Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Positioning method is reliable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ion thruster beam test system based on Faraday probe array

ActiveCN105116436ALarge amount of data informationRealize positioning installationX/gamma/cosmic radiation measurmentElectricityIon current

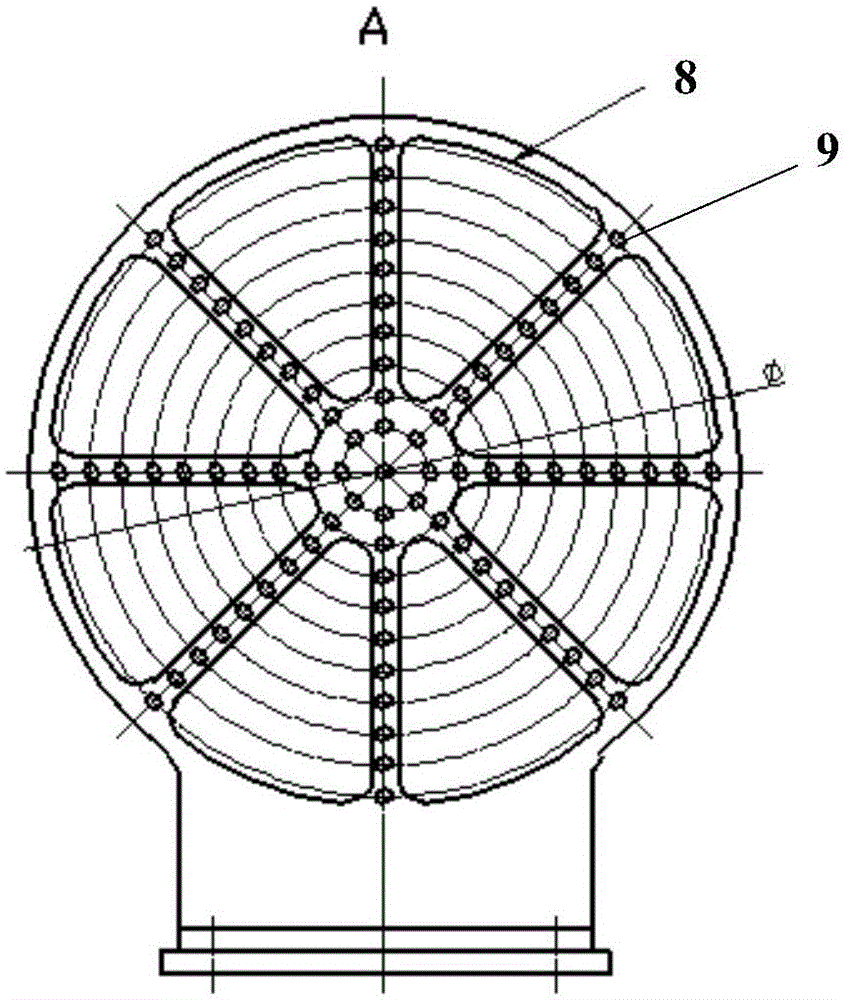

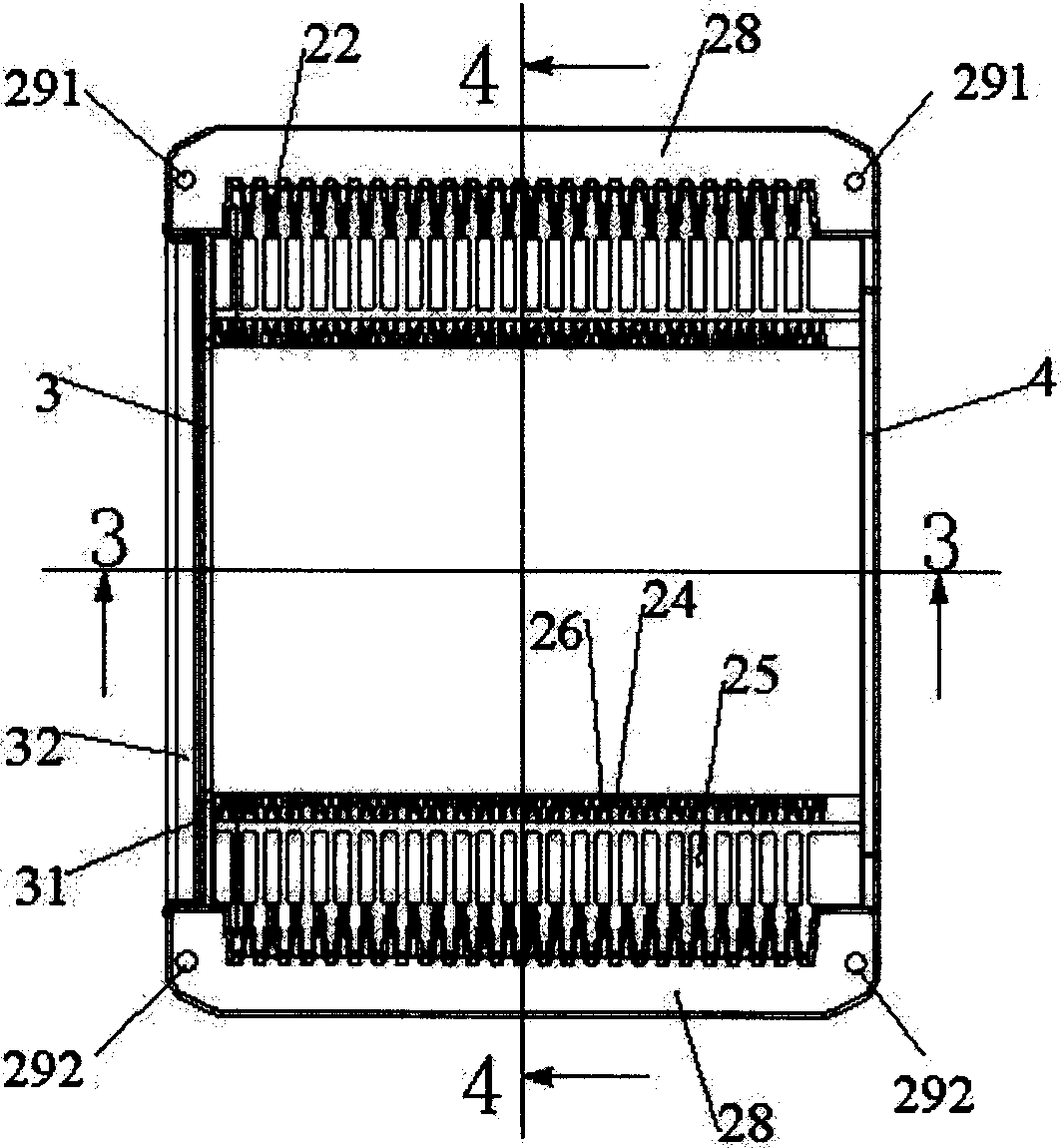

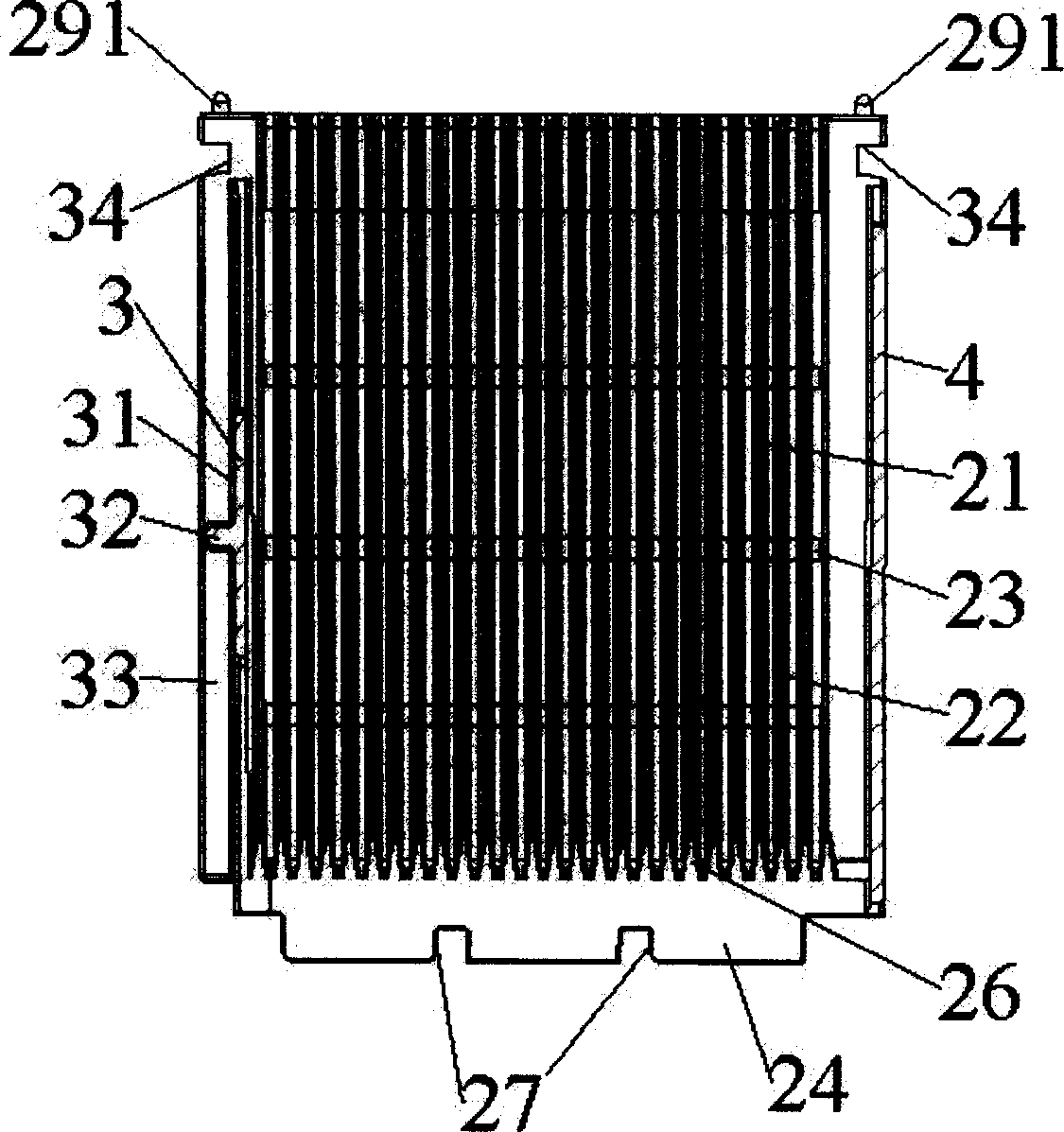

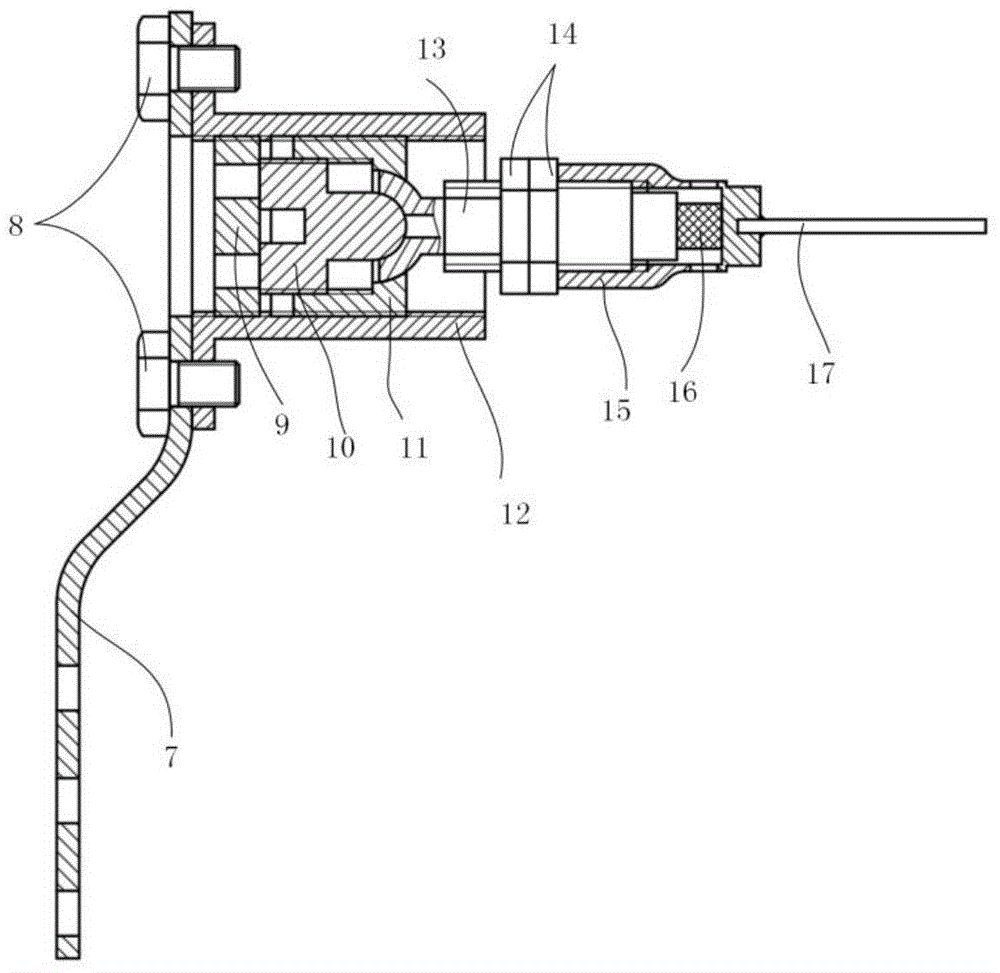

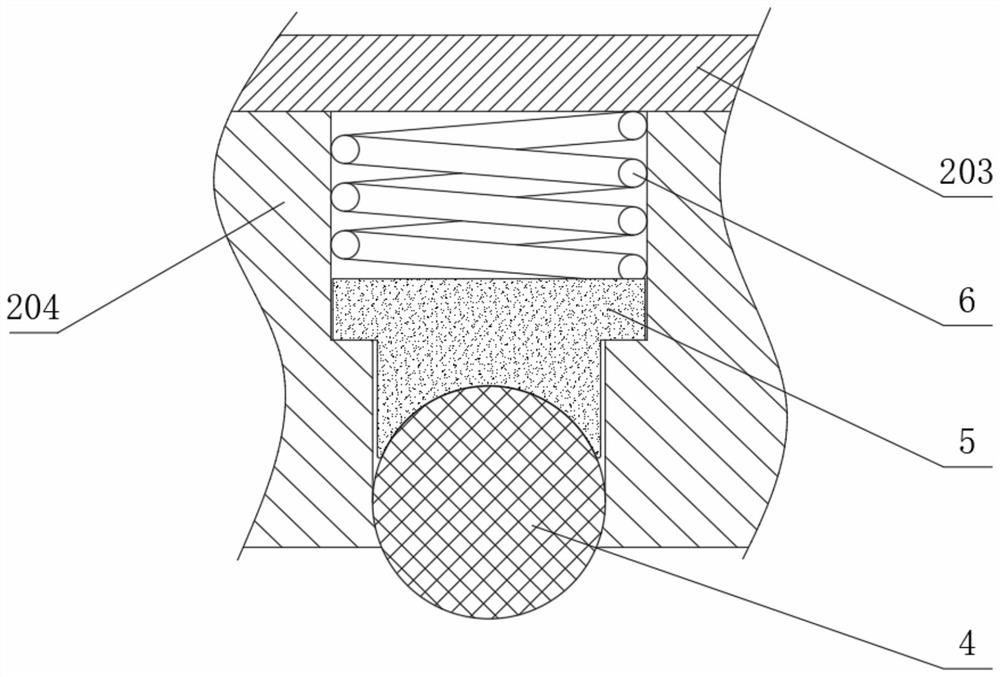

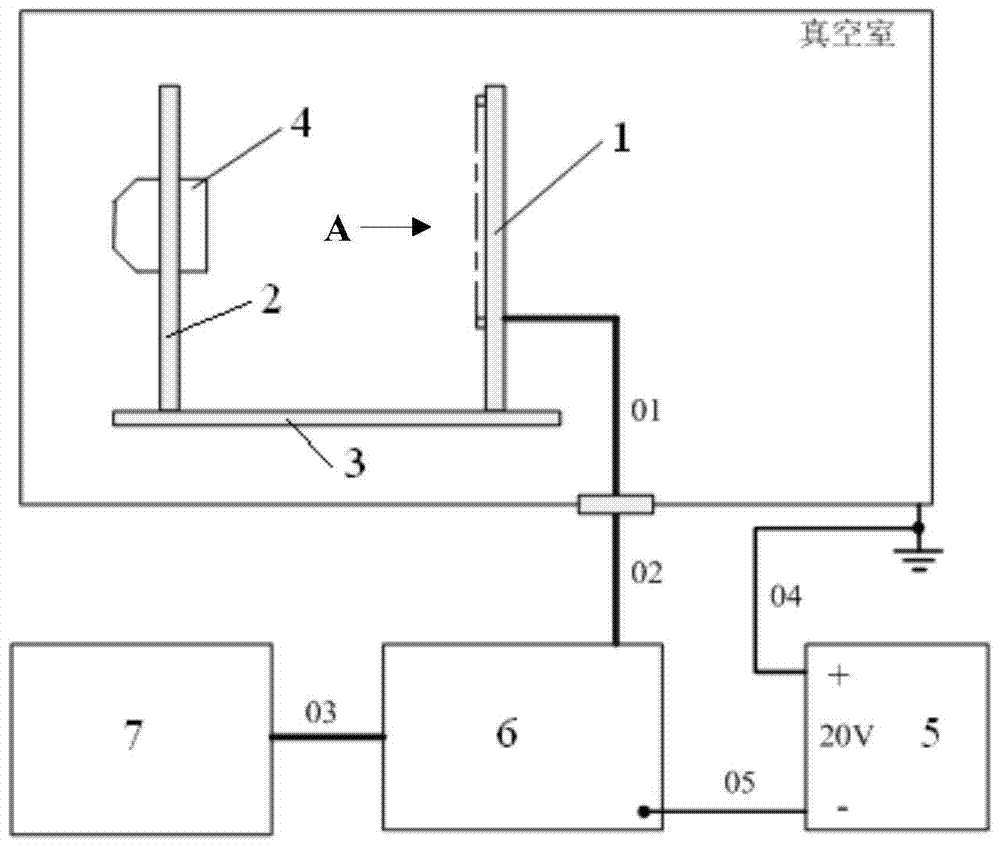

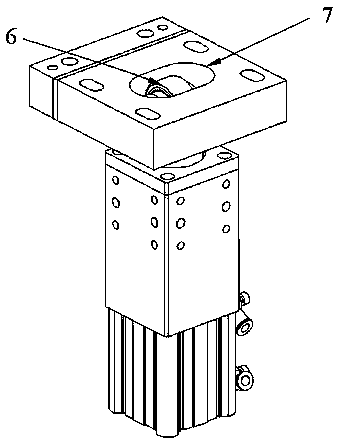

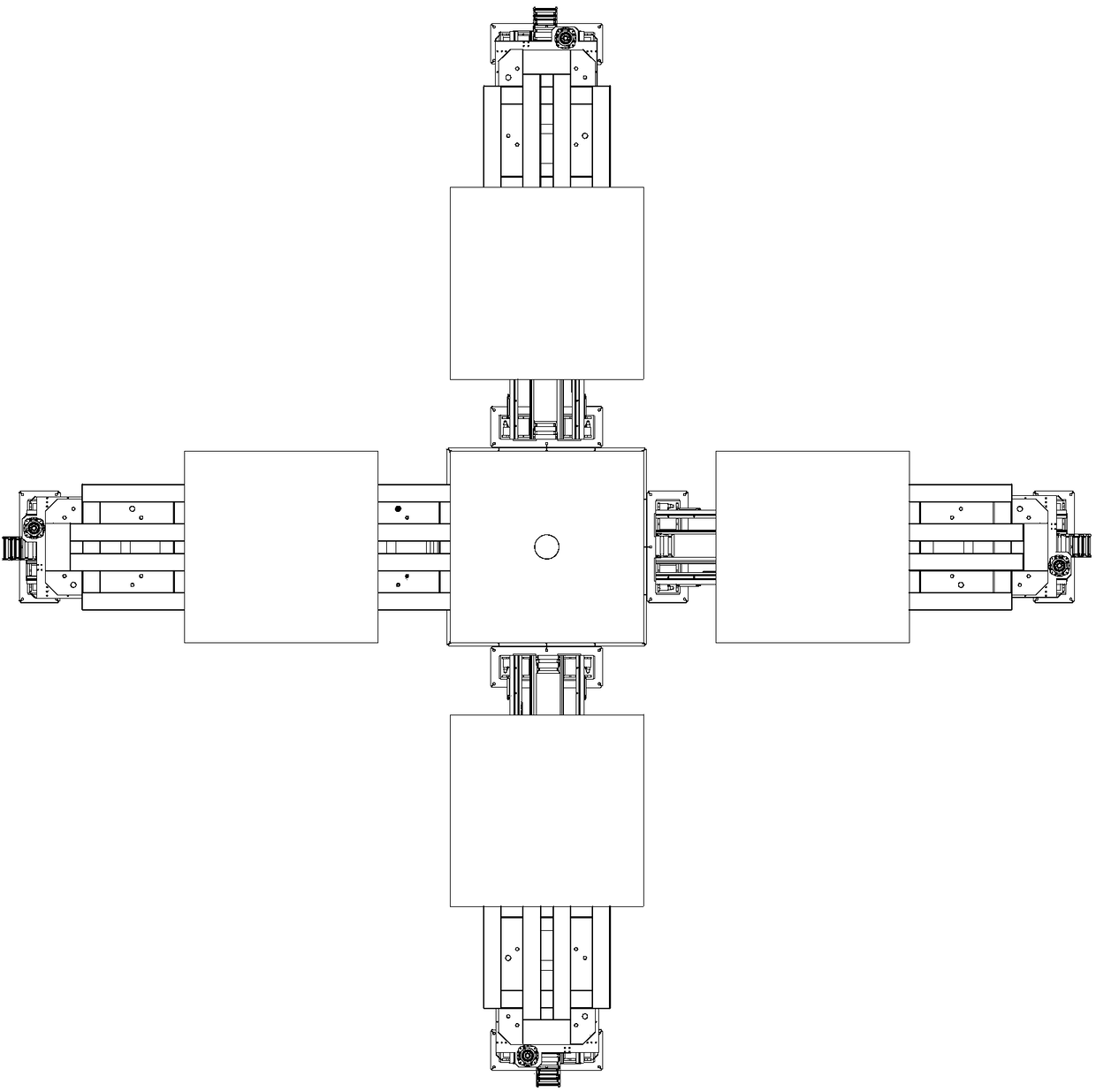

The present invention discloses an ion thruster beam test system based on a Faraday probe array. According to the present invention, the Faraday probes are arranged in a surface array manner, all probe test signals are acquired synchronously, the data information amount is large, and the whole test and the data processing can be finished usually in only several minutes. A shielding outer sleeve is arranged at the outer side of an ion current catch tray of each Faraday probe and is used to shield the stray ions flying to the side surface of the ion current catch tray, thereby guaranteeing that the ions are only collected on the right side of the ion current catch tray. The