Automatic assembling machine for intersecting bearing and skeleton oil seal

A skeleton oil seal and assembly machine technology, which is applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of damage to the harmonic reducer, overall precision reduction, skeleton oil seal damage, etc., to achieve improved sealing and high degree of automation , Eliminate errors and correct effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

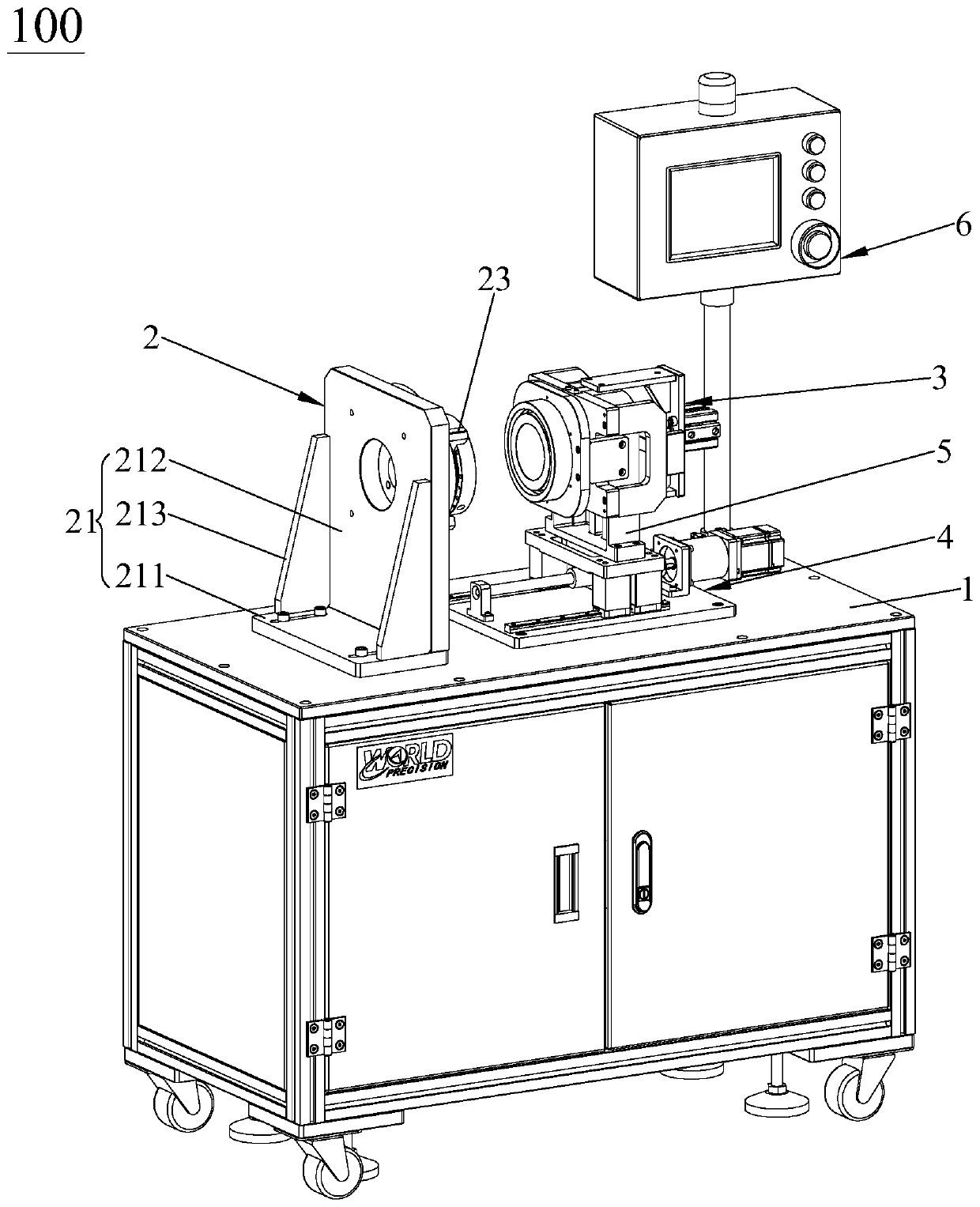

[0026] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

[0027] see Figure 1 to Figure 2 , the cross bearing and skeleton oil seal automatic assembly machine 100 of the present invention is suitable for the occasion of press-fitting the bone oil seal into the cross bearing 200 . The cross bearing 200 includes an inner ring 201 and an outer ring 202 , and a groove 203 is provided between the inner ring 201 and the outer ring 202 for the skeleton oil seal 300 to be pressed into. It is worth noting that the structures of the cross bearing 200 and the framework oil seal 300 are well known to those skilled in the art, so they will not be repeated here.

[0028] see Figure 2 to Figure 6 The cross bearing and skeleton oil seal automatic assembly machine 100 of the present invention includes a workbench 1, a clamp mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com