Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Eliminate manual errors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

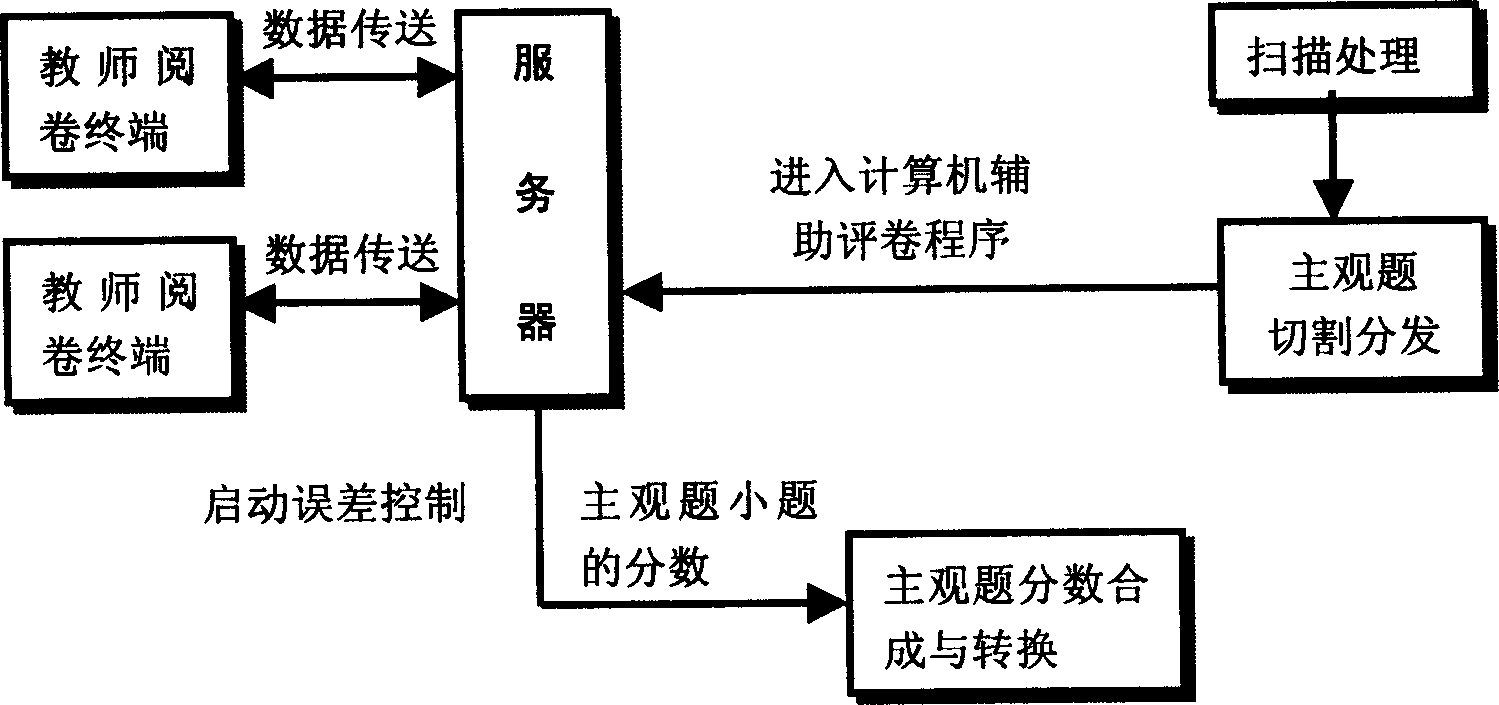

Network exanmination paper go-over method for subjective question

The invention discloses a method used to online review subject items. Its steps include answer card scanning and inputting, image curving and dispatching, computer aided grading and error control and grade composing and conversion. The invention adapts to entrance examination for college, self-teach examination, adult entrance examination for college, entrance examination for high school and other society examinations. Adopting the invention, reviewing error of subjection items is controlled to furthest realize equality and justice in process of reviewing and misjudge is avoided by adopting special treatment on question test papers to guarantee examinees' benefit.

Owner:SHENZHEN SEA SKY LAND TECH

Grit removal device for grit chamber

InactiveCN103505913AExtended service lifeEasy to fixSettling tanks feed/dischargeSedimentation settling tanksProgrammable logic controllerInductor

The invention discloses a grit removal device for a grit chamber. The grit removal device comprises a grit chamber main body, a grit discharge pump, an inductor and a motor, wherein one end of the grit discharge pump is arranged on the inner bottom surface of the grit chamber main body, the other end of the grit discharge pump is arranged on one side of the top end of the grit chamber main body, the inductor is arranged above the inner bottom surface of the grit chamber main body, the motor is connected with the grit discharge pump, and a PLC (Programmable Logic Controller) cabinet is connected with the inductor and the motor respectively through a data line. The grit removal device is simple in structure, convenient to install and free of manual operation errors in traditional grit removal work, the manual operations can be reduced, the labor cost can be lowered, the sewage treatment efficiency can be improved, and the service life of the grit chamber can be prolonged.

Owner:吴佳倩

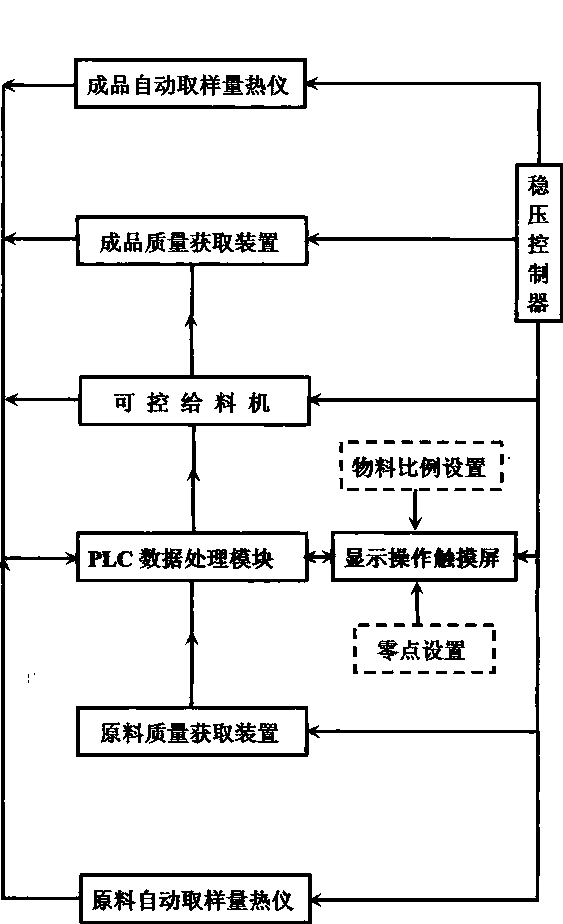

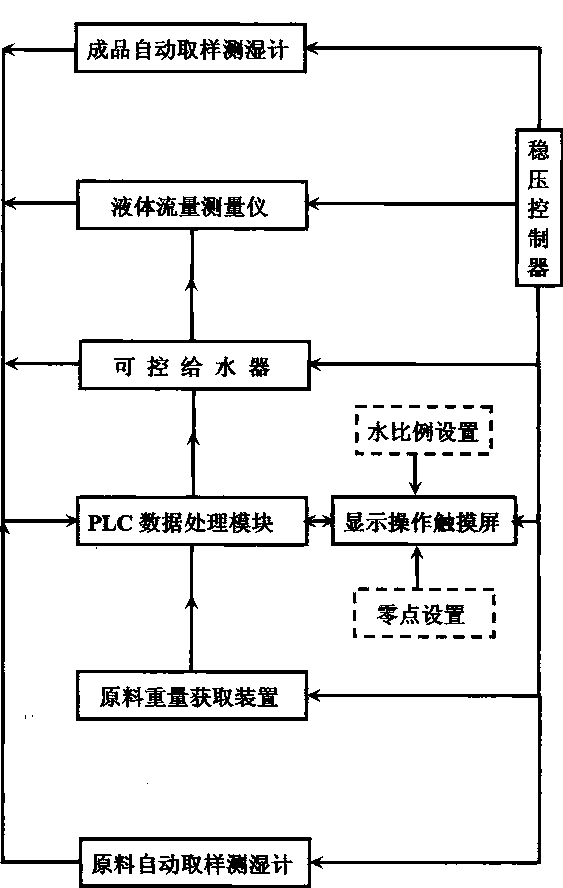

Automatic and continuous batching system

InactiveCN103657510AAvoid continuityAvoid efficiencyMixer accessoriesProgrammable logic controllerProcess engineering

The invention discloses an automatic and continuous batching system which is applicable to a plurality of processes of industrial production of solid materials mixed with materials with certain heat values, wherein the automatic and continuous batching system comprises an automatic raw material sampling calorimeter, a raw material quality acquiring device, a PLC (Programmable Logic Controller) data processing module, a controllable feeder, a finished product quality acquiring device, an automatic finished product sampling calorimeter, a constant-pressure controller and a display operation touch screen, wherein two parameter settings including a material proportion setting and a zero point setting are designed on the display operation touch screen. The automatic and continuous batching system has the advantages that due to the system, full-automatic and high-precision continuous batching in a batching link in the industrial production process is realized; the defects of discontinuous container measurement feeding and low efficiency are avoided; meanwhile, the error in manual operation in the links of producing and batching is eliminated; the influences on the batching precision caused due to a plurality of factors are avoided; the feeding precision is greatly improved; the materials of production enterprises are saved; the automatic and continuous batching system protects the environment; the batching labor is reduced; the capacity is improved.