shielding outer sleeve is directly and electrically connected with a disc-type metal support by the metal contact, so that a bias voltage can be supplied to the disc-type metal support by just one conducting wire, and the biggest advantages of the mode are that: the number of the probe leads is reduced substantially, the structure is simplified, and the reliability is improved.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

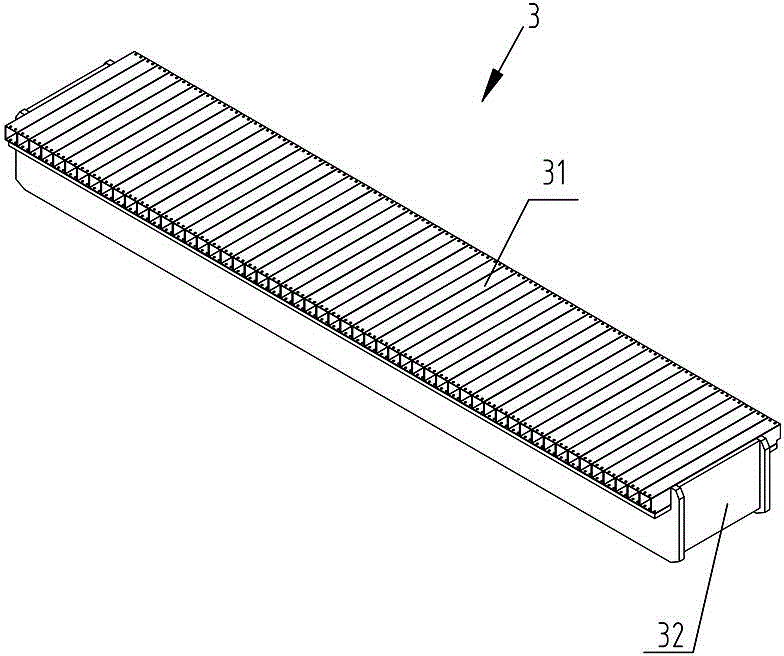

Silicon wafer carrier

InactiveCN1622308ASmooth inflow and outflowClosely connectedSemiconductor/solid-state device manufacturingPolyvinylidene difluorideSolar cell

The present invention relates to container for bearing silicon slice, such as silicon slice for solar cell. The silicon slice bearer can wear acid and alkali washing solution under certain temperature for long time, and has certain rigidity, precise external size and strict weight for the requirement of silicon slice producing line and washing apparatus. Structurally, the silicon slice bearer is one case with opened top and bottom, two flat inclined side walls with inside toothed bars arranged in certain intervals, one H-shaped end wall and one plate end wall. Each of the side walls has three outside horizontal beams, conic leg, horizontal bottom gaps and conic teeth, two positioning slots and square notch for clamping silicon slice protecting bars. The container is made with PVDF and through injection molding.

