturing method of galvanized water pipe internally coated with stainless steel

A technology for stainless steel pipes and manufacturing methods, which is applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., which can solve the problems of poor mechanical strength of plastic pipes, affect the bonding strength, and damage the galvanized layer, etc., so that it is not easy to crack and environmentally friendly. Excellent performance and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

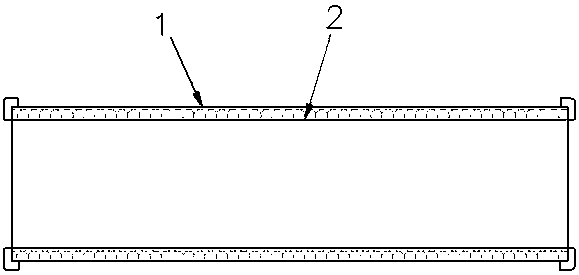

[0021] see figure 1 , the present invention provides a technical solution: a method for manufacturing a galvanized water pipe covered with stainless steel, comprising the following steps:

[0022] A. Grind the surface of the galvanized water pipe 1, rinse it repeatedly with clean water after removing the burrs, and then dry it in a ventilated place to ensure that the surface of the galvanized water pipe is clean and improve the subsequent bonding strength;

[0023] B. After polishing the surface of the stainless steel pipe 2, immerse it in a detergent to remove surface oil stains, then rinse it repeatedly with clean water and then dry it to ensure that the surface of the stainless steel pipe is clean and improve the subsequent bonding strength;

[0024] C. Spray a layer of high-strength adhesive on the inner wall of the galvanized water pipe and the outer wall of the stainless steel pipe;

[0025] D. Then put the galvanized water pipe on the outside of the stainless steel pip...

Embodiment 2

[0030] A method for manufacturing a galvanized water pipe covered with stainless steel, comprising the following steps:

[0031] A. Grind the surface of the galvanized water pipe 1, rinse it repeatedly with clean water after removing the burrs, and then dry it in a ventilated place to ensure that the surface of the galvanized water pipe is clean and improve the subsequent bonding strength;

[0032] B. After polishing the surface of the stainless steel pipe 2, immerse it in a detergent to remove surface oil stains, then rinse it repeatedly with clean water and then dry it to ensure that the surface of the stainless steel pipe is clean and improve the subsequent bonding strength;

[0033] C. Spray a layer of high-strength adhesive on the inner wall of the galvanized water pipe and the outer wall of the stainless steel pipe;

[0034] D. Then put the galvanized water pipe on the outside of the stainless steel pipe;

[0035] E. After that, put the stainless steel pipe into the rea...

Embodiment 3

[0039] A method for manufacturing a galvanized water pipe covered with stainless steel, comprising the following steps:

[0040] A. Grind the surface of the galvanized water pipe 1, rinse it repeatedly with clean water after removing the burrs, and then dry it in a ventilated place to ensure that the surface of the galvanized water pipe is clean and improve the subsequent bonding strength;

[0041] B. After polishing the surface of the stainless steel pipe 2, immerse it in a detergent to remove surface oil stains, then rinse it repeatedly with clean water and then dry it to ensure that the surface of the stainless steel pipe is clean and improve the subsequent bonding strength;

[0042] C. Spray a layer of high-strength adhesive on the inner wall of the galvanized water pipe and the outer wall of the stainless steel pipe;

[0043] D. Then put the galvanized water pipe on the outside of the stainless steel pipe;

[0044] E. After that, put the stainless steel pipe into the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com