Owner:CHENGDU VONXAN AUTOMATION SCI & TECH

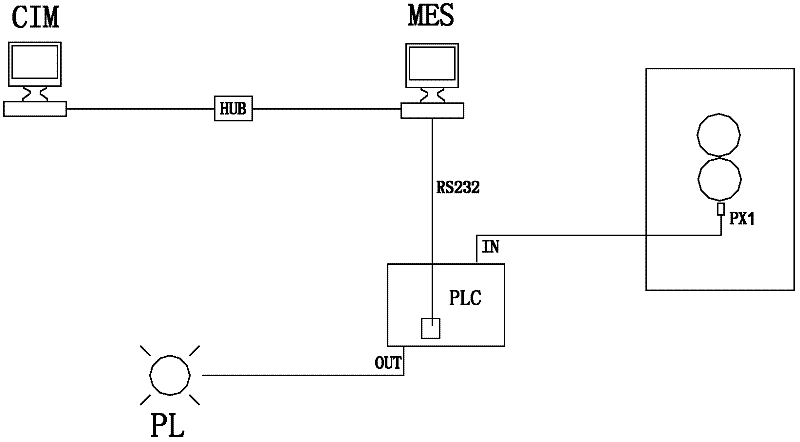

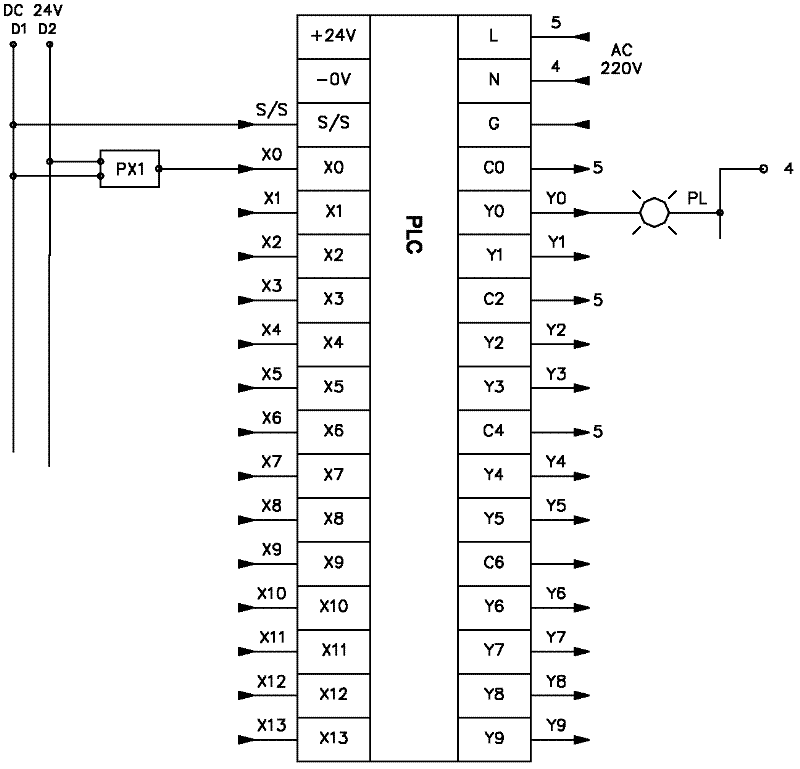

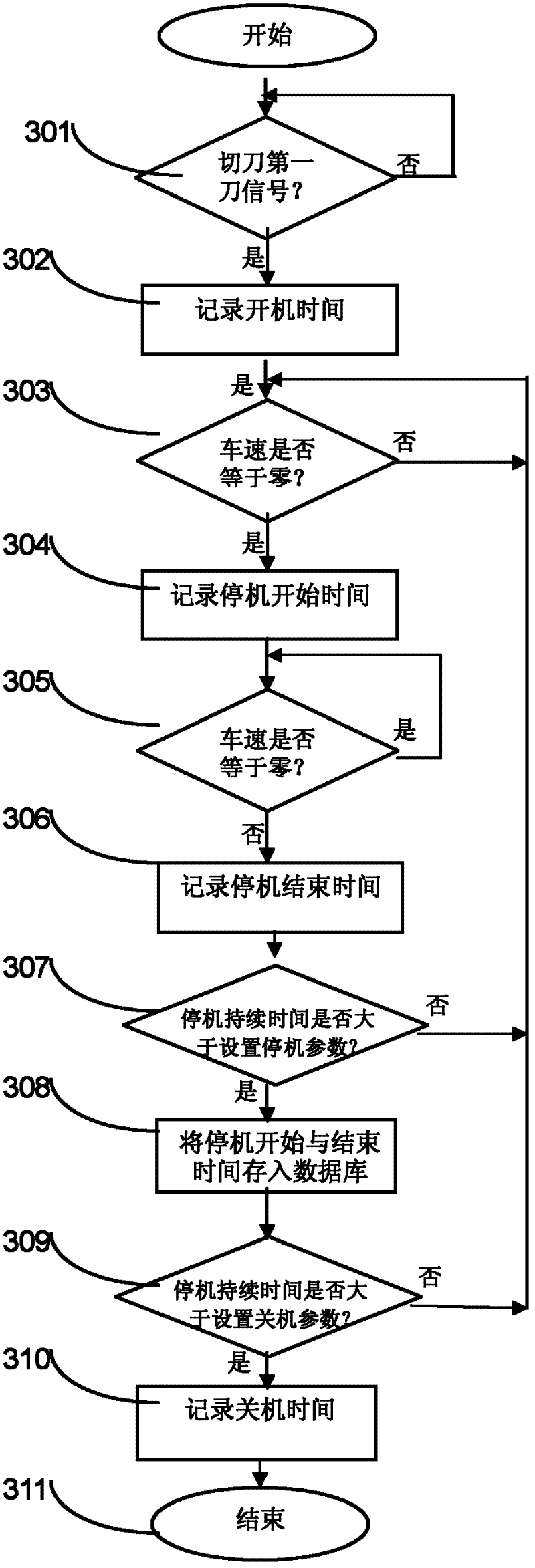

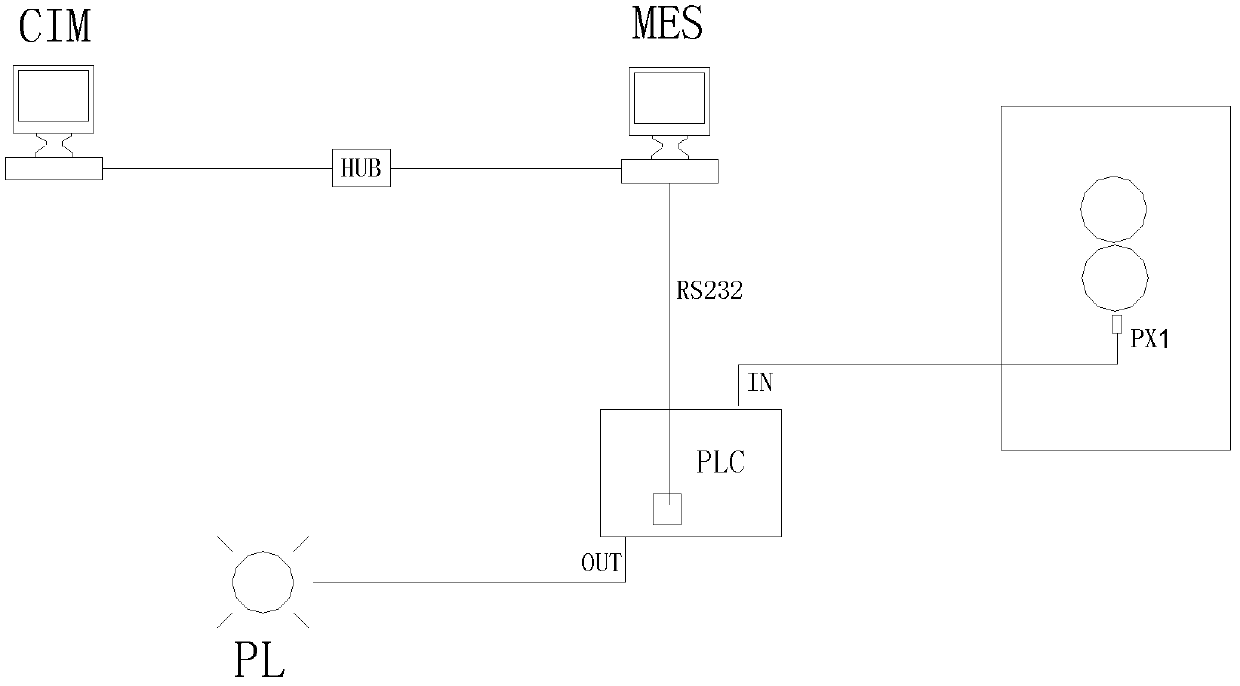

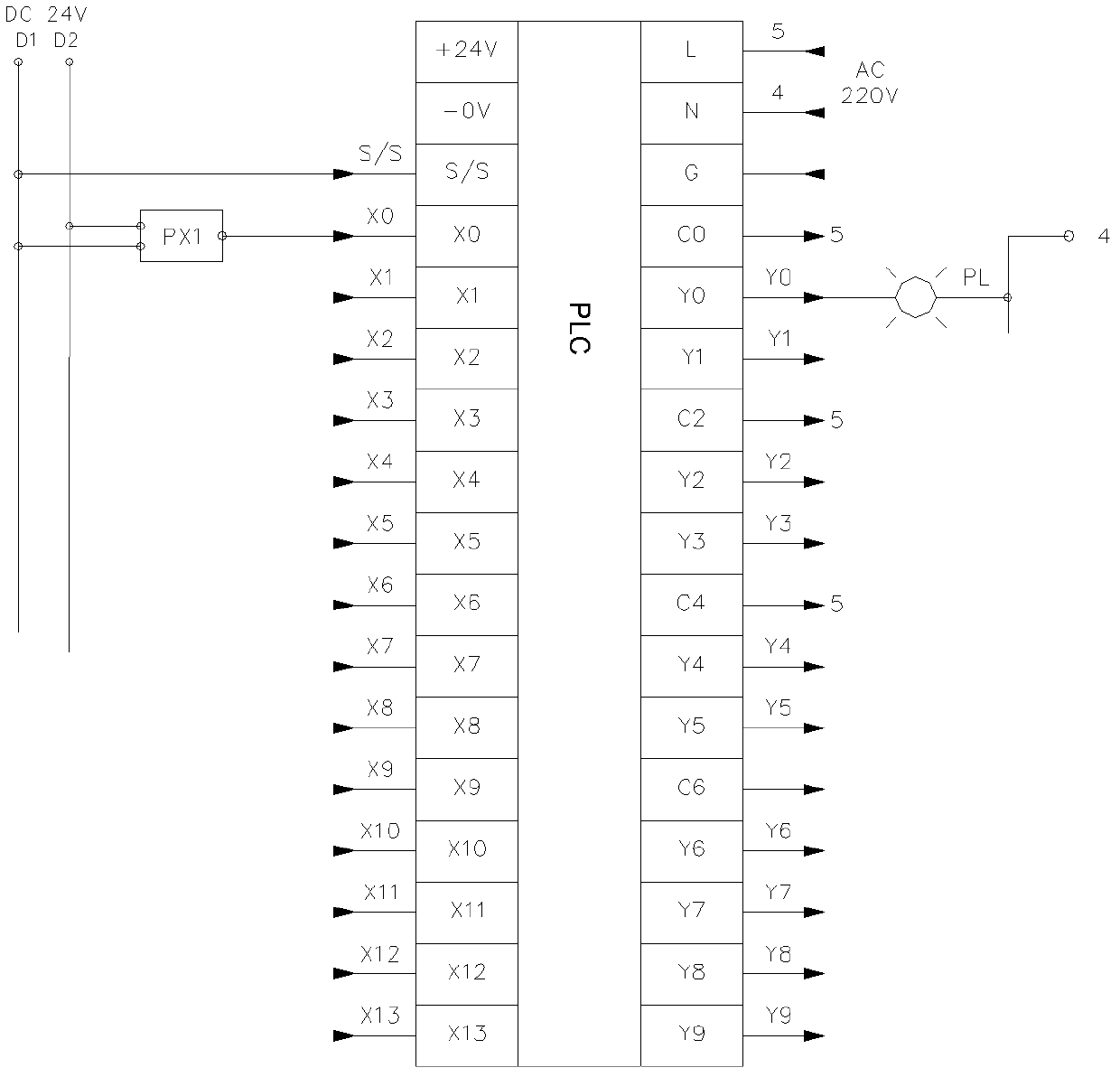

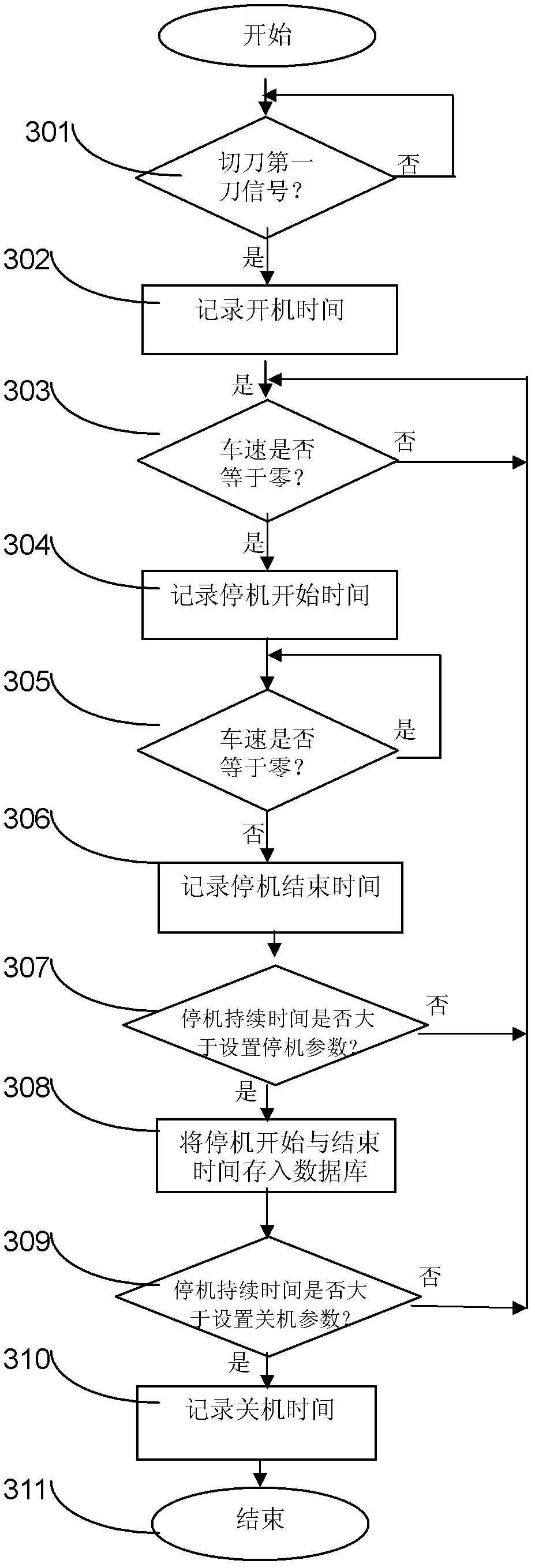

Equipment overall efficiency detecting method

ActiveCN102645595AEliminate manual errorsExclude omissionsElectrical testingProgramme control in sequence/logic controllersStart timeStop time

The invention relates to an equipment overall efficiency detecting method. The method comprises the following steps of inputting data: 302) recording starting time; 303) turning on a proximity switch (PX1), acquiring vehicle speed, and judging whether the vehicle speed is zero or not, if so, performing the next step, otherwise, returning to the 303) step; 304) recording stop beginning time; 305) acquiring the vehicle speed through the proximity switch, and judging whether the vehicle speed is zero or not, if so, performing the next step, otherwise, returning to the 304) step; 306) recording stop ending time; 307) judging whether the continuous time is more than a stop parameter or not, if so, performing the next step, otherwise, returning to the 303) step; 308) recording the stop beginning time and the stop ending time in an equipment efficiency database; and 309) judging whether the continuous time is more than a set stop parameter or not, if so, recording stop time, otherwise, returning to the 303) step. The method also comprises the steps of outputting data, i.e. 401) acquiring Q and N, 402) researching the equipment efficiency database, 403) acquiring T1 and T0, and 404) calculating output T, P and I.

Owner:MINGWEI MACHINERY DONGWAN

Touch screen calibrating method and system

ActiveCN103793112ACorrected accuracy deteriorationReduce precisionInput/output processes for data processingTouchscreenAdaptive capacity

The invention provides a touch screen calibrating method which comprises the steps of switching the work state of a touch screen from the normal touch mode to the calibration mode, conducting regular calibration or deep calibration on a touch spot according to the touch precision change of the touch screen, and switching the work state of the touch screen from the calibration mode to the normal touch mode after the regular calibration or deep calibration is finished. The invention further discloses a touch screen calibrating system. According to the touch screen calibrating method and system, precision deterioration of the touch screen caused by transportation damage or using environment difference can be effectively amended, adaptive capacity is good, and manual operation errors can be removed effectively to realize higher precision.

Owner:TIANJIN XITONG ELECTRONICS EQUIP CO LTD

Full-automatic service robot for collecting cash

The invention discloses a full-automatic service robot for collecting cash. The full-automatic service robot is applied to the cash collecting link of modern markets and shops and is characterized in that a man-machine intercom display operation screen, multifunctional grabbing hands, a cash receiving and changing device, an automatic packer and a commodity bar code recognizer are included and are respectively and independently connected with a data processing module and used for bidirectional data transmission. The full-automatic service robot has the advantages that the market cash collecting link is achieved automatically and conveniently, the defect of low manual cash collecting efficiency is overcome, the manual operation errors of the cash collecting link are eliminated, the influence caused by many factors on the cash collecting efficiency is avoided, cash collecting speed is greatly improved, the employment cost of shopping places is saved, the shopping time of consumers is saved, and the business volume of the shopping places is improved.

Owner:CHENGDU VONXAN AUTOMATION SCI & TECH

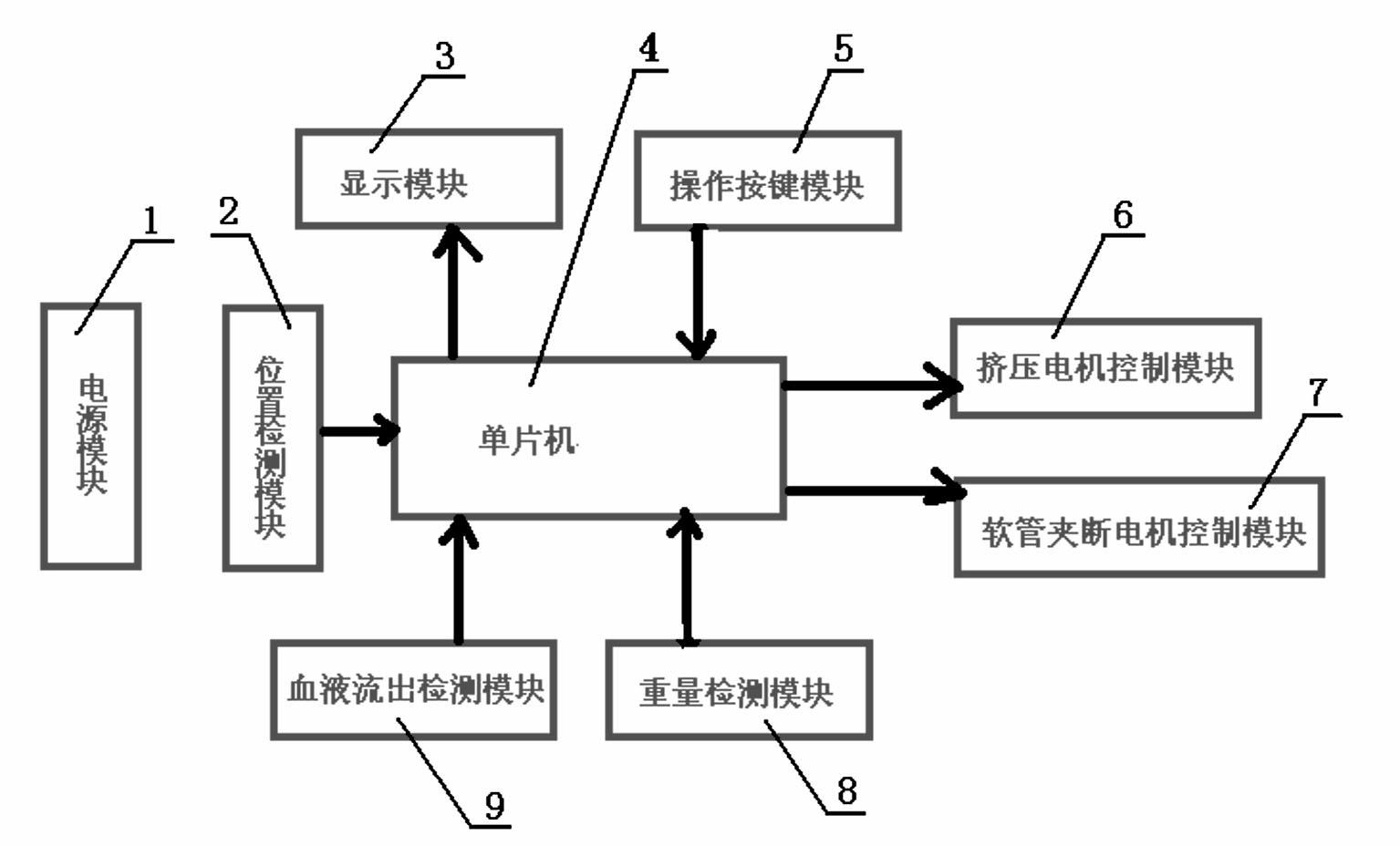

Automatic blood plasma separation meter

InactiveCN102671430ARealize start-stop controlRealize automatic controlLiquid separation auxillary apparatusBlood plasmaBlood separation

The invention discloses an automatic blood plasma separation meter which is provided with a plasma separating clip for clamping a blood bag, a blood bag hose clip and a hose clip control device, wherein the plasma separating clip is controlled by an extruding motor; the extruding motor is connected with an extruding motor control module; the extruding motor control module is controlled by output data of a single chip microcomputer; the single chip microcomputer is connected with a display module; the output data of a blood flowing-out detection module is connected with the single chip microcomputer; a weight detecting module and an operation key module are connected with the single chip microcomputer; a position detecting module is connected with the single chip microcomputer; and a power supply module is used for supplying power to each module. Compared with the prior art, the automatic blood plasma separation meter has the advantages of simple structure, convenience for operation and low cost, and can be used for realizing automatic blood separation, reducing artificial errors and mistakes, saving manpower resource and reducing the labor intensity.