Owner:BEIJING PLASTICS RES INST

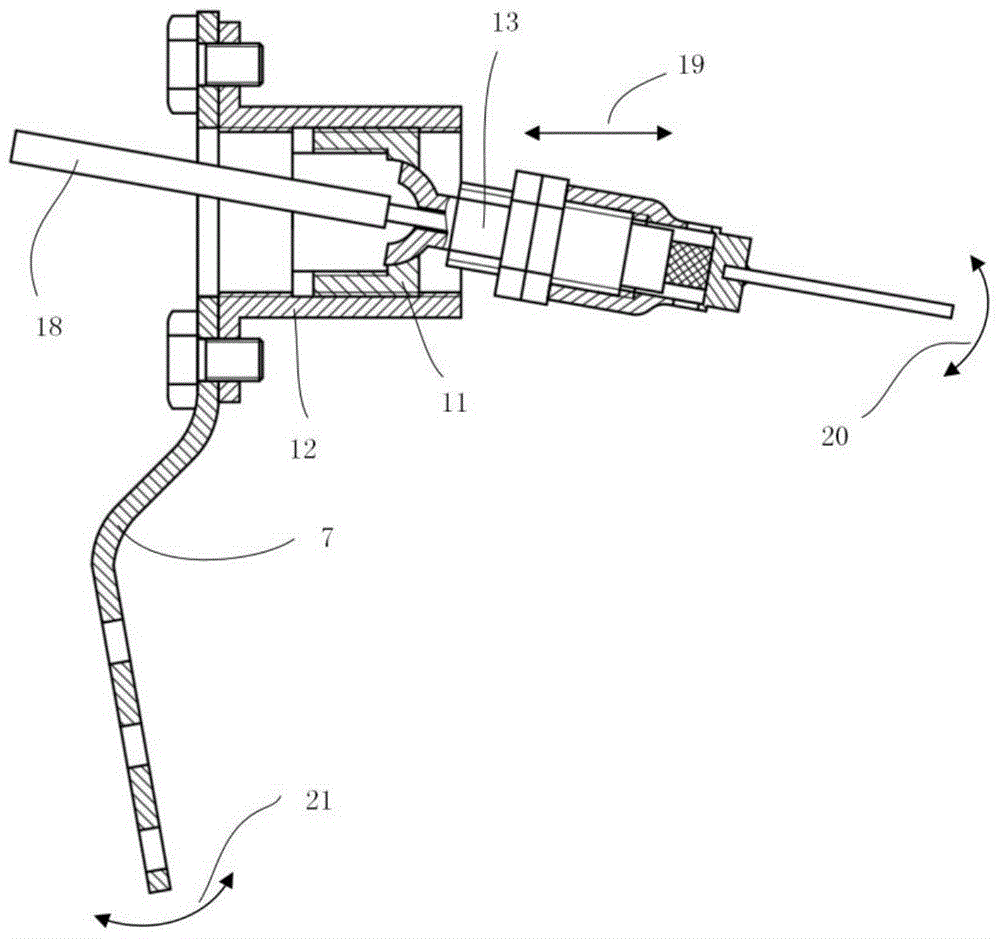

Hearing compensation actuator capable of bidirectional positioning

InactiveCN104902422AMeet the requirements of individual differencesLarge displacement outputDeaf-aid setsCouplingHearing aid

Disclosed is a hearing compensation actuator capable of bidirectional positioning. The actuator comprises a lead wire, an embedded member, a fixation member and a coupling rod. The actuator employs a piezoelectric stack as a vibration element, is miniaturized in structure, is fixed at a scull through the fixation member and provides a supporting condition for the embedded member; the embedded member realizes axial positioning through threaded connection and realizes radial positioning through spherical pair connection, and a bidirectional positioning function facilitates operative implantation; and the length of the coupling rod is adjustable, and the coupling rod can act on different ear auditory ossicles and meets the treatment requirement for sensorineural and conductive hearing damage. The hearing compensation actuator provided by the invention is reasonable in design and simple in structure, thereby being applied to optimized design of a hearing-aid apparatus.

Owner:SHANGHAI JIAO TONG UNIV

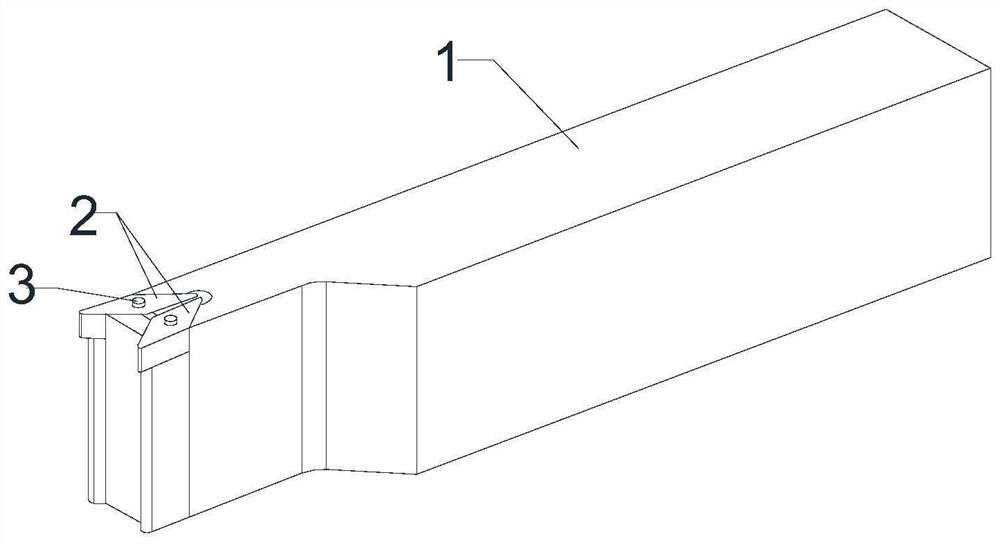

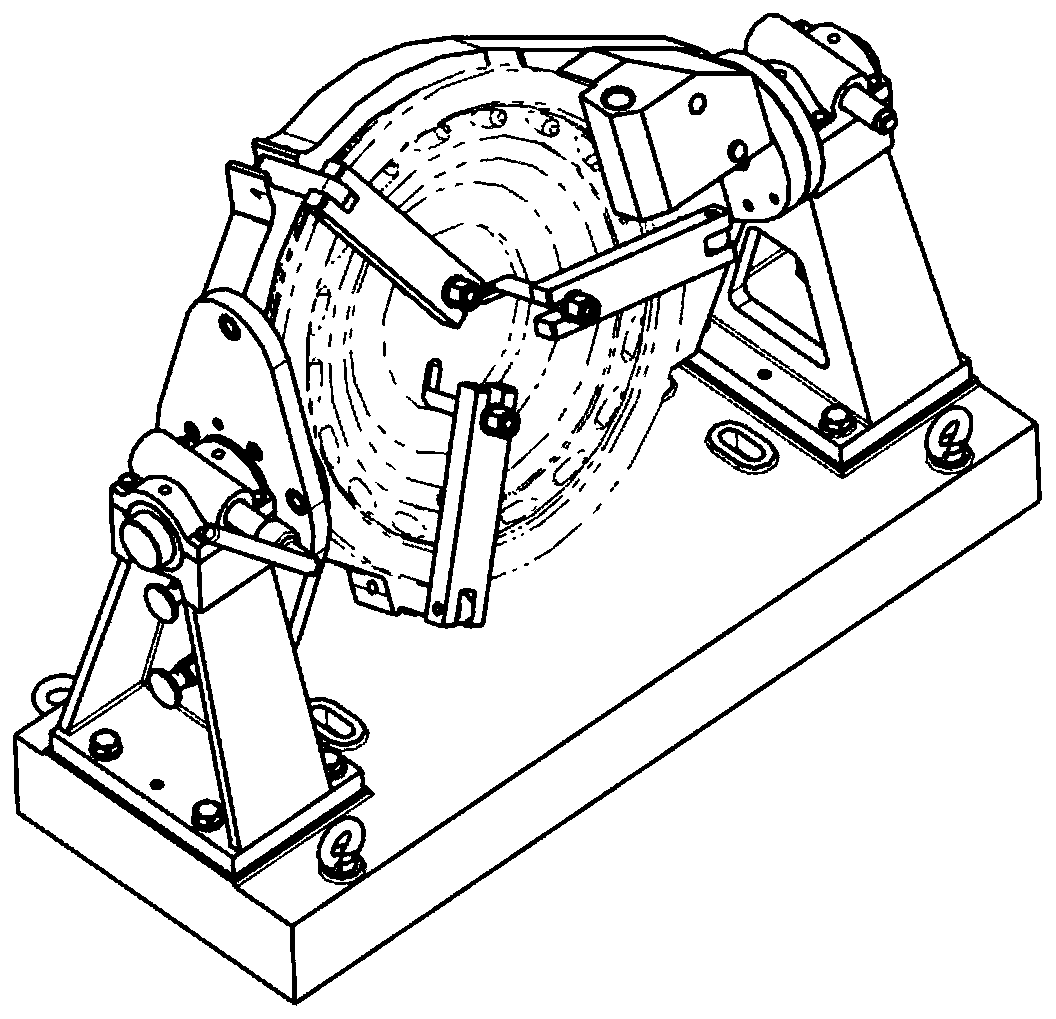

Diagonal hole drilling mold for nozzle ring of engine

ActiveCN109079204APositioning method is reliableAchieve positioningPrecision positioning equipmentPositioning apparatusNozzle

The invention relates to a diagonal hole drilling mold for a nozzle ring of an engine. The diagonal hole drilling mold comprises a base, supports, a positioner, a mandrel, a bearing, a tangential clamping cover, a bearing cap, an indexing plate and the like. The left and right supports are fixed to the base through pins and bolts, the bearing is mounted in center holes in the upper ends of the left and right supports, the mandrel is connected with a positioning plate through the pins and the bolts and is placed in bearing holes at two ends separately, the bearing cap is located at the upper end of a bracket, the tangential clamping cover is located between the bearing cap and the bearing, and one end of the tangential clamping cover is connected with a handle nut. The mandrel is locked during work. The indexing plate is connected with a lug at the left side of the positioning plate through the pins and the bolts, and a special angle is formed between the indexing plate and the lug. When a drilling mold works, a diagonal hole is processed from the front face and the back face by positioning the drilling mold through positioning holes in two ends of the indexing plate position. Positioning rings and the positioning plate are connected through the pins and the bolts, and the positioning is achieved by the cooperation of an excircle and an inner hole of the nozzle ring. The diagonal hole drilling mold has the advantages of being high in positioning precision, convenient to operate, high in practicality and the like, and can be used for processing complex diagonal holes.

Owner:XIAN SPACE ENGINE CO LTD

Wireless sensor network node positioning method of ecological niche grey wolf optimization DV-Hop algorithm

InactiveCN110062327AImprove search capabilitiesPositioning method is reliableNetwork topologiesBroadcast service distributionWireless sensor networkingWireless sensor network

The invention discloses a wireless sensor network node positioning method of an ecological niche grey wolf optimization DV-Hop algorithm. The method comprises: a beacon node broadcasting a beacon to anetwork, the beacon comprising position information and hop count information of the beacon node, and the beacon being spread out in a flooding mode in the network; after obtaining the position information and the hop count, each node estimating the average distance of each hop between the nodes, and then estimating the distance between the beacon nodes; the beacon nodes refining the average distance per hop by using a ecological niche grey wolf optimization algorithm, and changing the fitness value of the beacon nodes by comparing the distances between the beacon nodes with the ecological niche radius; calculating the position of the unknown node through the beacon node, recording the coordinate of the unknown node, and converting the calculated position information of the unknown sensorbeacon node into the position information of the known sensor beacon node. The method has the advantages that the global search capability can be improved, the positioning error is reduced, and the positioning precision is improved.

Owner:SHANGHAI MARITIME UNIVERSITY

Bag supplying and bag feeding device and method for full-automatic vacuum packaging production line

The invention discloses a bag supplying and bag feeding device for a full-automatic vacuum packaging production line. The bag supplying and bag feeding device comprises a bag supplying part and a bagfeeding part; the bag supplying part comprises a machine base and at least one set of bag supplying unit mounted on the machine base, and the bag supplying unit comprises a bag pushing cylinder, a bagpushing plate connected to the bag pushing cylinder, a bag pressing cylinder, a bag pressing plate connected to the bag pressing cylinder and a pair of bag hanging rods. Packaging bags penetrate through the bag hanging rods through handle holes and are limited between the bag pushing plate and the bag pressing plate, the bag pushing plate is driven by the bag pushing cylinder to push the packaging bags on the bag hanging rods to move forward to perform bag feeding, and the bag pressing plate is driven by the bag pressing cylinder to block or leave the front ends of the bag hanging rods to limit the packaging bags on the bag hanging rods or to enable the bag feeding part to take the packaging bags. The bag supplying and bag feeding device for the full-automatic vacuum packaging productionline has the advantages of novel structure, ingenious property, high stability and high precision.

Owner:ZHANGZHOU LIZHAN TECH

Mounting tool and assembling method of array structural permanent magnet

ActiveCN104097174APrecise positioningThe positioning mandrel is positioned accuratelyMetal-working hand toolsEngineeringMagnet

The invention discloses a mounting tool and an assembling method of an array structural permanent magnet. The mounting tool of the array structural permanent magnet comprises a guide sleeve and a pushing piece, wherein the guide sleeve is communicated with a mounting tube of the permanent magnet in a butt joint manner, the pushing piece is used for pressing a permanent magnet block in the guide sleeve into the mounting tube, one end of the pushing piece is sheathed into the guide sleeve and can push the permanent magnet block in the guide sleeve along the length direction of the guide sleeve. The assembling method comprises the steps of communicating the guide sleeve and the mounting tube in the butt joint manner; placing the permanent magnet block into the guide sleeve, and pushing the permanent magnet block into the mounting pipe by the pushing piece. The mounting tool and the assembling method have the advantages that the operation is simple and convenient, safety and reliability are realized, and the permanent magnet block is effectively mounted.