Owner:南阳市中心血站

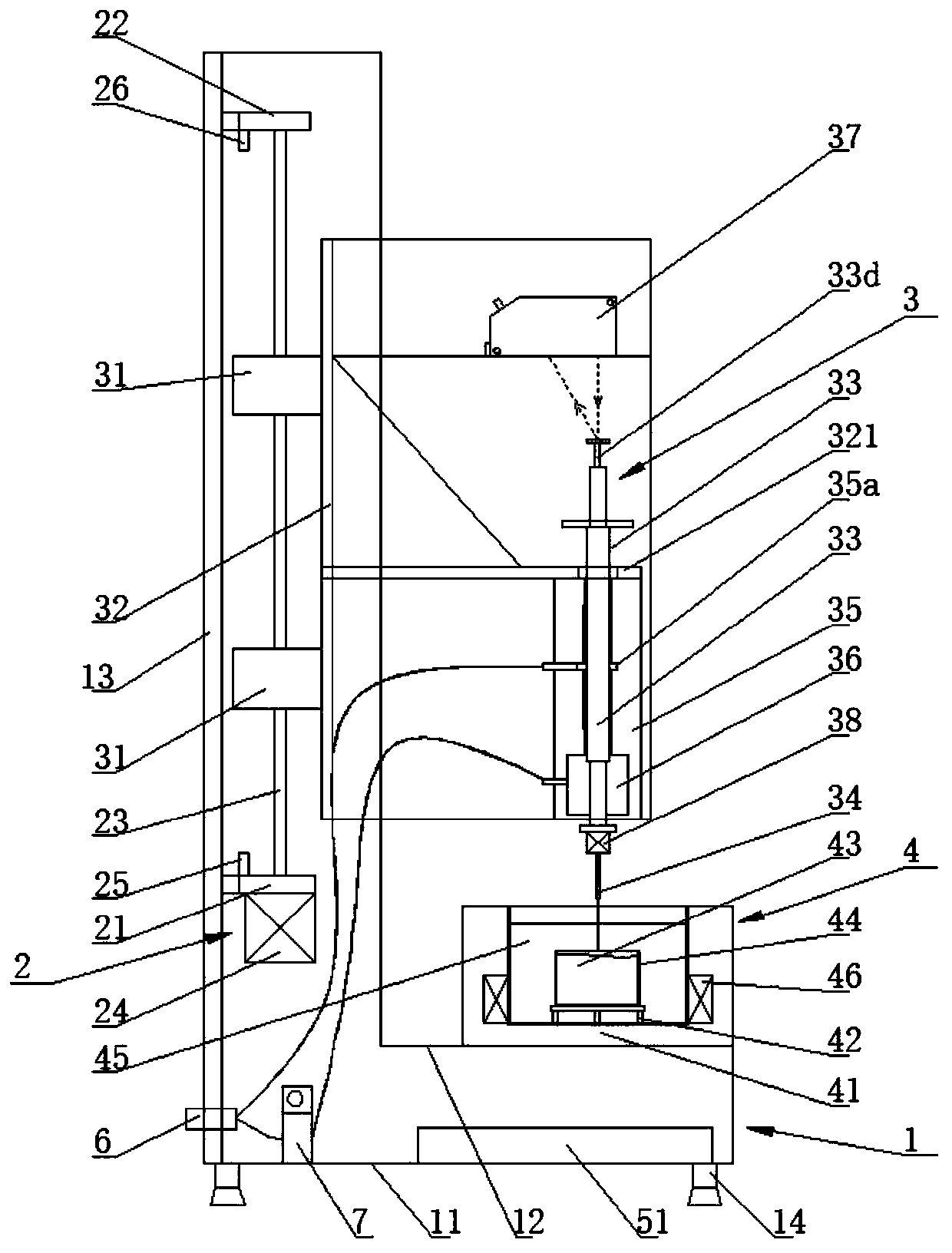

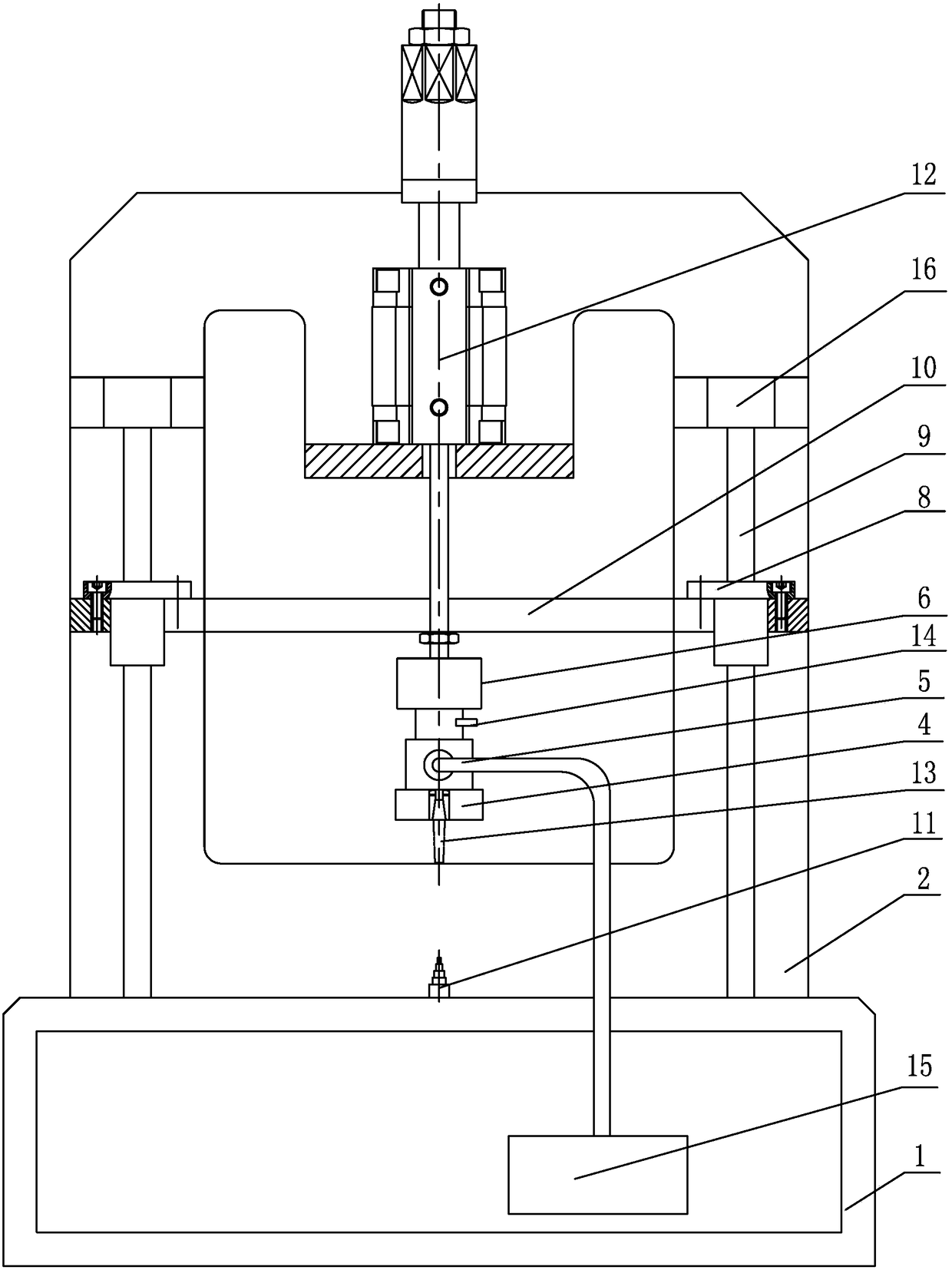

High-precision asphalt penetration tester

PendingCN111198148AImprove performance detection accuracyReduce contact frictionFlow propertiesPenetration indexAir bearing

The utility model discloses a high-precision asphalt penetration tester. The tester comprises a rack, a measuring rod and probe module, an up-and-down walking module, a sample placing module and a control module, wherein the measuring rod and probe module comprises a connecting seat, a measuring rod and probe bracket, a measuring rod and a probe; the measuring rod is of a columnar structure and comprises a balance weight part, a main body part and a clamping part from top to bottom. An air bearing sleeve structure is fixedly arranged on the measuring rod probe support, a measuring rod hole isformed in the center of the air bearing sleeve structure, and an air cylinder cavity is formed in the lower middle position of the bearing sleeve structure. A load sensor is arranged at the lower endof the measuring rod; and the sample placing module is provided with an electronic refrigeration sheet. According to the tester, an air bearing structure and a pneumatic clamping structure are adoptedto reduce contact friction, a force measuring sensor is adopted to realize automatic needle alignment, a laser displacement sensor is adopted to realize non-contact measurement, and an electronic refrigeration sheet is adopted to realize accurate constant temperature, so that the asphalt penetration index performance detection precision is high, the operation is convenient, and the automation degree is high.

Owner:INNER MONGOLIA UNIVERSITY +1

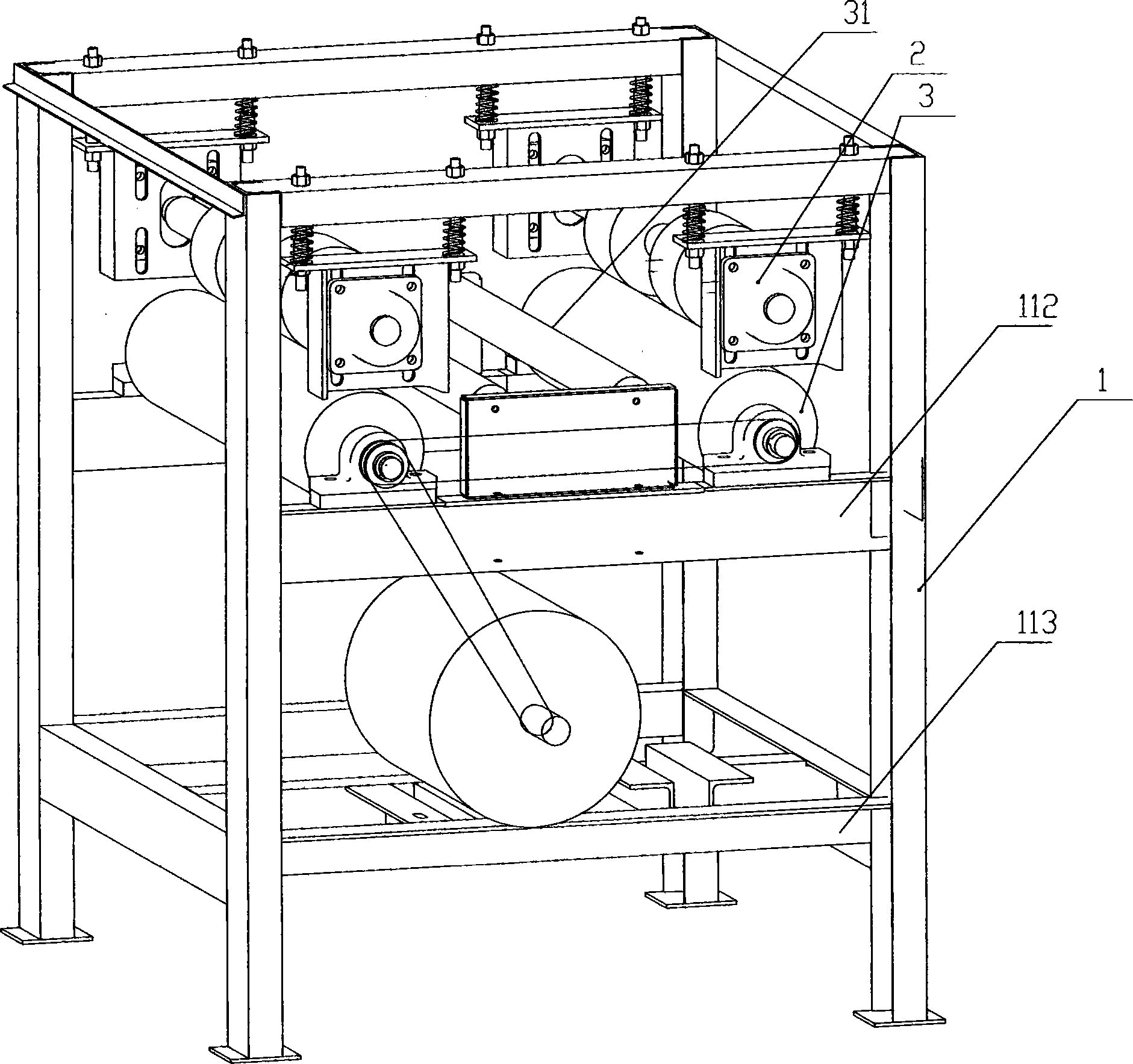

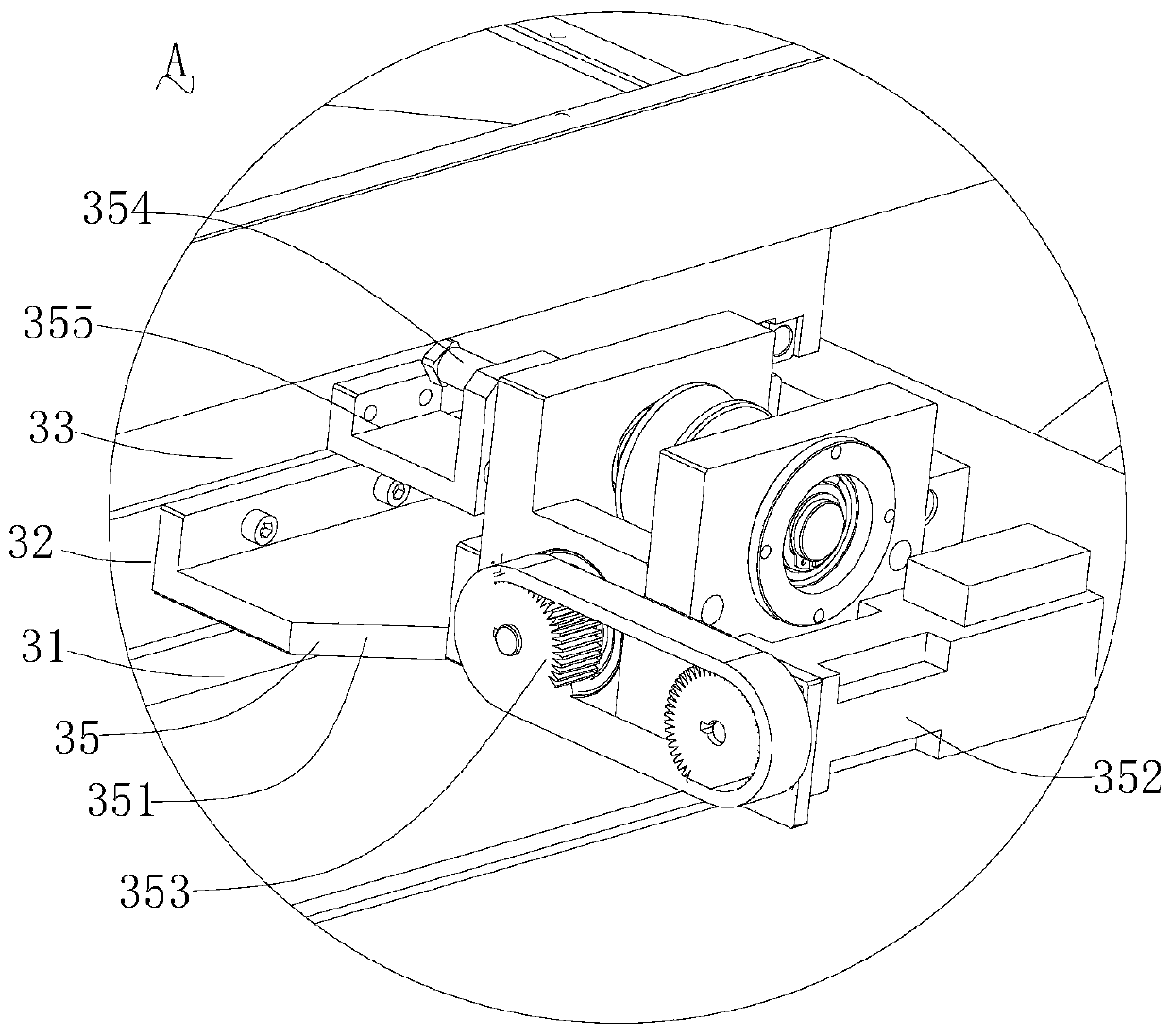

Automatic conveying film sticking machine

InactiveCN103832619AEliminate errorsEliminate surface air bubblesPackagingEngineeringPower transmission

The invention relates to an automatic conveying film sticking machine. The automatic conveying film sticking machine comprises a first unpowered conveying line, a second unpowered conveying line, a butyl sealer tape compaction tool and a film sticking device, wherein the first unpowered conveying line and the second unpowered conveying line are arranged on two sides of the butyl sealer tape compaction tool; the film sticking device is arranged at the end, through which a workpiece needing film sticking passes, of the butyl sealer tape compaction tool; the workpiece needing film sticking enters the butyl sealer tape compaction tool through the first unpowered conveying line, a film sticking action is completed through the film sticking device, and the film-sticked workpiece is output through the second unpowered conveying line; the butyl sealer tape compaction tool comprises an assembly welding frame, a rolling assembly and a transmission assembly, and the rolling assembly comprises a pair of upper rollers and a pair of lower rollers. The automatic conveying film sticking machine eliminates manual film sticking errors through high mechanical accuracy, and can prevent surface bubbles from occurring, enhance sticking force and improve production efficiency.

Owner:朱振西 +1

Motor rotor positioning system for hybrid vehicle and positioning method thereof

ActiveCN101594107AFlexible arrangementEliminate manual errorsElectronic commutatorsTesting equipmentZero crossing

The invention aims to provide a motor rotor positioning system for a hybrid vehicle and a positioning method thereof, which are suitable for the characteristics of a vehicle production line. The positioning system consists of a detection unit and a calibration unit, wherein the detection unit comprises a power device capable of driving a motor to be positioned to rotate, a detection host computer, a bar code scanner, a zero crossing detection device and a motor rotor position sensor arranged on the motor to be positioned, and the detection host computer is connected with the power device, the bar code scanner, the zero crossing detection device and the motor rotor position sensor; the calibration unit comprises a bar code scanner and a calibration host computer, and the calibration host computer is connected with a motor controller of the motor to be positioned; and the detection host computer and the calibration host computer are connected with a database server through a network respectively. The detection host computer detects the position angle value of the motor rotor through the zero crossing detection device and the motor rotor position sensor, transmits the position angle value to the calibration host computer, and further writes the position angle value into the motor controller so as to finish the positioning of the motor rotor.

Owner:CHERY AUTOMOBILE CO LTD

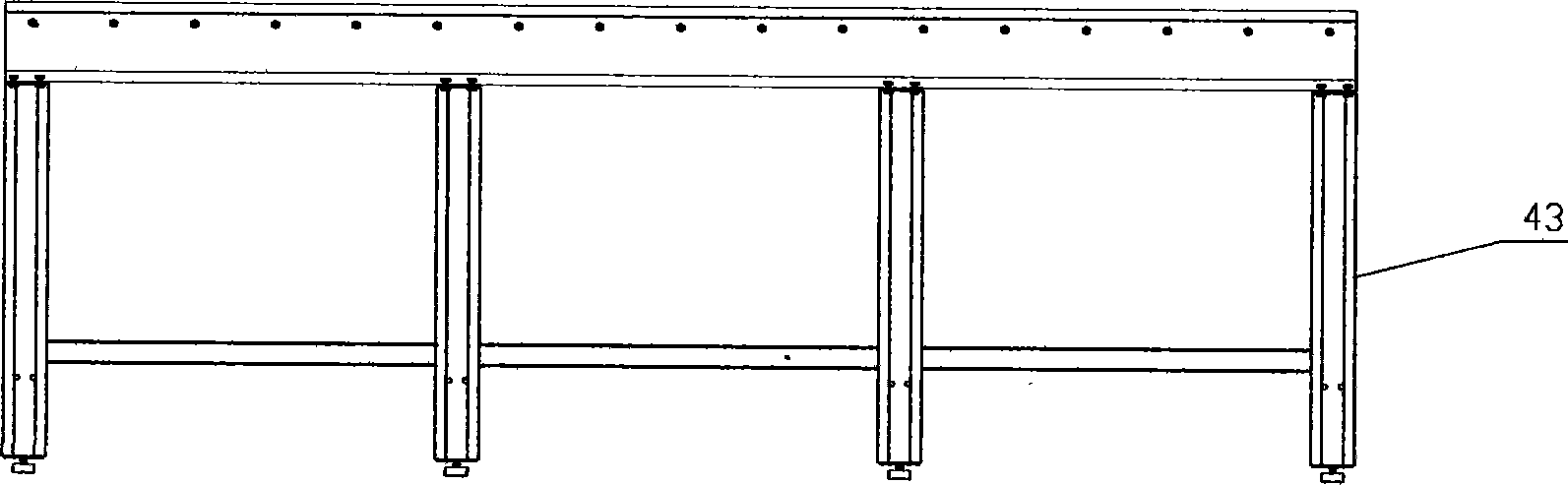

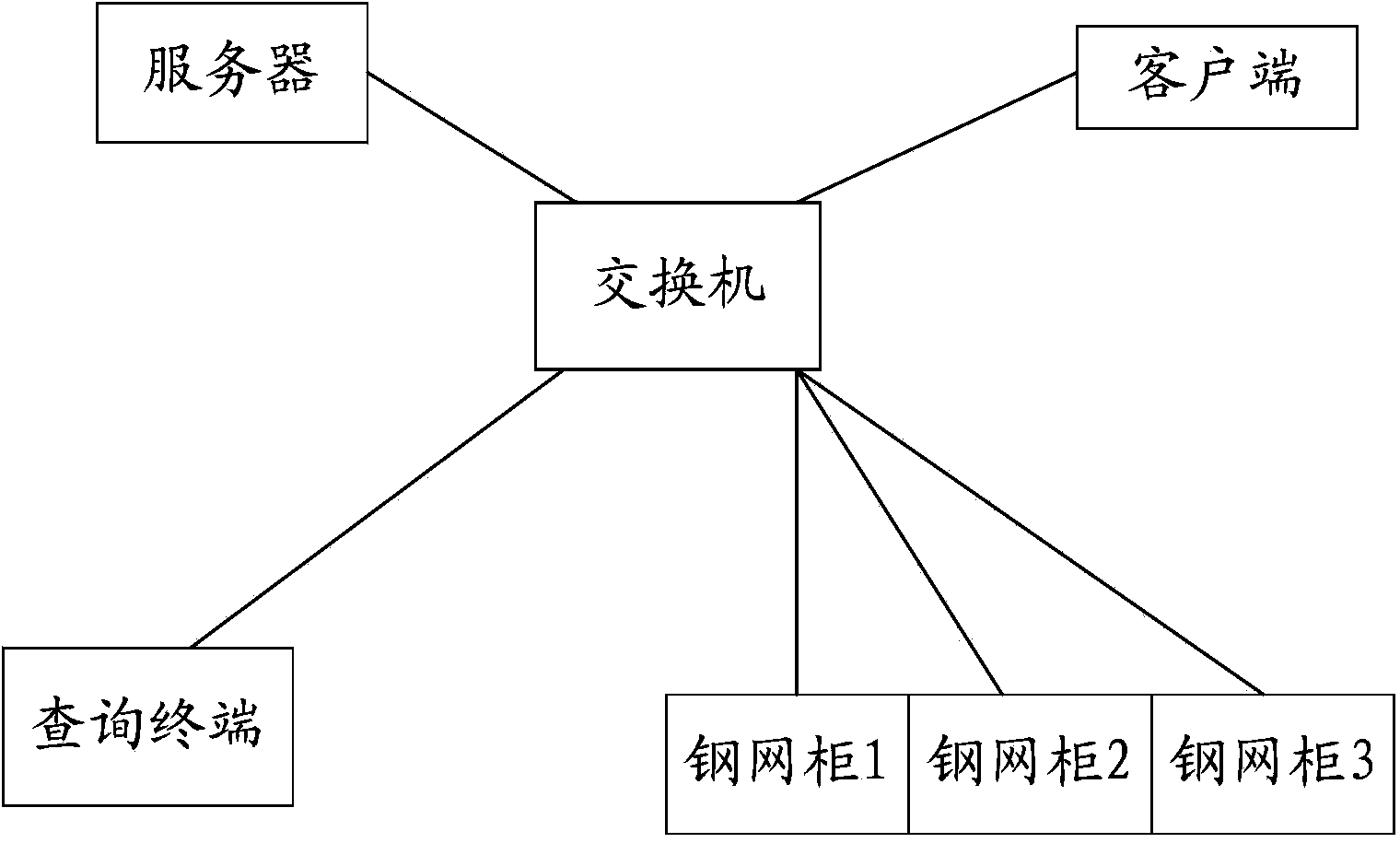

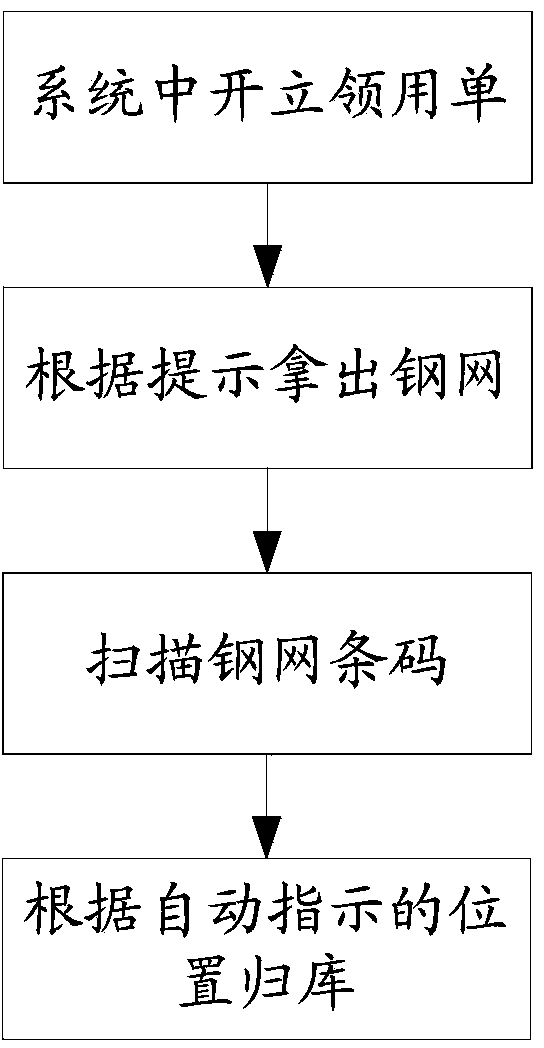

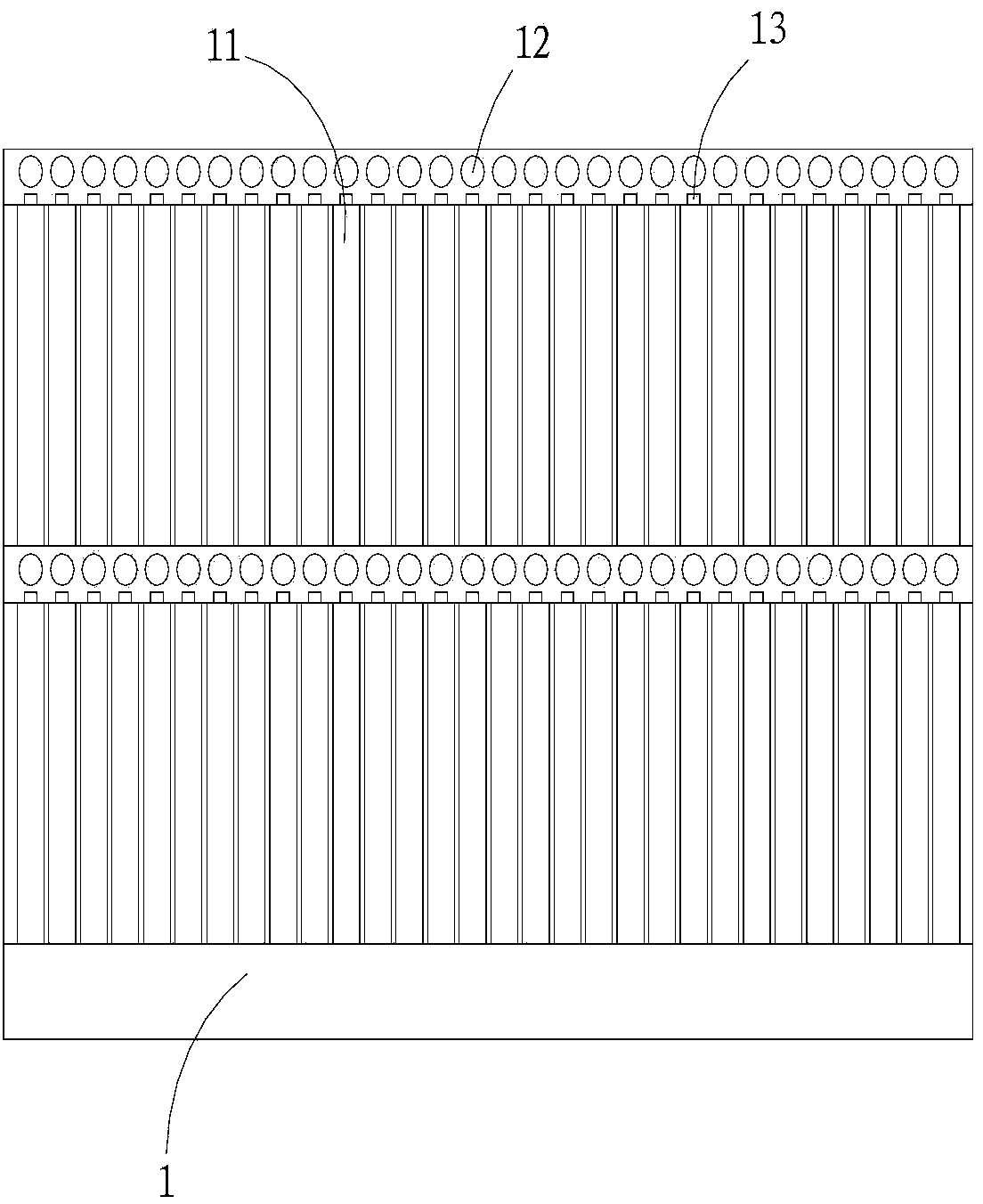

Method for managing steel meshes

InactiveCN103886410ASave search timeQuick and easy accessResourcesManufacturing computing systemsMetallurgyHolding room

The invention provides a method for managing steel meshes. The method includes the steps that bar codes are pasted to the steel meshes, wherein the bar codes are associated with related information of the steel meshes in a system; steel mesh storage positions are identified, and a steel mesh storage room view is built in the system, wherein the steel mesh storage room view is used for visually viewing the steel mesh storage conditions in steel mesh cabinets; when the steel meshes are requisitioned, a requisitioning bill is written in a client terminal or an inquiring terminal, the steel mesh cabinets automatically indicate the corresponding steel mesh storage positions and enable the steel meshes to be catapulted out, and an operator only requires to take out the steel meshes according to reminding; when the steel meshes are put in storage, the bar codes of the steel meshes are scanned at the inquiring terminal, the intelligent steel mesh cabinets automatically indicate the placement storage positions, and the operator only requires to place the steel meshes according to reminding. According to the method, intelligent management is achieved, the searching efficiency is high, and errors do not easily occur.

Owner:福建摩尔软件有限公司 +1

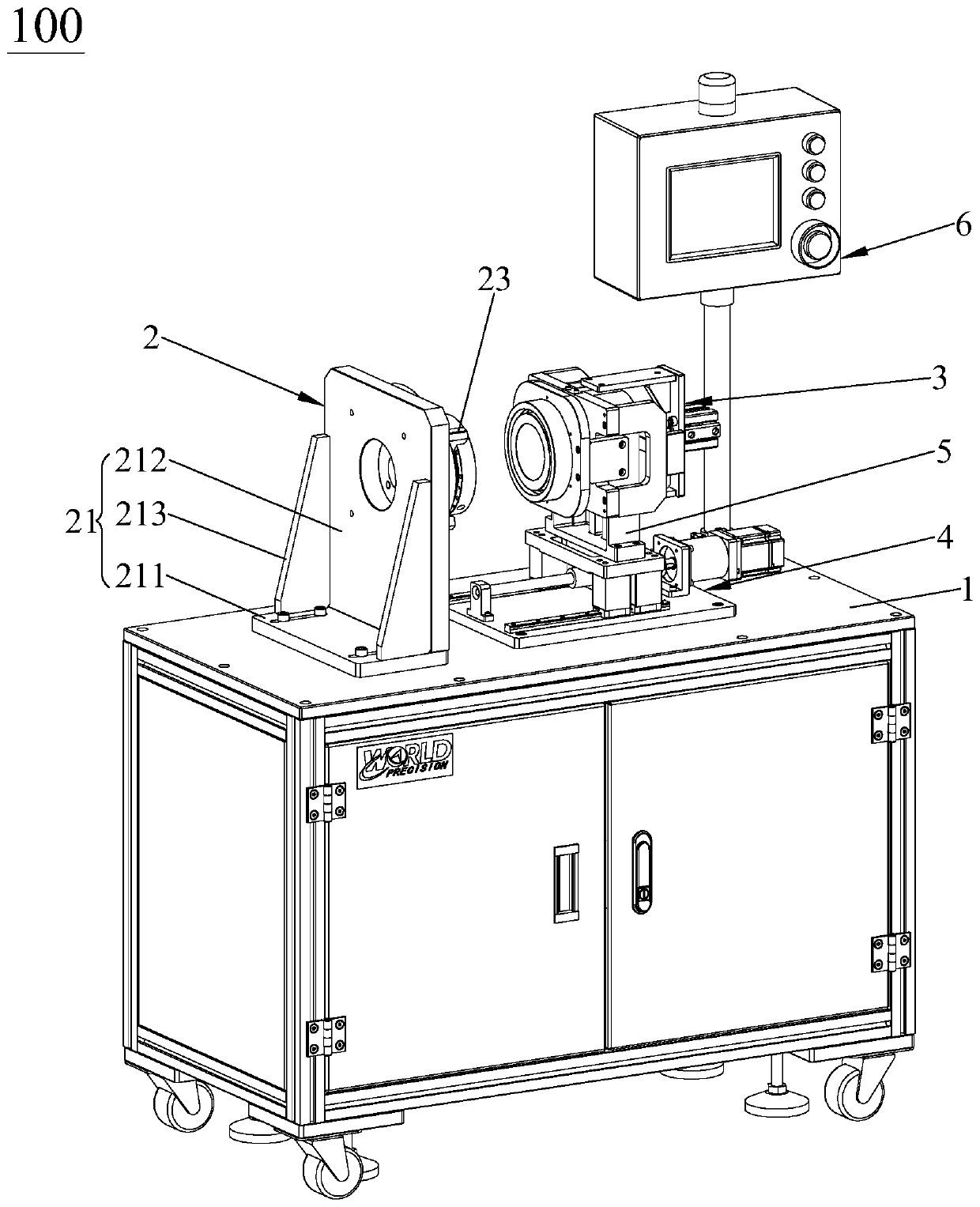

Automatic assembling machine for intersecting bearing and skeleton oil seal

PendingCN110561083AHigh degree of automationFree from damageMetal working apparatusReducerEngineering

The invention discloses an automatic assembling machine for an intersecting bearing and a skeleton oil seal. The automatic assembling machine comprises a working table, a clamp mechanism, a clamping mechanism used for clamping the intersecting bearing, and a carrying mechanism used for carrying the clamp mechanism. The clamp mechanism and the carrying mechanism are arranged on the working table. The clamp mechanism is installed at the output end of the carrying mechanism. The clamping mechanism and the clamp mechanism are arranged oppositely in the same direction. The carrying mechanism drivesa clamp to move in the direction close to or away from the clamping mechanism. The clamp mechanism comprises an inner pressing ring for pressing an inner ring of the intersecting bearing in an abutting against manner, an outer pressing ring for pressing an outer ring of the intersecting bearing in an abutting against manner, and an oil seal pressing ring arranged between the inner pressing ring and the outer pressing ring in a sliding manner. The inner pressing ring, the outer pressing ring and the oil seal pressing ring define a containing cavity used for containing the skeleton oil seal together. The oil seal pressing ring slides and pushes the skeleton oil seal to be pressed into the intersecting bearing. The automatic assembling machine is high in automation degree, assembling precision and assembling efficiency, the sealing performance of the intersecting bearing is improved, and the sealing performance of a harmonic speed reducer is ensured.