Owner:NAT UNIV OF DEFENSE TECH

A spring-biased pivot arm positioning primary suspension assembly

ActiveCN103600749BPositioning method is reliablePrevent movementAxle-boxes mountingEngineeringMechanical engineering

The invention discloses a spring-biased pivoting arm positioning primary suspension assembly, which includes a frame, an axle box, a primary spring mechanism and a pivoting arm positioning rubber joint, and the frame is provided with a spring for connecting with the primary spring mechanism Plate, one end of the spring in the spring mechanism used to connect with the spring plate is fixedly provided with a top positioning plate, and the top positioning plate is provided with a raised positioning ring and bolt holes for fixed connection with the spring plate, and the spring plate A positioning through hole for the positioning ring to pass through is provided on the top, and a positioning groove adapted to the positioning ring is provided at the position corresponding to the frame and the positioning through hole. The spring positioning method provided in the present invention is more reliable, and through the mutual cooperation of the positioning ring on the top of the spring and the positioning groove provided on the frame, the spring can be effectively prevented from moving in the horizontal and vertical directions, so the spring plate will not be affected by the spring. Driven to produce horizontal and vertical movement, thus effectively avoiding warping of the spring plate.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO LTD

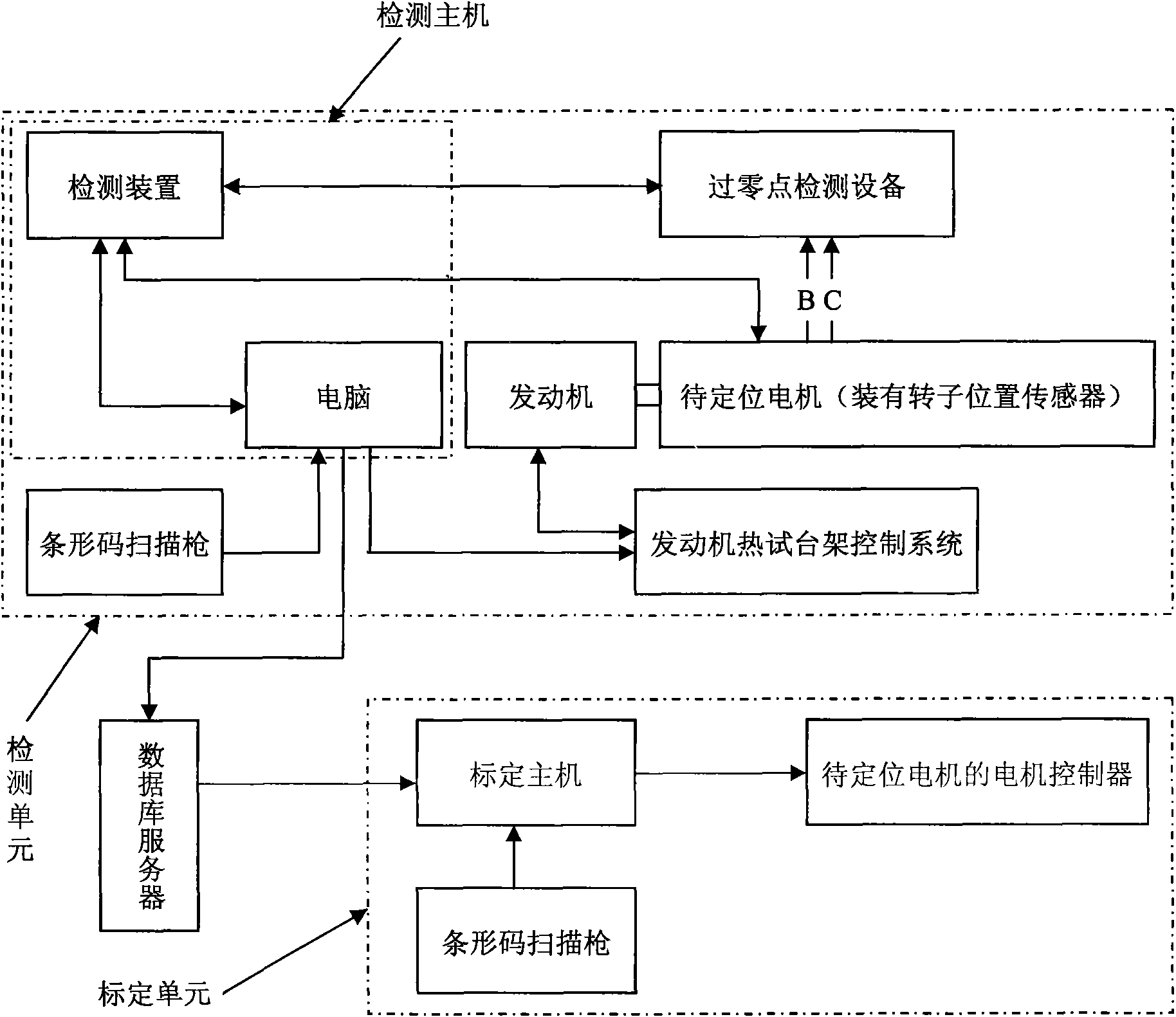

Motor rotor positioning system for hybrid vehicle and positioning method thereof

ActiveCN101594107AFlexible arrangementEliminate manual errorsElectronic commutatorsTesting equipmentZero crossing

The invention aims to provide a motor rotor positioning system for a hybrid vehicle and a positioning method thereof, which are suitable for the characteristics of a vehicle production line. The positioning system consists of a detection unit and a calibration unit, wherein the detection unit comprises a power device capable of driving a motor to be positioned to rotate, a detection host computer, a bar code scanner, a zero crossing detection device and a motor rotor position sensor arranged on the motor to be positioned, and the detection host computer is connected with the power device, the bar code scanner, the zero crossing detection device and the motor rotor position sensor; the calibration unit comprises a bar code scanner and a calibration host computer, and the calibration host computer is connected with a motor controller of the motor to be positioned; and the detection host computer and the calibration host computer are connected with a database server through a network respectively. The detection host computer detects the position angle value of the motor rotor through the zero crossing detection device and the motor rotor position sensor, transmits the position angle value to the calibration host computer, and further writes the position angle value into the motor controller so as to finish the positioning of the motor rotor.

Owner:CHERY AUTOMOBILE CO LTD

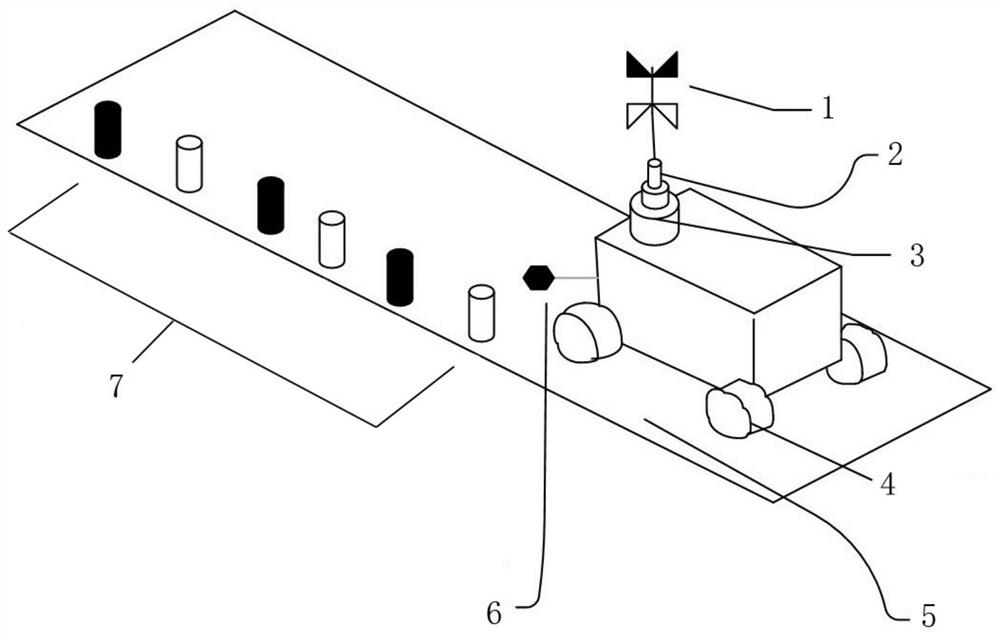

Novel inspection rail robot device

The invention discloses a novel inspection rail robot device. The novel inspection rail robot device comprises a robot system, a rail and a controller, the robot system runs on the rail and comprisesa vehicle frame, a stepping motor, wheels, a rotating mechanism, a camera and a color recognition sensor, the wheels are located below the vehicle frame, the stepping motor drives the wheels to rotatethrough a gear set, the rotating mechanism is fixed above the vehicle frame, the camera is fixed above a steering engine, and the color recognition sensor is fixed in front of the vehicle frame; a plurality of road signs with different colors are arranged on one side of the rail at equal intervals and divide the rail into a plurality of sections which are numbered and stored in the controller; the stepping motor, the rotating mechanism, the color recognition sensor and the camera are connected with the controller; and the controller judges the position of the robot system according to the color recognized by the color recognition sensor and the rotation data of the stepping motor. The inspection rail robot device is simple in structure and capable of achieving the accurate positioning function and improving the accuracy of inspection work.

Owner:XUZHOU NORMAL UNIVERSITY

Novel dual-blade-groove cutting tool

The invention discloses a novel dual-blade-groove cutting tool. The cutting tool comprises a tool bar and two profiling cutting blades; the two profiling cutting blades are installed on a same workingsurface of the end part of the tool bar; a main blade bit of a working end of one of the profiling cutting blades is skew to the left by an angle alpha, and a main blade bit of a working end of the other profiling cutting blade is skew to the right by an angle alpha; and the two profiling cutting blades are symmetrically distributed, and alpha is an acute angle. Compared with a standard groove cutting tool, the contacting area between the cutting tool and a cutting workpiece is reduced in the feeding process along the radial direction, so the radial cutting force is reduced; groove processingis conducted by back-and-forth and layer-by-layer feeding of the cutting tool along the axial direction, so the cutting force generated by processing is mainly axial and the radial cutting force is greatly reduced; and the problem of vibration in the process of processing is solved, the processing precision is improved, and processing efficiency is conveniently improved.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

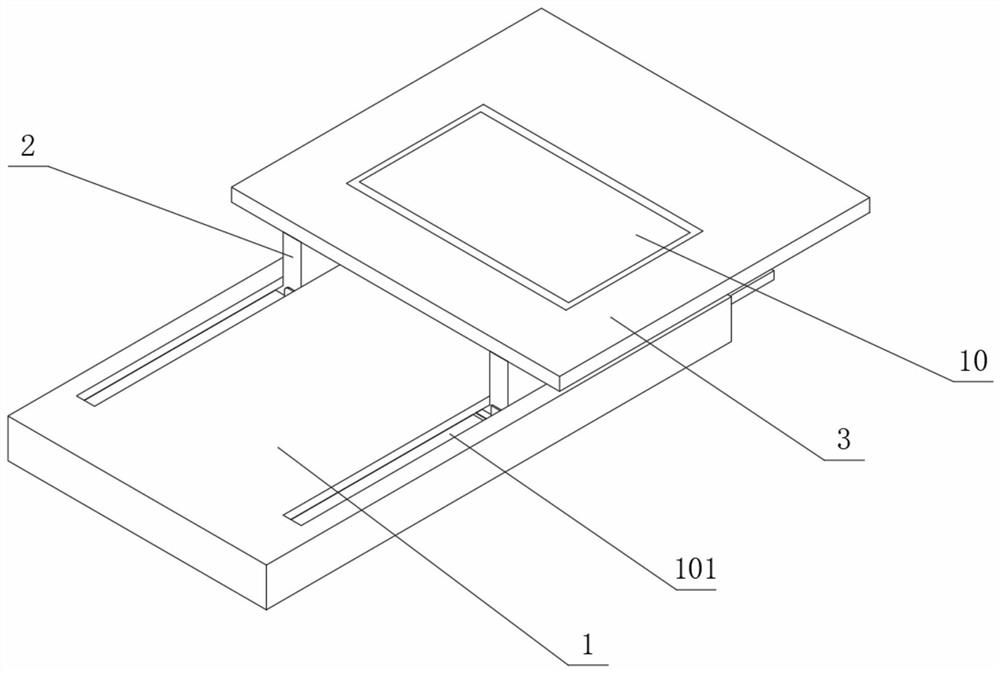

Special positioning device for liquid crystal module assembling machine

ActiveCN113311604AEnsure consistencyReduced precision requirementsNon-linear opticsGlass productionReduction driveControl engineering

The invention discloses a special positioning device for a liquid crystal module assembling machine, which comprises a turntable mechanism, an air supply path and a backlight four-side mechanical positioning mechanism, wherein the turntable mechanism is provided with a turntable power motor, and a power output shaft of the turntable power motor is connected with an input shaft of a turntable power transmission speed reducer; an output shaft of the turntable power transmission speed reducer is connected with an input shaft of a 90-degree operation cam indexer, the 90-degree operation cam indexer is installed on the turntable mechanism installation base, a four-station turntable is installed on an output shaft of the 90-degree operation cam indexer, four stations are evenly distributed on the four-station turntable, and each station is provided with a negative pressure workbench. According to the mechanism, perfect matching among backlight mechanical positioning, a backlight film tearing and fitting process and backlight material circulation is achieved, the positioning function is separated from stations, the defect that deviation exists in four mechanical positioning due to the fact that the positioning mechanism moves along with the stations is overcome, and the consistency of mechanical positioning on a single station can be guaranteed.

Owner:TAIYUAN FENGHUA INFORMATION EQUIP

Pyrography machine lower plate seat capable of automatically adjusting levelness

The invention relates to a pyrography machine lower plate seat capable of automatically adjusting levelness, which comprises a horizontal bottom plate, two parallel sliding chutes are formed in the top end of the bottom plate, a supporting seat in sliding connection with the sliding chutes is arranged in the sliding chutes, and a drawing board in clamping connection with the supporting seat is arranged at the top end of the supporting seat; a plurality of roller grooves are formed in the bottom end of the supporting seat in the length direction of the sliding grooves, rollers are arranged in the roller grooves, and shaft sleeves connected with the roller grooves in an up-down sliding mode are arranged between the roller grooves and the rollers. According to the pyrography machine lower plate seat capable of automatically adjusting the levelness, the rollers moving up and down in the roller grooves are used for keeping parallel to an upper plate, the situation that the lower plate seat cannot be tightly attached to the upper plate after being heated and deformed is effectively prevented, and the pyrography effect is guaranteed; the base plate is supported by a base capable of automatically adjusting the horizontal position, the base corrects the height difference of the four corners of the base by recognizing the inclined direction, the adjusting mode is accurate and reliable, and the levelness of the base and the drawing board on the base is effectively guaranteed.

Owner:福建欣弘机电设备有限公司

A Faraday Probe Array Based Ion Thruster Beam Testing System

ActiveCN105116436BLarge amount of data informationReduce in quantityX/gamma/cosmic radiation measurmentElectricityElectrical connection

The invention discloses an ion thruster beam test system based on a Faraday probe array. Faraday probes are arranged in a surface array, all probe test signals are collected synchronously, and the amount of data information is large. A complete test and data processing can be completed in minutes. There is a shielding jacket on the outside of the ion current collection disk of each Faraday probe, which is used to shield the stray ions flying to the side of the ion current collection disk, so as to ensure that only the front side collects ions; the shielding jacket is directly in contact with the disc-shaped metal bracket through metal To achieve electrical connection, only one wire can be used to supply the bias voltage to the disc-shaped metal support. The biggest advantage of this method is that the number of probe leads is greatly reduced, the structure is simplified, and the reliability is improved.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

Silicon wafer carrier

InactiveCN1303664CSmooth inflow and outflowClosely connectedSemiconductor/solid-state device manufacturingPolyvinylidene difluorideSolar cell

The present invention relates to container for bearing silicon slice, such as silicon slice for solar cell. The silicon slice bearer can wear acid and alkali washing solution under certain temperature for long time, and has certain rigidity, precise external size and strict weight for the requirement of silicon slice producing line and washing apparatus. Structurally, the silicon slice bearer is one case with opened top and bottom, two flat inclined side walls with inside toothed bars arranged in certain intervals, one H-shaped end wall and one plate end wall. Each of the side walls has three outside horizontal beams, conic leg, horizontal bottom gaps and conic teeth, two positioning slots and square notch for clamping silicon slice protecting bars. The container is made with PVDF and through injection molding.

Owner:BEIJING PLASTICS RES INST

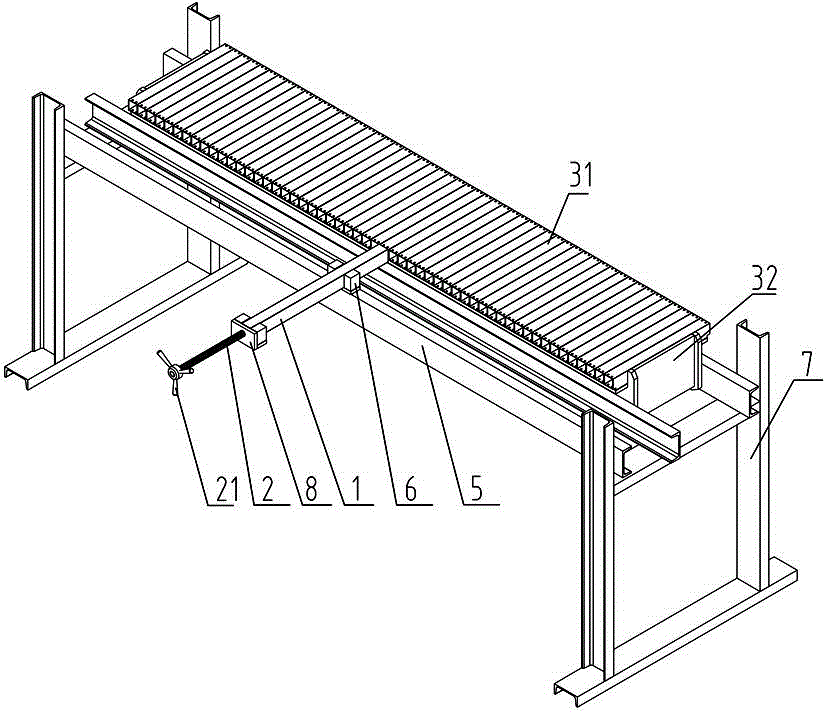

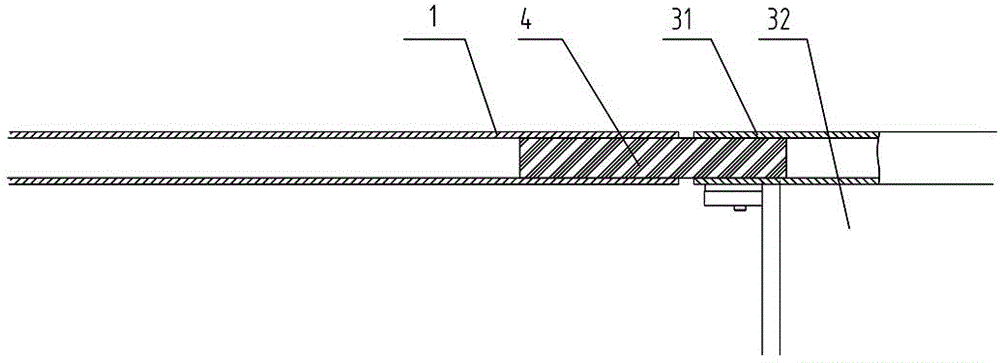

Transferring and loading platform flexible clamp positioning device

ActiveCN106624575AEasy to moveQuick guideWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention provides a transferring and loading platform flexible clamp positioning device. The device comprises a transferring and loading platform, a rail, a motor, guide rollers, guide plates, roller bolts, long kidney-shaped holes and the like. The transferring and loading platform is provided with a plurality of guide plates, and the length of each guide plate is larger than the width of the platform; the guide rollers are installed on one side of the guide plates and uniformly arranged in the length directions of the guide plates; the long kidney-shaped holes are formed in the bottoms of flexible clamps and are positioning holes of the clamps; the roller bolts are symmetrically arranged on across corners of the transferring and loading platform; each roller bolt is consistent with the center of the corresponding long kidney-shaped hole in the height direction and in clearance fit with the corresponding long kidney-shaped hole. Compared with the prior art, the rollers and the guide plates are used for guiding, the positioning mode that the roller bolts are matched with the long kidney-shaped holes is adopted, the device is simple in structure and flexible in operation, can rapidly move and guide the clamps and greatly improves the positioning accuracy of the clamps, and the positioning mode is more flexible and reliable.