Owner:DONGGUAN WORLD PRECISION MACHINERY

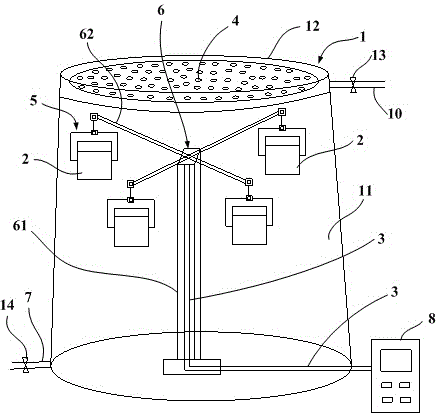

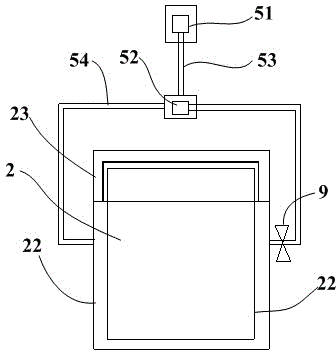

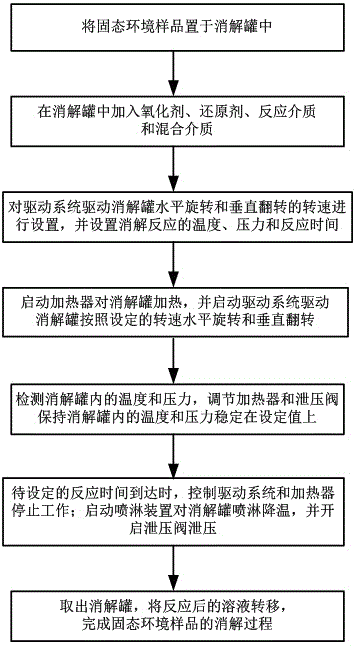

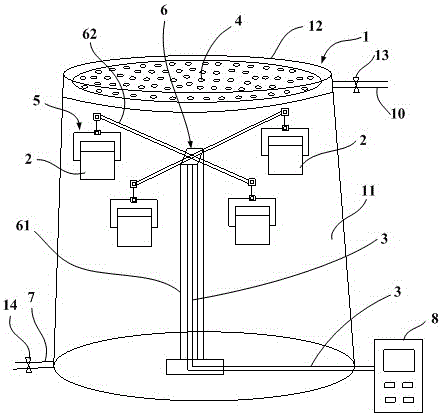

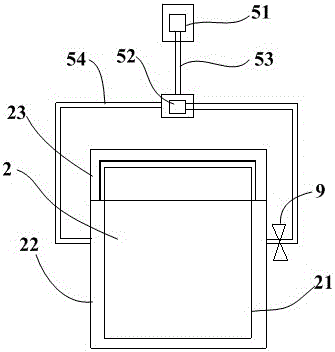

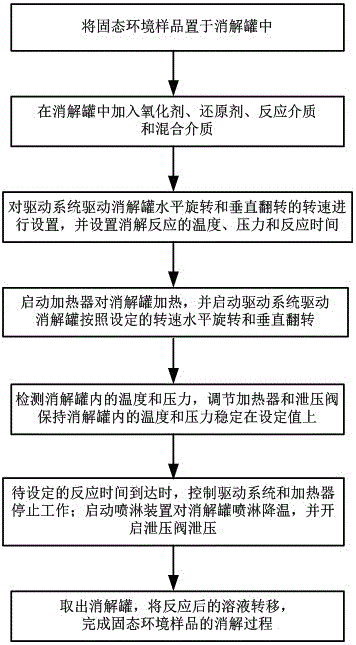

Digestor and digestion method for solid-state environmental sample

ActiveCN104359750AHigh degree of automationHigh temperature and high degree of automationPreparing sample for investigationDigestionPressure sensor

The invention discloses a digestor and a digestion method for a solid environmental sample. The digestor for the solid environmental sample comprises a condensation tank, a digestion tank and a driving system used for driving the digestion tank to horizontally rotate and vertically turn over, wherein the driving system is connected with the digestion tank, and the digestion tank is suspended in the condensation tank by virtue of a support; a heater, a temperature sensor and a pressure sensor are arranged in the digestion tank, a pressure relief valve is arranged outside the digestion tank and is communicated with the interior of the digestion tank by virtue of a pipeline; and a spraying device used for cooling the digestion tank is arranged in the condensation tank. The digestor for the solid environmental sample has the characteristics of high efficiency, high automation degree, high stability, easiness for operation, easiness in maintenance and the like, an experimental period is shortened, and the cost is also reduced. The digestion method provided on the basis of the digestor has the advantages that defects of the traditional method are quickly and efficiently overcome, the analysis capability is greatly improved, the experiment cost is effectively reduced, and higher security is realized.

Owner:OCEANOGRAPHIC INSTR RES INST SHANDONG ACAD OF SCI

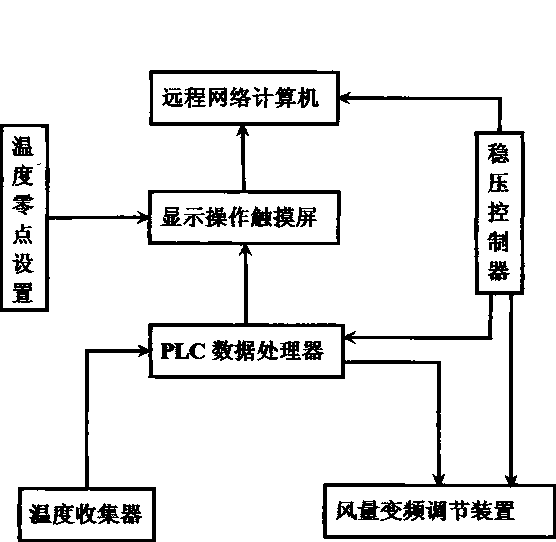

Automatic temperature regulating and controlling system

InactiveCN103673653AAvoid the disadvantages of low efficiency of manual adjustmentEliminate manual errorsAir supply regulationControl devices for furnacesBrickFrequency conversion

The invention discloses an automatic temperature regulating and controlling system applied to a roasting link of a kiln. The automatic temperature regulating and controlling system is characterized by comprising a temperature collection device, a PLC data processor, a display operational touch screen, a remote network computer, a blast capacity frequency conversion regulating device and a pressure stabilizing controller which are all connected; a zero temperature point is arranged on the display operational touch screen. The automatic temperature regulating and controlling system has the advantages that automatic temperature regulation and control in the roasting link of the kiln is achieved, the problems that the roasting link of a brick and tile kiln is low in automation degree and single in temperature detection function are solved, labor force in the temperature regulating and controlling process of a traditional kiln is reduced, and the yield is increased.

Owner:CHENGDU VONXAN AUTOMATION SCI & TECH

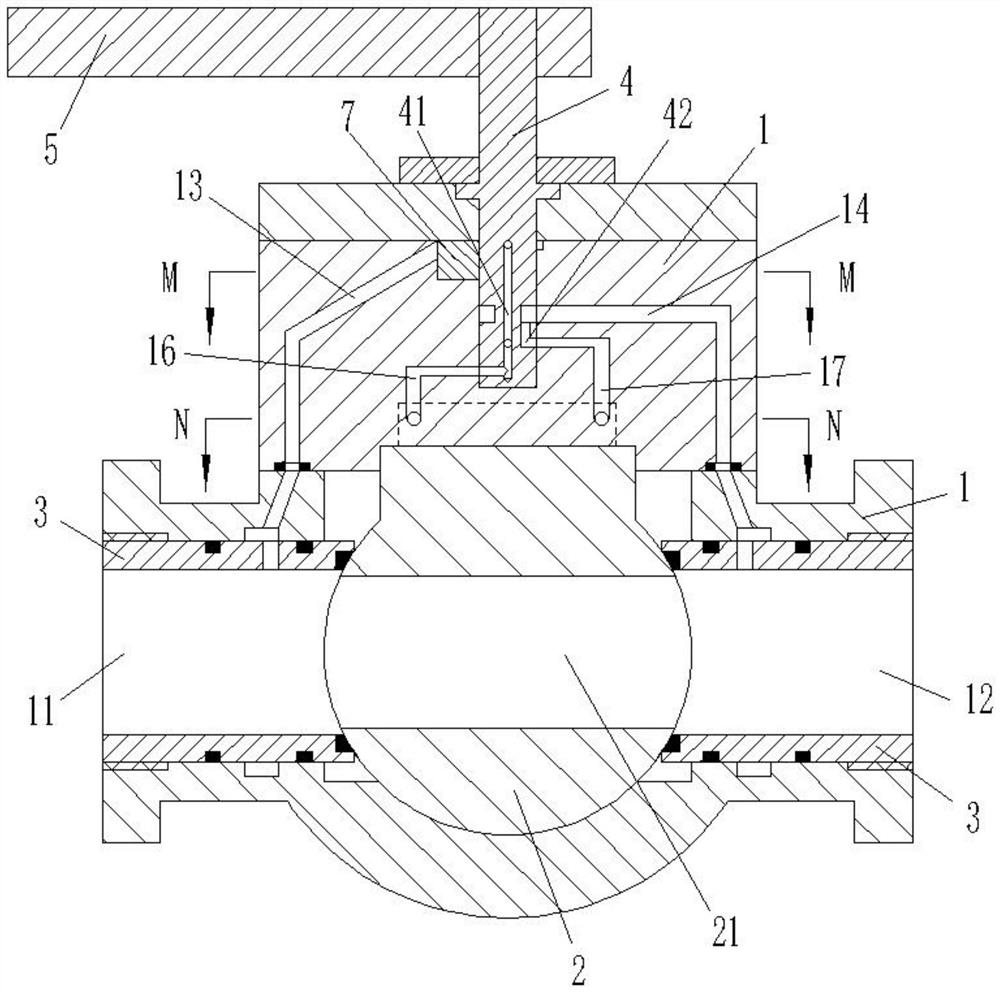

Ball valve

ActiveCN113028091AReduce usageReduce manufacturing costPlug valvesOperating means/releasing devices for valvesLine tubingIndustrial engineering

The invention belongs to the technical field of pipeline valves, and discloses a ball valve which comprises a valve body and a valve ball. The valve body is provided with an inlet, an outlet, an inlet runner, an outlet runner and a control groove, and the valve ball is located in the valve body and provided with a control plate and a through hole. The control plate extends into the control groove to divide the control groove into a first control groove and a second control groove, and the control plate can reciprocate along the control groove to drive the valve ball to rotate relative to the valve body so as to control the communication relation between the through hole and the inlet and the communication relation between the through hole and the outlet. One end of the inlet runner communicates with the inlet, the other end of the inlet runner selectively communicates with the first control groove and the second control groove, one end of the outlet runner communicates with the outlet, and the other end of the outlet runner selectively communicates with the second control groove and the first control groove. The ball valve is used in a high-pressure pipeline, not only is low in manufacturing cost, but also has smaller weight and size, and has higher installation flexibility and use convenience.

Owner:TIANJIN CHINA NUCLEAR TECH IND CO LTD

Automatic continuous water distribution system

InactiveCN103676756AAvoid continuityAvoid efficiencyProgramme control in sequence/logic controllersWater useDistribution system

The invention discloses an automatic continuous water distribution system applied in multiple industrial production water distribution links. The system is characterized in that the system comprises a raw material automatic sampling and moisture measuring meter, a raw material weight acquisition device, a PLC data processing module, a controllable water supply device, a liquid flow measuring instrument, a finished product automatic sampling and moisture measuring instrument, a voltage stabilizing controller, and a display operation touch screen. The display operation touch screen is provided with two parameter settings which are a water proportion setting and a zero point setting. The automatic continuous water distribution system has the advantages that the fully automatic high precision continuous water supply of a water distributing link in an industrial production process is realized, the disadvantages of discontinuous container measurement water supply and low efficiency are avoided, the errors of artificial operations in production water distribution links are eliminated, the influence of many important factors on the water adding precision is avoided, the precision of water adding is greatly raised, the water consumption of a producer is saved, the environment is protected, the labor is reduced, and the productivity is raised.