Owner:SHANGAHI SHOW KYOEL AUTOMOTIVE EQUIP +1

Scenic spot position positioning method based on facility number database

InactiveCN110830916AAccurately reflect the actual positionQuick reliefData processing applicationsNavigational calculation instrumentsData miningDatabase

The invention discloses a scenic spot position positioning method based on a facility number database, and the method comprises the steps: numbering fixed facilities of a scenic spot according to a preset rule, and marking the numbers on the corresponding fixed facilities; respectively describing the physical address of each fixed facility, and establishing a corresponding relationship between thephysical address of each fixed facility and the serial number of the fixed facility; establishing a position database according to the corresponding relationship between the physical address and thenumber of the fixed facility; a to-be-positioned person obtains the number of at least one fixed facility closest to the to-be-positioned person and provides the number to a management center worker;a management center worker acquires the corresponding physical address from the position database according to the serial number and sends the physical address to a field worker closest to the physical address; and the field worker goes to the to-be-positioned person according to the physical address. Positioning is carried out based on the number of the fixed facility, and the actual position ofthe to-be-positioned person can be accurately reflected.

Owner:四川智胜慧旅科技有限公司

Flexible fixture positioning device for transfer platform

ActiveCN106624575BEasy to moveQuick guideWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention provides a transferring and loading platform flexible clamp positioning device. The device comprises a transferring and loading platform, a rail, a motor, guide rollers, guide plates, roller bolts, long kidney-shaped holes and the like. The transferring and loading platform is provided with a plurality of guide plates, and the length of each guide plate is larger than the width of the platform; the guide rollers are installed on one side of the guide plates and uniformly arranged in the length directions of the guide plates; the long kidney-shaped holes are formed in the bottoms of flexible clamps and are positioning holes of the clamps; the roller bolts are symmetrically arranged on across corners of the transferring and loading platform; each roller bolt is consistent with the center of the corresponding long kidney-shaped hole in the height direction and in clearance fit with the corresponding long kidney-shaped hole. Compared with the prior art, the rollers and the guide plates are used for guiding, the positioning mode that the roller bolts are matched with the long kidney-shaped holes is adopted, the device is simple in structure and flexible in operation, can rapidly move and guide the clamps and greatly improves the positioning accuracy of the clamps, and the positioning mode is more flexible and reliable.

Owner:SHANGAHI SHOW KYOEL AUTOMOTIVE EQUIP +1

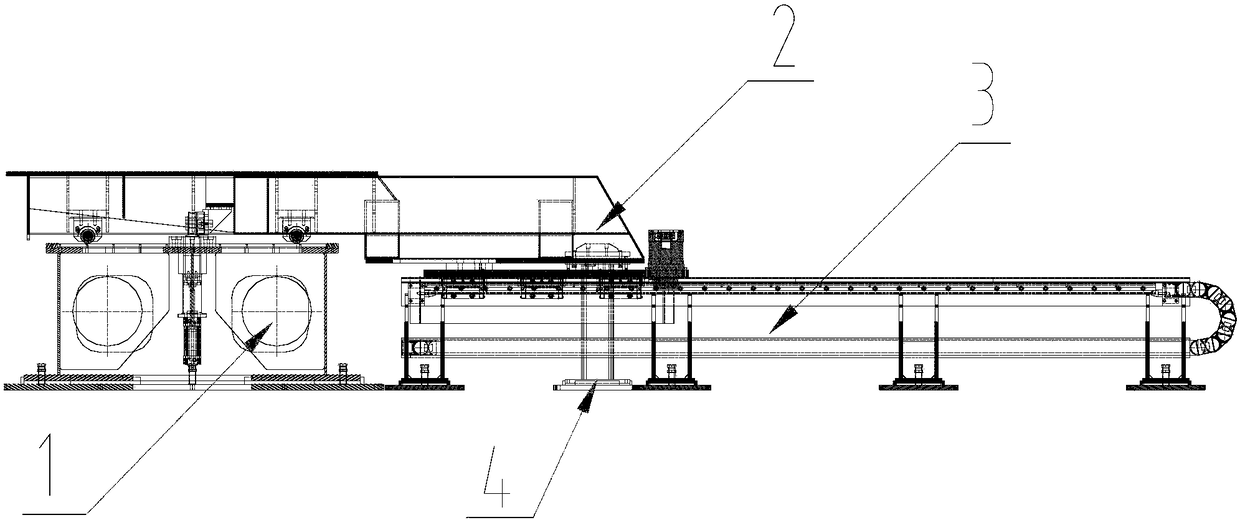

Multi-vehicle edge rolling flexible switching system

The invention relates to a multi-vehicle edge rolling flexible switching system which is composed of a center working station and a plurality of conveying line mechanisms. Each conveying line mechanism comprises a sliding table unit and a rail unit, wherein the sliding table unit is installed on the rail unit and moves along the rail unit, the sliding table unit is provided with a positioning component, and the positioning component is composed of a pair of positioning rollers provided with gaps. Compared with the prior art, a flexible rail system is used for edge rolling of vehicle body doorcovers, self driving mechanisms arrive the center working station to be accurately positioned, robot edge rolling work is achieved, equipment increase from one vehicle type to four vehicle types according to plan needs can be achieved without influencing production, and achievement can be achieved without line stopping; and a gear motor is used for driving the sliding table units to move to the working position, then a positioning shaft is used for locking the sliding table units, vehicle type switching at random can be achieved, the occupied land is small, the speed is high, and noise is low.

Owner:FFT PRODION SYST SHANGHAI

Drilling mold for oblique hole in engine nozzle ring

ActiveCN109079204BPositioning method is reliableAchieve positioningPrecision positioning equipmentPositioning apparatusEngineeringBolt connection

An engine nozzle ring inclined hole drilling mold, including a base, a support, a locator, a mandrel, a bearing, a tangential clamping sleeve, a bearing cover, an indexing plate, etc., and the left and right supports are fixed on the base by pins and bolts, The bearing is installed in the center hole of the upper end of the left and right supports. The mandrel and the positioning plate are connected by pins and bolts, and are respectively placed in the bearing holes at both ends. The bearing cover is located at the upper end of the support. The tangential clamping sleeve is located between the bearing cover and the bearing. Attach the handle nut to lock the arbor while working. The indexing plate and the left ear of the positioning plate are connected by pins and bolts, and form a specific angle. When the drilling template is working, it is positioned through the positioning holes at both ends of the indexing plate, and the oblique holes are processed from the front and back. The positioning ring and the positioning plate are connected by pins and screws, and the positioning is realized through the cooperation of the outer circle and the inner hole of the nozzle ring. The invention has the advantages of high positioning accuracy, convenient operation, strong practicability, etc., and can be used for processing complex inclined holes.

Owner:XIAN SPACE ENGINE CO LTD

Welding gun flexible positioning device and method for robot

PendingCN114669852AThe positioning method is simpleStrong maneuverabilityResistance electrode holdersPhysicsEngineering

The welding gun flexible positioning device for the robot is characterized by comprising a trapezoid support, a cross beam support, a welding gun positioning unit, a dustproof cover, a rotating air cylinder, a welding gun supporting unit, a welding gun female head for locking a welding gun through a welding gun positioning pin, a position sensor for detecting the connection relation between a gun replacing disc male head of the welding gun and a gun replacing disc of the welding gun female head, and a position sensor for detecting the position of the welding gun female head. Positioning is simple and reliable, and operability is high; the positioning method comprises the steps that the two welding guns are both hung on the welding gun flexible positioning device, the robot drives the gun replacing disc male head to move to the position near the device, the robot drives the gun replacing disc male head to be inserted into the female head on the welding gun, welding gun positioning locking and site specifications are relieved, and the 6s site quality management regulation is met.

Owner:CHINA FIRST AUTOMOBILE

Installation tooling and assembly method of permanent magnet with array structure

ActiveCN104097174BAvoid installation inconvenienceSimple and fast operationMetal-working hand toolsEngineeringMagnet

The invention discloses a mounting tool and an assembling method of an array structural permanent magnet. The mounting tool of the array structural permanent magnet comprises a guide sleeve and a pushing piece, wherein the guide sleeve is communicated with a mounting tube of the permanent magnet in a butt joint manner, the pushing piece is used for pressing a permanent magnet block in the guide sleeve into the mounting tube, one end of the pushing piece is sheathed into the guide sleeve and can push the permanent magnet block in the guide sleeve along the length direction of the guide sleeve. The assembling method comprises the steps of communicating the guide sleeve and the mounting tube in the butt joint manner; placing the permanent magnet block into the guide sleeve, and pushing the permanent magnet block into the mounting pipe by the pushing piece. The mounting tool and the assembling method have the advantages that the operation is simple and convenient, safety and reliability are realized, and the permanent magnet block is effectively mounted.

Owner:NAT UNIV OF DEFENSE TECH

A press-fitting tooling and press-fitting process for steering knuckle needle roller bearings

ActiveCN107443048BReduce in quantityPositioning method is reliableVehicle componentsMetal working apparatusNeedle roller bearingPull force

The invention provides a press-fitting tool and a press-fitting process for a steering knuckle rolling needle bearing. The press-fitting tool comprises a power part and a press-fitting part which are fixedly connected, wherein the power part comprises an oil cylinder and a connecting plate; one end of the connecting plate is connected with a steering knuckle, and the other end of the connecting plate is connected with the oil cylinder; the press-fitting part comprises a guide rod, guide sleeves and a baffle block; the guide sleeves are separately arranged at the left end and the right end of the guide rod; the baffle block is arranged between the two guide sleeves; and a telescopic pole of the oil cylinder penetrates through the connecting plate and is detachably connected with the guide rod. According to the structural feature that two main pin shaft holes of the steering knuckle are coaxial, a rolling needle bearing is positioned and is pressed through the guide rod and the two guide sleeves, pushing-pulling force generated by the oil cylinder drives the guide rod to advance and retract, so that the baffle block is driven to separately press the rolling needle bearing into the main pin shaft holes, and therefore, the oil cylinder can act once to complete press-fitting work of two rolling needle bearings, positioning is reliable and assembly quality is high; and moreover, press-fitting operation can be performed on a roller path frame, so that operation is simple and convenient.

Owner:重汽(济南)车桥有限公司

Probe electrospray ionization and mass spectrometry combined living body analysis system

PendingCN112858452AFacilitated ionizationEfficient sprayingMaterial analysis by electric/magnetic meansESI mass spectrometryFluid phase

The invention relates to a probe electrospray ionization and mass spectrometry combined living body analysis system. The system comprises a probe electrospray ionization (PESI) system, a spray system and a mass spectrometry system; the spray system comprises a solvent tank, an infusion pump, a compressed air or nitrogen tank, an atomizer, a fog drop screener, a spray pipe and a columnar fog atmosphere; the system further comprises a microscopic positioning system. According to the spray system, continuous and stable columnar mist is generated, and efficient spraying and ionization are achieved; meanwhile, the spray pipe is far away from a metal probe, so that the internal space is effectively released, and the system can have an operation space and is convenient to use; the spray system adopts a conventional liquid chromatography pump to pump out the solvent, and a micro-injection pump is not needed, so that the cost is saved; the system is not limited by a used solvent and is wide in application range; the microscopic positioning system can analyze and measure organs of tiny animals of insects, and a positioning method is accurate and reliable.

Owner:SHIMADZU (CHINA) CO LTD

A Split Type Cycloidal Disk CNC Milling Positioning Fixture

ActiveCN103934705BSimple structureNeutral goodPositioning apparatusGear-cutting machinesNumerical controlArchitectural engineering

The invention relates to a split cycloid disc numerical-control milling and positioning clamp which comprises a mold, an inner expansion sleeve, an outer expansion sleeve and bolts. The center of the mold is provided with a circular-ring-shaped groove and a cylindrical boss, wherein the circular-ring-shaped groove and the cylindrical boss share the same axis. The outer circumferential face of the cylindrical boss is coaxially connected with the inner expansion sleeve in a sleeved mode, and the inner circumferential face of the circular-ring-shaped groove is coaxially connected with the outer expansion sleeve. The outer edge of the mold is provided with two or more sets of bolt holes, and the bolts connected with T-shaped tables of a numerical-control milling machine are arranged in the bolt holes. The features that the expansion sleeves are good in centering performance and large in expanding force are utilized, the inner expansion sleeve and the outer expansion sleeve are used for being matched with the cylindrical boss and the circular-ring-shaped groove respectively to position an inner split disc and an outer split disc, the positioning manner is simple, accurate and reliable, after a cylindrical pin is used for being matched with a mold cylindrical pin hole to circumferentially position the inner split disc and the outer split disc, the same numerical-control program can be used for milling cycloidal tooth faces of the inner split disc and the outer split disc, and the positioning manner is simple and reliable.

Owner:JIANGSU TAILONG MACHINERY GRP CO CO LTD

A Reversible Beam Divergence Angle Movement Measuring Mechanism

ActiveCN105044763BExtended service lifeReduce temperature requirementsX/gamma/cosmic radiation measurmentMeasurement deviceInverted u

The invention discloses a reversible beam divergence angle mobile measurement mechanism. Through a reversible mechanism, a beam divergence angle measurement device can be moved out of a beam area after measurement or during the measuring process. The defect that beam divergence angle measurement is difficult and sensors and cables are easily short-circuited and damaged during long-term ignition of an ion thruster is solved. A rack is a double-layer structure: a rotating device is installed at the upper layer and the lower layer is a cavity with an opening. A crank is an inverted U-shaped structure. One arm of the crank is fixed on the rotating device, and the other arm of the crank is fixed on the beam divergence angle measurement device. In a test state, a test surface of the beam divergence angle measurement device is positioned in a test area and in a vertical state. When the beam divergence angle measurement device withdraws from the test, the rotating device rotates under the control of a stepper motor, and the crank drives the beam divergence angle measurement device to overturn downwards. The crank is contained into the second-layer cavity of the rack. The test surface of the beam divergence angle measurement device departs from the test area and is in a horizontal state.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

Motor rotor positioning system for hybrid vehicle and positioning method thereof

ActiveCN101594107BImprove performancePrecise positioningElectronic commutatorsProduction linePosition angle

The invention aims to provide a motor rotor positioning system for a hybrid vehicle and a positioning method thereof, which are suitable for the characteristics of a vehicle production line. The positioning system consists of a detection unit and a calibration unit, wherein the detection unit comprises a power device capable of driving a motor to be positioned to rotate, a detection host computer, a bar code scanner, a zero crossing detection device and a motor rotor position sensor arranged on the motor to be positioned, and the detection host computer is connected with the power device, the bar code scanner, the zero crossing detection device and the motor rotor position sensor; the calibration unit comprises another bar code scanner and a calibration host computer, and the calibration host computer is connected with a motor controller of the motor to be positioned; and the detection host computer and the calibration host computer are connected with a database server through a network respectively. The detection host computer detects the position angle value of the motor rotor through the zero crossing detection device and the motor rotor position sensor, transmits the position angle value to the calibration host computer, and further writes the position angle value into the motor controller so as to finish the positioning of the motor rotor.

Owner:CHERY AUTOMOBILE CO LTD

A method of processing and assembling a riveted frame

The invention discloses a method for processing and assembling a riveted frame, comprising the following steps: independently processing a positioning support, a positioning joint, and a frame fixing bracket to size, including processing a unified processing and detection reference on the frame fixing bracket, and Process the precise positioning structure on the positioning joint and the positioning support; process the riveted clamp, and rough-machine the profile and mounting holes of the riveted clamp; assemble the positioning joint and the positioning support to the fixed bracket of the frame; After assembling the riveting clamps to the fixed bracket of the frame based on the precise positioning structure, the profile surface and mounting holes are finished according to the unified processing and inspection standard to size; after installing each locator to the mounting holes on the riveting clamping plate, the riveting clamp with locators The panels are then assembled to the jig fixing brackets. Combining effectively solves the technical problem of relatively large processing and assembling errors of the existing large-scale riveting frames, thereby improving the processing and assembling accuracy and quality of the riveting frames. It also shortens the processing and assembling cycle of the riveting frame.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

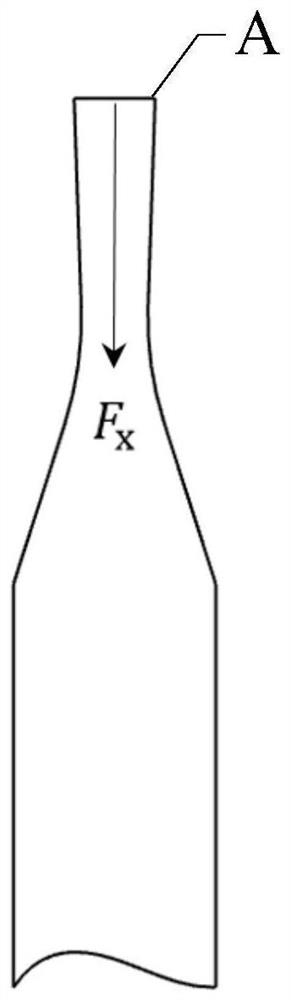

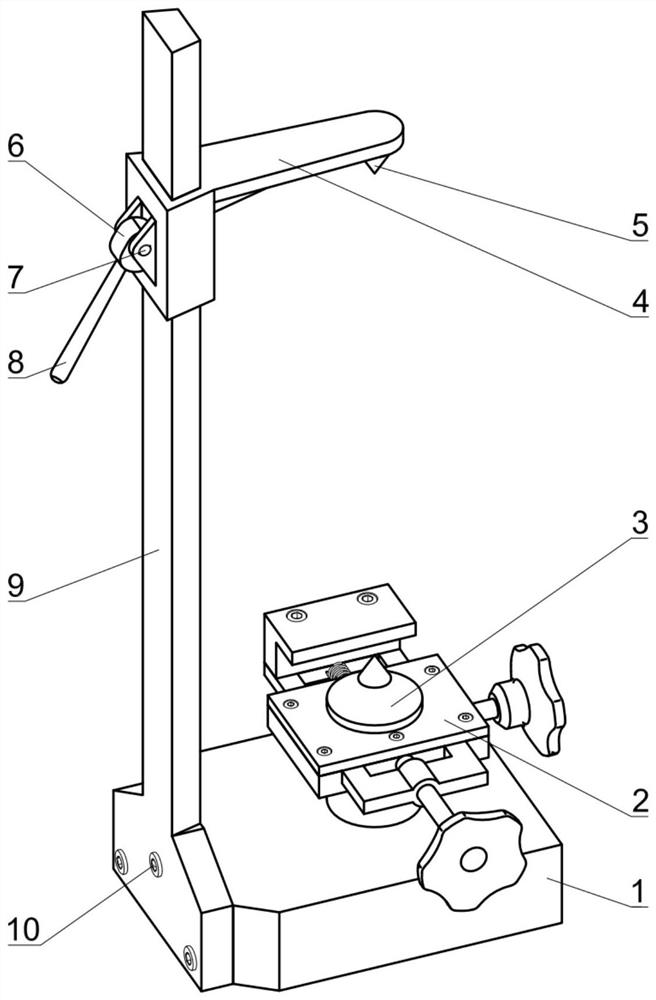

A blade measuring fixture and measuring method

ActiveCN111975672BLow costShorten the timeWork holdersMechanical measuring arrangementsStructural engineeringMechanical engineering

The invention discloses a blade three-coordinate measuring fixture and a measuring method, comprising a base, a fixed top, a movable top seat, a column, a pressing block assembly and a handle. The pressing block assembly includes a pressing block, a cover plate, a guide groove plate, a guide plate, a pressing handle, and an angle locking handle. The pressing block assembly is arranged on the fixed top and can rotate around the fixed top; the movable top seat is arranged on the column and can move up and down along the column. The measurement method in the present invention adopts an iterative method to establish a coordinate system, only six characteristic points are needed to establish a coordinate system, and the method is simple. The measurement method realizes batch detection of blades and improves measurement efficiency. The present invention uses the central holes at both ends of the blade blank as the positioning reference, which improves the positioning accuracy. Due to the universality of the characteristics of the central hole on the end surface, the present invention is applicable to the measurement and positioning of various types of blades, and has strong versatility; the clamping angle of the blades can be adjusted , which is convenient for the three-coordinate stylus to step on the point.

Owner:江苏腾沅机械科技有限公司

2D turntable for monitoring

ActiveCN104500938BSaving positioningPositioning method is reliableStands/trestlesAerospace engineering

Owner:田东昊润新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com