Owner:CHENGDU VONXAN AUTOMATION SCI & TECH

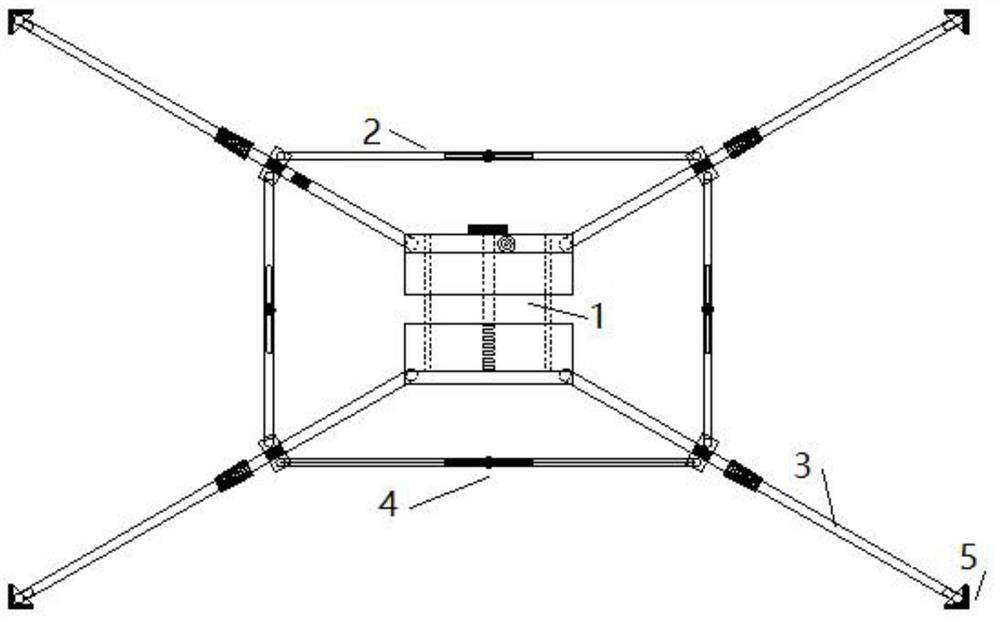

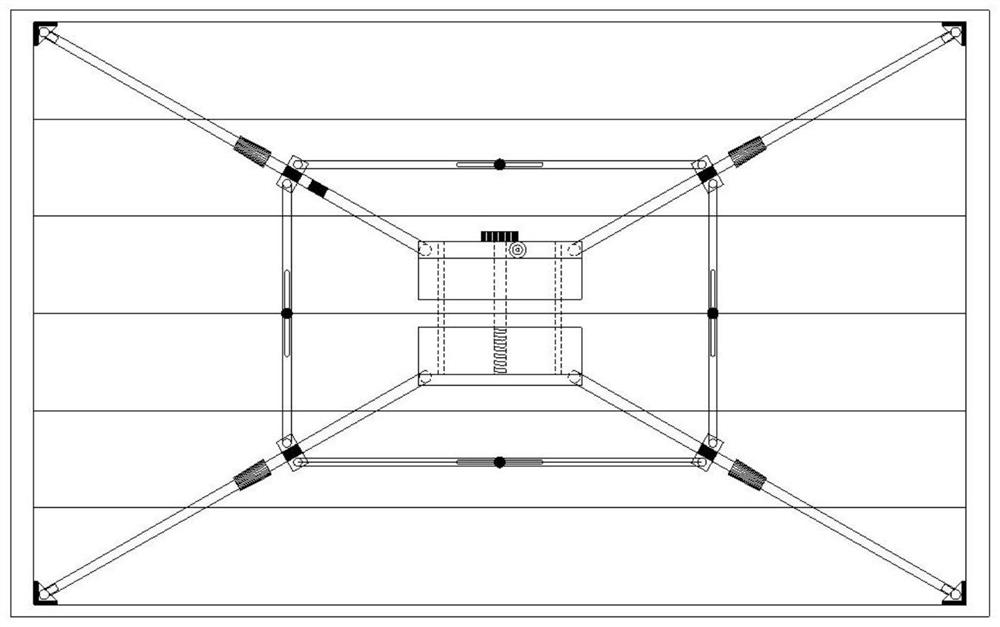

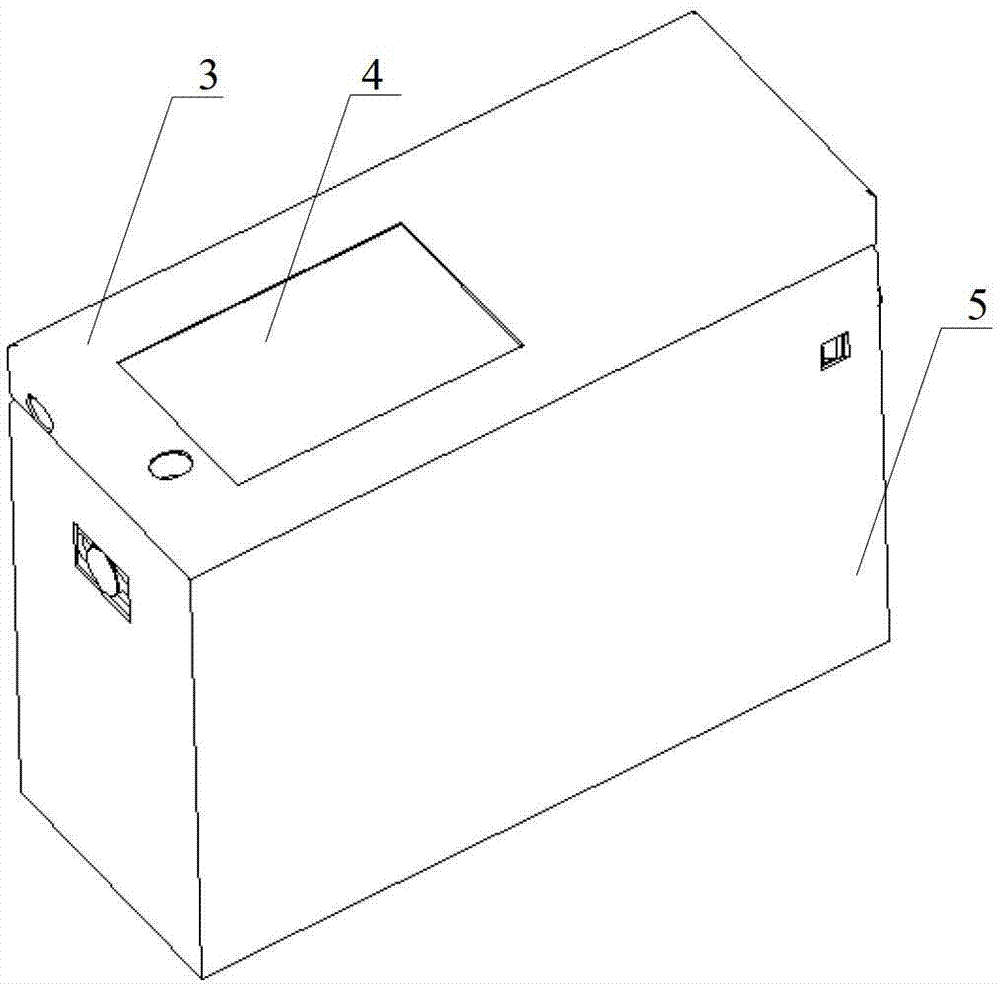

Exploration rock core digital image acquisition device

PendingCN114352900AEliminate manual errorsGuaranteed image qualityStands/trestlesRock coreComputer graphics (images)

The invention relates to an exploration rock core digital image acquisition device in the technical field of digital image acquisition equipment. The exploration rock core digital image acquisition device comprises a camera tray clamp used for fixing and lifting a camera; the four telescopic supporting rods are used for adjusting the mounting height of the camera tray clamp and are symmetrically arranged relative to the center of the camera tray clamp; the horizontal limiting stabilizing rod is used for transversely limiting the four telescopic supporting rods; and the limiting feet are arranged at the lower ends of the four telescopic supporting rods. Manual process control is replaced by the device, manual operation errors are basically eliminated, and the image quality is ensured; the device is completely designed according to the requirement of an image acquisition method required by digital image identification, the acquired digital image is high in quality, and the device is suitable for intelligent identification of rock core digital images; the device can be used for hanging awning cloth, so that the interference of ambient light to acquired images is eliminated, and the light of all image results is uniform; the device is easy to install, can be stored and is easy to operate.

Owner:长江三峡勘测研究院有限公司(武汉)

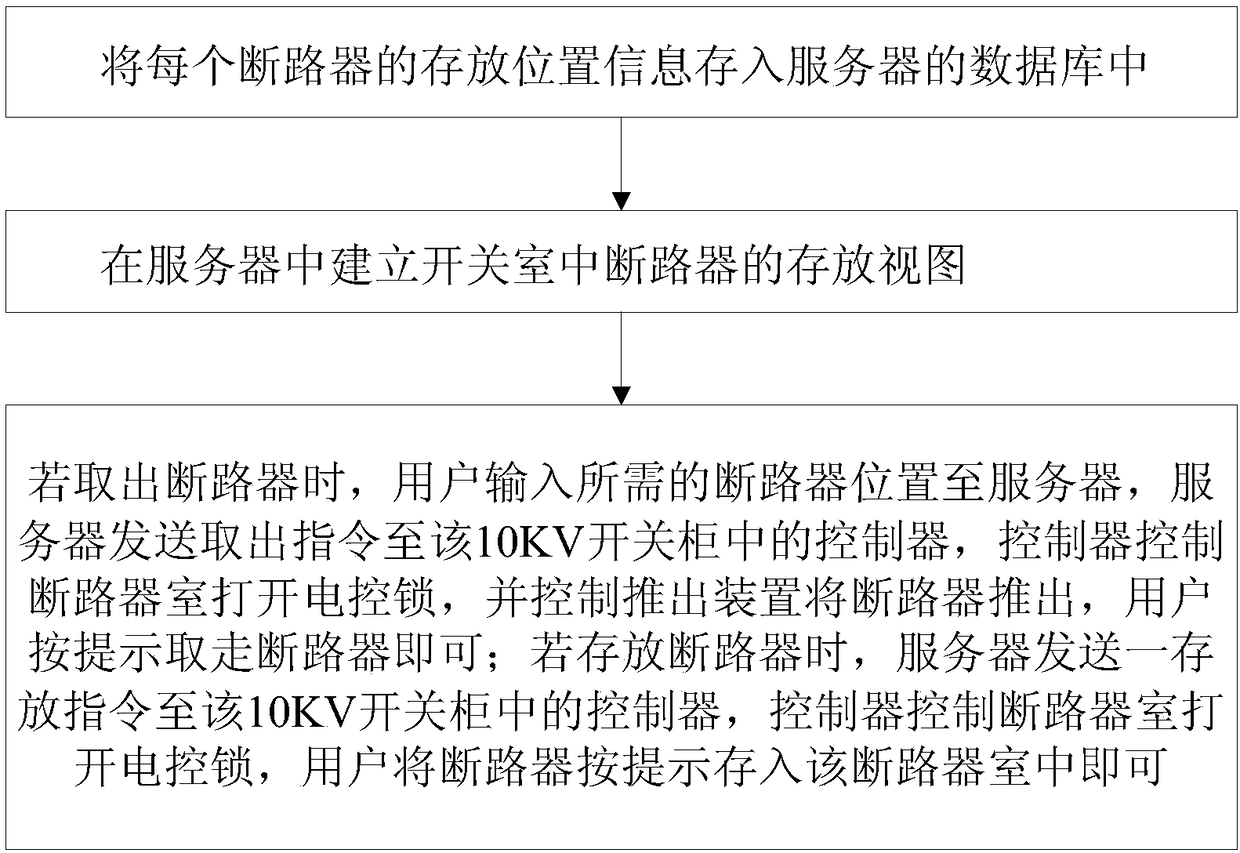

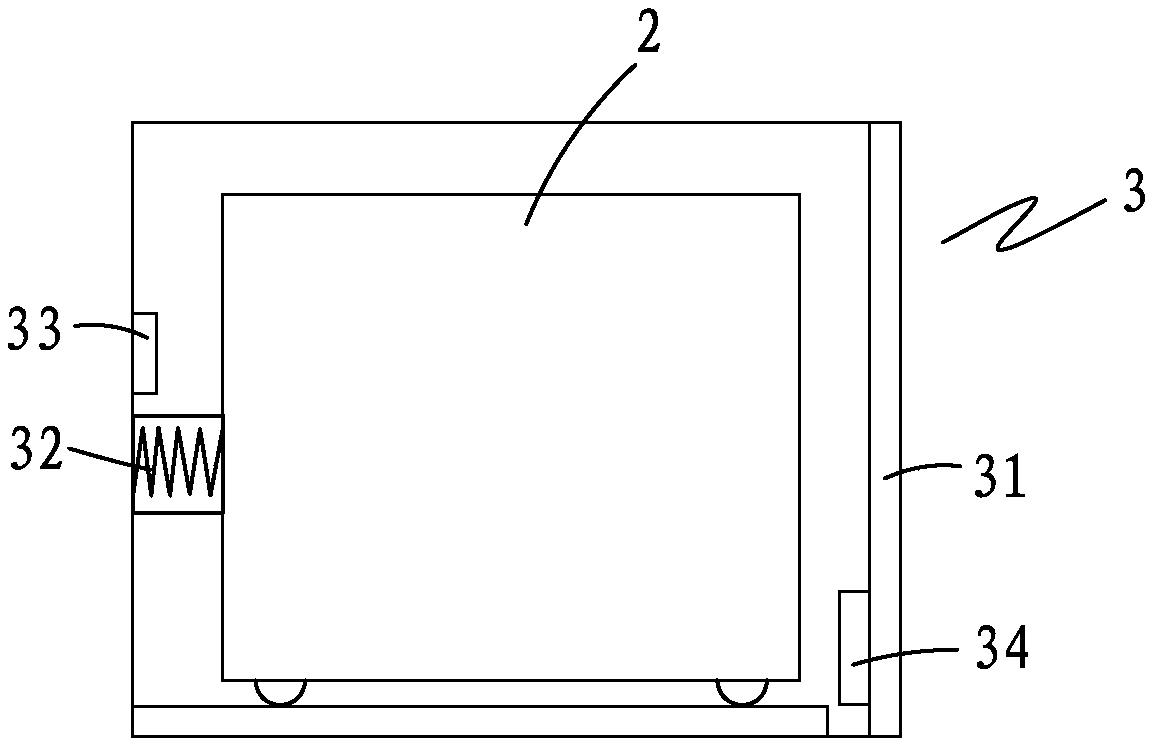

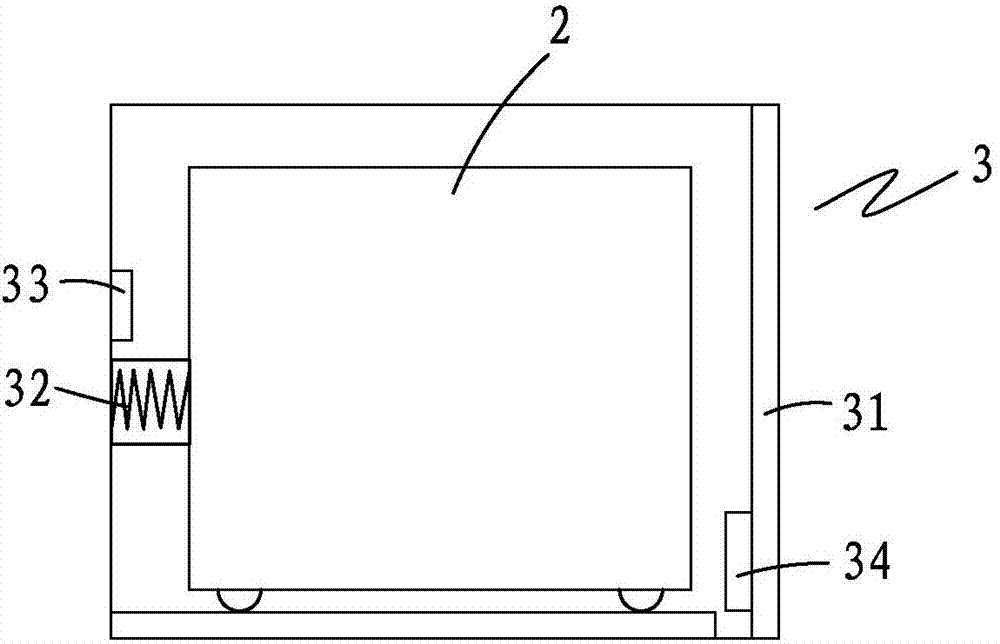

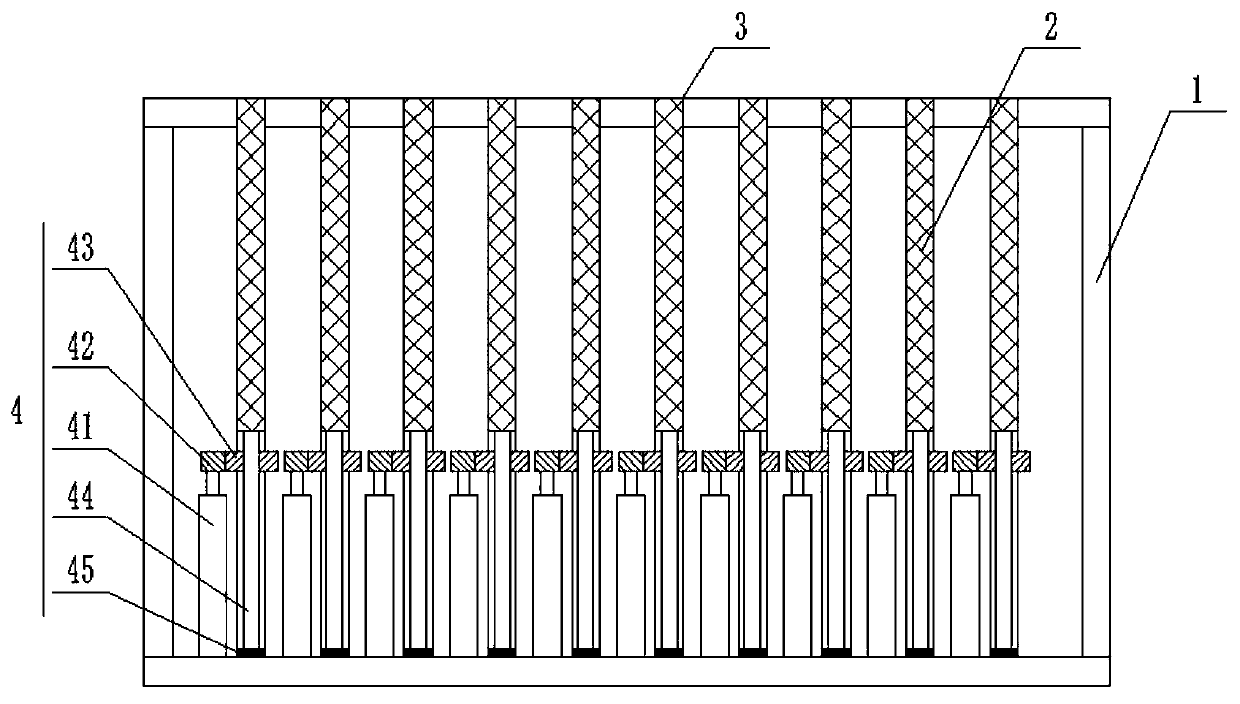

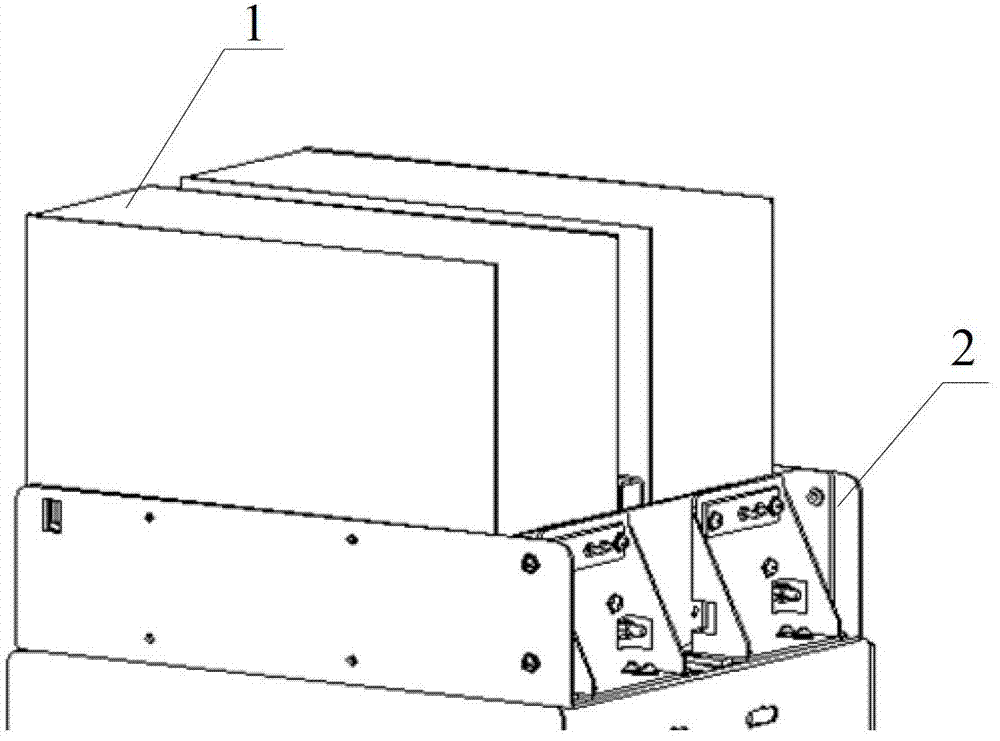

A circuit breaker management method

InactiveCN107069460BSave search timeShorten working timeSwitchgear with horizontal withdrawalSubstation/switching arrangement casingsSwitchgearEmbedded system

The invention proposes a breaker managing method. The method comprising: requiring a 10KV switchgear; saving the placing position information of each breaker in a server database; establishing a storage view for the breakers in the switch chamber; if new breakers are to be taken out, inputting by a user the positions of the required breakers to the server; sending the take-out instruction by the server to the controller of the 10KV switchgear; controlling by the controller the breaker chamber to open the door plate and controlling the push device to push the breakers out; taking away the breakers by the user according to the instruction; if the breakers are to be placed, sending a storage instruction by the server to the controller of the 10KV switchgear; controlling by the controller the breaker chamber to open the door plate; and storing the breakers in the breaker chamber by the user according to the instruction. With the method, the working efficiency is raised.

Owner:SHANDONG POLYTECHNIC COLLEGE

Breaker managing method

InactiveCN107069460ASave search timeShorten working timeSwitchgear with horizontal withdrawalSubstation/switching arrangement casingsUser inputSwitchgear

The invention proposes a breaker managing method. The method comprising: requiring a 10KV switchgear; saving the placing position information of each breaker in a server database; establishing a storage view for the breakers in the switch chamber; if new breakers are to be taken out, inputting by a user the positions of the required breakers to the server; sending the take-out instruction by the server to the controller of the 10KV switchgear; controlling by the controller the breaker chamber to open the door plate and controlling the push device to push the breakers out; taking away the breakers by the user according to the instruction; if the breakers are to be placed, sending a storage instruction by the server to the controller of the 10KV switchgear; controlling by the controller the breaker chamber to open the door plate; and storing the breakers in the breaker chamber by the user according to the instruction. With the method, the working efficiency is raised.

Owner:SHANDONG POLYTECHNIC COLLEGE

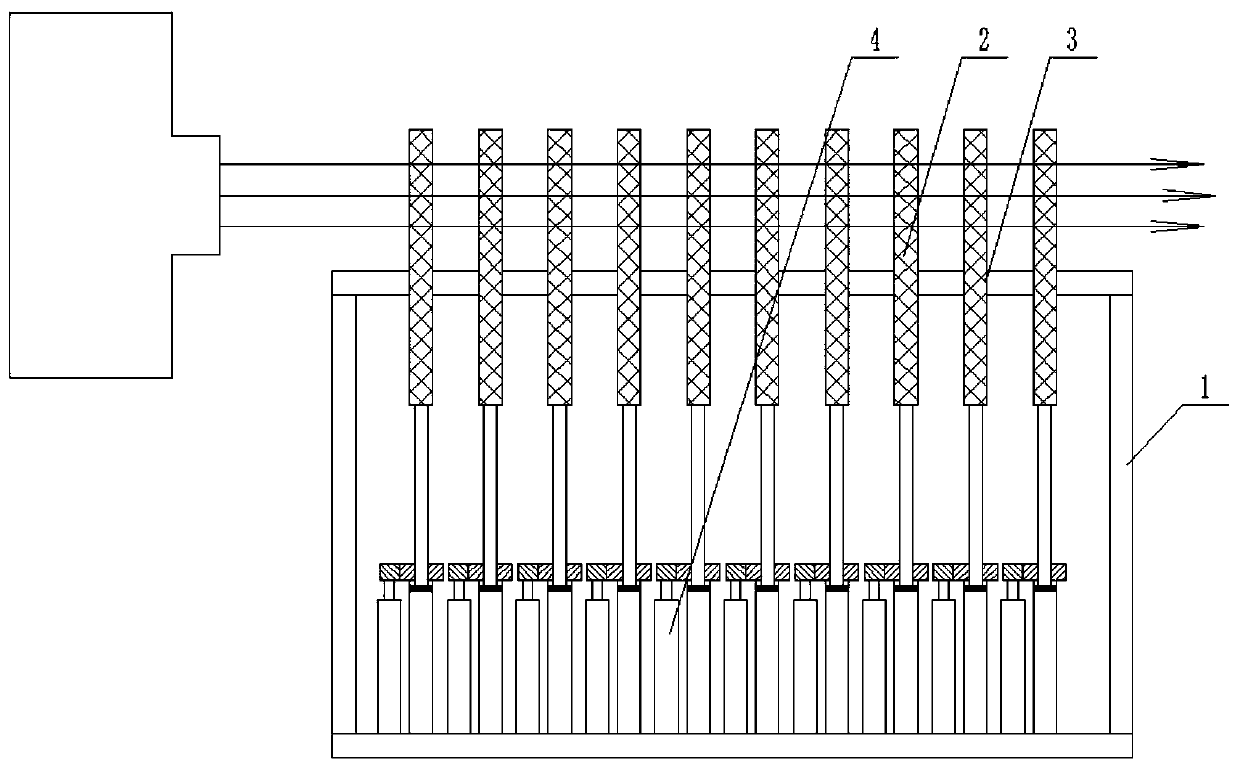

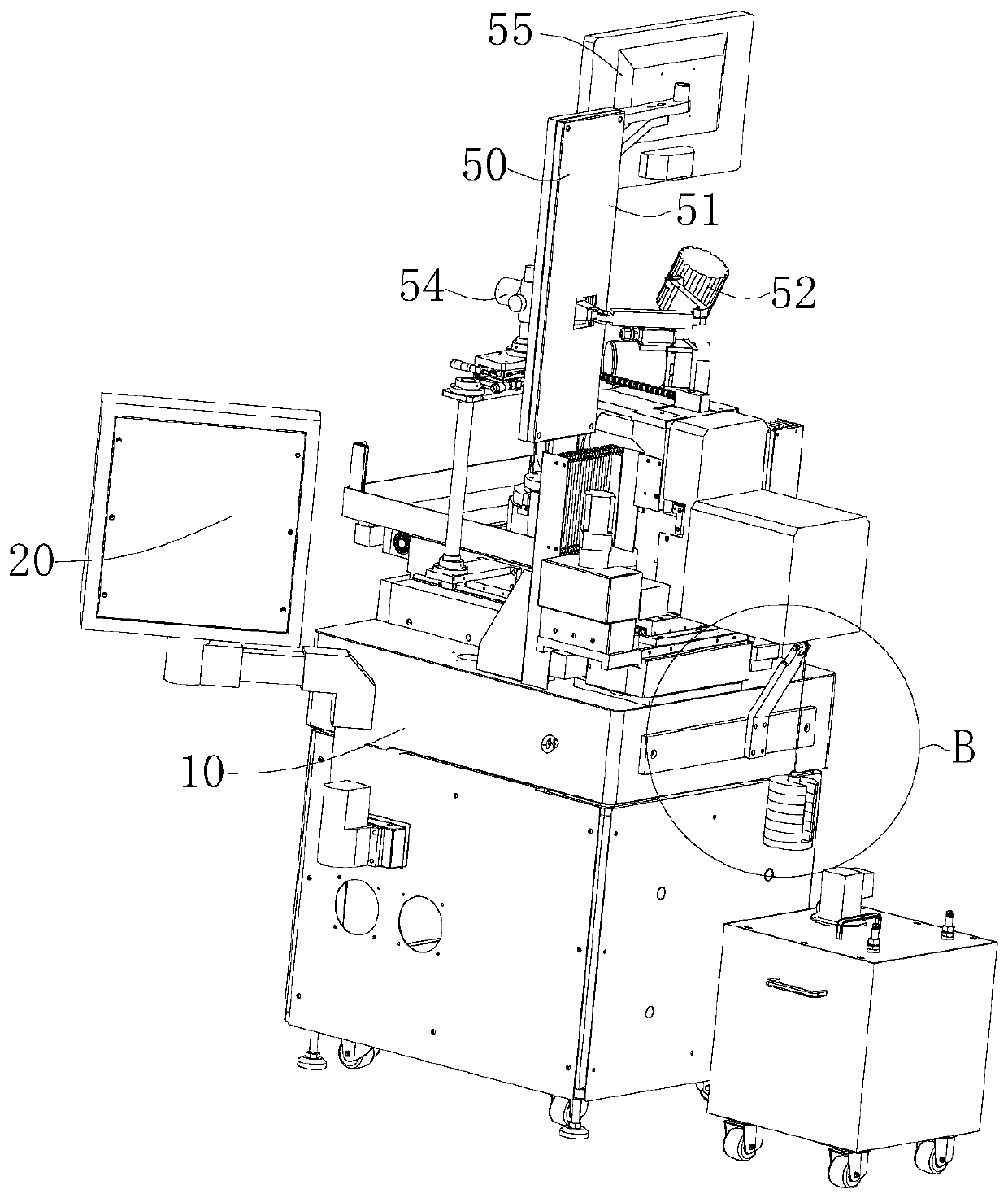

Automatic adjusting device of CBCT x-ray filter

PendingCN109770931AEnhanced inhibitory effectAdjustable thicknessRadiation diagnosticsX-ray filterX-ray

The invention provides an automatic adjusting device of a CBCT x-ray filter. The device overcomes the deficiencies of the prior art and achieves fully-automatic and precise operation and a good imaging effect. According to the adopted technical scheme, the automatic adjusting device of the CBCT x-ray filter comprises a box body and filter plates, the box body is of a fully enclosed structure, anda plurality of long holes are transversely formed in an upper plate of the box body; the filter plates are vertically arranged in the box body and used for absorbing low-energy X-rays and inhibiting the X-rays from scattering and correspond to the long holes which are formed just in the upper portions one to one, the bottom of each filter plate is provided with a lifting mechanism, and the liftingmechanisms are fixedly disposed in the box body. The filter plates can be lifted out of the long holes for filtering the X-rays through the corresponding lifting mechanisms. The device can be widelyapplied to the field of radiography.

Owner:上海伽玛星科技发展有限公司

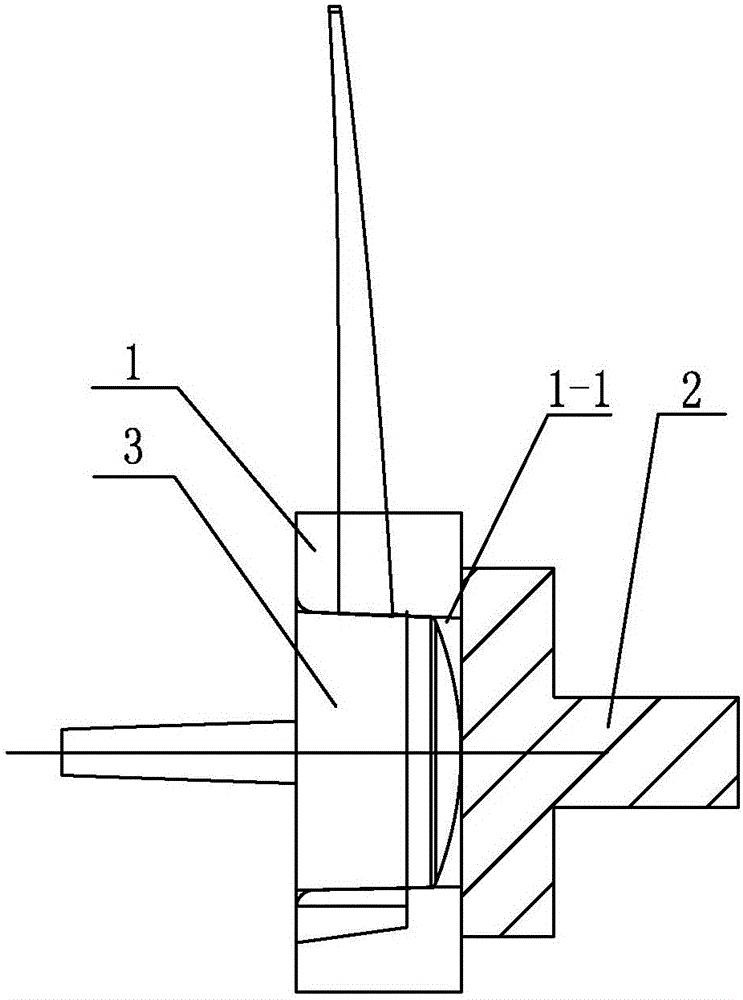

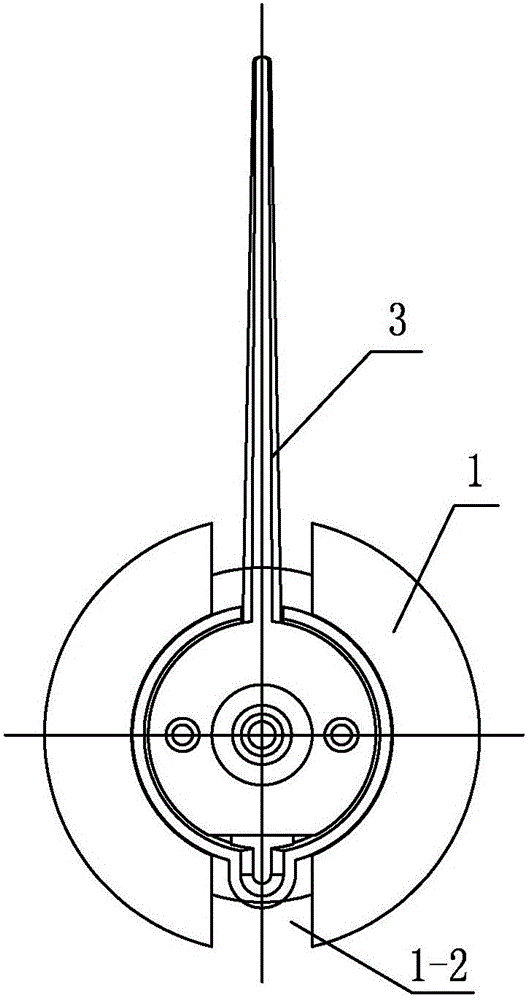

An automobile instrument pointer shaft detection device

ActiveCN105783676BEliminate manual errorsGuaranteed parallelismAngles/taper measurementsOptical axisFeeler gauge

The invention discloses a detector for a pointer shaft of an automobile instrument, relates to shaft detectors and aims at solving the problems that in traditional detection a pointer shaft is placed in a small optical axis manually, a non-key part is detected by a filler gauge, the size of a key part of the pointer shaft is obtained via theoretical reckoning, and further a detection result is fuzzy and inaccurate and has large error and the detection type is single. The detector comprises a pedestal, a vertical plate, a pointer fixing seat, a linear bearing, a pointer plate, a cylinder, a vacuum pump and two guide posts, the vertical plate is fixedly mounted on the pedestal, the two guide posts are arranged on the pedestal in parallel vertically, the vertical plate over the pointer plate is provided with the cylinder which is arranged vertically, a driving rod of the cylinder penetrates the pointer plate and is fixedly connected with the pointer plate, the tail end of the driving rod of the cylinder is connected with the pointer fixing seat, the pointer fixing seat is provided with a vacuum cavity communicated with an installation groove, and the vacuum pump is communicated with the vacuum cavity of the pointer fixing seat via a negative-pressure air tube. The detector is used for instrument pointer shaft detection.

Owner:AEROSPACE HI TECH HLDG GROUP

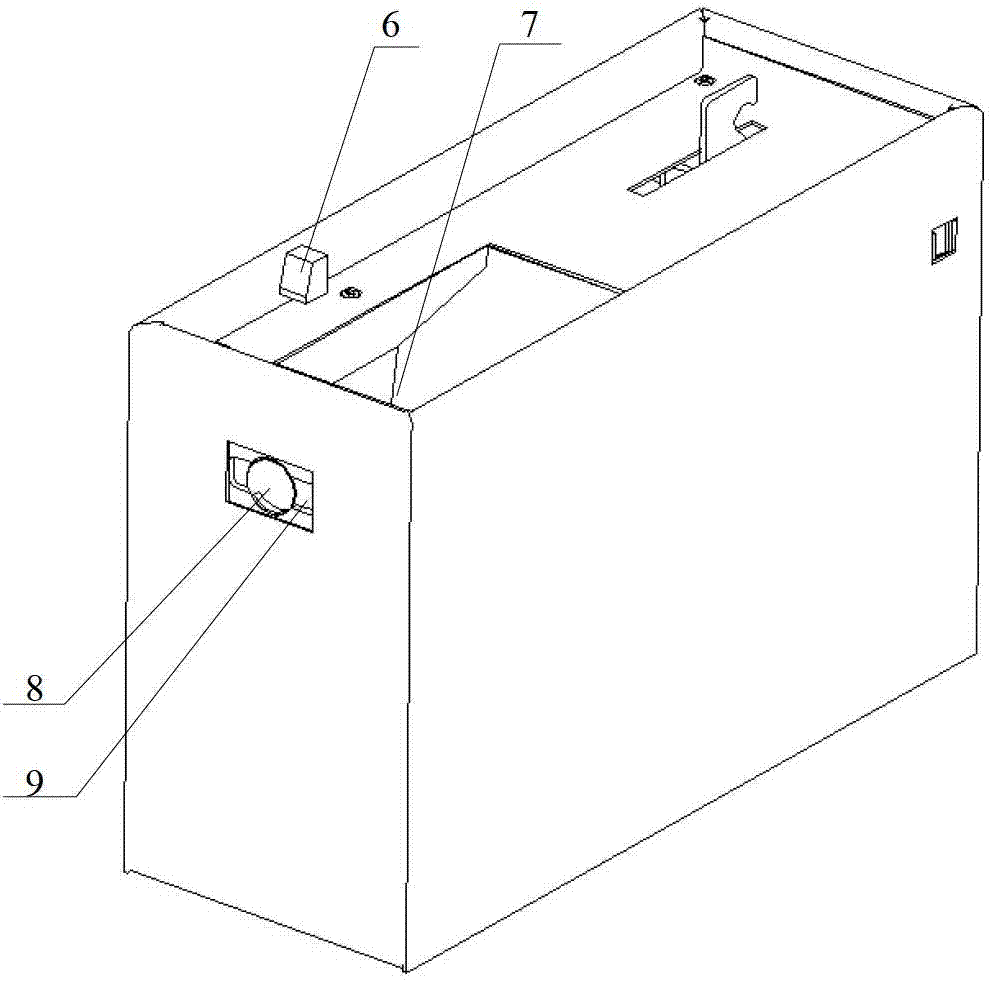

Cash box of a coin handling machine

ActiveCN102968848BEfficient managementAccurate collectionCoin countersData processing systemLocking mechanism

The invention discloses a cashbox of a coin processor, comprising a box body and a box cover; a locking bar fixed on the box cover is hooked by a locking plate which is fixed on a lock cylinder and capable of rotating along with the lock cylinder, so that the box cover is locked; the box body comprises a coin cabin and an information button mounted on the box body through an information button mounting frame; and the information button is used for storing cashbox information and used as the unique identifier and identification. Through being matched with a reader-writer, the cashbox can be used for accurately and rapidly acquiring the information data in the whole circulation process of the cashbox, so that the cashbox can be effectively managed through a data processing system, and errors caused by manual operation can be stopped; and due to the adoption of a self-locking mechanism of the cashbox, working staffs cannot directly contact with coins in the cashbox if no legal opening tools are provided, so that the safety of the coins is further ensured, the problem that the coins is possibly contacted illegally by maintenance personnel during the operation of the coin processor is solved, and the cashbox can be widely applied to coin collection and transportation of financial mechanisms.

Owner:BEIJING AEROSPACE MEASUREMENT & CONTROL TECH

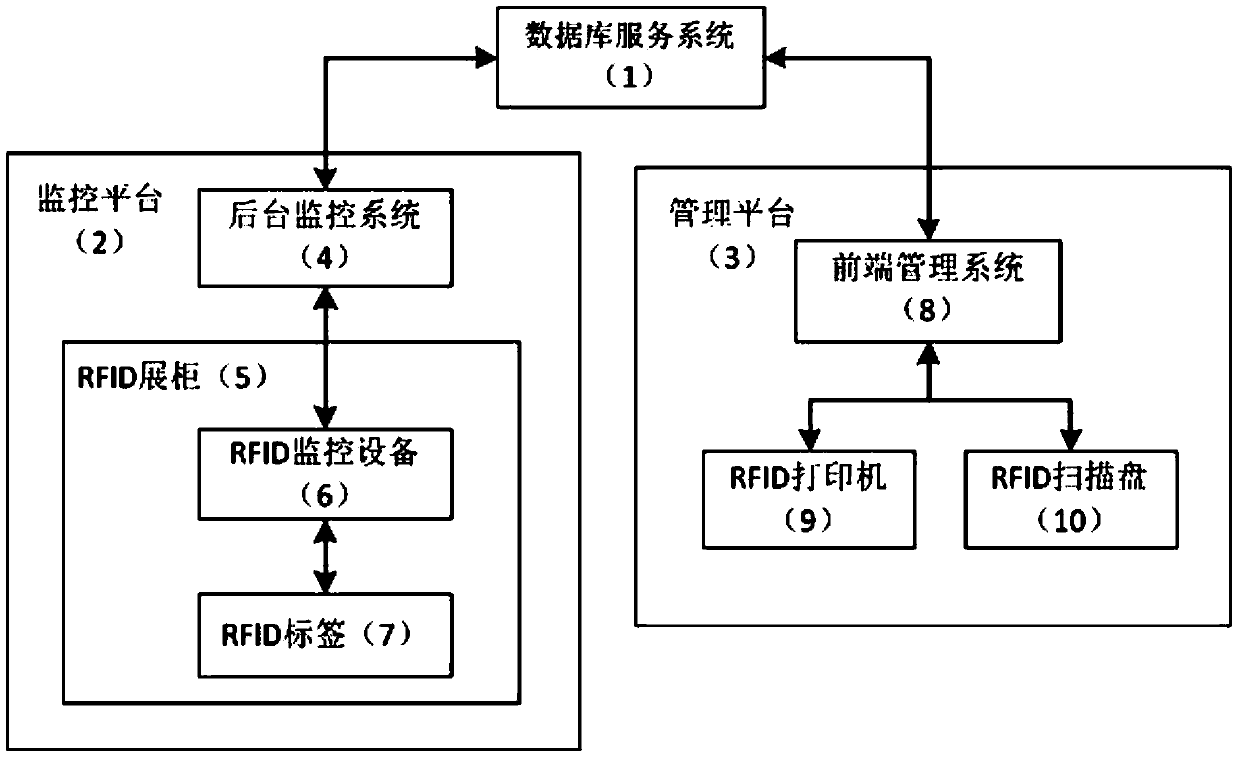

An intelligent showcase monitoring management system based on a radio frequency identification technology

InactiveCN109685172AImprove accuracyImprove real-time performanceCo-operative working arrangementsMonitoring systemDatabase services

The invention discloses an intelligent showcase monitoring and management system based on a radio frequency identification technology, and aims to provide an intelligent showcase monitoring and management system which can realize automatic real-time inventory and automatic monthly settlement sales statistics and completely replace an original mode of manually counting monthly settlement on site, so that manpower resources are greatly saved, and the accuracy and real-time performance of data are improved. According to the technical scheme, the system comprises a background database service system, a monitoring platform and a management platform, The background database service system is connected with the monitoring platform and the management platform through a network; The monitoring platform obtains data from the background database service system; The monitoring platform is composed of a background monitoring system and an RFID showcase, and the background monitoring system and theRFID showcase are in connection and communication through a network. The management platform is composed of a front-end management system, an RFID printer and an RFID scanning disk. The invention relates to the field of intelligent showcase monitoring management systems.

Owner:广州卓正信息技术有限公司

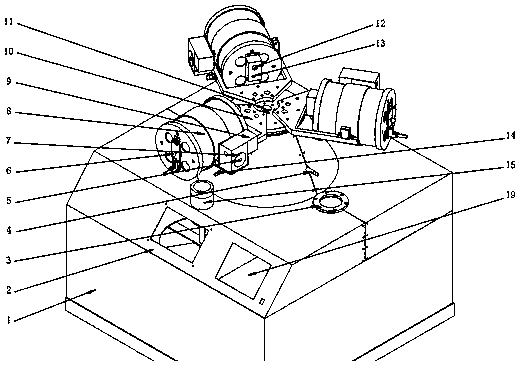

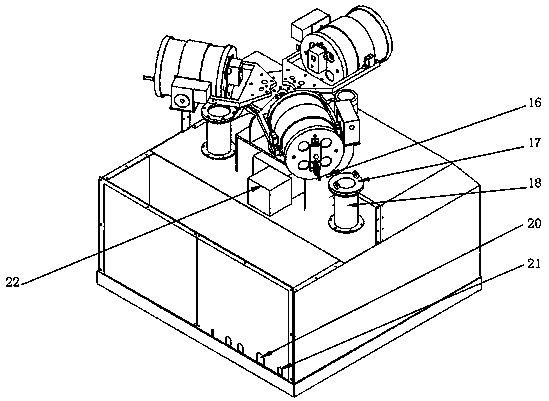

Knife flywheel grinding device

PendingCN110026900AGuaranteed yieldControl the sliding distanceGrinding carriagesGrinding drivesAutomatic controlFlywheel

The invention belongs to the technical field of knife flywheel grinding, and particularly relates to a knife flywheel grinding device. The device is characterized in that a mounting assembly comprisesa first sliding platform, a second sliding platform and a mounting positioning structure, wherein a knife flywheel is arranged on the mounting positioning structure; the first sliding platform can slide on a mounting seat and is capable of sliding the knife flywheel on the mounting positioning structure in a wide range, thus the mounting positioning structure is close to a grinding assembly; thesecond sliding platform is arranged, and a sliding control structure is arranged between the second sliding platform and the first sliding platform, so that the second sliding platform can be controlled to slide on the first sliding platform through a control assembly; in addition, the sliding distance of the second sliding platform can be accurately controlled through the control assembly, so that the error of the knife flywheel grinding size and the preset size is reduced. Therefore, the sliding control structure can be automatically controlled through the control assembly so as to ensure the feeding and returning distance accuracy, and as a result, the error of manual operation is removed, and the yield of the grinded knife flywheel can be ensured.

Owner:深圳市威雄精机有限公司

An instrument pointer shaft detection device

ActiveCN105783675BEliminate manual errorsGuaranteed parallelismAngles/taper measurementsOptical axisFeeler gauge

The invention discloses an instrument pointer shaft detector, relates to shaft detectors and aims at solving the problems that in traditional detection a pointer shaft is placed in a small optical axis manually, a non-key part is detected by a filler gauge, the size of a key part of the pointer shaft is obtained via theoretical reckoning, and further a detection result is fuzzy and inaccurate and has large error. The detector comprises a pedestal, a pointer plate, a probe plate, a vertical plate, a rapid clamp, a pointer fixing seat, two guide posts, two upper linear bearings and two lower linear bearings, wherein the vertical plate is fixedly mounted on the pedestal, the lower end of each guide post is provided with one lower linear bearing, the pointer plate is mounted on the two lower linear bearings, the middle of the pointer plate is provided with the pointer fixing seat, the probe plate is mounted on the two upper linear bearings, the middle of the probe plate is provided with the pointer shaft, the vertical plate over the probe plate is provided with the rapid clamp, and the pressure head end of the rapid clamp abuts against the probe plate. The detector is used for instrument pointer shaft detection.

Owner:AEROSPACE HI TECH HLDG GROUP

Decorative positioning device of automobile instrument pointer

InactiveCN105783967AEliminate manual errorsTime-saving and labor-saving detectionInstrumentsComputer science

The invention relates to a decorative positioning device of an automobile instrument pointer, and aims at solving the problem that a pointer positioning device, which helps pointer shaft detection, does not exist when a pointer shaft is detected by an instrument pointer shaft detector. The positioning device comprises a fixed block and a positioning block, a positioning groove whose size and shape match those of a pointer cap respectively is formed in the middle of one end surface of the fixed block, two trough slots arranged opposite to each other and penetrating the positioning groove are arranged in the end surface of the fixed block, and the other end surface of the fixed block is fixedly connected with the positioning block. The decorative positioning device is used to fix the automobile instrument pointer in an auxiliary manner during automobile instrument pointer shaft detection.

Owner:AEROSPACE HI TECH HLDG GROUP

A heat treatment experimental device

The invention discloses a heat treatment experiment device and belongs to the field of material heat treatment and performance tests. The heat treatment experiment device mainly comprises a plurality of heating furnaces, a rotary mechanism, a quenching workbench, a normalization workbench, a tail end quenching workbench, a furnace body support rotary mechanism, a furnace body, a circulating cooling system and an atmosphere protection system. The rotary mechanism supports the heating furnaces and drives the heating furnaces to rotate along a spindle. Under driving of the spindle, the furnace body can rotate to be above the set workbench, meanwhile, under driving of the furnace body rotary mechanism, the furnace body can rotate by 90 degrees, and the process that samples from the insides of the heating furnaces are subjected to oil quenching, water quenching, normalization and tail end quenching is completed. Traditional manual operation is replaced, and thus danger and measuring errors caused by manual operation are avoided completely. Artificial intelligence software is installed on an upper computer connected to the heat treatment experiment device, estimation judgment and experiment result prediction can be conducted on the set experiment parameters, the local operation process can be simulated through a virtual laboratory, and thus misoperation in the operation process is reduced. The heat treatment experiment device has wide experiment teaching application prospects and further has the characteristics of simple operation, high efficiency, safety, water saving and the like at the same time.

Owner:KUNMING UNIV OF SCI & TECH

A digestion device and digestion method for solid-state environmental samples

ActiveCN104359750BHigh degree of automationHigh temperature and high degree of automationPreparing sample for investigationDigestionPressure sensor

The invention discloses a digestor and a digestion method for a solid environmental sample. The digestor for the solid environmental sample comprises a condensation tank, a digestion tank and a driving system used for driving the digestion tank to horizontally rotate and vertically turn over, wherein the driving system is connected with the digestion tank, and the digestion tank is suspended in the condensation tank by virtue of a support; a heater, a temperature sensor and a pressure sensor are arranged in the digestion tank, a pressure relief valve is arranged outside the digestion tank and is communicated with the interior of the digestion tank by virtue of a pipeline; and a spraying device used for cooling the digestion tank is arranged in the condensation tank. The digestor for the solid environmental sample has the characteristics of high efficiency, high automation degree, high stability, easiness for operation, easiness in maintenance and the like, an experimental period is shortened, and the cost is also reduced. The digestion method provided on the basis of the digestor has the advantages that defects of the traditional method are quickly and efficiently overcome, the analysis capability is greatly improved, the experiment cost is effectively reduced, and higher security is realized.

Owner:OCEANOGRAPHIC INSTR RES INST SHANDONG ACAD OF SCI

A touch screen calibration method and system

ActiveCN103793112BCorrected accuracy deteriorationReduce precisionInput/output processes for data processingTouchscreenAdaptive capacity

The invention provides a touch screen calibrating method which comprises the steps of switching the work state of a touch screen from the normal touch mode to the calibration mode, conducting regular calibration or deep calibration on a touch spot according to the touch precision change of the touch screen, and switching the work state of the touch screen from the calibration mode to the normal touch mode after the regular calibration or deep calibration is finished. The invention further discloses a touch screen calibrating system. According to the touch screen calibrating method and system, precision deterioration of the touch screen caused by transportation damage or using environment difference can be effectively amended, adaptive capacity is good, and manual operation errors can be removed effectively to realize higher precision.

Owner:TIANJIN XITONG ELECTRONICS EQUIP CO LTD

Equipment overall efficiency detecting method

ActiveCN102645595BEliminate manual errorsExclude omissionsElectrical testingProgramme control in sequence/logic controllersStart timeStop time

The invention relates to an equipment overall efficiency detecting method. The method comprises the following steps of inputting data: 302) recording starting time; 303) turning on a proximity switch (PX1), acquiring vehicle speed, and judging whether the vehicle speed is zero or not, if so, performing the next step, otherwise, returning to the 303) step; 304) recording stop beginning time; 305) acquiring the vehicle speed through the proximity switch, and judging whether the vehicle speed is zero or not, if so, performing the next step, otherwise, returning to the 304) step; 306) recording stop ending time; 307) judging whether the continuous time is more than a stop parameter or not, if so, performing the next step, otherwise, returning to the 303) step; 308) recording the stop beginning time and the stop ending time in an equipment efficiency database; and 309) judging whether the continuous time is more than a set stop parameter or not, if so, recording stop time, otherwise, returning to the 303) step. The method also comprises the steps of outputting data, i.e. 401) acquiring Q and N, 402) researching the equipment efficiency database, 403) acquiring T1 and T0, and 404) calculating output T, P and I.

Owner:MINGWEI MACHINERY DONGWAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com